Process for production of silicon carbide molded article

A manufacturing method and molding technology, which can be used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of boron becoming an impurity, etc., and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

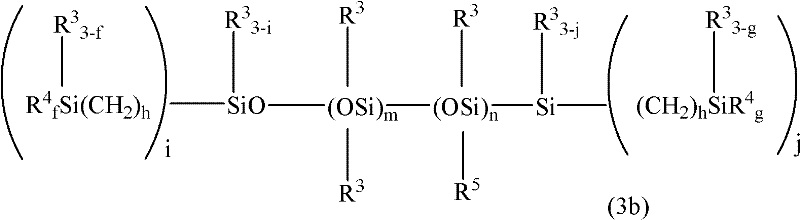

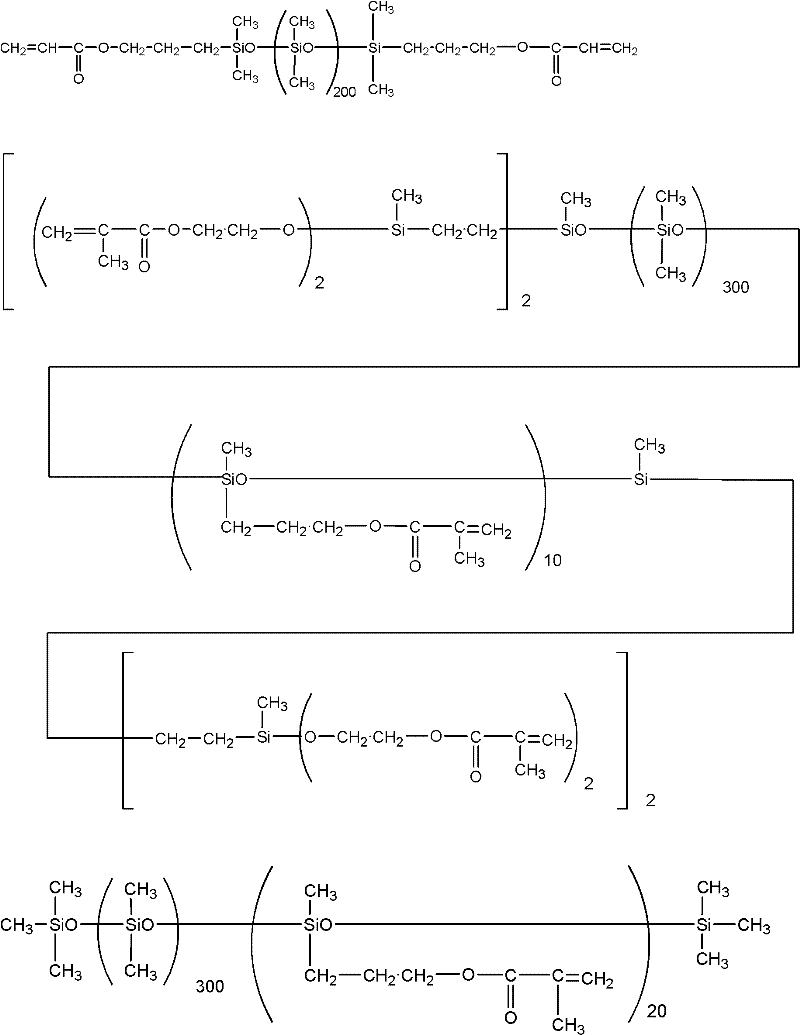

[0023] · Preparation of curable silicone composition:

[0024] The type of curable silicone composition used as a starting material in the method of the present invention is not particularly limited, and any curable type curable silicone composition can be used. Specific examples thereof include organic peroxide-curable, radiation-curable reactive, addition-curable reactive, and condensation-curable silicone compositions. From the viewpoint of making the resulting coating highly pure, organic peroxide-curable and radiation-curable reactive silicone compositions are advantageous, and the total content of impurity elements in the obtained silicon carbide compact can be suppressed to 1 ppm or less, preferably 0.5 ppm or less, more preferably 0.1 ppm or less. Examples of impurity elements include Fe, Cr, Ni, Al, Ti, Cu, Na, Zn, Ca, Zr, Mg, and B, and one or more of them may exist. Their total content can be suppressed as mentioned above.

[0025] Examples of organic peroxide-cu...

Embodiment 1

[0157] Material:

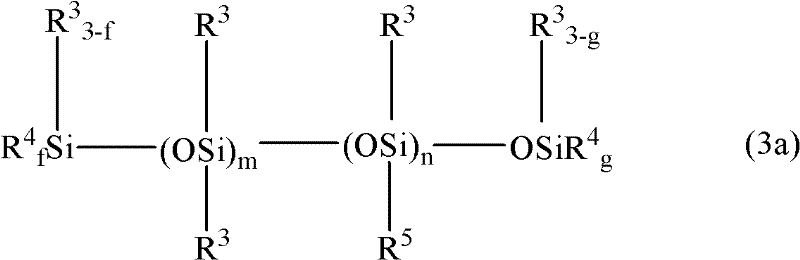

[0158] (A) 100 parts by mass of diorganopolysiloxane containing an alkenyl group in one molecule represented by the following formula,

[0159]

[0160] (wherein, n and m are n / m=4 / 1 and the viscosity of the siloxane reaches 600mPa.s at 25°C);

[0161] (B) 0.5 parts by mass of benzoyl peroxide;

[0162] (C) 33 parts by mass of diorganopolysiloxane having a hydrogen atom bonded to a silicon atom represented by the following formula,

[0163]

[0164] as well as

[0165] (D) 327 parts by mass of silicon carbide powder (average particle diameter: 1 μm) (that is, an amount to account for 50% by volume of the entire silicone composition).

[0166] The components (A) to (D) were put into a planetary mixer (registered trademark, mixer manufactured by Inoue Seisakusho Co., Ltd.), and stirred at room temperature for one hour to obtain a product having a viscosity of 3,000 at room temperature. mPa·s curable silicone composition. The curable silicone composi...

Embodiment 2

[0177] In Example 1, except that the amount of the component (D) was changed to 594 parts by mass (that is, the amount to reach 65% by volume of the entire silicone composition), similarly to Example 1, the amount of (A) ~Component (D) was put into a planetary mixer (registered trademark, mixer manufactured by Inoue Seisakusho Co., Ltd.), and stirred at room temperature for one hour to obtain a clay-like curable silicone composition at room temperature. . Put this curable silicone composition into an extrusion molding machine, and after continuous extrusion from a die with a diameter of 20 mm, cut it into a length of 10 mm with a metal wire, and place it in a length of 1 m near the exit of the die within 5 minutes. passed through a hollow electric hot air furnace heated to 150° C. to obtain a cylindrical silicone hardened molded product with a diameter of 20 mm and a length of 10 mm.

[0178] This silicone cured molded product was heated to 1000°C in a nitrogen atmosphere in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com