Manufacturing method of high aspect ratio micro structure of novel carbon-carbon nano tube composite material

A technology of carbon nanotubes and composite materials, which is applied in the field of preparation and molding of microstructures, can solve the problem that carbon or carbon nanotubes cannot be obtained cheaply and efficiently, and achieve good application prospects, good mechanical properties, and high resonance frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

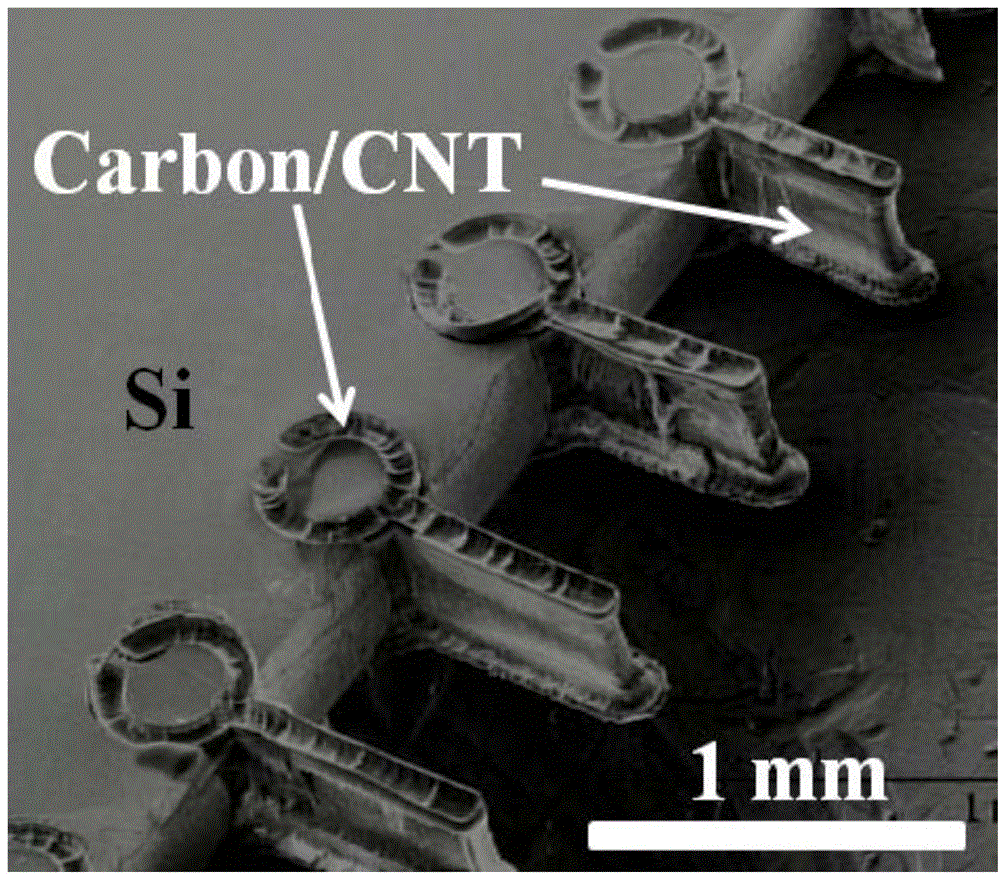

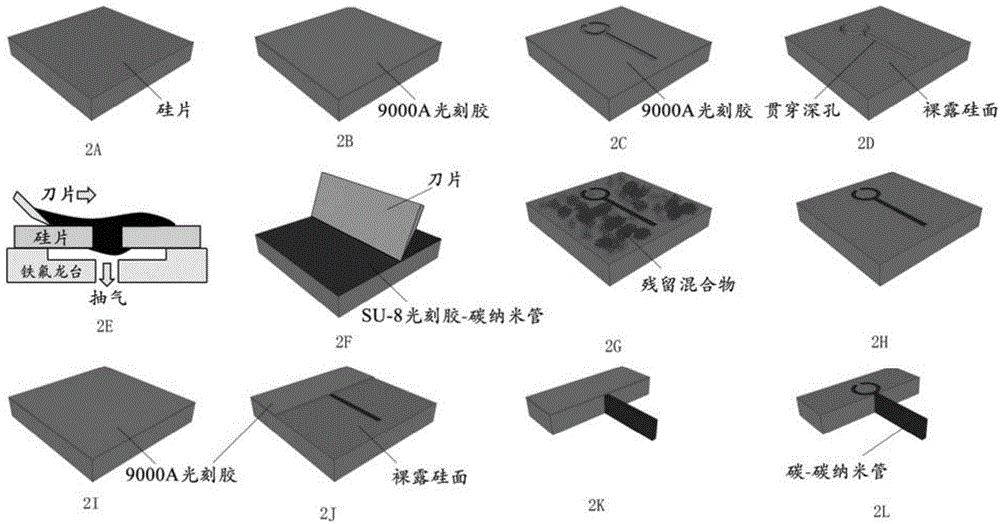

[0033] A method for making a micro-cantilever beam of a novel carbon-carbon nanotube composite material, comprising the following steps:

[0034] 1) Clean the wafer with a typical RCA cleaning process (see figure 2 A);

[0035] 2) Use 9000A photoresist to spin-coat glue on one surface of the silicon wafer described in 1), and the rotating speed is: the first step, 5s, 500rpm; the second step, 30s, 2500rpm (see figure 2 B);

[0036] 3) Using a mask with a cantilever beam geometry, perform photolithography on the silicon wafer that has been glued as described in step 2), and the exposure dose is 400mJ / cm 2 ;

[0037] 4) Immerse the silicon wafer described in step 3) in RD-6 developer solution, No. 1 deionized water, and No. 2 deionized water in sequence; the immersion and development time is: RD-6 developer solution, 35s; No. 1 deionized water Water, 40s; No. 2 deionized water, 40s (see figure 2 C);

[0038] 5) carry out ICP-RIE deep etching to the sample with photoresi...

Embodiment 2

[0049] A method for making a micro-cantilever beam of a novel carbon-carbon nanotube composite material, comprising the following steps:

[0050] 1) Clean the silicon wafer with a typical RCA cleaning process;

[0051] 2) Use 9000A photoresist to spin-coat glue on one surface of the silicon wafer described in step 1), the speed is, the first step: 5s, 500rpm, the second step: 30s, 2500rpm;

[0052] 3) Using a reticle with a micro-cantilever geometry, perform photolithography on the silicon wafer that has been glued as described in step 2), and the exposure dose is 400mJ / cm 2 ;

[0053] 4) Immerse the silicon wafer described in step 3) in RD-6 developing solution, No. 1 deionized water, and No. 2 deionized water in sequence. Water, 40s, No. 2 deionized water, 40s;

[0054] 5) carry out ICP-RIE deep etching to the sample with photoresist pattern described in step 4), form the deep hole that runs through the silicon chip, obtain micro silicon mold;

[0055] 6) Carry out 1200 ...

Embodiment 3

[0066] A method for making a micro-cantilever beam of a novel carbon-carbon nanotube composite material, comprising the following steps:

[0067] 1) Clean the silicon wafer with a typical RCA cleaning process;

[0068] 2) Use 9000A photoresist to spin coat glue on one surface of the silicon wafer described in step 1), the speed is: the first step, 5s, 500rpm; the second step, 30s, 2500rpm;

[0069] 3) Using a mask with a cantilever beam geometry, perform photolithography on the silicon wafer that has been glued as described in step 2), and the exposure dose is 400mJ / cm 2 ;

[0070] 4) Dip the silicon wafer described in step 3) into RD-6 developer, No. 1 deionized water, and No. 2 deionized water in sequence. Soaking and developing time: RD-6 developer, 35s; No. 1 deionized water, 40s; No. 2 deionized water, 40s;

[0071] 5) carry out ICP-RIE deep etching to the sample with photoresist pattern described in step 4), form the deep hole that runs through the silicon chip, obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com