Mold applied to resin-based cement-based light-transmitting concrete

A light-transmitting concrete and cement-based technology, applied in the field of molds, can solve the problems of not meeting the strength requirements, difficult to demould, insufficient molding accuracy, etc., and achieve the effects of good mechanical properties, light-transmitting properties, and high reuse times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

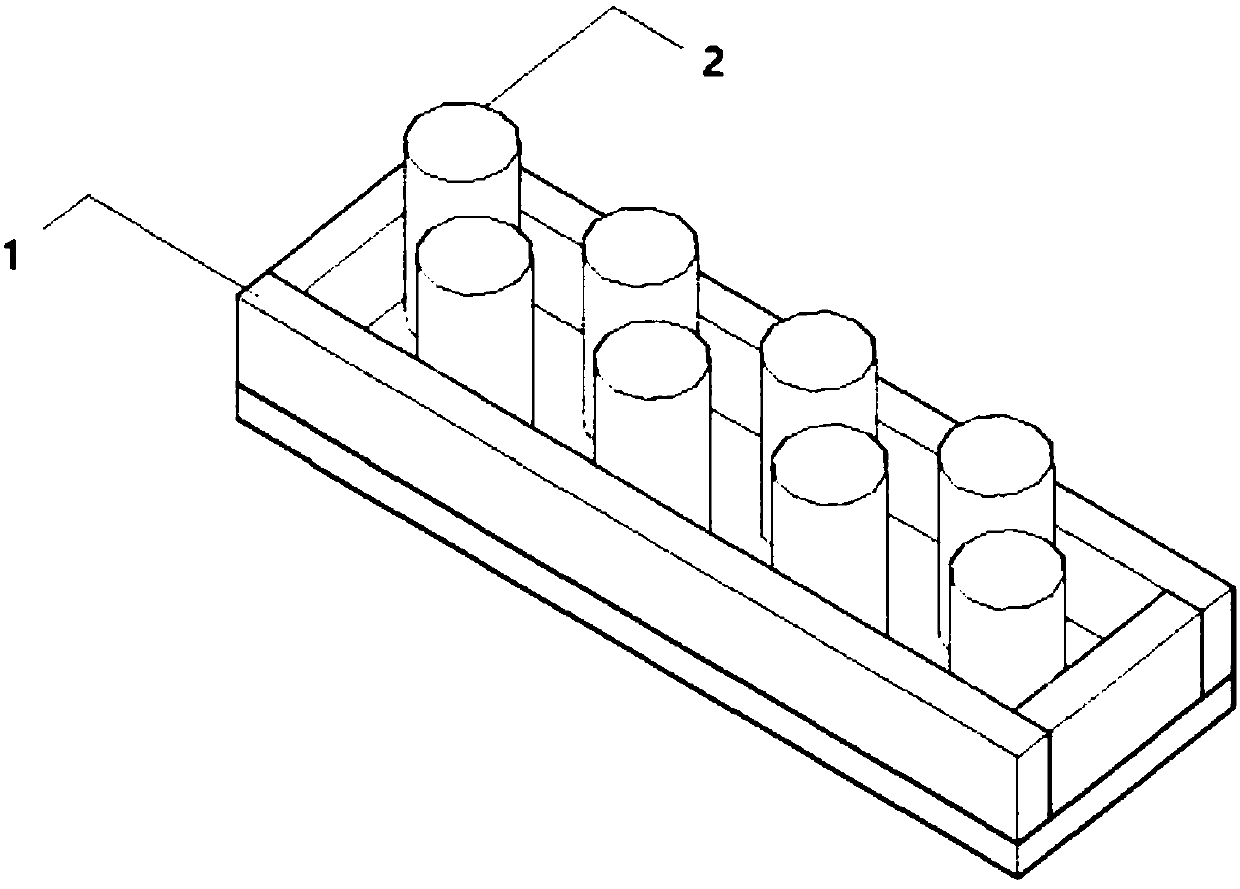

[0040] The object of the present invention is to provide a kind of cement-based translucent concrete mould, which is applied to resin, which can easily obtain a silica gel mold, and then utilize the silica gel mold to obtain a prefabricated resin block (such as Figure 8 shown)

[0041] The role of the prefabricated resin block is to insert it into the uncured concrete. After it is solidified, the resin can transmit light, making the concrete as a whole transparent.

[0042] The present invention provides a resin-based cement-based light-transmitting concrete mold, and the process of using the mold to prepare a prefabricated resin block is as follows:

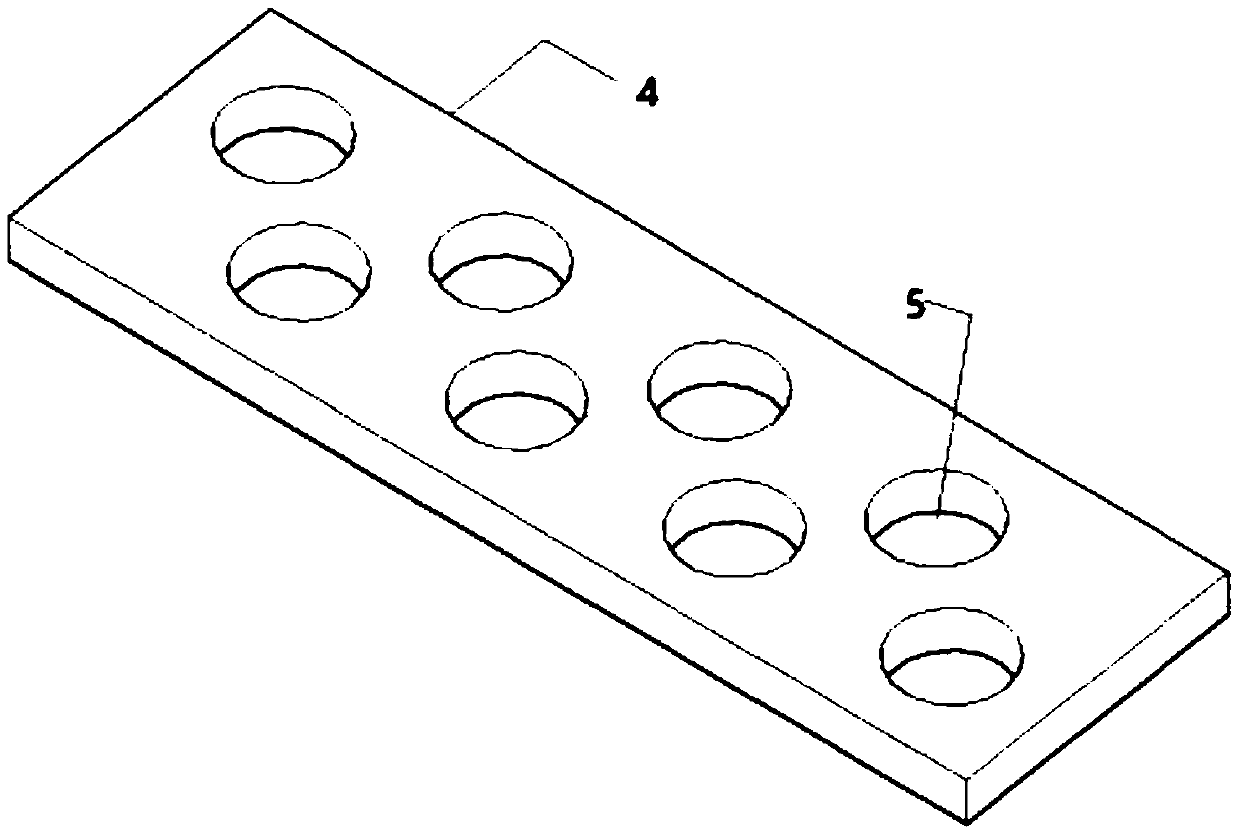

[0043] 1) Make a prefabricated resin block prototype: such as figure 1 , using an acrylic column to make a cylindrical prefabricated resin block prototype 2 with a height of 40mm and a radius of 10mm.

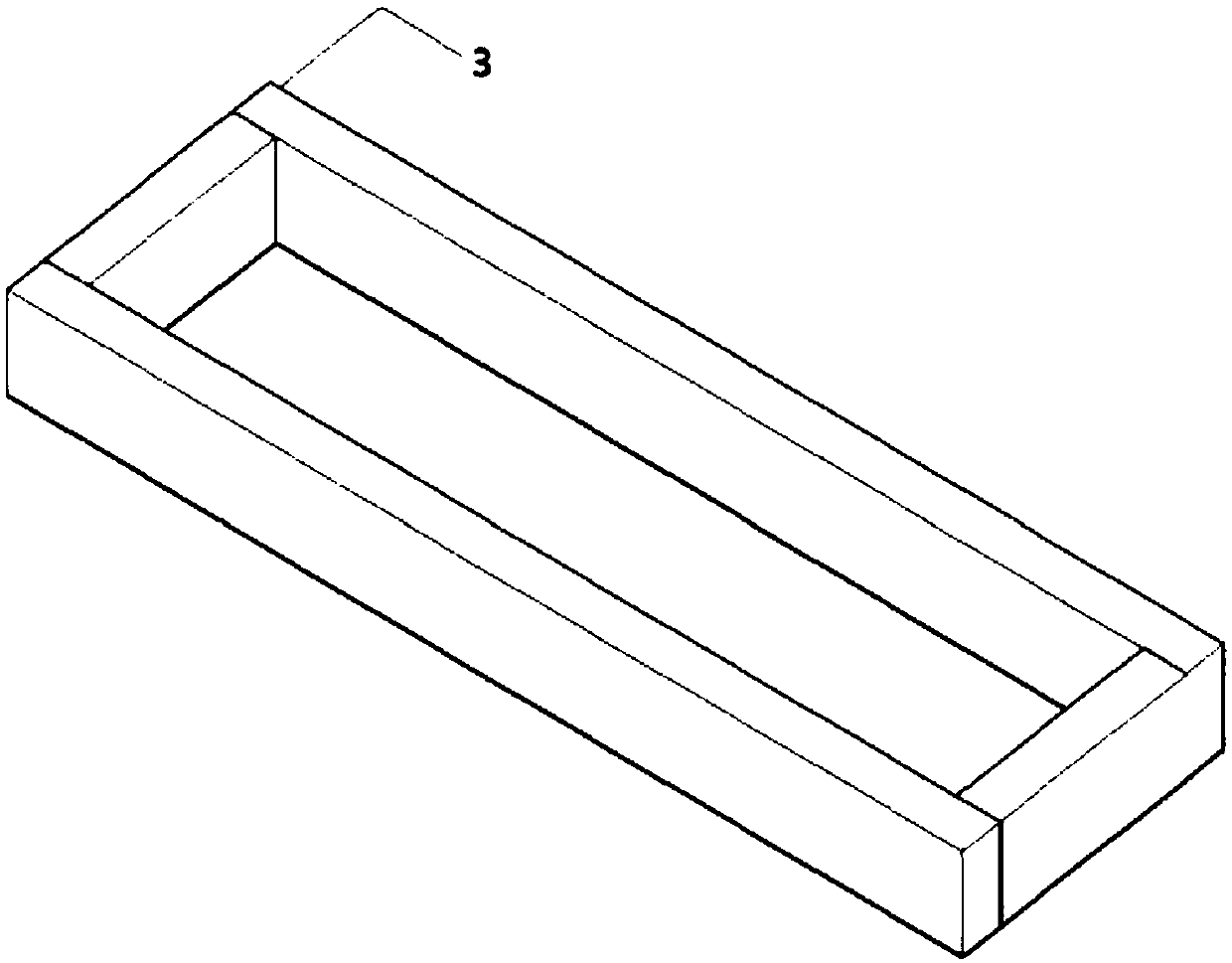

[0044] 2) Make the lower enclosure mold: such as figure 1 , Make a 176*56*8mm bottom plate with an acrylic plate. 176*20*8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com