Method for manufacturing three-dimensional silicon mold directly bonded by low-temperature plasma activation

A direct bonding, plasma technology, applied in gaseous chemical plating, fabrication of microstructure devices, processes for producing decorative surface effects, etc. , micro-mold is difficult and other problems, to achieve the effect of less pollution, enhanced stability and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

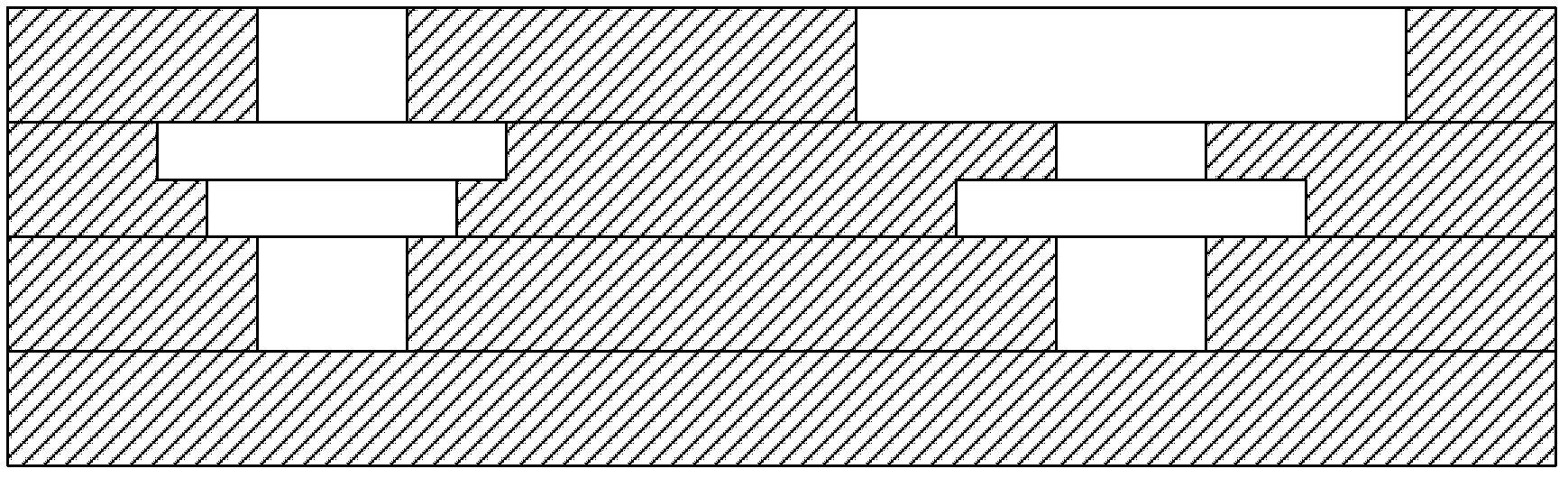

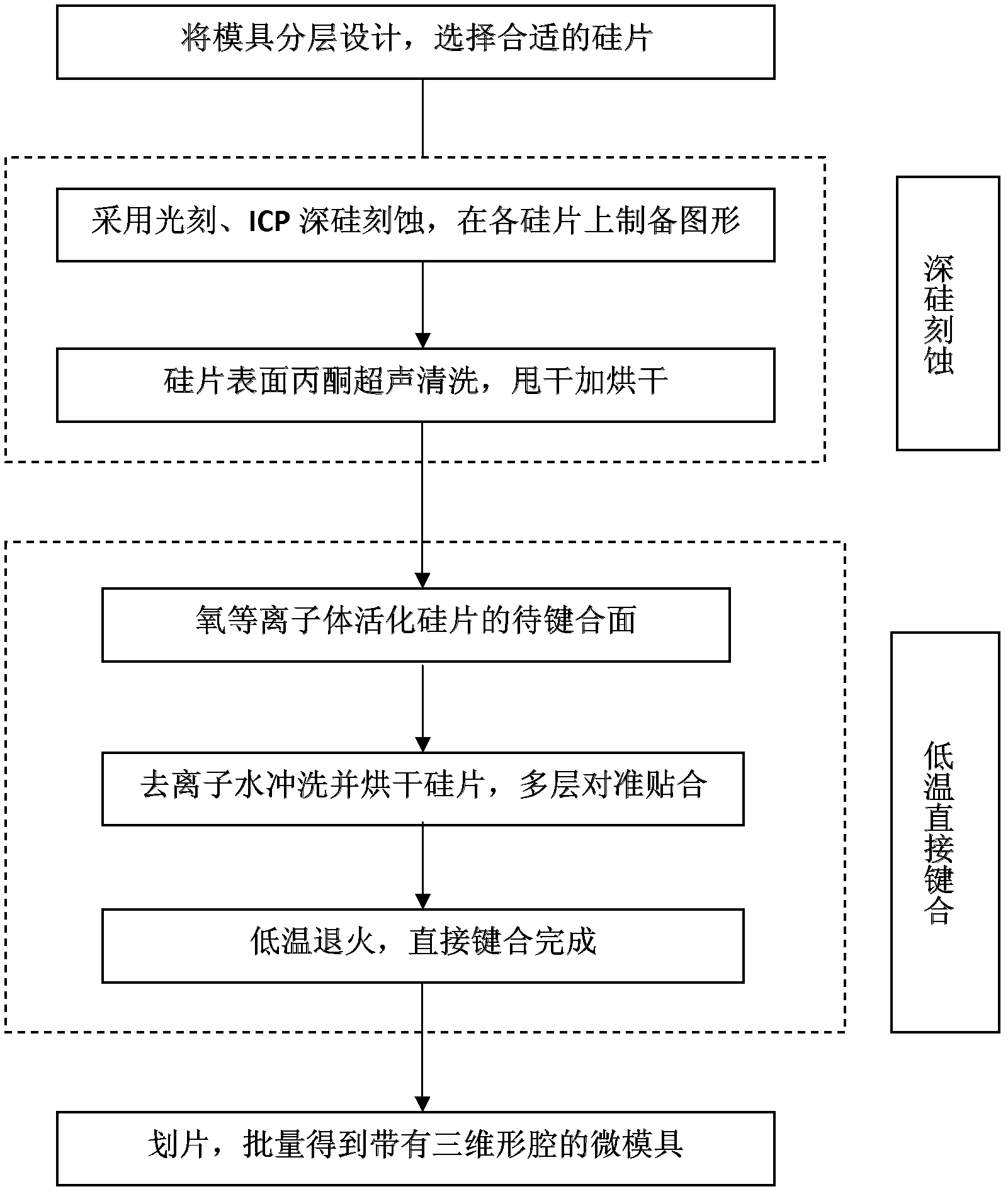

[0026] figure 1 For the mold of the three-dimensional micro-parts to be prepared in this embodiment, figure 2 Realize the process flow chart of this mold for the present invention. Divide the part into 4 layers in the Z direction, select 4 silicon wafers of corresponding thickness, the middle two layers of silicon wafers are double-thrown silicon wafers, and the top and bottom silicon wafers are single-thrown silicon wafers.

[0027] The method of photolithography and ICP (inductively coupled plasma) deep silicon etching is used for each layer of silicon wafers, and the structural patterns of the corresponding layers of the parts to be prepared are accurately etched. The first and third layers of silicon wafers are etched through at one time. The second layer of silicon wafer requires photolithography and ICP etching on the front and back sides to realize the stepped cavity in the silicon wafer; the photolithography and ICP deep silicon etching process is: uniform glue on th...

Embodiment 2

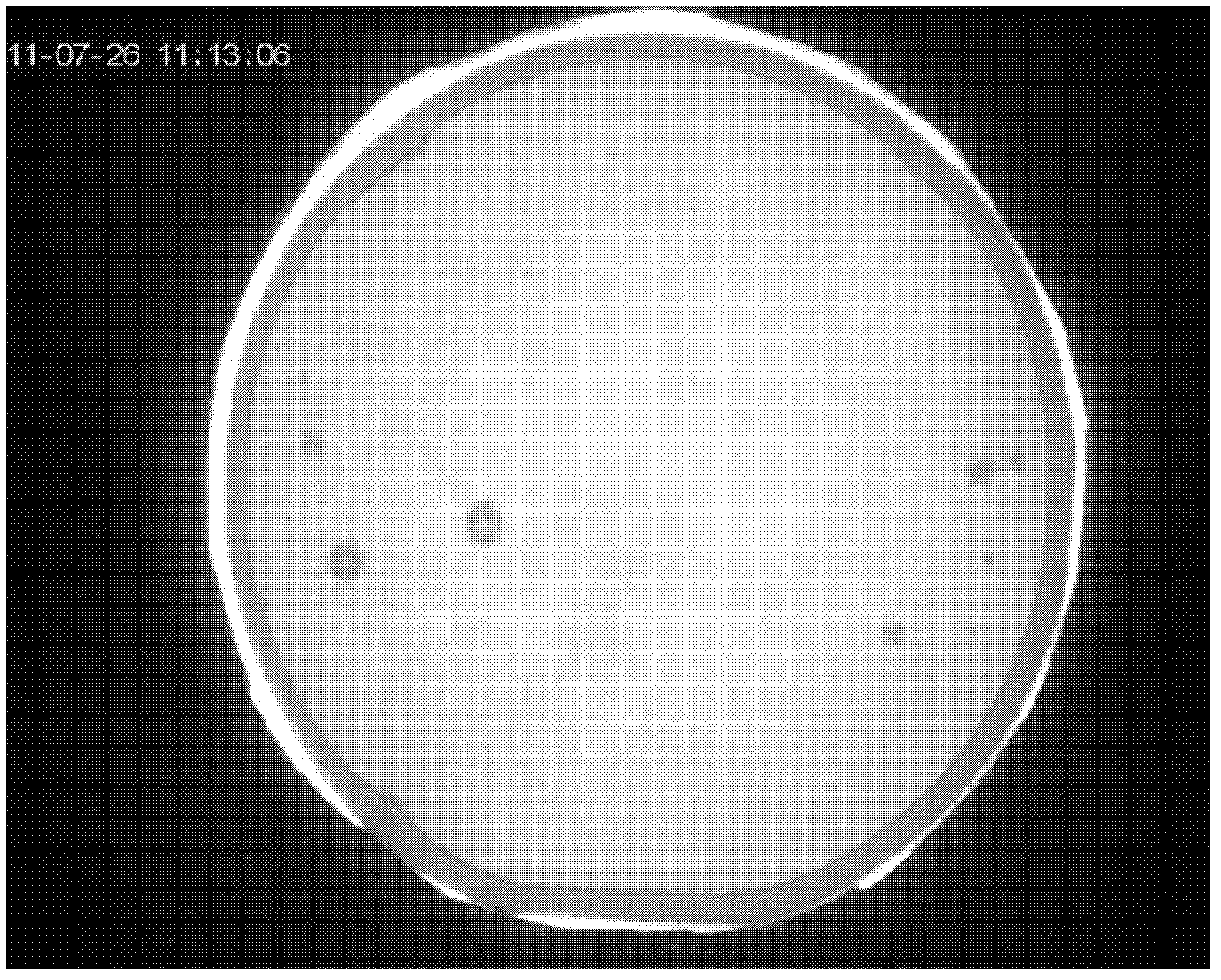

[0034] image 3 It is the effect diagram of low-temperature plasma activation of silicon-silicon double-layer direct bonding, and its process steps:

[0035] The newly shipped 2-inch silicon wafers are not wet-cleaned, but are directly cleaned and activated by oxygen plasma, with a flow rate of 50sccm, a radio frequency power of 150W, and an activation time of 20s; each silicon wafer after activation is rinsed with deionized water for 3 minutes , spinning and drying plus drying, lamination of silicon wafers;

[0036] Anneal the laminated multi-layer silicon wafer at a temperature of 160°C for 72 hours to complete the double-layer direct bonding of the silicon wafer.

Embodiment 3

[0038] Figure 4 It is the effect diagram of direct bonding of three layers of silicon wafers

[0039] The materials are 2 pieces of 2-inch silicon wafers with single throwing and 1 piece of 2-inch silicon wafers with double throwing;

[0040] The newly shipped 2-inch silicon wafers are not wet-cleaned, but are directly cleaned and activated by oxygen plasma. One polished surface of all wafers is activated once, and the other side of double-polished wafers is activated twice. The plasma equipment used is domestic ME-RIE, the surface activation atmosphere is oxygen flow rate 100sccm, radio frequency power 100W, activation time 5s;

[0041] Rinse each silicon wafer after activation with deionized water for 3 minutes, spin dry and dry, and align and bond all silicon wafers in order from top to bottom (double-polished silicon wafers are in the middle layer);

[0042] Anneal the laminated multi-layer silicon wafers at a temperature of 300°C for 12 hours to complete the multi-lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com