Patents

Literature

244results about How to "Reduce local stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

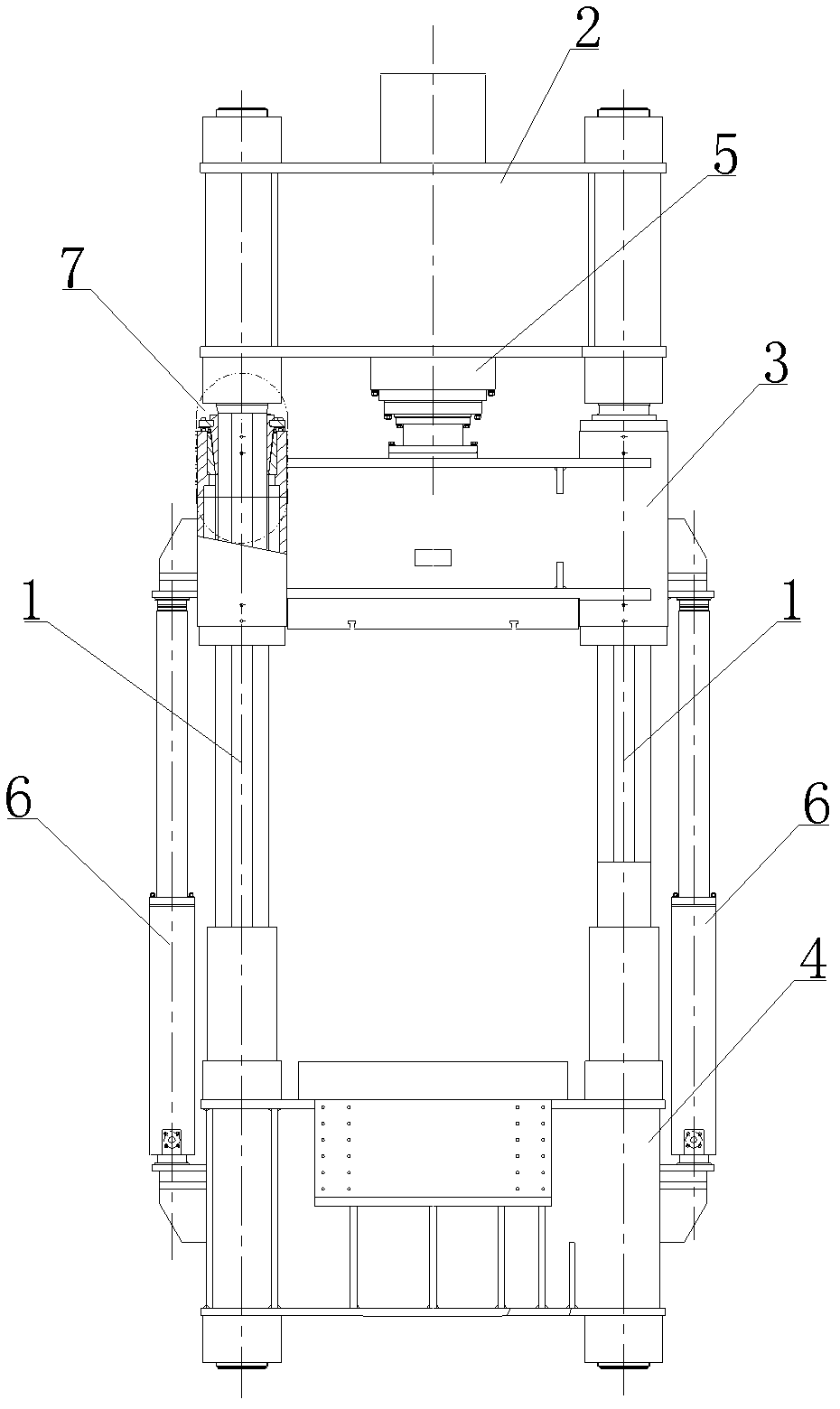

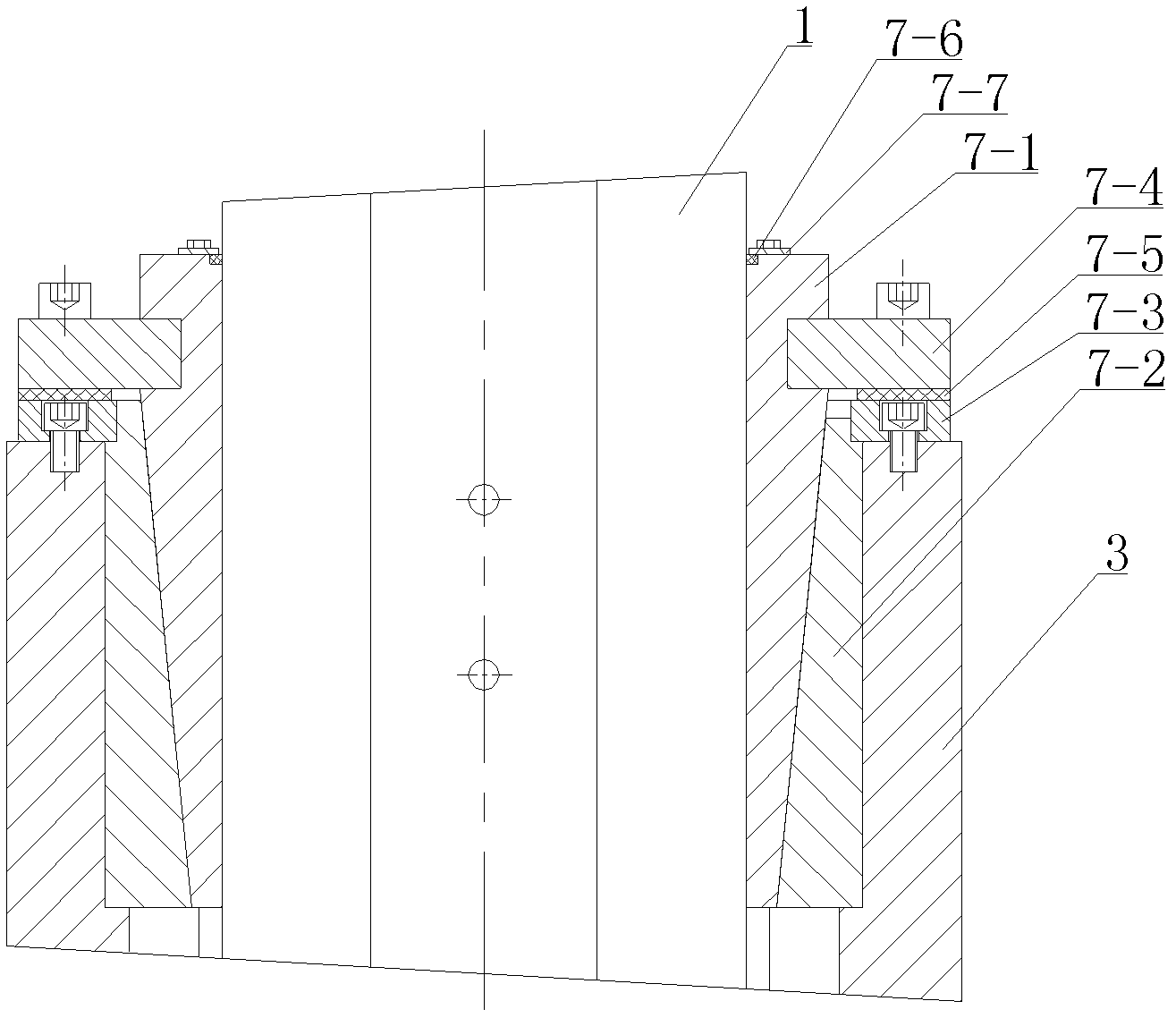

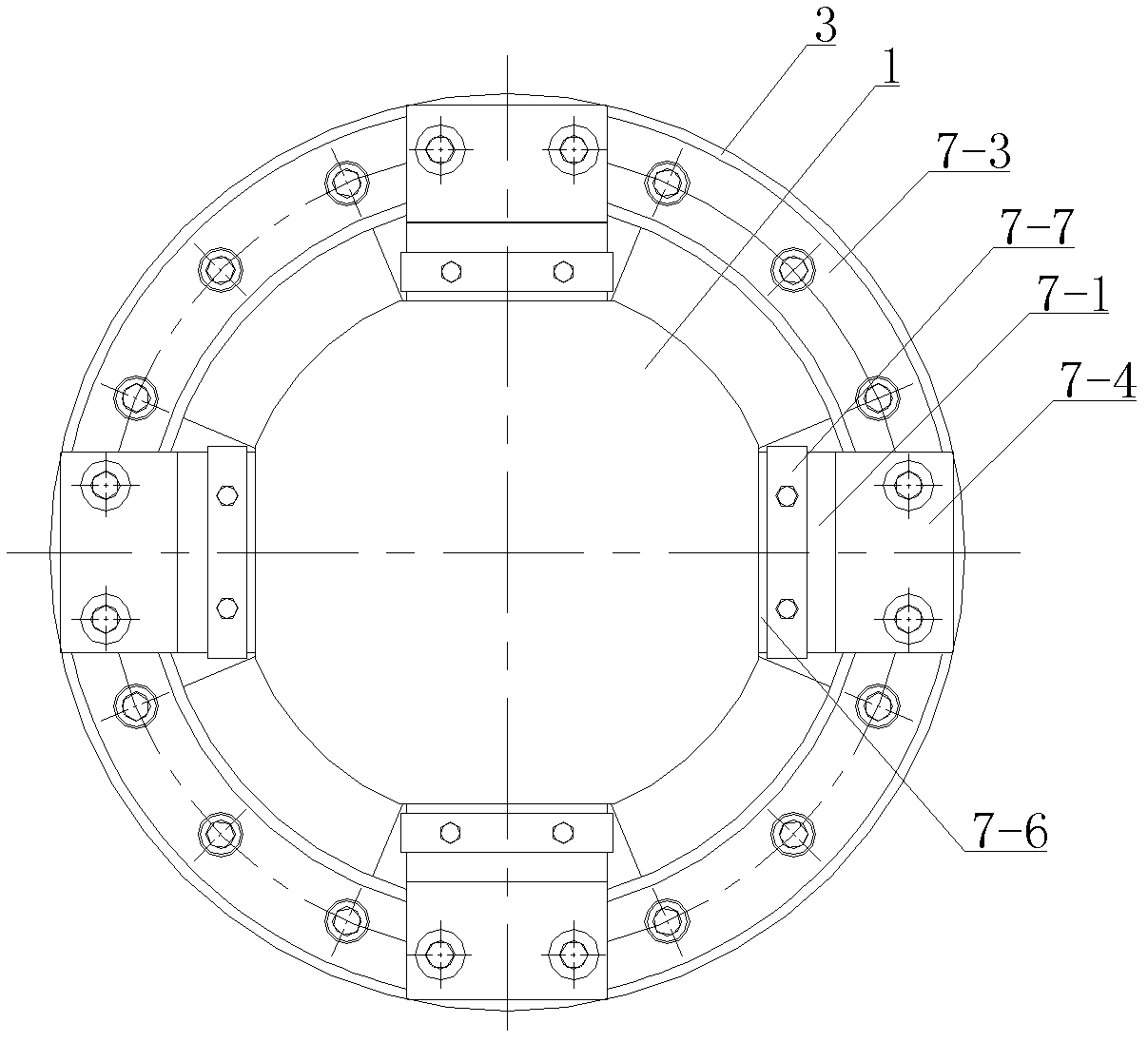

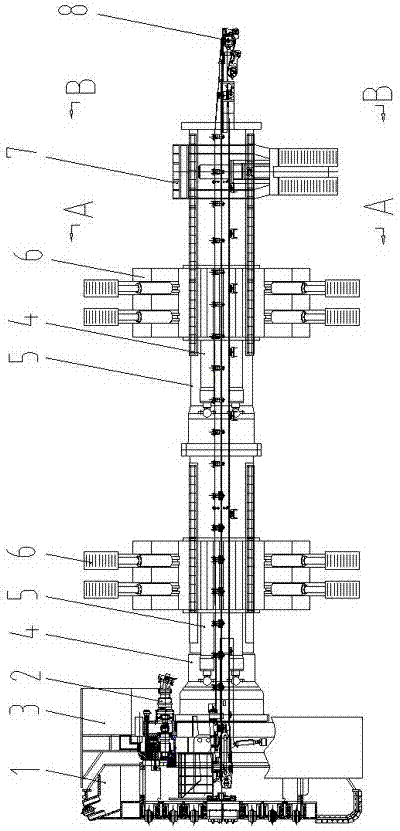

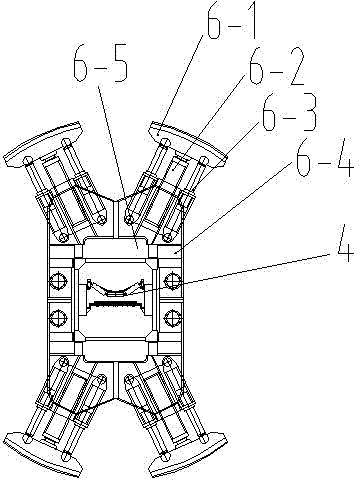

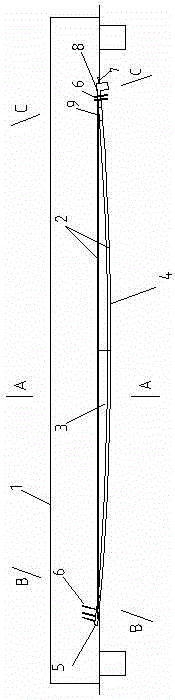

Four-column forging hydraulic machine

The invention relates to a four-column forging hydraulic machine which is composed of columns, an upper beam, a middle beam, a lower beam, a working oil cylinder and a return cylinder. A column guiding structure is arranged between the middle beam and the columns. The four-column forging hydraulic machine is characterized in that the column guiding structure comprises four groups of guiding assemblies composed of guiding plates and wedge plates, the wedge plates are pressed and fixed in the middle beam through pressing plates, supporting plates are arranged close to the upper ends of the guiding plates, adjusting pads are arranged between the supporting plates and the pressing plates, the lower end of a piston rod of the working oil cylinder is provided with a cylindrical cavity, the cylindrical cavity is internally provided with a first spherical pad and a spherical column, a supporting sleeve is sleeved outside the spherical column, a support structure is arranged at the upper part of a raised part at the lower end of the supporting sleeve, an elastic pad is arranged between the supporting structure and the raised part, and the lower end of the supporting sleeve is internally provided with a second spherical pad. According to the structure, the columns and the guiding structure are in surface contact, so that the local stress is reduced, and the traction injury of the columns is avoided. In addition, the second spherical pad, the spherical column and the first spherical pad are rotated in a matching way, therefore, the deflection of the piston rod along the axis is avoided, and the traction injury and the damage of the working oil cylinder and the piston rod are reduced.

Owner:TIANJIN TIANDUAN PRESS CO LTD

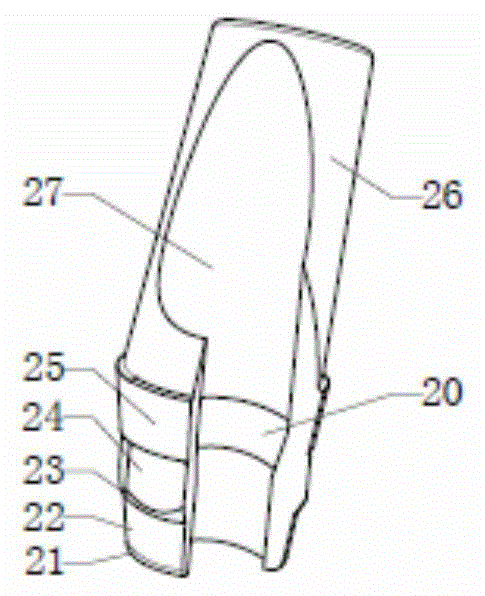

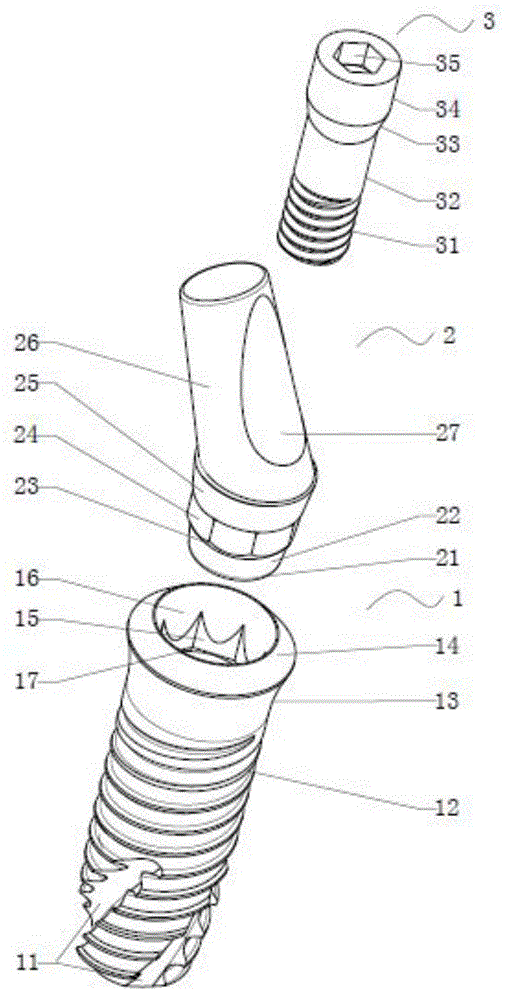

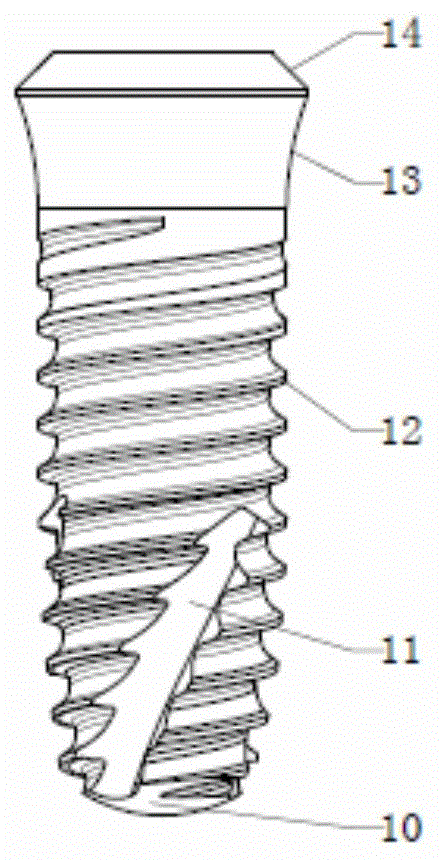

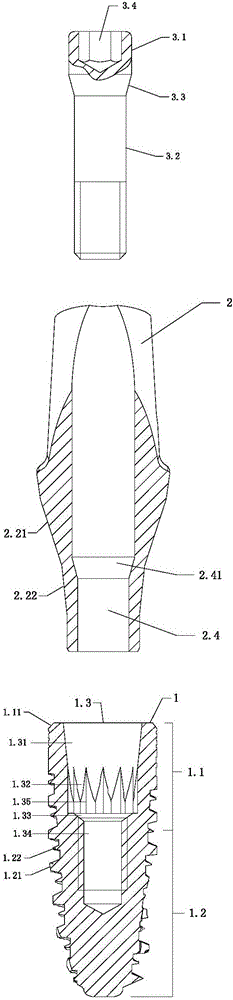

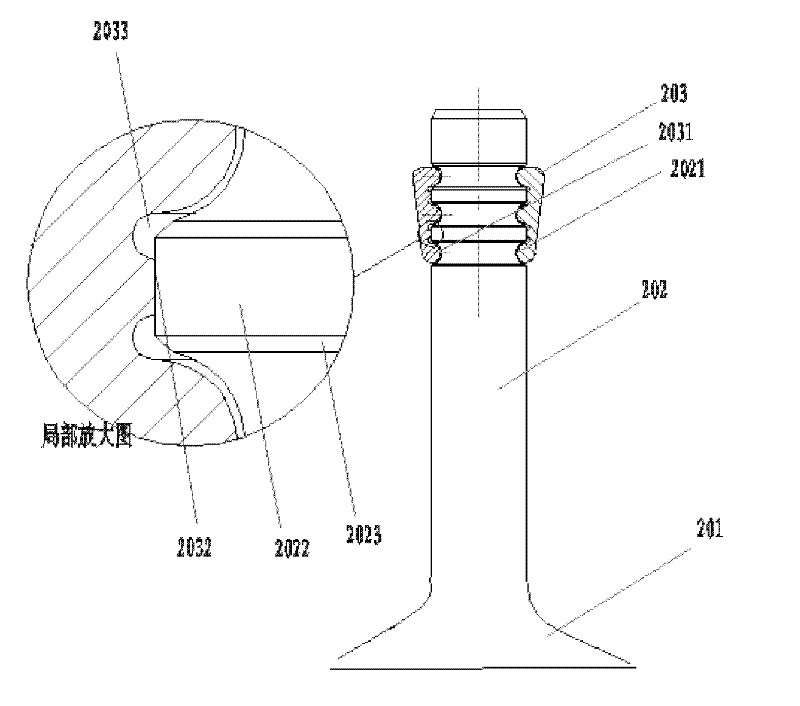

Artificial dental abutment, artificial dental multi-part implanting system and implanting method

InactiveCN103550002AReasonable structureCompact structureDental implantsUltimate tensile strengthDentition

The invention provides an artificial dental abutment, an artificial dental multi-part implanting system and an implanting method. A crown connection section and an implant connection section are respectively arranged at two ends of the artificial dent abutment, wherein the included angle of the axis of the crown connection section and the axis of the implant connection section is 10-30 degrees. The artificial dental abutment can adapt to various oral implanting conditions and angles. An artificially implanted tooth has a harmonious and beautiful repairing effect with surrounding tissues and remained dentition by adopting the abutment. The invention discloses an artificial dental multi-part implanting system comprising the artificial dental abutment, wherein the implant is a multi-part and nonsubmerged technology combined implant, is high in stability and strength, and can adapt to various oral implanting conditions and angles, can be used for effectively reducing the local stress, shortening the healing time and reducing the hurt of patients.

Owner:DALIAN SANSHENG SCI & TECH DEV

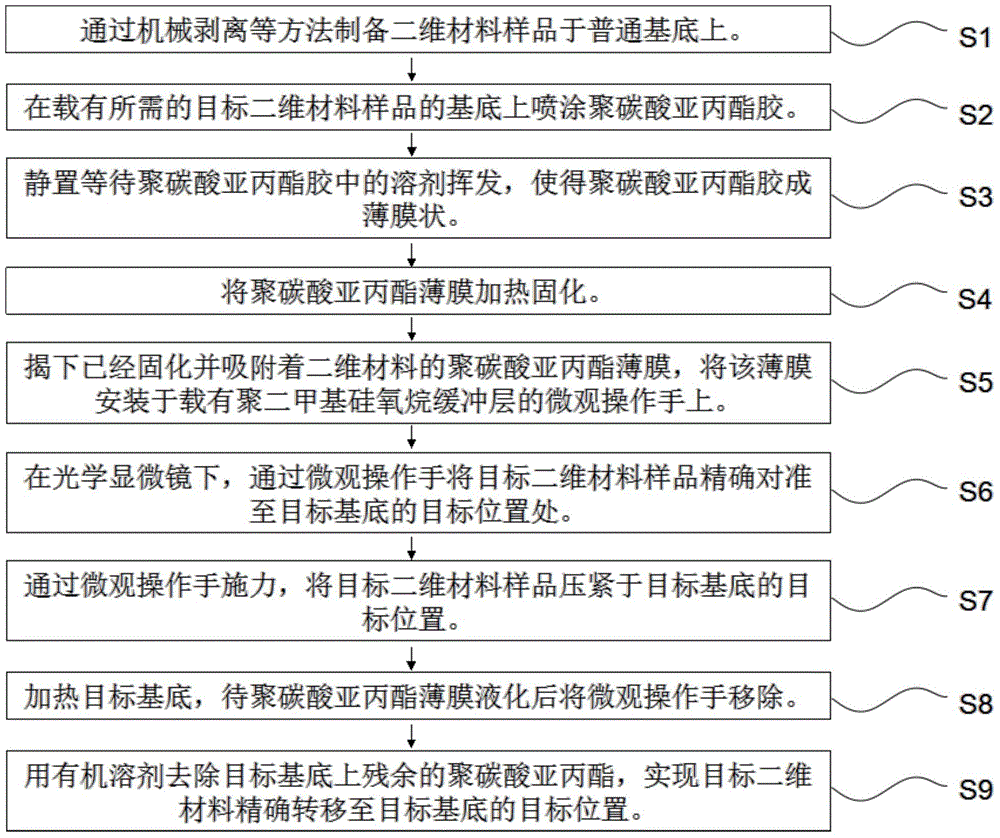

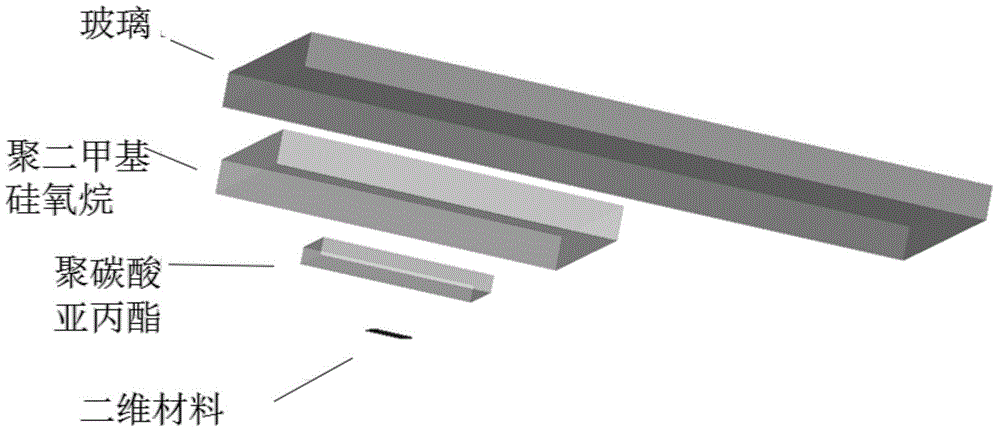

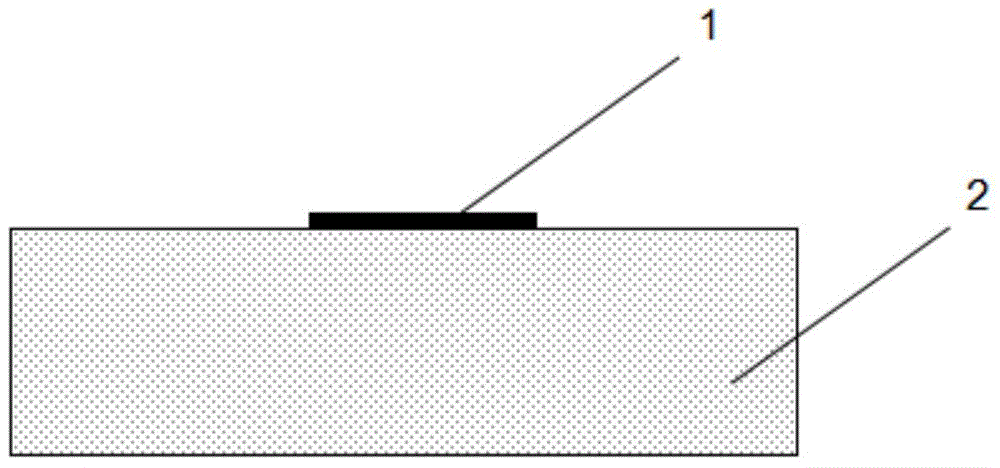

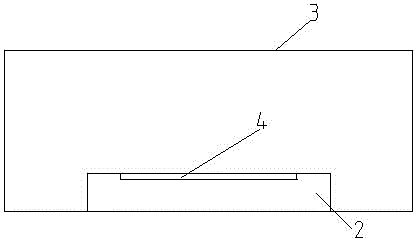

Controllable flexible transfer method of two-dimensional materials

InactiveCN104960286AControlled Flexible Transfer MethodLoose size requirementsCeramic layered productsOrganic solventEngineering

The invention discloses a controllable flexible transfer method of two-dimensional materials. The controllable flexible transfer method includes the steps: adopting a mechanical striping method or other methods to obtain a target two-dimensional material to be transferred; spraying polypropylene carbonate glue on the surface of the two-dimensional material; standing and heating to solidify the polypropylene carbonate glue to enable the two-dimensional material to be adhered below a formed polypropylene carbonate thin film; mounting the thin film on a micro manipulator carrying a polydimethylsiloxane buffering layer, and accurately aligning the thin film to a target position of a target substrate with the help of an optical microscope; heating to melt the polypropylene carbonate thin film, and using organic solvent to remove residual polypropylene carbonate. By the controllable flexible transfer method, accurate and controllable transfer of the two-dimensional material is realized. The method is simple in process, high in efficiency, wide in application range and high in expandability and has wide using prospect in the fields of microelectronics, biological detection and batteries.

Owner:SOUTHEAST UNIV

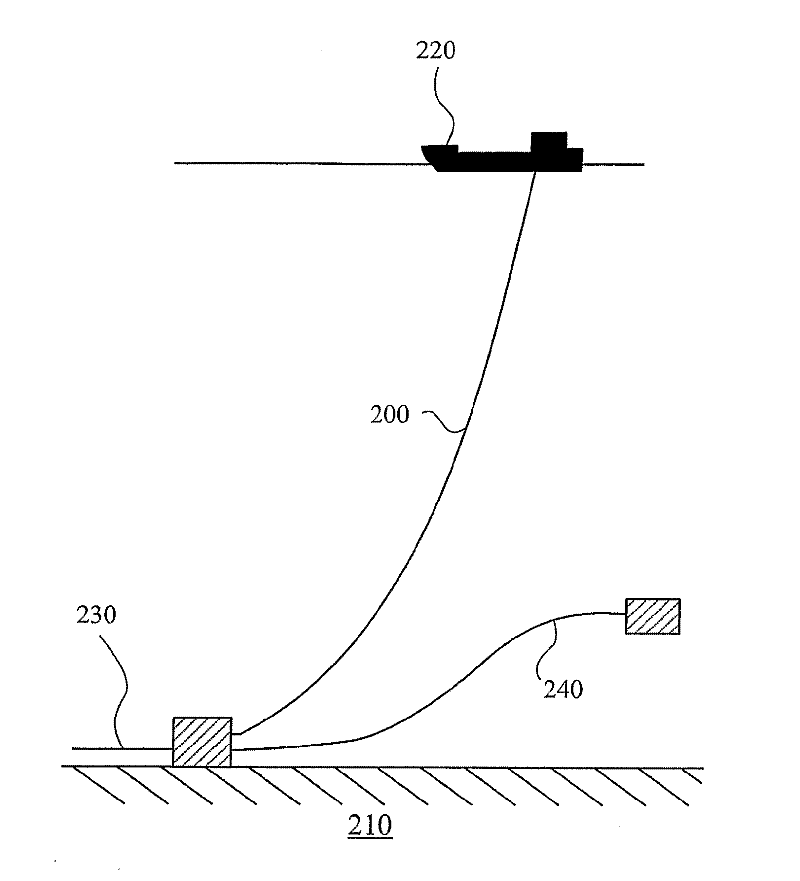

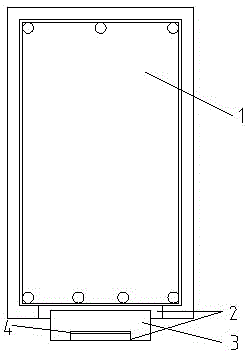

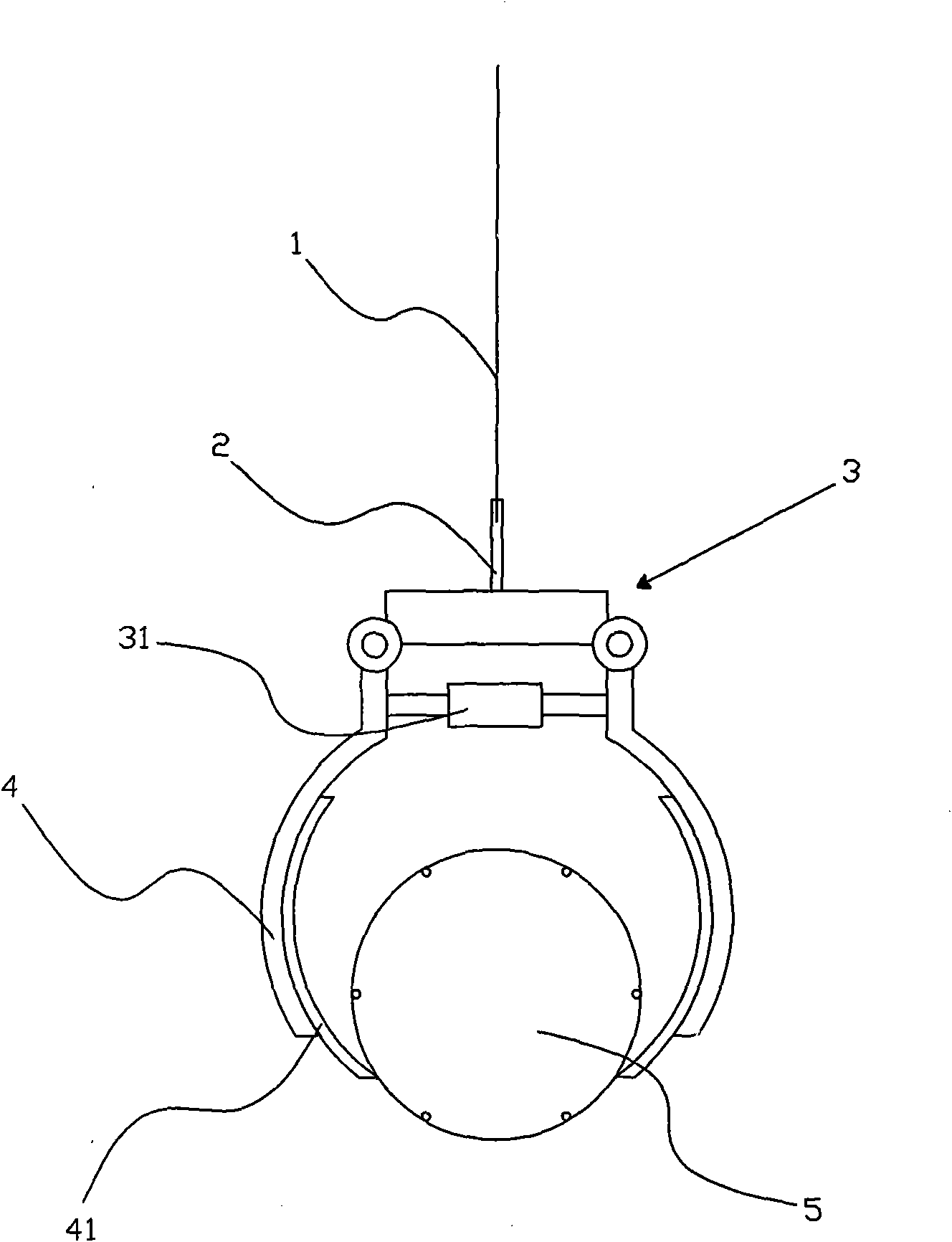

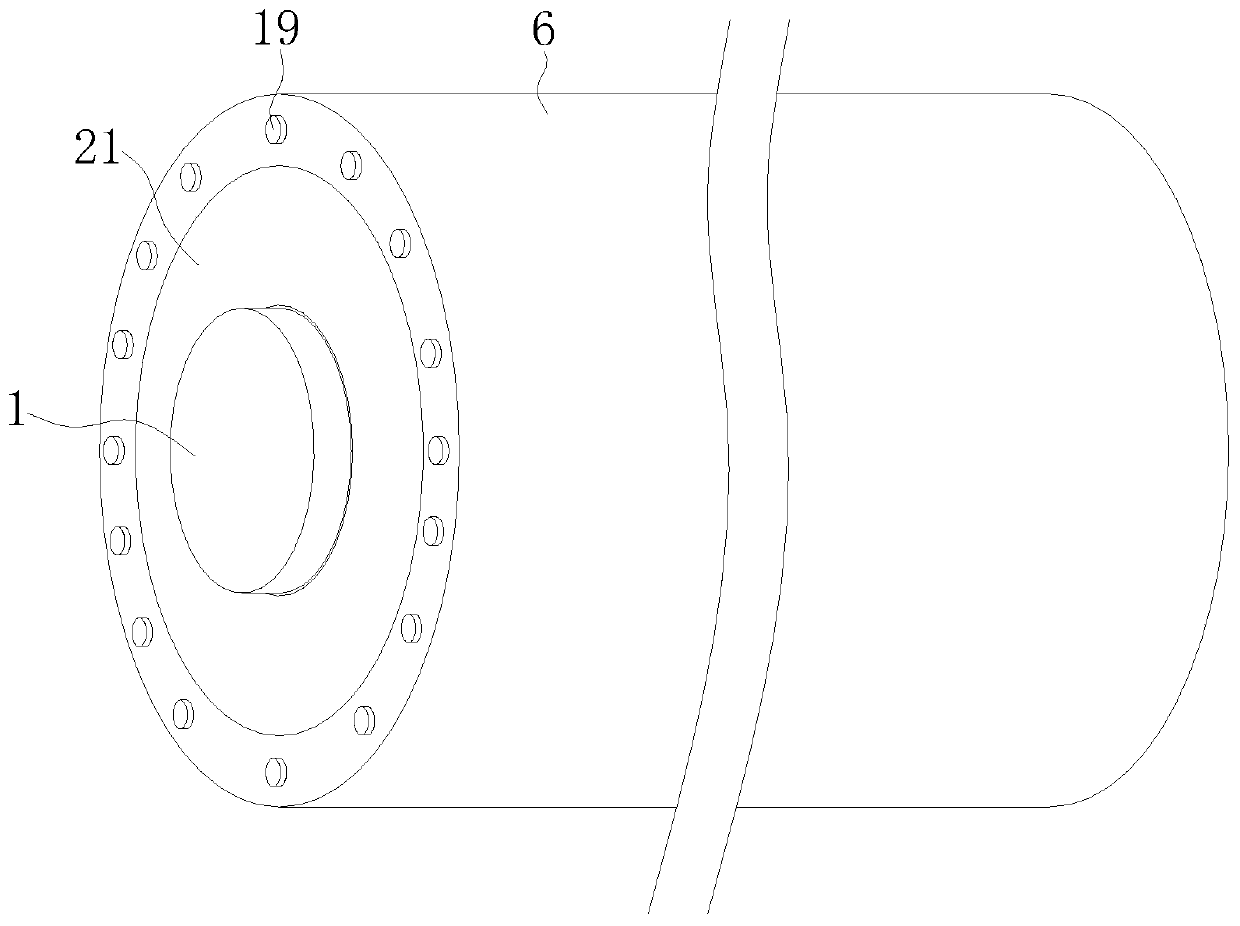

Ocean floating body powered adjustable negative-pressure vacuum sucking disc type connector

ActiveCN105757109AReduce local stressAvoid sudden disastersSuction cupsTime delaysPneumatic pressure

The invention discloses an ocean floating body powered adjustable negative-pressure vacuum sucking disc type connector which comprises a cylinder and vacuum sucking discs, wherein the cylinder comprises a cylinder shell and an air pump; a cavity is formed inside the cylinder shell and connected with the air pump; a first opening and a second opening are formed in two ends of the cavity and respectively communicated with a connecting tube and branch tubes; the tail ends of the branch tubes are respectively connected with a plurality of vacuum sucking discs acting on a module; the air pressure inside the cavity is adjusted through the air pump. Therefore, the absorbing force of a vacuum sucking disc absorbing module can be adjusted. The ocean floating body powered adjustable negative-pressure vacuum sucking disc type connector disclosed by the invention is connected with two modules through the sucking discs respectively, so that the relatively large connecting force is effectively scattered; the connecting force of the modules can be freely adjusted; once the modules have faults, the two modules are not immediately separated but certain time delay is available, so that sudden dangers can be effectively avoided, time for rush repairing and remediation can be provided, and convenience in assembling and disassembling can be achieved.

Owner:JIANGSU UNIV OF SCI & TECH +1

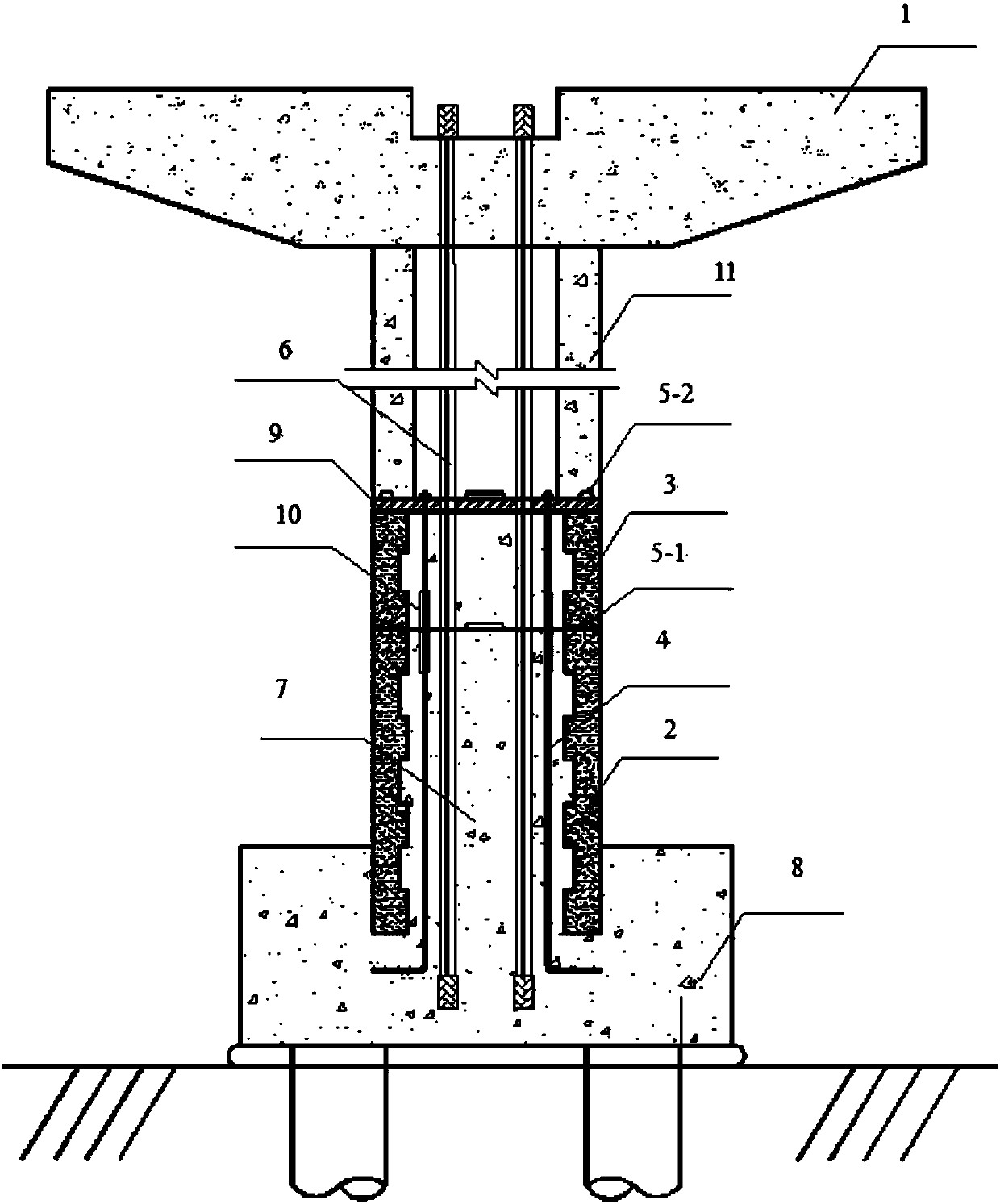

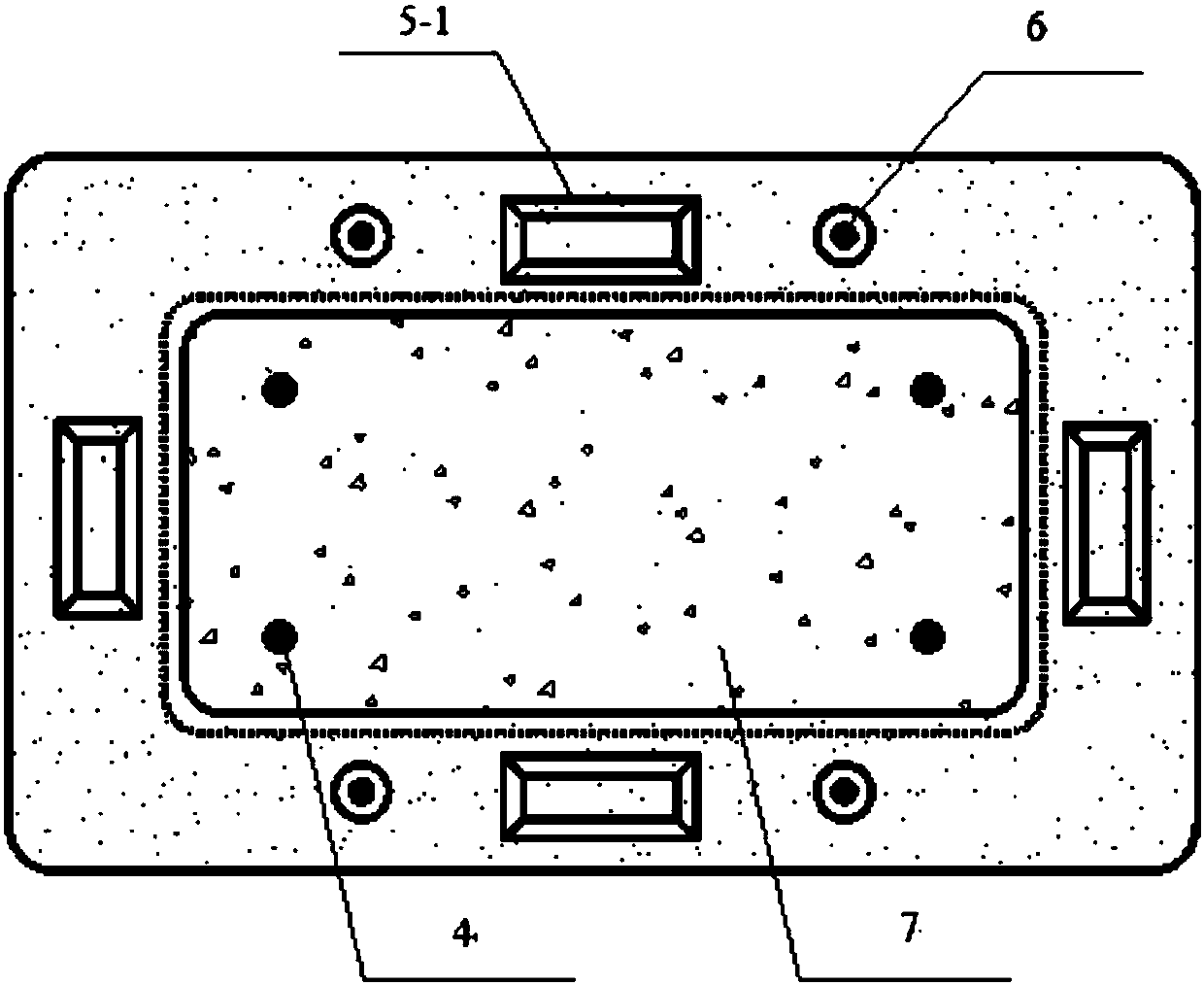

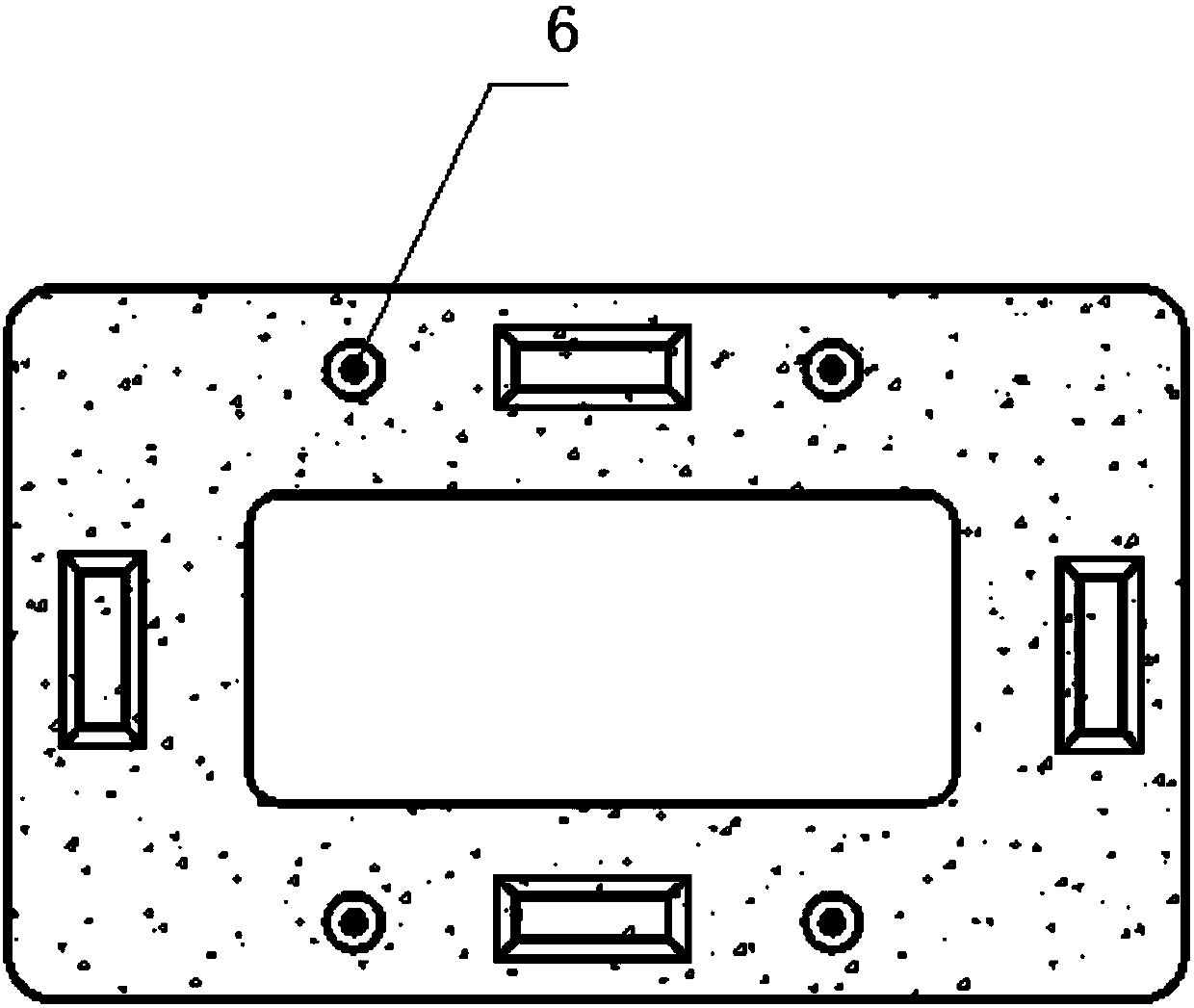

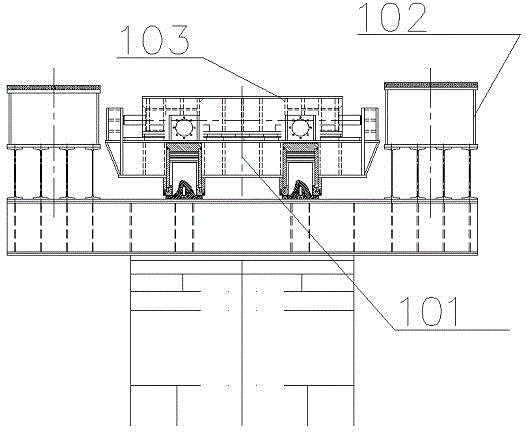

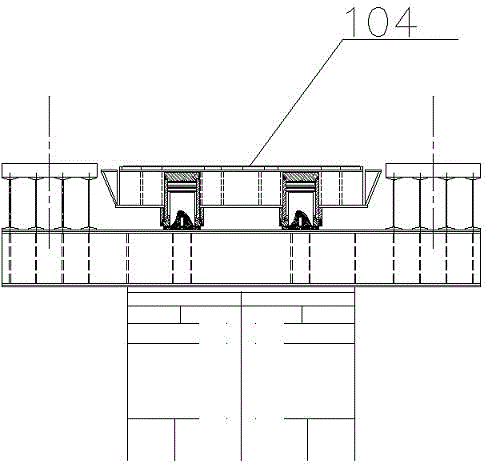

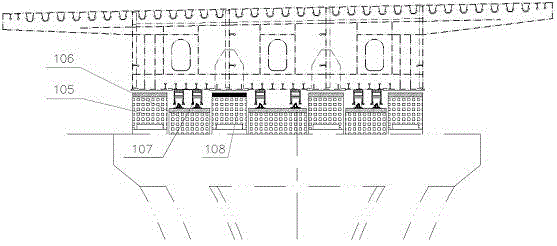

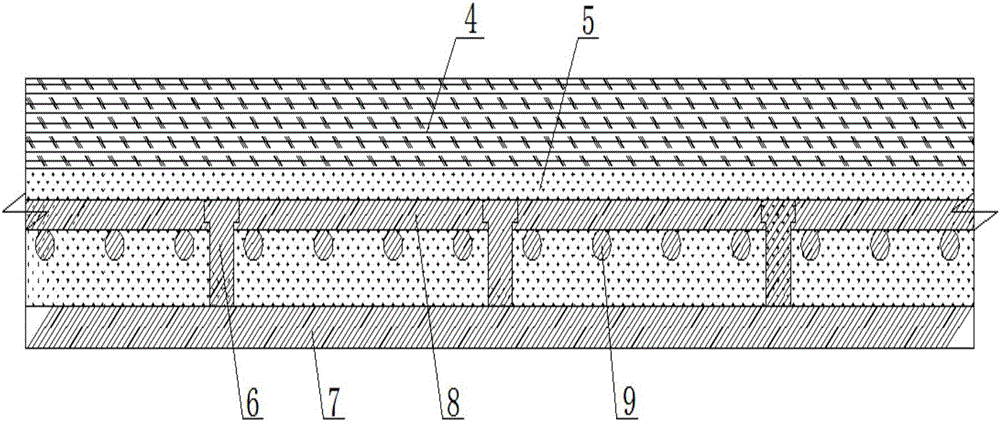

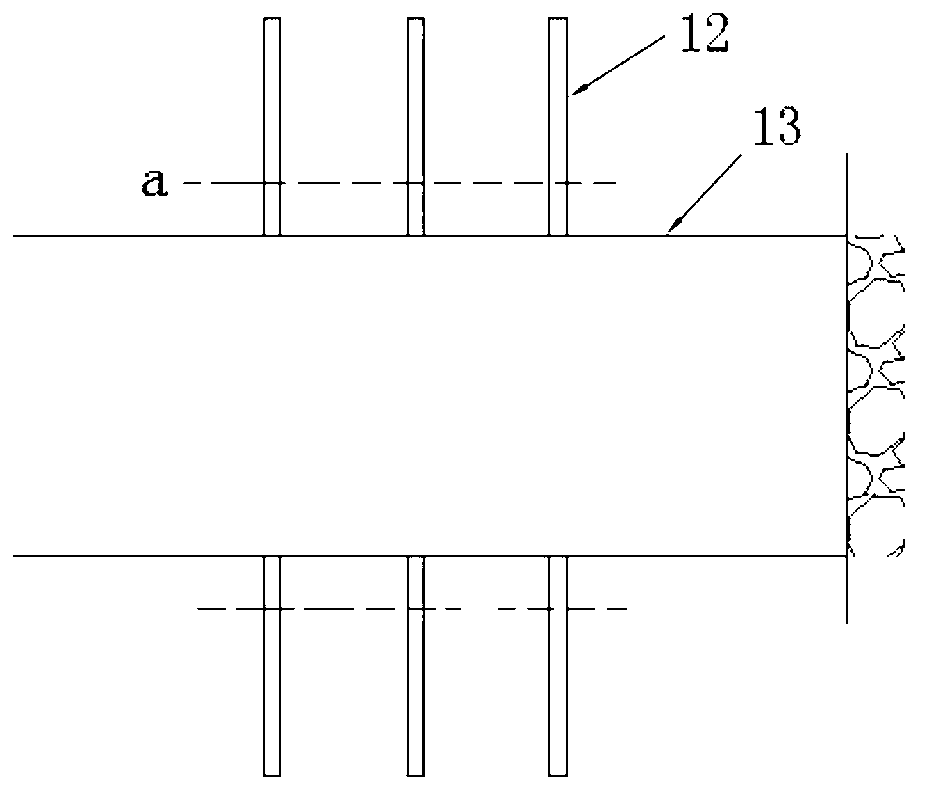

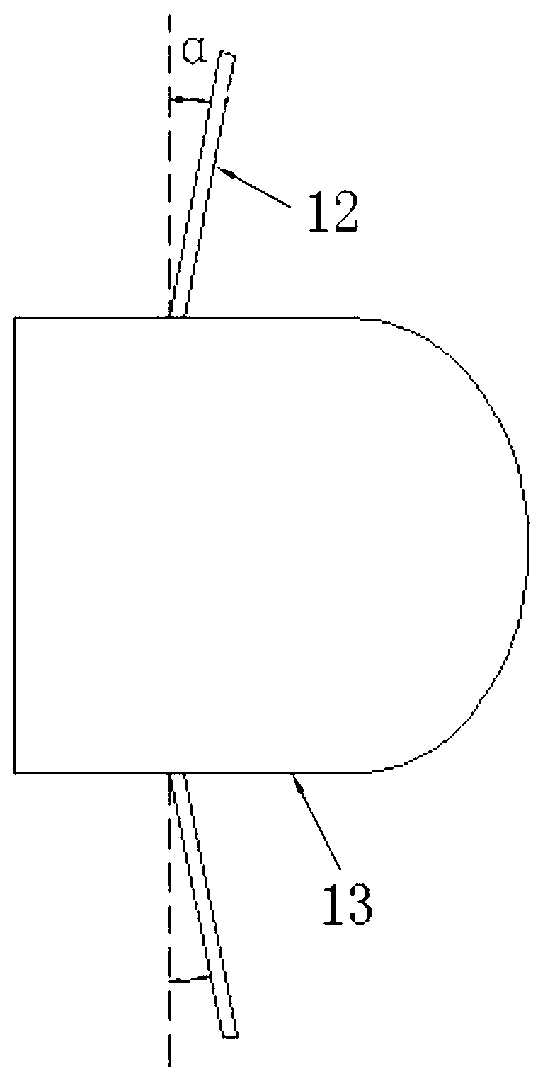

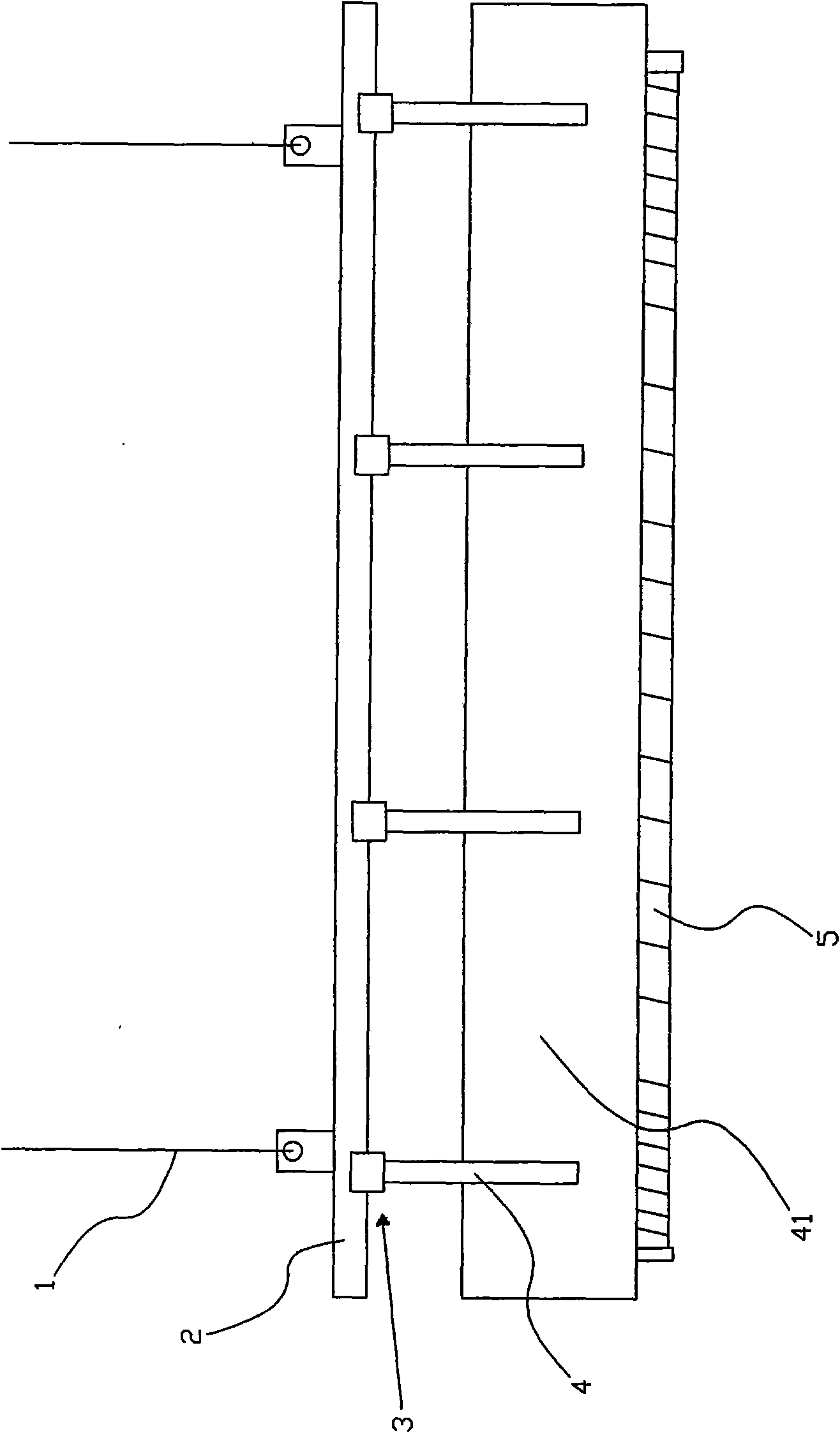

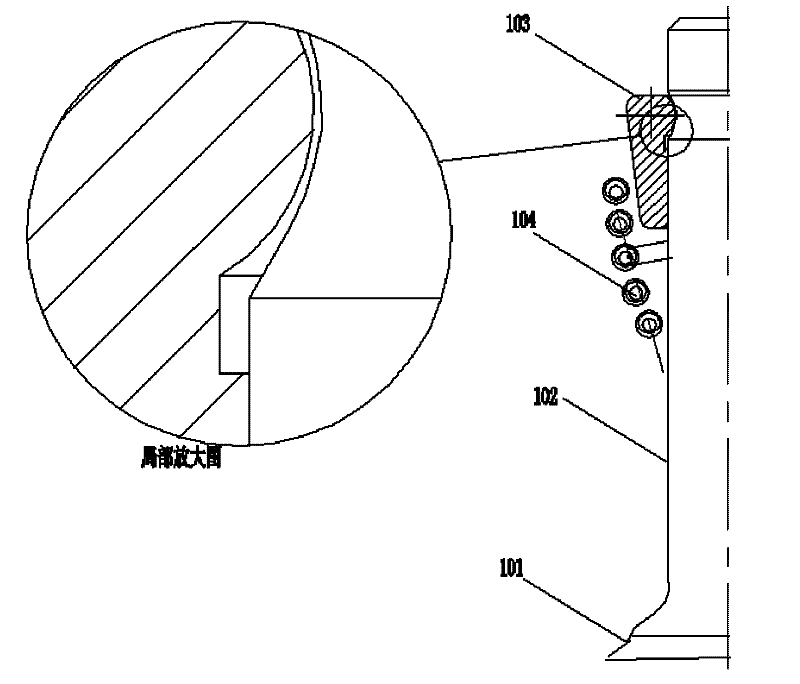

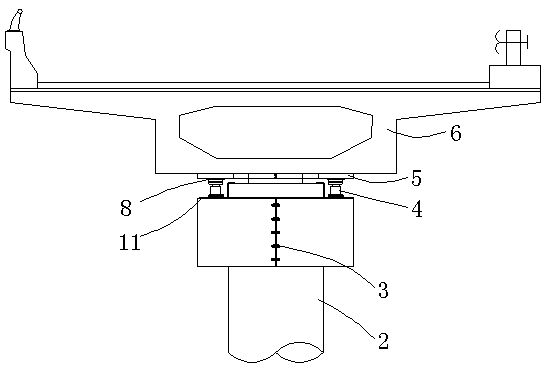

Prefabricated fabricated pier suitable for moderate-strong earthquake area and construction method of prefabricated fabricated pier

PendingCN107794837AGood mechanical propertiesReduce earthquake damageBridge structural detailsBridge erection/assemblyStress distributionSheet steel

The invention discloses a prefabricated fabricated pier suitable for a moderate-strong earthquake area and a construction method of the prefabricated fabricated pier. The prefabricated fabricated piercomprises a bearing platform, a pier body, a steel reinforcing cage, a cover beam and prestressed steel bars. The bearing platform is fixed on the top surface of a pile foundation. The steel reinforcing cage is arranged in the pier body. The bottom of the steel reinforcing cage is fixedly connected with the bearing platform. The top of the pier body is fixedly connected with the cover beam. The four prestressed steel bars are distributed in a rectangular shape. One ends of the prestressed steel bars are located in the bearing platform, and the other ends of the prestressed steel bars are located at the top of the cover beam. The steel reinforcing cage comprises a bearing platform steel reinforcing cage and a pier body steel reinforcing cage. The pier body steel reinforcing cage comprisesan energy dissipation steel bar, a longitudinal bar and a stirrup. The pier body comprises common concrete, a bottom UHPC sleeve, a transition UHPC sleeve, a steel plate and a prefabricated segment. According to the prefabricated fabricated pier suitable for the moderate-strong earthquake area and the construction method of the prefabricated fabricated pier, the technical scheme of combination ofthe UHPC sleeves and the common concrete, combination of consolidation and assembling and combination of part of the unbounded energy dissipation steel bar and the steel plate is adopted, and the prefabricated fabricated pier has the advantages of low damage under the earthquake action, high energy dissipation ability, uniform local stress distribution and the like, and can be applied to bridges in the moderate-strong earthquake area.

Owner:NANJING UNIV OF SCI & TECH

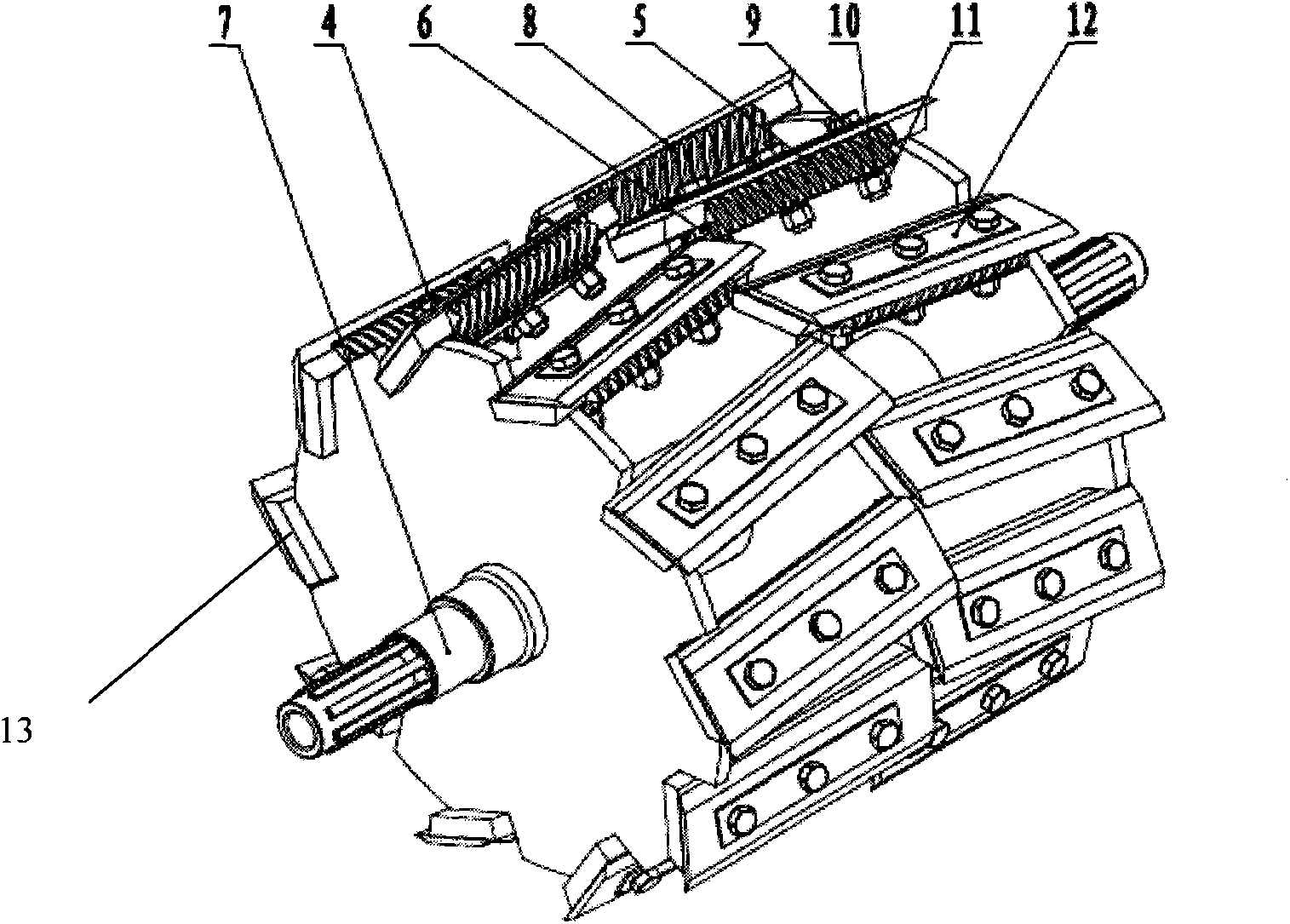

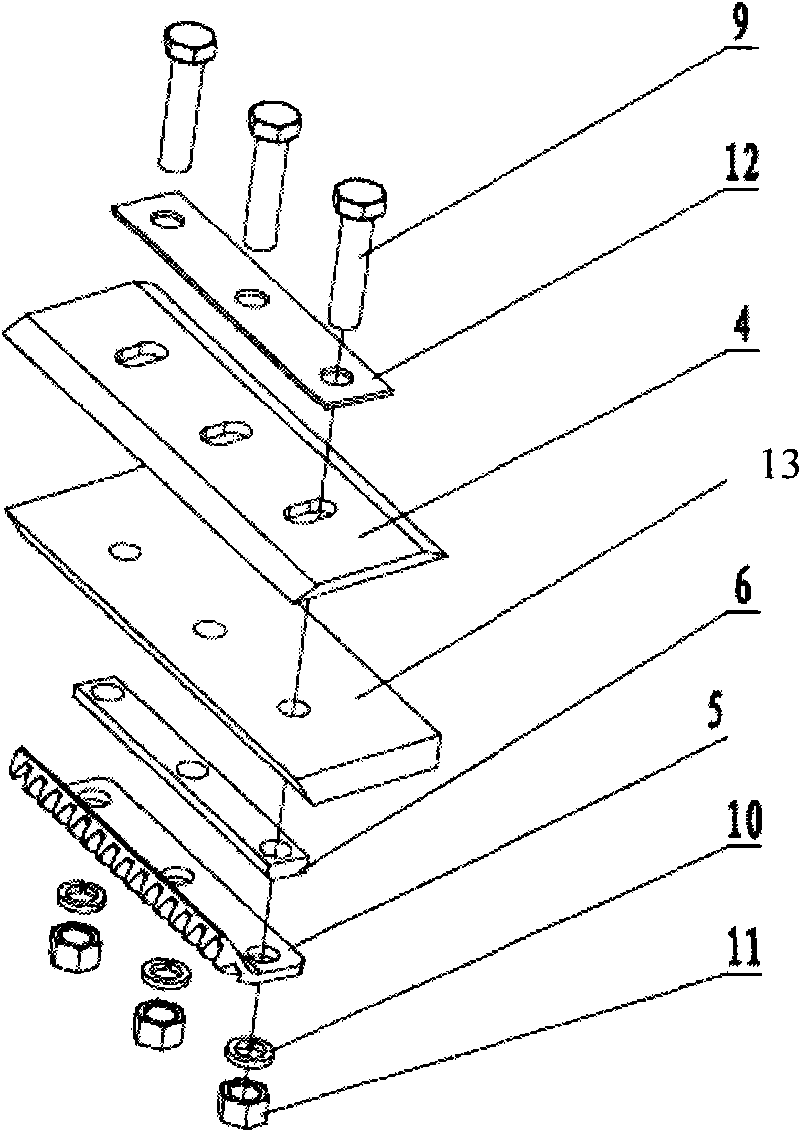

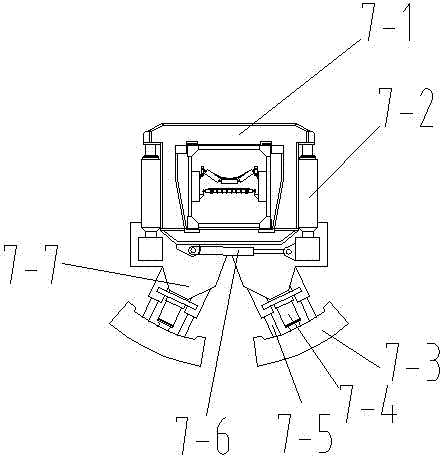

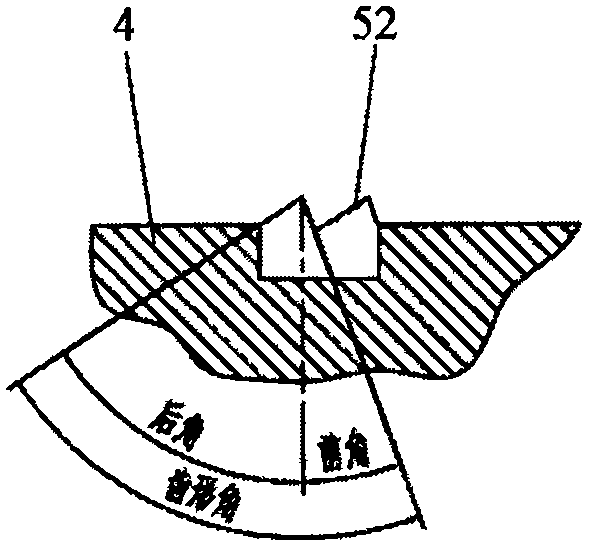

Shredding and rubbing device for silage harvester

The invention relates to a shredding and rubbing device for a silage harvester. The shredding and rubbing device comprises a shredding mechanism and a rubbing mechanism. The rubbing mechanism comprises friction blocks, middle cushion blocks and a concave plate. The friction blocks are fixedly connected to the lower ends of movable cutter bases, and the middle cushion blocks are arranged between the friction blocks and the movable cutter bases. The friction blocks comprise the left thread friction blocks and the right thread friction blocks. The left thread friction blocks are D-type left thread rasp bar steel, and the right thread friction blocks are D-type right thread rasp bar steel. The left thread friction blocks and the right thread friction blocks are installed on the movable cutter bases on the left side and the movable cutter bases on the right side respectively in a staggered mode. The concave plate is fixedly connected to the lower end of a shredding cylinder shell, and gap adjustment bolts are arranged on the two sides of the concave plate. In the working process, crops are cut into sections through movable cutters and fixed cutters, the crops are changed to be in a shred shape under the rubbing function of the concave plate and the friction blocks after cut into the sections, and quality of silage is improved.

Owner:MENOBLE

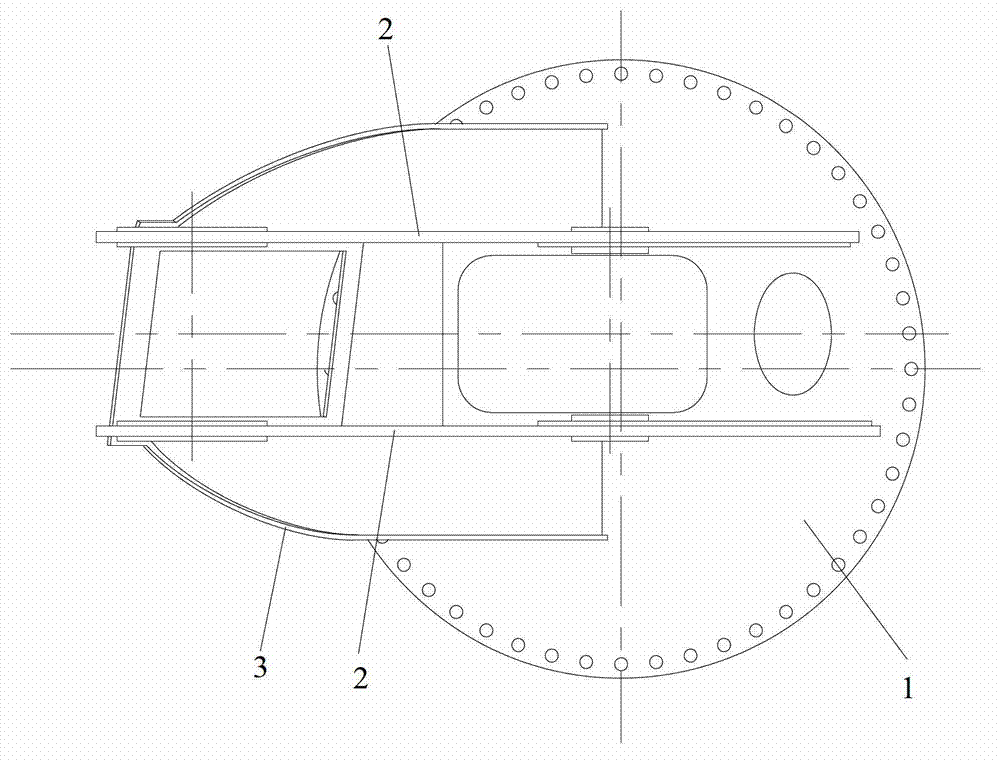

Short-distance coincident section heading machine

ActiveCN103670433AReduce equipment costsReduce construction costsTunnelsSupporting systemShortest distance

The invention discloses a short-distance coincident section heading machine. The short-distance coincident section heading machine is formed by connecting a cutterhead, a driving portion, a shield, a thrust and supporting system, a tail supporting system and a dreg outlet conveyor in sequence. The short-distance coincident section heading machine is characterized in that the thrust and supporting system comprises at least two main beam thrust supporting shoe systems, each main beam thrust supporting shoe system comprises a main beam, thrust oil cylinders and supporting shoes, the supporting shoes of each main beam thrust supporting shoe system are arranged in an X-shaped mode, and at least one pair of supporting shoe pins are arranged on each azimuth angle of each supporting shoe. According to the short-distance coincident section heading machine, due to the facts that the whole machine is reasonably designed, especially, the main beam thrust supporting shoe systems are designed in a modular mode, and the supporting shoes are designed, the purpose that repeated coincident section excavation is achieved, section excavation of subway station crossing is achieved, and a new idea is provided for development and improvement of other heading machines.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

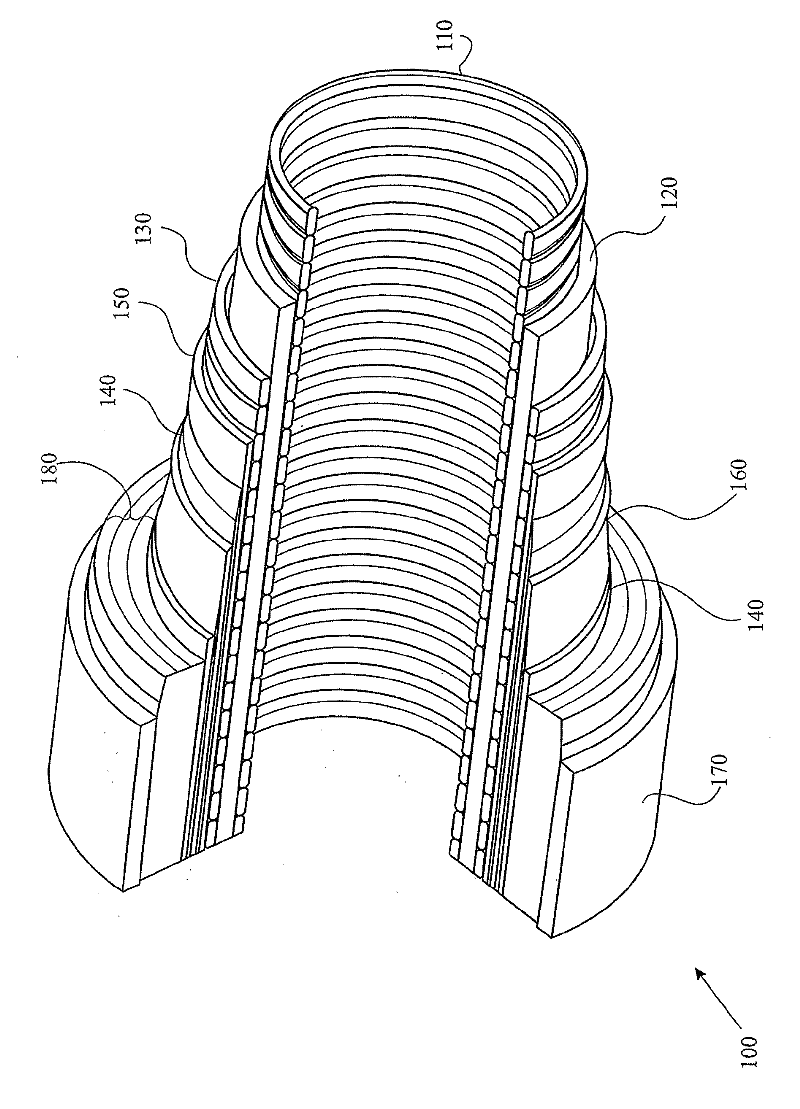

Flexible pipe having pressure armour layer and components thereof

InactiveCN102245953AIncrease hydrostatic external pressureIncrease static external pressureFlexible pipesMechanical engineeringClassical mechanics

An elongate tape element and method of manufacturing flexible pipe body are disclosed. The elongate tape element (12) which is for providing at least one helically wound layer of windings in a flexible pipe body (10), comprises an elongate body having a base surface (20), a top surface (22) opposed to the base surface and opposed first and second side walls (24, 26) extending between the base and tope surface wherein at least one surface and / or side wall of the body comprises a recessed region for receiving a respective portion of a tape element holder member when said tape element is wound to form a layer of windings.

Owner:GE OIL & GAS UK LTD

Composite energy absorption device for collision and application

InactiveCN104691467AHigh energy absorption efficiencyProtection securityBumpersInterference fitEnergy absorption

The invention provides a composite energy absorption device for collision. The composite energy absorption device comprises an extruding part and a bursting part, wherein an accommodating cavity and fiber layers stacked on the side wall of the accommodating cavity are arranged in the bursting part; the accommodating cavity is filled with an energy absorption material; the fiber layers is divided into a silk fiber layer arranged on the inner layer and multiple carbon fiber layers stacked on the outer side of the silk fiber layer; the fiber arrangement angles in the carbon fiber layers are different; the extruding part comprises an extruding rod and an extruding plate; the extruding rod and the accommodating cavity are in interference fit, when the extending rod receives external force, one end of the extruding rod extends into the accommodating cavity and extrudes the energy absorption material, and the other end of the extruding rod is connected with the extruding plate.

Owner:HUAQIAO UNIVERSITY

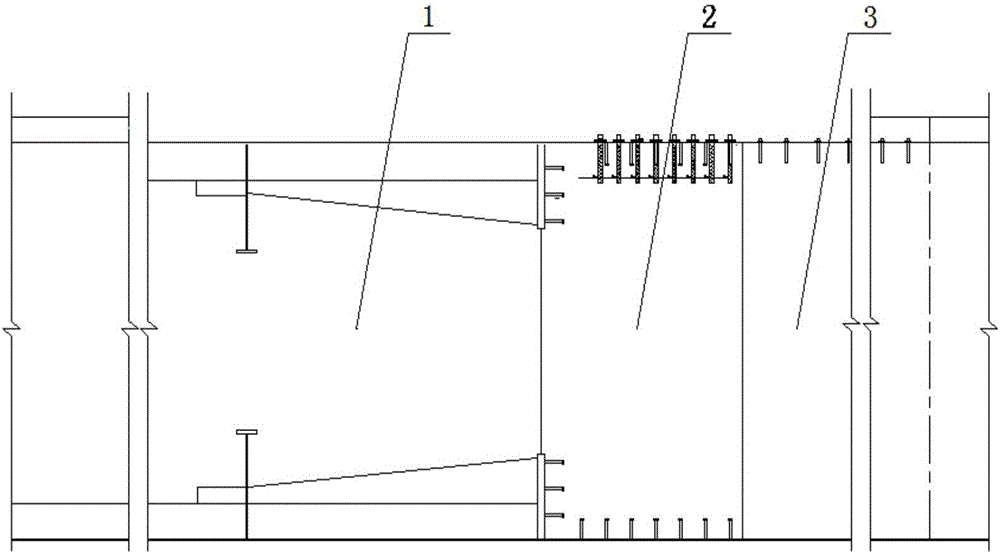

Girder-declining construction method for steel box girder spanning railway trunk line

InactiveCN103556575AGuaranteed stabilityEnsure stabilityBridge erection/assemblyStructural engineeringBox girder

The invention relates to a girder-declining construction method for a steel box girder spanning a railway trunk line. The girder-declining construction method comprises the following stages: a first stage: firstly, adopting a walking type pushing device for directly declining a girder for 20-40cm, and then using a jacking device on the lower part of the walking type pushing device for declining the girder for 40-60cm, and causing the steel box girder to fall onto an I-shaped steel; a second stage: erecting at least three girder-declining supporting pads on a permanent supporting base of the steel box girder, causing the steel box girder to fall onto the girder-declining supporting pads on the position of the supporting base and declining the girder for 8-15cm, and then declining the girder for 10-20cm at each time and declining the girder for 100cm; and a third stage: using a three-way jack for declining the girder till the girder is in place. According to the girder-declining construction method adopting the technical scheme, the steel box girder has a single box integrated fracture surface structure, so that the whole stability of the steel box girder is ensured during the girder-declining process. Meanwhile, a 20mmX850mmX850mm steel plate is additionally arranged in a stressed position of a base plate of the steel box girder, so that the local stress of the base plate of the steel box girder is reduced.

Owner:CHINA RAILWAY 15TH CONSTR BUREAU GRP +1

Chemical annealing method for making amorphous silicon battery more stable

InactiveCN101235492AFacilitate recombination optimizationAtomic structure relaxationChemical vapor deposition coatingSemiconductor devicesSilicon membraneCompound (substance)

The invention discloses a chemical annealing method for improving the stability of intrinsic amorphous silicon thin film, which comprises: alternating the growth of silicon film whose thickness is 2-10 nanometers and the chemical annealing treatment in the process that plasmas are used to intensify a chemical vapor deposition method to generate hydrogenated amorphous silicon, sufficiently rebuilding and loosening atomic structures of hydrogenated silicon material, and lowing the electronic defect concentration. The material is in particular suitable for i layers in p-i-n type photovoltaic devices.

Owner:BEIJING XINGZHE MULTIMEDIA TECH

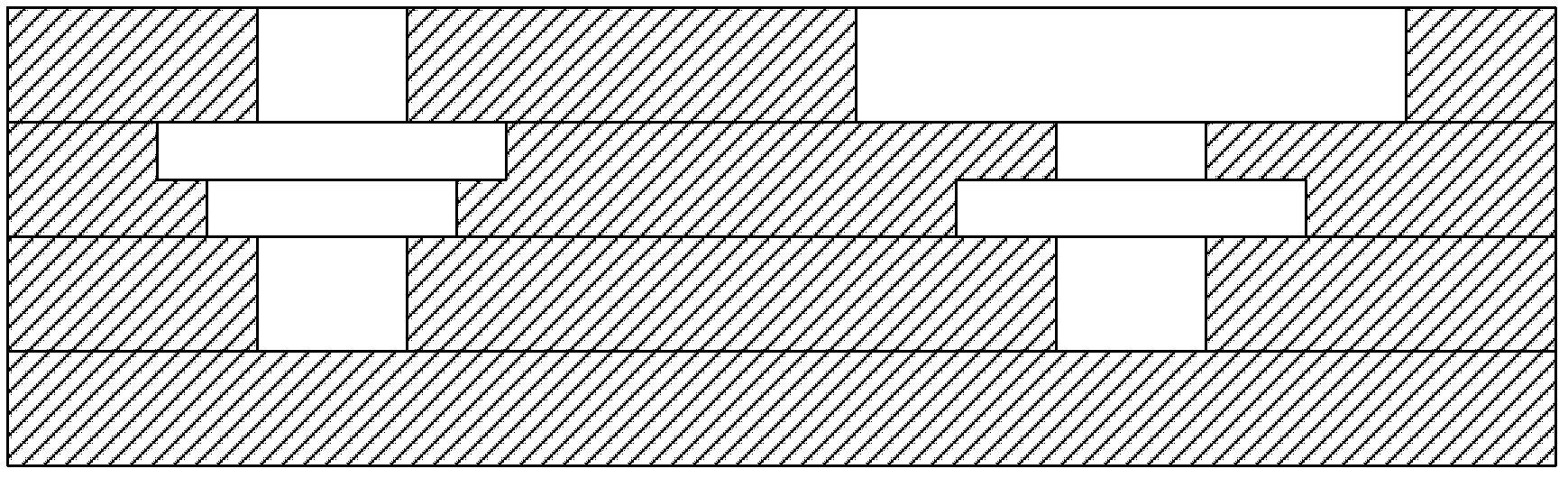

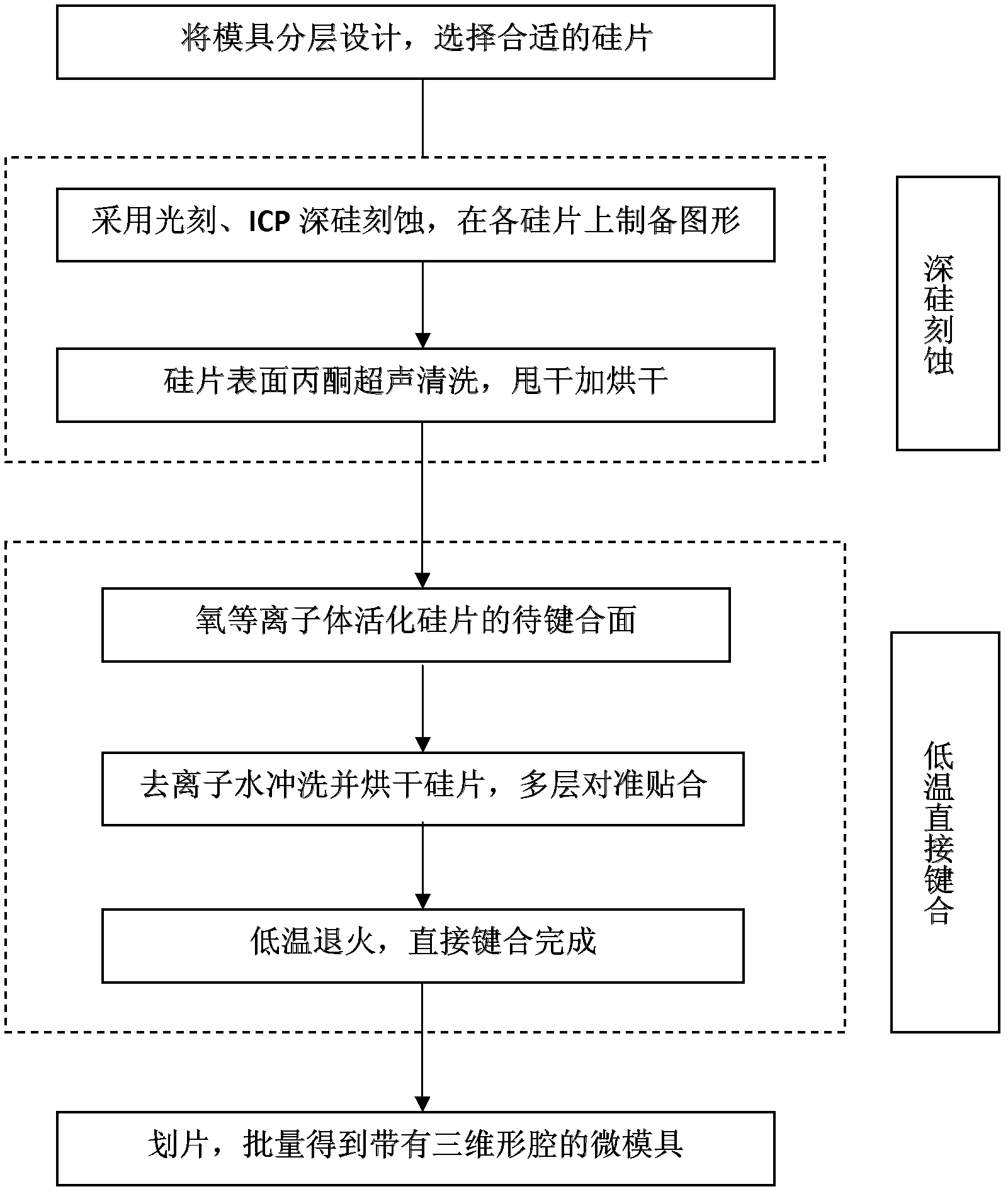

Method for manufacturing three-dimensional silicon mold directly bonded by low-temperature plasma activation

InactiveCN102431961AEasy to operateImprove controllabilityDecorative surface effectsChemical vapor deposition coatingMicro structureSilicon mold

The invention provides a method for manufacturing a three-dimensional silicon mold directly bonded by low-temperature plasma activation. The method comprises the following steps of: designing a micro-mold to be manufactured in the Z direction in a laminated manner; selecting silicon chips with appropriate thicknesses as substrates on all layers, and accurately etching the silicon chips on all the layers by a photoetching or inductively-coupled plasma (ICP) deep silicon etching method to form a structural graphic of a mold corresponding layer; cleaning the surfaces of all the silicon chips, performing plasma activation, pre-bonding, and annealing at a low temperature to finish the direct bonding of a plurality of layers of silicon chips; and finally, scribing to acquire three-dimensional micro silicon molds in batches. The method is suitable for efficiently manufacturing the silicon mold with a stepped high depth-to-width ratio three-dimensional micro structure (such as a micro gear shaft, a micro stepped shaft, a micro pump and the like) in a microelectromechanical system (MEMS) device at high accuracy.

Owner:HUAZHONG UNIV OF SCI & TECH

Maintaining and reinforcing method of bridge steel-concrete composite segment

InactiveCN106758877AImprove the forceReduce concentrated stressIn situ pavingsBridge structural detailsSand blastingShear capacity

The invention relates to a maintaining and reinforcing method of a bridge steel-concrete composite segment. The method is characterized by include the following operation steps that (1) the bridge deck is cleaned; (2) measurement and detection are performed; (3) sand blasting for derusting is performed; (4) detection is performed; (5) spraying of an anti-corrosion layer is performed; (6) welding of shear nails is performed; (7) a shearing device is mounted; (8) glue injection is performed; (9) a reinforcing mesh is mounted; (10) a high-tenacity concrete layer is poured; (11) high-temperature steam curing is performed; (12) a water-proof bonding layer is laid; and (13) an asphalt layer is laid. The maintaining and reinforcing method of the bridge steel-concrete composite segment is scientific and reasonable in design and capable of effectively improving bridge deck stress, reducing concentrated stress of the steel-concrete composite segment, increasing the anti-shear capacity of the composite segment, preventing bridge deck fracture and ensuring driving safety.

Owner:天津市交通科学研究院

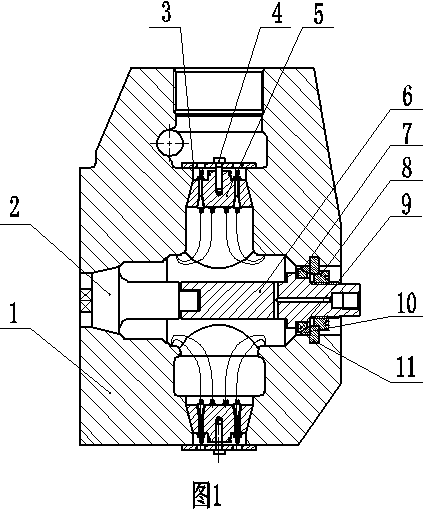

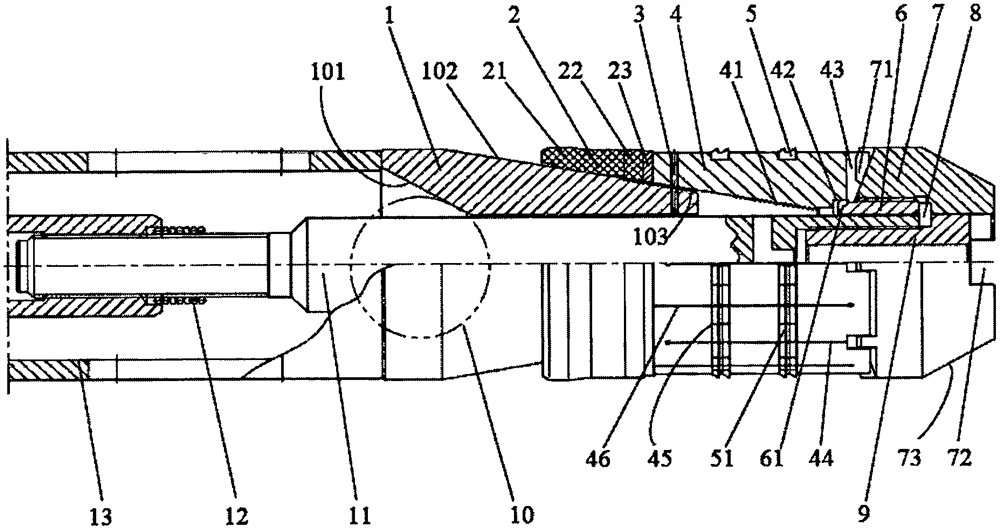

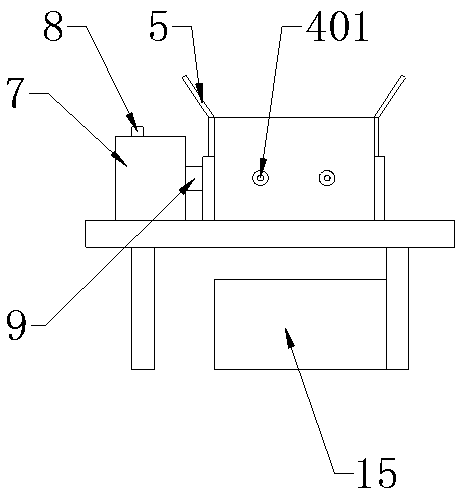

Self-tightening sealing and stress testing device for self-enhancing of ultrahigh-pressure pump head body

ActiveCN103711688AGuaranteed sealing reliabilityReduce local stressPump testingPositive displacement pump componentsCombined usePump head

The invention relates to a self-tightening sealing and stress testing device for self-enhancing of an ultrahigh-pressure pump head body, belonging to the technical field of self-enhancing of a pump head body of an ultrahigh-pressure container. The self-tightening sealing and stress testing device comprises an ultrahigh-pressure pump head body, a horizontal sealed taper rod, a signal lead-out seal taper, a horizontally sealed adjusting rod, an O-shaped seal ring, a signal lead-out rod, an organic glass sealed taper ring, quick-plugging joints, high-strength enameled wires, a strain gauge and a wiring transition plate. All sealing surfaces of the device adopt taper surface hard sealing, the higher the hydraulic pressure in the inner cavity of the pump head body is, the larger the pressure on the sealing surfaces is, and the reliability of sealing under ultrahigh pressure can be guaranteed; in assembling, the sealing of the sealing surfaces in low-pressure or non-pressure state can be controlled by thread pretightening force. The self-tightening sealing and stress testing device has the characteristics of being convenient to install, and convenient and fast to wire. According to the device, the difficulty in testing the stress of the container wall by leading out a wire from the ultrahigh-pressure sealed container can be solved by adopting the combined use of the organic glass sealed taper ring, the O-shaped seal ring and the wire lead-out rod.

Owner:YANGTZE UNIVERSITY +1

Full-soluble fracture bridge plug with novel structure

PendingCN112901113AImprove stress conditionEliminate chippingDrilling rodsSealing/packingRatchetSlip ring

The invention discloses a full-soluble bridge plug with a novel structure, and belongs to a bidirectional locking single-slip full-soluble bridge plug. The full-soluble bridge plug comprises a male tap, a sealing assembly, a screw, a slip female tap, a slip ring, a shear ring pressing cap, a base, a shear ring, a shear ring seat, a soluble ball and the like. The tap surface of the male tap is sleeved with the sealing assembly and the slip female tap; the sealing assembly comprises a wedge-shaped rubber barrel, a rubber pad and a metal ring; the slip female tap is of a radial elastic claw structure; one to three rectangular ring grooves are formed in the outer portion of the slip female tap; a plurality of slip particles are assembled in the ring grooves to form the slip ring; a male ratchet and a female ratchet are arranged on the male tap and the slip female tap respectively; and during setting, the male and female ratchets are tightly engaged into a whole, the tooth tip of the slip ring is fully engaged into the inner wall of a casing pipe, and the bridge plug is bidirectionally locked on the inner wall of the casing pipe. The bridge plug can be dissolved by fracturing flow-back fluid or oil and gas reservoir well fluid, is small in size and higher in applicability, and improves the fracturing well completion efficiency.

Owner:湖北亿井石油技术开发有限公司

Method for strengthening reinforced concrete girder by using slightly curved and tensioned carbon fiber plates

ActiveCN104100100AEasy to manufactureIncrease profitBuilding repairsBuilding material handlingEpoxyFiber

The invention relates to a method for strengthening a reinforced concrete girder by using slightly curved and tensioned carbon fiber plates, and belongs to the technical field of new material application and engineering strengthening. The method is mainly characterized in that a slightly curved concrete base plate is adhered to an adhesion surface on the bottom of the reinforced concrete girder via epoxy resin; an outward surface of the slightly curved concrete base plate is in the shape of a micro-rise arc; the carbon fiber plates are paved in grooves formed in protecting walls on two sides of the slightly curved concrete base plate; two ends of each carbon fiber plate are clamped via anchorage devices; the anchorage devices at the fixed ends of the carbon fiber plates are fixed in the reinforced concrete girder via high-strength cotters; and the anchorage devices at the tensioned ends of the carbon fiber plates are fixedly connected with guiding and positioning plates through high-strength screws. By the method, prestressing force generated by the carbon fiber plates can be uniformly transmitted to the reinforced concrete girder, the local stress of the anchorage devices is reduced, and the carbon fiber plates can be safely enclosed for a long time; and the tensioning anchorage devices has the characteristics of safety, reliability and easiness and convenience in manufacturing. The method has the advantages of high material using rate, easiness and convenience in construction procedure and high structural durability. Moreover, the method has the remarkable application prospect in the reinforcement project of reinforced concrete structures which are wide in application and high in quantity.

Owner:YANGZHOU UNIV

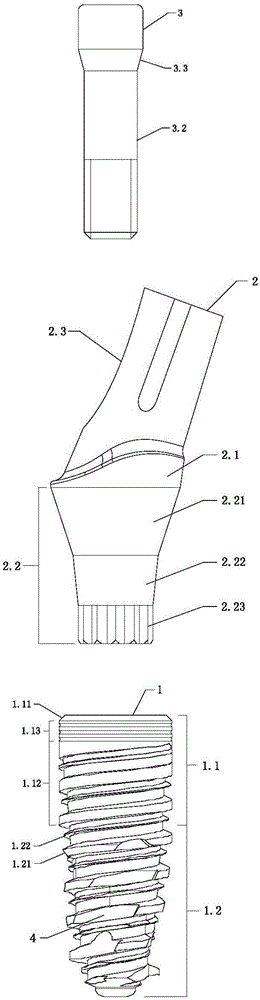

Ceramic rotation-resistant angle base station implant system

InactiveCN106725933ACoordinating Restoration EffectsBeautiful repair effectDental implantsSystem stabilityEngineering

The invention discloses a ceramic rotation-resistant angle base station implant system, which comprises an implant, an artificial tooth base station and a center bolt, wherein a dental crown connecting section and an implant connecting section are respectively arranged on two ends of the artificial tooth base station; an included angle between an axis of the dental crown connecting section and an axis of the implant connecting section ranges from 12 degrees to 45 degrees; the implant is provided with a connecting hole matched with the implant connecting section of the artificial tooth base station; a step hole matched with the center bolt is formed in the artificial tooth base station; an internal thread matched with an external thread of the center bolt is also arranged in the connecting hole of the implant; a screw rod of the center bolt penetrates through the step hole so as to be in screw-thread fit to the implant. The implant system has high stability and strength, can be suitable for various oral implantology conditions and angles, and is beneficial for effectively reducing local stress, shortening healing time and reducing patient wounds.

Owner:DALIAN SANSHENG SCI & TECH DEV

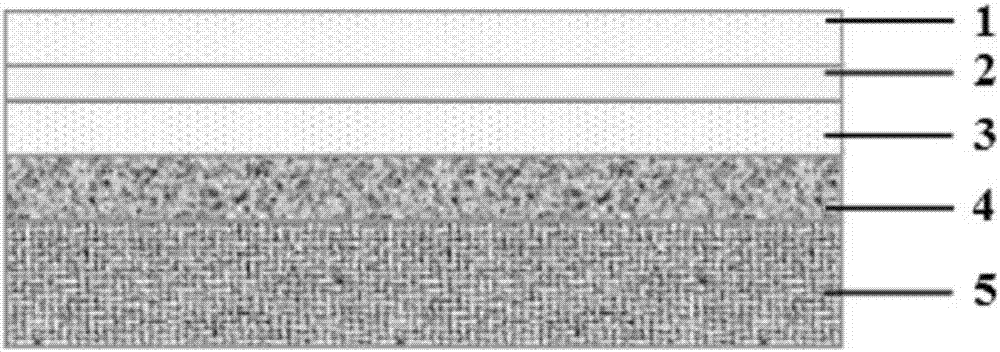

An external-layer fabric of fire-fighting heat-insulating protective clothing

InactiveCN106863931AThickness is easy to controlGood flexibilitySynthetic resin layered productsLaminationEngineeringRadiant heat

The invention relates to a layered structure of a fabric, in particular to an outer fabric of fire-fighting and heat-insulating protective clothing, belonging to the technical field of fire-fighting and heat-insulating protective clothing. An outer fabric for fire-fighting and heat-insulating protective clothing, characterized in that it includes a first aluminized layer, a high-temperature-resistant polymer film layer, a second aluminized layer, an adhesive adhesive layer, and a base cloth layer; the first aluminized layer layer and the second aluminum-coated layer are plated on both sides of the high-temperature-resistant polymer film layer, and the second aluminum-coated layer and the base cloth layer are bonded by an adhesive layer. The double-sided aluminum plating of the high temperature resistant polymer film has good anti-radiation heat penetration performance, which makes the fabric have an excellent function of reflecting radiant heat; the high temperature resistant polymer film and the aluminum coating layer are closely combined to strengthen the aluminum coating layer effect.

Owner:SHANGHAI FIRE RES INST OF THE MIN OF PUBLIC SECURITY

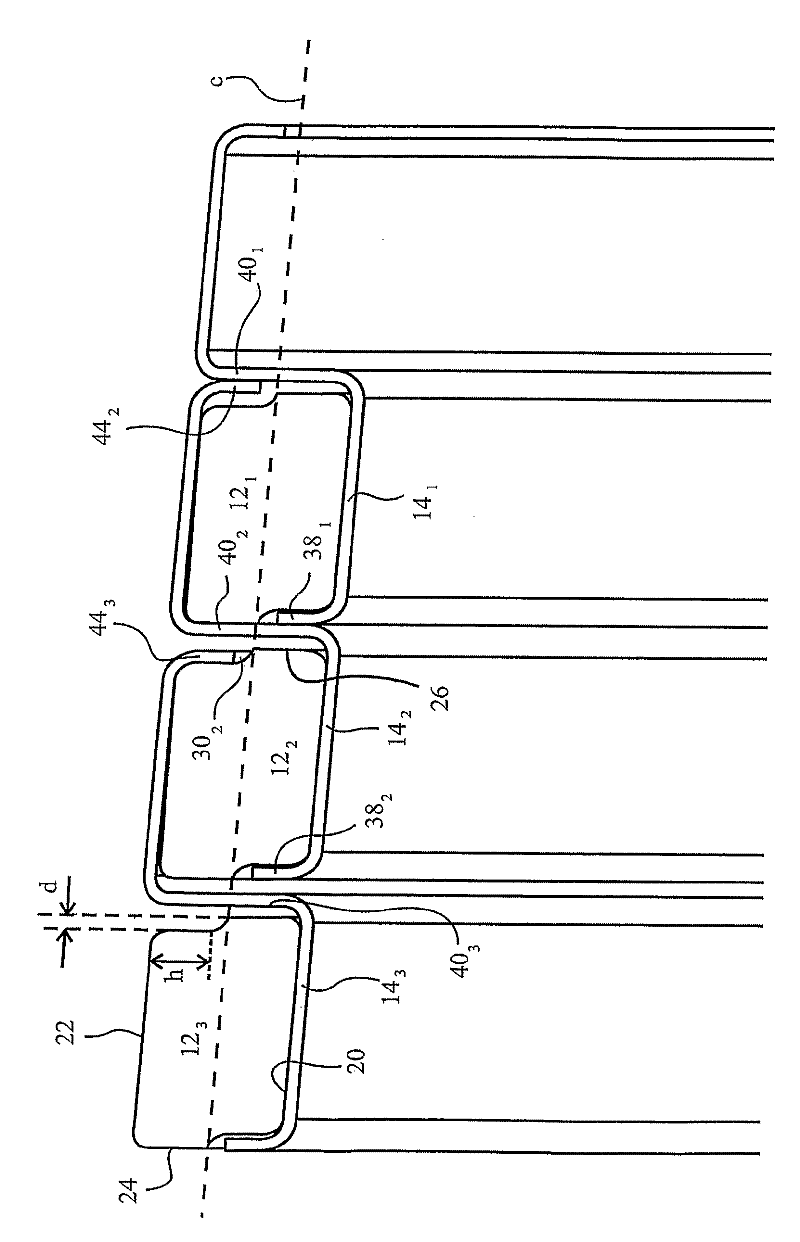

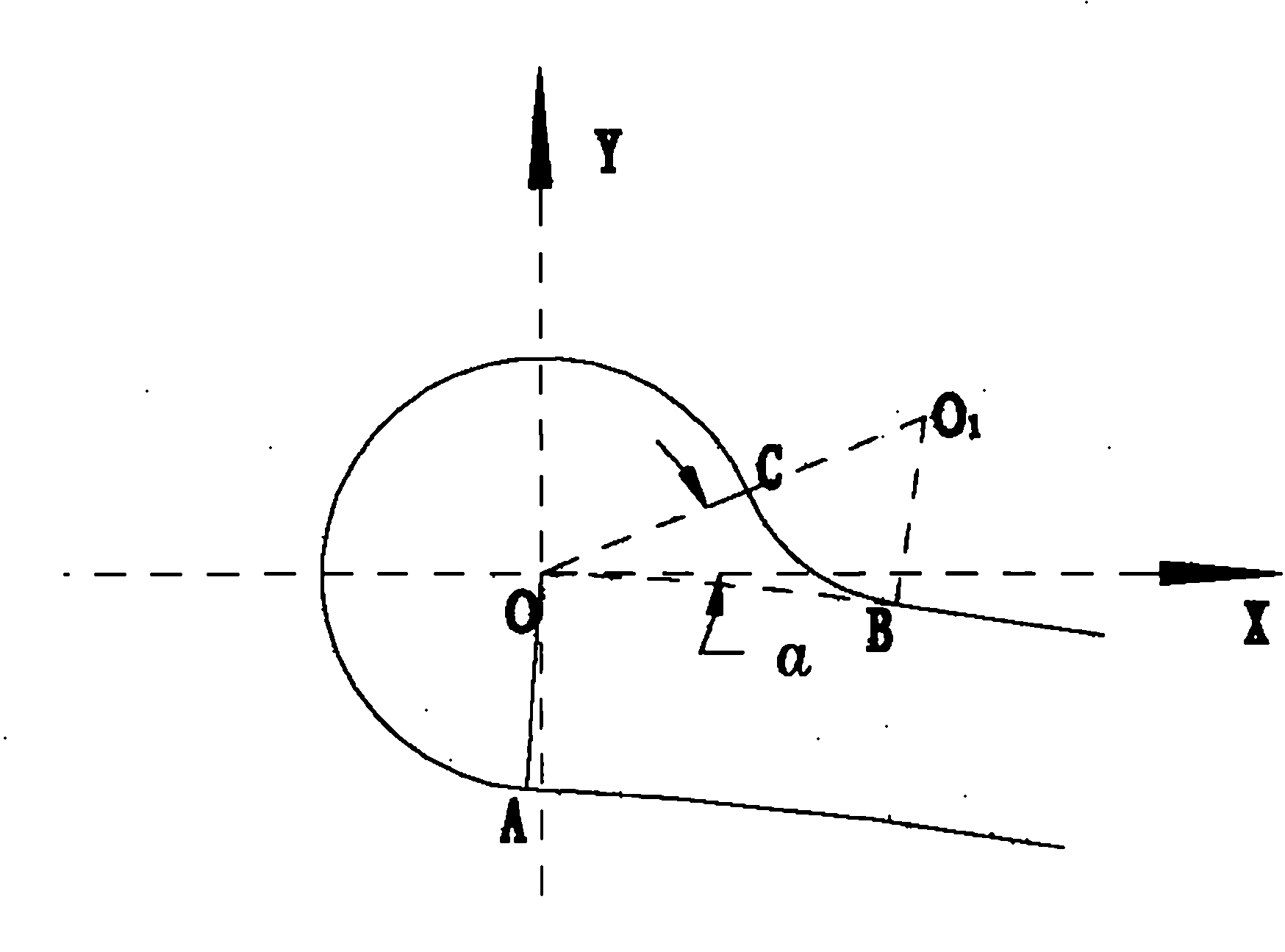

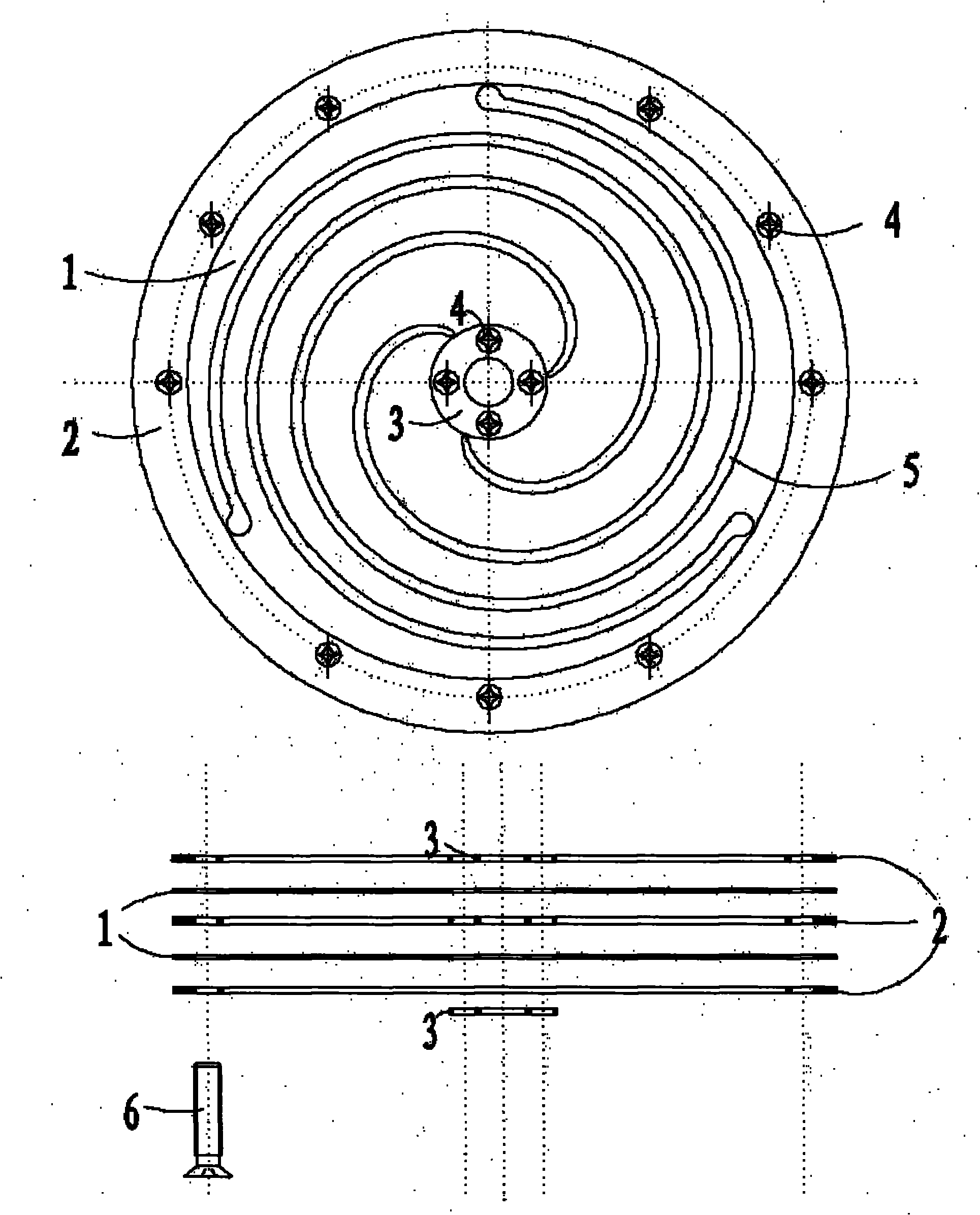

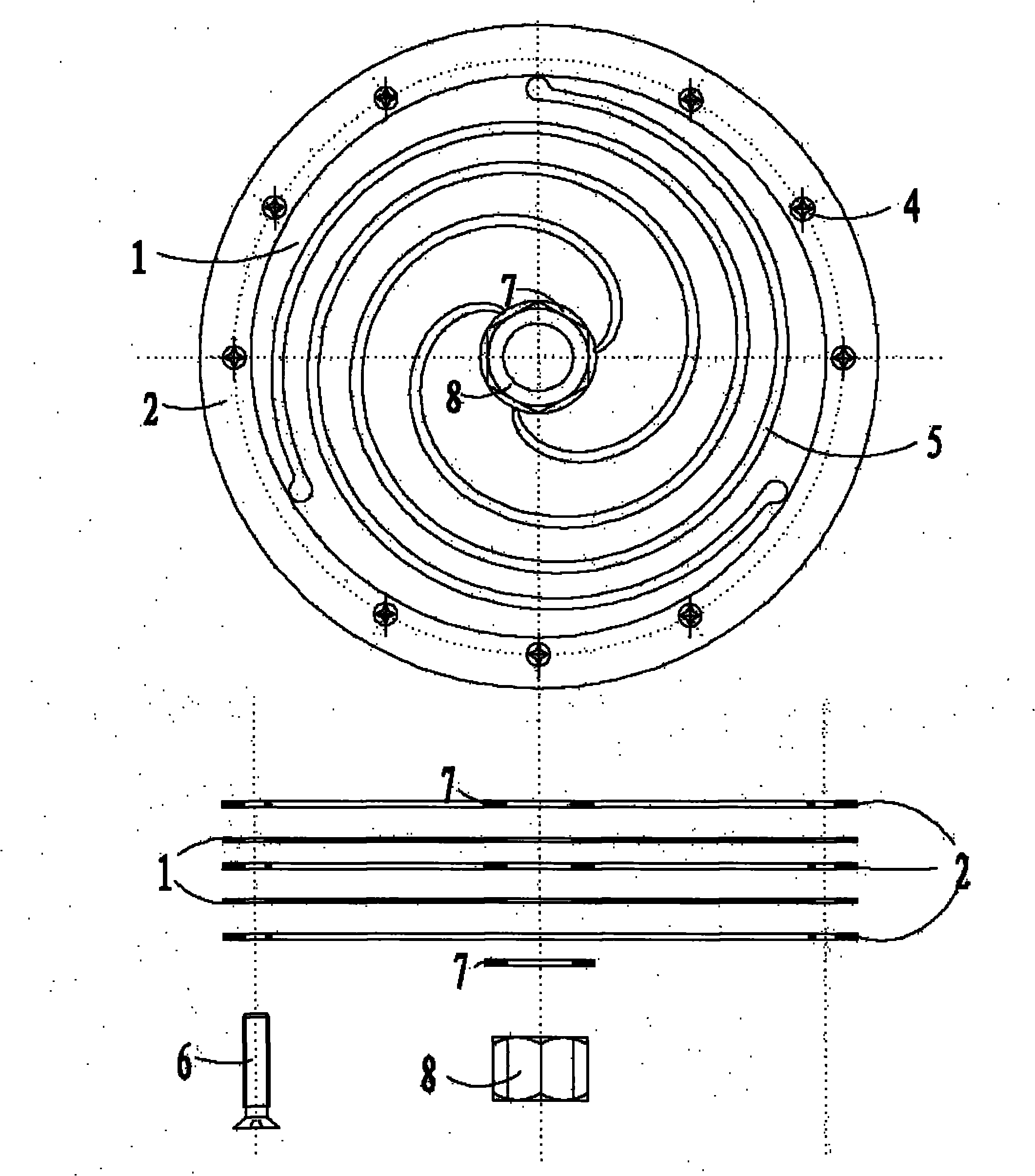

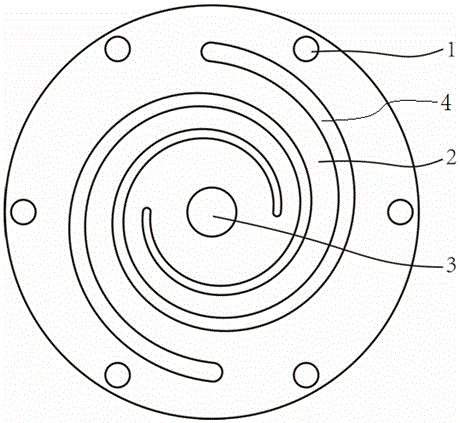

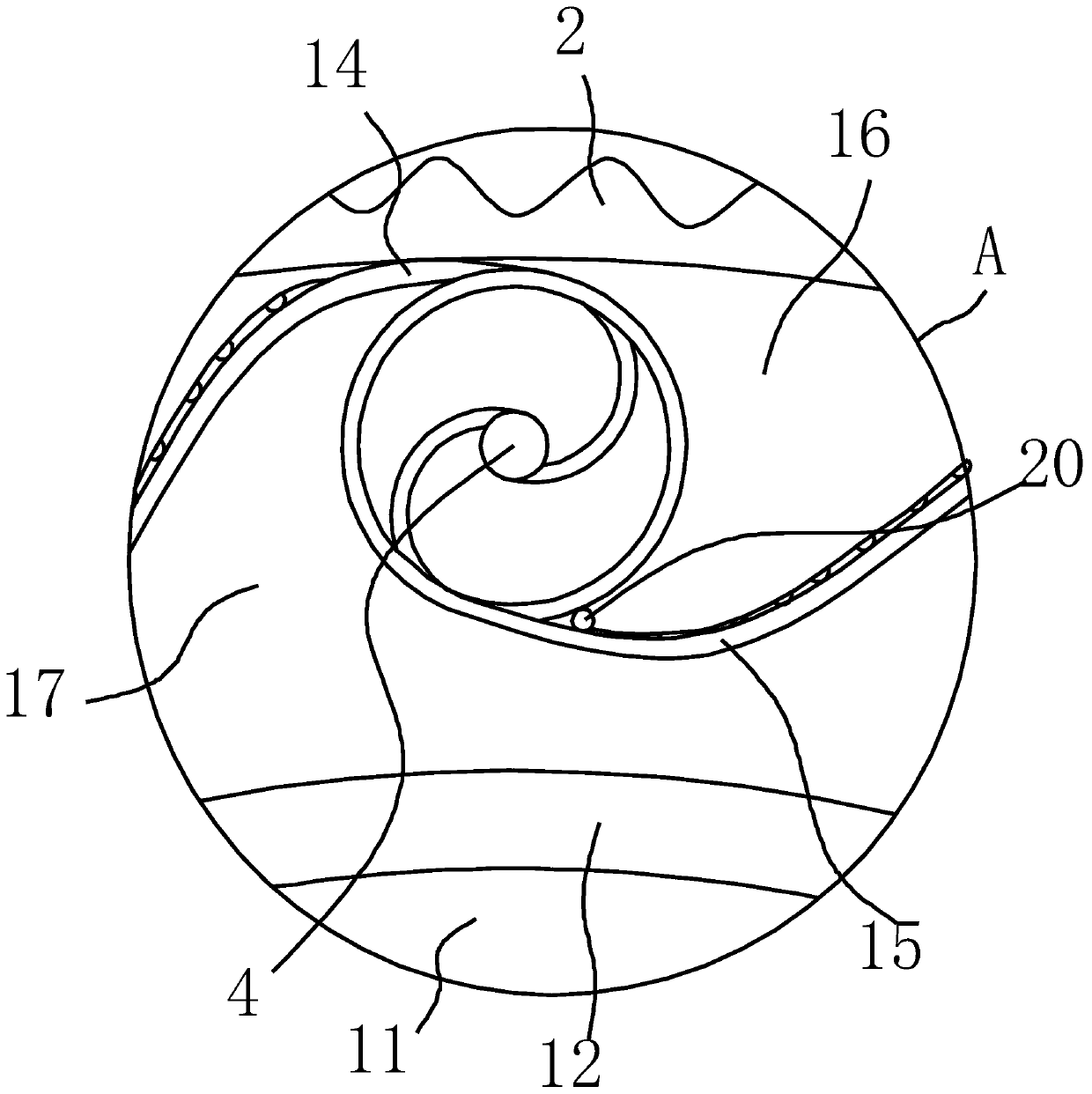

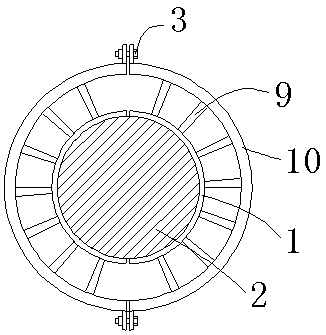

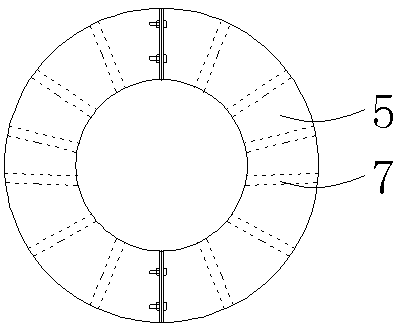

Flexible spring

InactiveCN101893050AUniform stress distributionReduce deformationMultiple spring combinationsPistonEngineering

The invention discloses a flexible spring, comprising an outer ring spacer and an inner ring spacer. A through hole for a piston shaft is formed at the center of the spring and the outer ring of the spring is provided with a plurality of mounting holes. The invention is characterized in that three spring vortex groove lines are determined by using a Fermat curvilinear equation, wherein the three lines are evenly distributed at 120 degrees; the starting positions and the ultimate positions of the inner side curve and the outer side curve of the vortex groove can be controlled through changing the initiation and generation angle alpha of the vortex groove lines and the grazing angle theta of the vortex groove lines; and the inner side curve and the outer side curve of the vortex groove can be obtained by changing the starting radius A and the vortex coefficient B of the vortex groove lines, which are in different geometric shapes, and the inner and outer side curves are smoothly transited and closed. The flexible spring of the invention has even stress distribution, small local stress and deformation, proper axial rigidity and larger radial rigidity.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

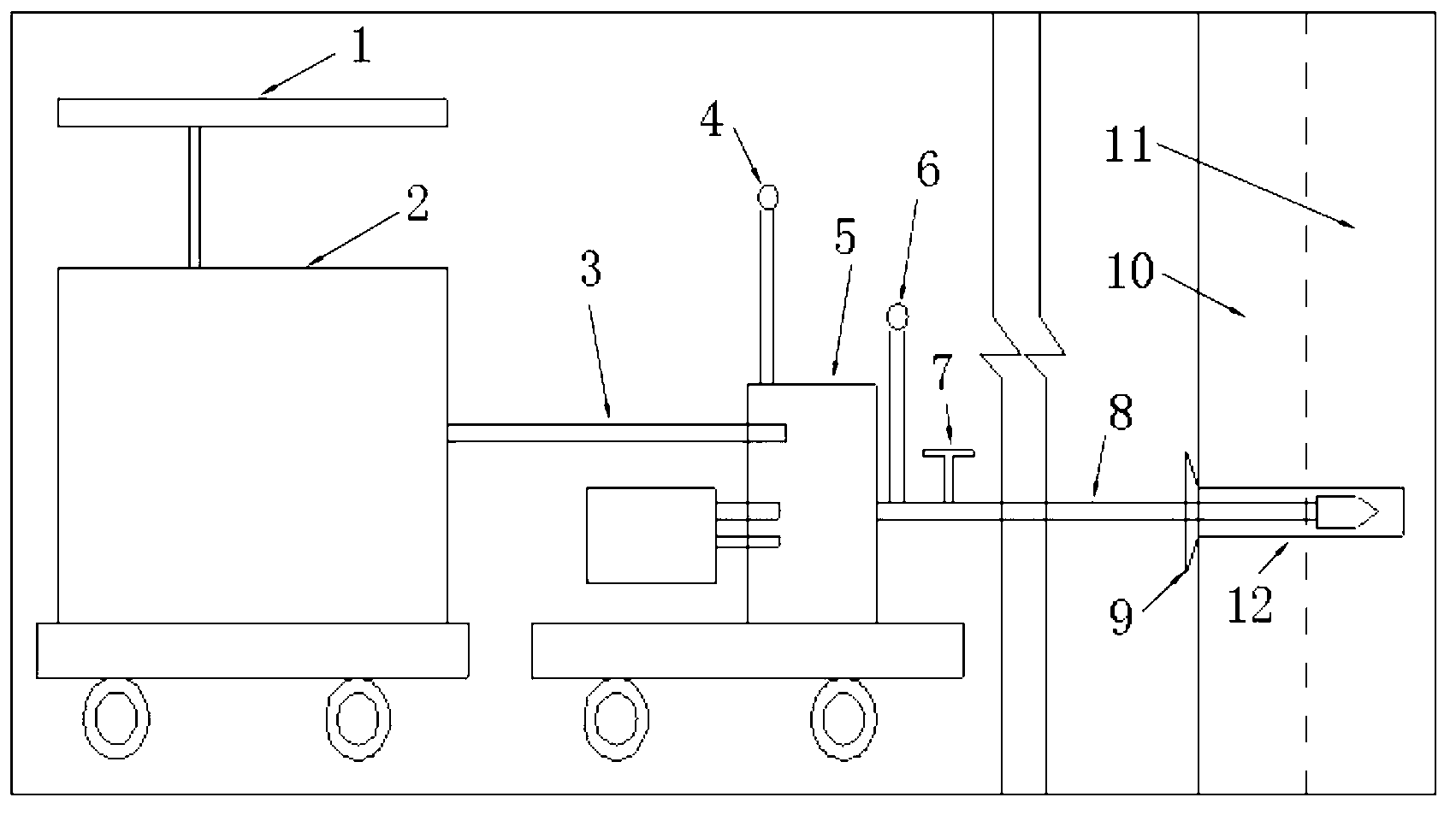

Pressure relief method of coal bed high-pressure waterpower bedding drilling and cutting

The invention discloses a pressure relief method of coal bed high-pressure waterpower bedding drilling and cutting. The pressure relief method of the coal bed high-pressure waterpower bedding drilling and cutting comprises: a plurality of drill hole positions are respectively distributed in surfaces of two sides of coal bodies and a surface of a head-on coal body in a heavily stressed concentration area of a transportation crossheading of a driving face; a hydraulic drilling rig is adopted to drill the drill hole positions, a preset dip angle is formed by the direction of drilling and a horizontal plane, and when a drill hole reaches the projected depth, the hydraulic drilling rig is stopped to drill; an end of a drill stem of the hydraulic drilling rig is connected with a jet device, and the jet device and the drill stem are both fed in the drill hole which is drilled; the hydraulic drilling rig is started to drive the drill stem and the jet device to rotate and carry out seam cutting operation, and a pressure relief cavity is formed in each coal body, the steps are repeated, the other drill hole positions are respectively carried out on a drilling operation and a seam cutting operation, and at last the pressure relief of each coal body is achieved. By the adoption of pressure relief method of the coal bed high-pressure waterpower bedding drilling and cutting, local stress of each coal body are effectively transferred and reduced, the whole pressure relief effect of a region of heavily stressed concentration is achieved, pressure arriving times are reduced, pressure arriving strength and degree of damage are reduced, and safety production is guaranteed.

Owner:HUATING COAL GRP

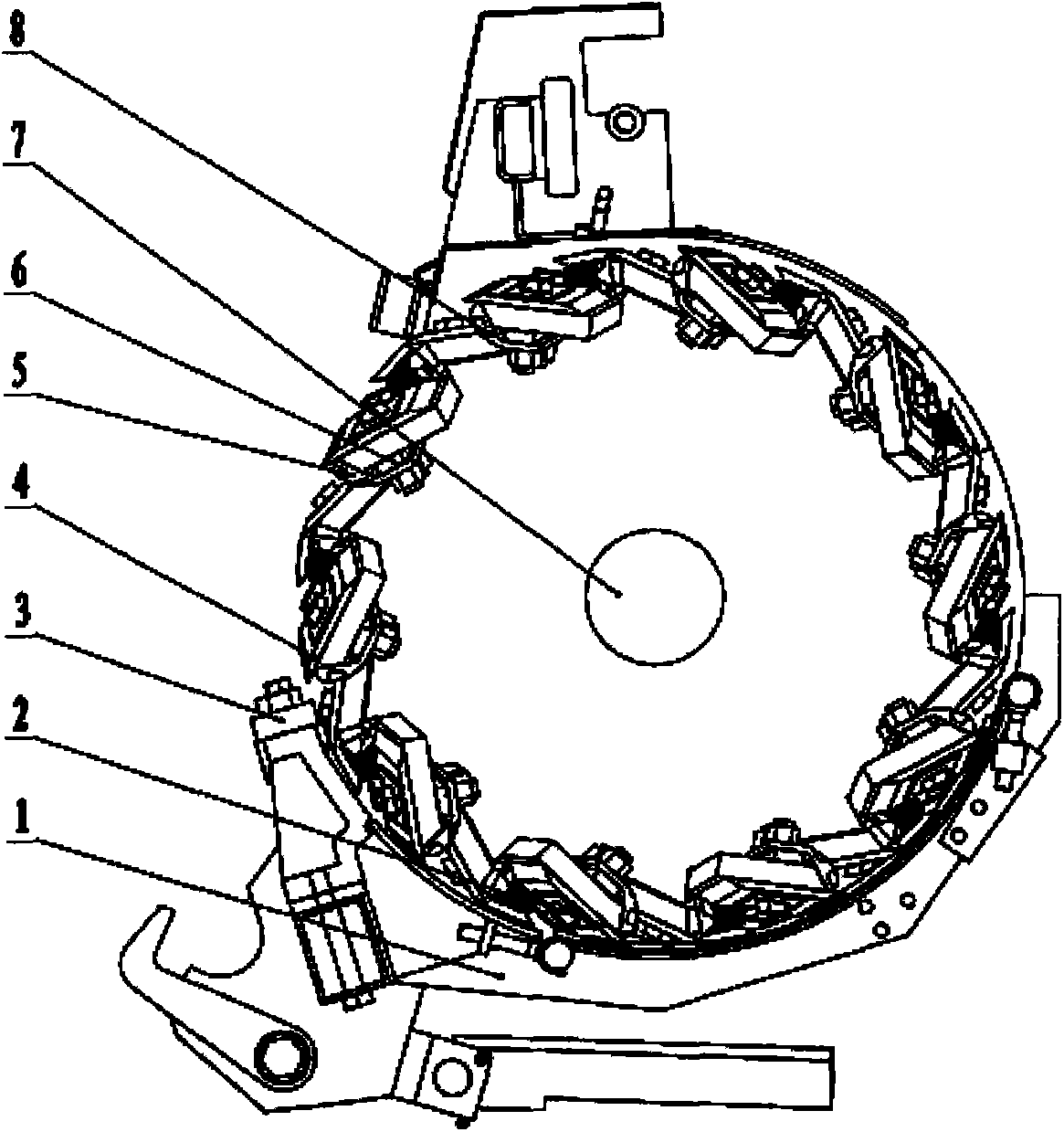

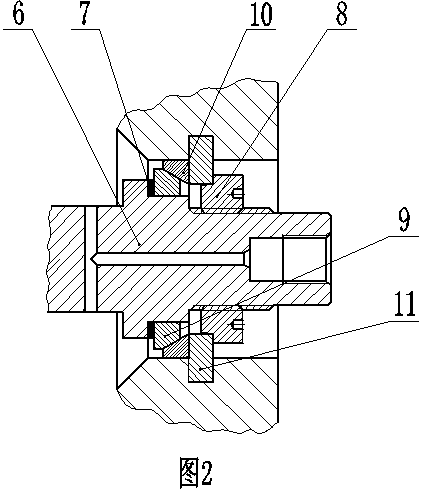

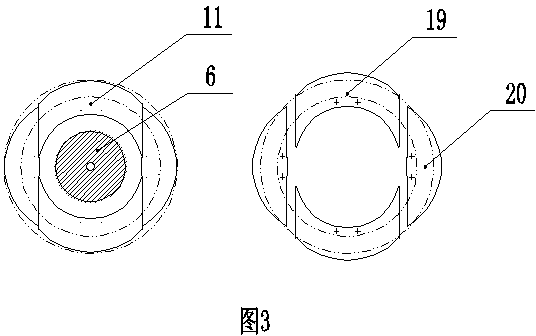

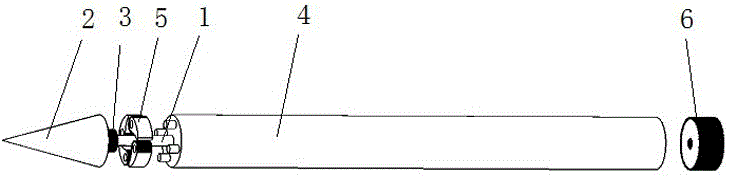

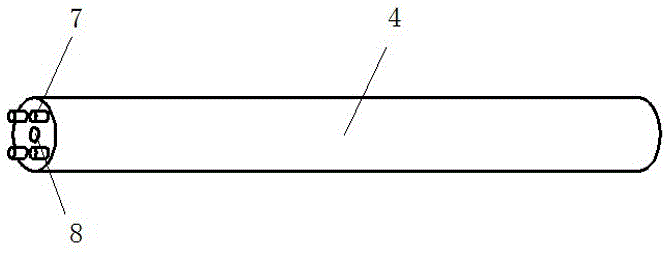

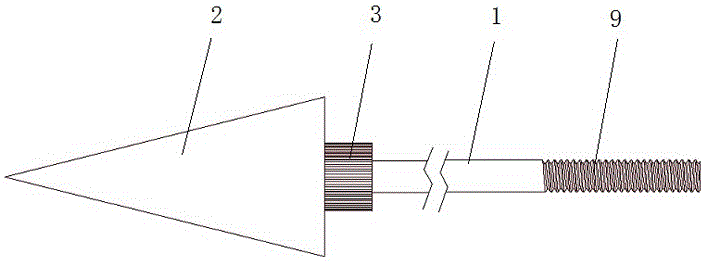

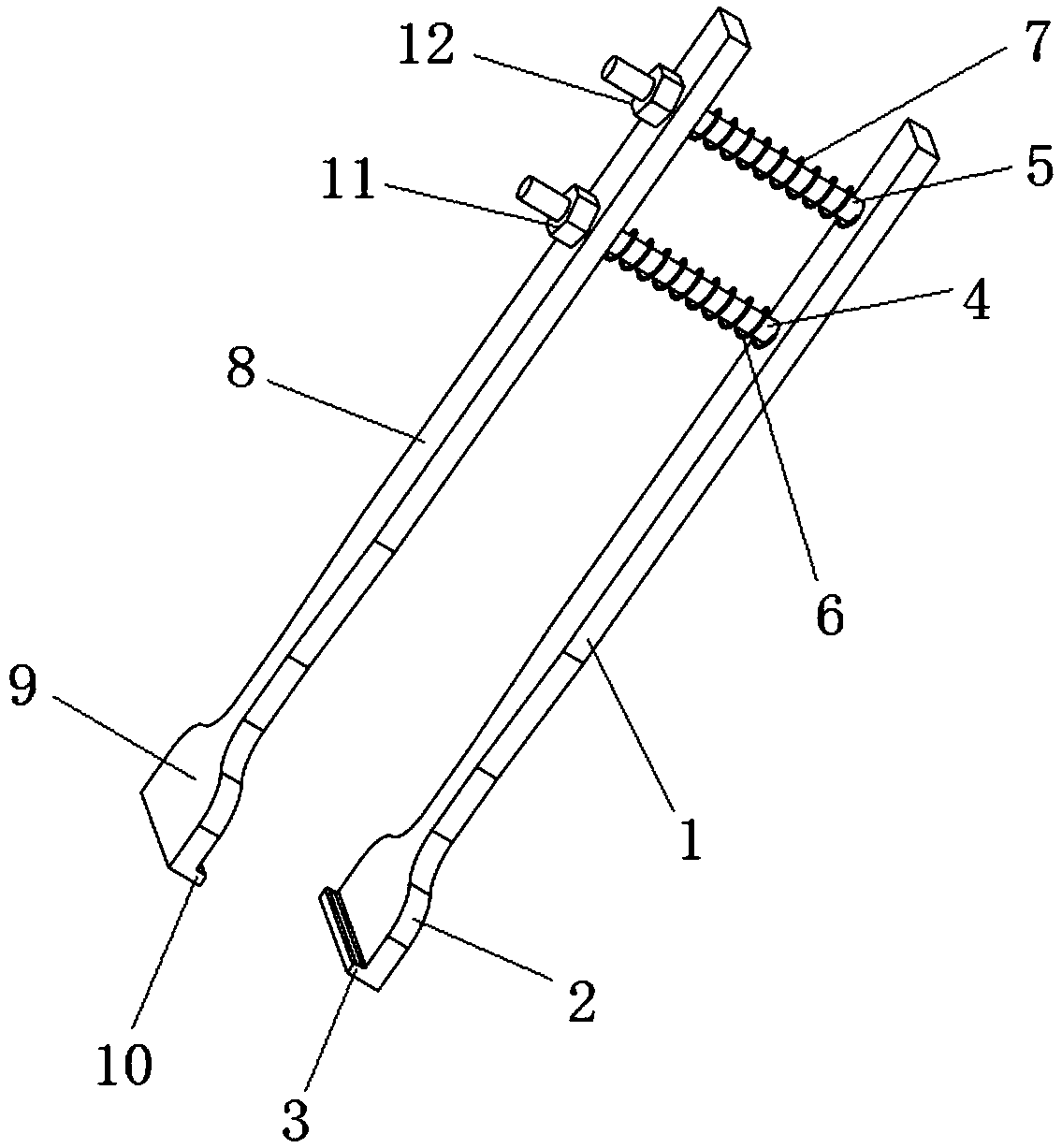

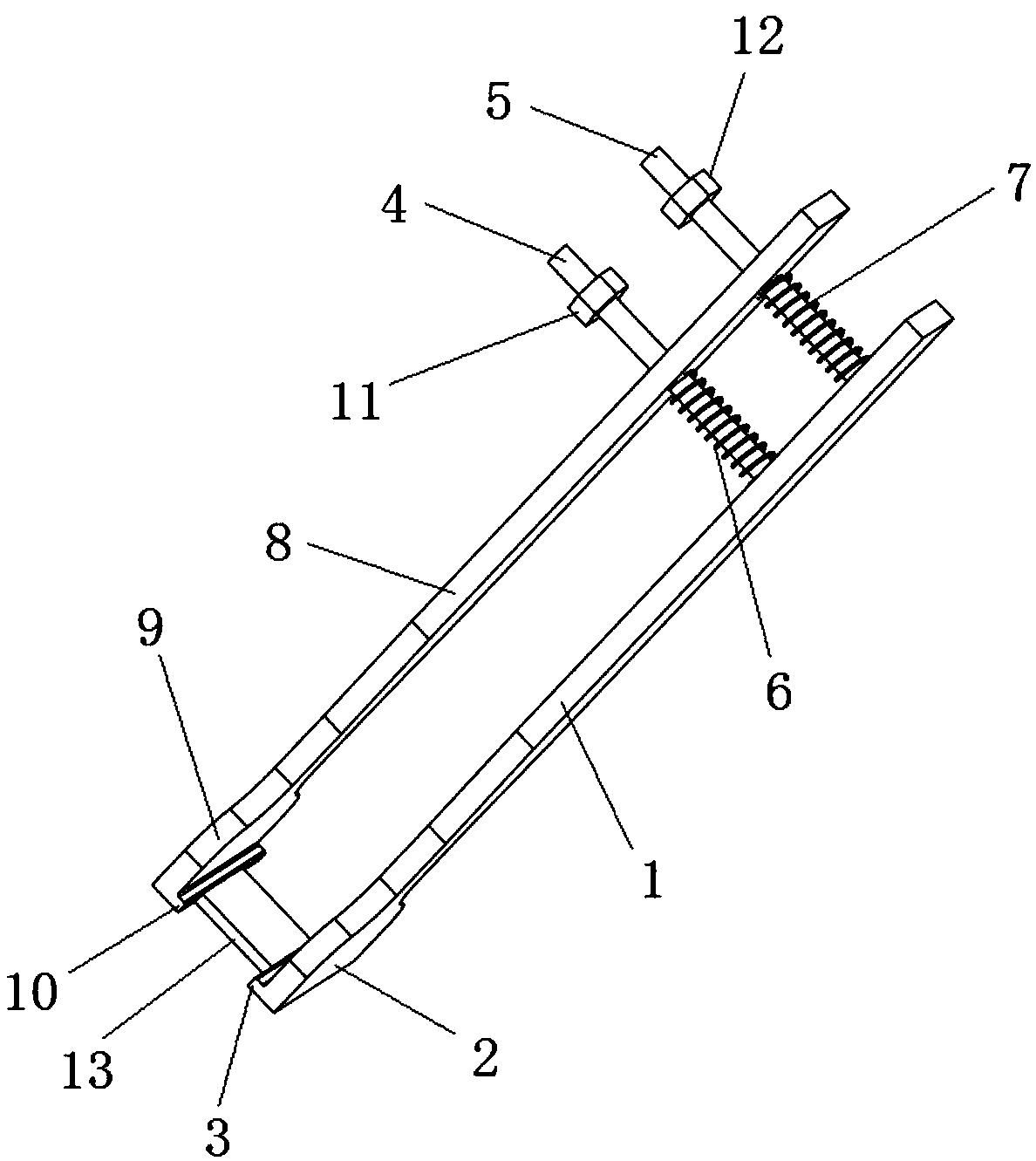

Percutaneous skin-puncture traction retractor radially unfolded in visual endoscopy

ActiveCN106606368AReduce local stress on the skinGood for recoveryCannulasSurgical needlesPostoperative recoveryMedicine

The invention relates to percutaneous skin-puncture traction retractor radially unfolded in a visual endoscopy, and solves the problems that the existing operation retractor can only be retracted in one retractor direction, the established operation space is high in limitation, the retractor is small in thrust face and high in partial stress, and postoperative recovery is affected. The percutaneous skin-puncture traction retractor comprises a central core rod and a sleeve which are embedded in an internal-external manner; the front end of the central core rod extends out of the front end of the sleeve, and a tip cone for skin puncture is arranged at the front end of the central core rod; a plurality of externally-unfolded group valves which are around the central core rod are arranged between the back end of the tip cone and the front end of the sleeve; arc-shaped tooth surfaces are arranged on the inner sides of the externally-unfolded group valves; gear rings correspondingly matched the arc-shaped tooth surfaces are arranged on the rod body of the central core rod; and the back end of the central core rod extends out of the back end of the sleeve to be used as a turning driving end. According to the percutaneous skin-puncture traction retractor, by virtue of the externally-unfolded group valves which can be unfolded in a swinging manner, the operation space under skin is established in one step and the operation space is supported in all directions, so that partial skin stress is lowered, postoperative recovery is facilitated, it is more convenient to establish the operation space, and the operation efficiency is improved.

Owner:ZHEJIANG CANCER HOSPITAL

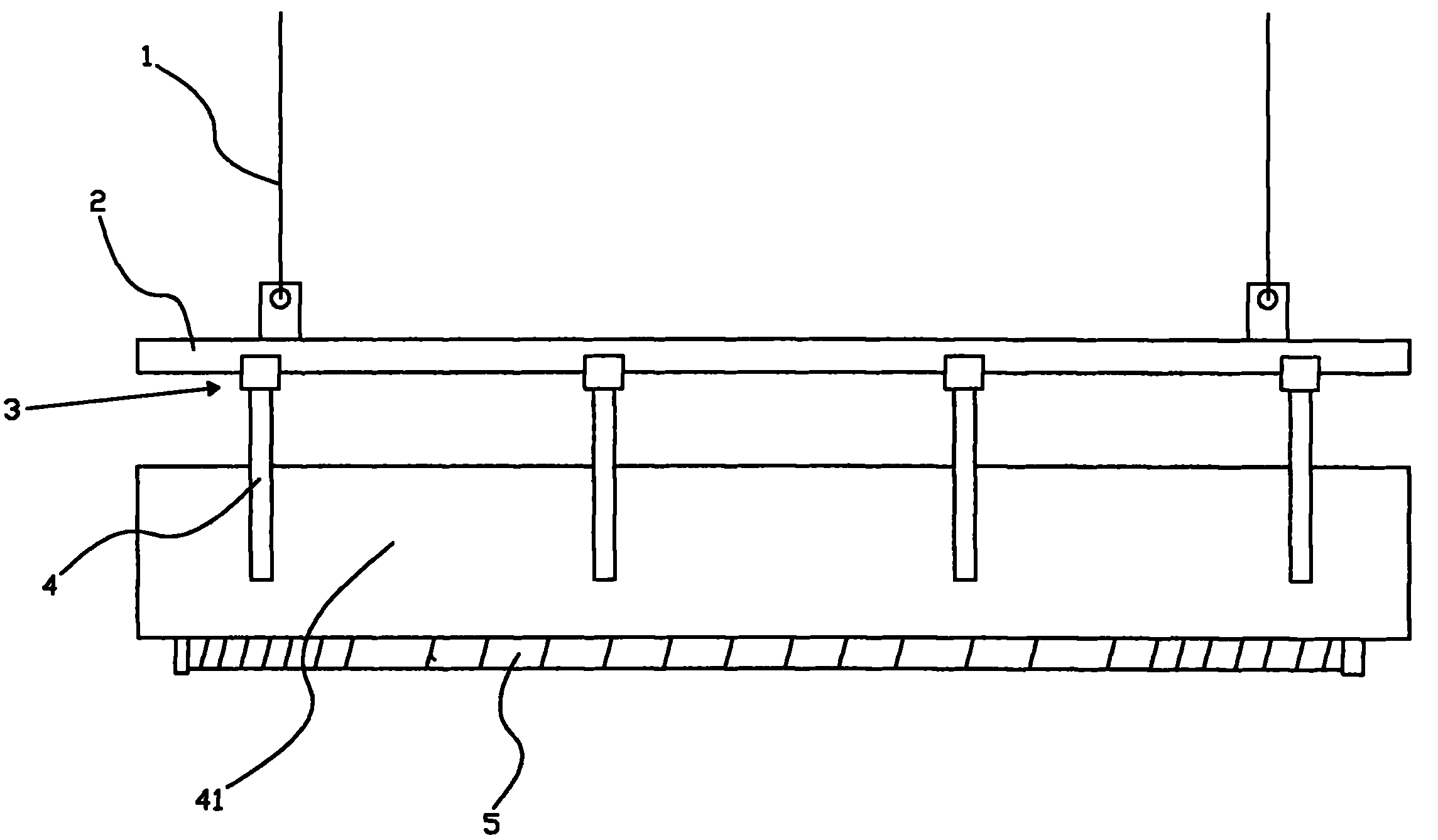

Steel cage lifting device for tubular pile industry

InactiveCN101774504AEven by forceWork safely and efficientlyLoad-engaging elementsBulkheads/pilesManipulatorDesoldering

The invention discloses a steel cage lifting method for the tubular pile industry, which comprises steel wire ropes connected on a crane. The lower parts of the steel wire rope are lifted with a bracket. Two or more steel wire ropes are provided. The bracket is fixedly provided with a clamping mechanism. Both ends of the clamping mechanism are provided with expansion links. The tail ends of the expansion links are connected with mechanical arms. The lifting process of the steel cage does not need the operator to hook the cage and adopts the mechanical arms to clamp so that the stress of each point of the steel cage is uniform, the phenomenons of deformation or desoldering, cracking and the like of the steel cage cannot occur, and the working process is safer and more efficient.

Owner:GUANGDONG SANHE PILE CO LTD

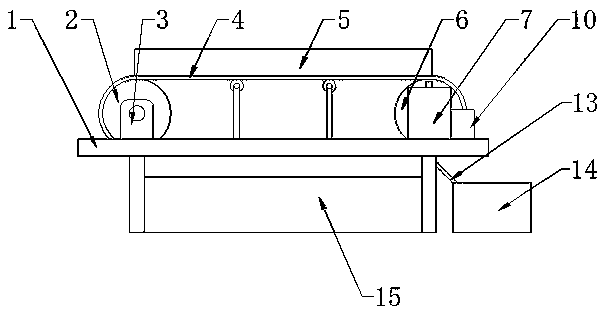

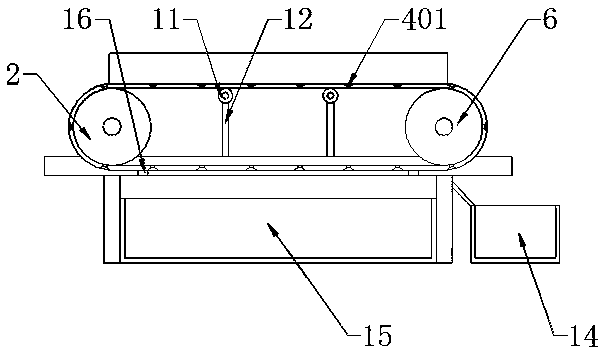

Belt conveyor for wastewater treatment solid garbage

InactiveCN108674885AEasy dischargeImprove delivery efficiencyConveyorsCleaningSurface layerWastewater

The invention provides a belt conveyor for wastewater treatment solid garbage. The belt conveyor comprises a rack, a driven roller, a belt, a driving roller, a rotary motor, a storage battery, a garbage can and a wastewater collection box. The driven roller is movably mounted at the left end of the top of the rack, and the driving roller is movably mounted at the right end of the top of the rack.The belt is movably mounted on the surface layers of the driven roller and the driving roller. The rotary motor is fixedly mounted on the right side of the top of the rack and is located in front of the driving roller. The storage battery is fixedly mounted at the right end of the rotary motor. The garbage can is fixedly mounted on the right lower side of the rack. The wastewater collection box isfixedly mounted at the bottom of the rack. The belt conveyor for the wastewater treatment solid garbage is provided with a through hole groove, wastewater can be guided into the through hole groove through the Y-shaped through hole groove, and therefore the wastewater can be fast drained into the wastewater collection box, the tightening force of the belt can be reduced, and the conveying efficiency of the solid garbage can be improved; and the belt conveyor is suitable for production and use of the belt conveyor and has good development prospects.

Owner:朱越

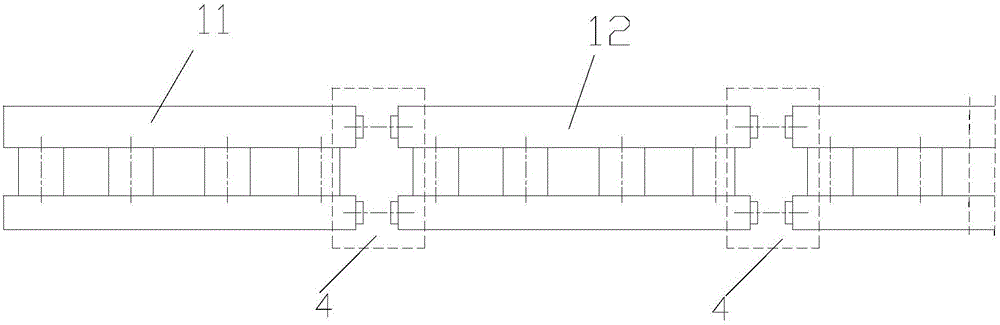

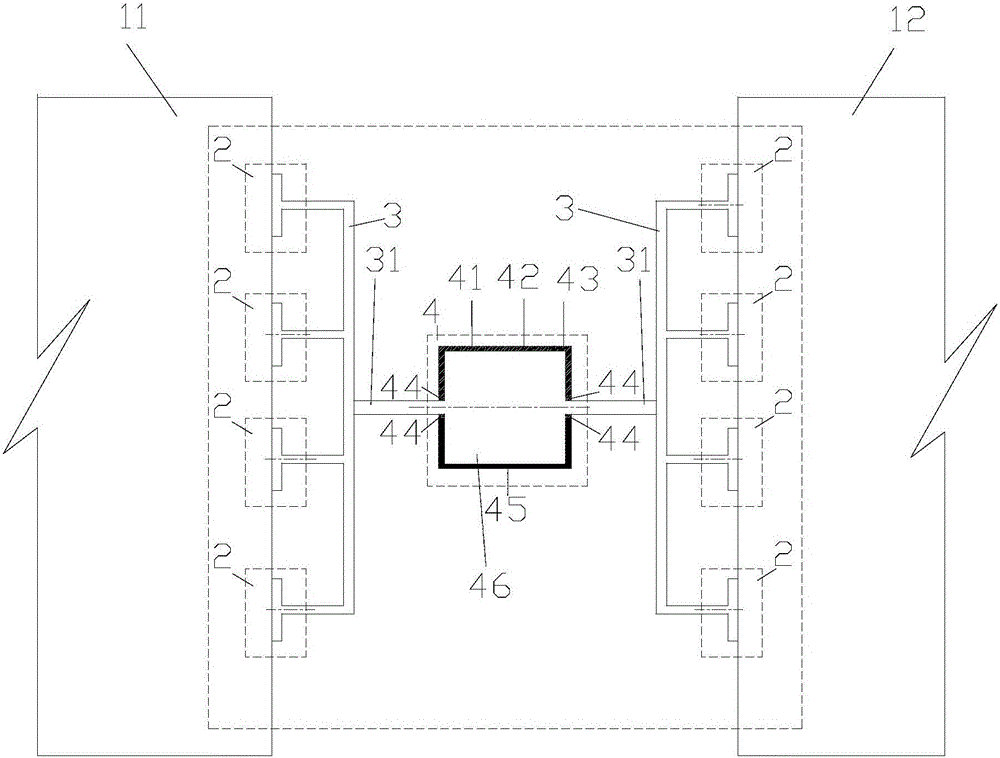

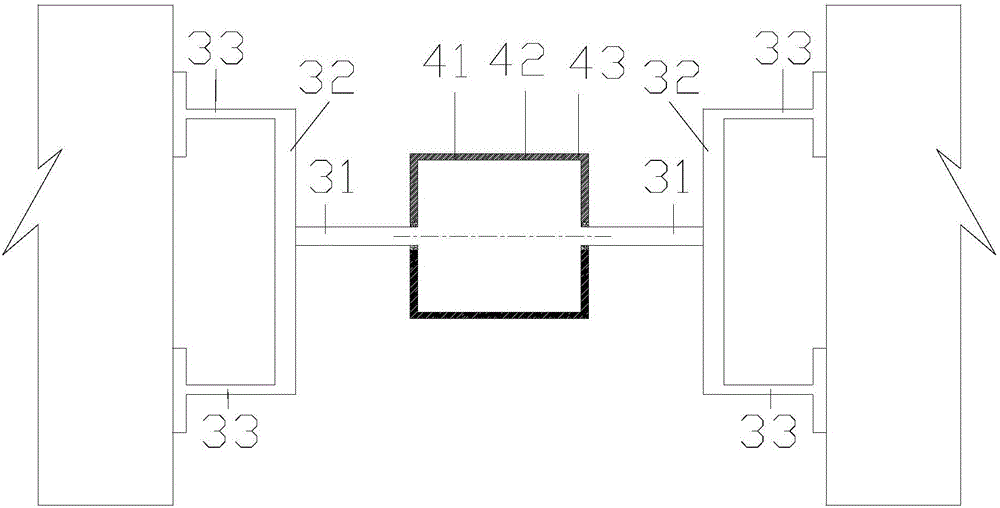

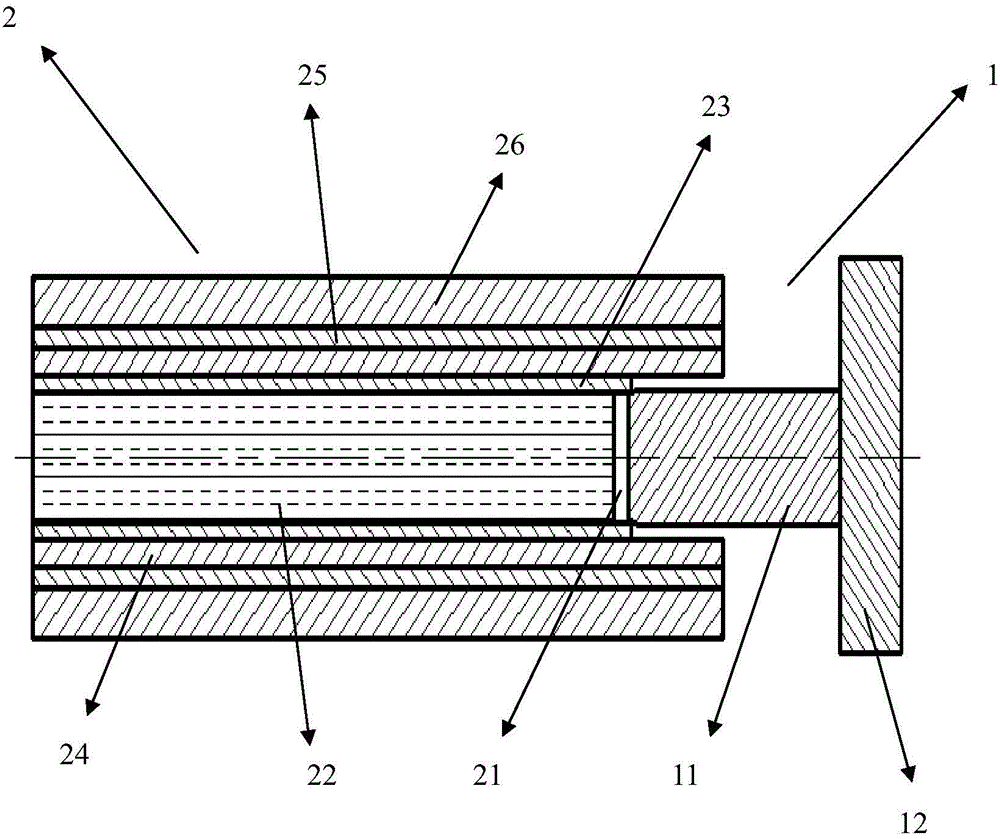

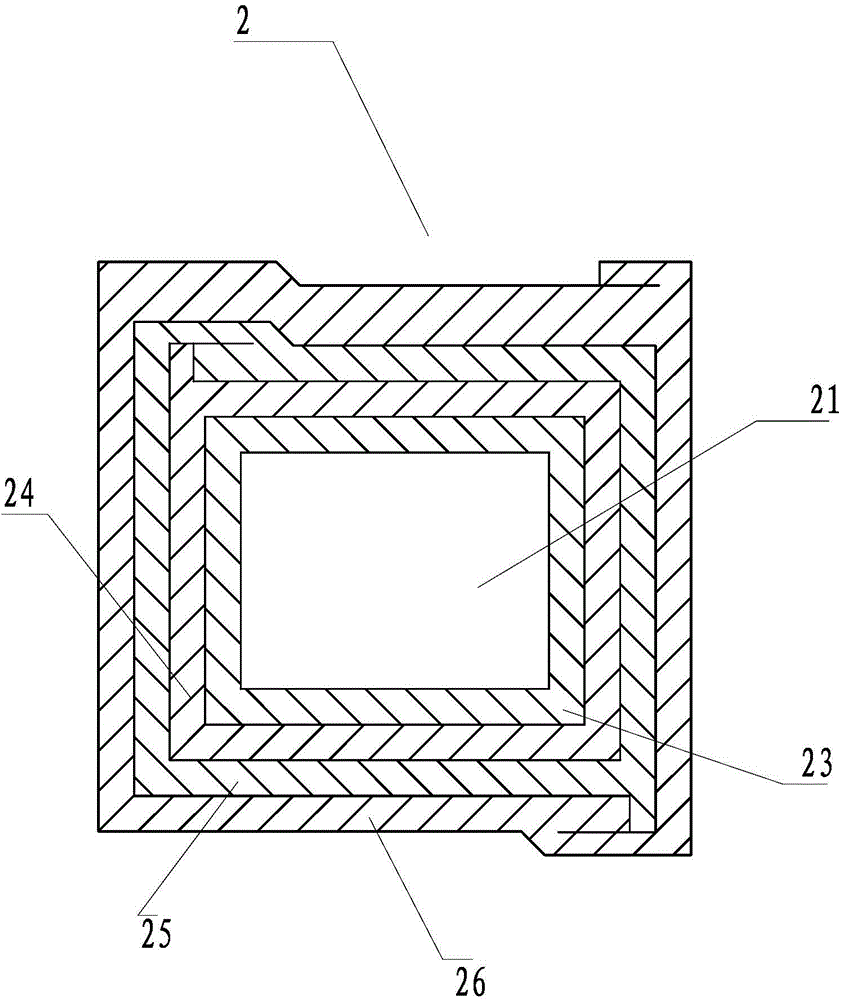

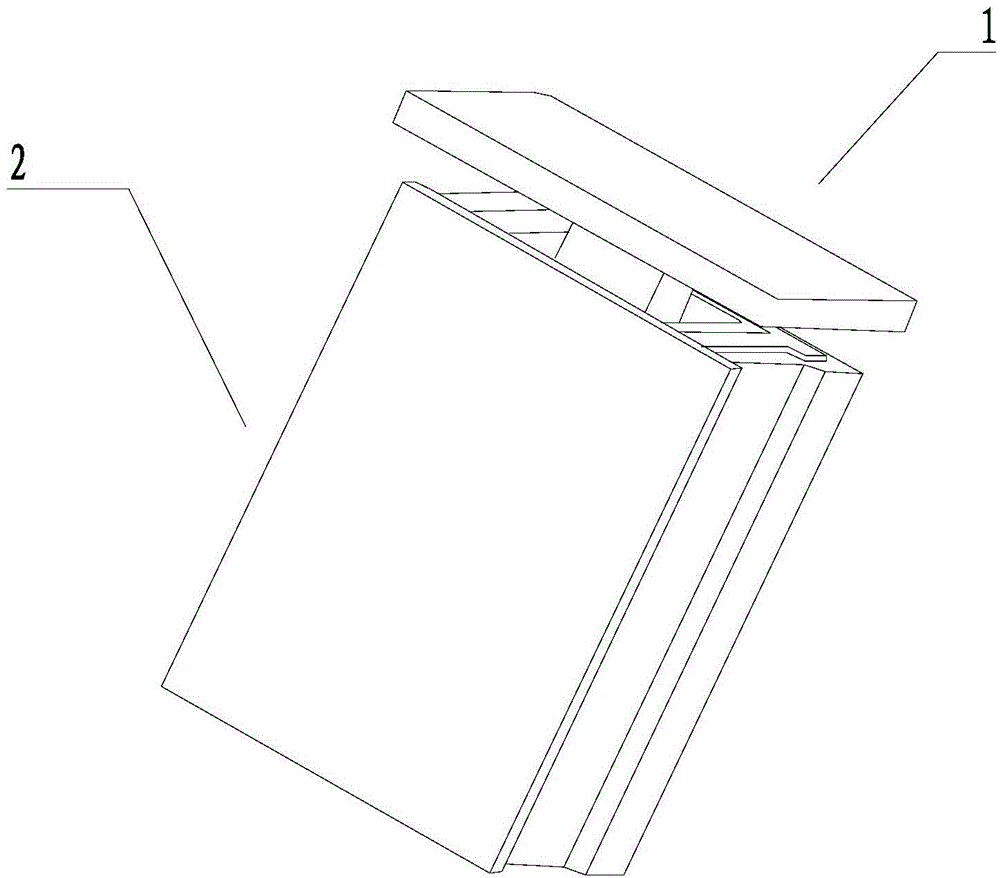

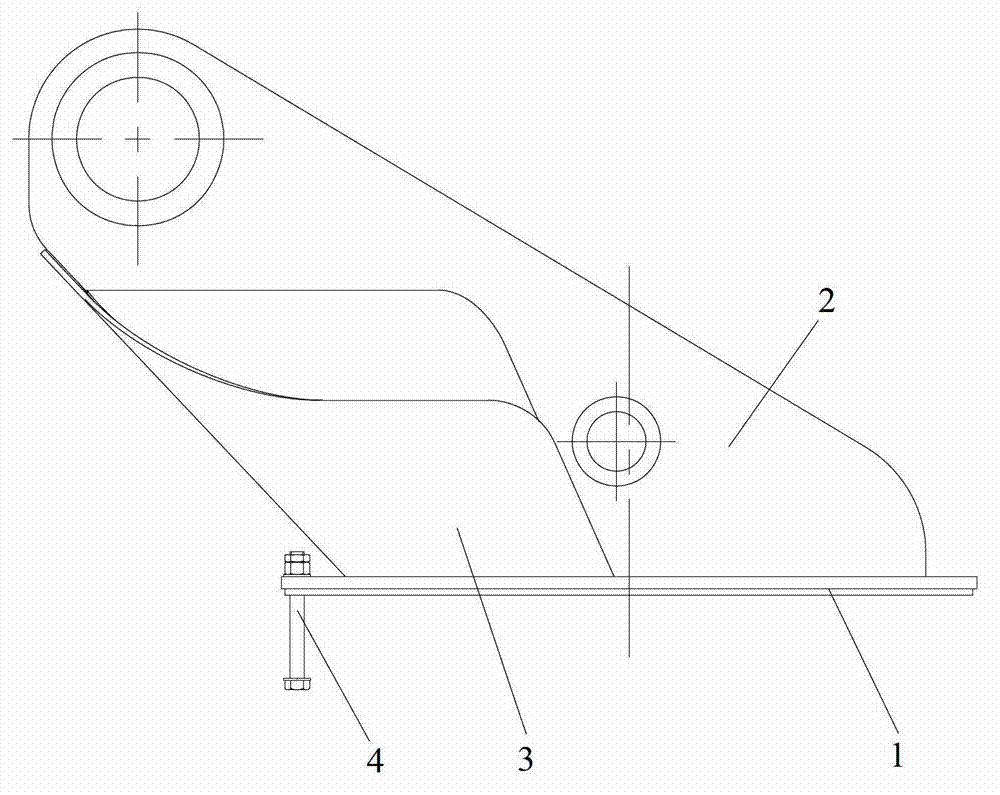

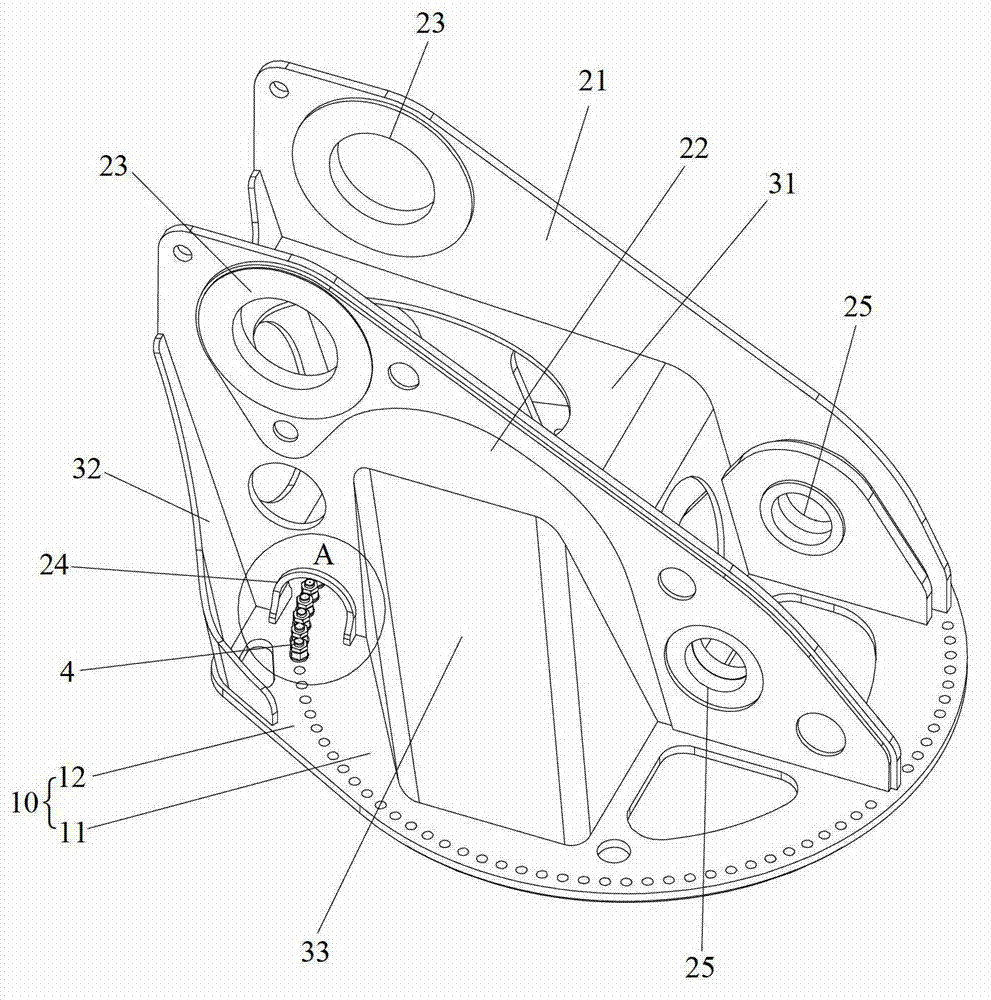

Engineering machine and turntable thereof

ActiveCN102878396AGradient slopeHigh strengthStands/trestlesBuilding material handlingEngineeringUltimate tensile strength

The invention discloses an engineering machine turntable which comprises a base (10), a first mounting member (21) and a second mounting member (22). The first mounting member (21) and the second mounting member (22) are used for mounting an engineering machine and are respectively fixed on the base. The base (10) comprises a circular part (11) and an extension part (12) extending from one side of the round part (11). The downside of the first mounting member (21) and the downside of the second mounting member (22) are fixed on the circular part (11) and the extension part (12) respectively in the extension direction of the extension part (12). The base is structurally modified, and accordingly inclination of stressed sides of the first and second mounting members is alleviated so as to reduce local stress and to improve strength of the turntable. The invention further discloses an engineering machine with the engineering machine turntable.

Owner:ZOOMLION HEAVY IND CO LTD

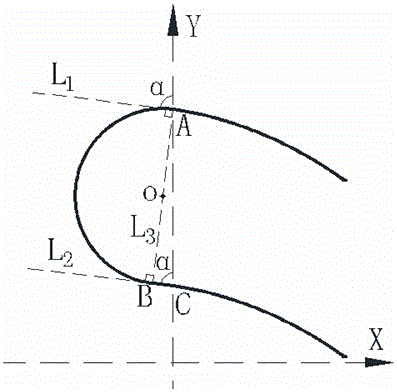

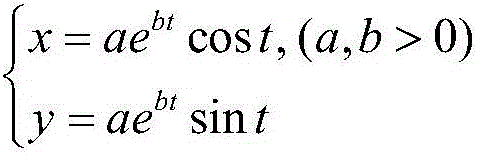

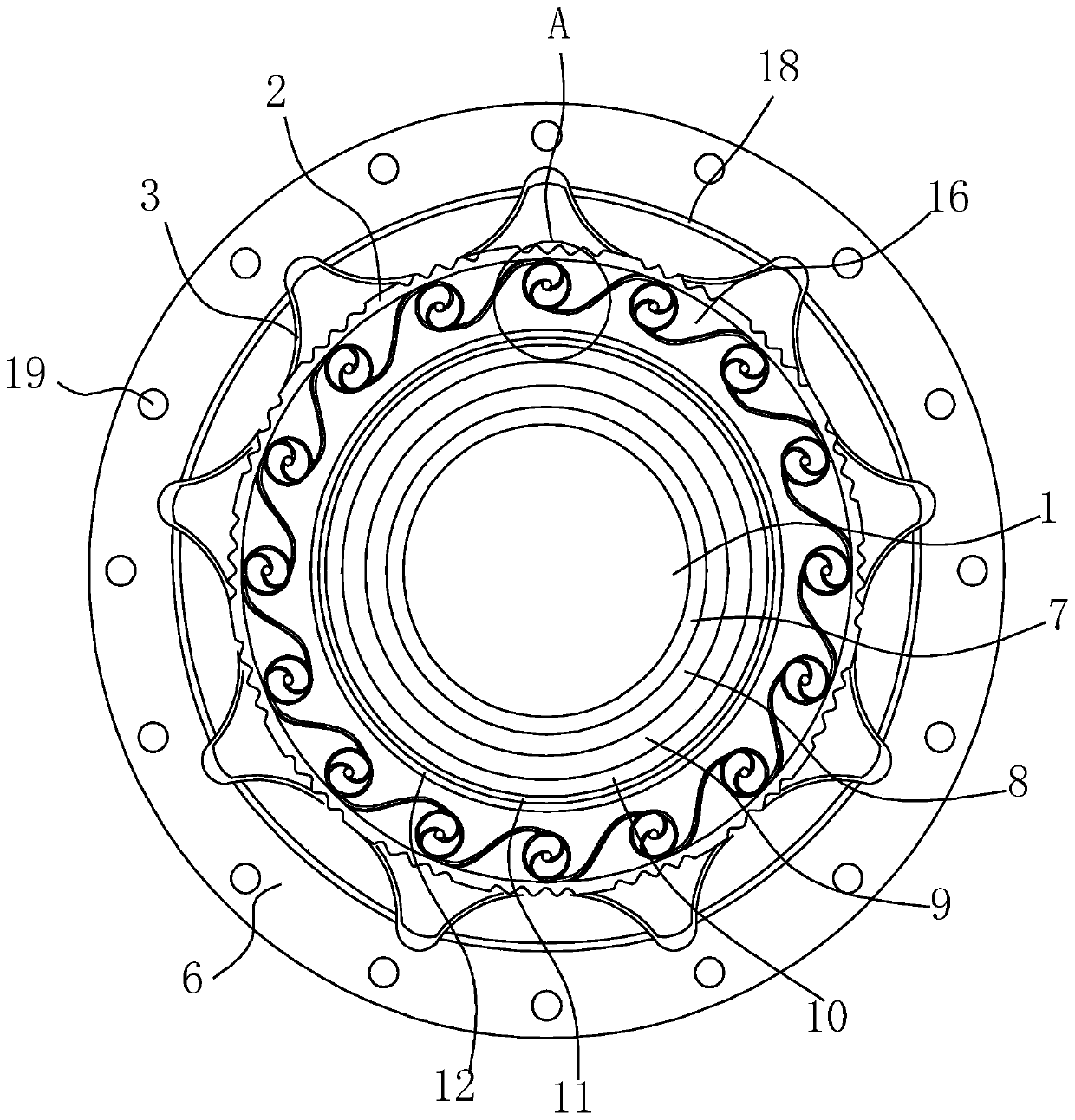

Equiangular-spiral leaf spring

ActiveCN106051036AUniform stress distributionReduce local stressNon-rotating vibration suppressionStress distributionEngineering

The invention relates to an equiangular-spiral leaf spring. The left spring comprises two vortex arms and two vortex grooves, wherein the two vortex grooves are symmetrically distributed at an angle of 180 degrees; vortex groove profiles are determined with the equiangular spiral equation as follows: r=ae<btheta> (a and b are larger than 0), a and b are constants, a refers to the adjustable vortex line pole deviation distance, b refers to the adjustable profile expansion speed, r refers to the polar radius, e refers to the Napierian base, and theta refers to the polar angle. Different leaf springs adopt different a and b values, vortex groove profiles which are deviated from poles in different positions and have different shapes can be obtained by changing parameters a and b of the profiles, starting positions and end positions of the vortex groove profiles can be controlled by changing the polar angle theta, and the leaf springs in different shapes can be designed according to different actual performance requirements. Seal ends of the equiangular-spiral vortex grooves are in semi-circular and linear smooth transition. The leaf spring is uniform in stress distribution, small in local stress, simple in profile and seal method design, convenient to machine, high in reliability and long in service life and has the higher radial rigidity and certain axial rigidity.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

High-strength bending-resistant photoelectric composite cable

ActiveCN110031944AIncrease the bearing surfaceReduce stressFibre mechanical structuresYarnInformation transmission

The invention provides a high-strength bending-resistant photoelectric composite cable comprising an optical fiber body, a curved unloading layer, a curved unloading body, movable unloading rods, a unloading dividing ring and an outer protective layer, wherein the surface of the optical fiber body is wrapped with a loose tube, the outer surface of the loose tube is wrapped with an inner water blocking layer, the outer surface of the inner water blocking layer is covered with an inner protective layer, and the outer surface of the inner protective layer is wrapped with an outer water blocking layer. The field high-strength and bending-resistant photoelectric composite cable, which relates to the field of photoelectric composite cables, concentrates the final force center around the outer portion of the optical fiber body and distributes to each of the movable unloading rods by changing the external force direction and unloading force for multiple times, and protects the photoelectric composite cable by combining the loose tube, the inner water blocking layer, the inner protective layer, the outer water blocking layer and the spun yarn, thereby effectively solving the problem that the general photoelectric composite cable is easily bent when subjected to a severe force at certain point when hit by external force, the force bearing points of the photoelectric composite cable are concentrated on one side, and the bending of the photoelectric composite cable causes loss and great influence on information transmission.

Owner:CHONGQING EASTFUL ELECTRIC WIRE & CABLE CO LTD

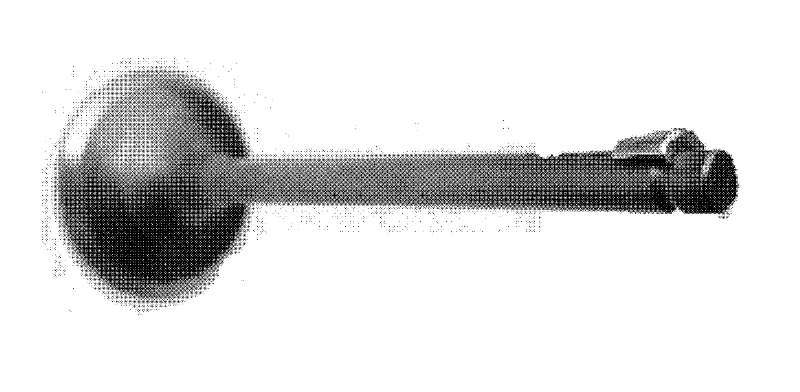

Engine valve device

InactiveCN102410058AReduce local stressAvoid wear and tearMachines/enginesLift valveEdge surfaceConvex side

The embodiment of the invention provides an engine valve device. The device comprises a valve, a valve rod and a valve lock clip, wherein the lower end of the valve rod is connected with the valve; at least three lock clip grooves are arranged on the upper end of the valve rod; convex bands are arranged at intervals among the lock clip grooves, two edges of each convex band are crossed with the edges of each lock clip groove through a slope surface; the inner side of the valve lock clip comprises at least three convex edge surfaces which are corresponding to the lock clip grooves; concave bands corresponding to the convex bands are arranged at intervals among the convex edge surfaces; two edges of each concave band are connected with the root part of each convex edge surface through small grooves; the height of each convex edge surface of the valve lock clip is less than the depth of each lock clip groove; and the diameter of each convex band is less than that of each concave band. In the embodiment of the invention, the valve rod can rotate around the axis of the valve rod under the action of a spring so as to prevent air leakage.

Owner:ZHEJIANG CFMOTO POWER CO LTD

A bridge beam lifting system mounted on a pier

InactiveCN109024316ASimple structureEasy to fixBridge erection/assemblyBridge strengtheningStructural engineeringEngineering

The invention discloses a bridge beam lifting system installed on a bridge pier, includes pier fixtures and lifting assemblies, An upper surface of that pier fix device is formed with a horizontal support platform, the lifting assembly includes an upward jack disposed on the support platform in the circumferential direction of the pier, characterized in that the lifting assembly further comprisesa horizontal annular force equalizing ring, wherein the force equalizing ring is sleeved outside the bearing at the upper end of the pier, the upper surface of the force equalizing ring is a jacking force applying surface which is connected with the bridge, and the lower surface of the force equalizing ring is a jacking force receiving surface which is connected with the upper end of the jack. Theintegral lifting system of the beam body of the bridge without the cover beam of the lower structure is simple in structure, good in fixing effect and stability, convenient in construction, capable of better realizing synchronous jacking and protecting the safety of construction.

Owner:YANGTZE NORMAL UNIVERSITY

Tweezers for clamping substrate in clean room

The invention discloses tweezers for clamping a substrate in a clean room. The tweezers comprise a fixing arm. A first clamping plate is connected to the lower end of the fixing arm. A first rubber strip is connected to the edge of the tail end of the first clamping plate. The upper part of the fixing arm is connected with a first guide post and a second guide post of the fixing arm, wherein the first guide post and the second guide post are parallel to each other and perpendicular to the fixing arm, the first guide post and the second guide post are connected with a movable arm, a second clamping plate is connected to the lower end of the movable arm, and a second rubber strip is connected to the edge of the tail end of the second clamping plate. A first spring is connected to the outer ring of the first guide post, and a second spring is connected to the outer ring of the second guide post. A first fixing block is connected to the tail end, close to the movable arm, of the first guide post, and a second fixing block is connected to the tail end, close to the movable arm, of the second guide post. The tweezers have the beneficial effects that the tweezers do not need to be replaced when clamping the side edges of substrates with the large changes in size, and the edge collapse and pollution to the surfaces of the substrates do not occur.

Owner:湖州正鸣塑胶科技有限公司

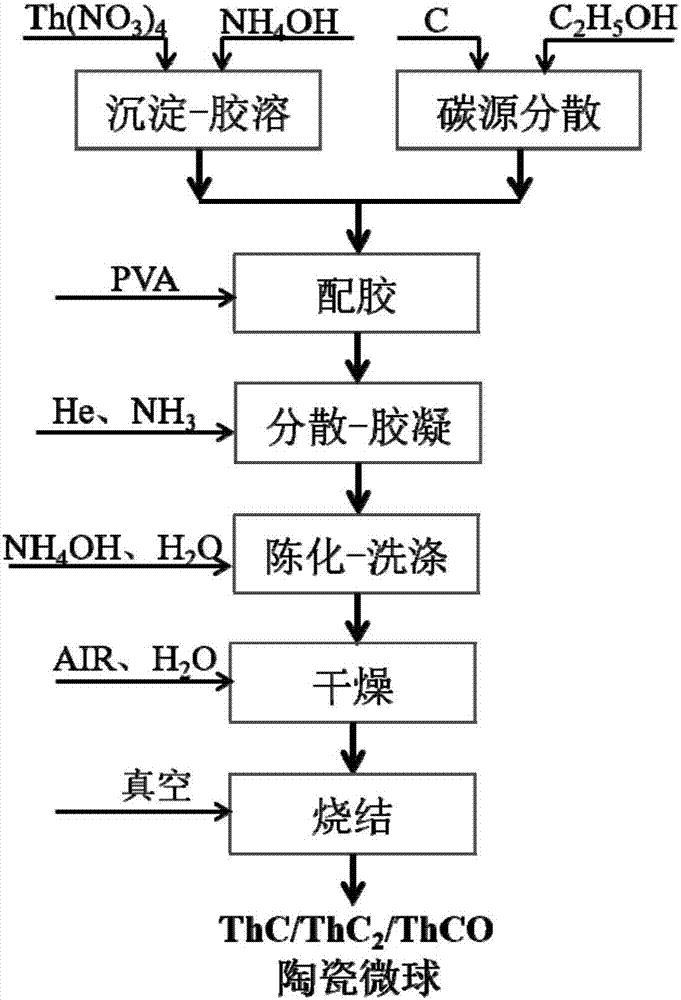

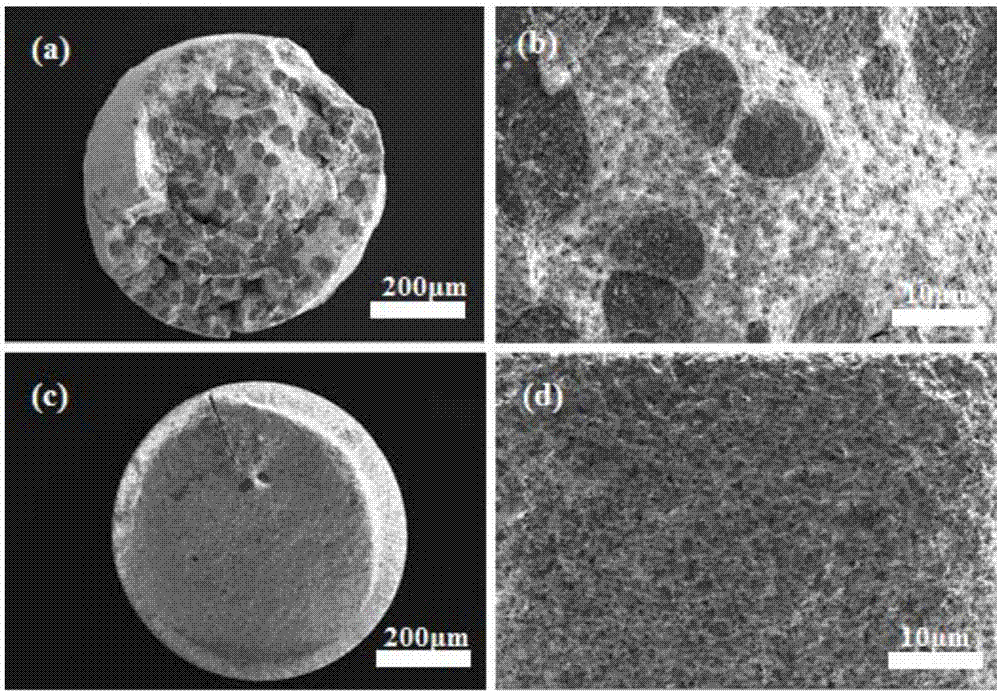

Method for preparing ceramic microspheres of thorium-based carbides and/or thorium-based oxycarbides

ActiveCN107134299AReduce the probability of ruptureNo crackNuclear energy generationReactor fuel susbtancesMicrosphereHydrolysis

The invention relates to a method for preparing ceramic microspheres of thorium-based carbides and / or thorium-based oxycarbides. The method comprises the following steps: dripping a thorium nitrate solution into ammonium hydroxide so as to form a hydrolysis solution; adding polyvinyl alcohol while stirring the hydrolysis solution so as to form sol; dispersing carbon powder by utilizing an organic reagent which is mutually soluble with water so as to form pre-dispersed carbon powder; adding the sol into the pre-dispersed carbon powder so as to form a carbon-containing colloidal solution; dispersing the carbon-containing colloidal solution into liquid drops, and enabling the liquid drops to sequentially pass through a helium area, an ammonia gas area and an ammonium hydroxide area so as to form gel particles; ageing the gel particles in stronger ammonia water, washing with deionized water, adding the washed gel particles into a drying furnace, controlling the humidity, heating and drying so as to form the dried gel particles; and adding the dried gel particles into a sintering furnace, heating and sintering under vacuum conditions, thereby obtaining the ceramic microspheres. According to the preparation method disclosed by the invention, the ceramic microspheres of thorium-based carbides and / or thorium-based oxycarbides are prepared through a simple process.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com