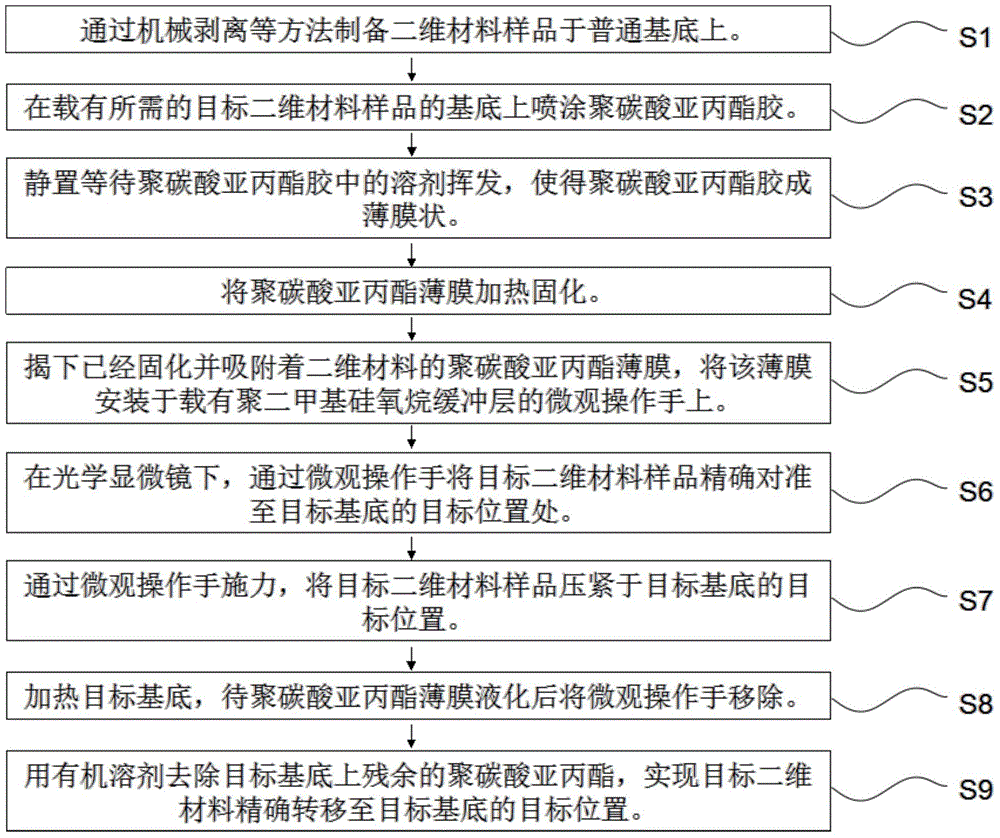

Controllable flexible transfer method of two-dimensional materials

A technology of two-dimensional materials and transfer methods, which is applied in the field of two-dimensional material transfer, can solve the problems of random distribution, poor strength, and small area of thin-layer two-dimensional materials, and achieve the effects of good compatibility, small impact and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

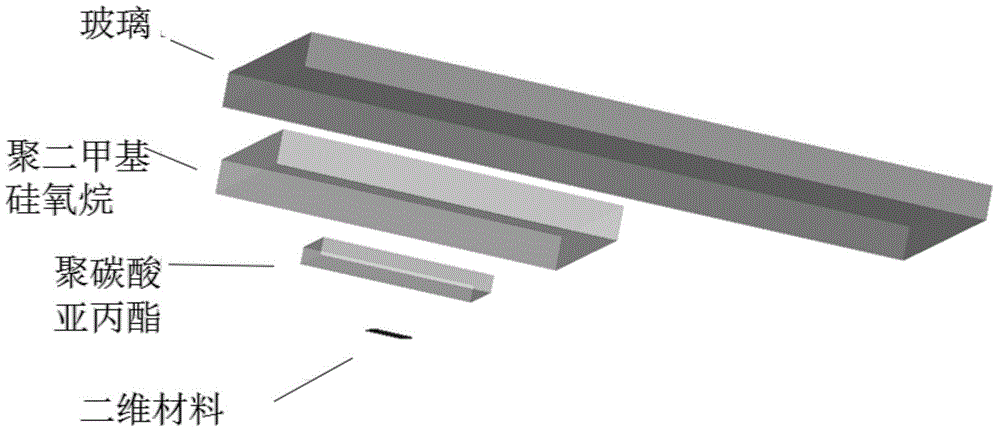

[0042] SiO 2 The mechanically exfoliated molybdenum disulfide thin film sample on the / Si substrate is accurately transferred to a small hole on a silicon nitride film and covers the small hole without destroying the silicon nitride film, including the following steps:

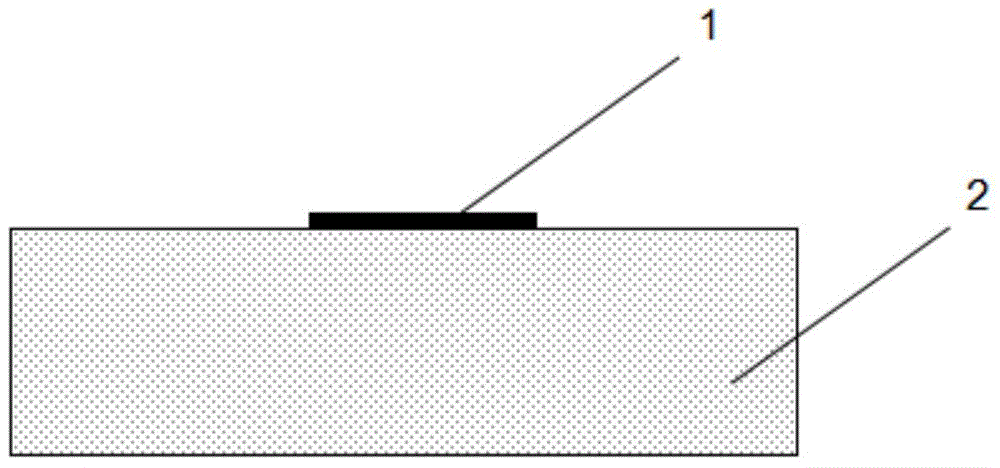

[0043] 1) Place the molybdenum disulfide sample obtained by mechanical exfoliation on SiO 2 / Si substrate, and then look for and select the required target two-dimensional material samples under the microscope, as shown in the attached image 3 Shown; the selected sample is a double-layer molybdenum disulfide flake, and its plane size is a parallelogram with a length of 8 μm and a width of 7 μm; SiO 2 The thickness is 280nm;

[0044] 2) On SiO loaded with the desired target 2D material sample 2 / Si substrate is coated with polypropylene carbonate glue solution, the concentration of polypropylene carbonate glue is 0.125g / ml, and solvent is acetone;

[0045] 3) Stand still, wait for 3 hours, until the aceton...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is that in step 1), the size of the molybdenum disulfide sheet can also be any size from 1 μm×1 μm to 10mm×10mm; 2 The thickness can also be 200nm, 400nm, 500nm or 600nm and so on. Others are the same as in Example 1.

Embodiment 3

[0055] The difference between this embodiment and embodiment 1 is: in step 2), the concentration of polypropylene carbonate glue is 0.2g / ml etc.; Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com