Semiconductor laser source

A laser light source and semiconductor technology, applied in the direction of semiconductor lasers, semiconductor laser devices, lasers, etc., can solve the problems of large volume, complex structure, and high requirements for operators, and achieve strong flexibility, convenient adjustment, and ensure efficiency and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

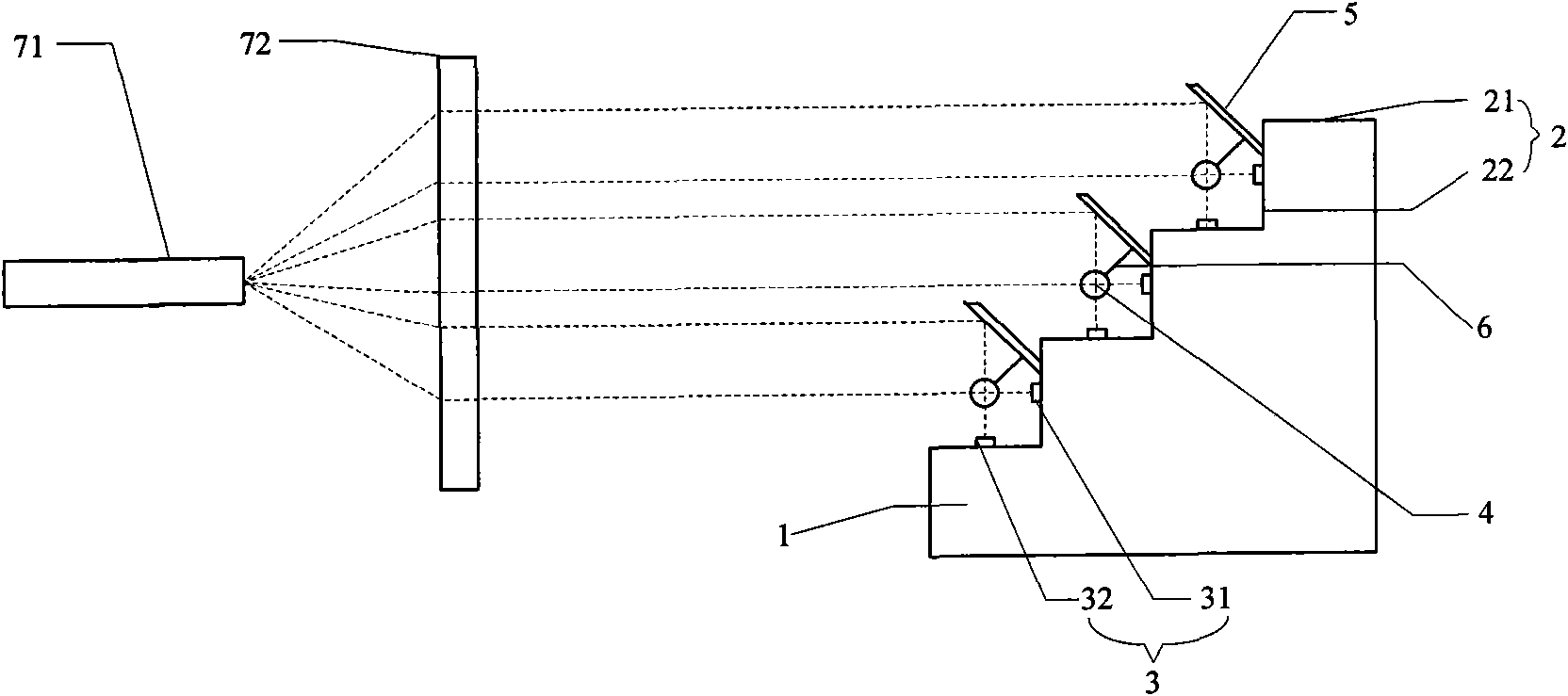

[0027] figure 1 It is a schematic diagram of the working principle of a specific embodiment of the semiconductor laser light source of the present invention.

[0028] A heat sink with N steps, each of which includes a vertical mounting surface and a horizontal mounting surface, wherein N is a natural number; 2 (N-1) semiconductor lasers, including (N -1) first semiconductor lasers and (N-1) second semiconductor lasers arranged on the horizontal mounting surface, the optical axis of the output light of the first semiconductor laser is perpendicular to the vertical mounting surface, and the output light of the second semiconductor laser The optical axis is perpendicular to the horizontal installation surface, and the first semiconductor laser intersects at a point the output light optical axis of the second semiconductor laser arranged on the horizontal installation surface of the next step; it is arranged above each second semiconductor laser for adjustment The reflector of th...

Embodiment 2

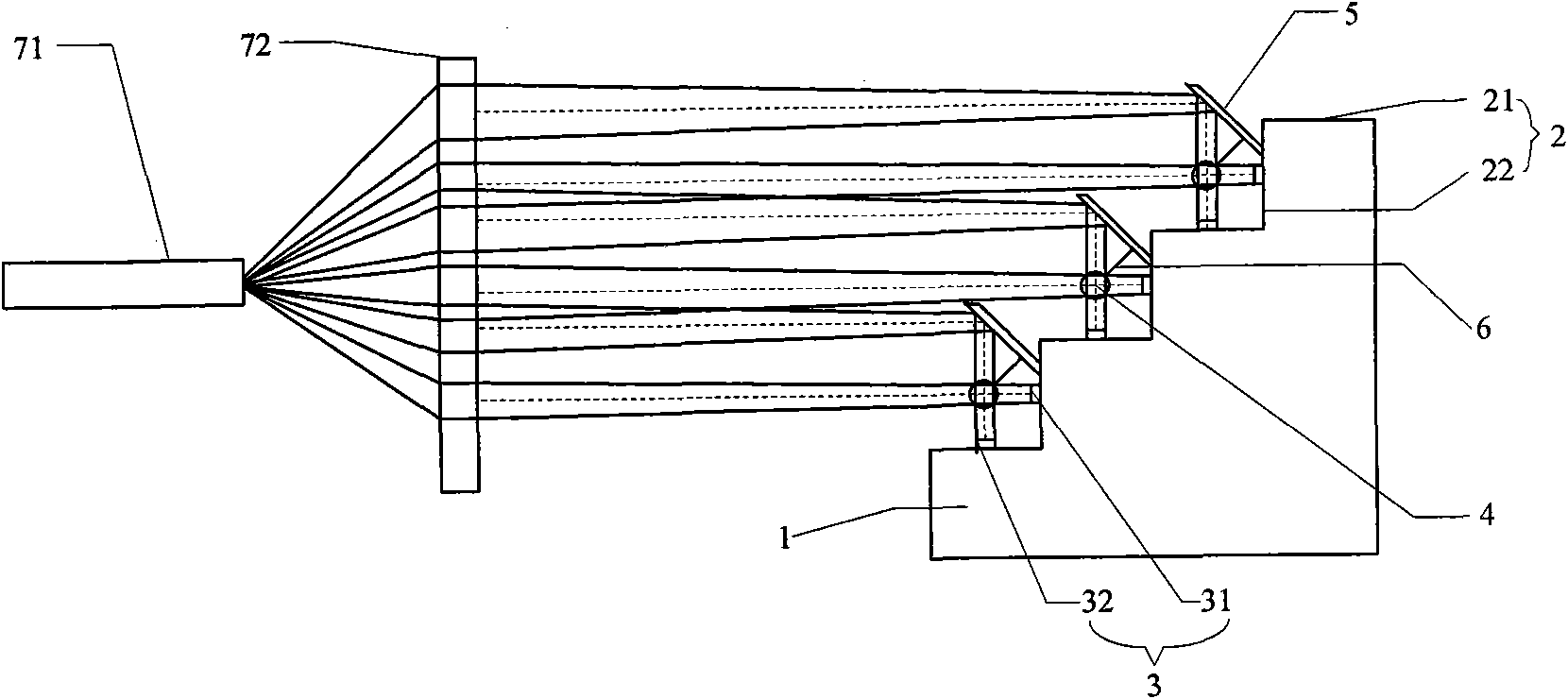

[0047] figure 2 It is a schematic diagram of the working principle of another specific embodiment of the semiconductor laser light source of the present invention.

[0048] see figure 2 As shown, the semiconductor laser light source disclosed in the present invention has the same main structure as that of Embodiment 1, the difference is that the output light of the semiconductor laser 3 is not exactly the same wavelength of light, and the divergence angles of the output light of each semiconductor laser 3 are different. , overlap is allowed between the collimated beams.

[0049] Therefore, in this embodiment, the red, blue, and green semiconductor lasers can be arranged on a stepped heat sink to be used as a white light source.

Embodiment 3

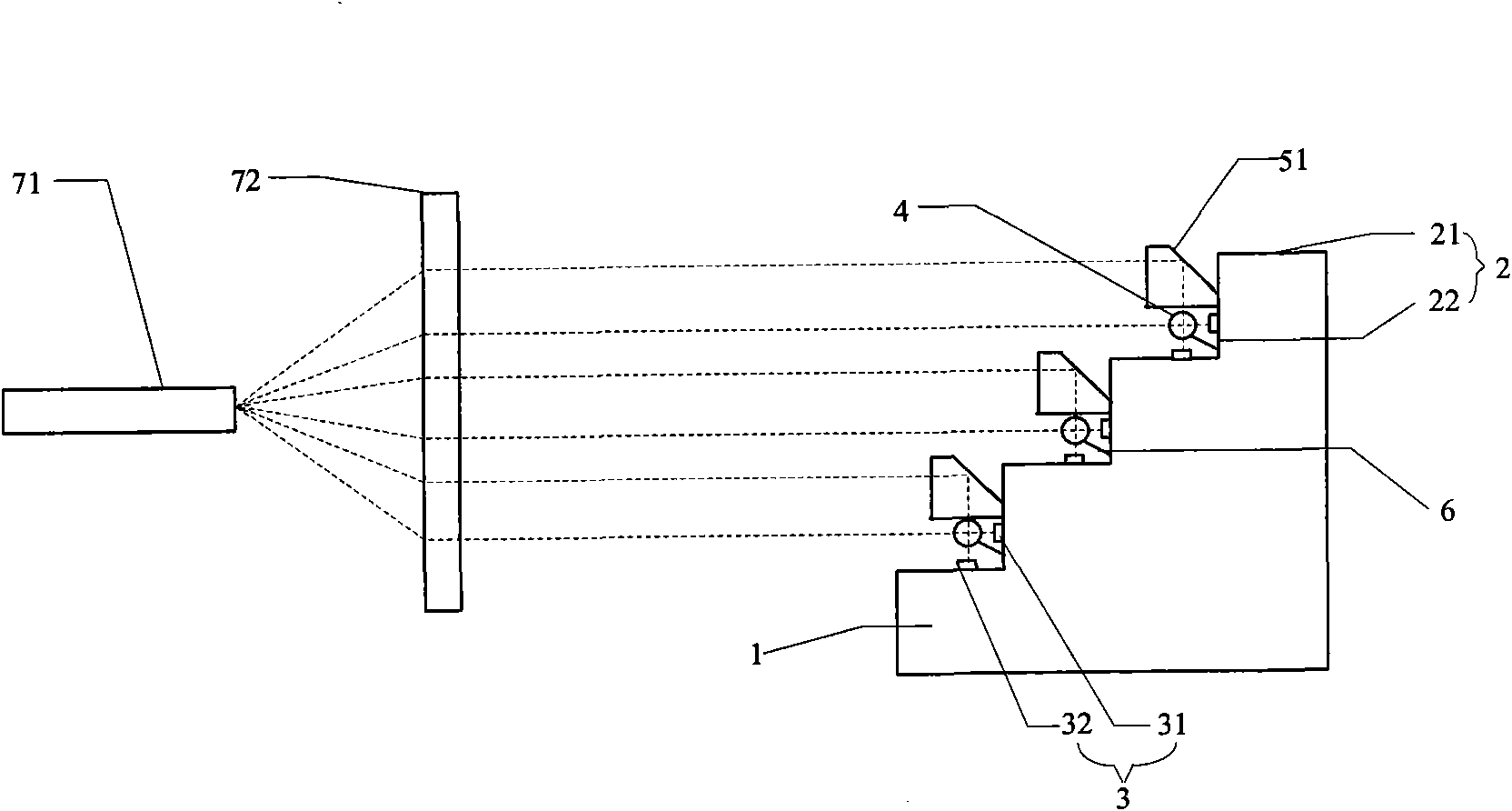

[0051] image 3 It is a schematic diagram of the working principle of another specific embodiment of the semiconductor laser light source of the present invention.

[0052] see image 3 As shown, the semiconductor laser light source disclosed in the present invention has a heat sink 1 with four steps 2, and each step 2 includes a vertical installation surface 22 and a horizontal installation surface 21;

[0053] 6 semiconductor lasers, including 3 first semiconductor lasers 31 arranged on the vertical mounting surface 22 and 3 second semiconductor lasers 32 arranged on the horizontal mounting surface 21, the uppermost one horizontal mounting surface 21 and the lowermost one No semiconductor laser is arranged on the vertical mounting surface 22, the output light optical axis of the first semiconductor laser 31 is perpendicular to the vertical mounting surface 22, the output light optical axis of the second semiconductor laser 32 is perpendicular to the horizontal mounting surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com