Patents

Literature

50 results about "Micro manipulator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

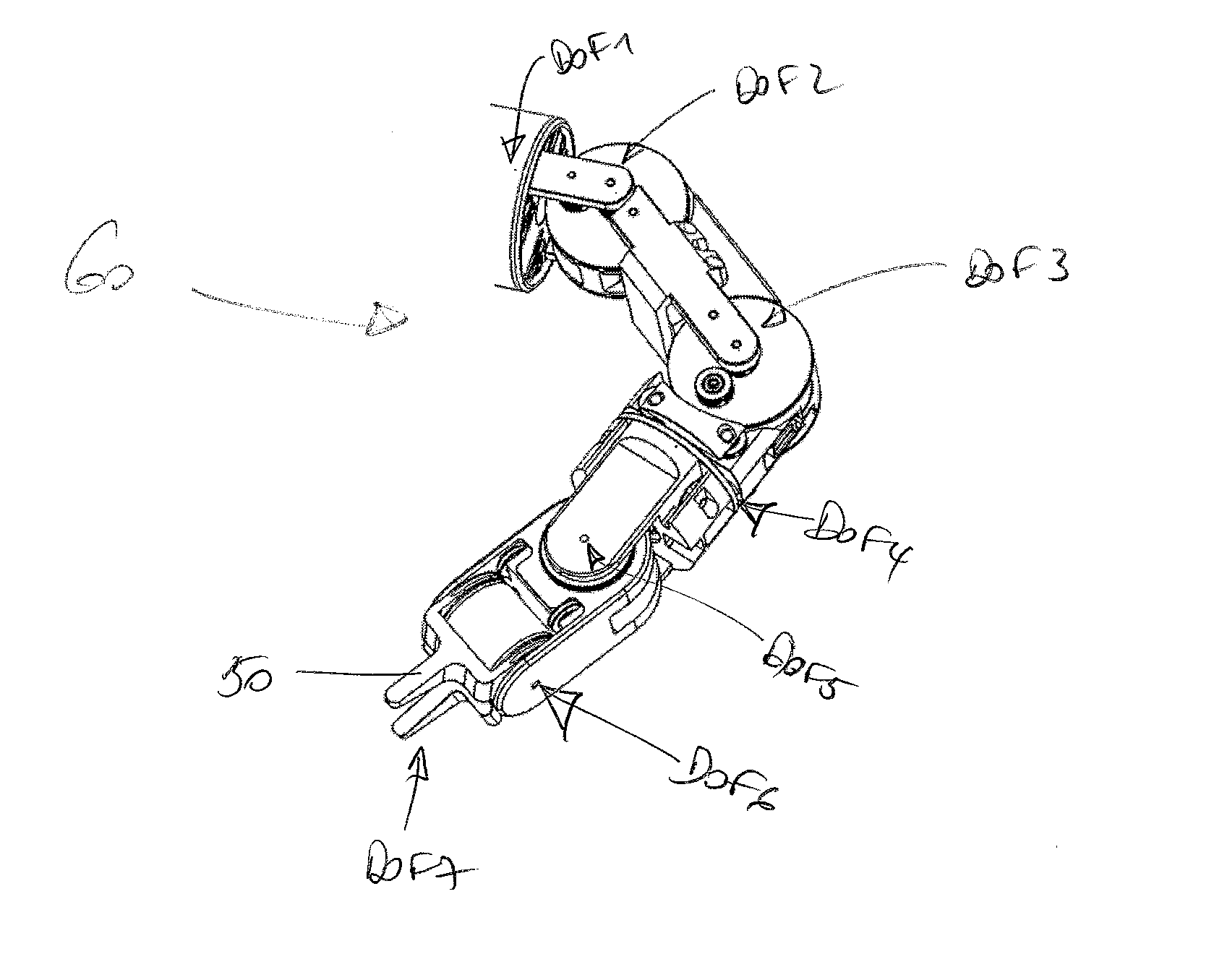

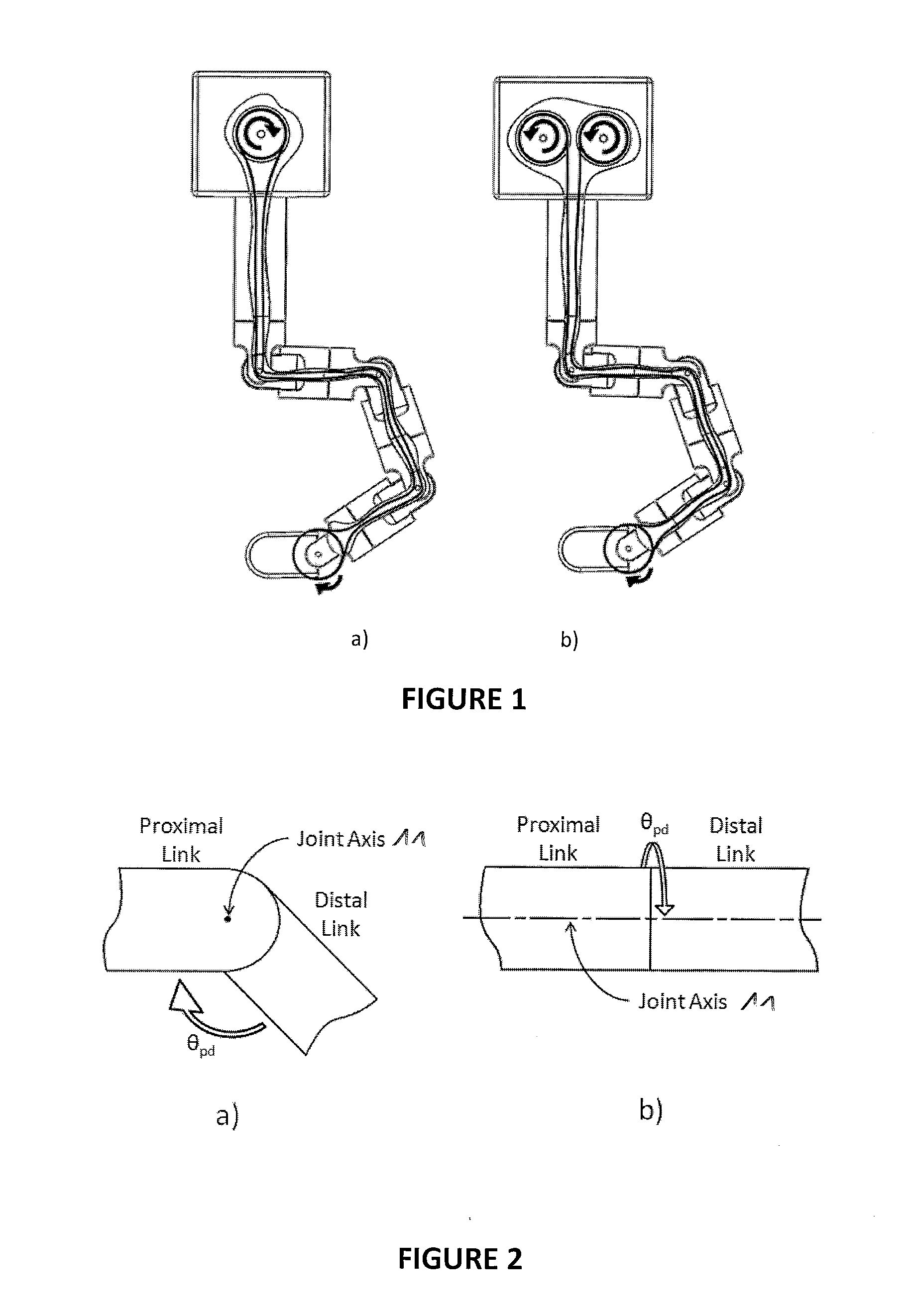

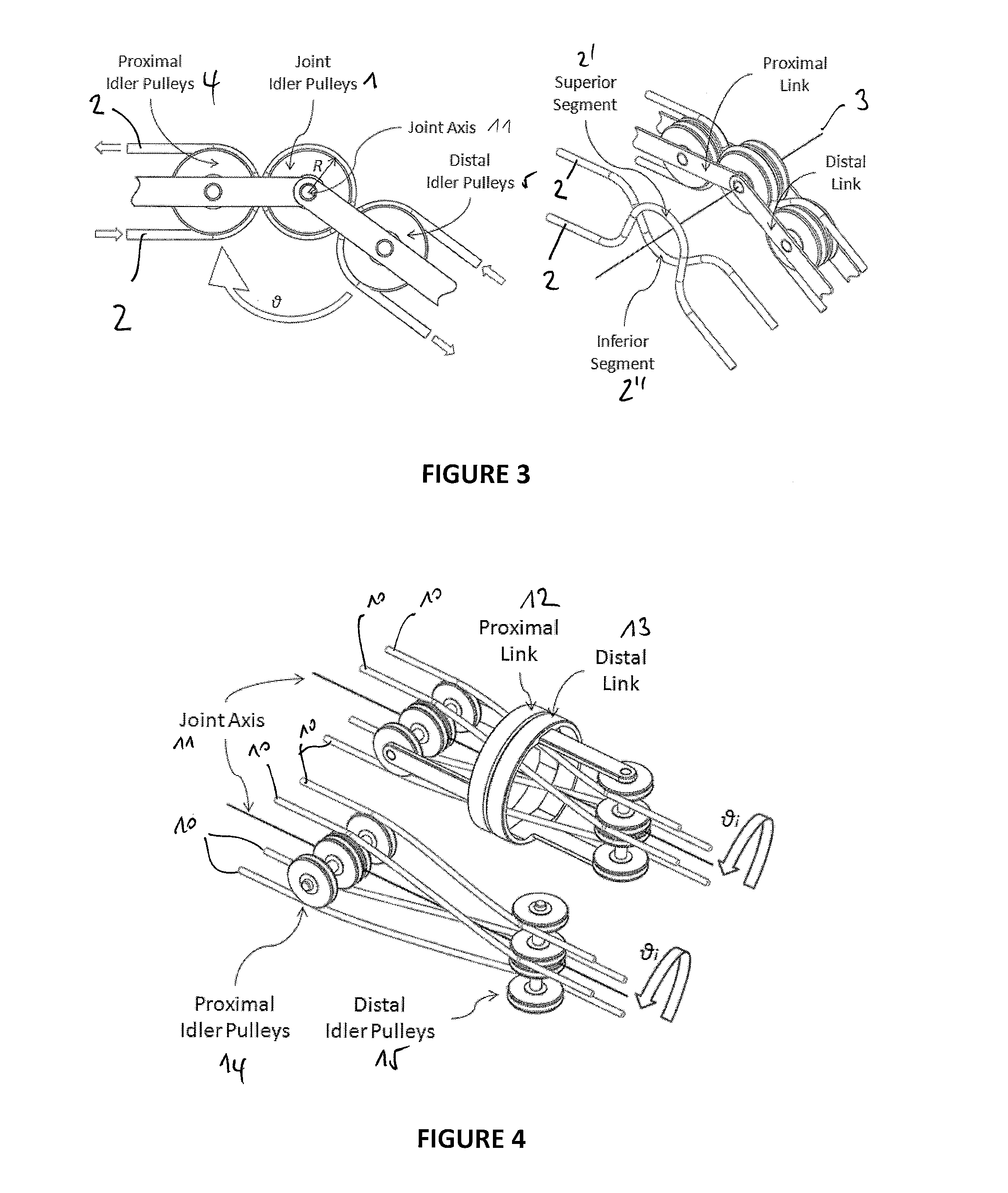

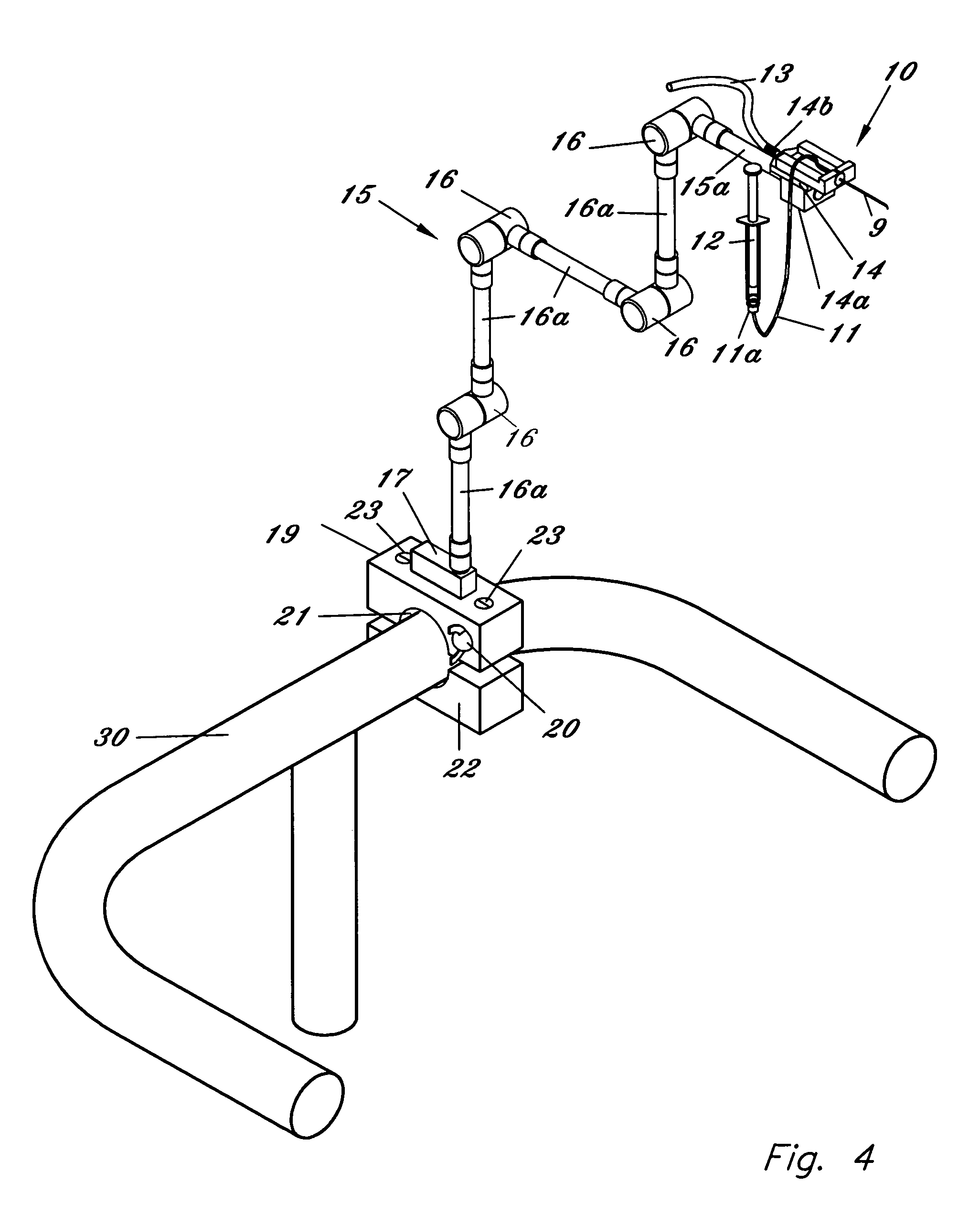

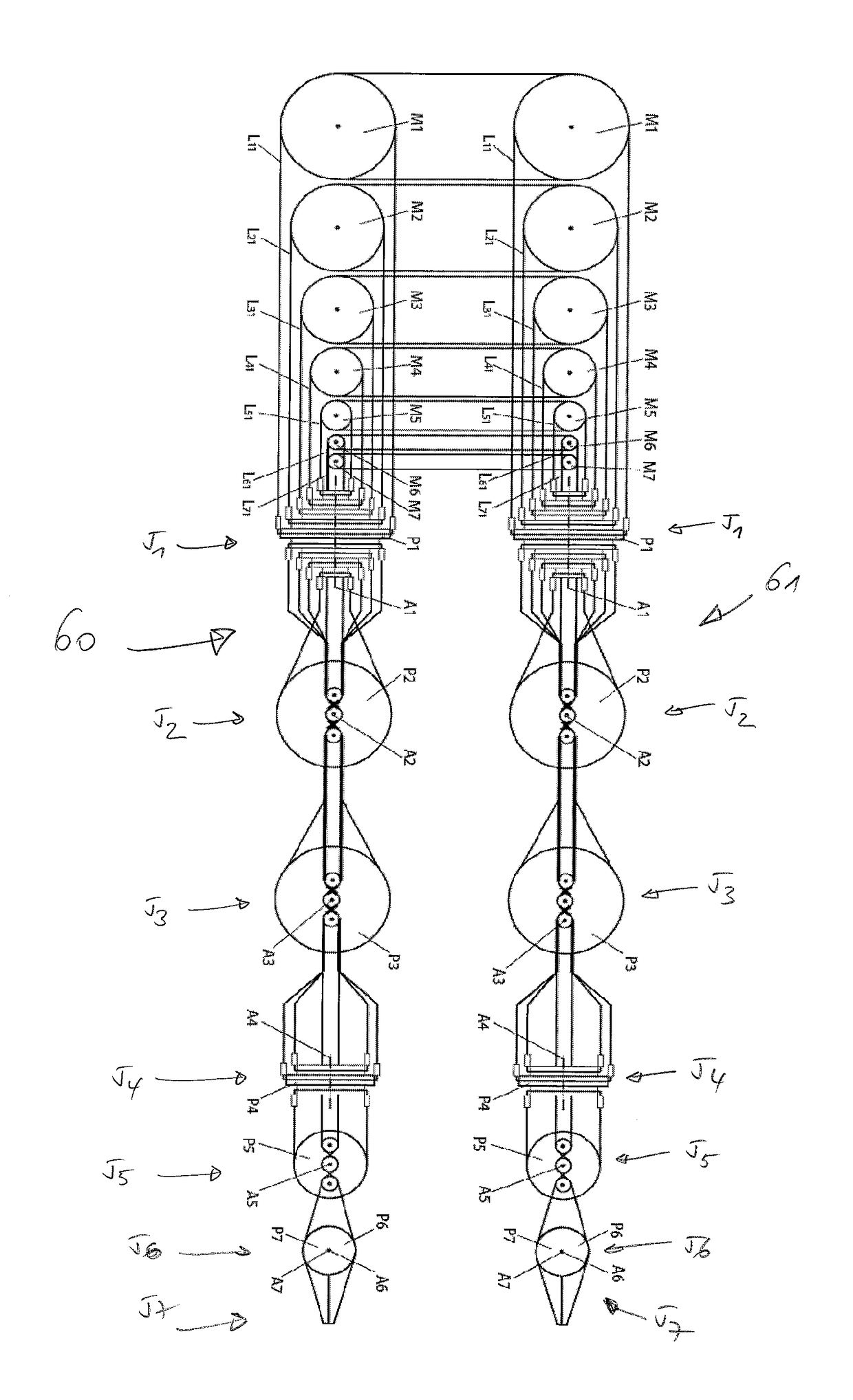

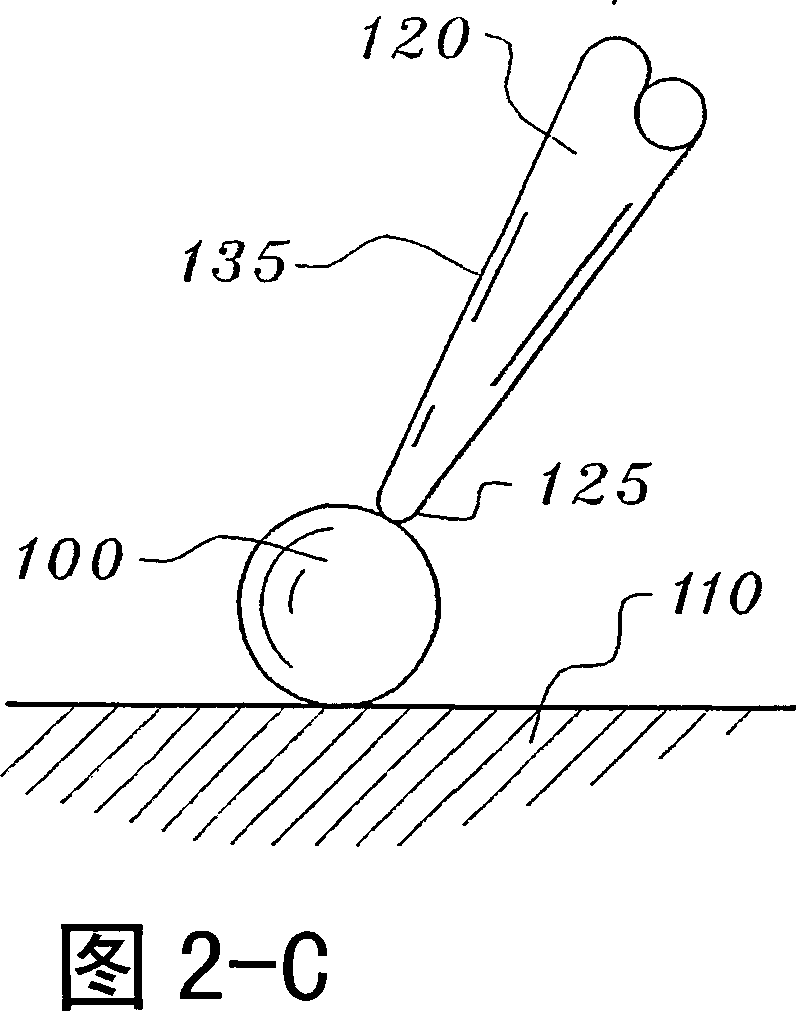

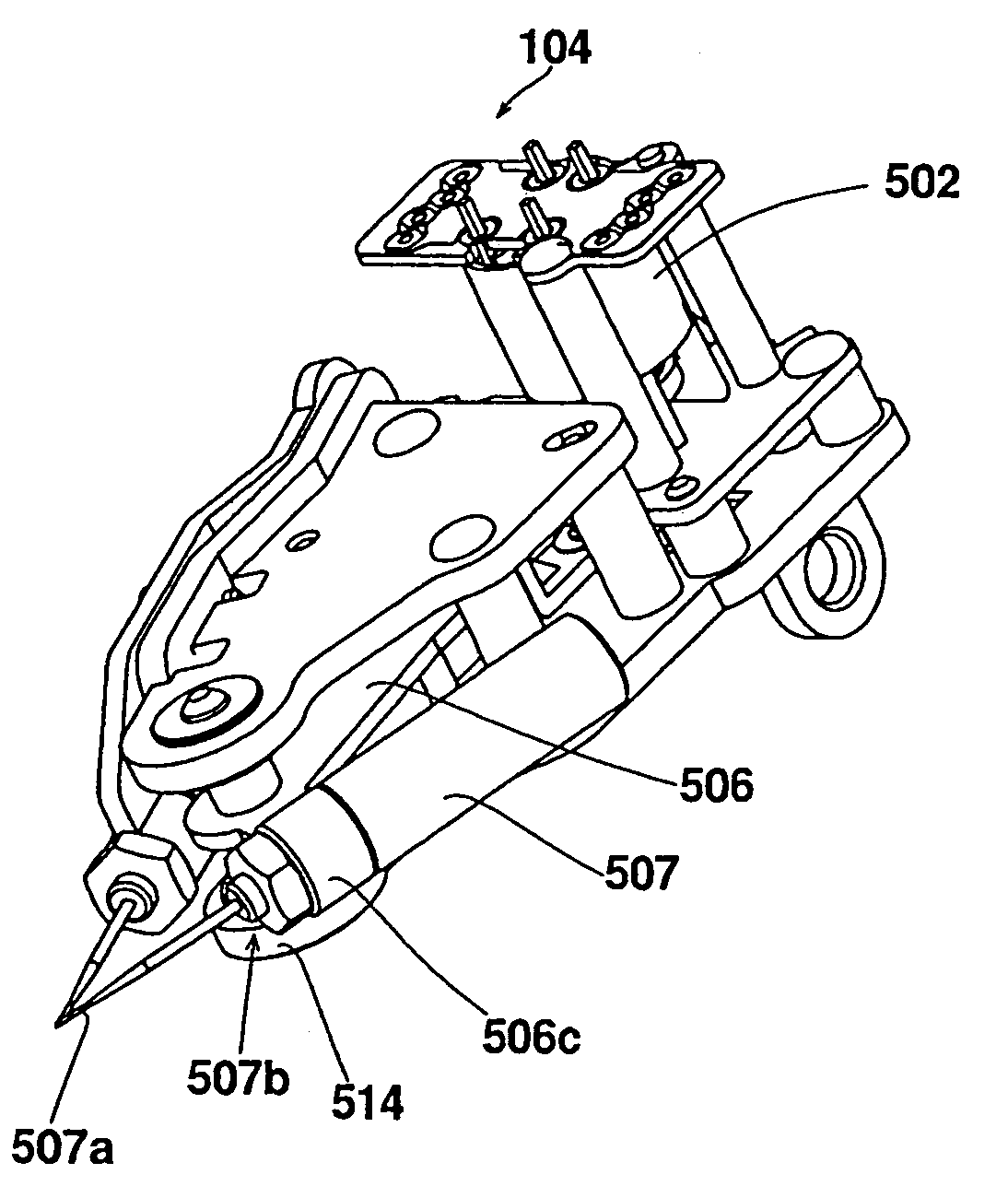

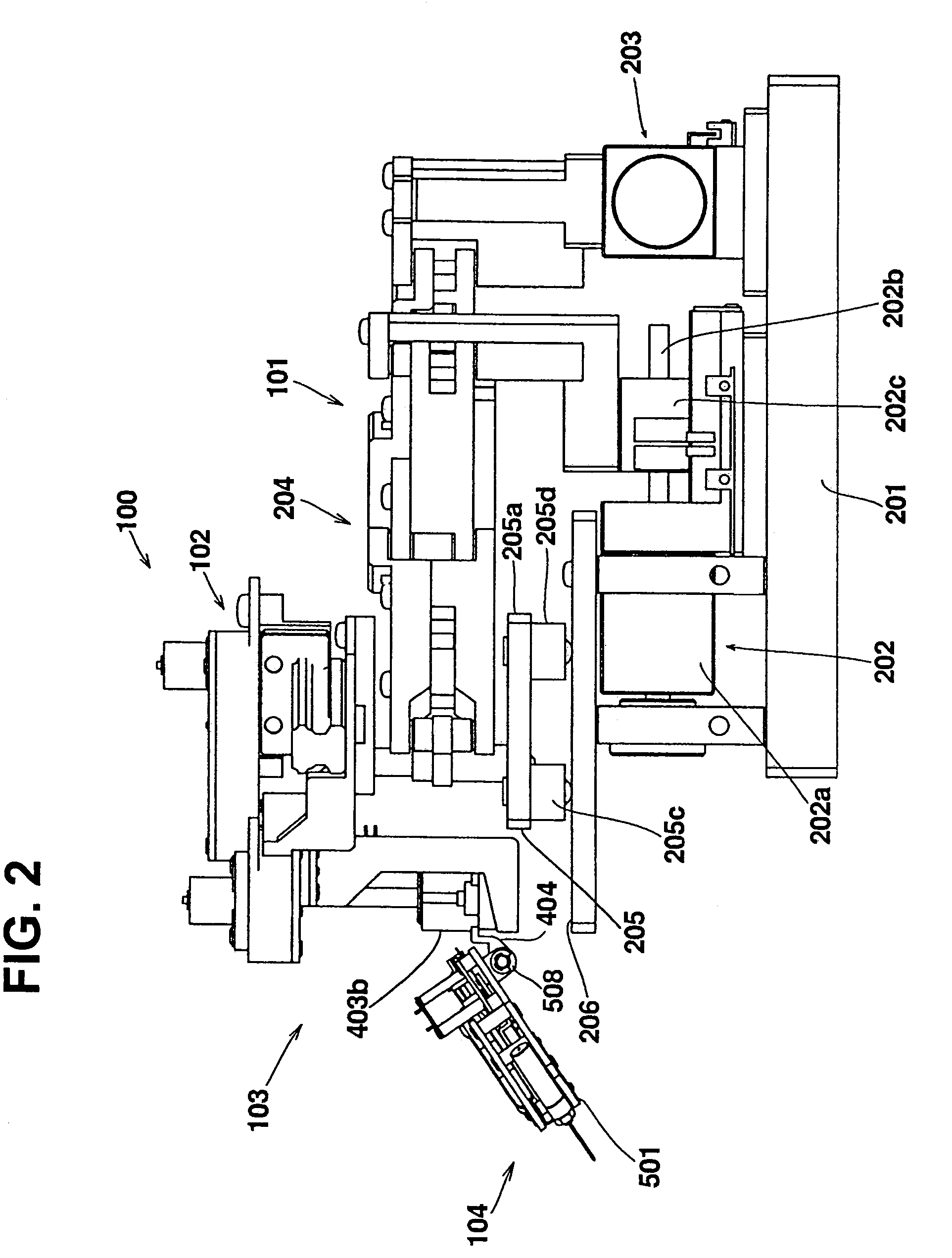

Mechanical manipulator for surgical instruments

ActiveUS20130304084A1Solve the lack of stiffnessSolve the lack of precisionDiagnosticsSurgical manipulatorsConventional laparoscopyEngineering

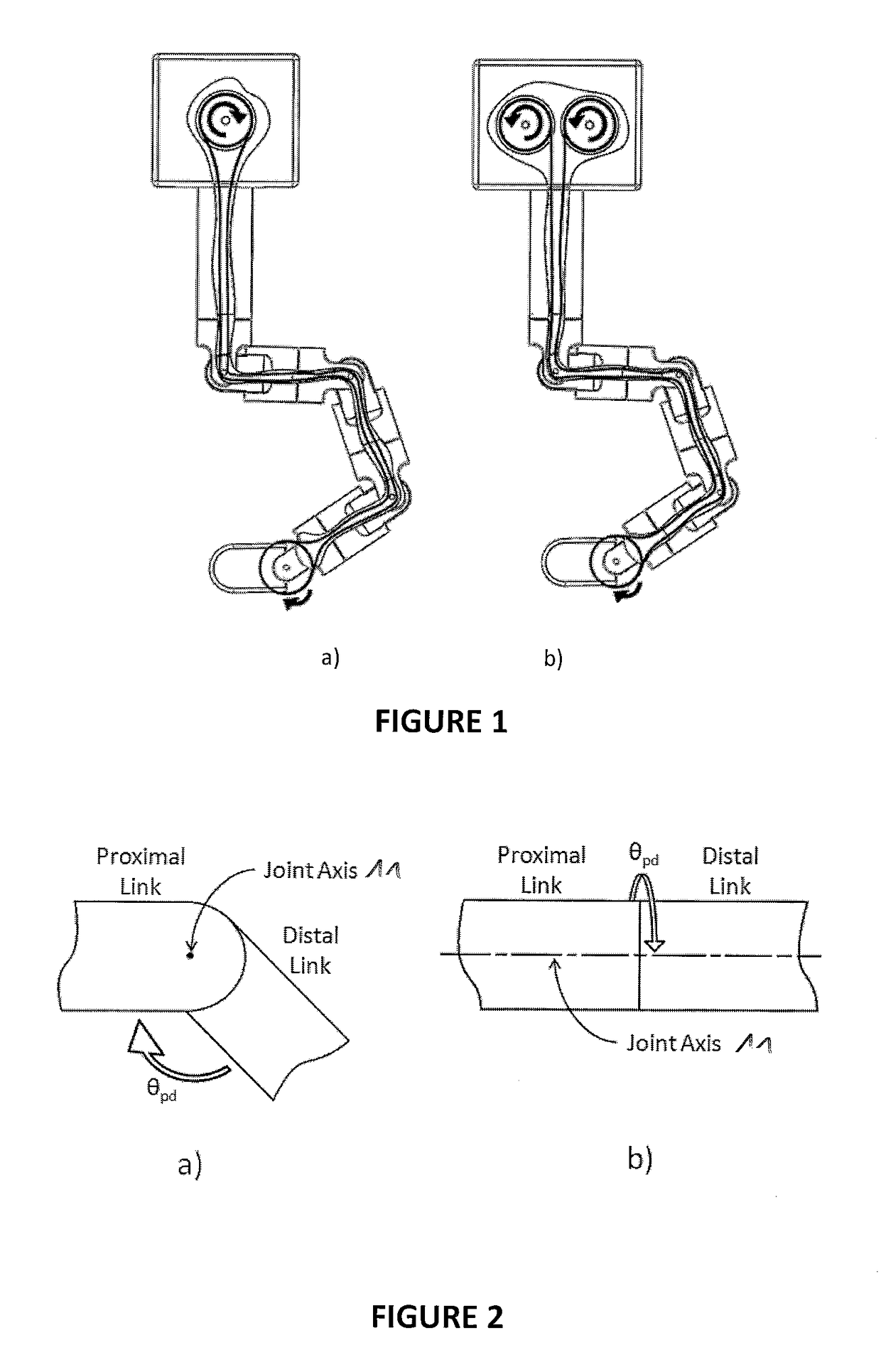

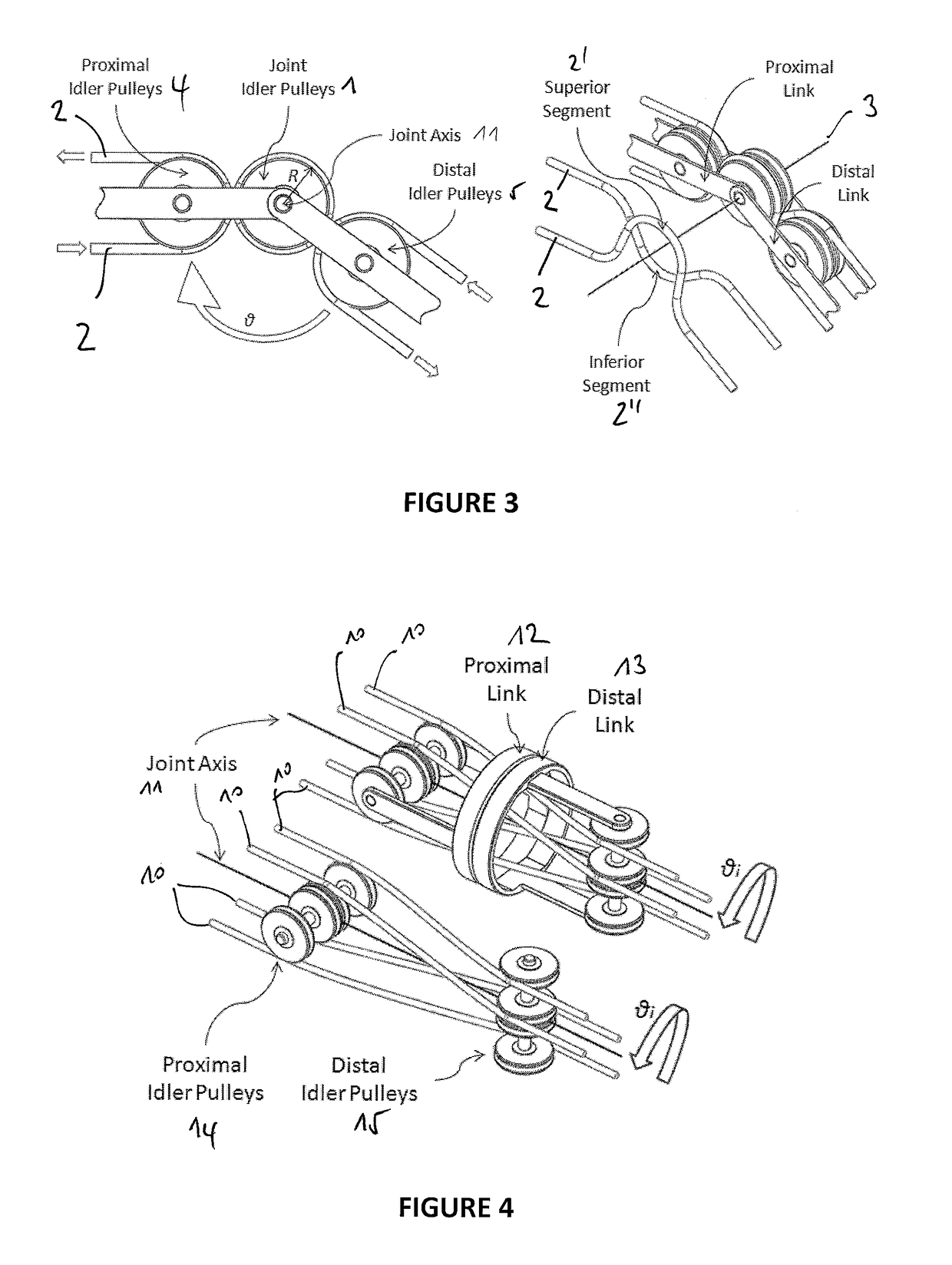

A novel mechanical system, based on a new cable driven mechanical transmission, able to provide sufficient dexterity, stiffness, speed, precision and payload capacity to actuate multi-DOF micro-manipulators. Besides the possibility of being used in several articulated surgical instruments and robotic systems for surgery or other applications involving remote manipulation, it enables the design of a novel fully mechanical surgical instrument, which offer the advantages of conventional laparoscopy (low cost, tactile feedback, high payload capacity) combined with the advantages of single port surgery (single incision, scarless surgery, navigation through several quadrants of the abdominal cavity) and robotic surgery (greater degrees of freedom, short learning curve, high stiffness, high precision, increased intuition). The unique design of the proposed system provides an intuitive user interface to achieve such enhanced manoeuvrability, allowing each joint of a teleoperated slave system to be driven by controlling the position of a mechanically connected master unit.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

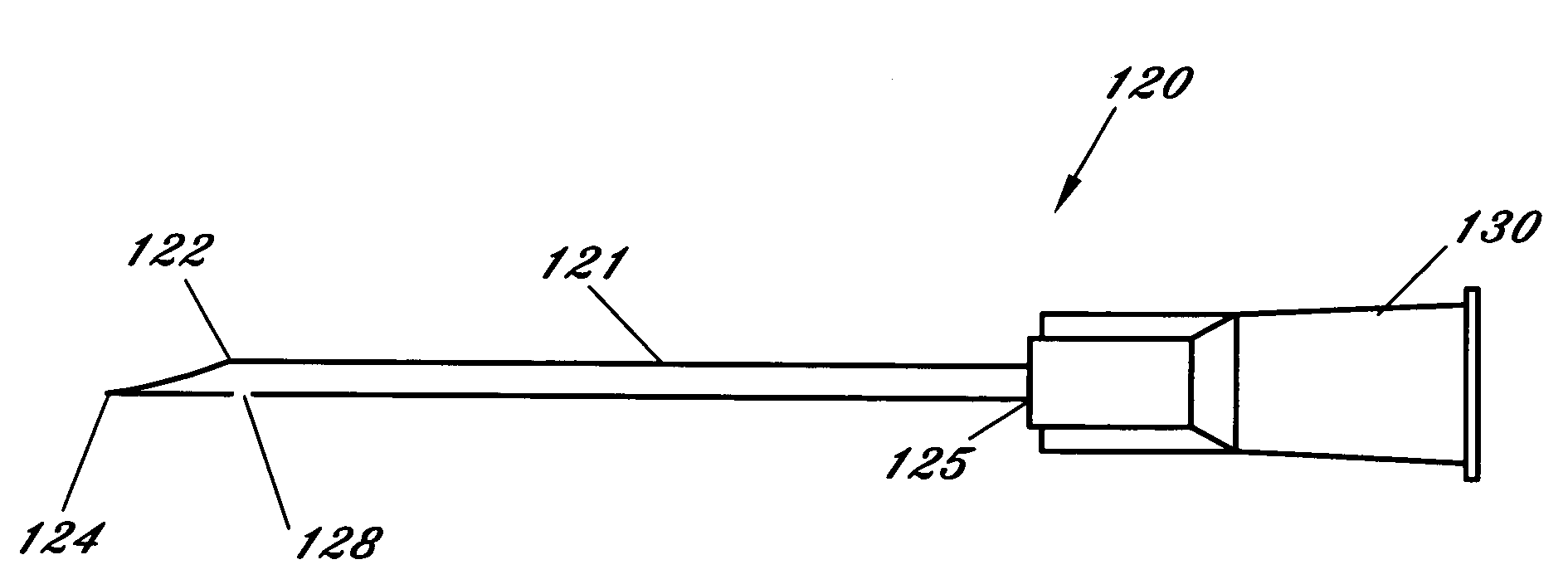

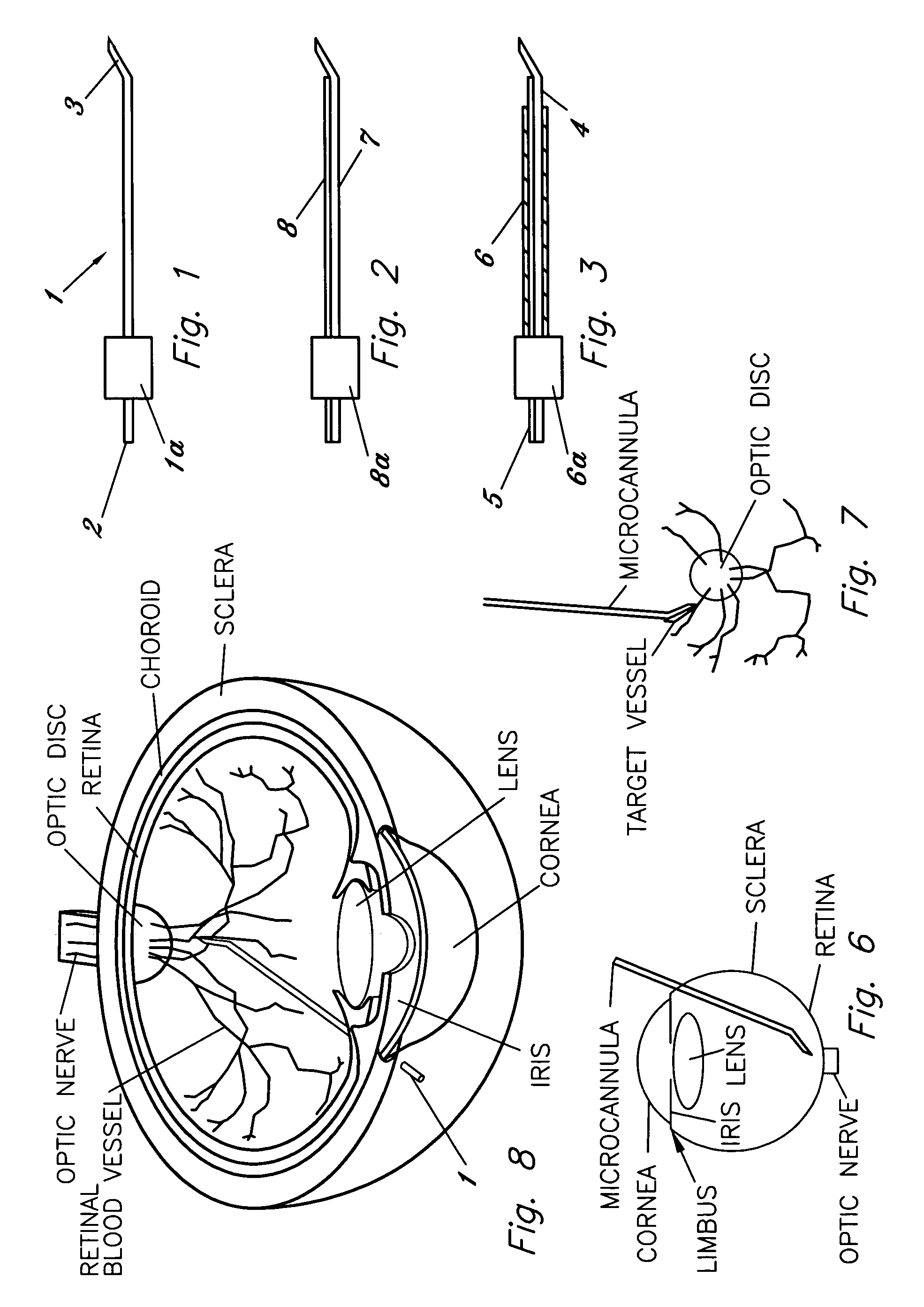

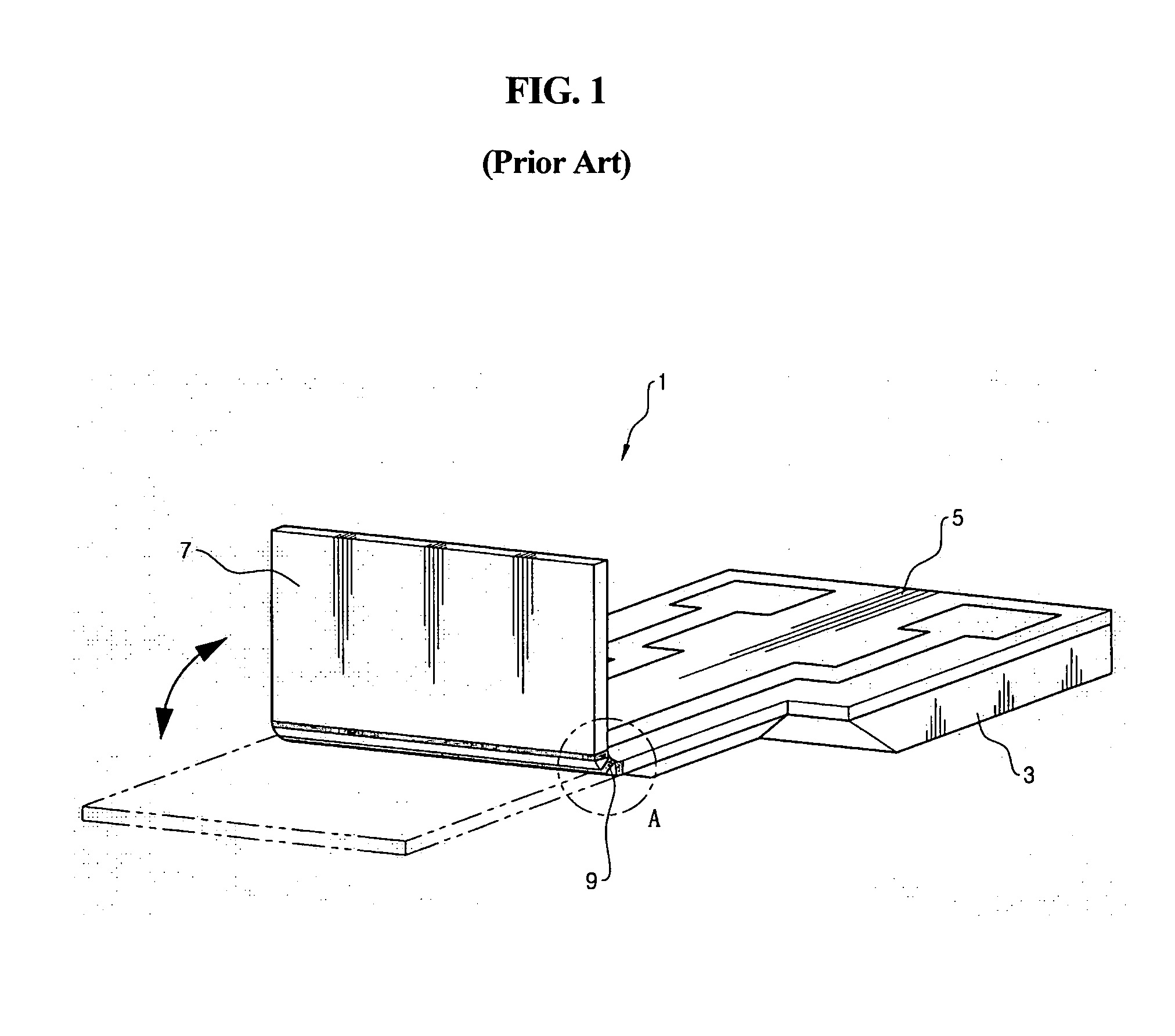

Ocular implant needle

InactiveUS6936053B1Easily perforate designated blood vesselMinimize bleedingStentsEye surgeryDiseaseOptic nerve

An apparatus and method for safely cannulating a blood vessels, including but not limited retinal blood vessels, is described. In one embodiment, the apparatus can consist of a micropipette / microcannula, micromanipulator and positioner mounted to a base, which is attached to a wrist rest commonly used in eye surgery. The micropipette / microcannula is connected to tubing such that a medication may be injected through the micropipette / microcannula into the blood vessel or conversely, a small quantity of material may be removed from a blood vessel. Alternatively, a catheter, wire or stent may be placed through the micropipette / microcannula to treat or diagnose an area remote from the insertion site. The ability to cannulate a retinal blood vessel should be efficacious in the treatment of vein and artery occlusion, ocular tumors and other retinal, vascular and optic nerve disorders that would benefit from diagnosis and / or treatment. In another embodiment, a self-sealing needle is provided which allows the perforation of a blood vessel or other structure and the minimization of hemorrhaging when the needle is withdrawn from the blood vessel / structure. Another embodiment discloses an ocular implant needle.

Owner:JNW PARTNERS

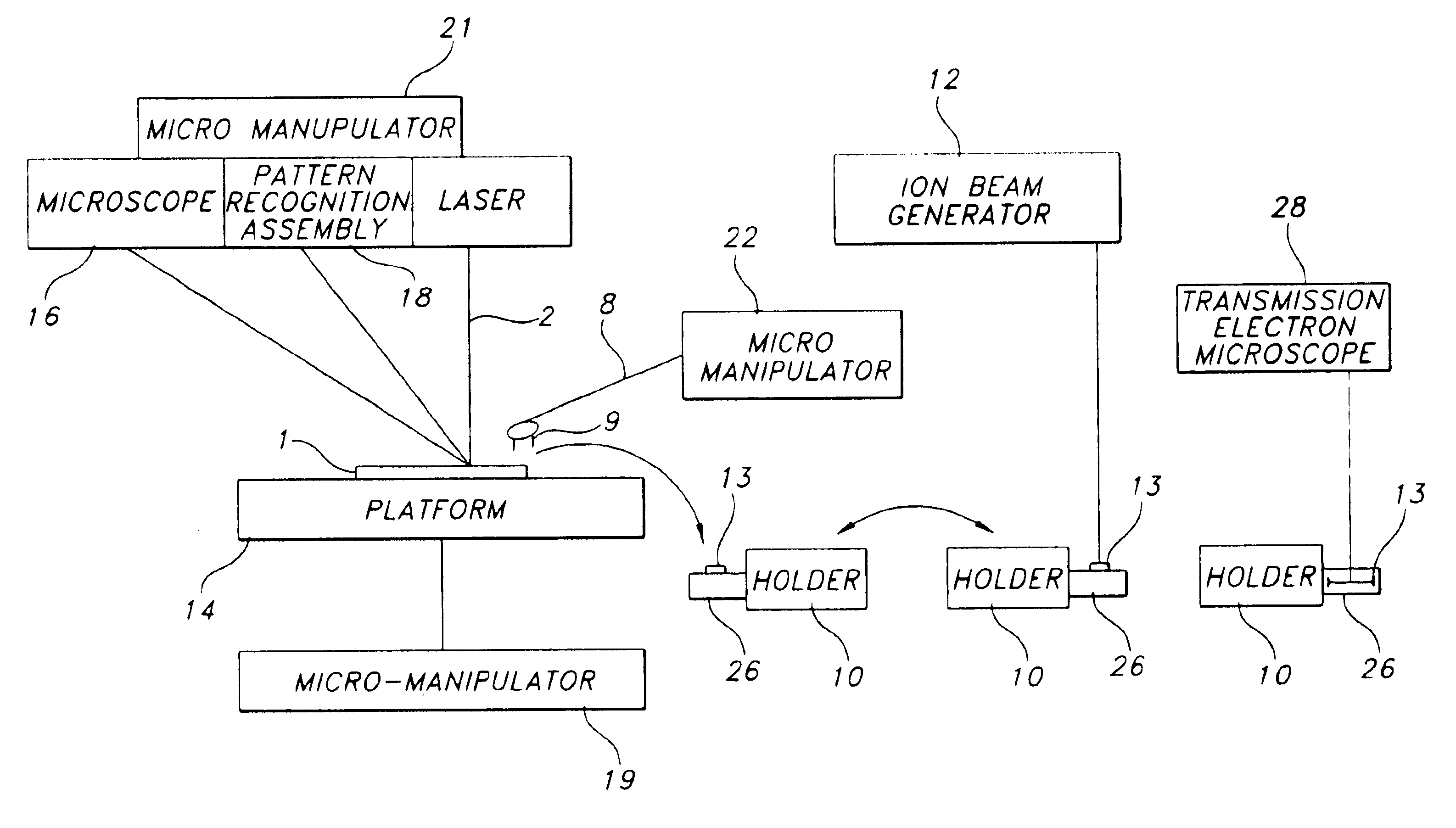

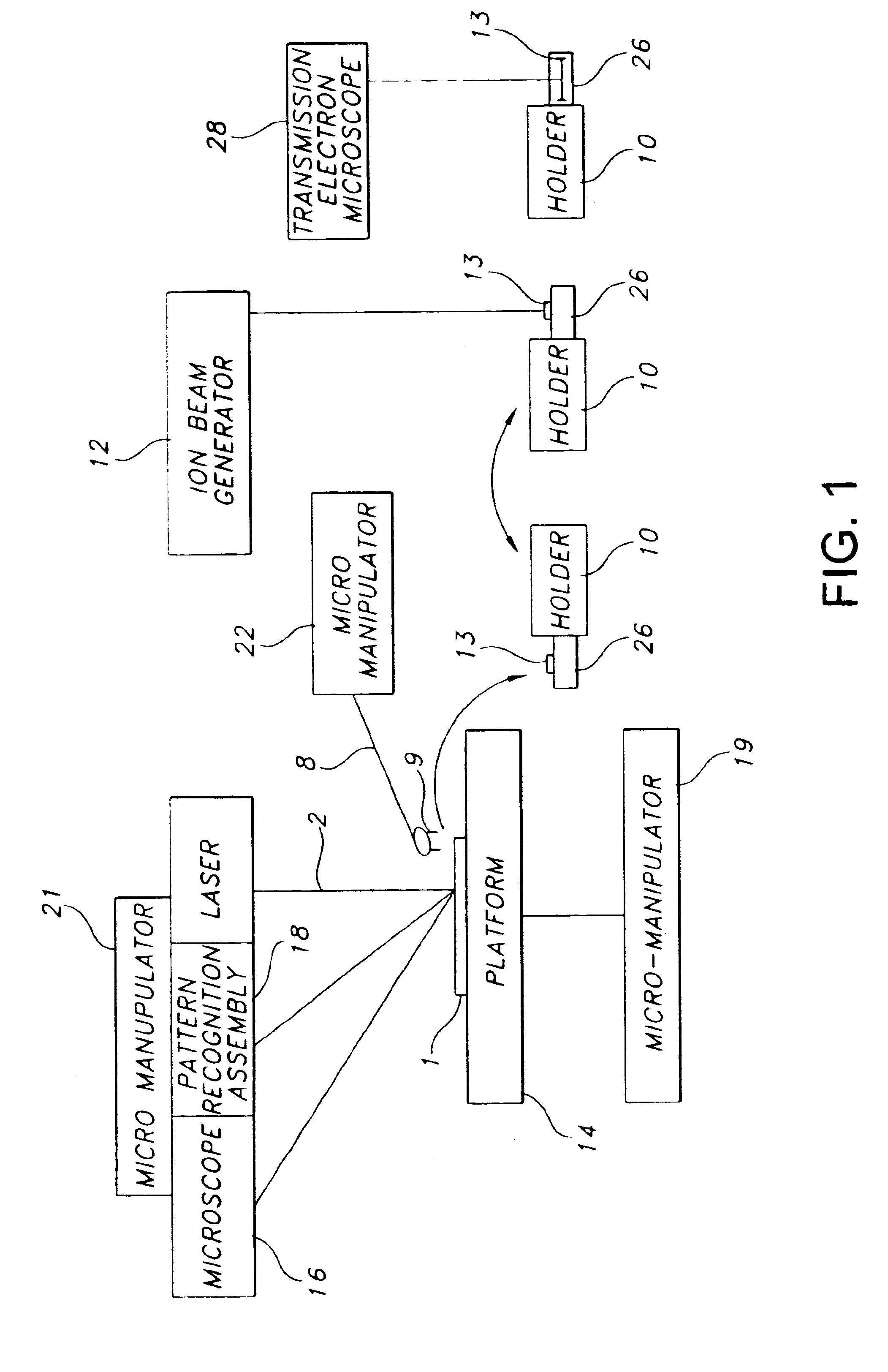

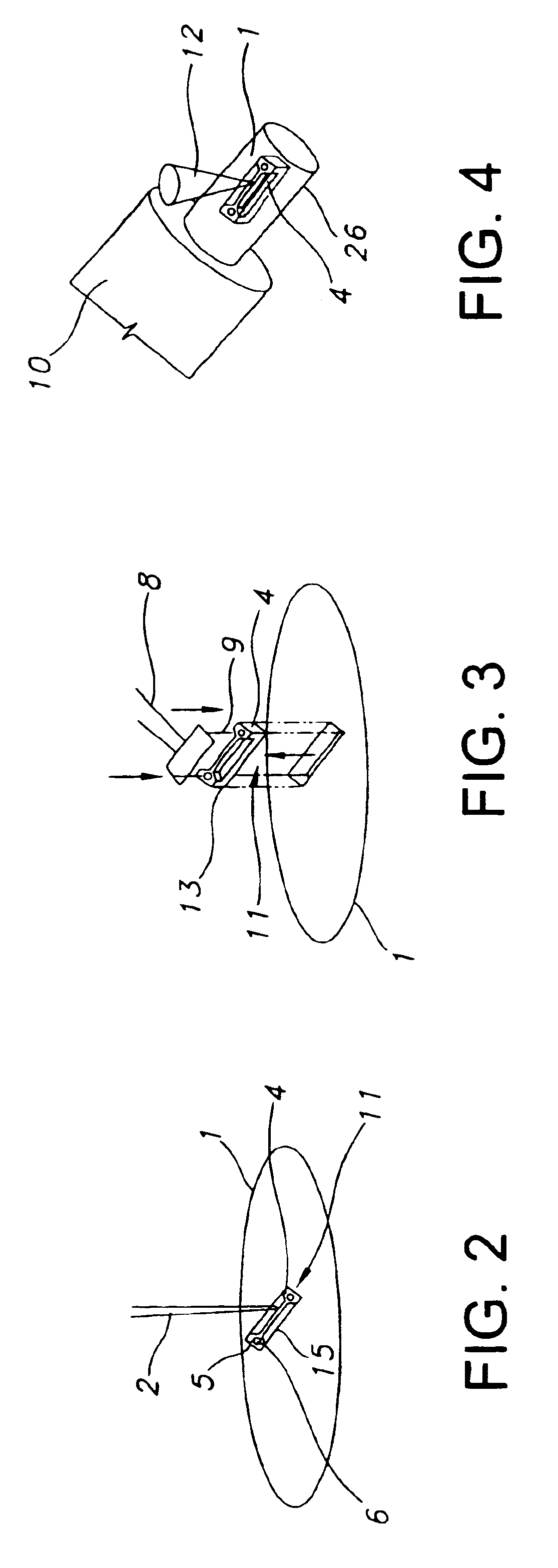

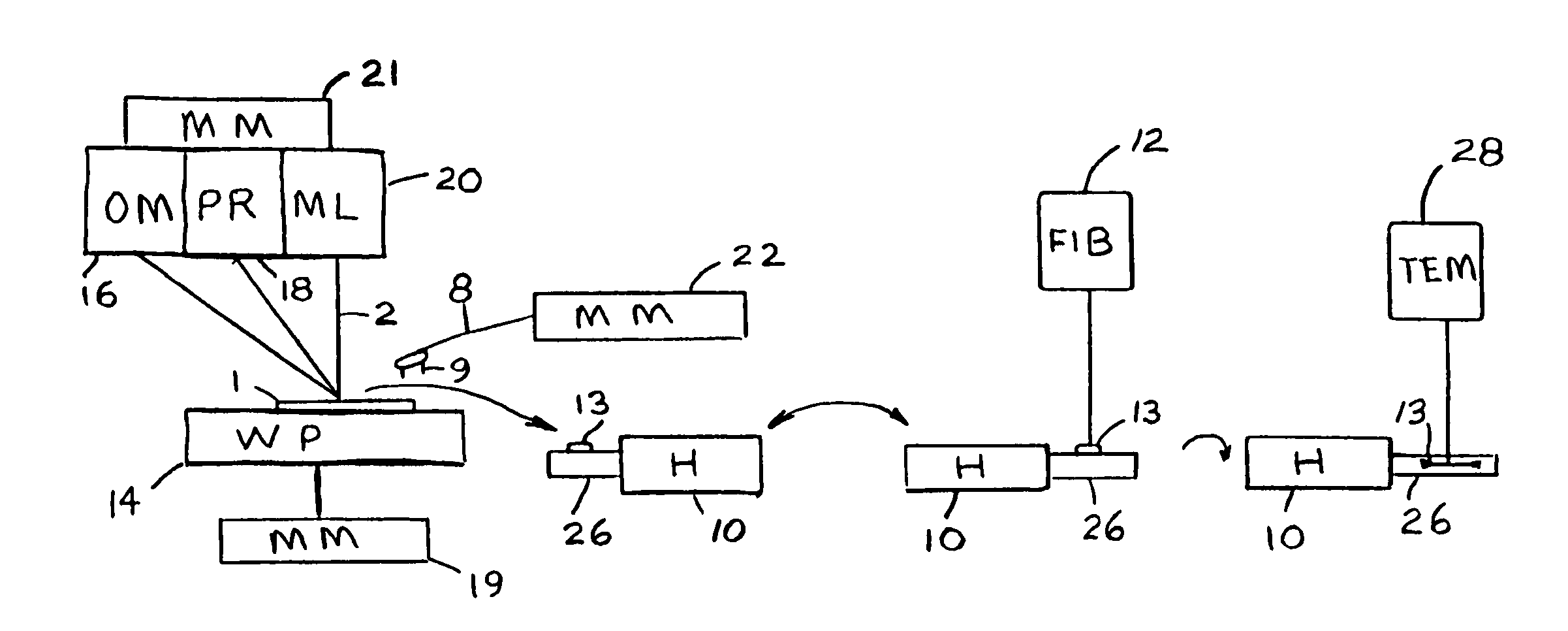

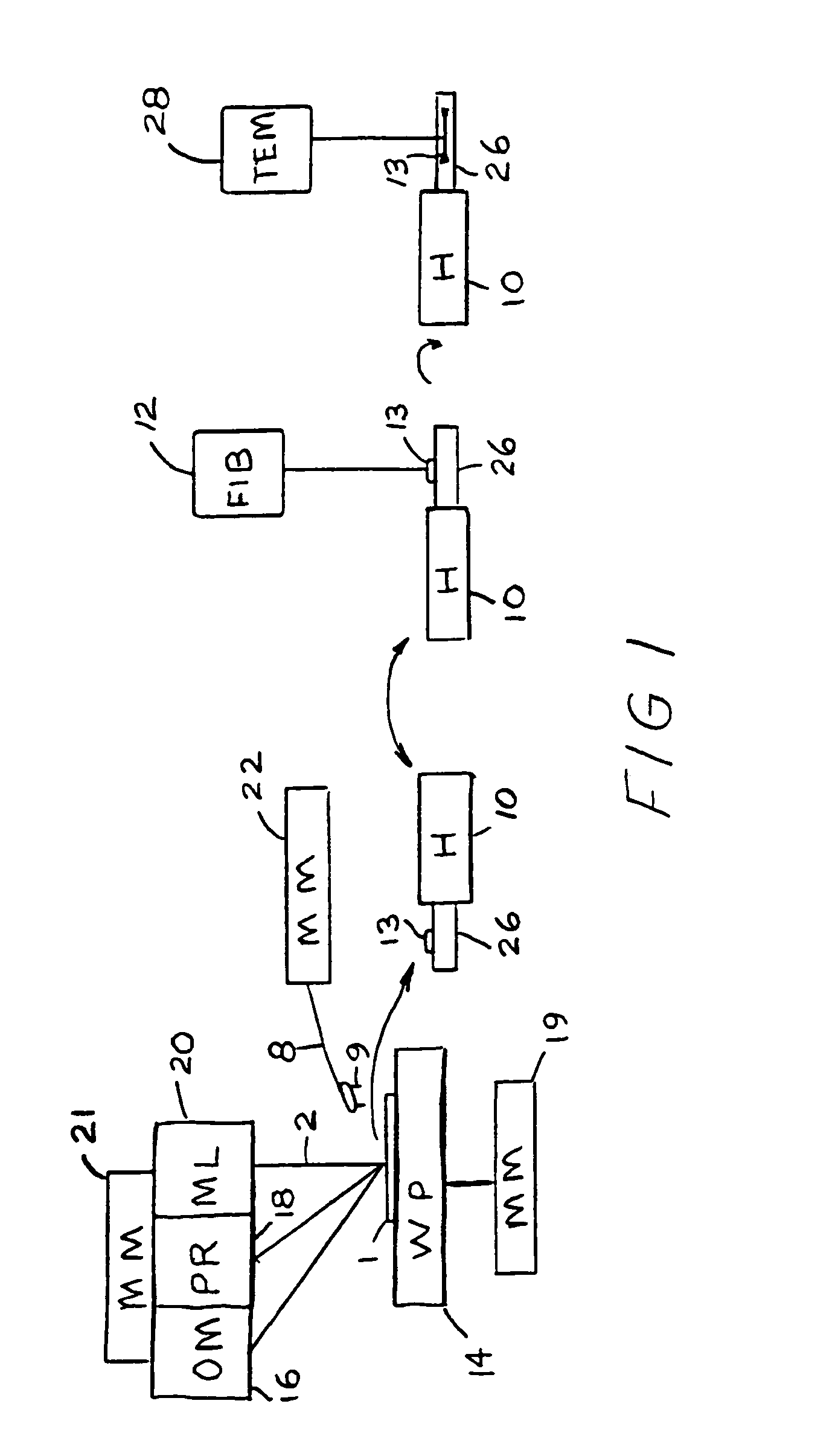

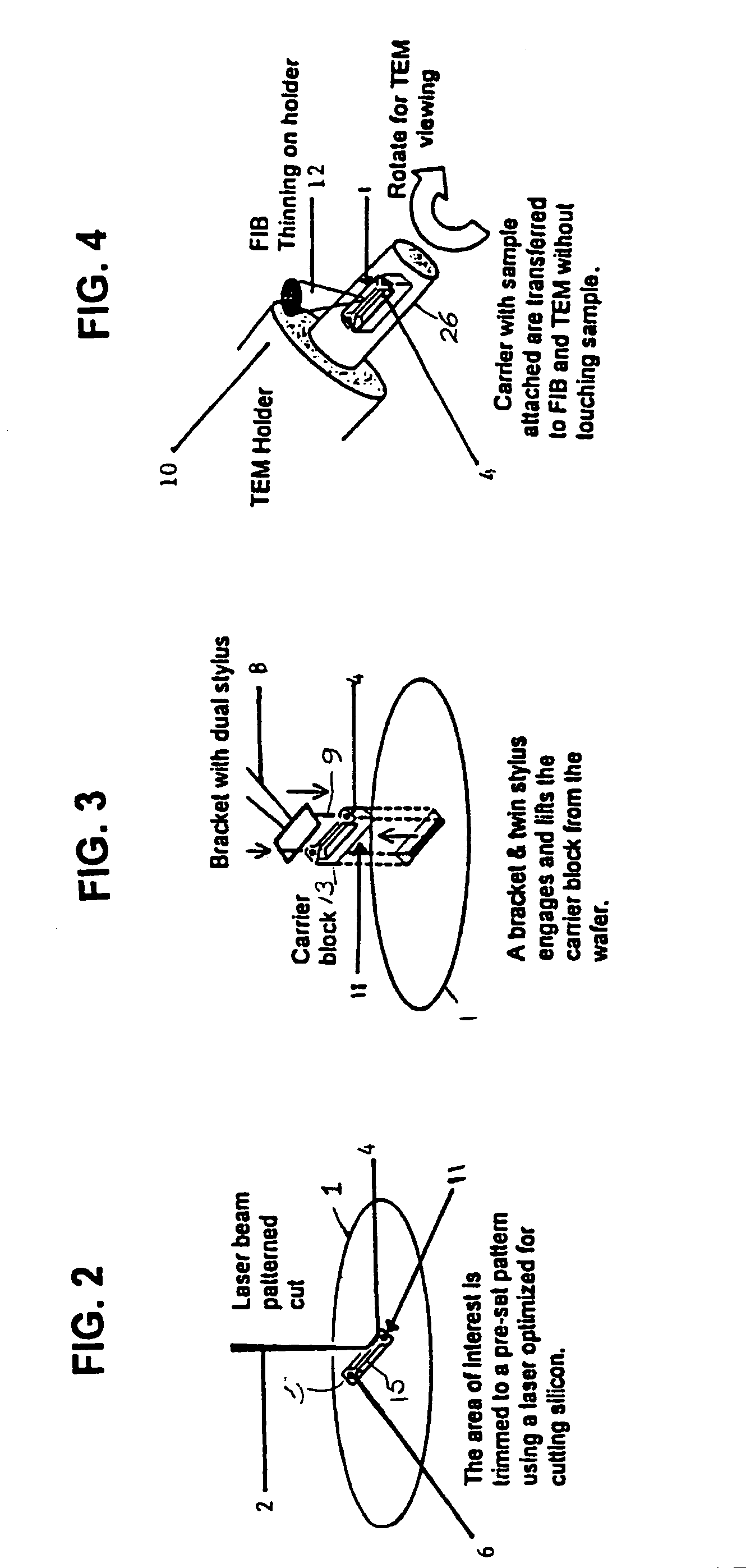

Transmission electron microscope sample preparation

InactiveUS6841788B1Easy to useProvide protectionElectric discharge tubesPreparing sample for investigationElectron microscopeThinning

Sample preparation apparatus and method includes a wafer stage platform with an optical microscope and integrated pattern recognition to automatically address specific locations on the wafer sample of interest. A laser attaches to the optical microscope to mill a set pattern around the area of interest. A precision micro-manipulator engages the sample support structure, extracts the structure, and places the structure in a TEM holder or holder tip. The holder or holder tip can then be placed inside a FIB for final thinning, followed by direct transfer into the TEM.

Owner:OXFORD INSTR AMERICA

Transmission electron microscope sample preparation

InactiveUS6982429B2Thermal damageEliminate damageMaterial analysis using wave/particle radiationElectric discharge tubesElectron microscopeThinning

Sample preparation apparatus and method includes a wafer stage platform with an optical microscope and integrated pattern recognition to automatically address specific locations on the wafer sample of interest. A laser attaches to the optical microscope to mill a set pattern around the area of interest. A precision micro-manipulator engages the sample support structure, extracts the structure, and places the structure in a TEM holder or holder tip. The holder or holder tip can then be placed inside a FIB for final thinning, followed by direct transfer into the TEM.

Owner:OXFORD INSTR AMERICA

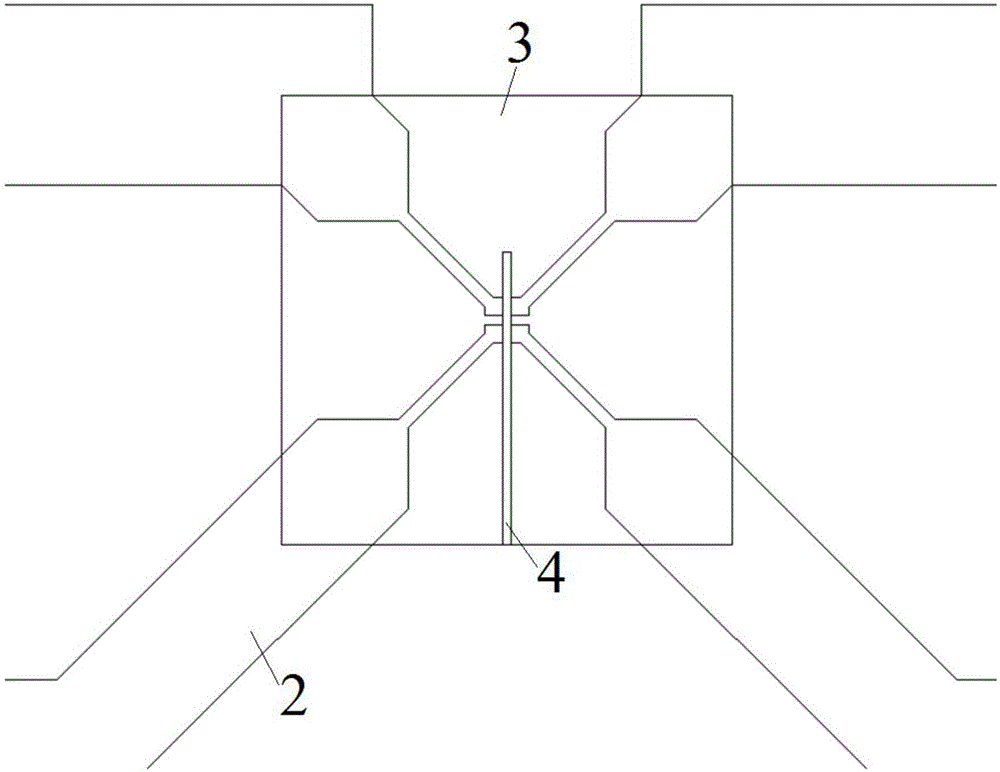

Nanometer material transmission electron microscope in-situ testing chip, preparation method and applications thereof

ActiveCN105136822AReduce the conditions of useReduce use costTelevision system detailsMaterial analysis using wave/particle radiationHeterojunctionElectron

The present invention discloses a nanometer material transmission electron microscope in-situ testing chip, a preparation method and applications thereof, and belongs to the technical field of nanometer material performance in-situ testing. The chip comprises a silicon substrate, insulating layers and a film window, wherein the insulating layer respectively grows on both surfaces of the silicon substrate, a metal film or device or a semiconductor function film or device grows on the chip front surface insulating layer so as to apply various physical and chemical effects on a sample, the center of the chip is provided with the film window, and the film window region is provided with a electron beam penetrating long hole or electron beam penetrating long groove having a large aspect ratio. According to the present invention, the transmission electron microscope sample can be subjected to in-situ measurement under the atomic scale resolution, the nano-wire samples and the nano-tube samples can be subjected to in-situ characterization, the bulk samples and the heterojunction interface samples can be subjected to in-situ characterization, the placement of the sample through the micro manipulator in the focused ion beam system and the laboratory can be achieved, and the sample transferred and fixed on the chip can be continuously processed by using the ion reduction equipment.

Owner:NANJING UNIV

Mechanical manipulator for surgical instruments

ActiveUS10092359B2Solve the lack of stiffnessSolve the lack of precisionDiagnosticsSurgical manipulatorsConventional laparoscopyOperability

A novel mechanical system, based on a new cable driven mechanical transmission, able to provide sufficient dexterity, stiffness, speed, precision and payload capacity to actuate multi-DOF micro-manipulators. Besides the possibility of being used in several articulated surgical instruments and robotic systems for surgery or other applications involving remote manipulation, it enables the design of a novel fully mechanical surgical instrument, which offer the advantages of conventional laparoscopy (low cost, tactile feedback, high payload capacity) combined with the advantages of single port surgery (single incision, scarless surgery, navigation through several quadrants of the abdominal cavity) and robotic surgery (greater degrees of freedom, short learning curve, high stiffness, high precision, increased intuition). The unique design of the proposed system provides an intuitive user interface to achieve such enhanced maneuverability, allowing each joint of a teleoperated slave system to be driven by controlling the position of a mechanically connected master unit.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

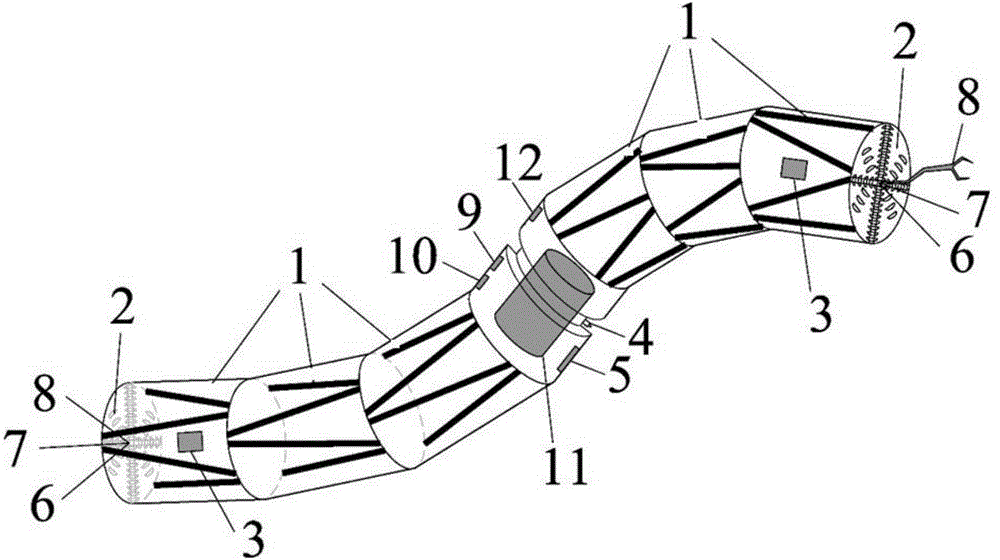

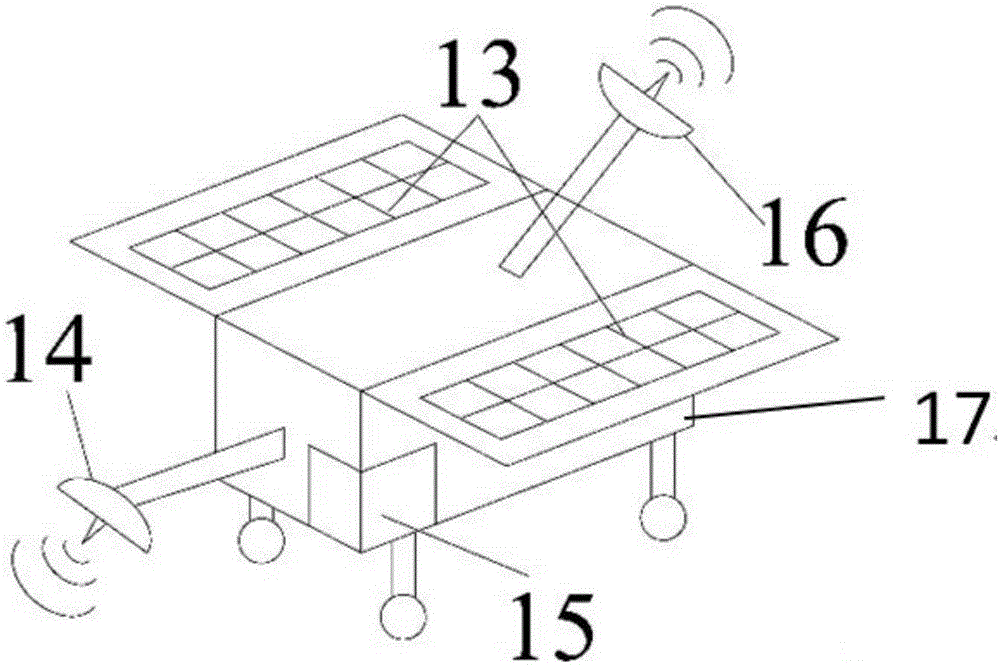

Miniature underground crawling self-shielding detection robot

The invention relates to a miniature underground crawling self-shielding detection robot comprising a molting snake shielding robot and an earth surface auxiliary robot. The molting snake shielding robot can crawl underground, an annular 3D printing nozzle on the side wall sprays adhesive onto the surrounding soil to form a high-strength shield shell, and the molting snake shielding robot carries an electromagnetic probe, a camera, a micro manipulator, a pressure sensor and a temperature sensor and can detect the soil structure of the shallow layer of a planet. The earth surface auxiliary robot follows the molting snake shielding robot to synchronously move on the surface of the earth, uses electromagnetic wave to wirelessly transmit power to the molting snake shielding robot and sends collected data to a space transfer station, and can detect and sample the surface of the earth. By using the miniature underground crawling self-shielding detection robot of the invention, network detection of the shallow layer of a planet can be realized. The robot makes up for the defect of the existing method which can only detect the surface. A complete detected shallow layer soil structure can be provided for engineering geology, engineering survey, planet surface detection and other related fields, and the basic physical and mechanical parameters of the underground rock and soil mass can be obtained.

Owner:TONGJI UNIV

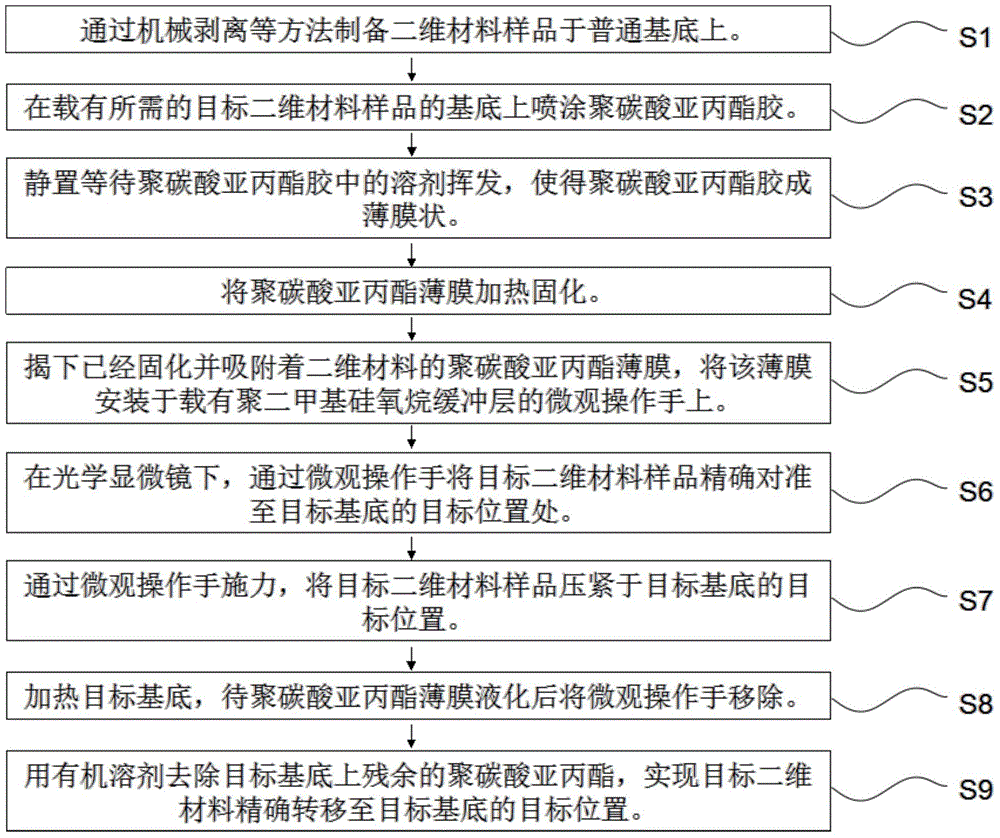

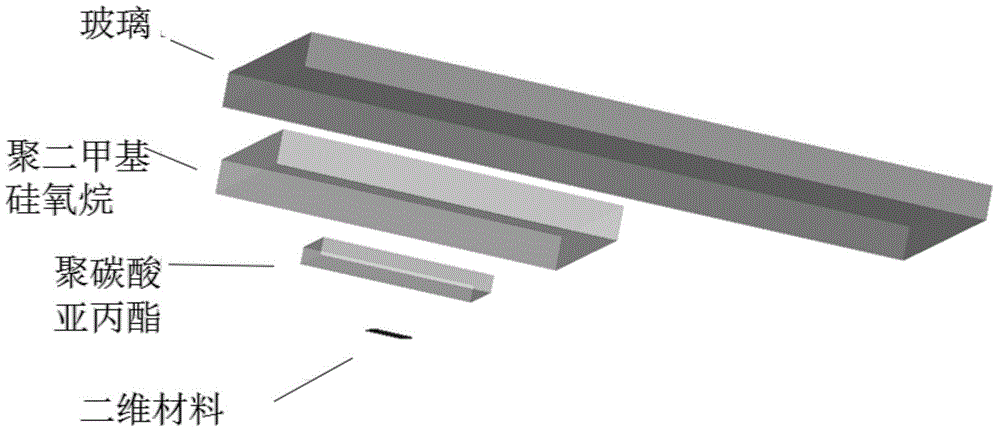

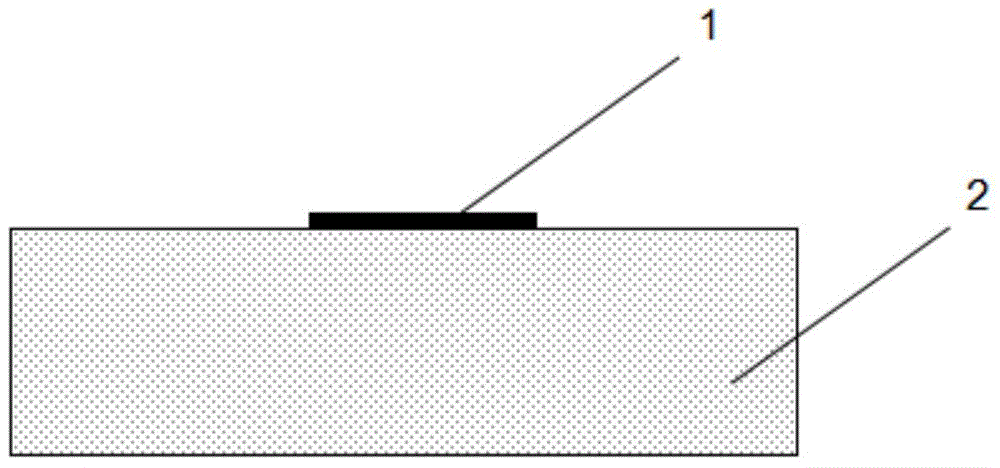

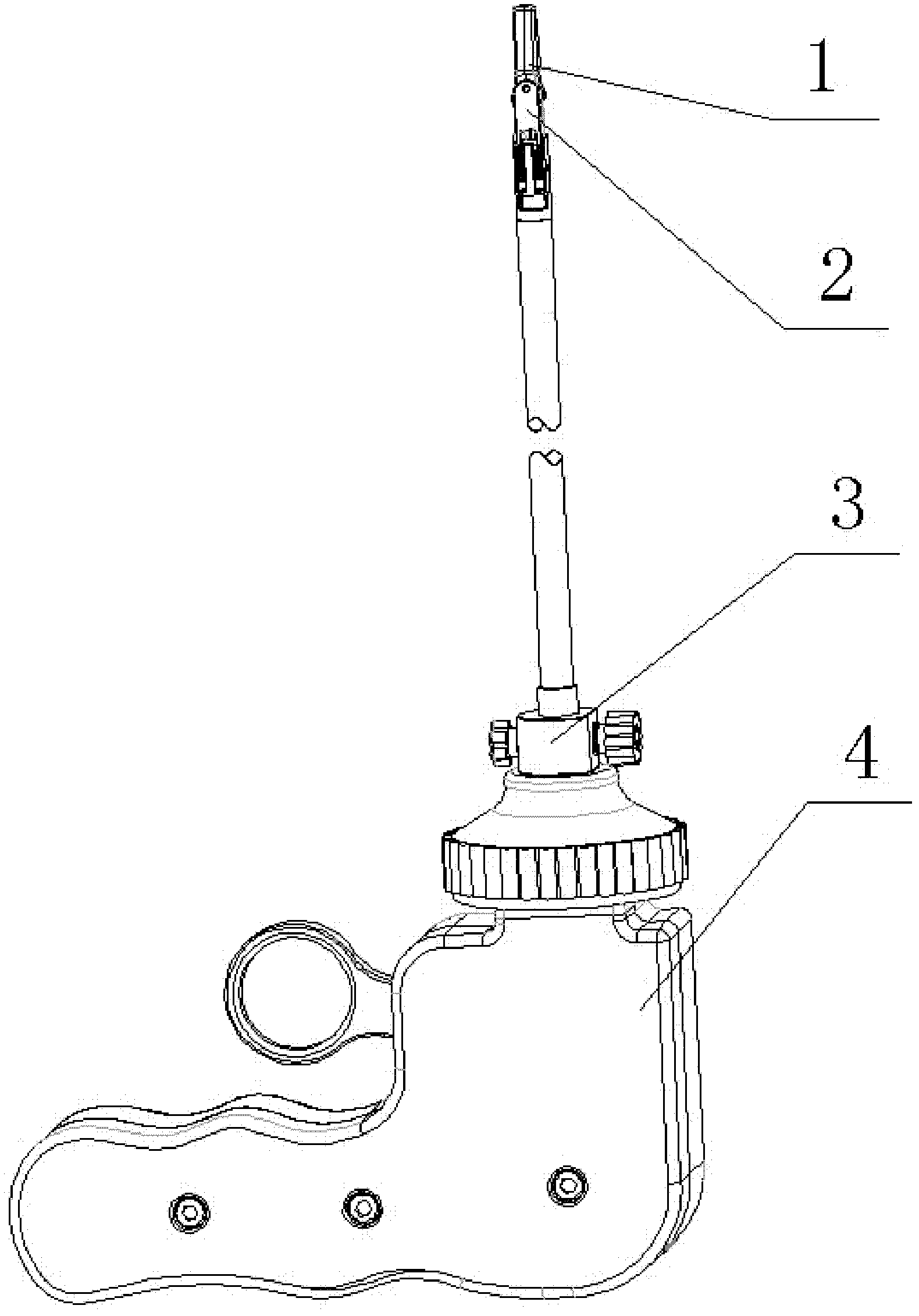

Controllable flexible transfer method of two-dimensional materials

InactiveCN104960286AControlled Flexible Transfer MethodLoose size requirementsCeramic layered productsOrganic solventEngineering

The invention discloses a controllable flexible transfer method of two-dimensional materials. The controllable flexible transfer method includes the steps: adopting a mechanical striping method or other methods to obtain a target two-dimensional material to be transferred; spraying polypropylene carbonate glue on the surface of the two-dimensional material; standing and heating to solidify the polypropylene carbonate glue to enable the two-dimensional material to be adhered below a formed polypropylene carbonate thin film; mounting the thin film on a micro manipulator carrying a polydimethylsiloxane buffering layer, and accurately aligning the thin film to a target position of a target substrate with the help of an optical microscope; heating to melt the polypropylene carbonate thin film, and using organic solvent to remove residual polypropylene carbonate. By the controllable flexible transfer method, accurate and controllable transfer of the two-dimensional material is realized. The method is simple in process, high in efficiency, wide in application range and high in expandability and has wide using prospect in the fields of microelectronics, biological detection and batteries.

Owner:SOUTHEAST UNIV

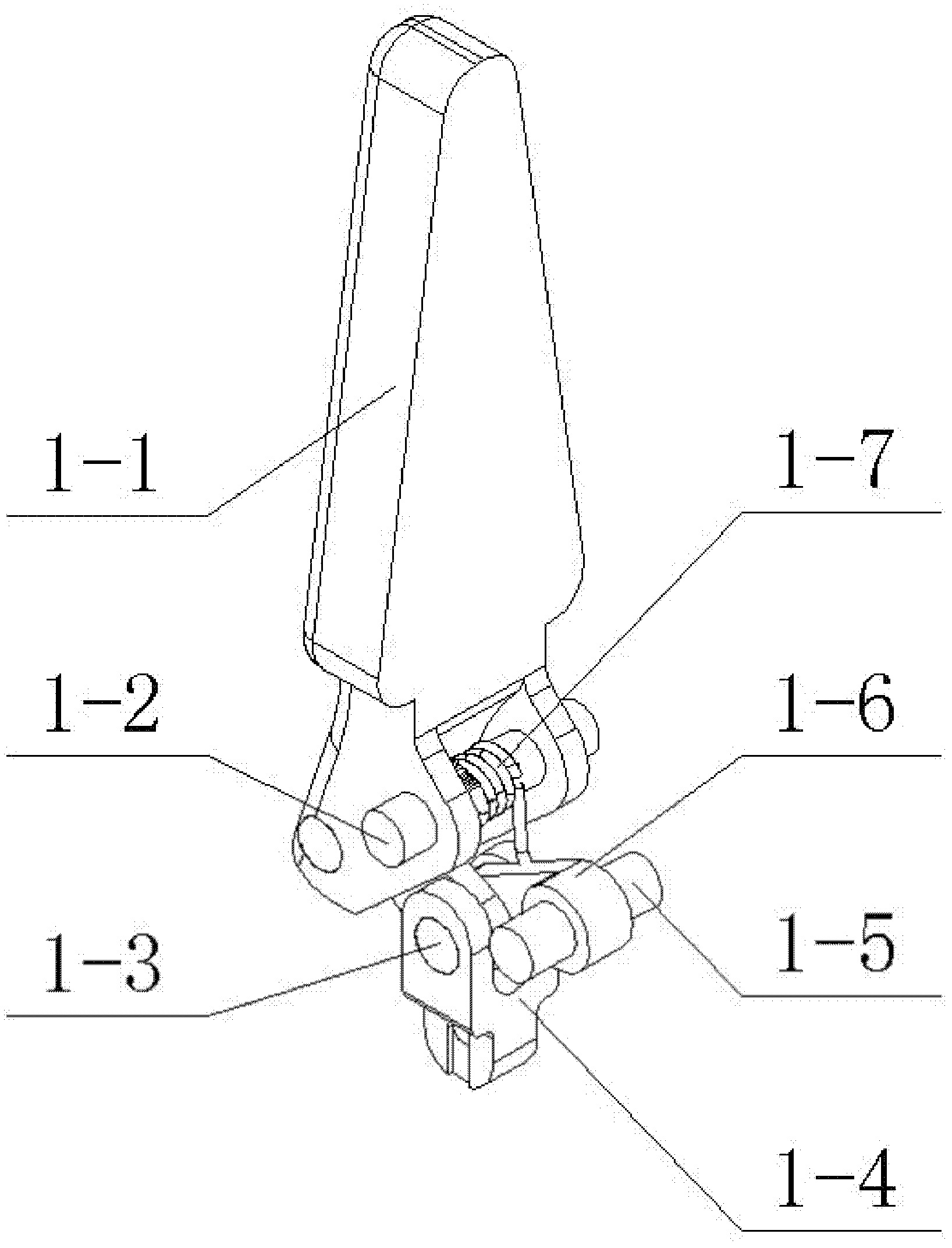

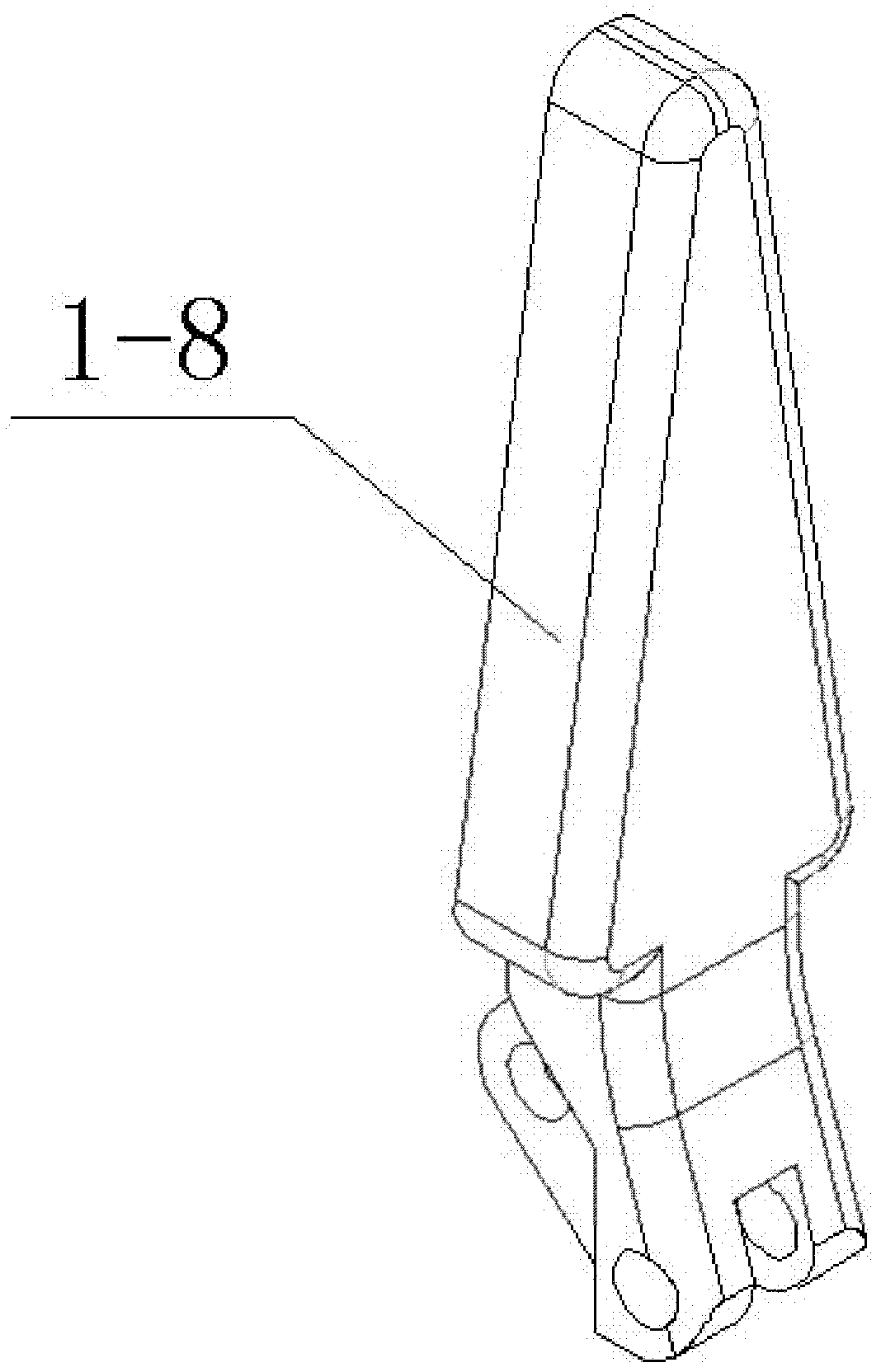

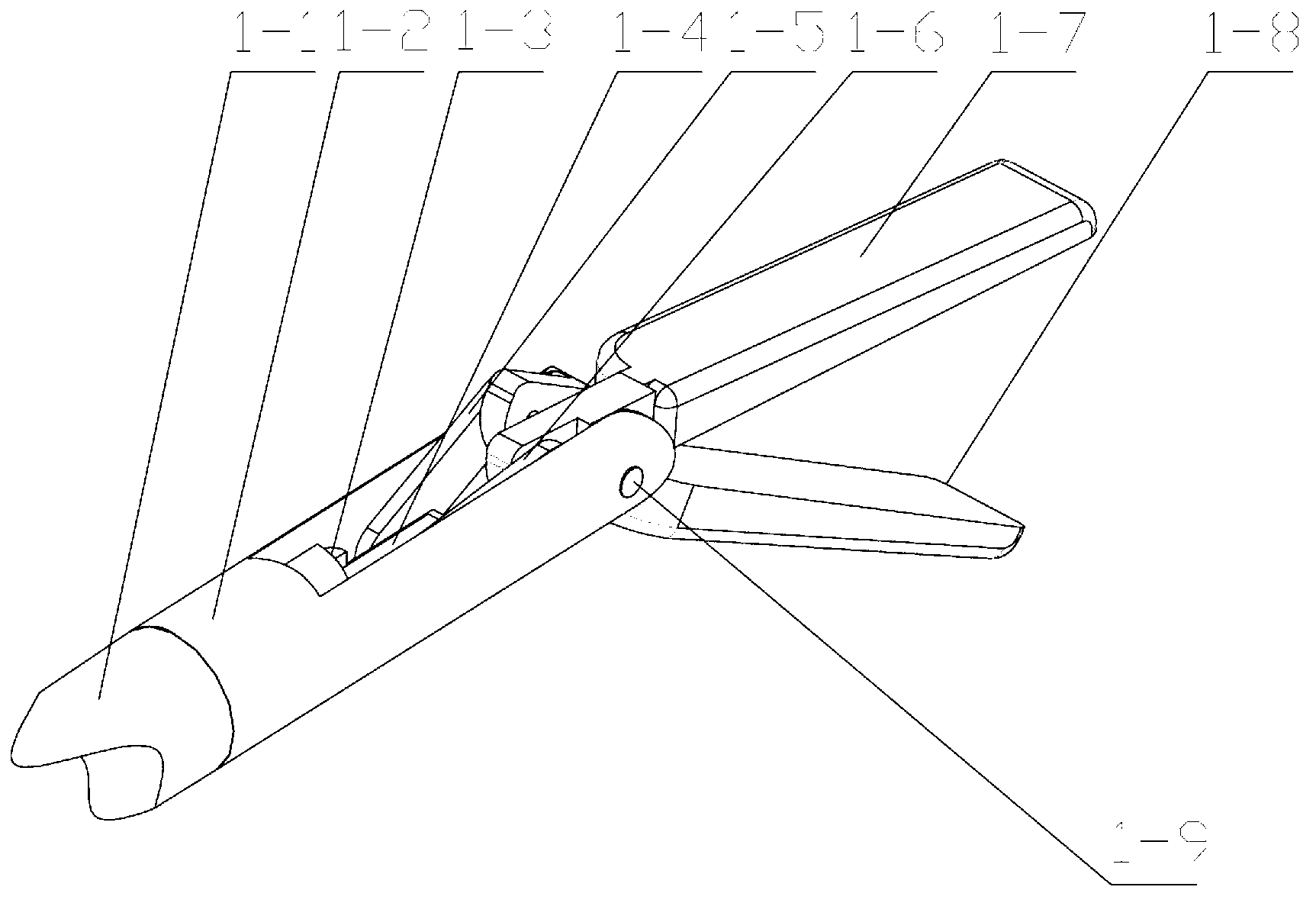

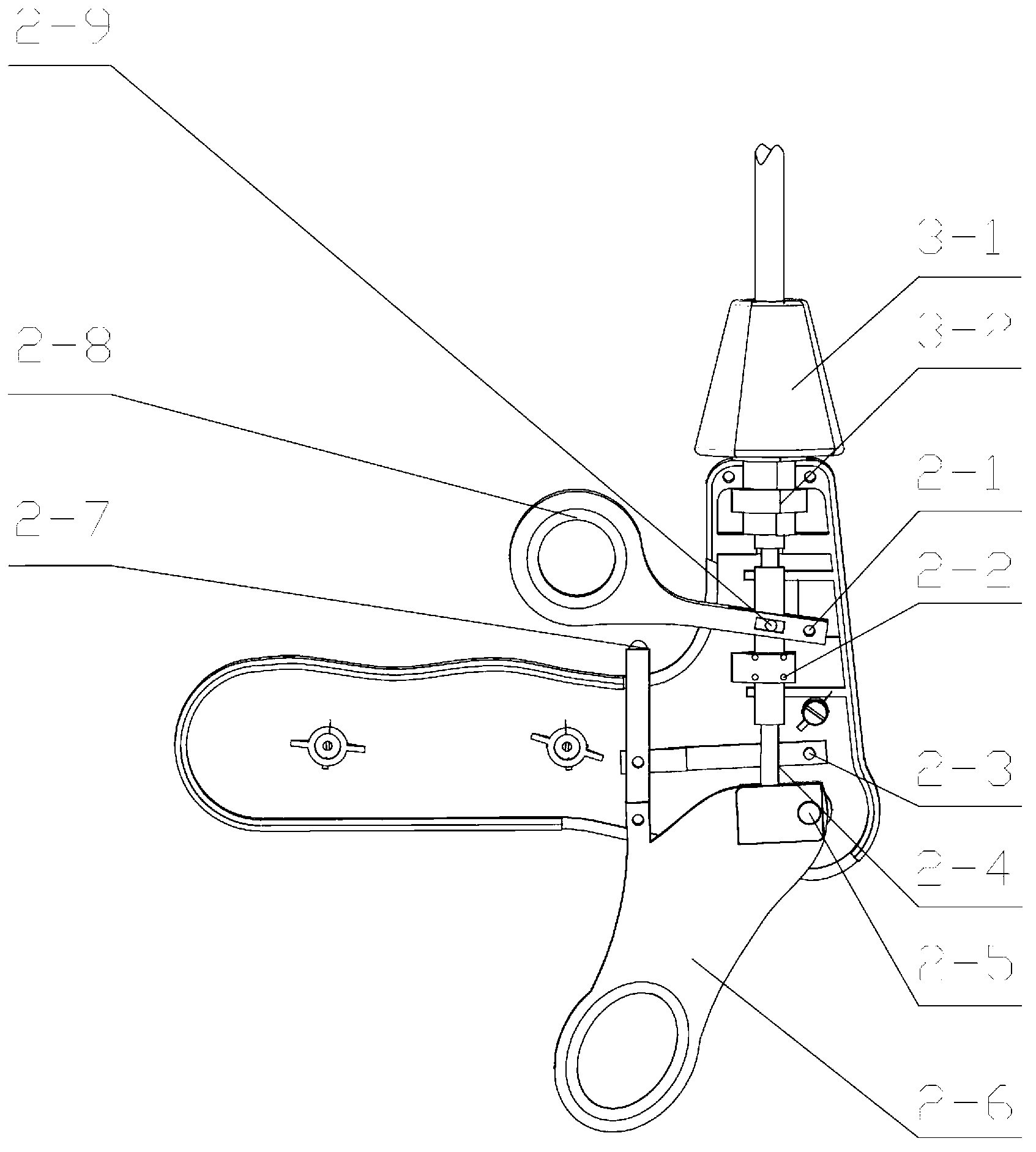

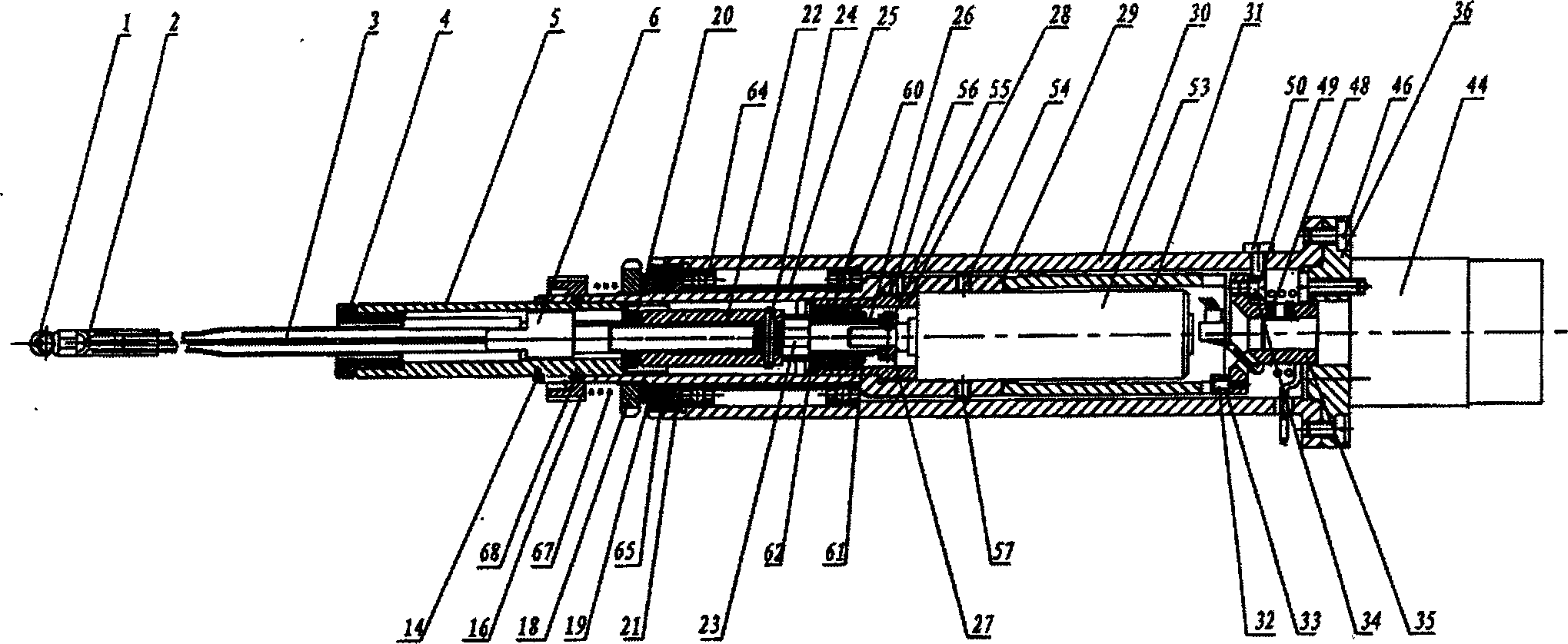

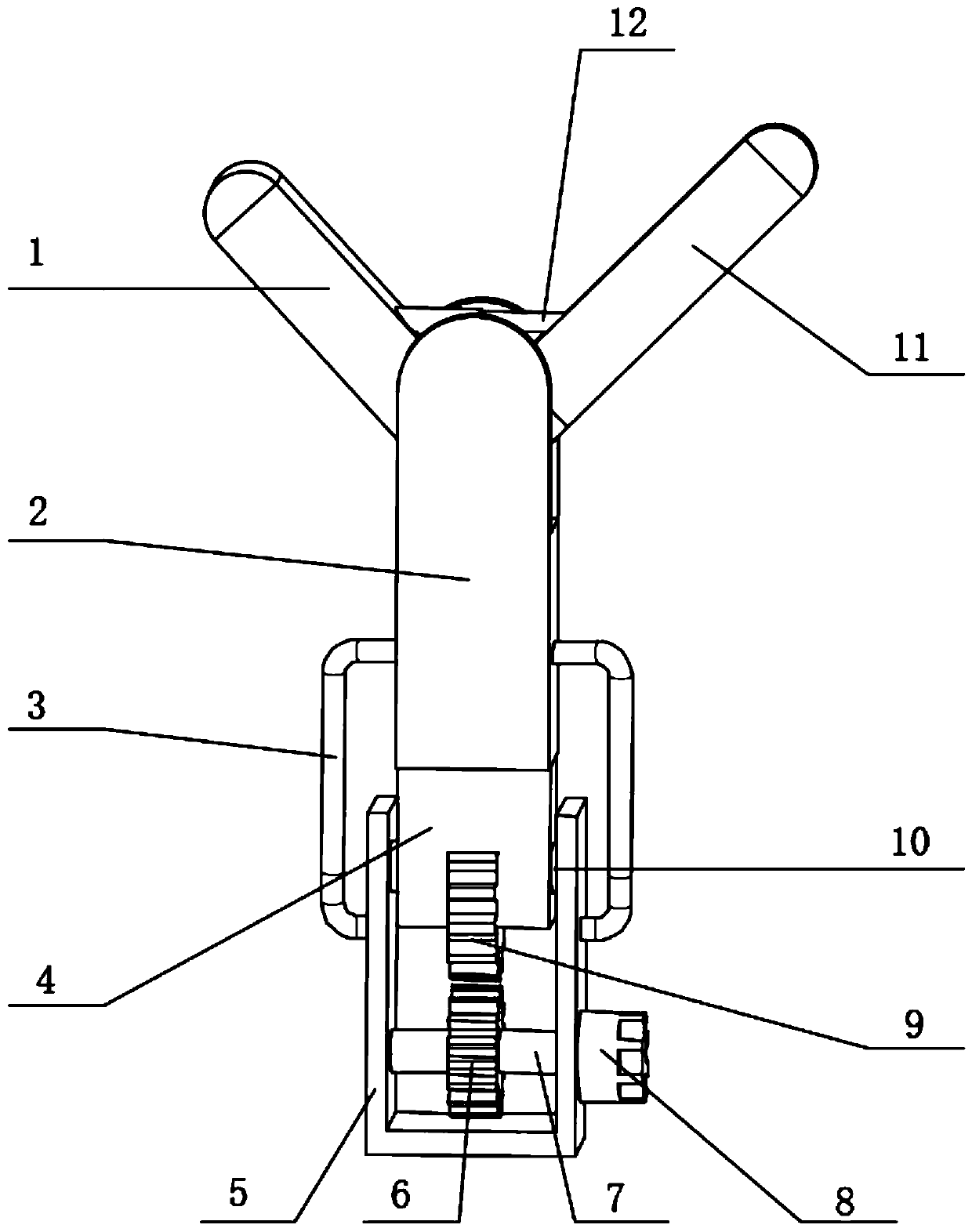

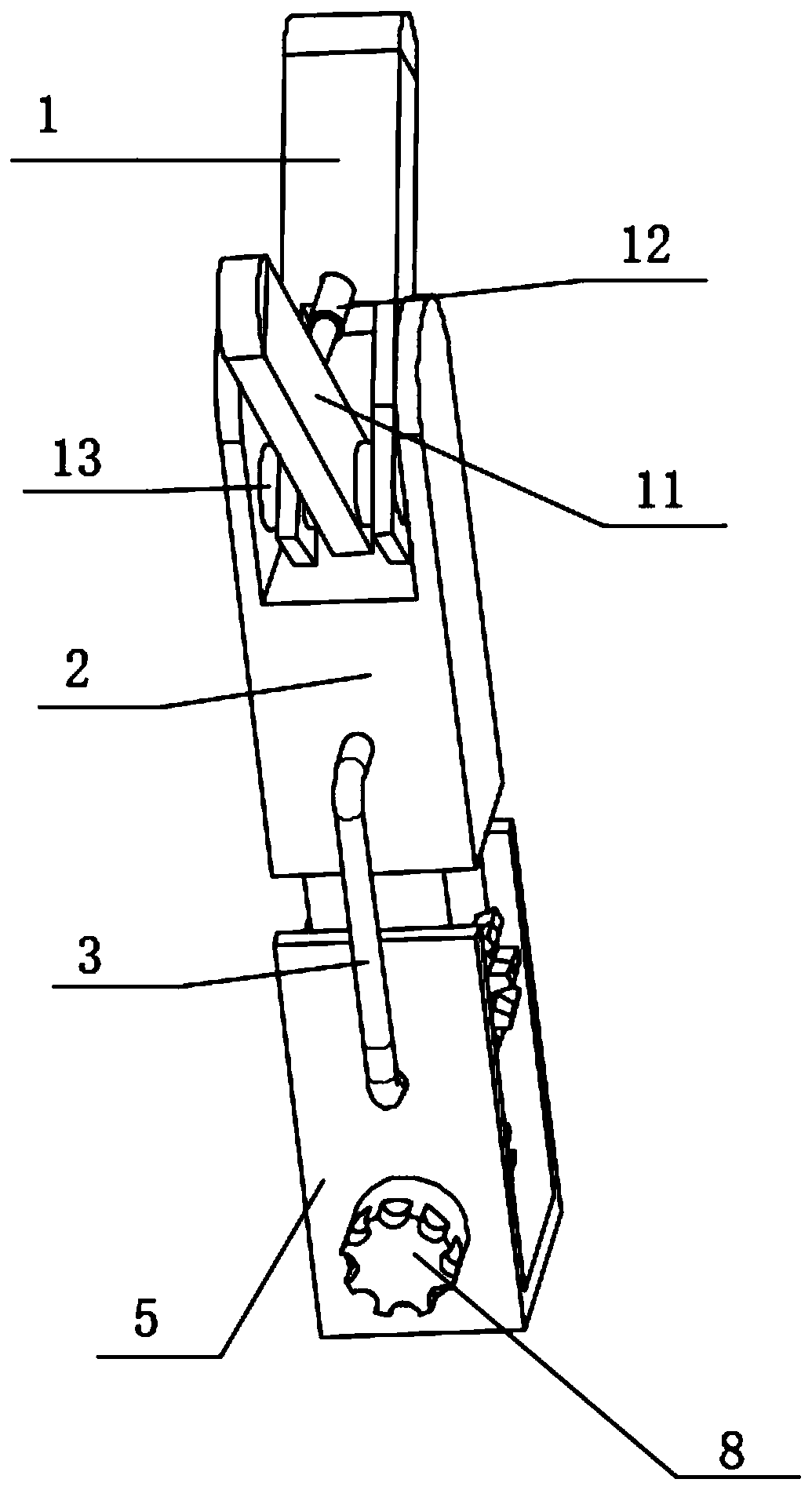

Manual three-degree-of-freedom micro manipulator for minimally invasive surgery

InactiveCN102525658AImprove stabilityIncrease flexibilityDiagnosticsSurgical robotsMinimal invasive surgerySurgical operation

The invention aims to provide a manual three-degree-of-freedom micro manipulator for minimally invasive surgery. The micro manipulator comprises a fingertip clamping mechanism, a fingertip pitching mechanism, a rotating mechanism and a handle part, wherein the fingertip clamping mechanism is arranged on the fingertip pitching mechanism; the fingertip pitching mechanism is arranged on the rotatingmechanism; the rotating mechanism is connected with the handle part; and the fingertip clamping mechanism comprises a clamping rotating shaft, a reset torsion spring, a traction bridge, a connecting plate and two clamping flaps, wherein the two clamping flaps are arranged together through the reset torsion spring to form a clamping head, the connecting plate is connected with the reset torsion spring, the clamping rotating shaft is arranged below the two clamping flaps, and the traction bridge is connected with the connecting plate. The manual three-degree-of-freedom micro manipulator for theminimally invasive surgery has three degrees of freedom of clamping, pitching and rotating, is good in stability and flexibility of the finger mechanism, simple in structure and easy to operate, and can meet the requirements of the current minimally invasive surgery.

Owner:HARBIN ENG UNIV

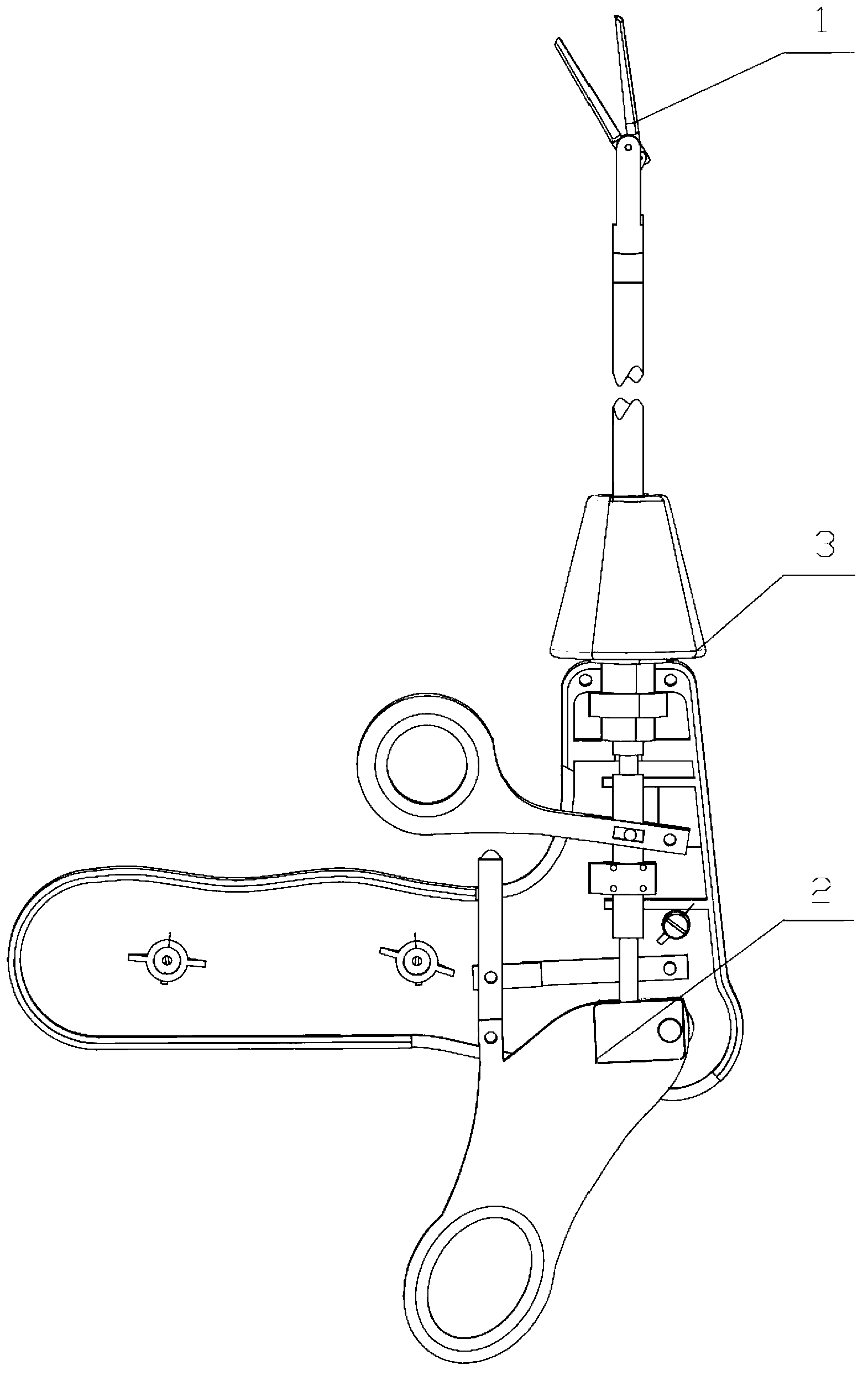

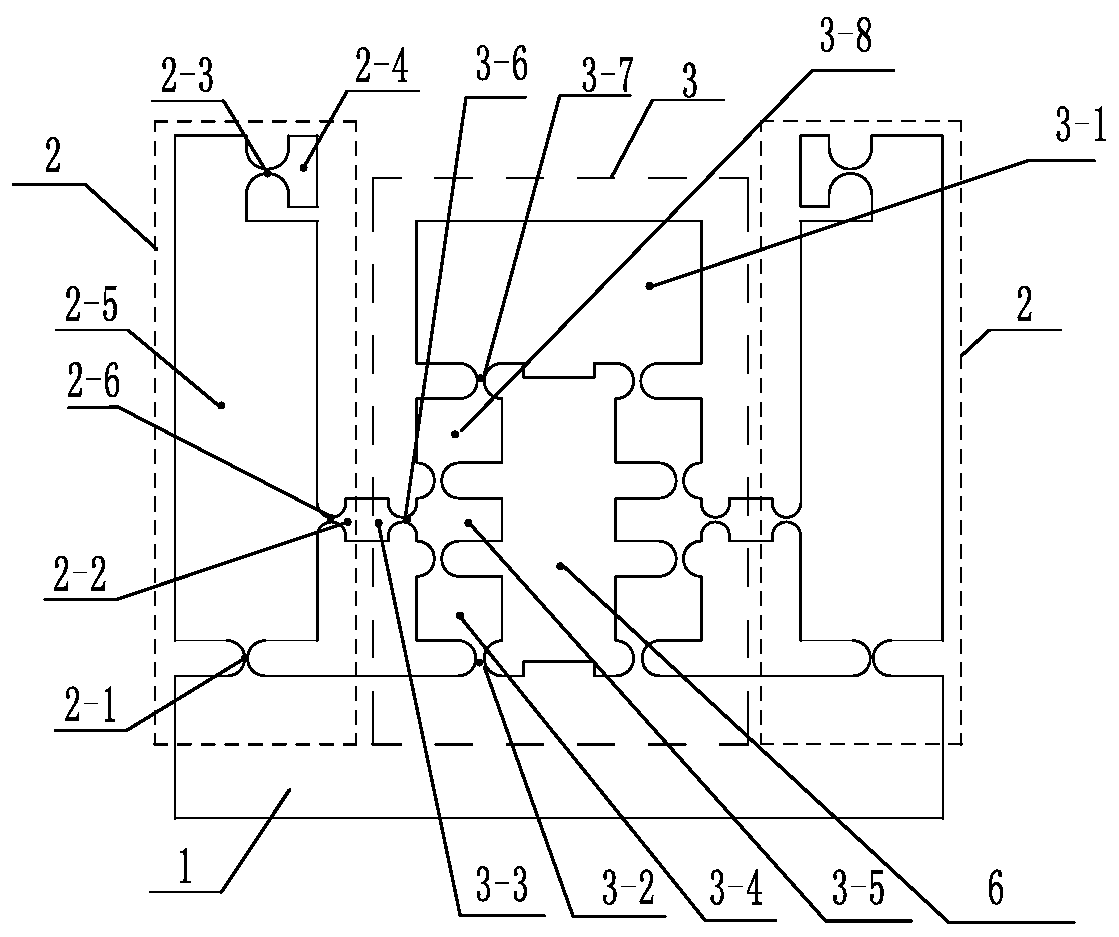

Manual multi-degree of freedom micro-manipulator for surgical operation

InactiveCN102973321AImprove stabilityIncrease flexibilityDiagnosticsSurgical robotsSurgical operationThree degrees of freedom

The invention aims to provide a manual multi-degree of freedom micro-manipulator for a surgical operation. The manual multi-degree of freedom micro-manipulator for the surgical operation comprises a fingertip clamping mechanism, a driving mechanism and a rotating joint, wherein the driving mechanism is connected with the fingertip clamping mechanism and controls the clamping and pitching of the fingertip clamping mechanism, and the rotating joint is connected with the fingertip clamping mechanism and controls the rotation of the fingertip clamping mechanism. The manual multi-degree of freedom micro-manipulator for the surgical operation has three degrees of freedom of clamping, pitching and rotating, and is good in stability and flexibility of a finger mechanism, simple in structure, easy to operate and capable of better meeting requirements of present minimally invasive surgeries.

Owner:三亚哈尔滨工程大学南海创新发展基地

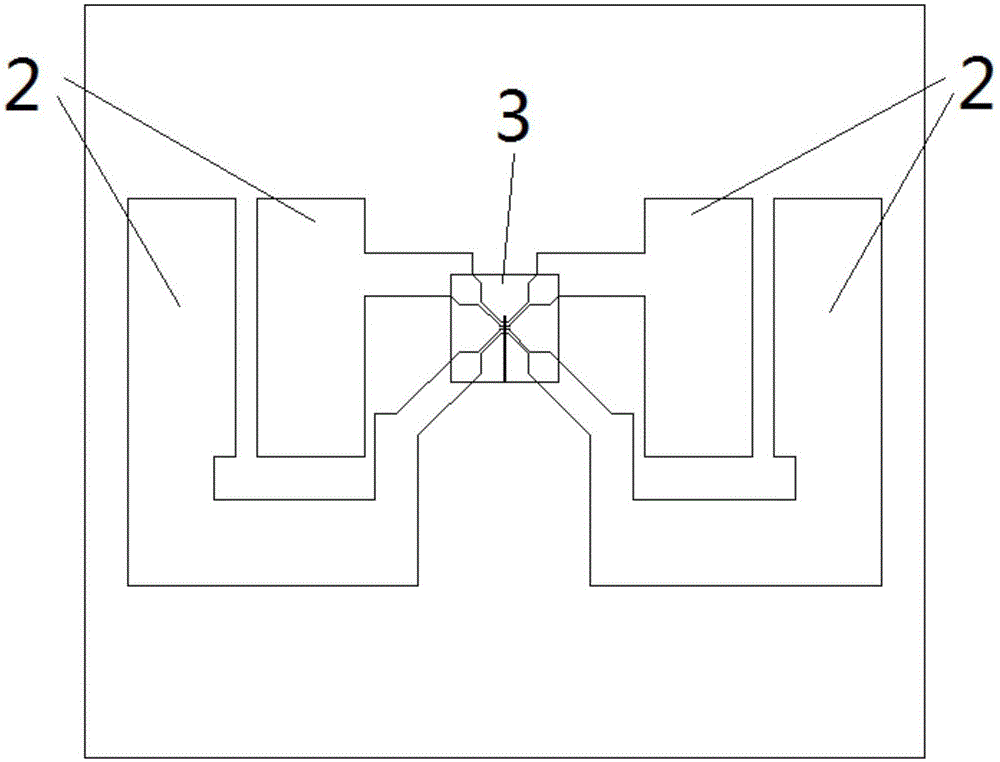

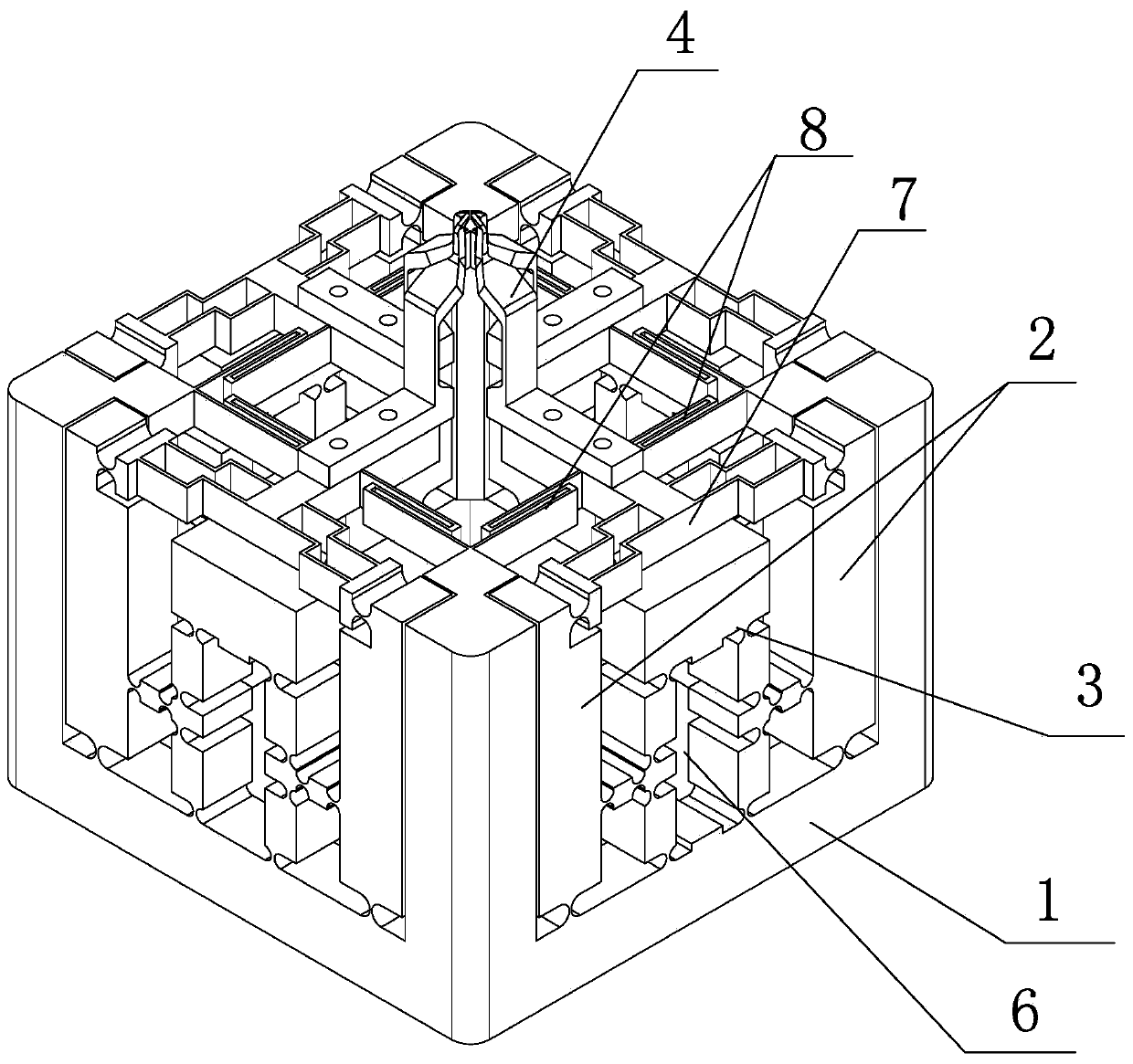

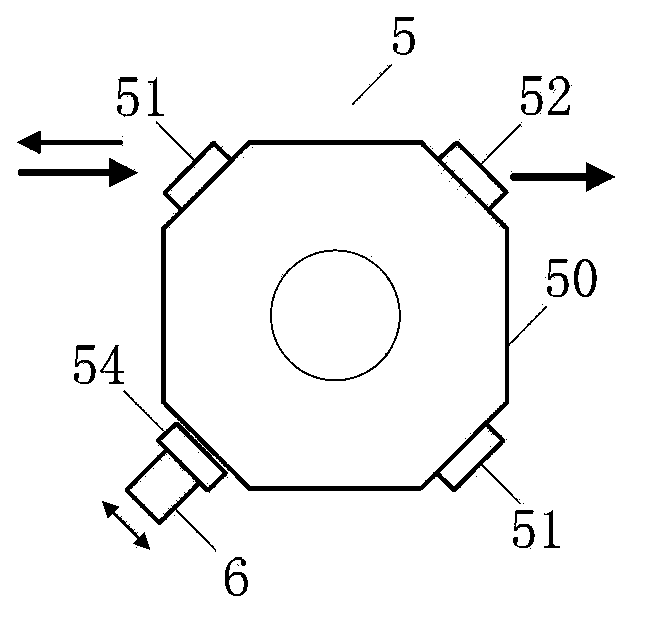

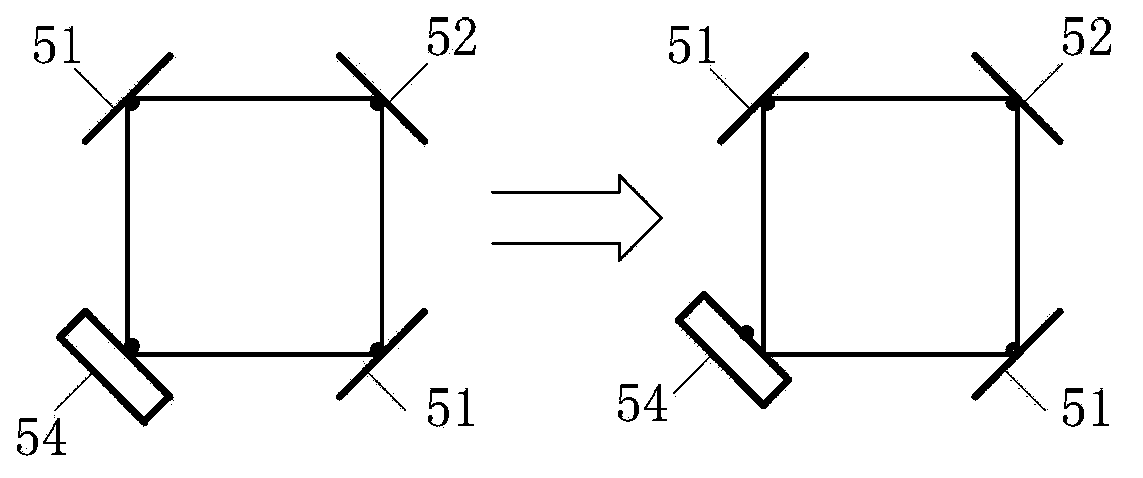

Symmetric spatial three-dimensional micro manipulator with three-stage motion amplifying mechanism

ActiveCN109909976AFirmly connectedActive releaseProgramme-controlled manipulatorGripping headsShaped beamThree stage

The invention discloses a symmetric spatial three-dimensional micro manipulator with a three-stage motion amplifying mechanism. The micro manipulator is small in size, compact in structure, stable andreliable in clamping force and high in movement precision. The micro manipulator is composed of a base and a plurality of amplification clamping modules, wherein each amplification clamping module comprises a piezoelectric ceramic driver, a bridge type displacement amplification mechanism, two lever displacement amplification mechanisms, a Z-shaped beam displacement amplification mechanism, two flexible guide mechanisms and a clamping jaw; the piezoelectric ceramic driver is arranged between the base and the movable end of the bridge type displacement amplification mechanism; and the piezoelectric ceramic driver drives the movable end of the bridge type displacement amplification mechanism, the output end of the bridge type displacement amplification mechanism drives the input ends of thelever displacement amplification mechanisms, the output end of each lever displacement amplification mechanism drives the input end of the Z-shaped beam displacement amplification mechanism, and theoutput end of the Z-shaped beam displacement amplification mechanism is fixedly connected with the clamping jaw. The micro manipulator is compact in structure, stable and reliable in clamping force, low in cost and high in movement precision.

Owner:TIANJIN UNIV

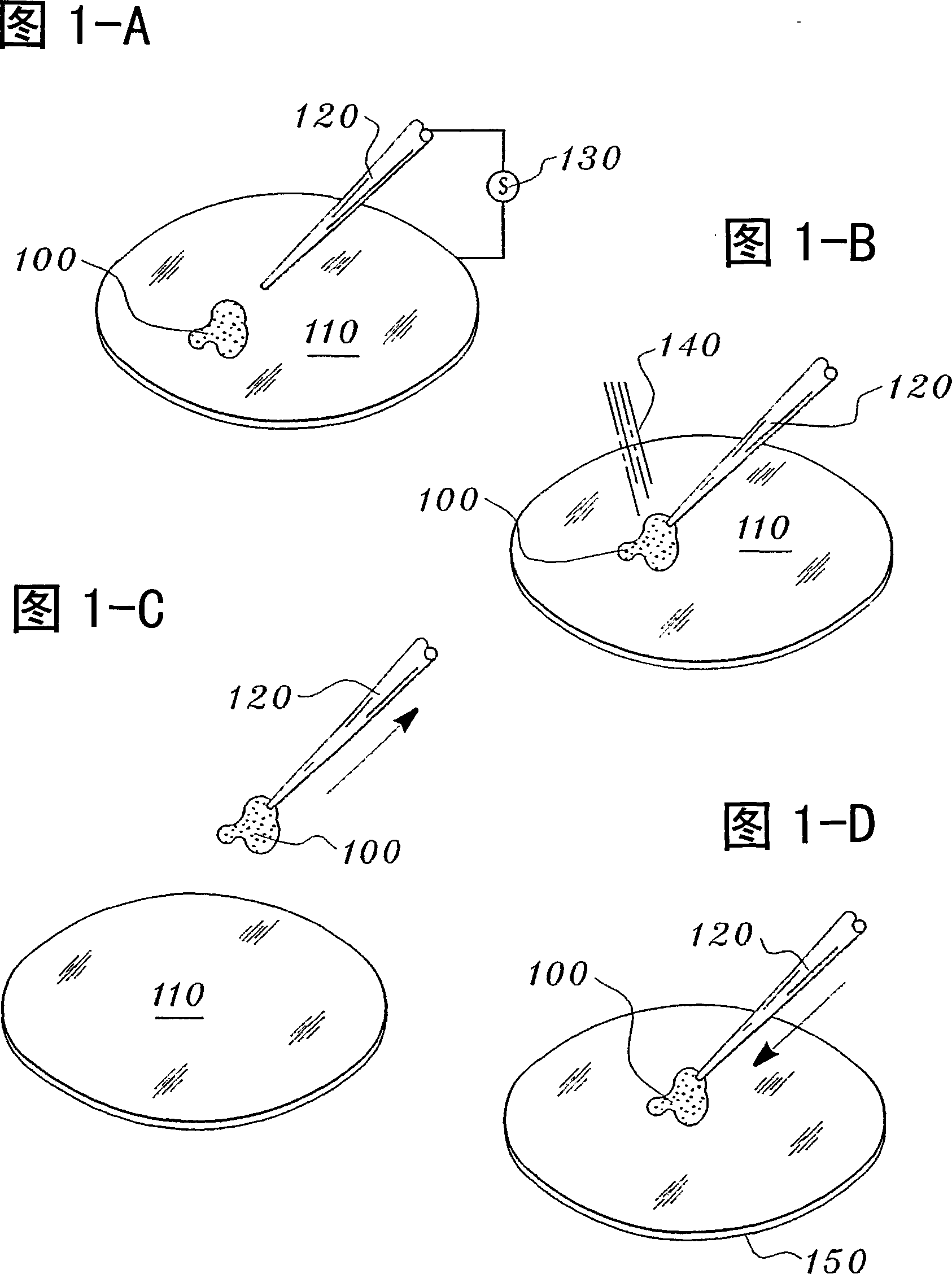

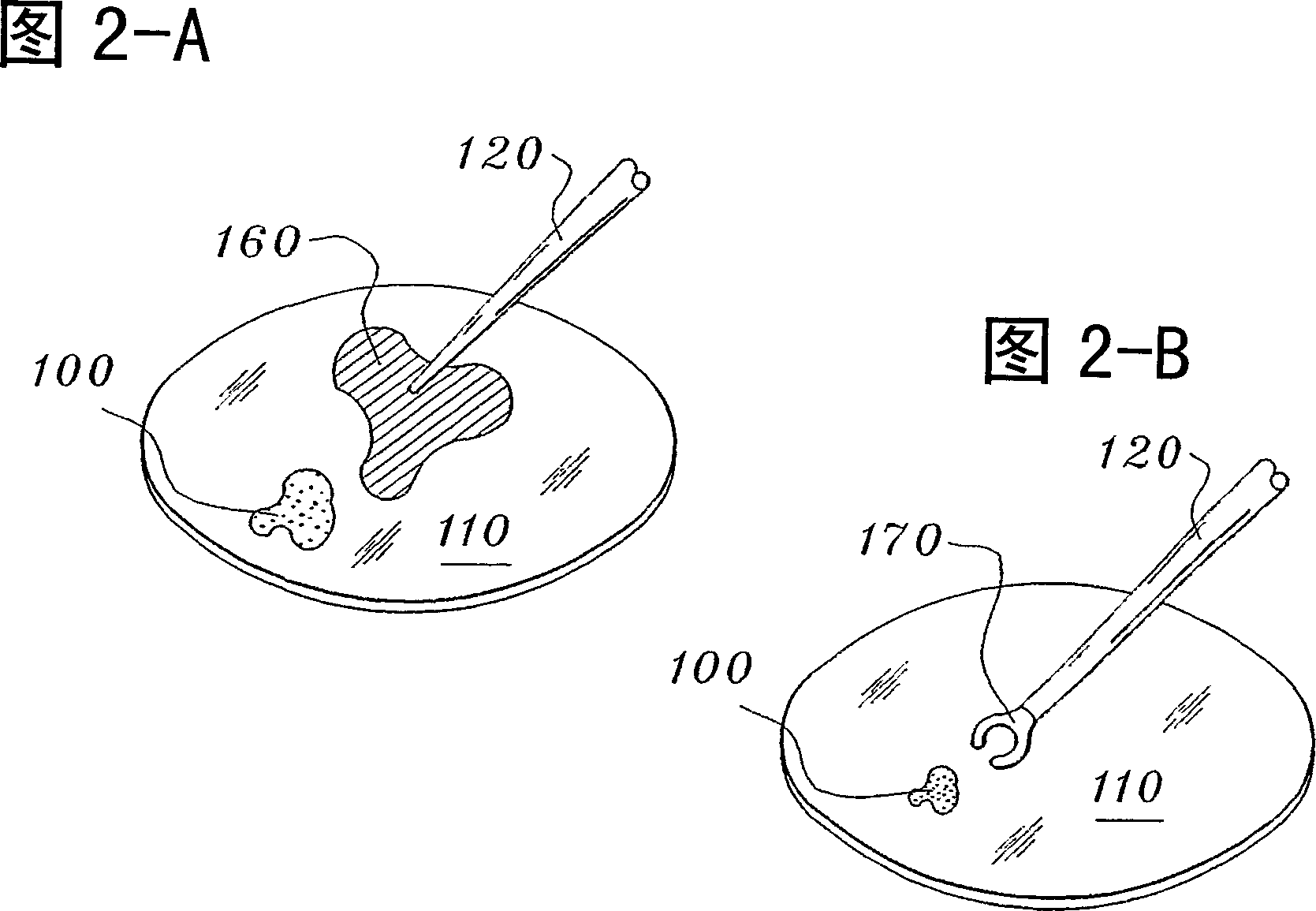

Method for manipulating microscopic particles and analyzing the composition thereof

We disclose a method for analyzing the composition of a microscopic particle resting on a first sample surface. The method comprises positioning a micro-manipulator probe near the particle; attaching the particle to the probe; moving the probe and the attached particle away from the first sample surface; positioning the particle on a second sample surface; and, analyzing the composition of the particle on the second sample surface by energy-dispersive X-ray analysis or detection of Auger electrons. The second surface has a reduced or non-interfering background signal during analysis relative to the background signal of the first surface. We also disclose methods for adjusting the electrostatic forces and DC potentials between the probe, the particle, and the sample surfaces to effect removal of the particle, and its transfer and relocation to the second sample surface.

Owner:OMNIPROBE

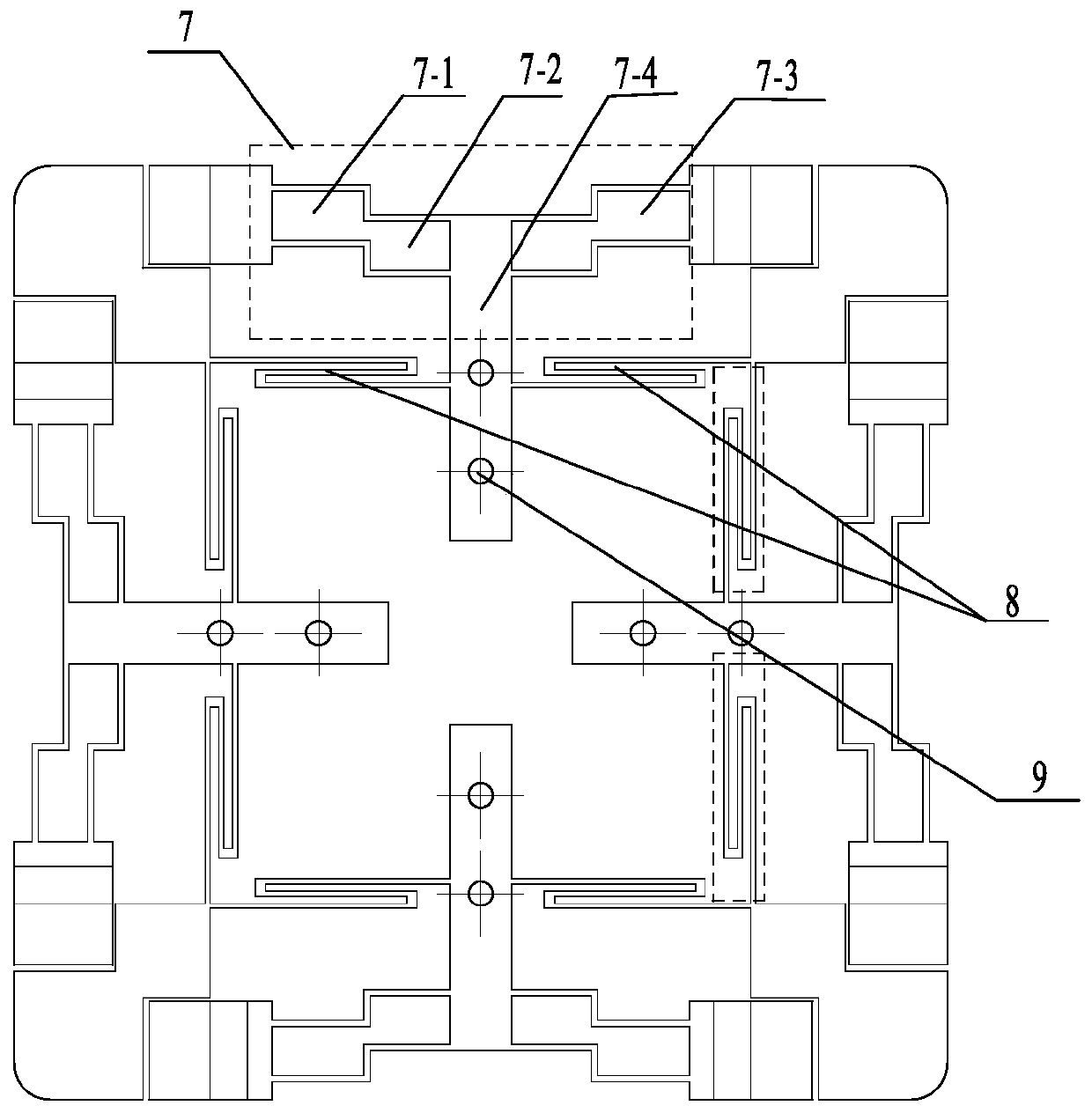

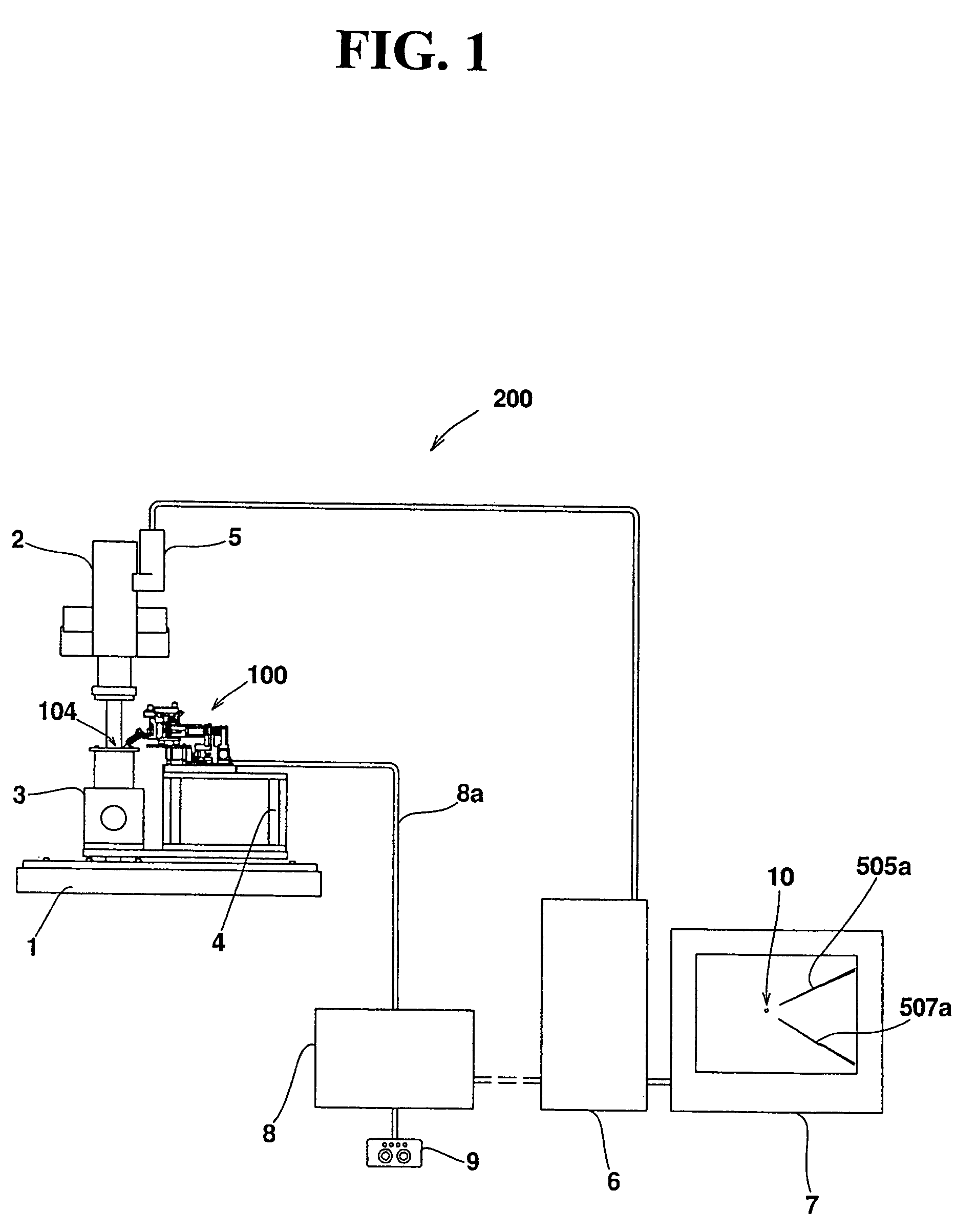

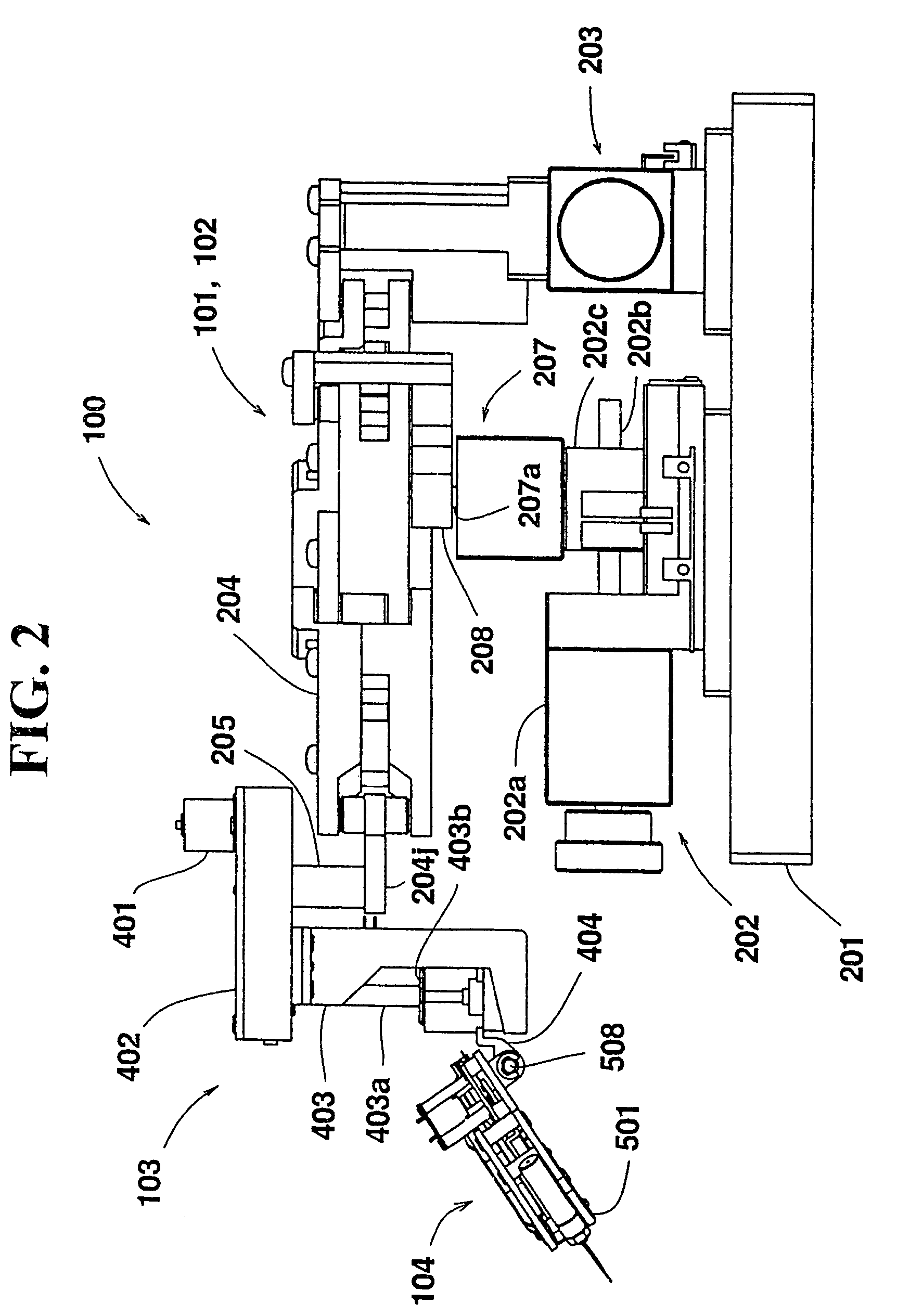

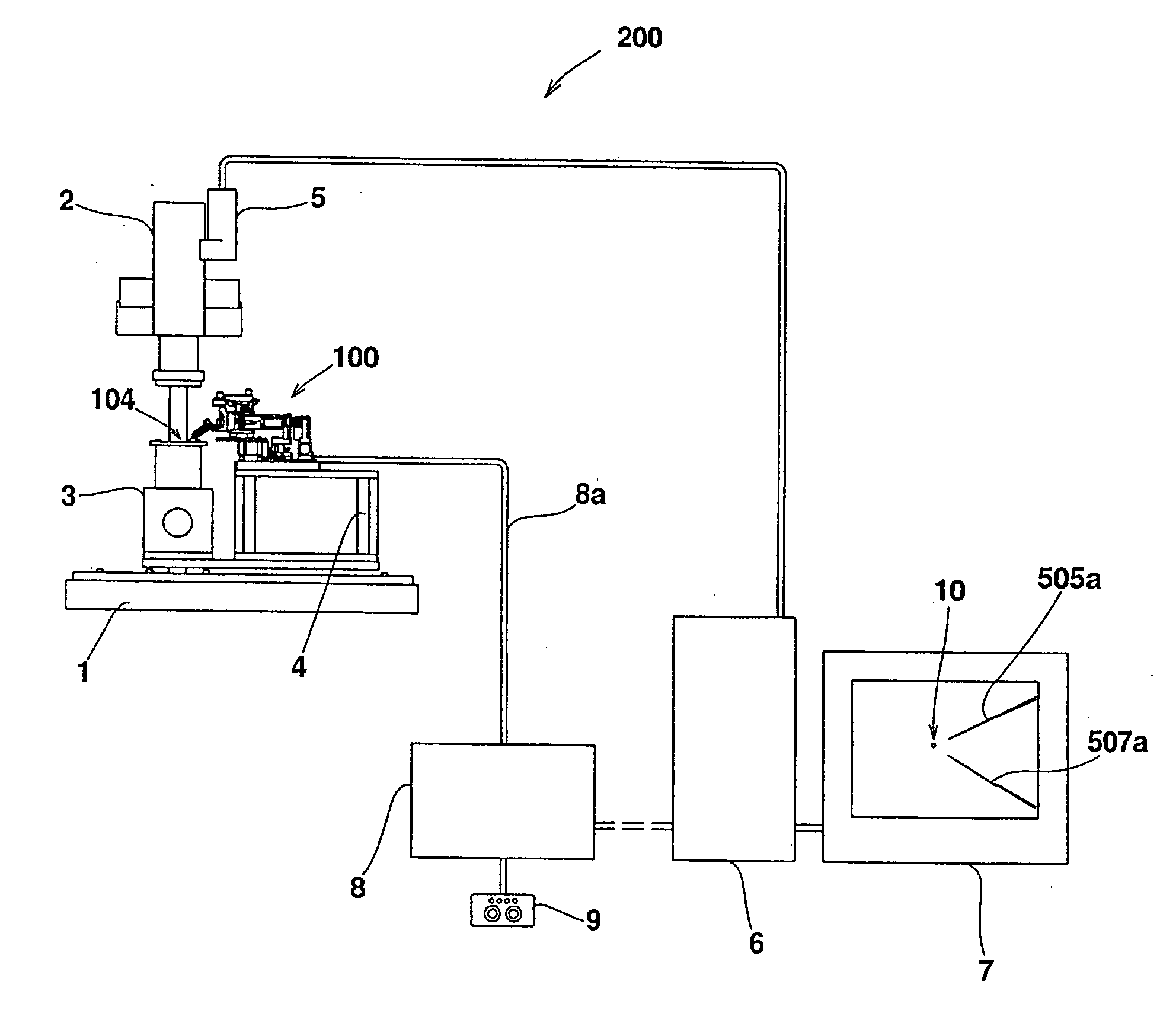

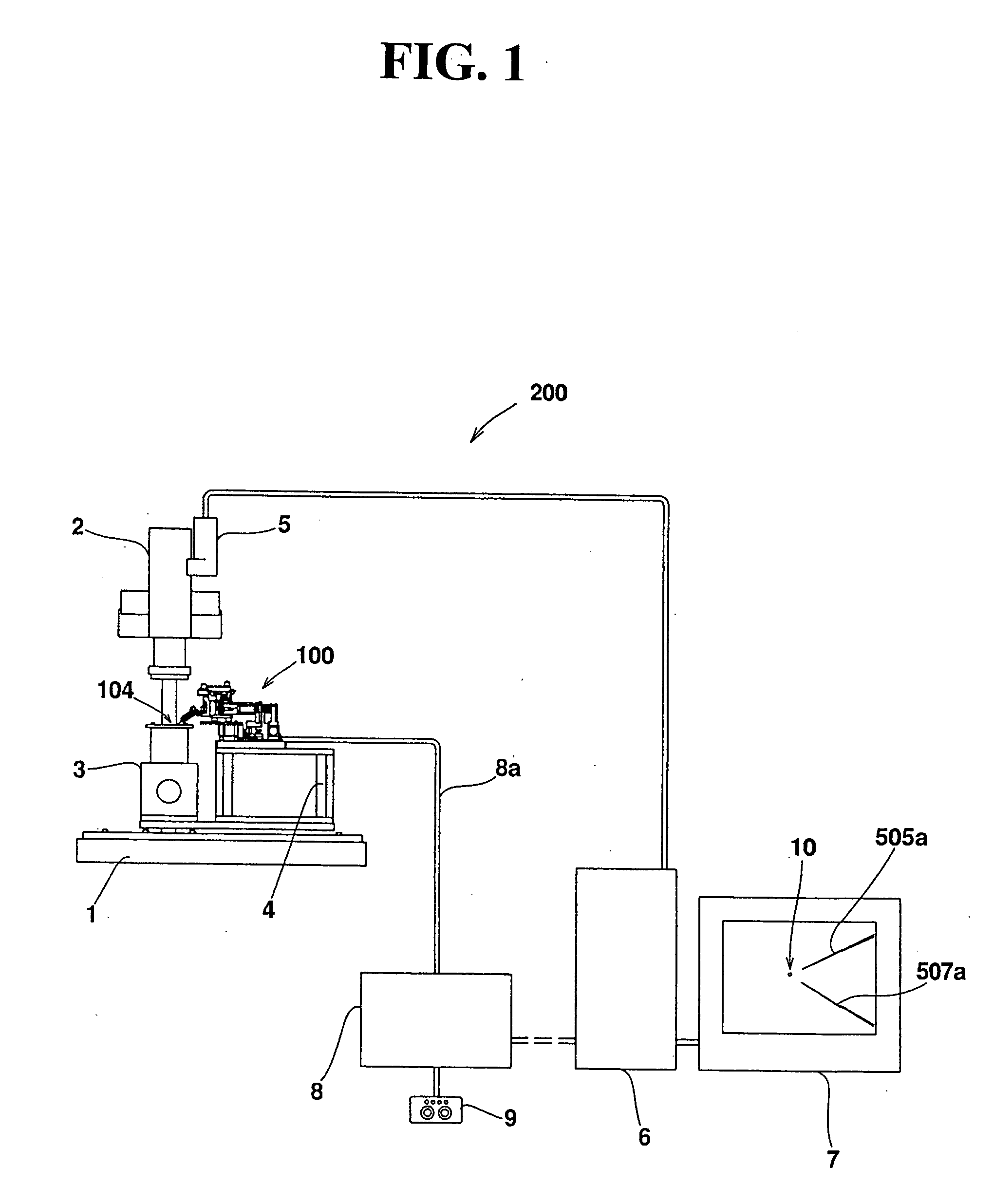

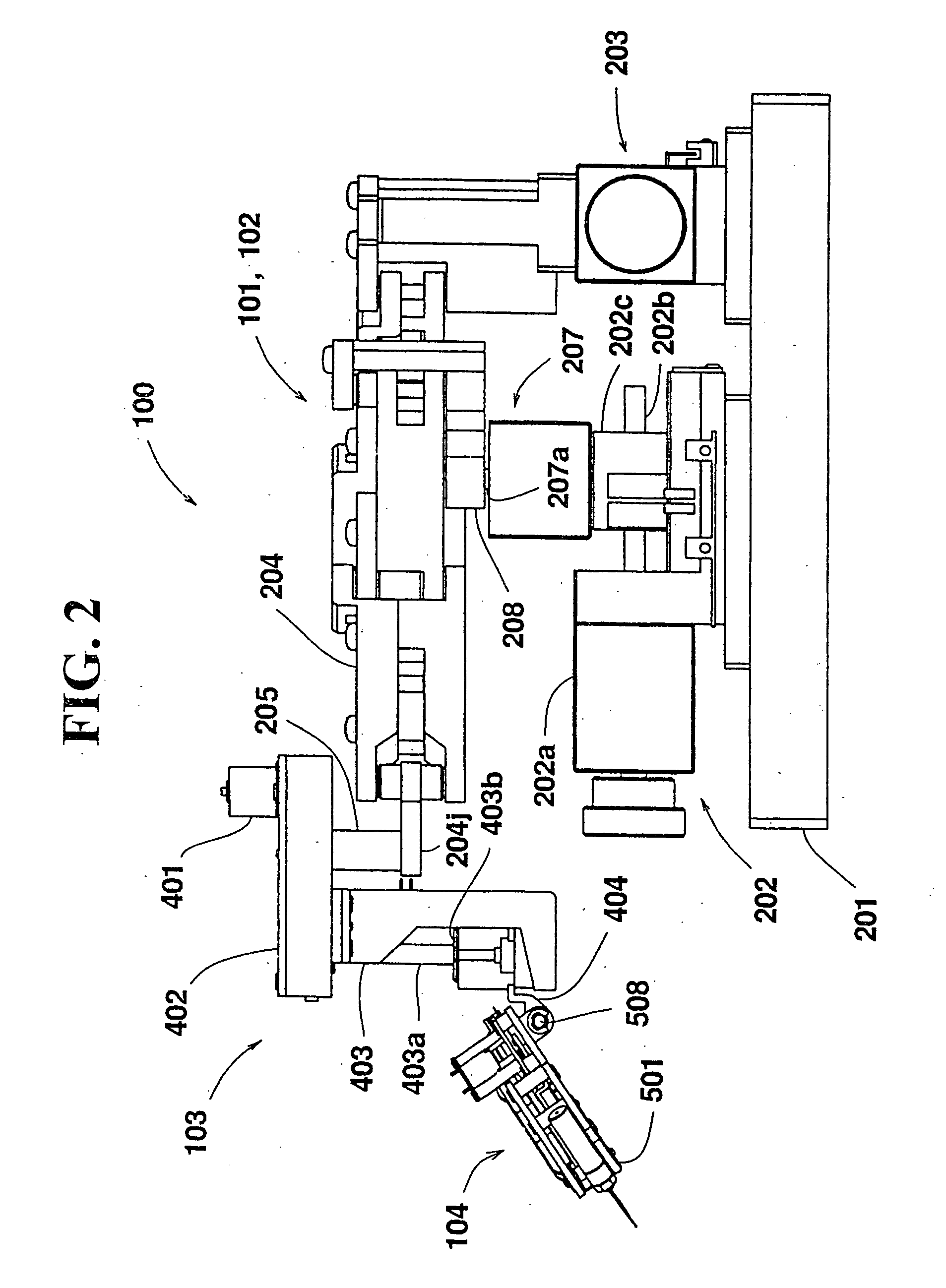

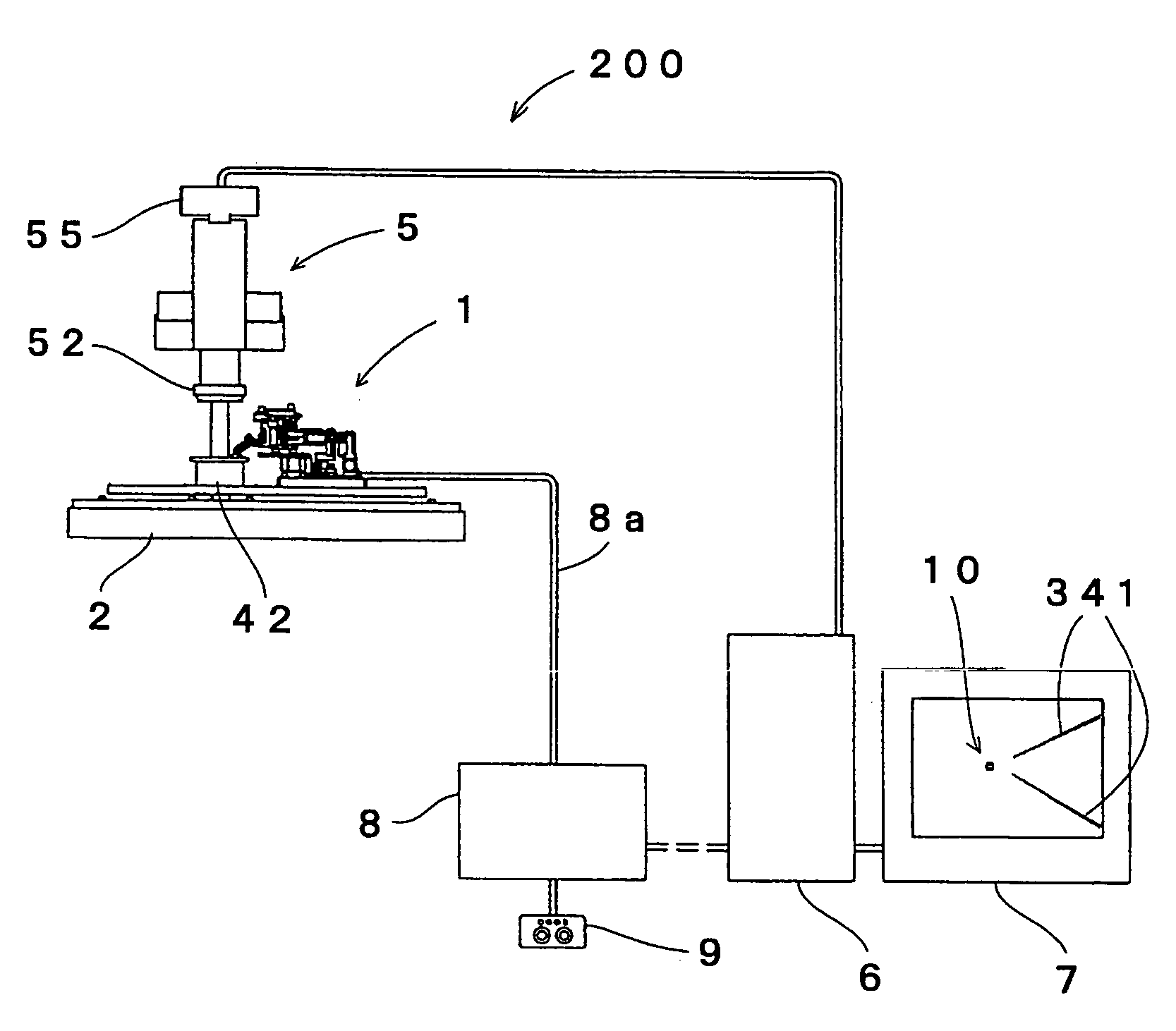

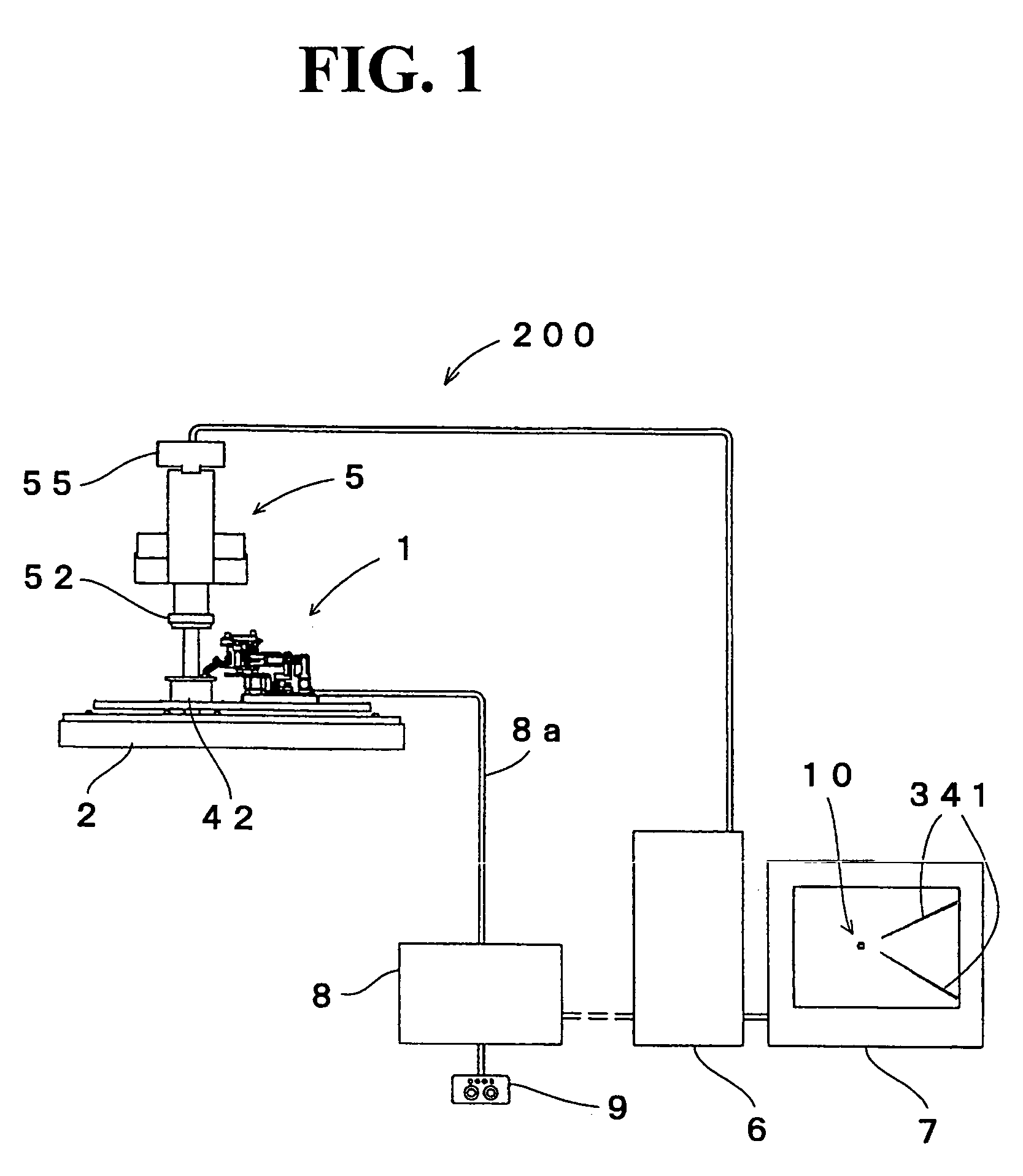

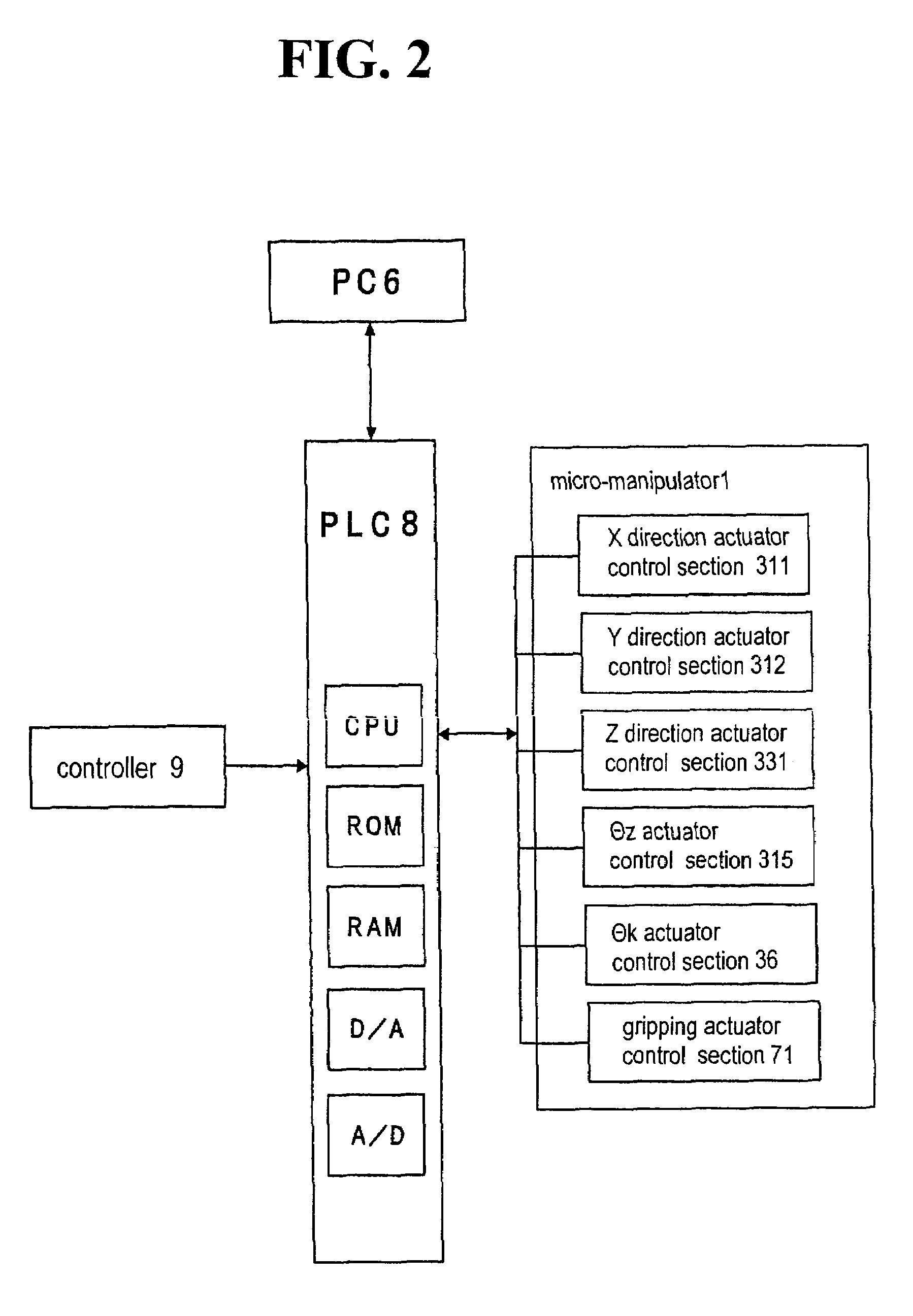

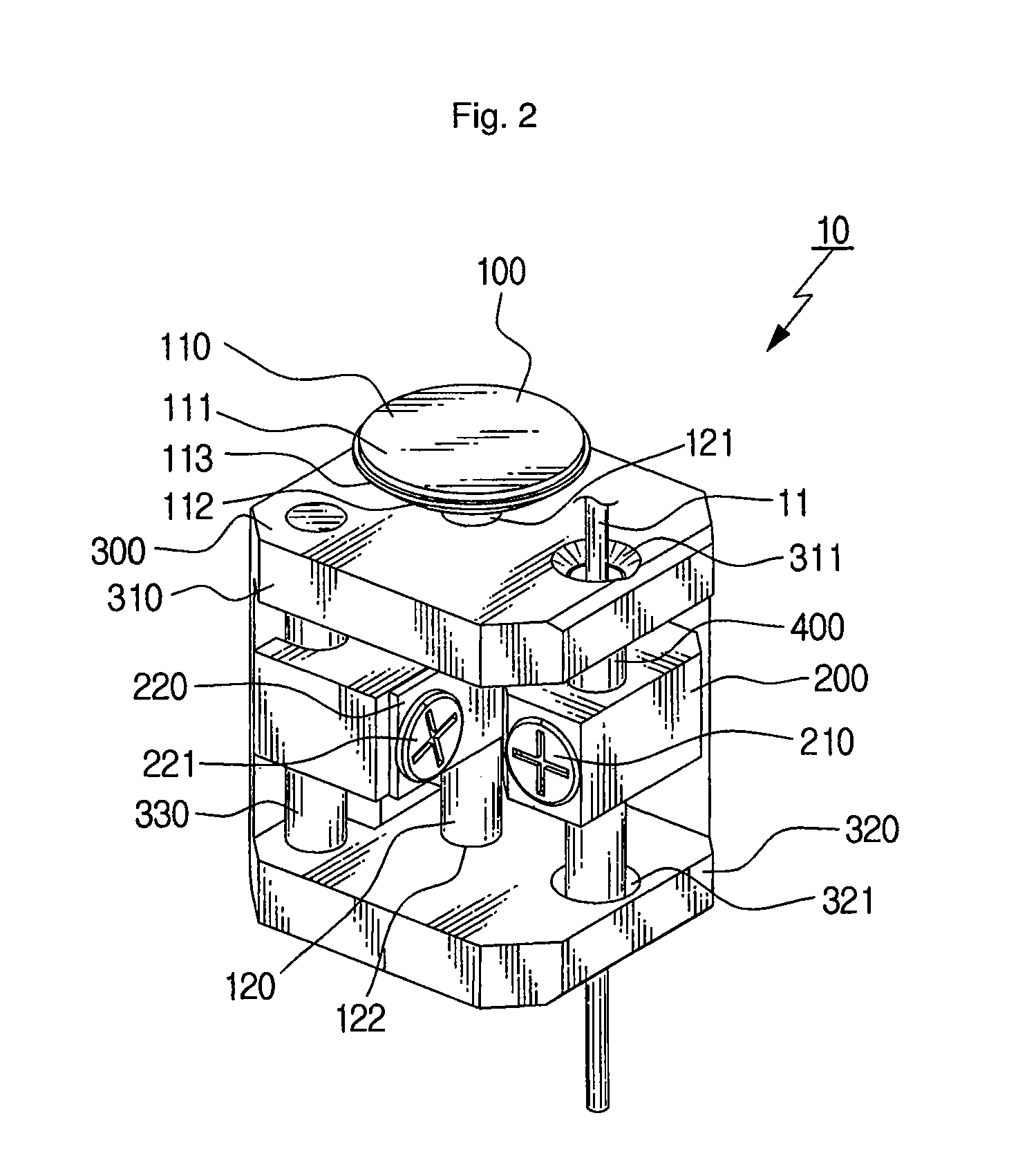

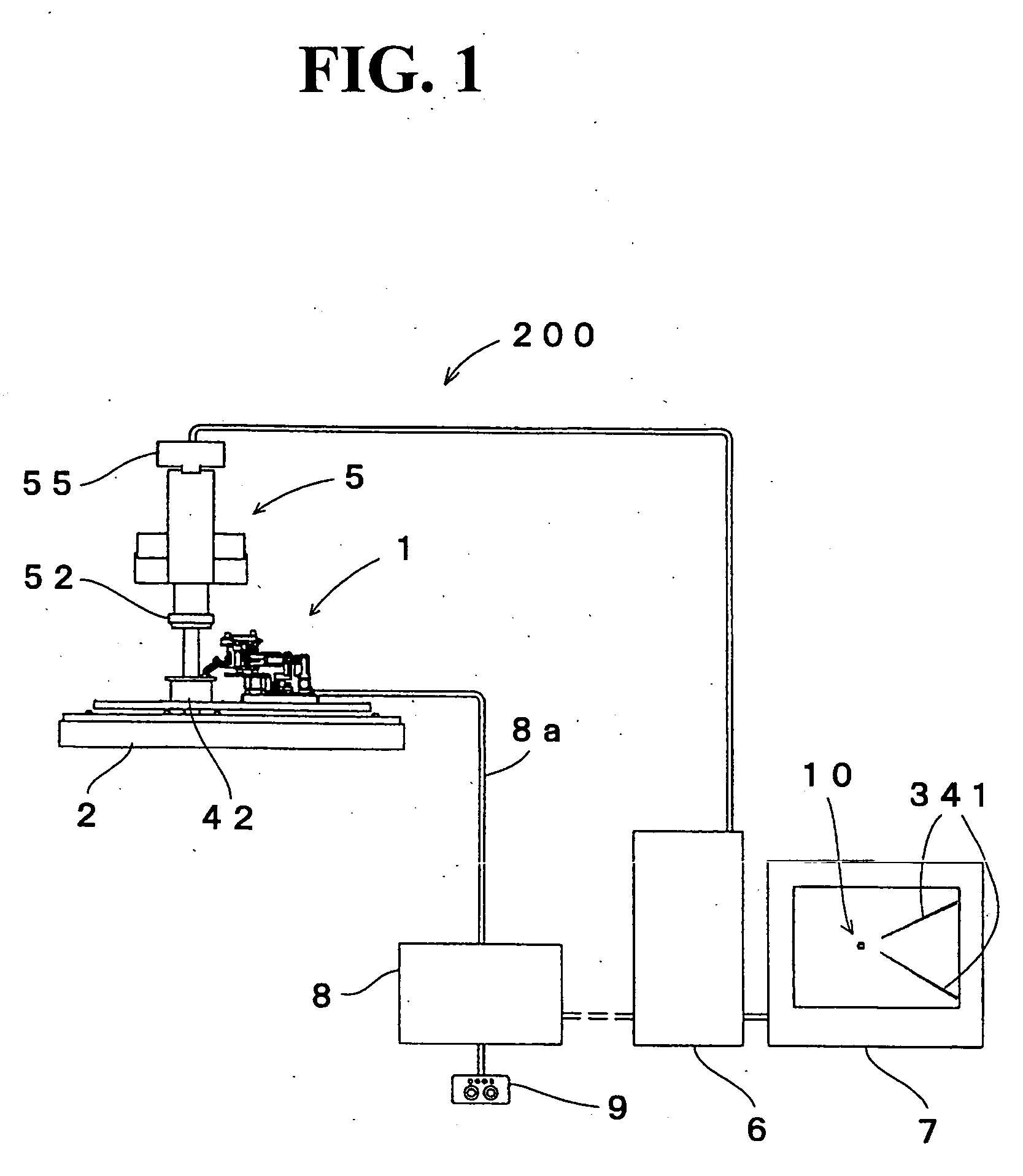

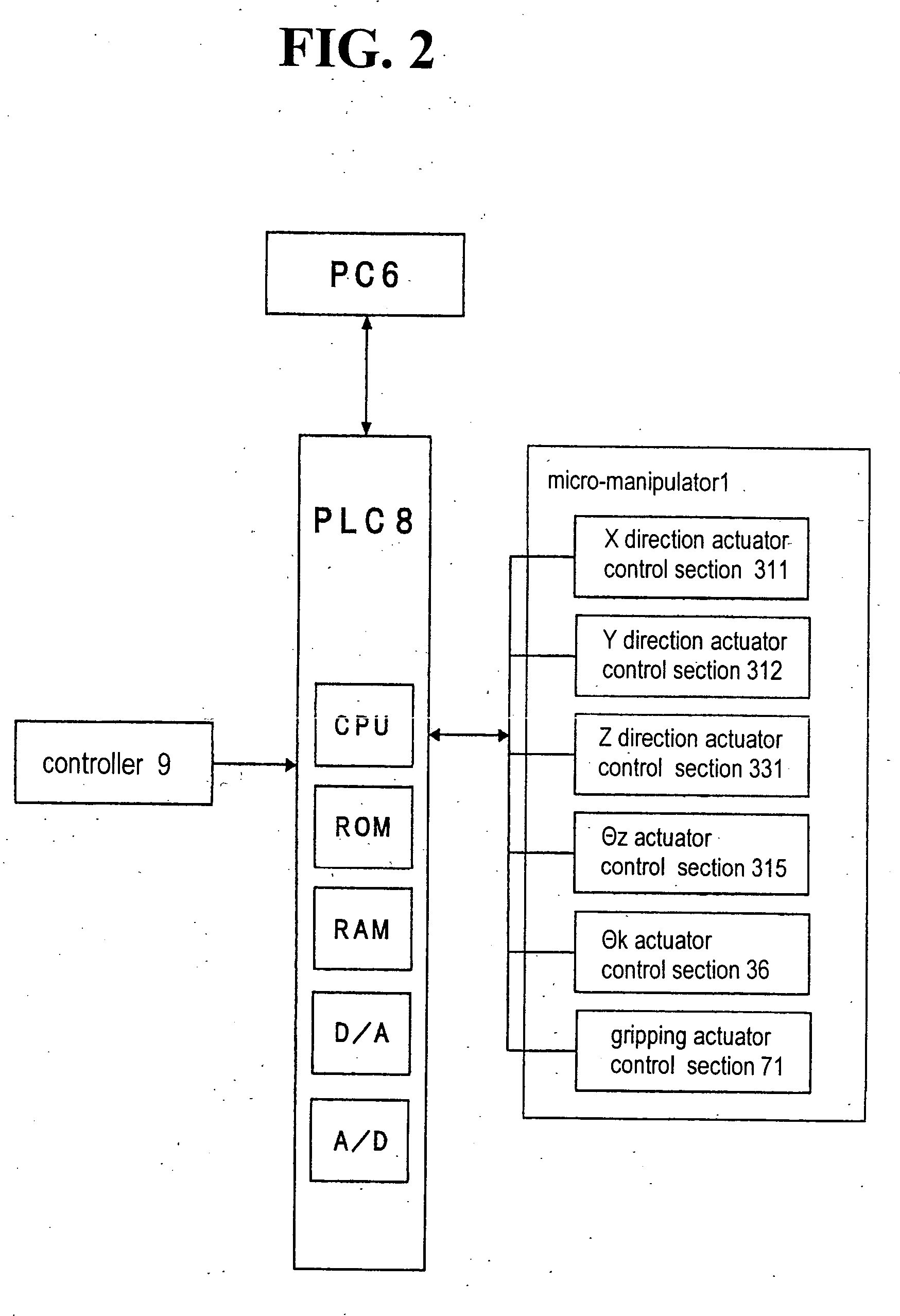

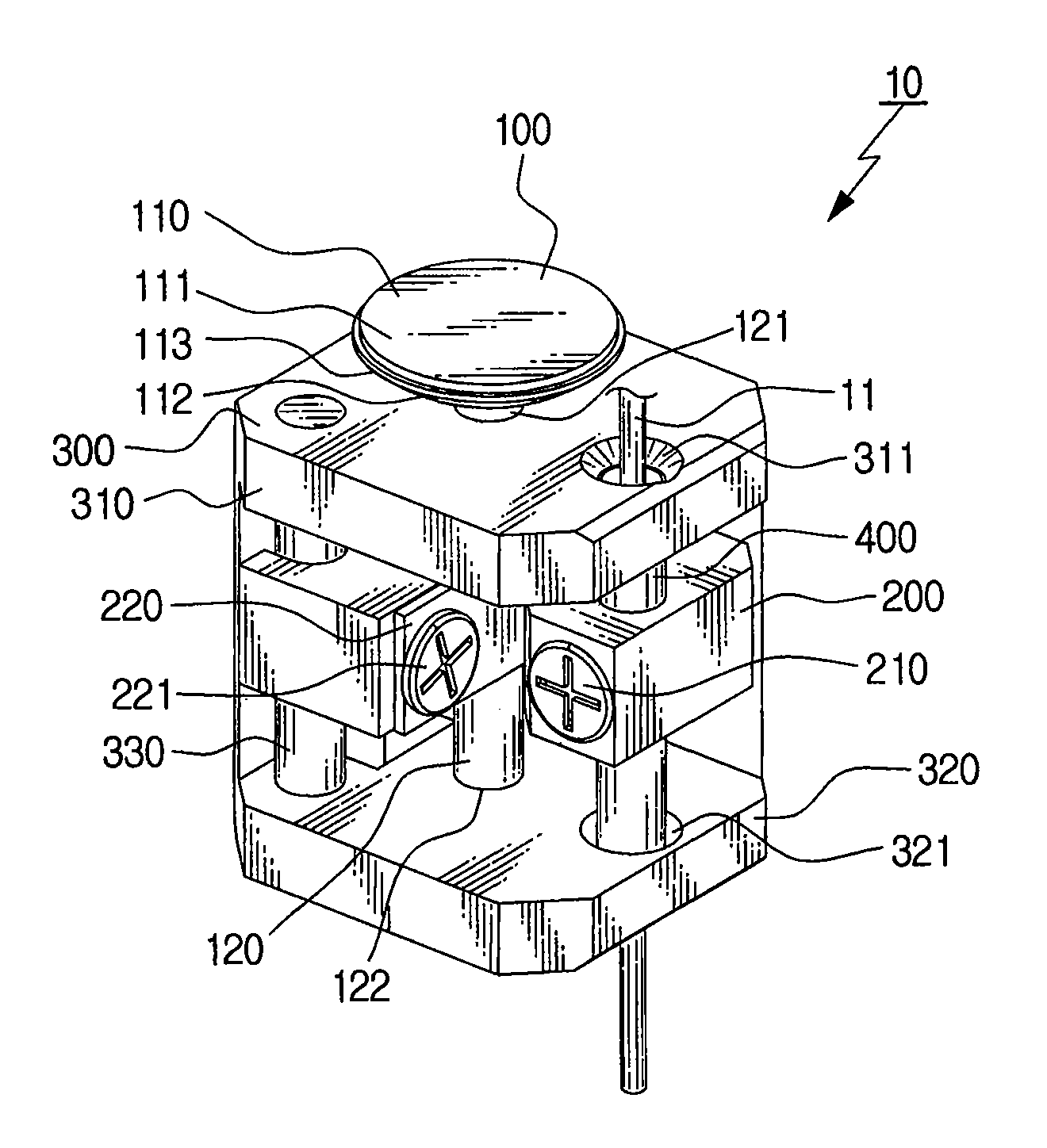

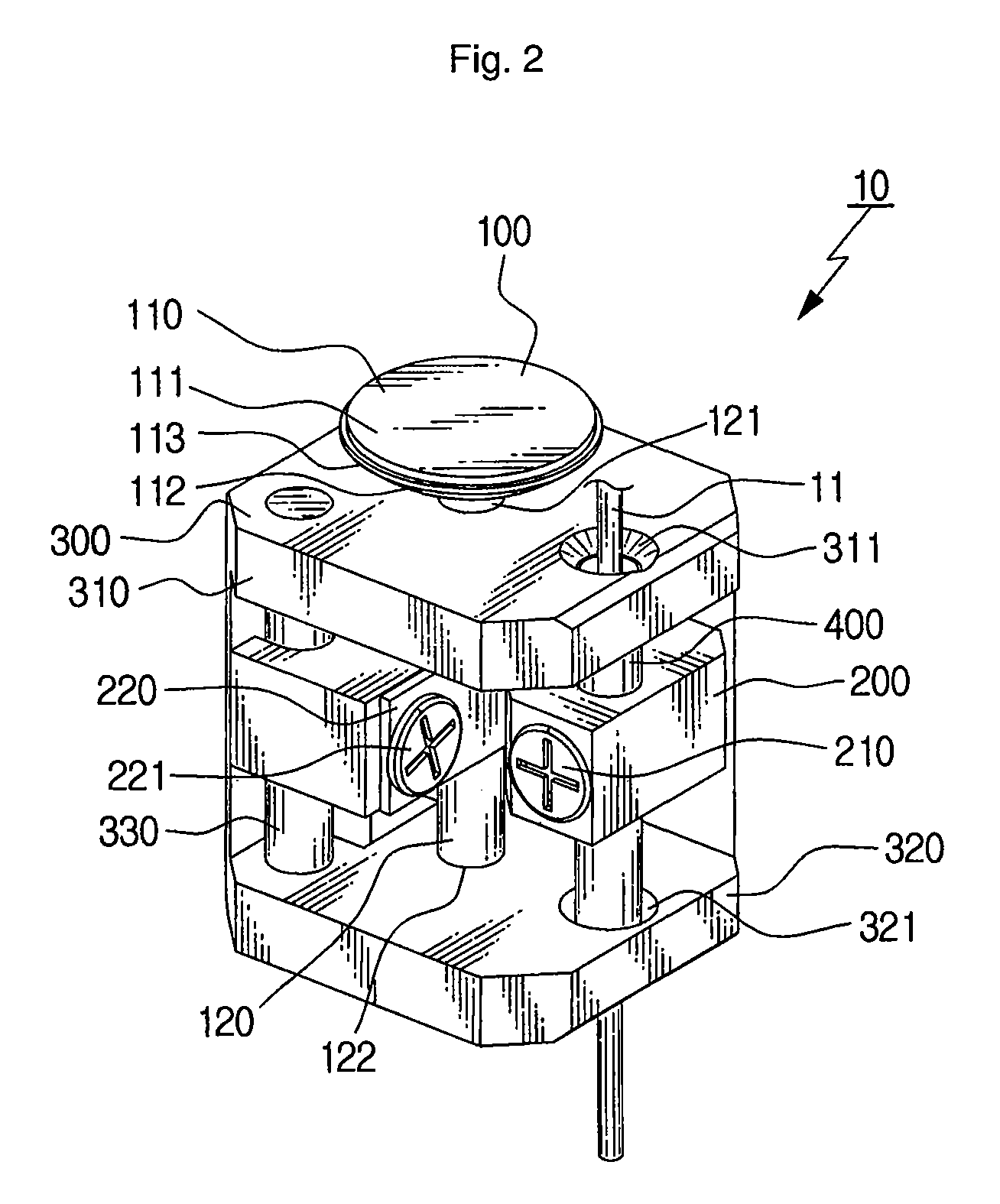

Micro-manipulator

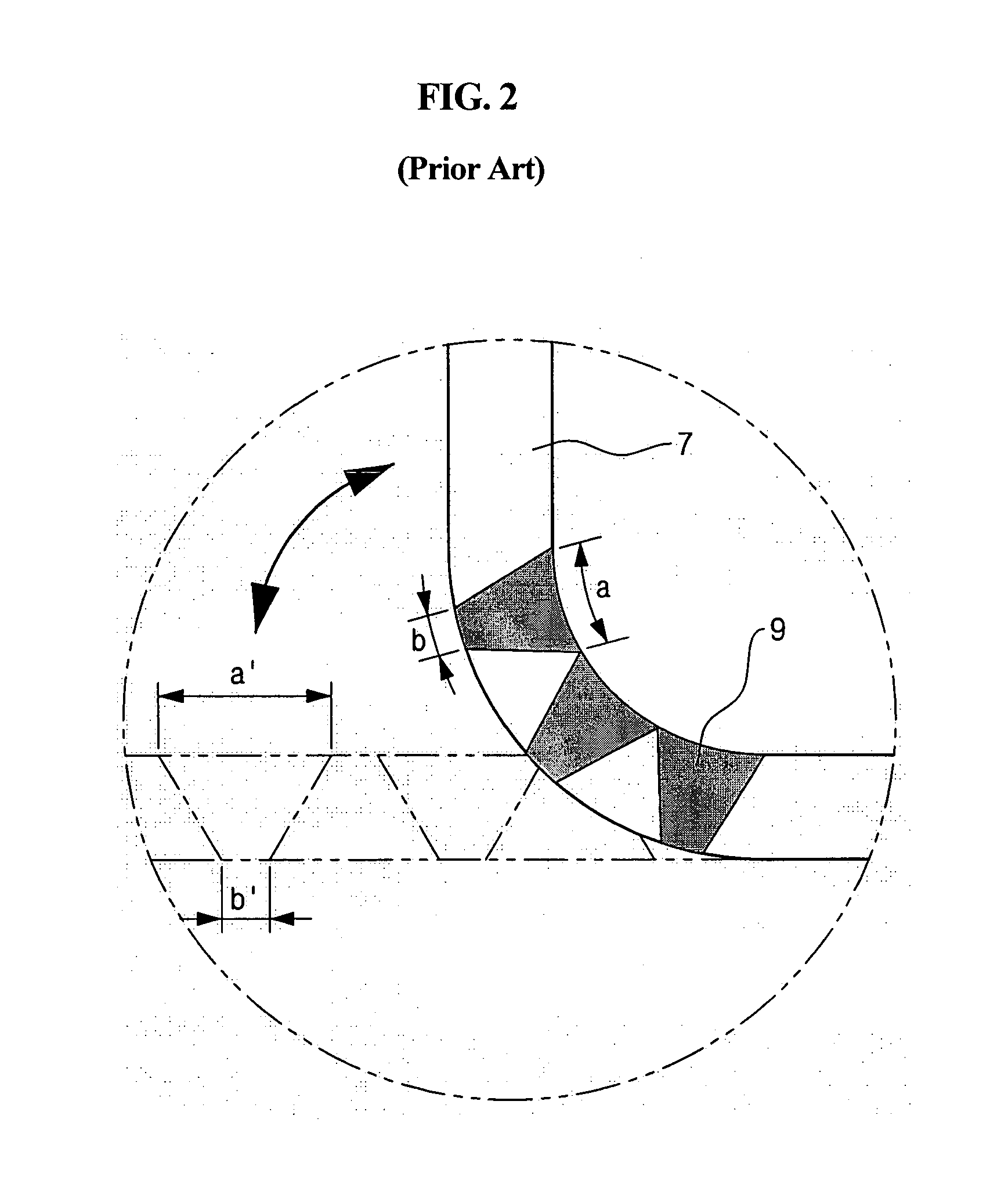

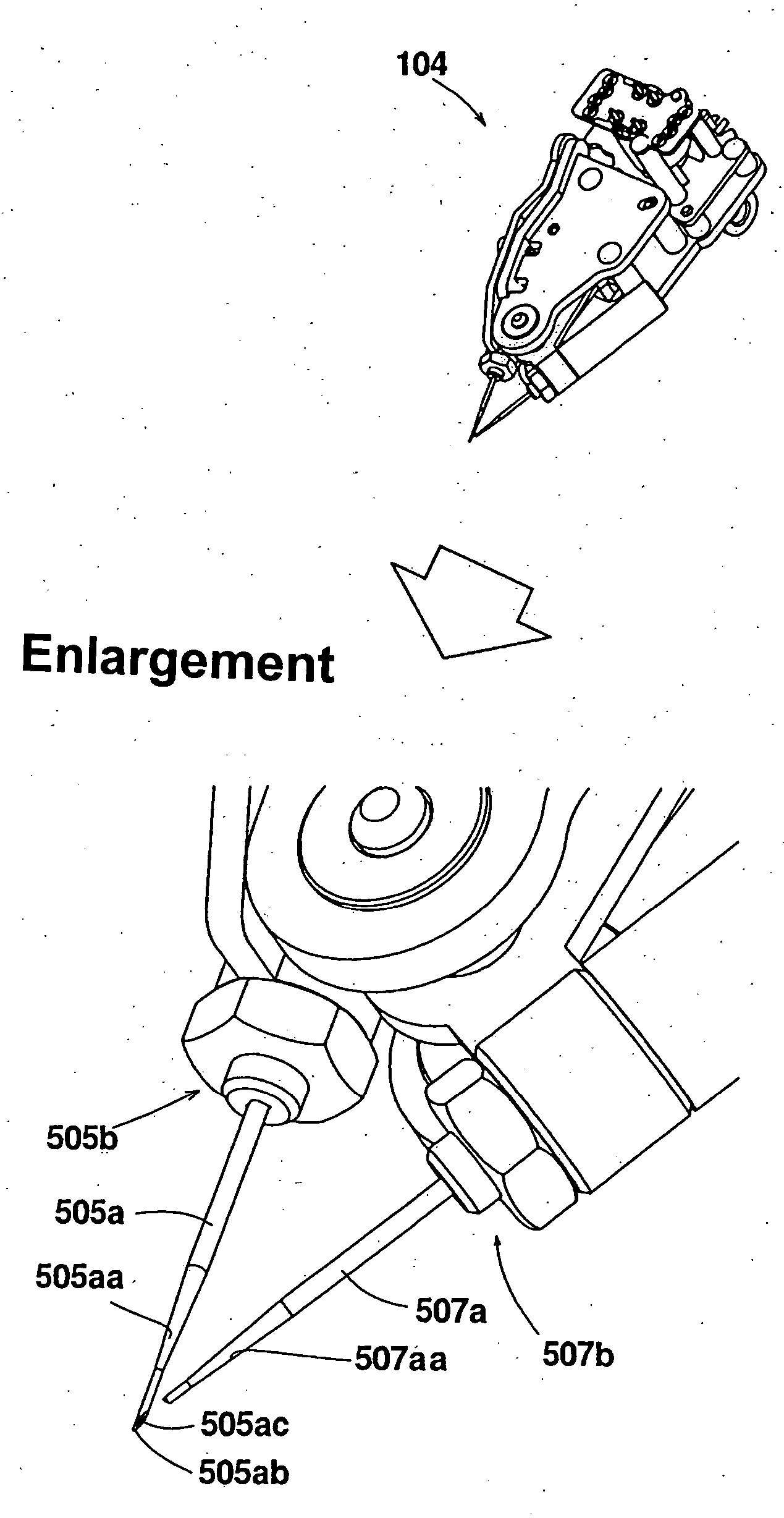

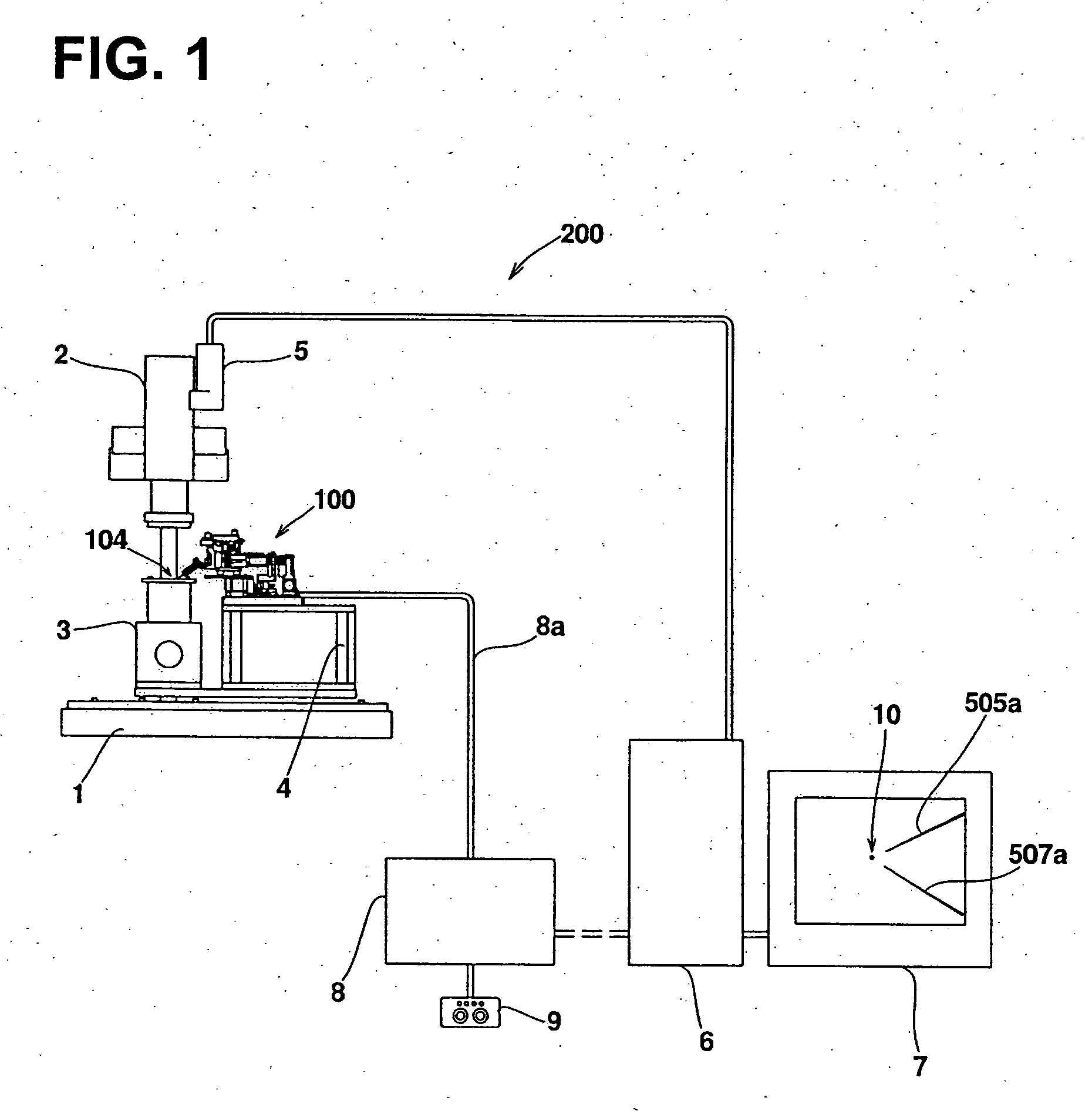

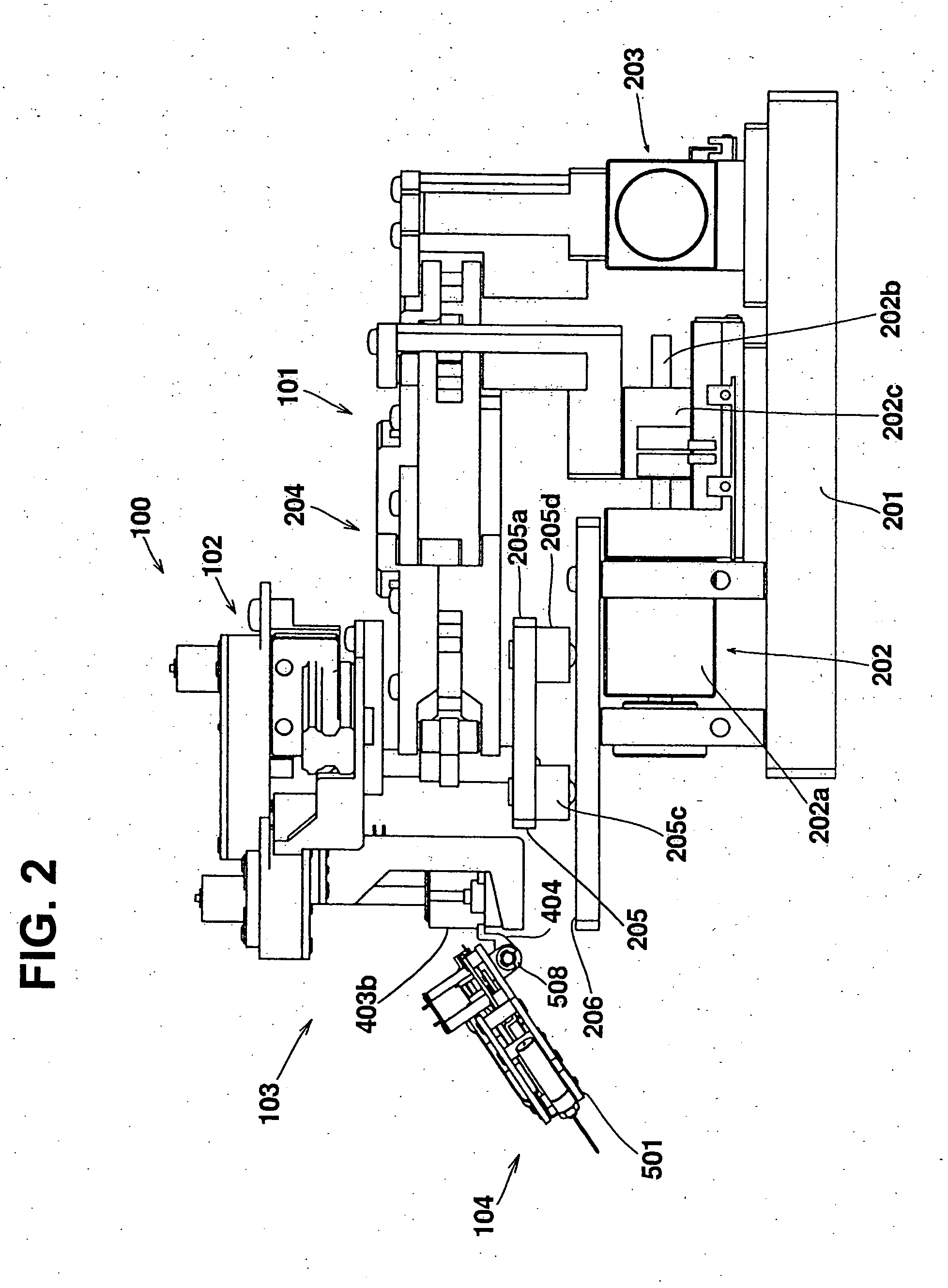

ActiveUS7568880B2Precise positioningAccurate and fast positioningProgramme-controlled manipulatorMechanical apparatusEngineeringField of view

A compact micro-manipulator with low energy consumption accurately and quickly positions a micro-material in a visual field of a microscope. A micro-manipulator operable to grip micro-material by bringing leading ends of the gripping fingers in close proximity includes an XY drive unit that drives a handling unit in X and Y directions, a drive unit that changes a positional direction of the handling unit in order to swing the gripping fingers around leading ends of the gripping fingers, and a Z drive unit that drives the handling unit in the Z direction.

Owner:TOKYO INST OF TECH +1

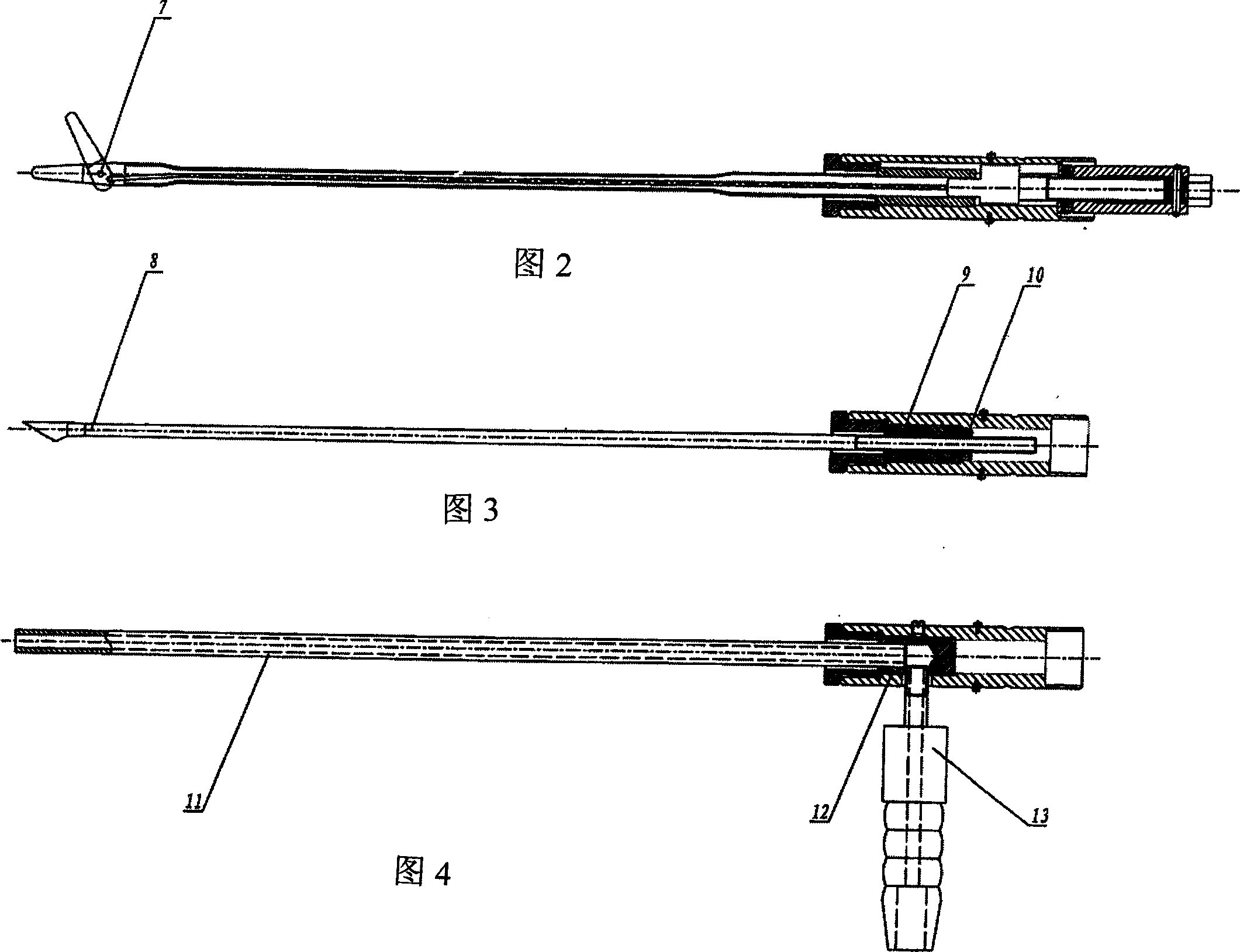

Micro manipulator used for throat surgery

InactiveCN1730246AReduce radial sizeSuitable for narrow spacesMicromanipulatorSurgeryThroatThroat surgery

The invention discloses a micro manipulator for throat operation, which comprises a body a finger tip mechanical mechanism, a remove mechanism, a rotation mechanism, a switch mechanism, and a limit mechanism. Compared with existing technique, this invention has benefit as: 1. the series-type envelope distribution can decrease finger radial size fit to narrow space; 2. the approximate crank rocker mechanism, which composes of a throat clamp, a pin, a drive steel wire and a screw, can transfer motion precisely and obtain required stretch angle.

Owner:TIANJIN UNIV

Micro-manipulator

ActiveUS20070023999A1Precise positioningAccurate and fast positioningProgramme-controlled manipulatorMechanical apparatusVisual field lossEngineering

A compact micro-manipulator with low energy consumption accurately and quickly positions a micro-material in a visual field of a microscope. A micro-manipulator operable to grip micro-material by bringing leading ends of the gripping fingers in close proximity includes an XY drive unit that drives a handling unit in X and Y directions, a drive unit that changes a positional direction of the handling unit in order to swing the gripping fingers around leading ends of the gripping fingers, and a Z drive unit that drives the handling unit in the Z direction.

Owner:TOKYO INST OF TECH +1

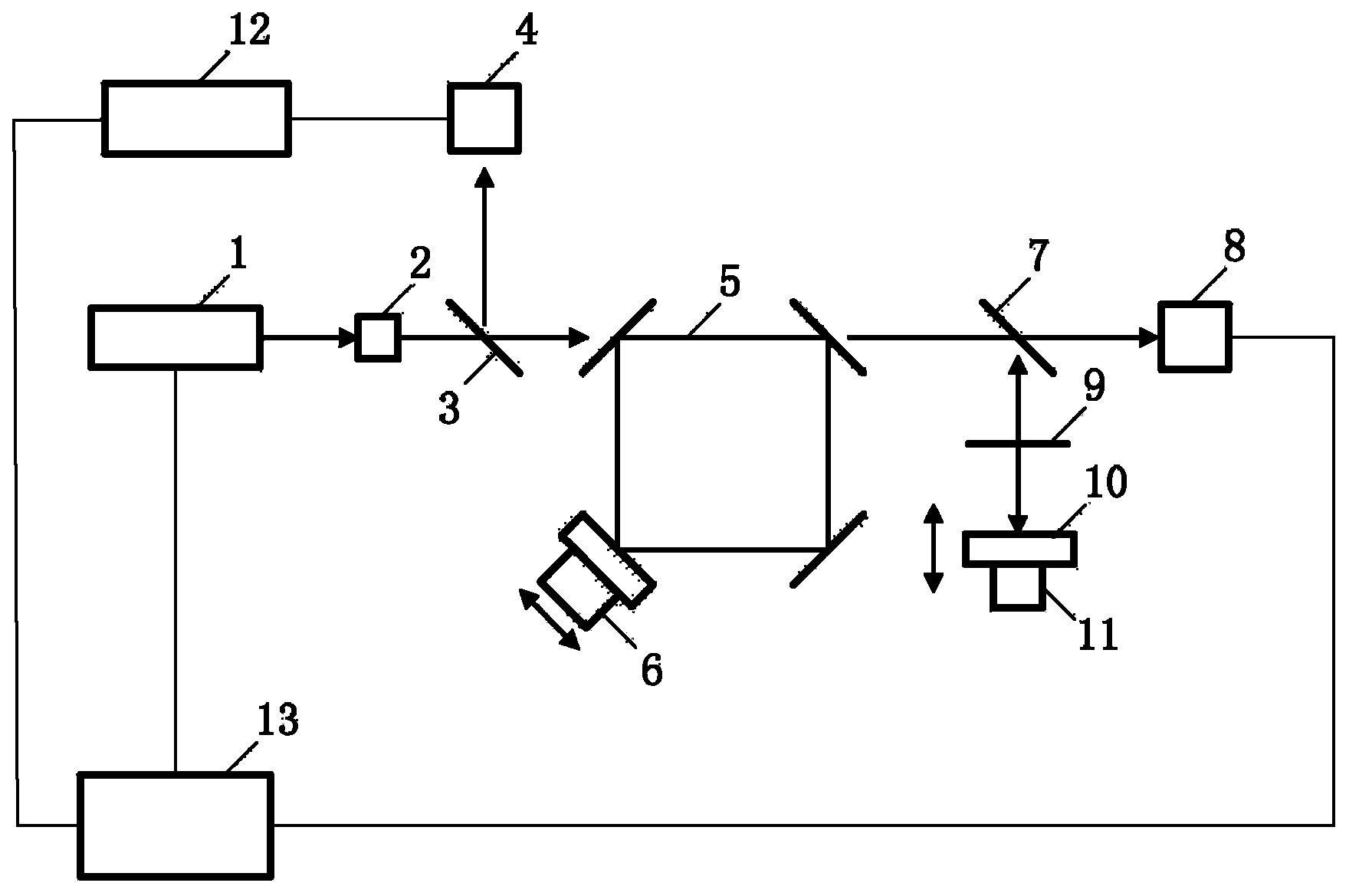

Device and method for measuring backscattering of laser gyroscope ultra-smooth reflecting mirror

ActiveCN103674487AHigh precisionReduce lock areaTesting optical propertiesFrequency stabilizationGyroscope

The invention belongs to the laser gyroscope technology, and relates to a device and method for measuring backscattering of a laser gyroscope ultra-smooth reflecting mirror. The device comprises an optical laser, a Faraday opto-isolator, a beam splitter A, a photoelectric intrusion-detector A, a ring-shaped resonant cavity, a micro-manipulator A, a beam splitter B, a photoelectric intrusion-detector B, an optical filter, a feedback mirror, a micro-manipulator B, a phase-locking amplifier and a frequency stabilization system. According to the invention, a part of energy of a pumping light beam is fed back to the ring-shaped resonant cavity to be in optical interference with backscattering in the cavity to improve the signal-to-noise ratio of backscattering signals of the ring-shaped resonant cavity; a reflecting mirror to be measured is enabled to move slightly along the mirror surface tangential direction to achieve accurate measurement for backscattering amplitude coefficient of the ultra-smooth reflecting mirror used by a laser gyroscope; the ultra-smooth reflecting mirror with small backscattering can be selected to be used for the adjustment of the laser gyroscope resonant cavity, so that important significance of reducing laser gyroscope locking areas and improving laser gyroscope precision is achieved.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

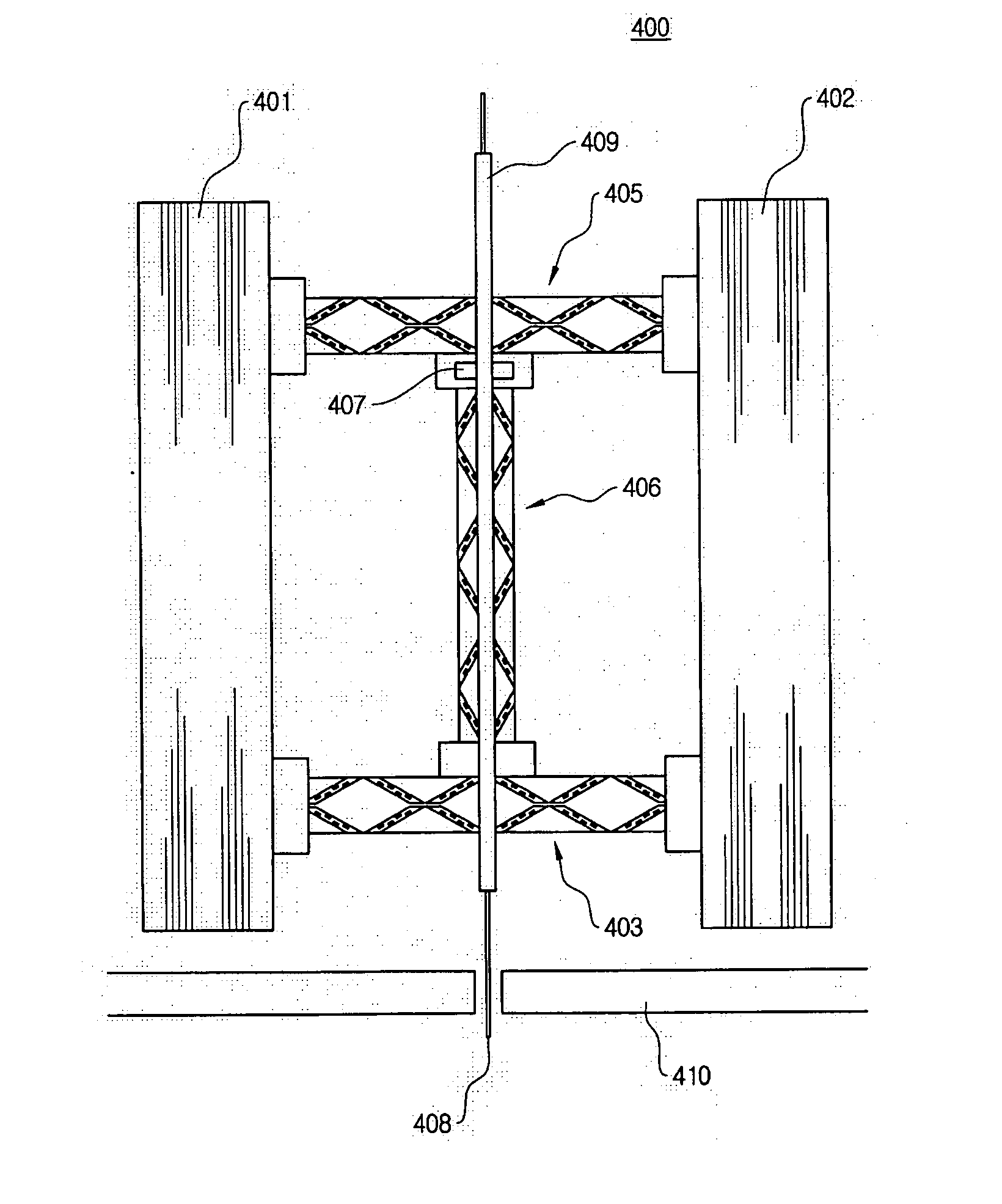

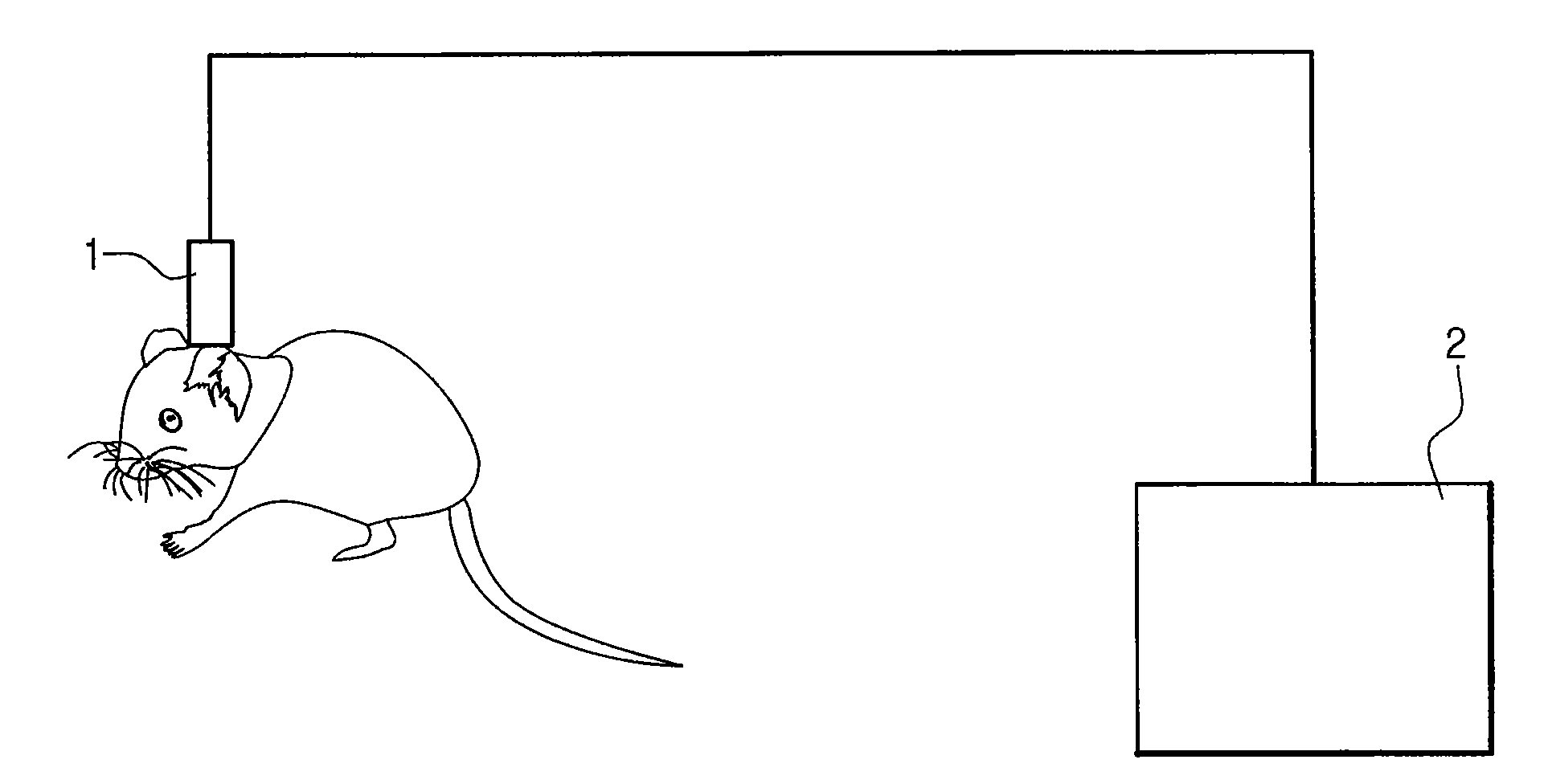

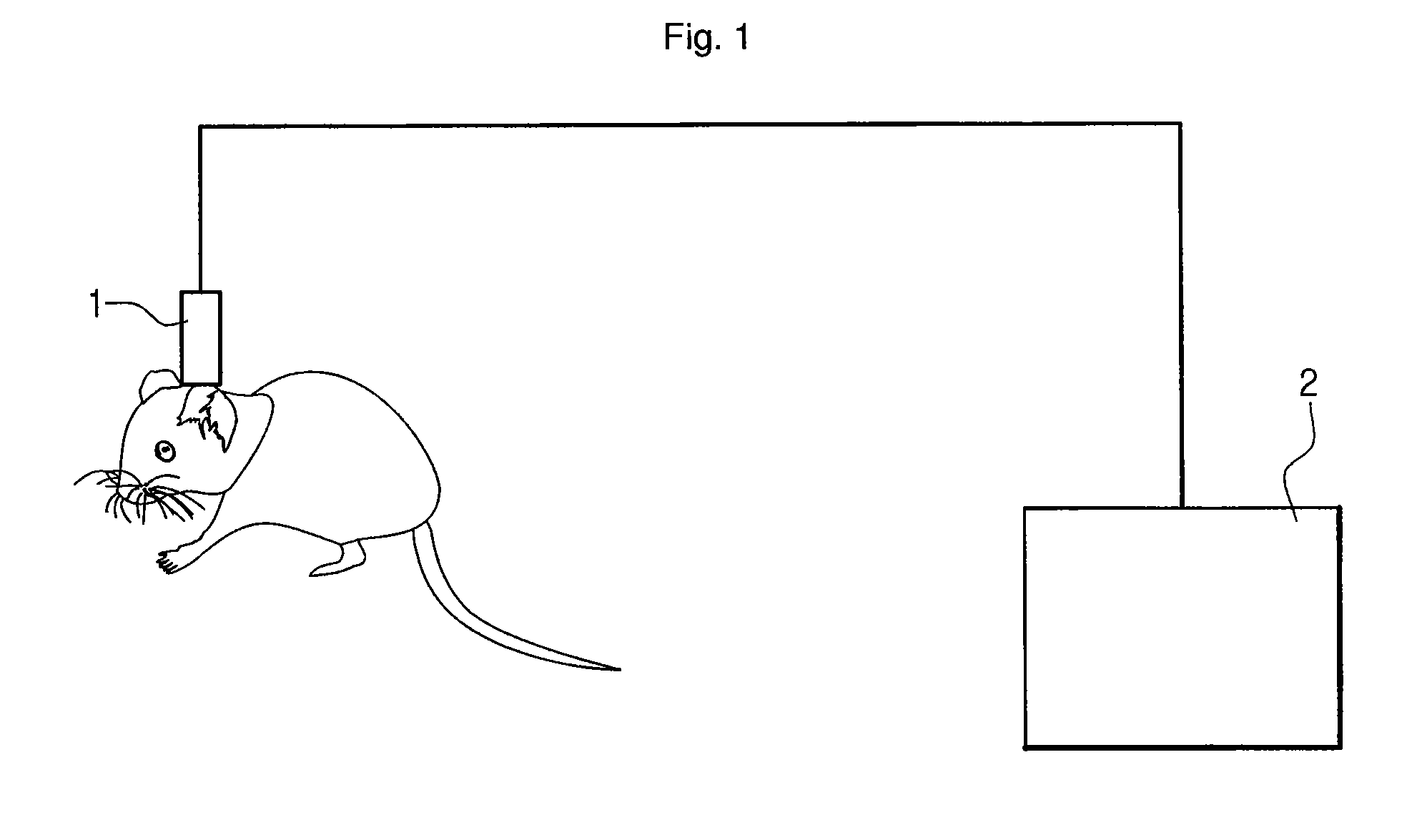

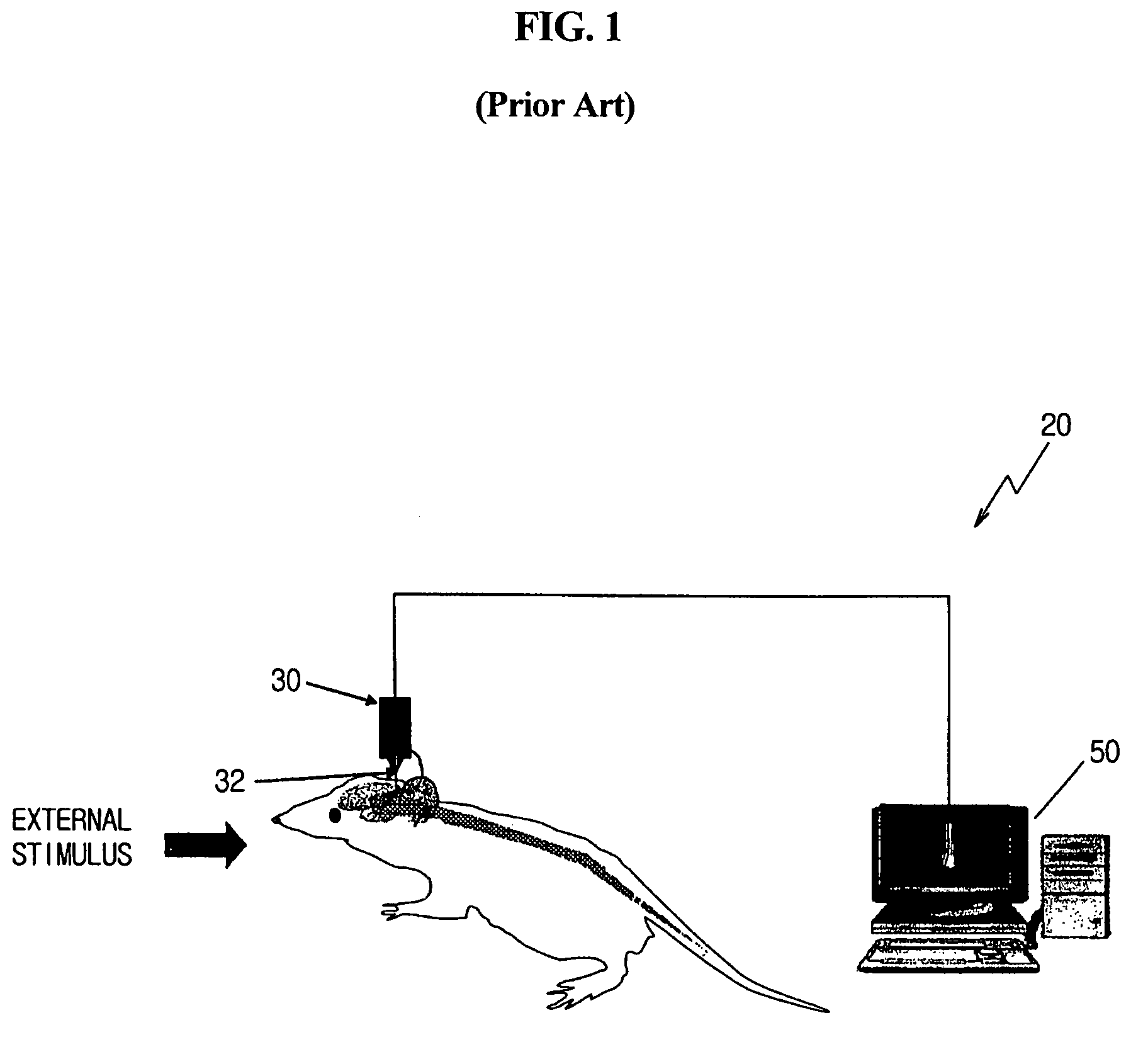

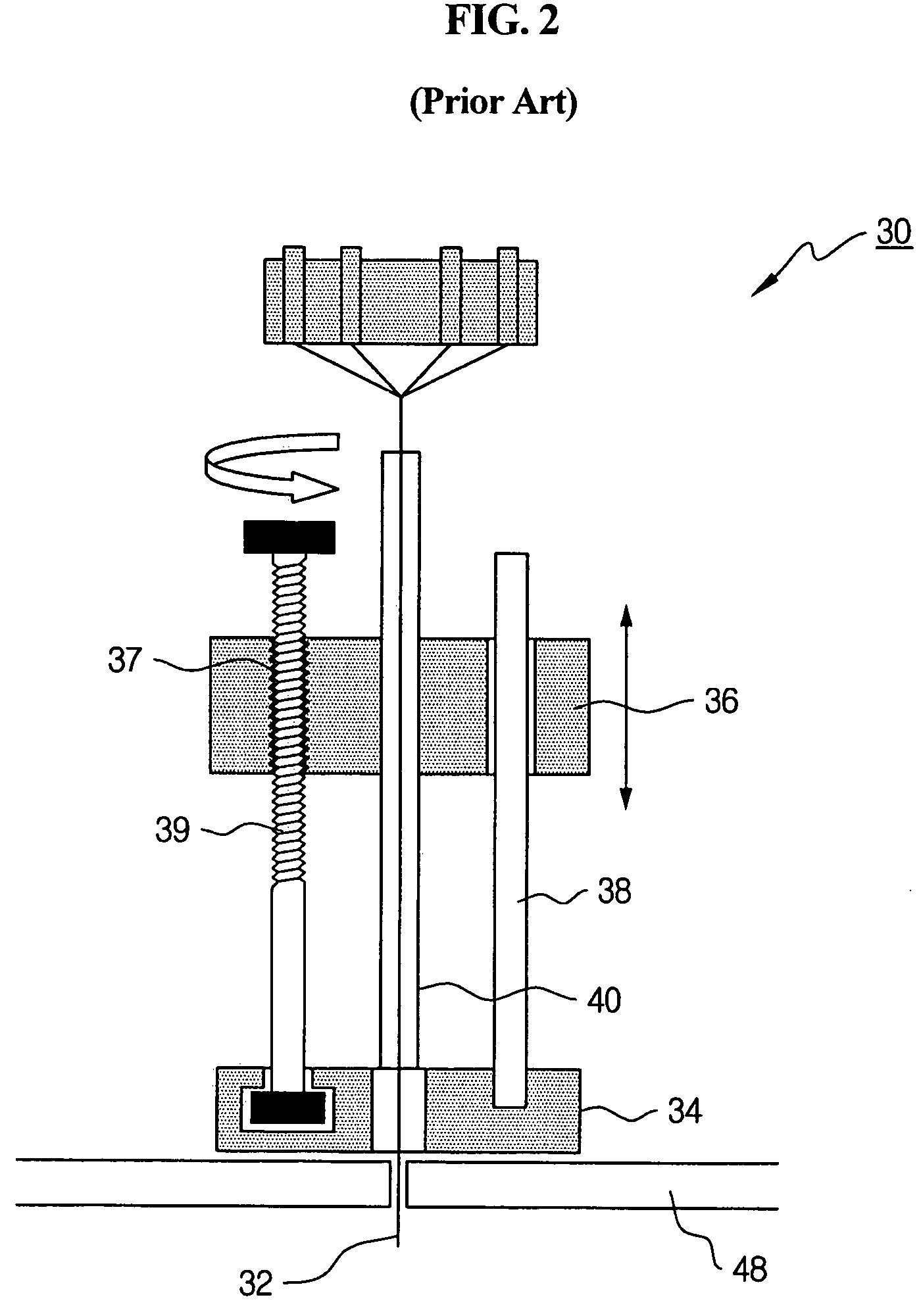

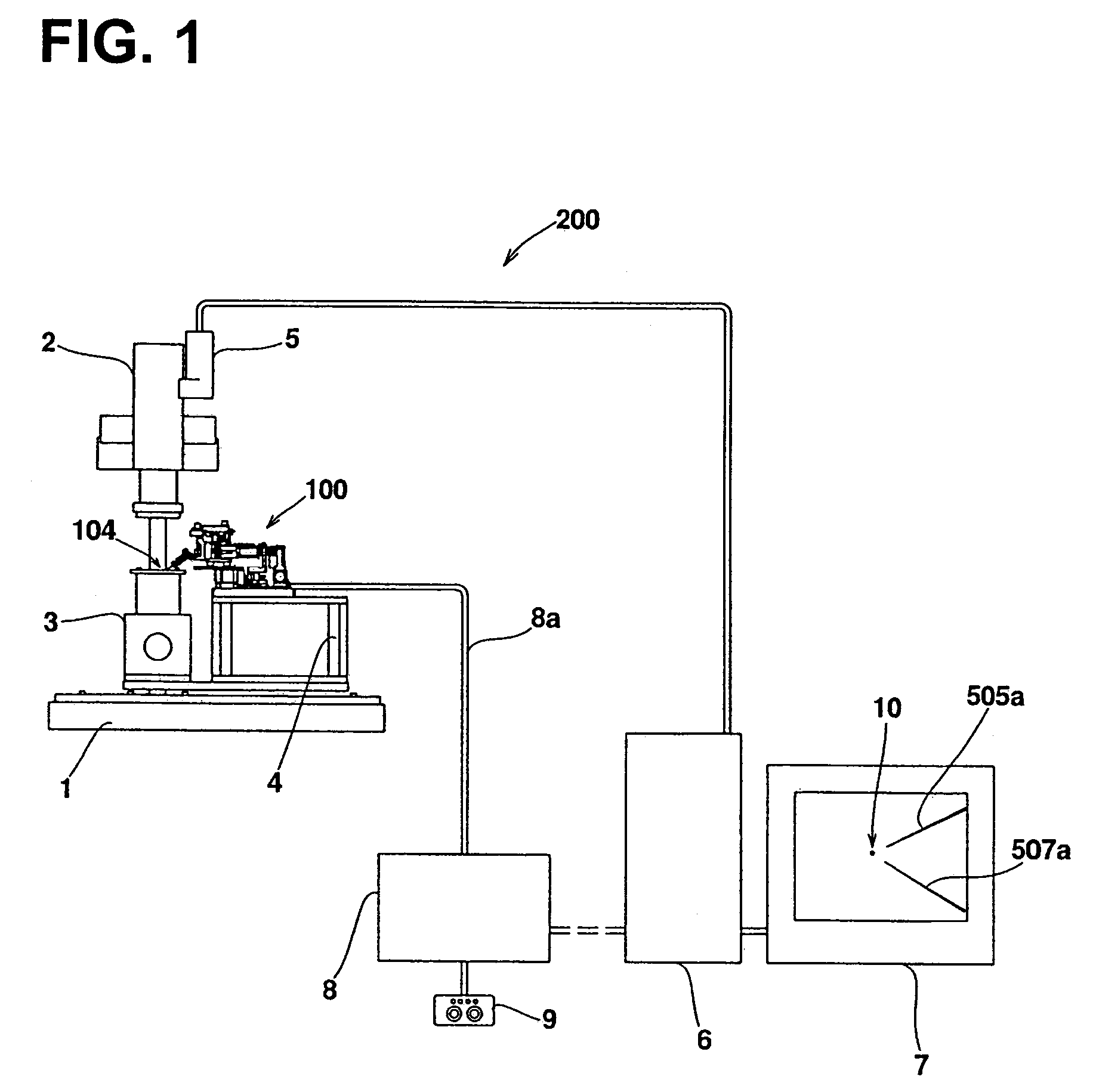

Polymer linear actuator for micro electro mechanical system and micro manipulator for measurement device of cranial nerve signal using the same

InactiveUS20070228868A1Piezoelectric/electrostriction/magnetostriction machinesDiagnostic recording/measuringLinear motionMeasurement device

A polymer linear actuator for a micro electro mechanical system (MEMS) and a micro manipulator for a measurement device of cranial nerve signal using the same are provided. The polymer linear actuator has first and second bodies positioned spaced apart to a distance from each other, and one or more pairs of V-type moving units connecting the first and second bodies together, wherein the moving units in pair are opposed to each other to convert a rotation motion of the respective moving units into a linear motion, thereby causing the first and second bodies to move linearly.

Owner:KOREA INST OF SCI & TECH

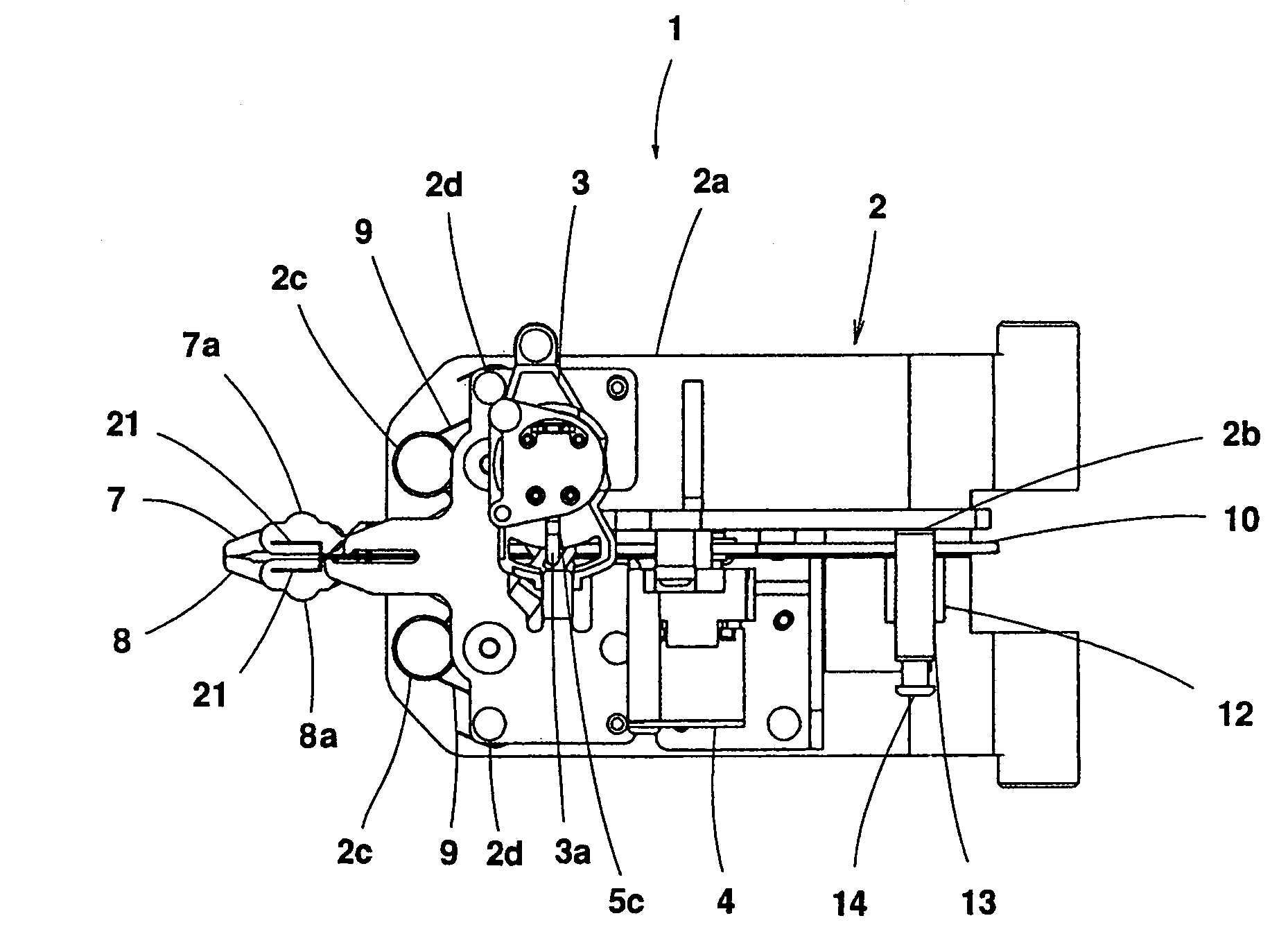

Micro-manipulator

InactiveUS20060182606A1Securely and more quickly gripSecurely and quickly gripMicroscopesLoad-engaging elementsActuatorMicro manipulator

A micro-manipulator has a handling mechanism for gripping micro-material with two gripping fingers. The handling mechanism has a fixed finger with an end effecter for touching the micro-material, a movable finger with an end effecter capable of rotating around a rocking shaft for touching the micro-material, and an actuator for rotating the movable finger. The actuator drive moves the movable finger so as to be capable of touching a leading end of the movable finger end effecter to a leading end of the fixed finger end effecter. The micro-manipulator can securely and quickly grip a micro-material in a microscope visual field.

Owner:NISCA KK

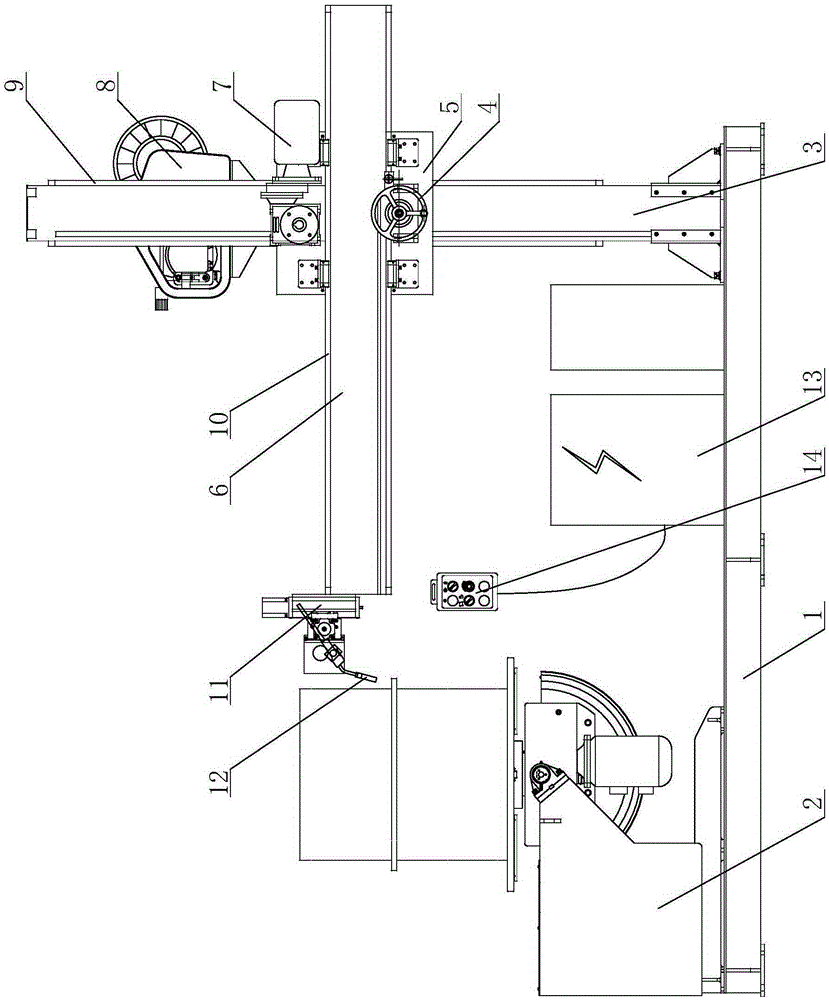

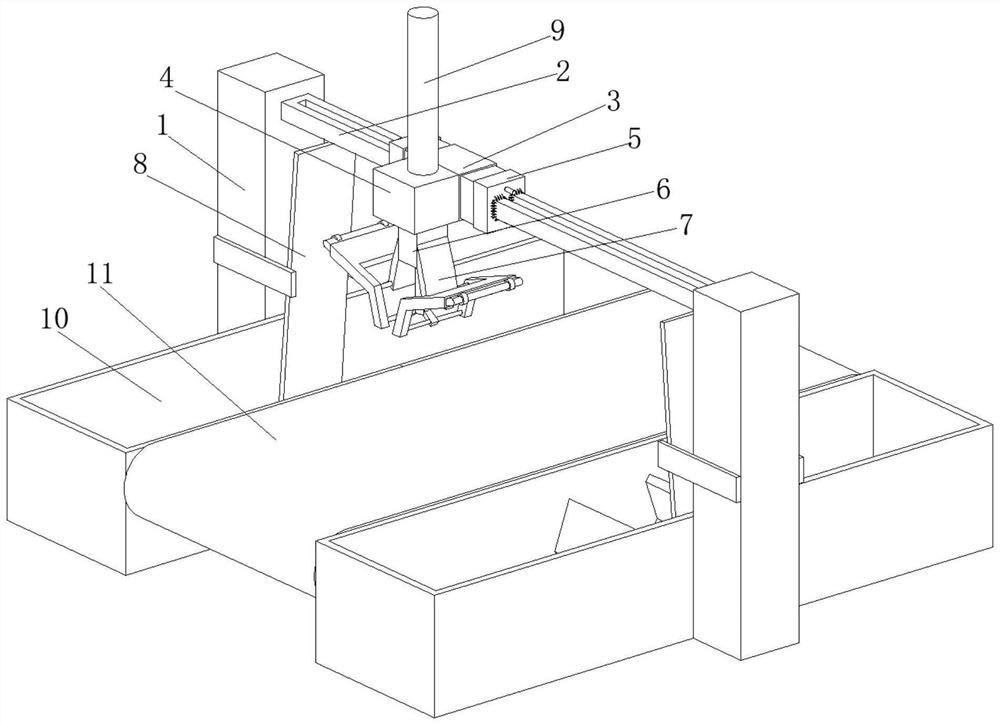

Pipe flange welding workstation

InactiveCN105382452ASimple structureCompact structureWelding/cutting auxillary devicesAuxillary welding devicesWorkstationUltimate tensile strength

The invention discloses a pipe flange welding workstation. The pipe flange welding workstation comprises a base, wherein a positioner is arranged on one end of the base; the positioner is electrically connected with a controller; a workbench which can drive a workpiece to rotate or turnover is arranged on the positioner; a stand column which is perpendicularly arranged is arranged at the other end of the base; a wire feeder is mounted on the stand column; the wire feeder is electrically connected with the controller; a lifting base is mounted on the stand column in an up-and-down moving manner; a cross arm is mounted on the lifting base in a horizontal moving manner; a precise micro manipulator is mounted on the end head of one end, which is close to the positioner, of the cross arm; the precise micro manipulator is controlled by the controller; a welding gun is mounted on the precise micro manipulator; the welding gun is electrically connected with the controller. The pipe flange welding workstation disclosed by the invention is simple and compact in structure, flexible and convenient to operate, durable, and convenient and swift to mount and dismantle. According to the pipe flange welding workstation, the production intensity is effectively reduced, the production cost is reduced, and the welding efficiency and the welding quality are improved.

Owner:WUXI SANHONG MACHINERY EQUIP

Micro-manipulator

Owner:NISCA KK

Micro-manipulator

A micro-manipulator includes a gripping device having two gripping fingers for gripping a micro-material, and a gripping finger moving device for moving at least one of the gripping fingers of the gripping device. An exciting device vibrates the gripping fingers when the gripping fingers of the gripping device are opened to release the micro-material.

Owner:TOKYO INST OF TECH +1

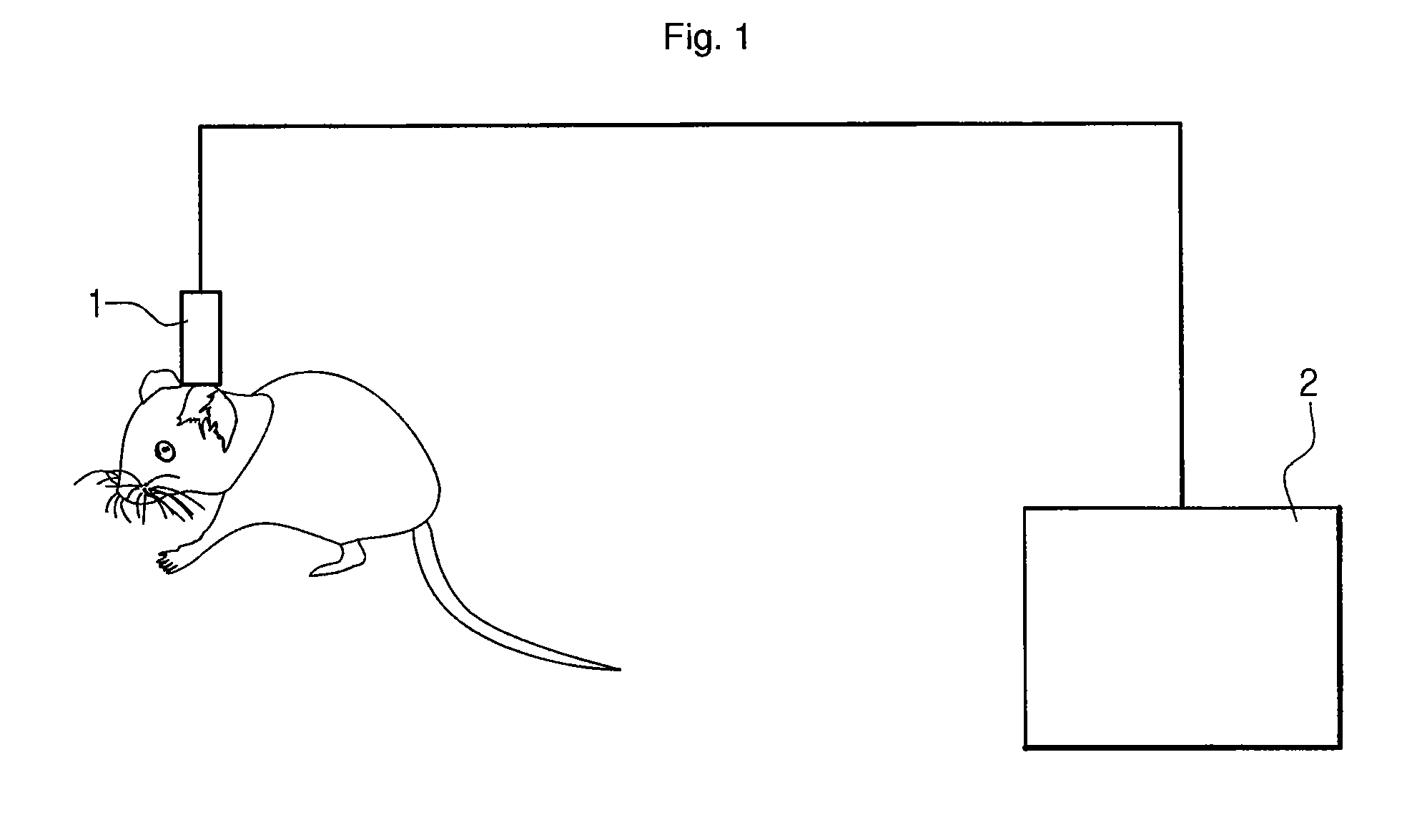

Micro manipulator for electrode movement in neural signal recording

InactiveUS20100168759A1Simple structureSmall sizeHead electrodesDiagnostics using vibrationsEngineeringNeuron

This disclosure relates to a micro manipulator having a simple structure and having high possibility of recording a biological signal of a neuron at a desired position by improving positioning resolution of an electrode disposed adjacent to a subject's brain neuron or an electrode holder attached with the electrode. The micro manipulator according to the disclosure includes: a motor which includes a shaft and a vibration portion; a mobile which is connected to the shaft so as to be movable along the shaft; and a frame which supports the motor, wherein an electrode is connected to the mobile in a direction parallel to a longitudinal direction of the shaft, and wherein when the mobile moves linearly in accordance with a vibration of the shaft due to the vibration portion, the electrode moves linearly.

Owner:KOREA INST OF SCI & TECH

Micro-manipulator

A micro-manipulator has grippers for gripping micro-material; an actuator for driving the grippers; a drive amount detection device for detecting a drive amount of the actuator; a power control device for controlling power supplied to the actuator so that a difference in a target drive amount of the input actuator and a drive amount detected by the drive amount detection device is small, after at least the grippers touch the micro-material; a gripping determination device for determining that grippers have gripped the micro-material based on the difference; and a resilience value calculation device for calculating a resilience value that represents a degree of softness of the micro-material by dividing the actuator drive force that is equivalent to the repulsive force of micro-material gripped by the grippers in proportion to power supplied to the actuator via the power control device.

Owner:NISCA KK

Micro manipulator for electrode movement in neural signal recording

InactiveUS8435250B2Simple structureExcellent resolution and positioning abilityHead electrodesDiagnostics using vibrationsEngineeringNeuron

This disclosure relates to a micro manipulator having a simple structure and having high possibility of recording a biological signal of a neuron at a desired position by improving positioning resolution of an electrode disposed adjacent to a subject's brain neuron or an electrode holder attached with the electrode. The micro manipulator according to the disclosure includes: a motor which includes a shaft and a vibration portion; a mobile which is connected to the shaft so as to be movable along the shaft; and a frame which supports the motor, wherein an electrode is connected to the mobile in a direction parallel to a longitudinal direction of the shaft, and wherein when the mobile moves linearly in accordance with a vibration of the shaft due to the vibration portion, the electrode moves linearly.

Owner:KOREA INST OF SCI & TECH

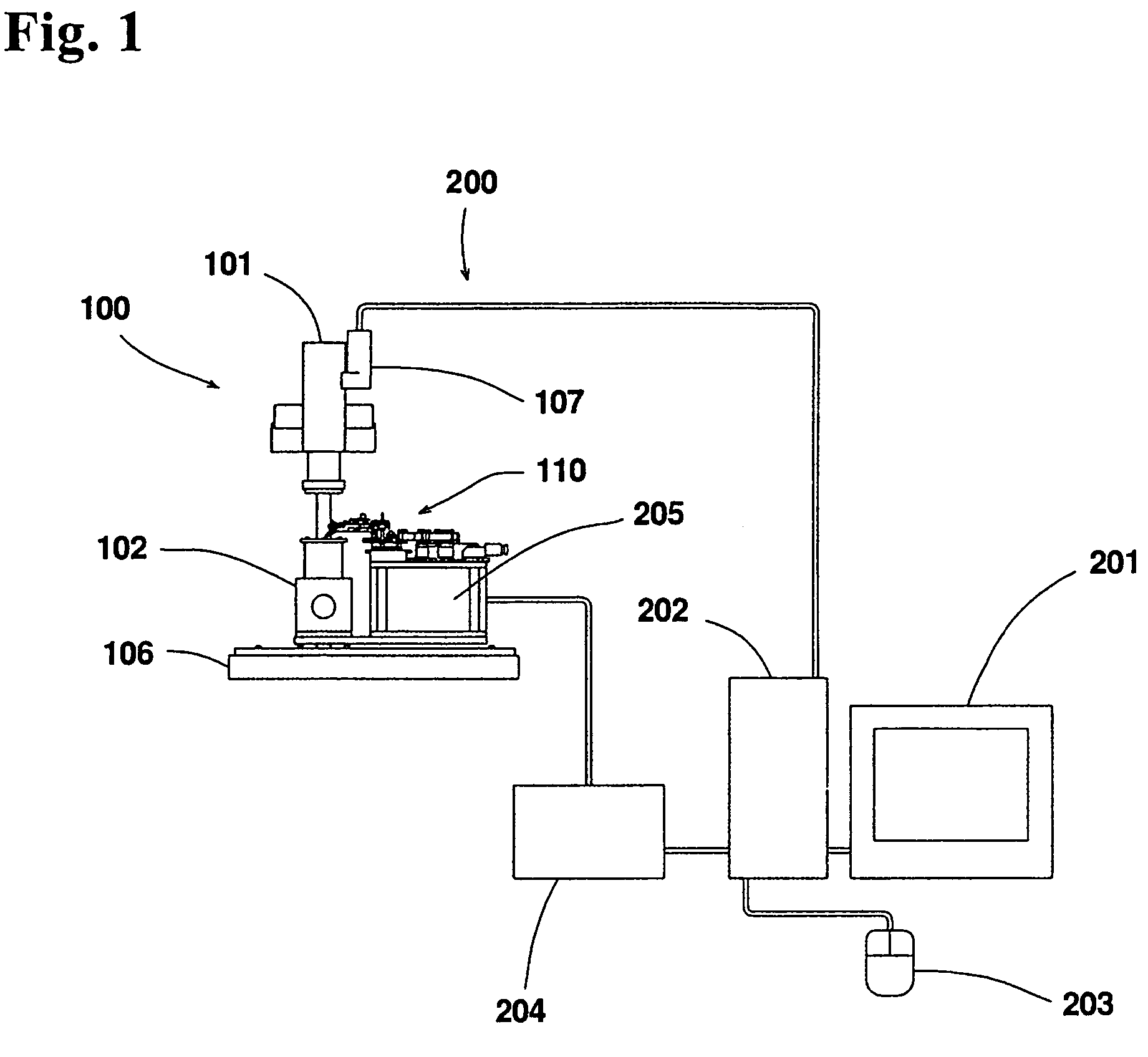

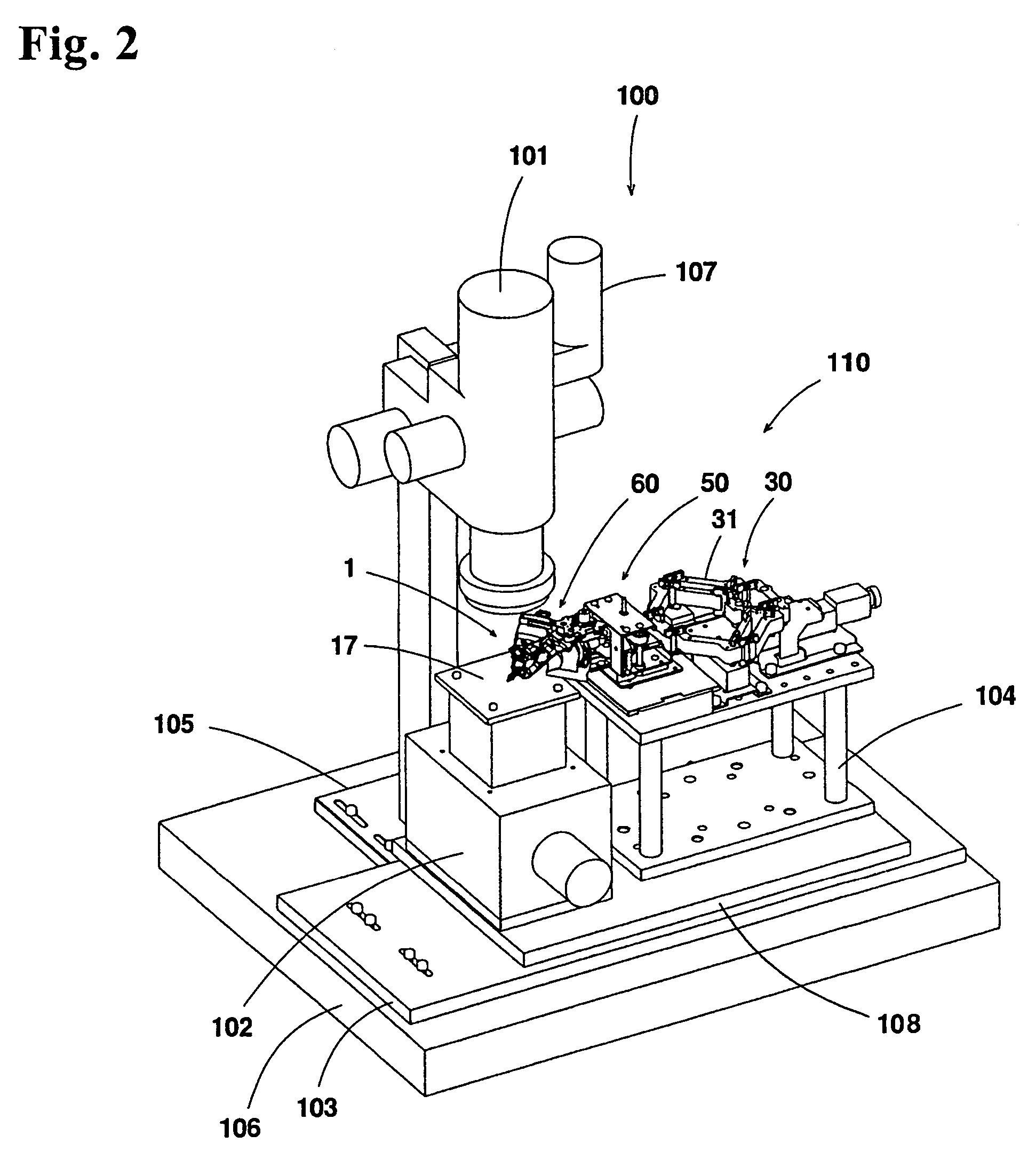

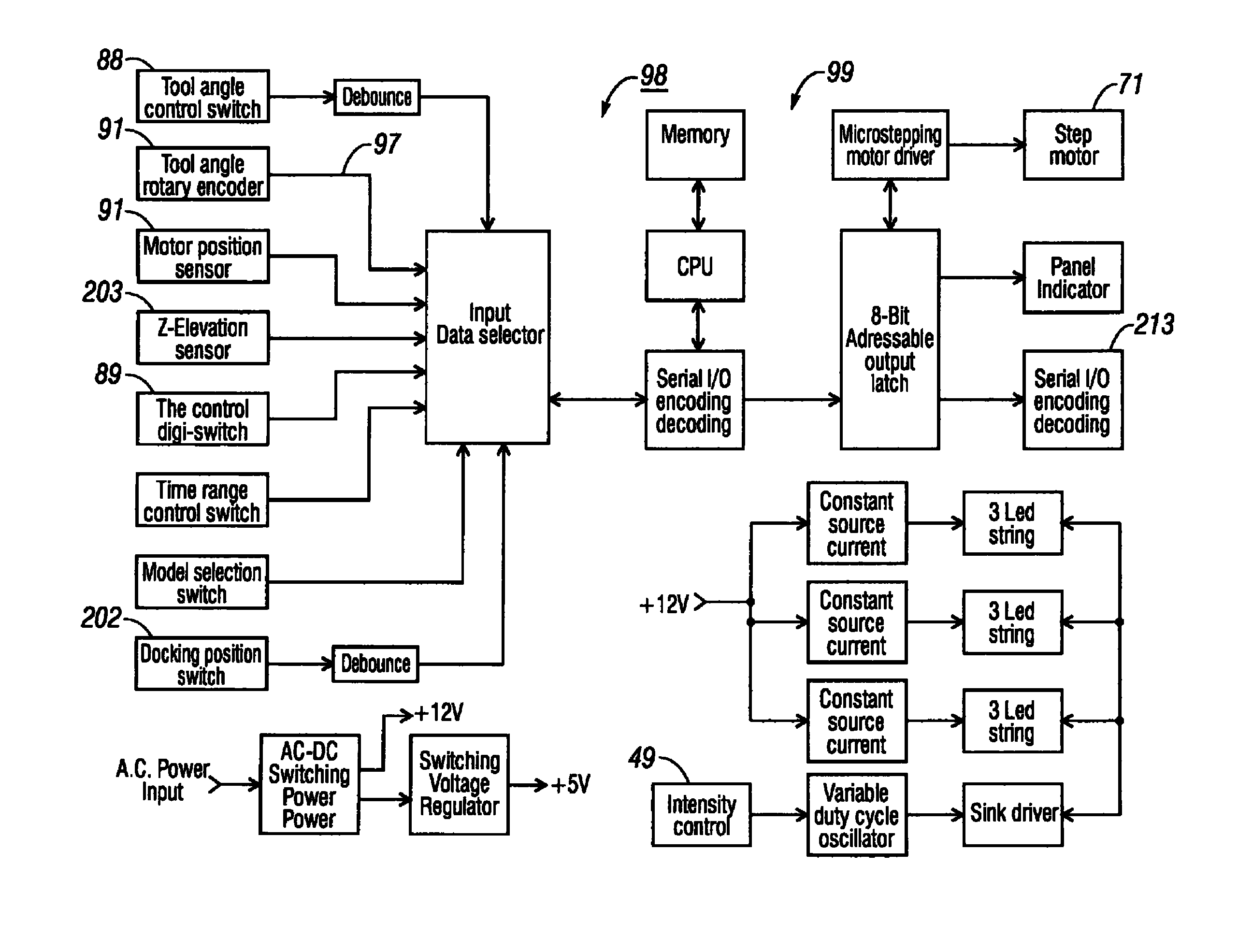

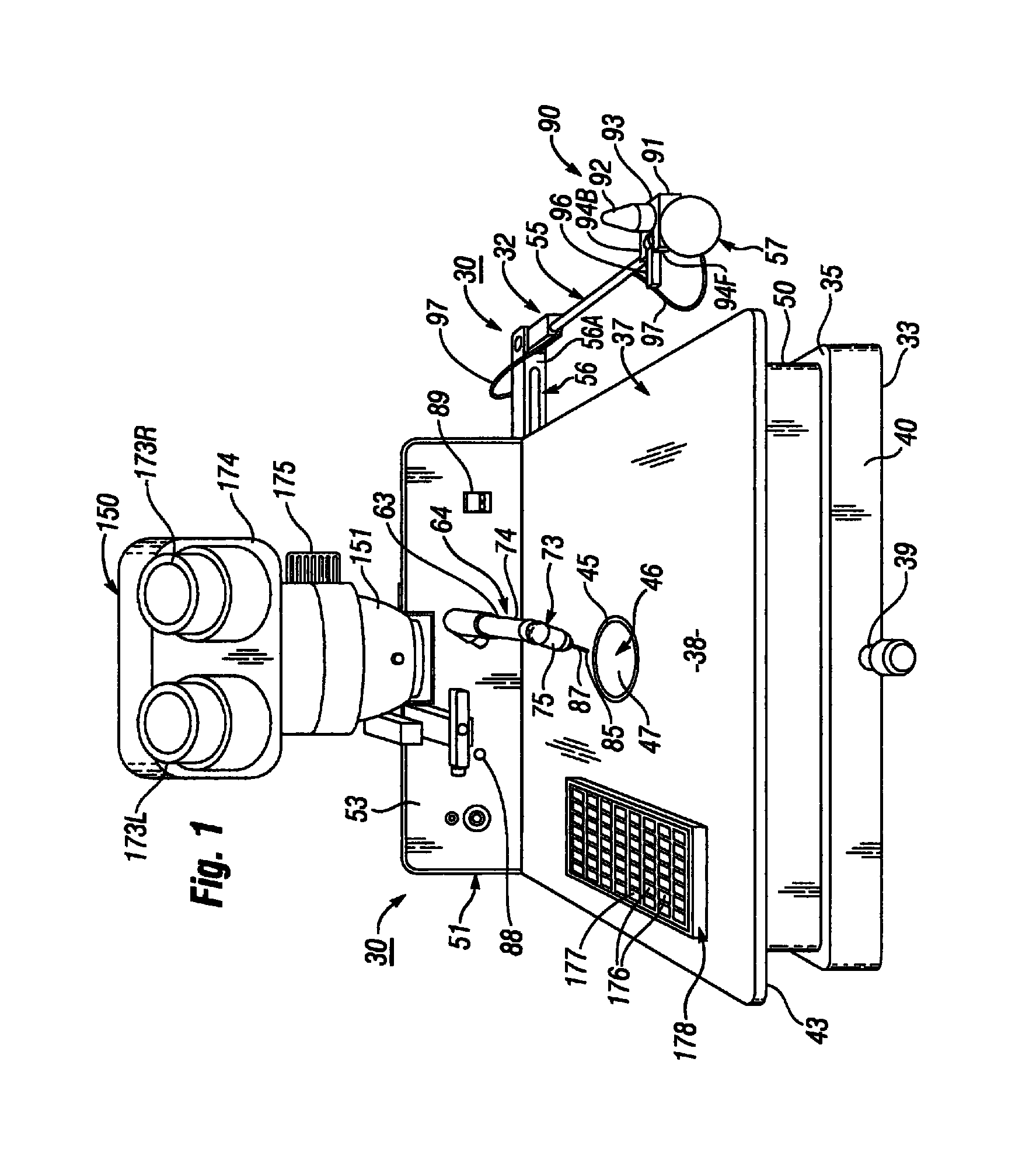

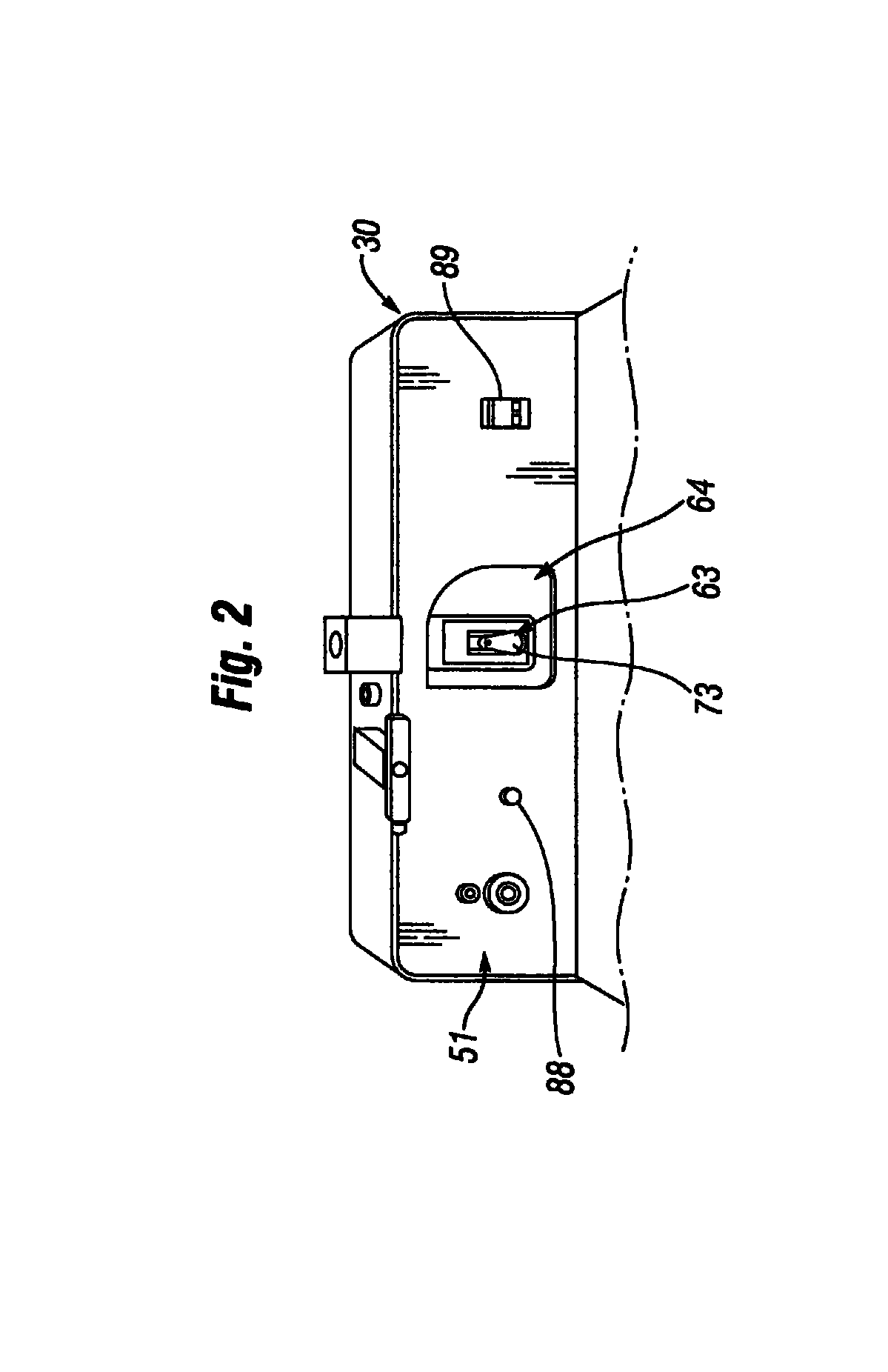

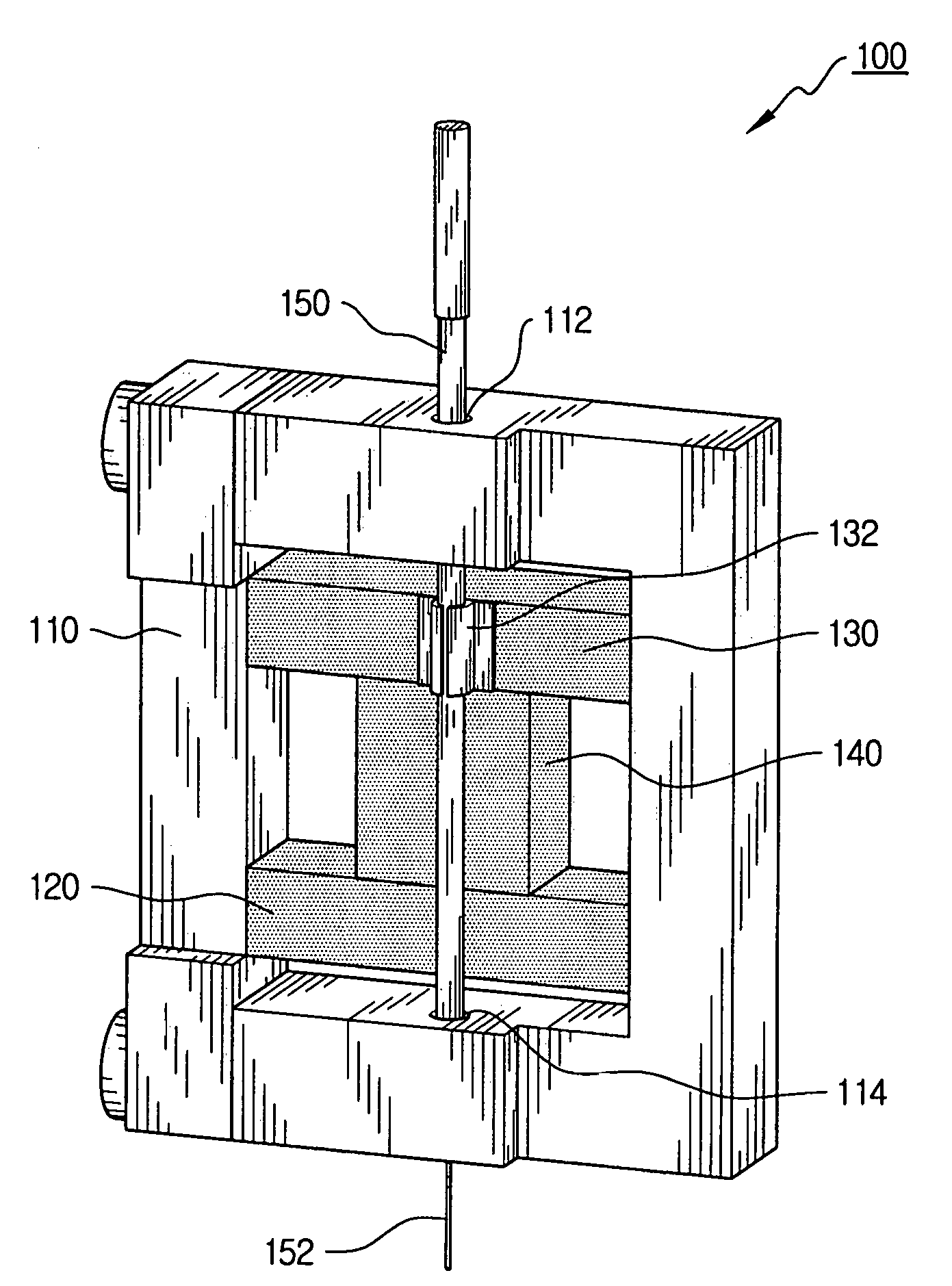

Micro-manipulator machine for harvesting and cryofreezing crystals

ActiveUS8349080B1Easy to operateManipulation is accurateAfter-treatment apparatusPolycrystalline material growthInput controlActuator

A micro-manipulator machine for harvesting and cryofreezing crystals for cryogenic storage and subsequent analysis includes a micropositioner mechanism for converting motions manually input to a position control knob to fractionally-scaled motions of a follower mechanism which includes a tool head support arm and tool head that releasably holds a filamentary polymer cryoloop for immersion into a liquid crystal growth media and extraction of a liquid drop containing a selected crystal from the media. A first automatic actuator mechanism orbits the tool head support arm, tool head, cryoloop, liquid drop and harvested crystal from a harvesting location to a retrieval location when the micropositioner input control arm has been moved manually away from the crystal harvesting location by the operator after extracting a crystal drop, and a second automatic actuator mechanism pivots the toll head into a flowing stream of a cryogenic gas to freeze the liquid drop and crystal.

Owner:WEST BOND

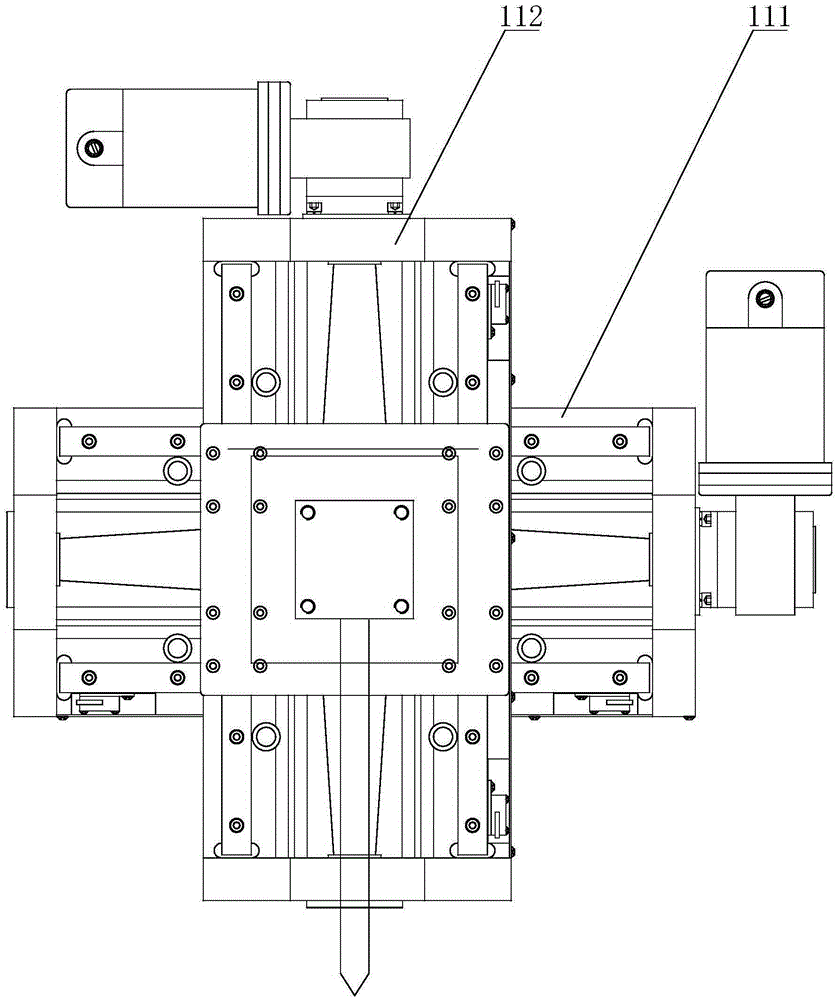

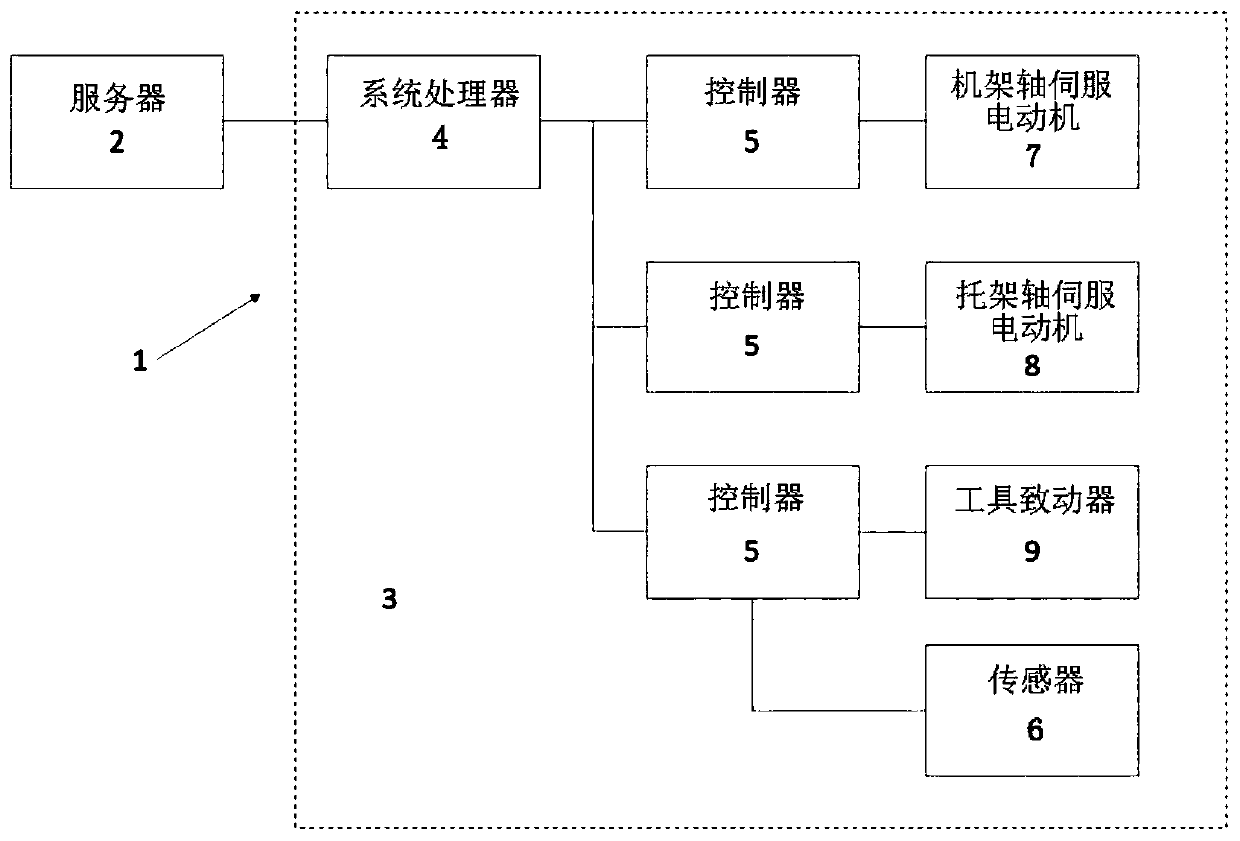

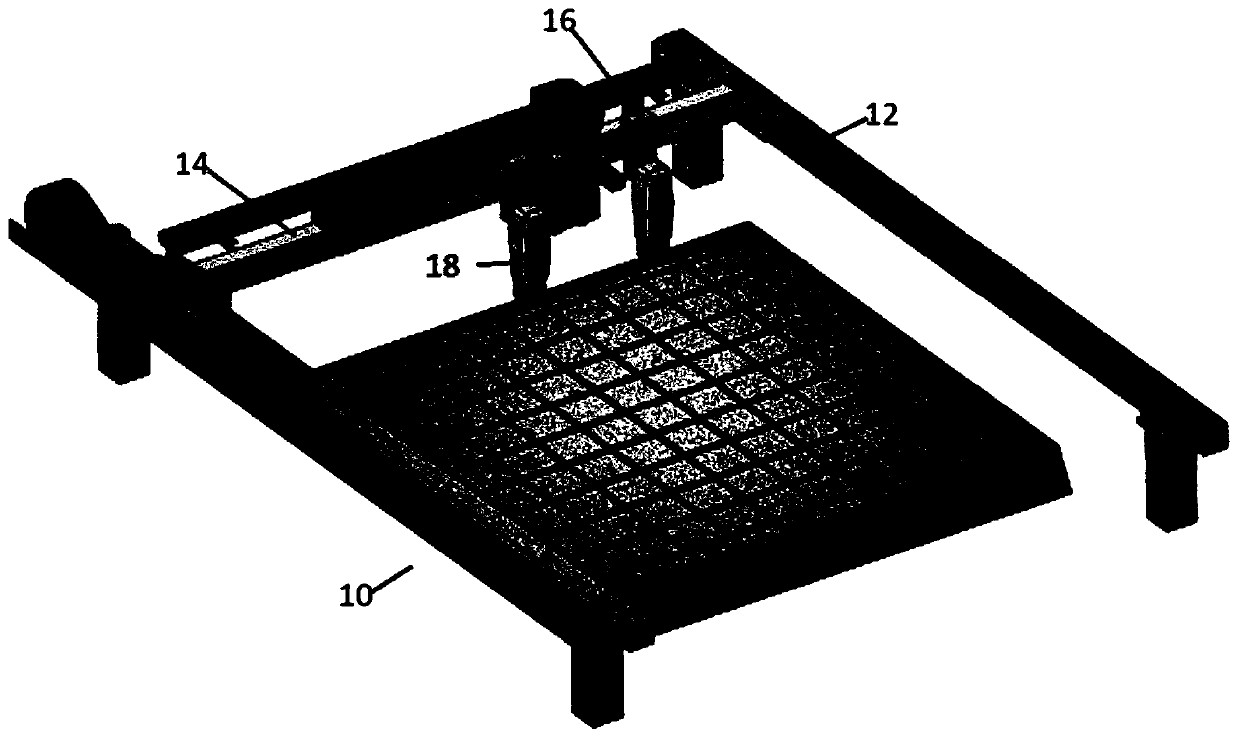

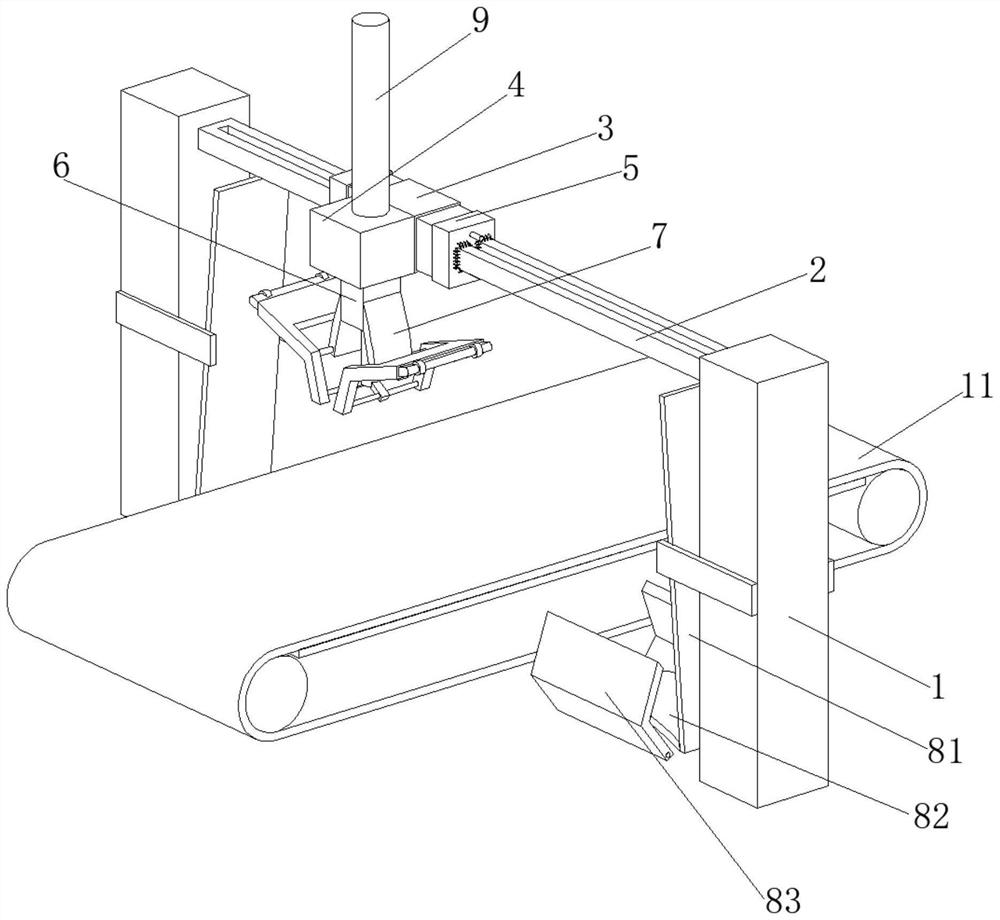

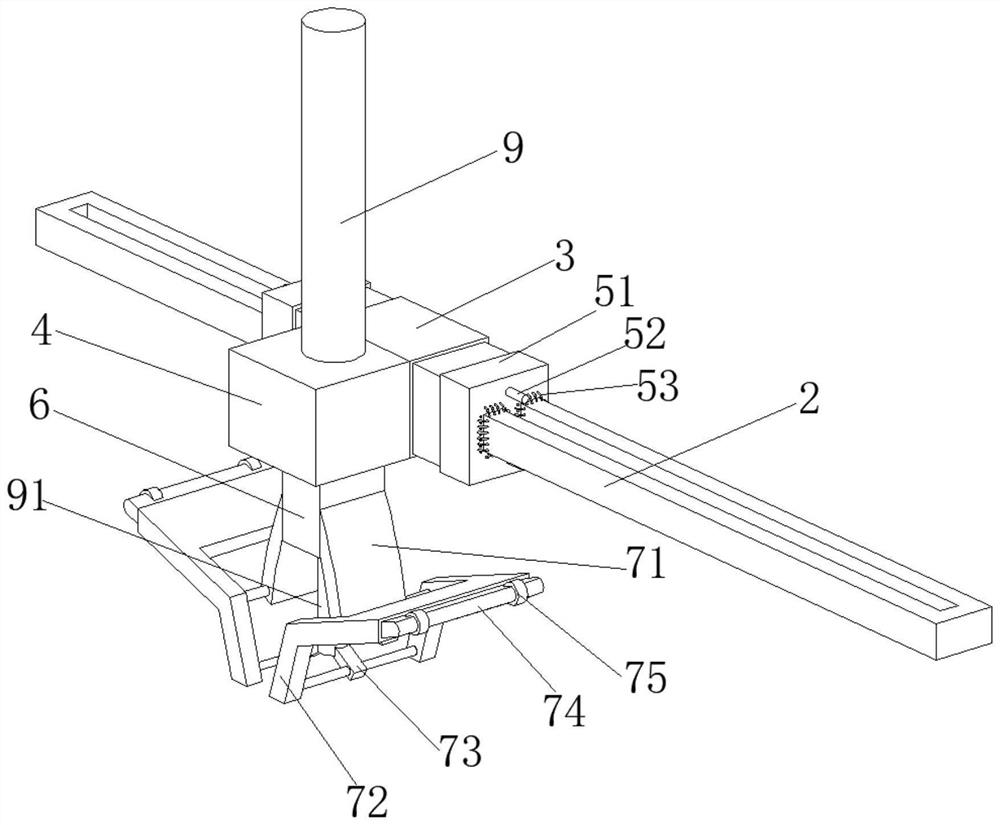

Steel bar joint identification using artificial intelligence vision

PendingCN110956230ACo-operative working arrangementsBuilding material handlingPattern recognitionAlgorithm

An apparatus or system for rebar (bar) contact identification using artificial intelligence vision includes a rebar tying tool connected to a micromanipulator; a macro manipulator which is used for moving the position of the micro manipulator, wherein the macro manipulator is adapted to move the micro manipulator on a first plane, and the micromanipulator is adapted to move the rebar tying tool ona second plane parallel to the first plane and on a first axis perpendicular to the second plane.

Owner:LOGISTICS & SUPPLY CHAIN MULTITECH R&D CENT LTD

Micro manipulator for movement of electrode, driving method thereof, and measuring device of brain signal using the same

ActiveUS7466063B2Precise positioningHigh range resolutionHead electrodesPiezoelectric/electrostriction/magnetostriction machinesElectricityMeasurement device

A micro manipulator for electrode movement, a driving method thereof, and a brain signal measuring device using the same are provided. The micro manipulator has a guide member having a rectangular hollow hole therein, first and second piezo-electric clamp bodies installed perpendicular to the movement direction of the electrode between the inner opposite sides in the hollow hole of the guide member such that respective both ends thereof are selectively fixed to or separated from the inner sides of the hollow hole depending upon whether of the application of electric power thereto, a drive piezo-electric body whose both ends are connected to the opposite faces, respectively, of the first and second clamp piezo-electric bodies to selectively expand or contract in parallel with the movement direction of the electrode depending upon whether of the application of electric power thereto, and an electrode holder holding therein the electrode and installed on the first or second clamp piezo-electric body in parallel with the expansion or contraction direction of the drive piezo-electric body.

Owner:KOREA INST OF SCI & TECH

Micro-manipulator

InactiveUS7631913B2Optimization mechanismReduce the overall diameterMicromanipulatorMicroscopesEngineeringActuator

A micro-manipulator has a handling mechanism for gripping micro-material with two gripping fingers. The handling mechanism has a fixed finger with an end effecter for touching the micro-material, a movable finger with an end effecter capable of rotating around a rocking shaft for touching the micro-material, and an actuator for rotating the movable finger. The actuator drive moves the movable finger so as to be capable of touching a leading end of the movable finger end effecter to a leading end of the fixed finger end effecter. The micro-manipulator can securely and quickly grip a micro-material in a microscope visual field.

Owner:NISCA KK

Miniature manipulator for logistics express carrying

PendingCN114455318APrevent slippingReduce frictionConveyorsCleaningAdhesive beltLogistics management

The invention relates to the technical field of manipulators, and discloses a micro manipulator for logistics express carrying, which comprises a manipulator body, the manipulator body comprises a slide rail, a linear motor, a fixed block, a support block, a clamping device, a cylinder and a push rod, the clamping device comprises a transmission plate, and the transmission plate is provided with a transmission shaft. The sides, away from the supporting blocks, of the transmission plates are rotationally connected with clamping plates through connecting rods, the ends, away from the air cylinders, of the push rods are rotationally connected with transmission rods, the inner walls of the clamping plates are slidably connected with sliding plates, the sides, away from the clamping plates, of the sliding plates are rotationally connected with rolling wheels, and the inner walls of the clamping plates are slidably connected with moving plates. The ejector pins in the push rod clamping device can be inserted into an adhesive tape to fix an express item, the situation that dust falls on the express item, consequently, the surface friction force of the express item is reduced can be prevented, and the express item is prevented from sliding off during clamping.

Owner:汪子辉

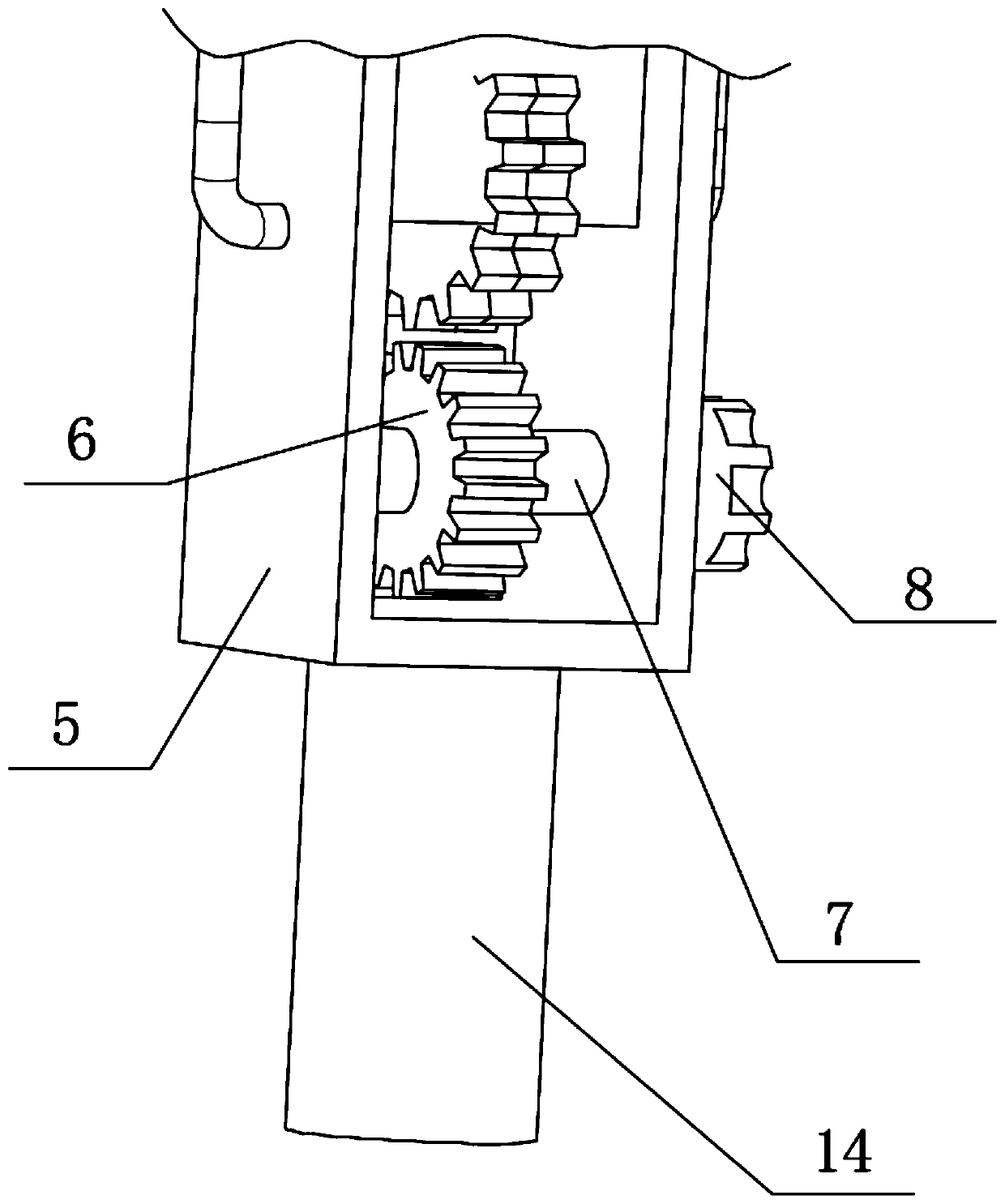

Manual three-freedom-degree micro manipulator for minimally invasive surgery

InactiveCN110680413AAccurate clampingEasy to useSurgical manipulatorsSurgical robotsRotational axisGear wheel

The invention discloses a manual three-freedom-degree micro manipulator for minimally invasive surgery. The manual three-freedom-degree micro manipulator for minimally invasive surgery comprises a fixing block and a connecting frame, wherein the same rotating shaft which is horizontally arranged is rotatably connected to the tops of the inner walls on two sides of the connecting frame; a connecting block is connected to the outer wall of the periphery of the rotating shaft in a sleeving manner; the outer wall of the top of the connecting block is fixedly connected with the outer wall of the bottom of the fixing block; the same first connecting shaft which is horizontally arranged is rotatably connected to the bottoms of the inner walls on two sides of the connecting frame; a driving gear is connected to the periphery outer wall of the first connecting shaft in a sleeving manner; a driven gear is mounted on the outer wall of the bottom of the connecting block; and the driven gear is meshed with the driving gear. According to the manual three-freedom-degree micro manipulator for minimally invasive surgery disclosed by the invention, the connecting block, the driven gear, the connecting frame and the driving gear are arranged, so that the fixing block on the connecting block can be driven to move in a front and rear manner, the moving range of the manipulator is enlarged, and theworking efficiency is improved; and the connecting rod is arranged, so that rotation of the fixing block on the connecting block can be more stable, and the using safety of the manipulator is improved.

Owner:北京明宣生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com