Steel bar joint identification using artificial intelligence vision

A technology of artificial intelligence and steel bars, applied in the direction of collaborative operation devices, construction material processing, instruments, etc., can solve problems such as high physical requirements, increased risk of injury, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

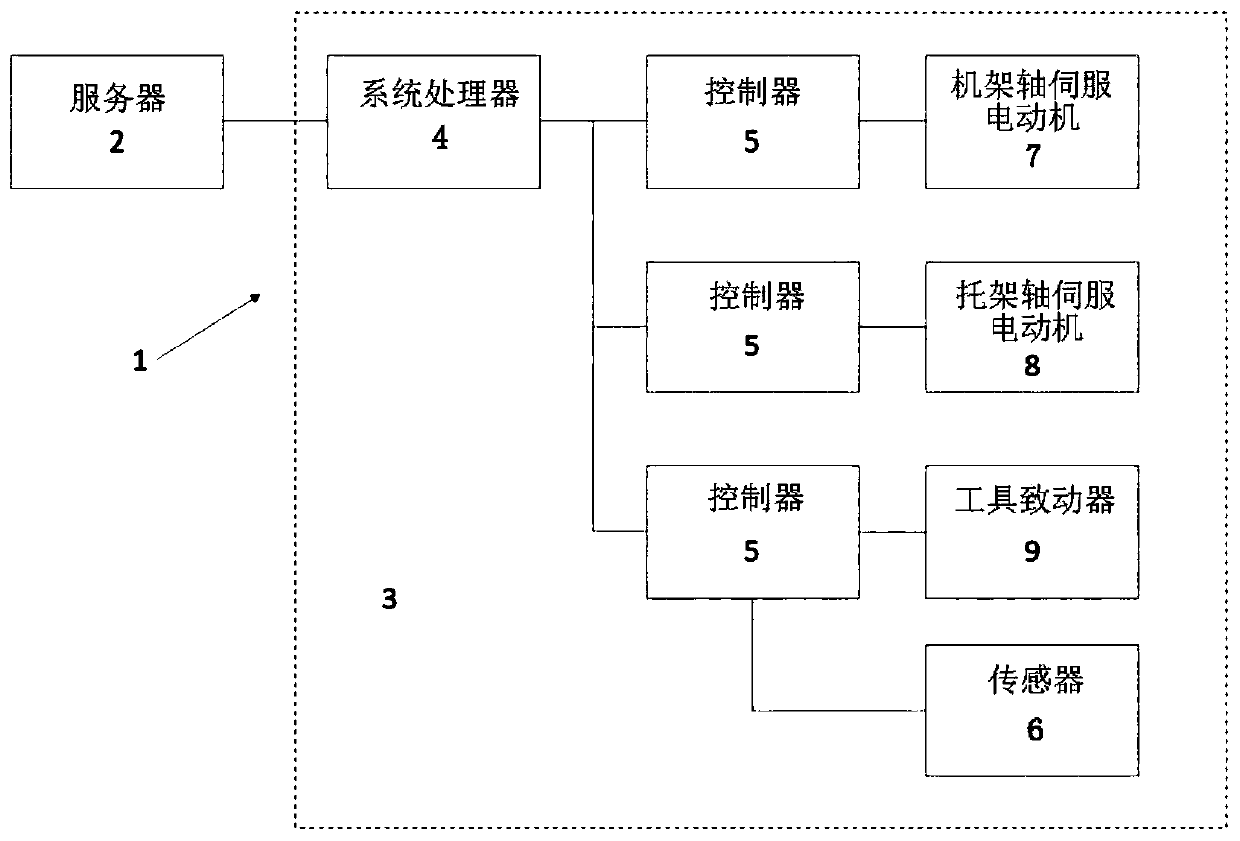

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

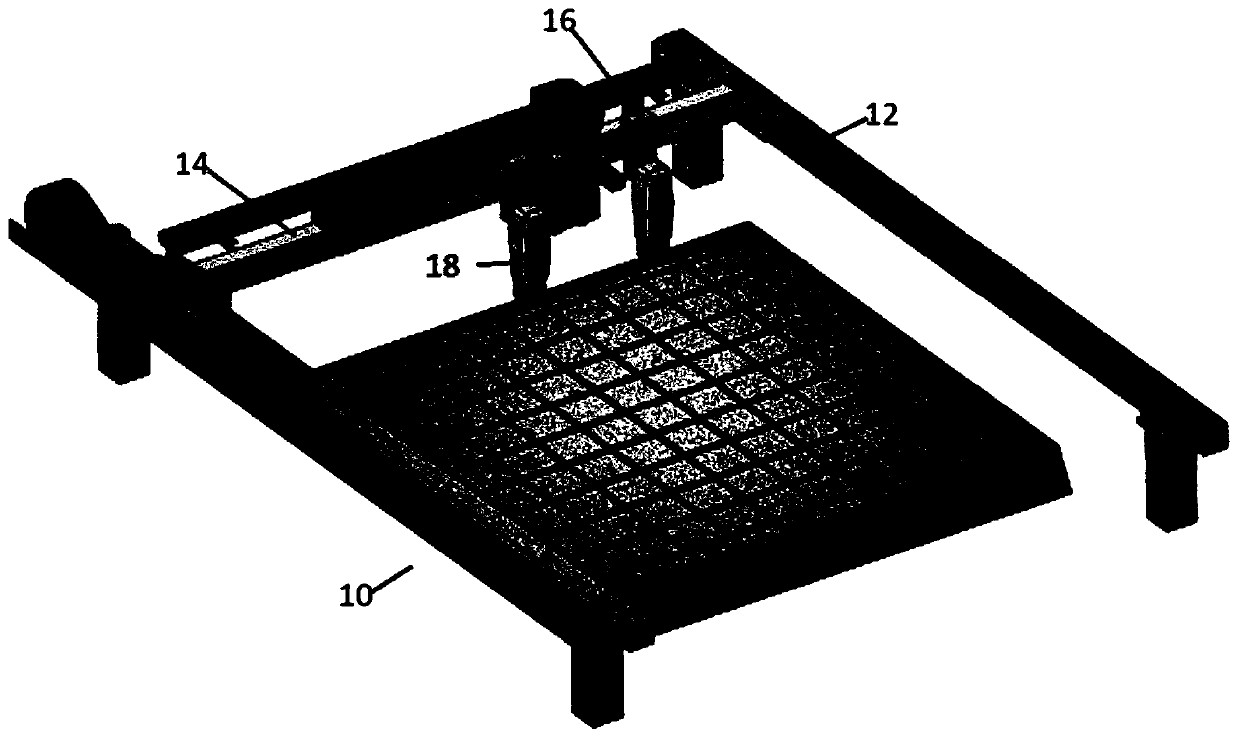

[0035] The inventors, through their own research, trials and experiments, have devised a routine that can use robotic tools to assist in the rebar binding process.

[0036] In one exemplary embodiment, an apparatus may be used to bundle longitudinal and transverse pavement rebar in a rectangular arrangement. The device may consist of a self-propelled frame assembly. The self-propelled frame assembly includes means for lifting each individual bar of the longitudinally aligned bars and for periodically placing the transverse bars in a plurality of binding straps disposed at selected intersections of the longitudinal and transverse bars Tied with raised transverse reinforcement. The self-propelled frame also includes means arranged transversely for supporting a plurality of longitudinal rebars and inserting transverse rebars underneath to receive the strapping; The frame assembly is intermittently driven on the frame to effect binding on every other longitudinal bar. The next ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com