Device and method for measuring backscattering of laser gyroscope ultra-smooth reflecting mirror

A technology of backscattering and laser gyroscope, applied in the field of laser gyroscope, can solve the problems of reducing the blocking threshold of laser gyroscope, not very effective, etc., and achieve the effect of convenient operation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below by means of specific embodiments:

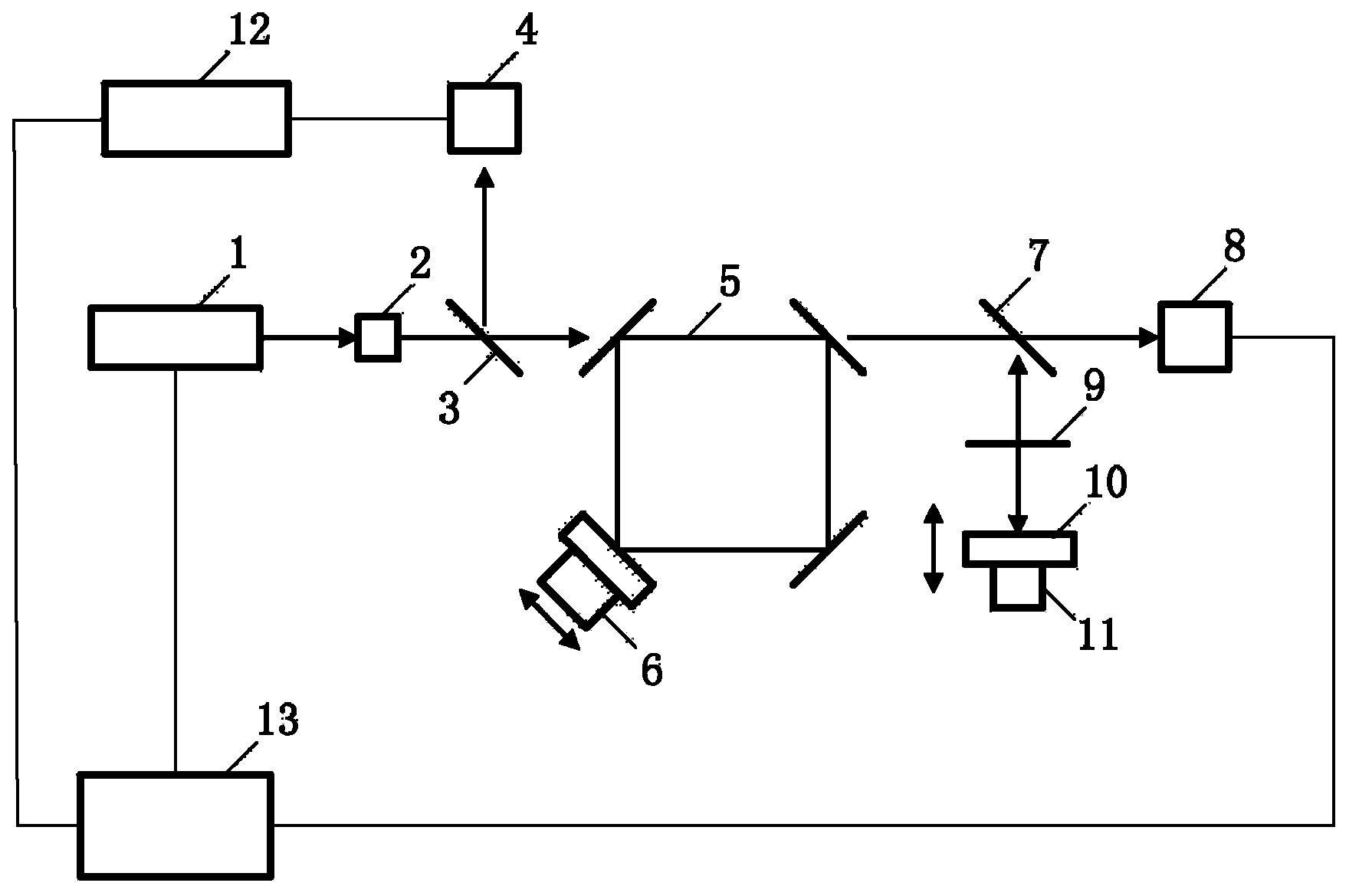

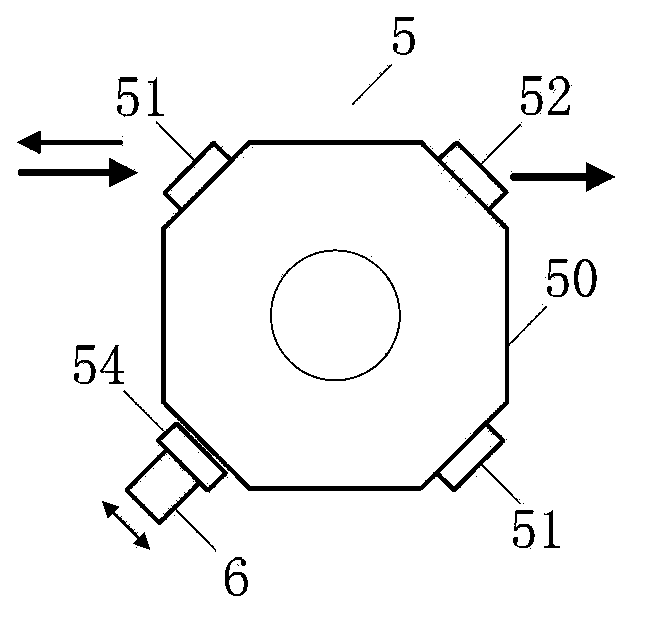

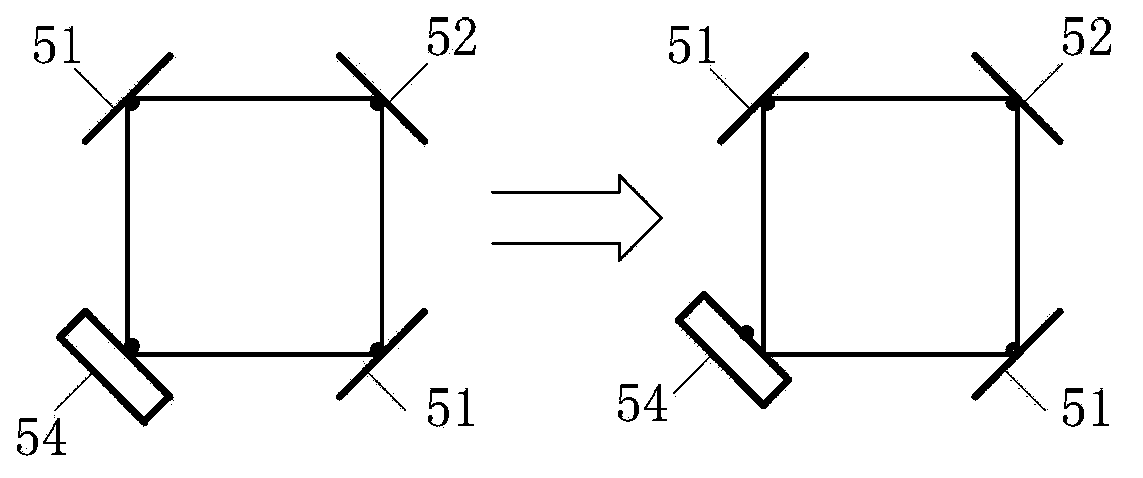

[0032] see figure 1 , which is a schematic diagram of the principle of a preferred embodiment of the laser gyro ultra-smooth mirror backscatter measurement device of the present invention. In this embodiment, the laser gyro ultra-smooth mirror backscatter measurement device includes a He-Ne laser 1, a Faraday optical isolator 2, a beam splitter A3, a photodetector A4, a ring resonator 5, and a micromanipulator A6 , beam splitter B7, photodetector B8, optical filter 9, feedback mirror 10, micromanipulator B11, lock-in amplifier 12, frequency stabilization system 13. Among them, the output beam of He-Ne laser 1 is incident into Faraday optical isolator 2, beam splitter A3, ring resonator 5, and beam splitter B7 in sequence; the outgoing light of beam splitter B7 is divided into two beams, and one beam is incident into The photodetector B8, another beam is incident on the optical fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com