Symmetric spatial three-dimensional micro manipulator with three-stage motion amplifying mechanism

A three-dimensional, micro-manipulator technology, applied in the field of micro-nano robots, can solve problems such as limiting the application range of micro-manipulation robots and increasing the difficulty of manipulator motion control, achieving the effects of compact structure, improved motion accuracy, and reduced parasitic displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

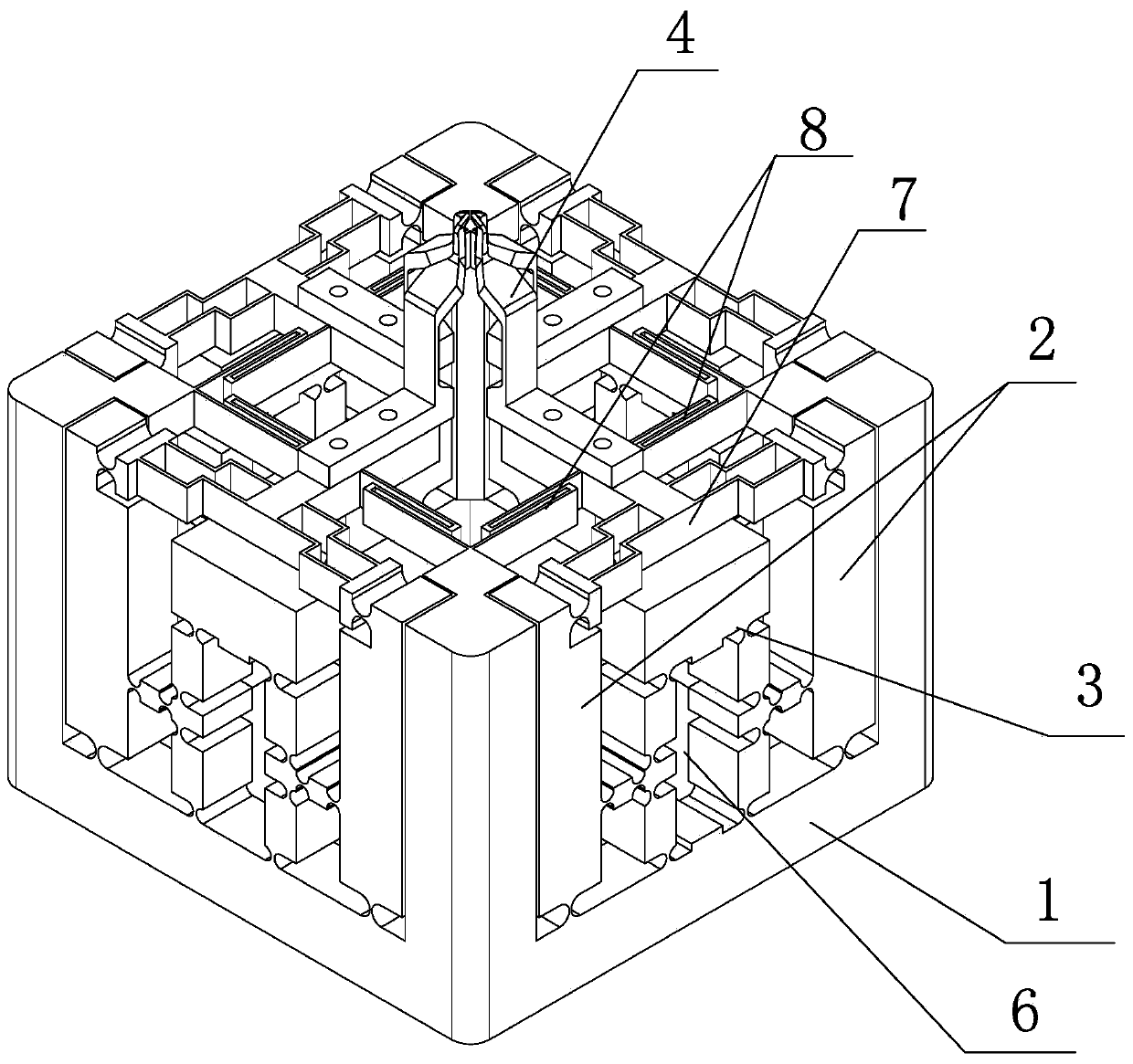

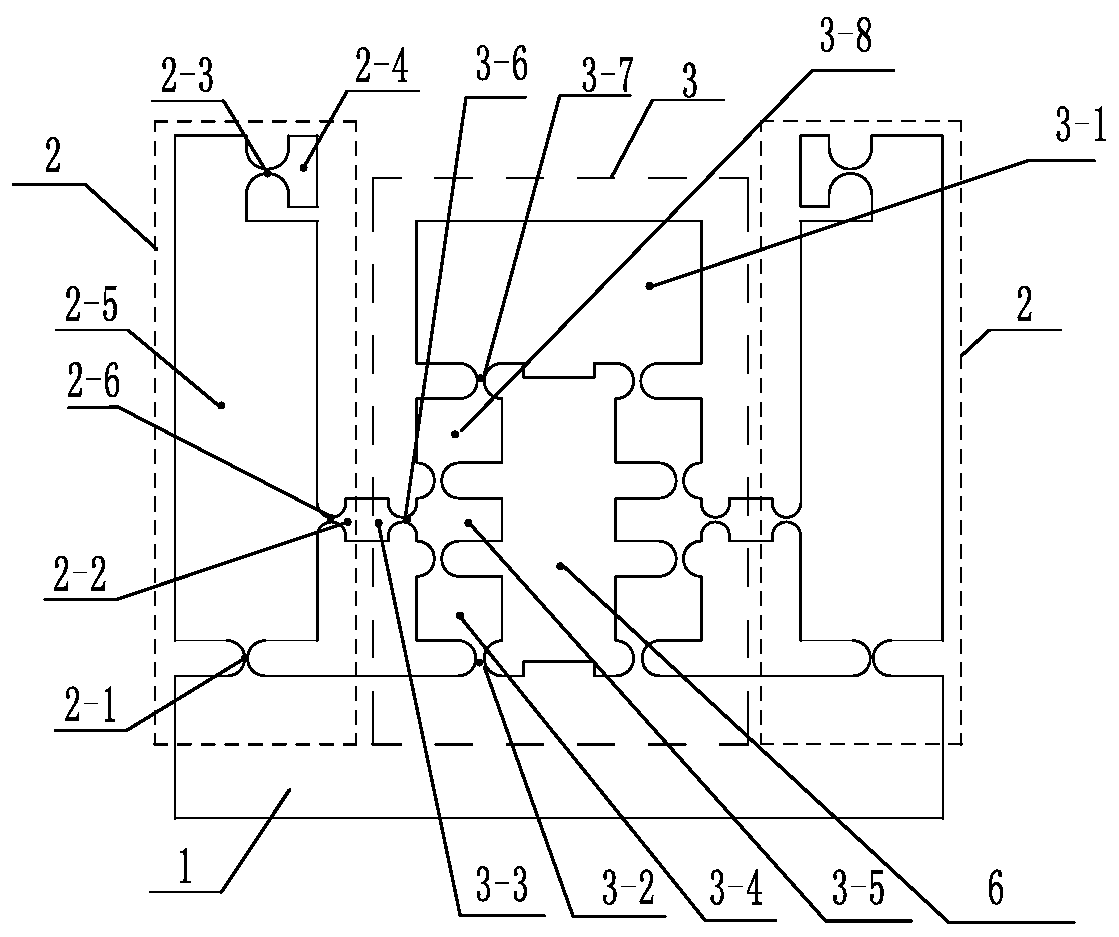

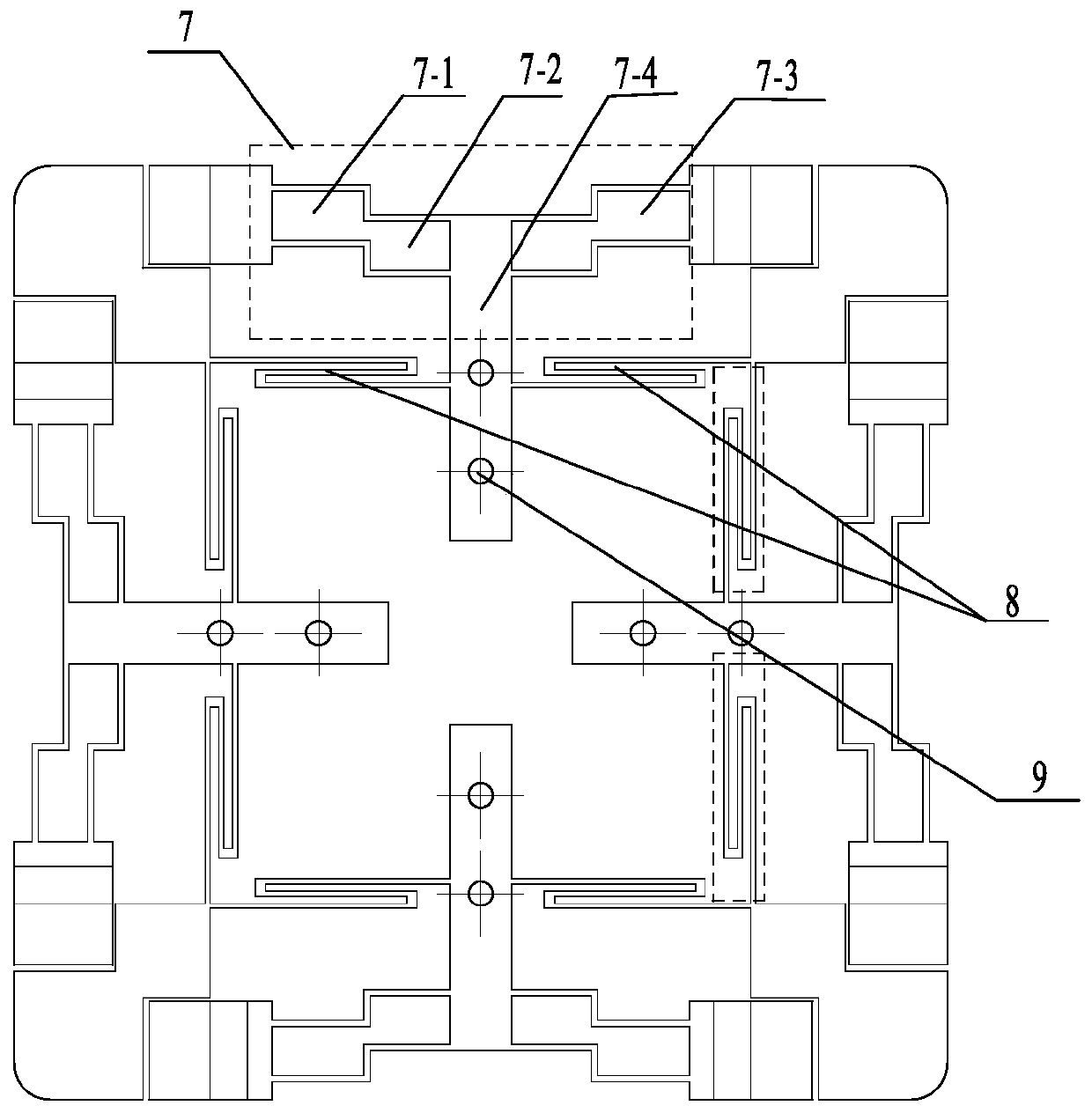

[0029] The structure diagram of the symmetrical three-dimensional micro-manipulator with three-stage motion amplification mechanism of the present invention is as follows: Figure 1-Figure 5 As shown, it consists of a base 1 and a plurality of enlarged clamping modules, and the number of enlarged clamping modules can be determined according to the needs of use. figure 1 It is a structural schematic diagram of an embodiment with four enlarged clamping modules. Each amplifying clamping module includes a piezoelectric ceramic driver 6 , a bridge-type displacement amplifying mechanism 3 , two lever displacement amplifying mechanisms 2 , a Z-beam displacement amplifying mechanism 7 , two flexible guide mechanisms 8 and clamping jaws 4 . The two lever displacement amplifying mechanisms 2 are symmetrically arranged on both sides of the bridge type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com