Patents

Literature

31results about How to "Simplify motion path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

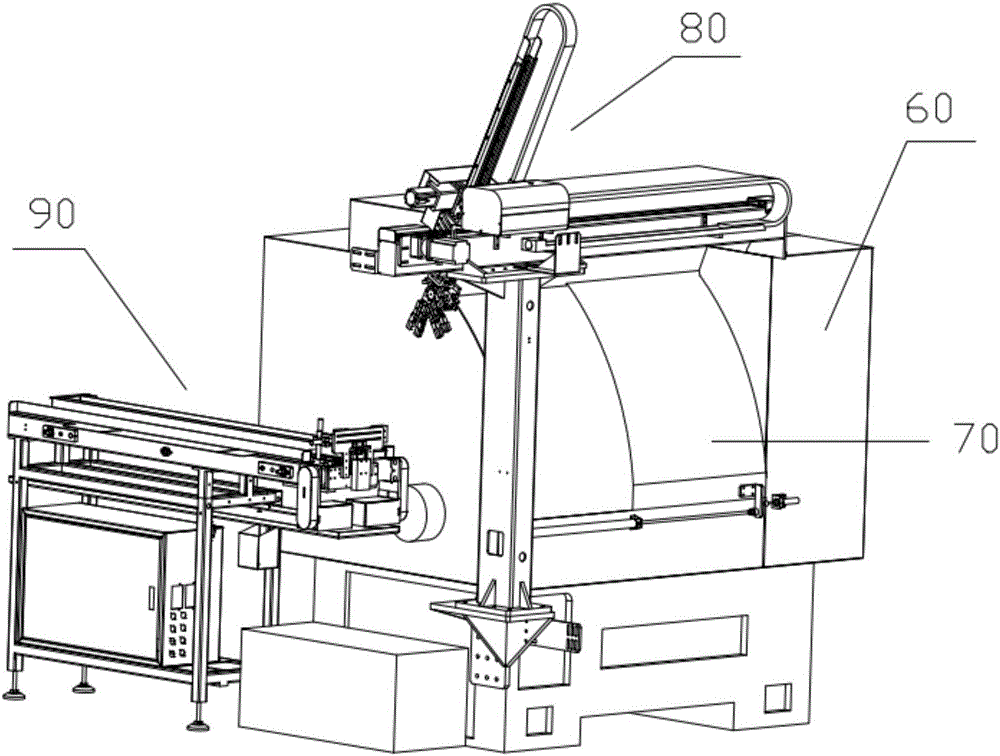

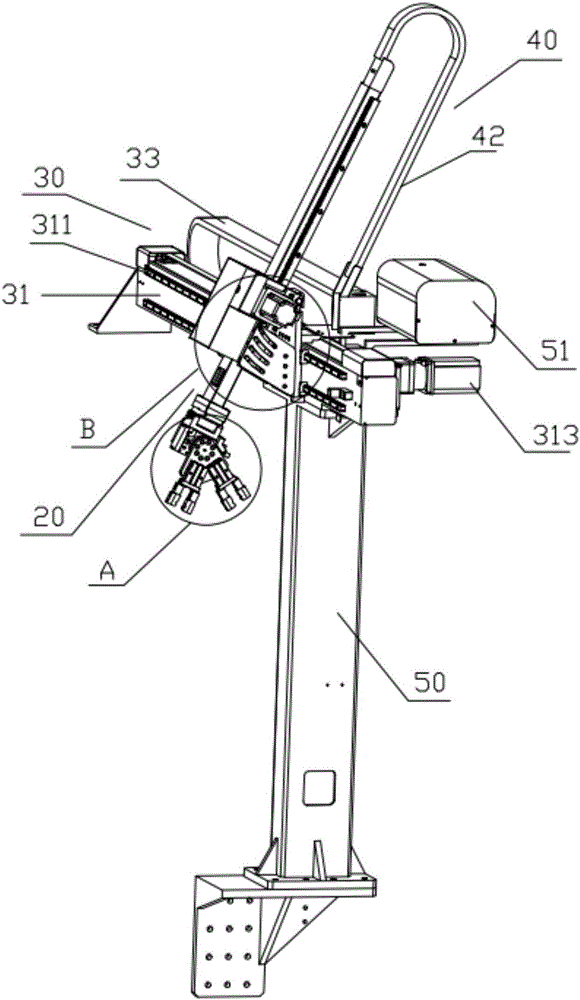

CNC (computer numerical control) machine tool

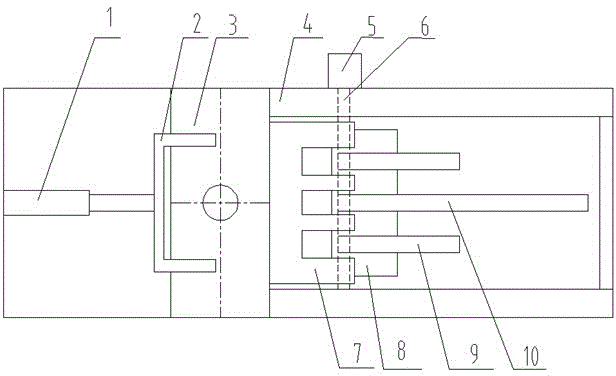

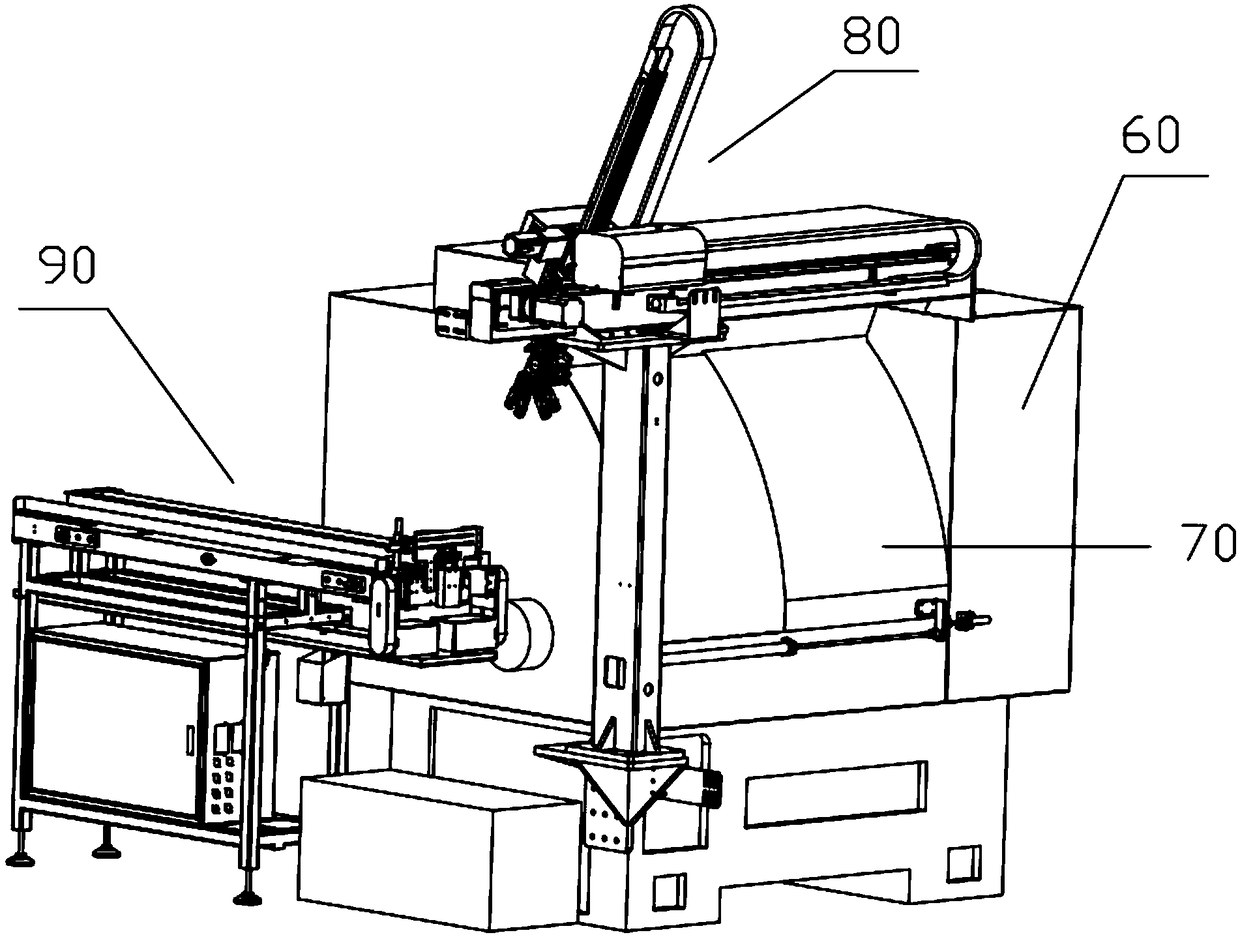

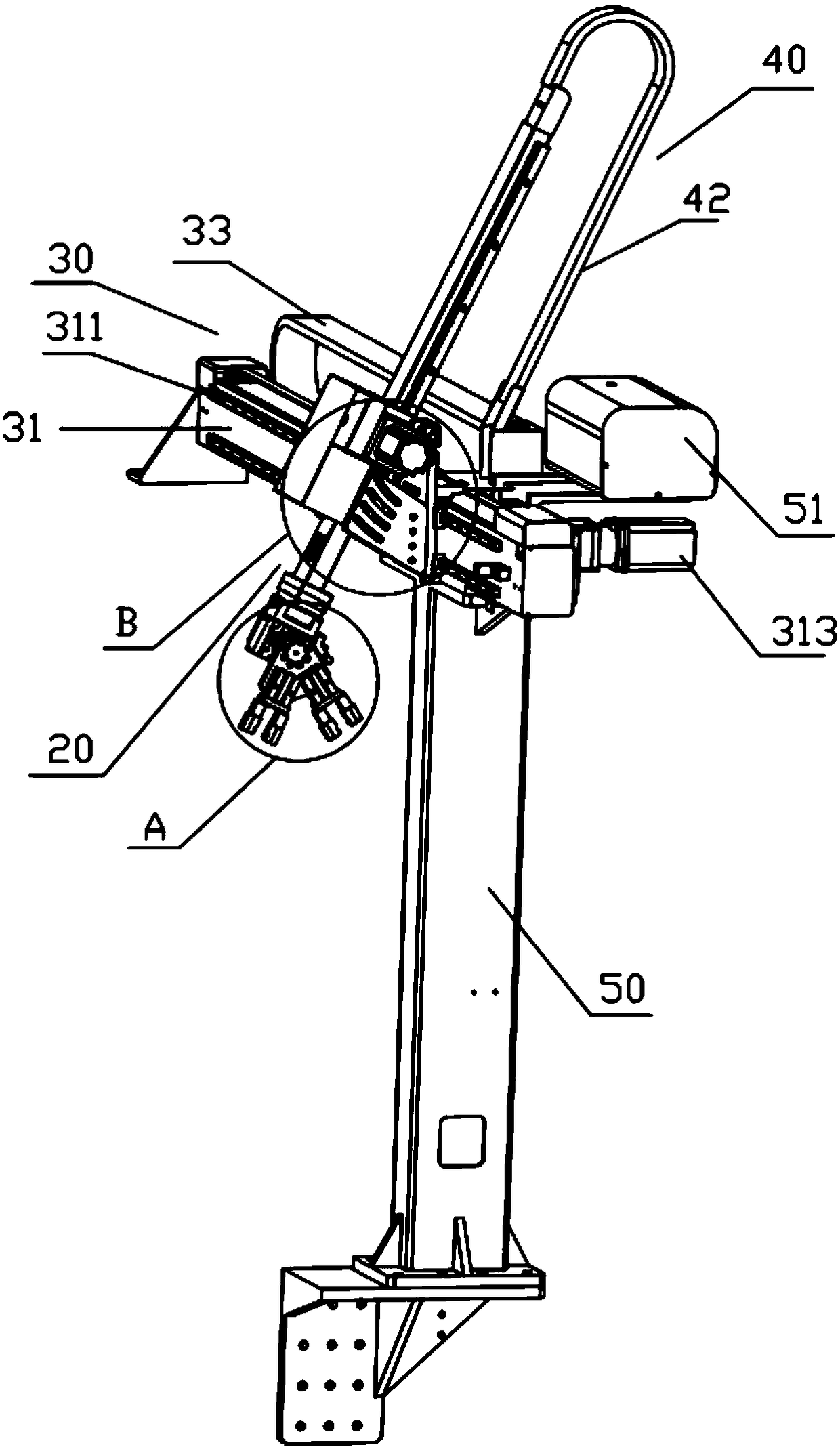

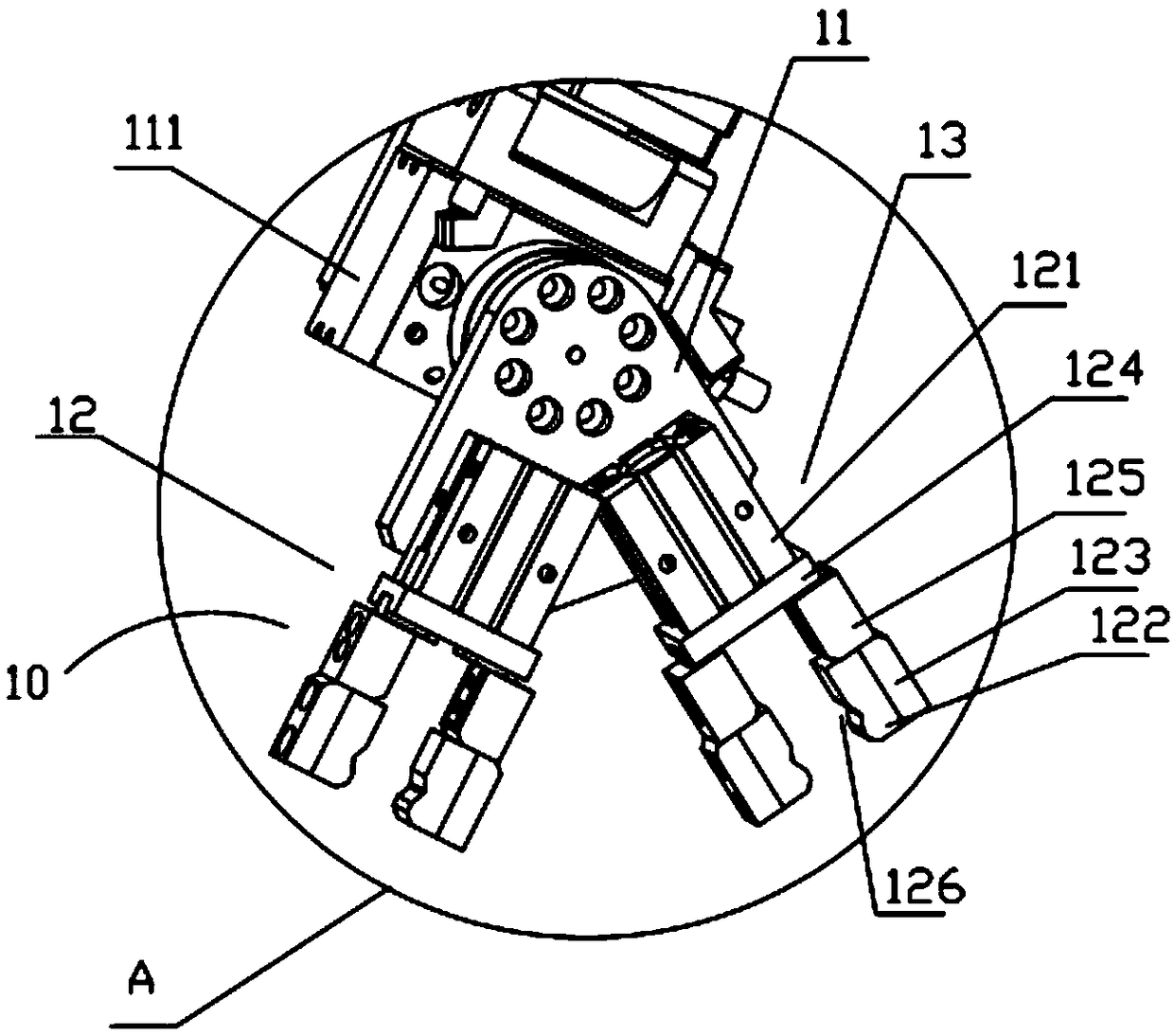

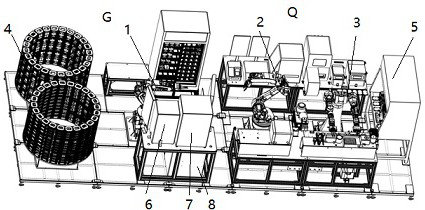

ActiveCN106363448AHigh degree of automationReduce labor costsProgramme-controlled manipulatorGripping headsManipulatorMachine tool

The invention discloses a CNC (computer numerical control) machine tool, which comprises a machine tool body and a protection door arranged on the machine tool body. The CNC machine tool is characterized by also comprising a material taking system, wherein the material taking system comprises a mechanical hand device and a material cabin; the mechanical hand device is arranged in front of the protection door and is used for feeding and material taking; the material cabin is arranged at one side of the machine tool body and is sued for putting and conveying processing parts. The CNC machine tool has the advantages that the structure is simple; the automation degree is high; the feeding and material taking of the processing parts can be automatically performed.

Owner:广州市新滘热处理厂

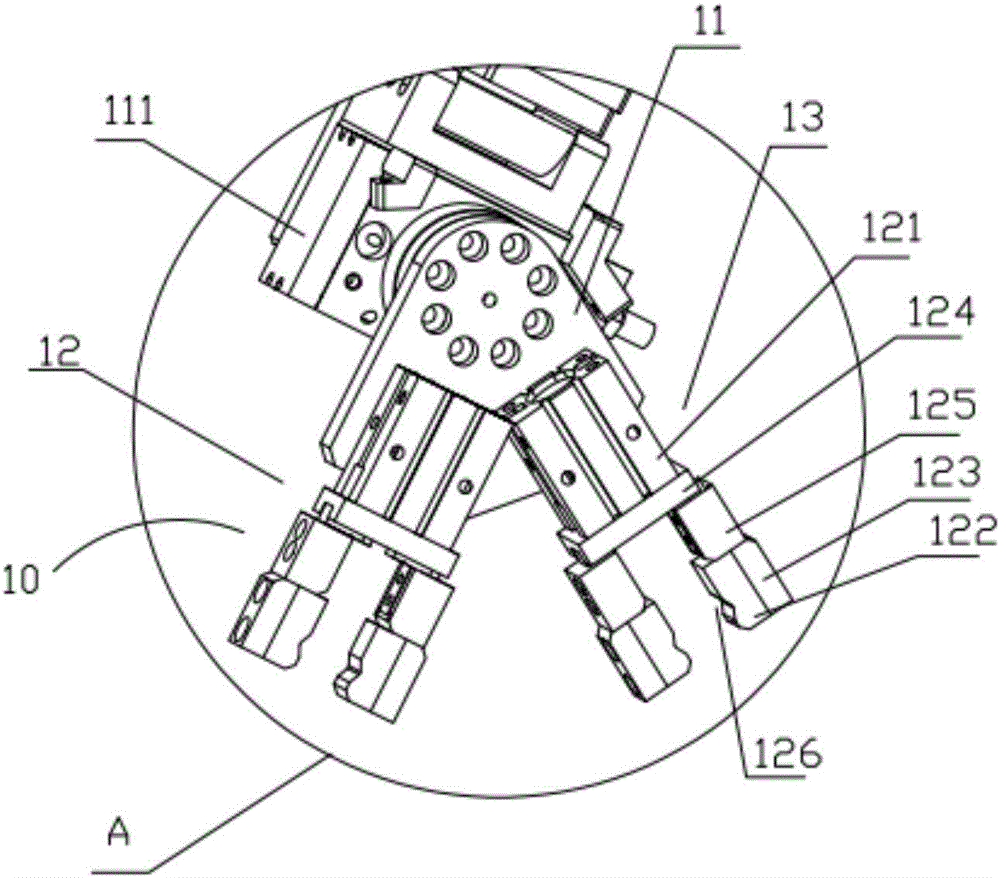

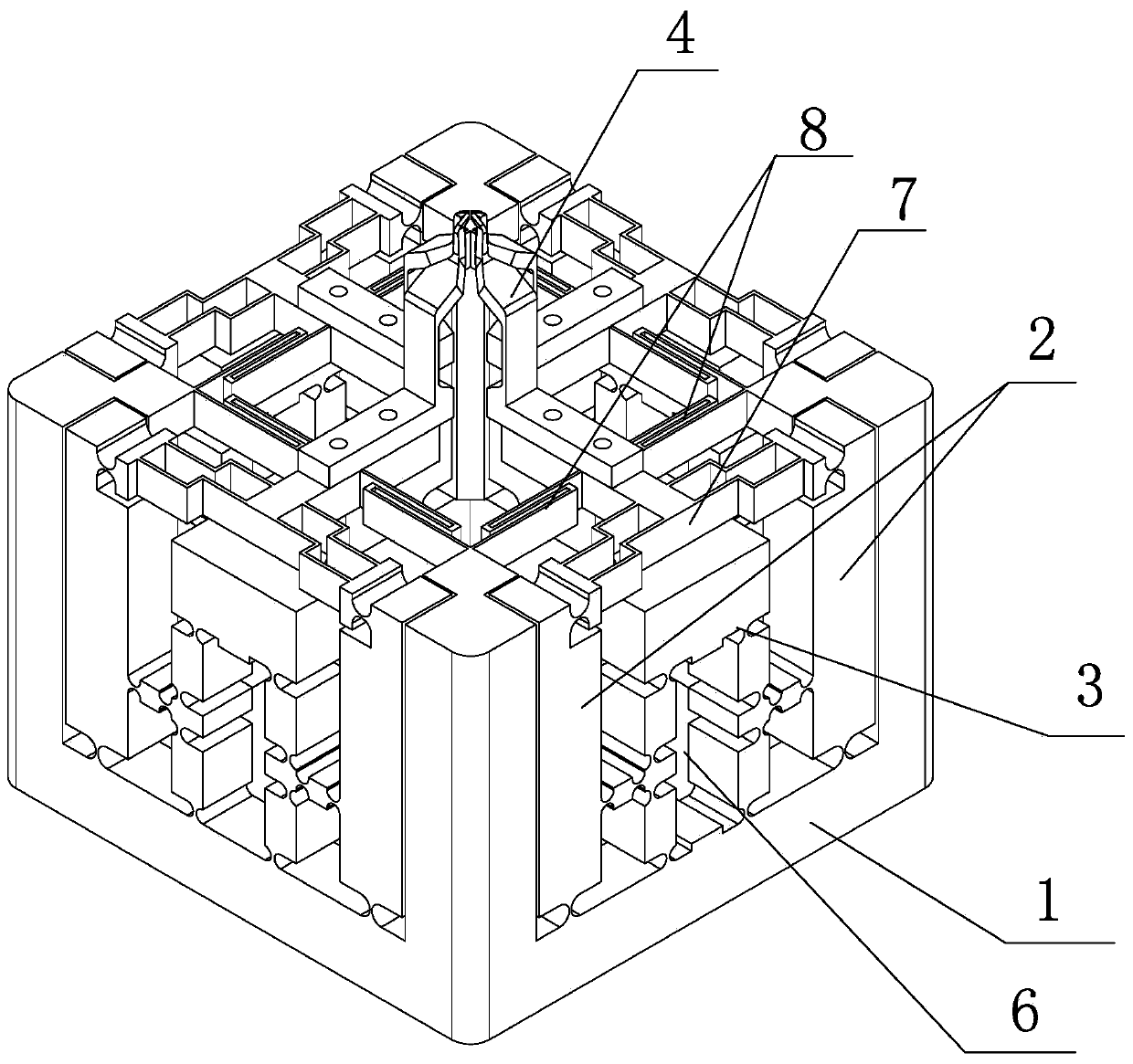

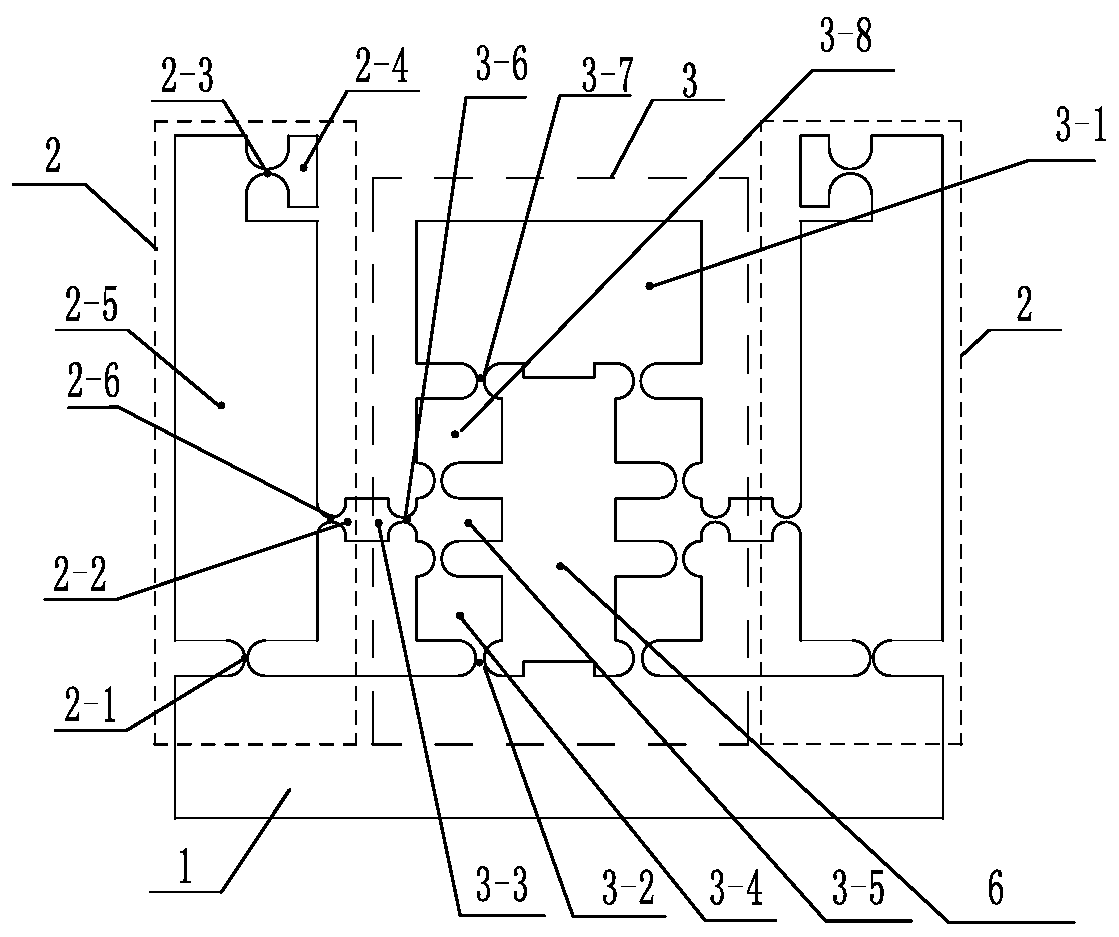

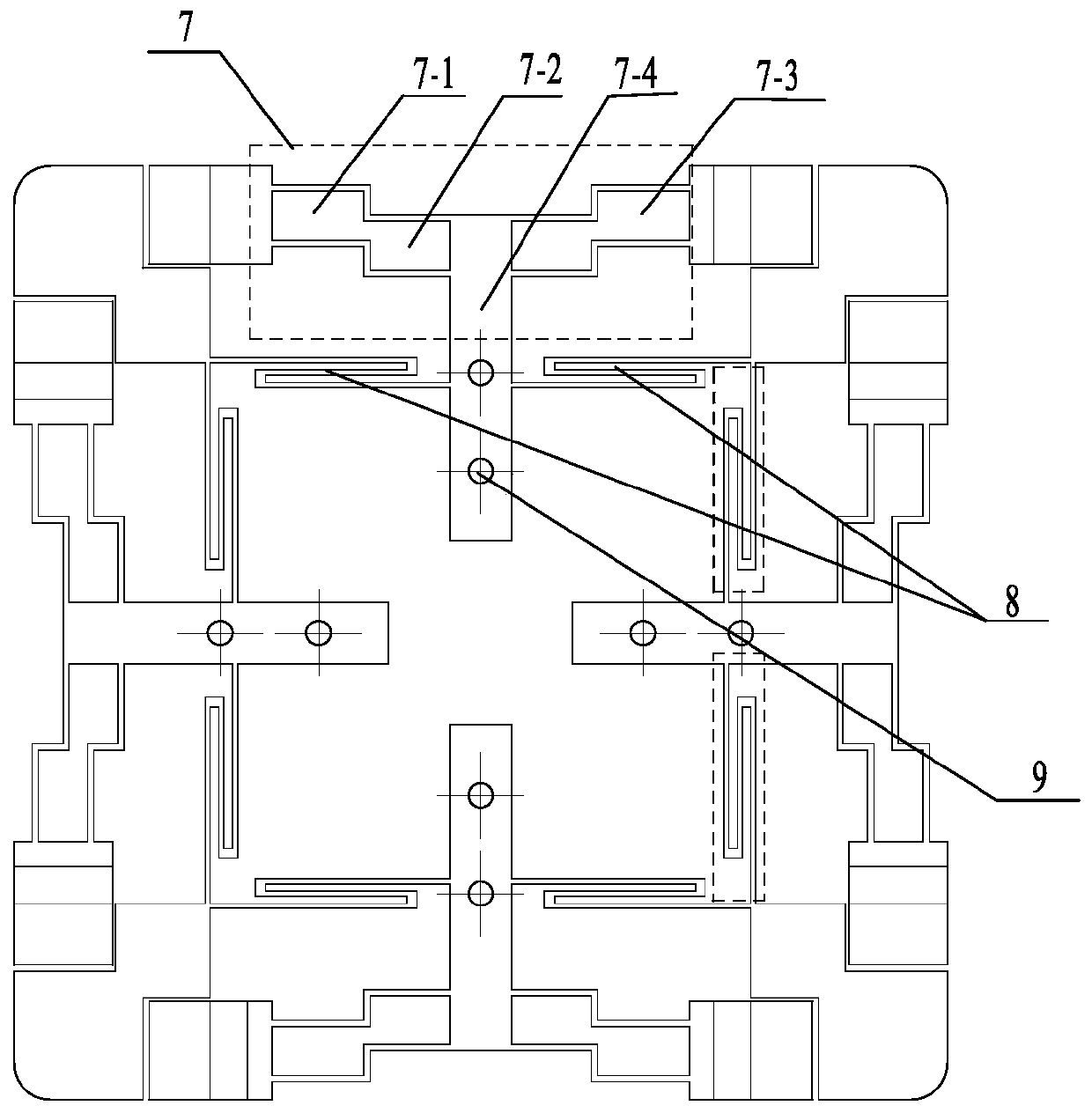

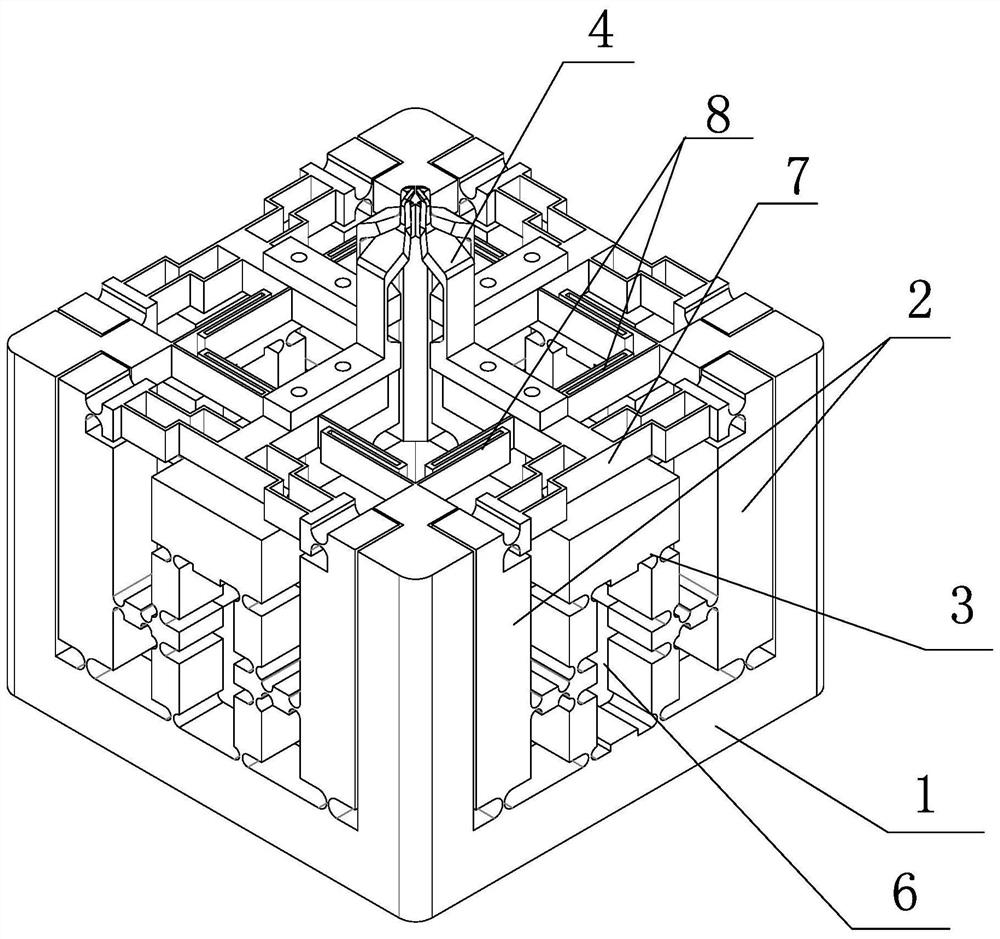

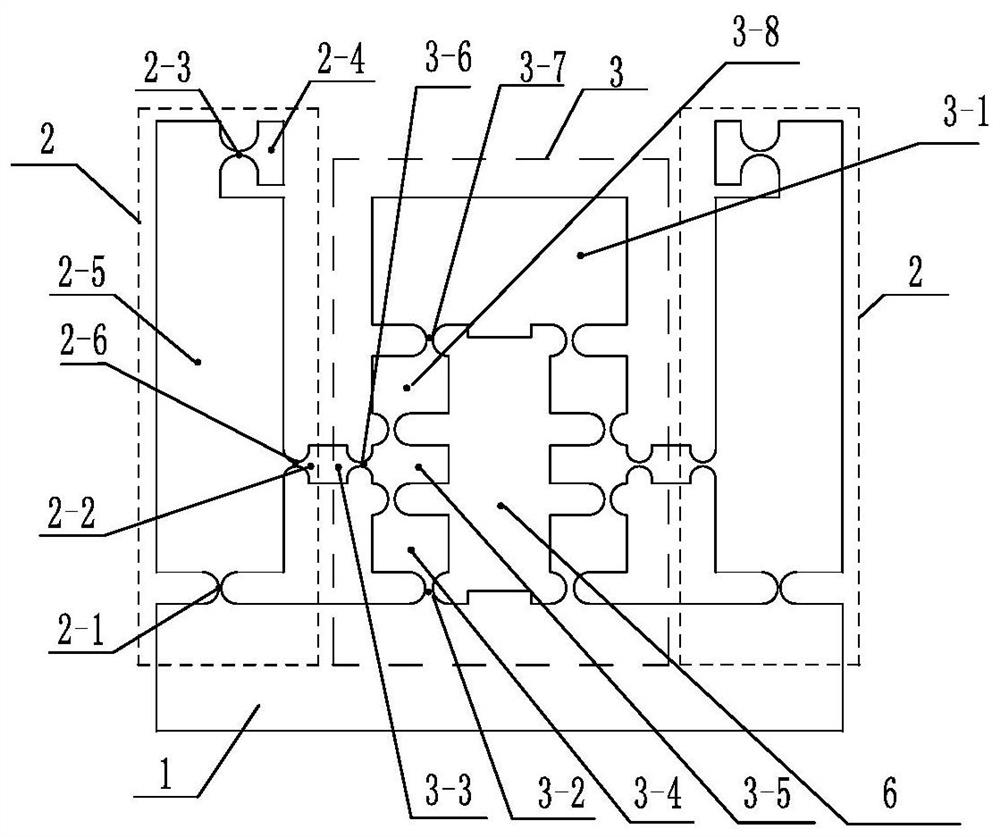

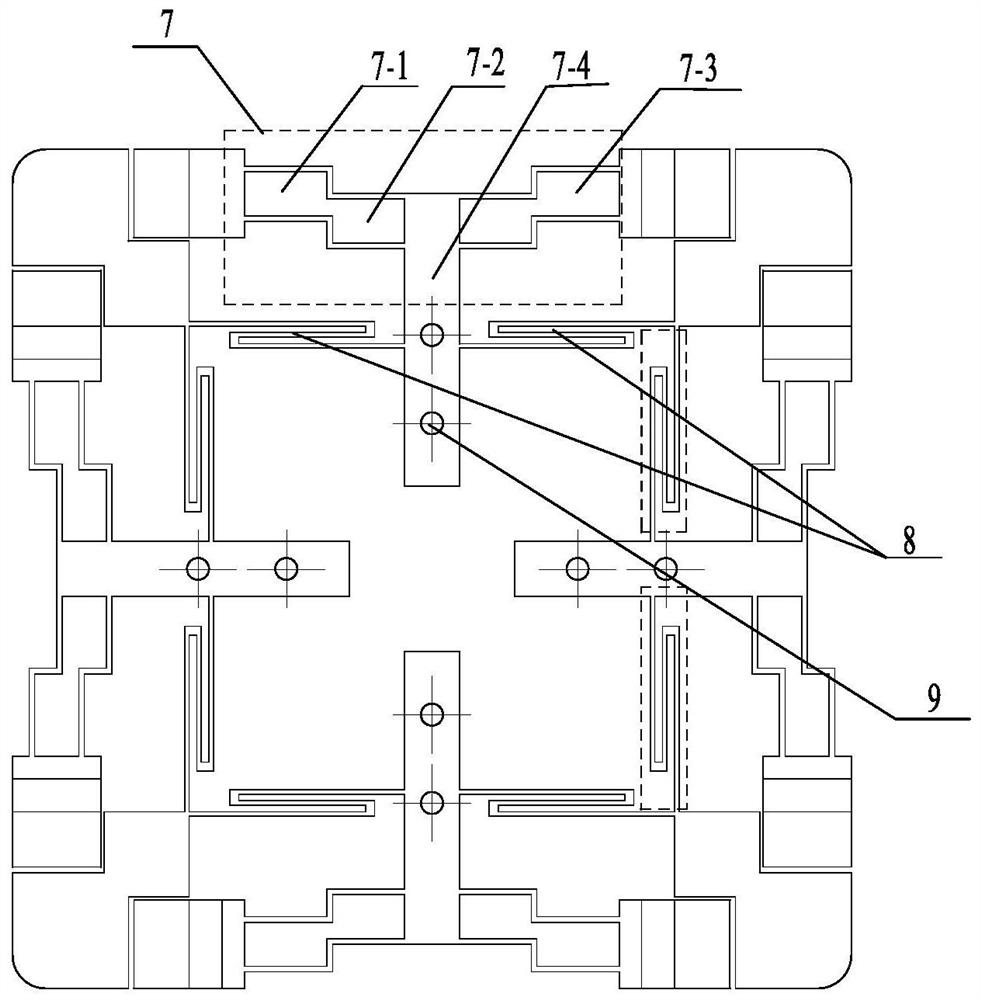

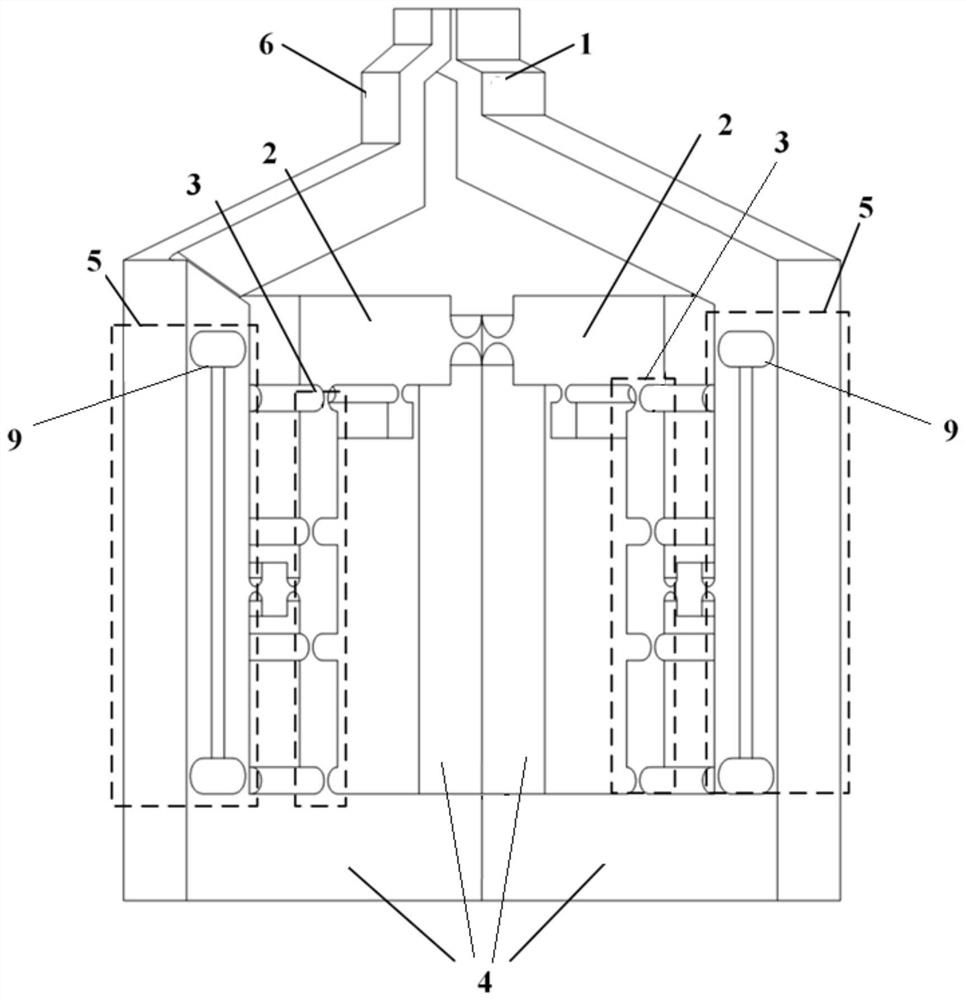

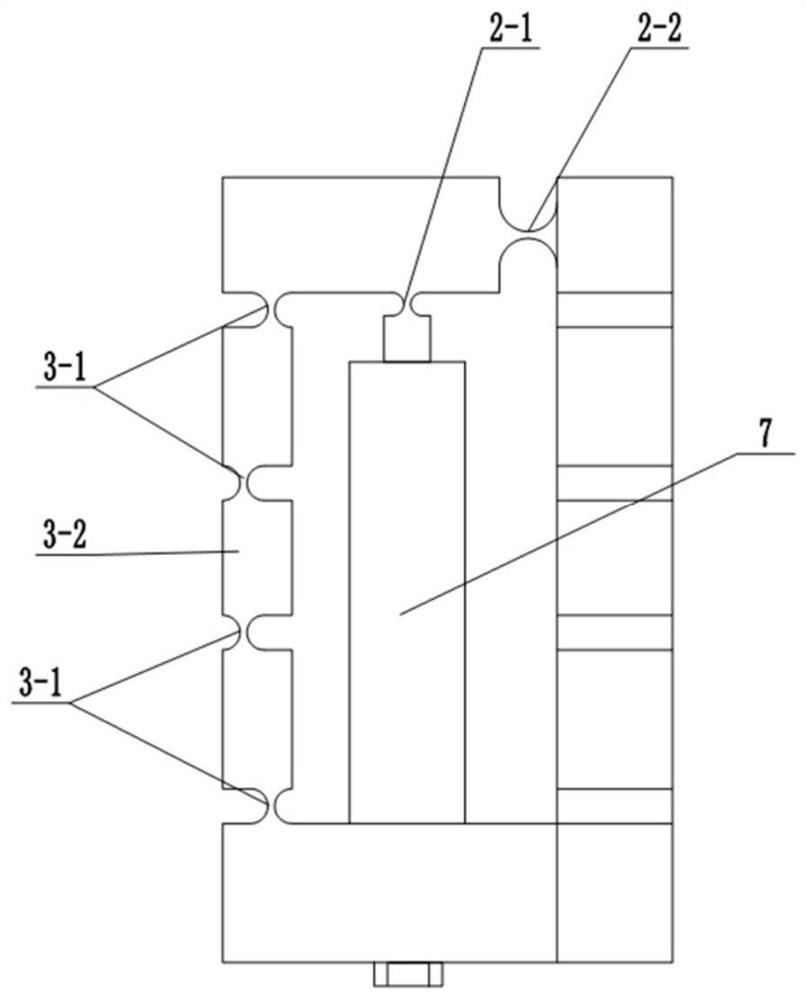

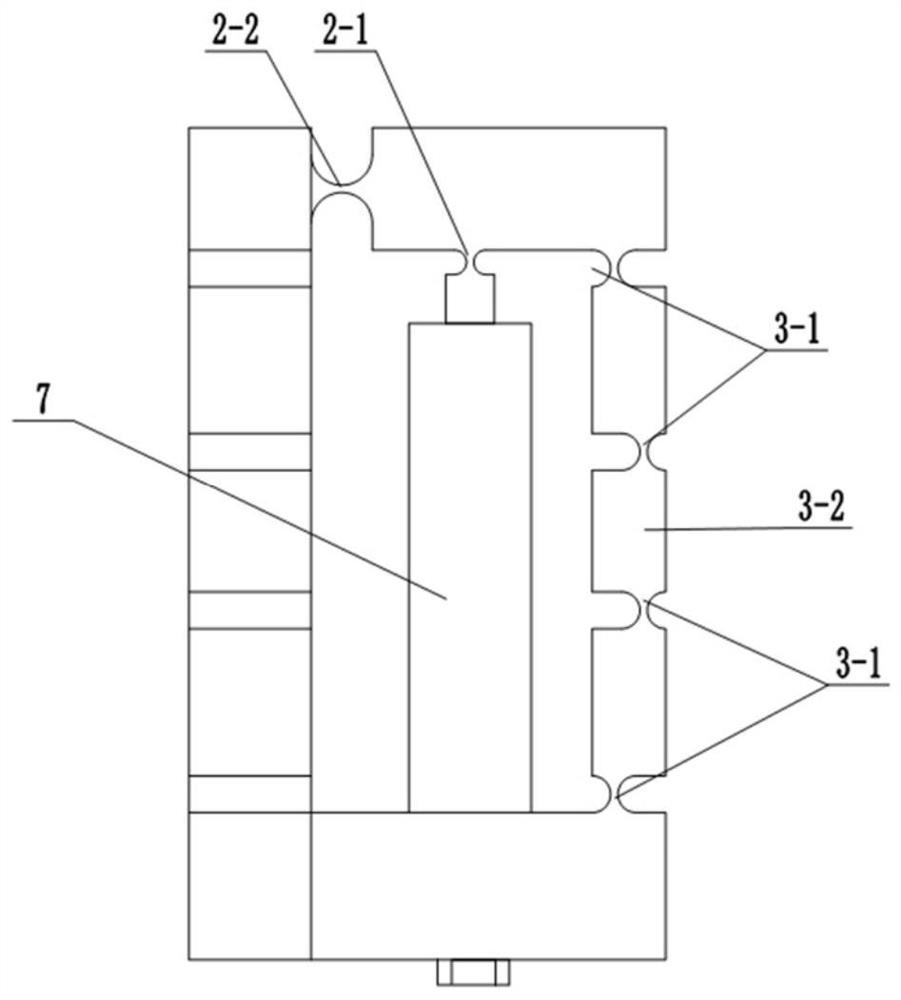

Symmetric spatial three-dimensional micro manipulator with three-stage motion amplifying mechanism

ActiveCN109909976AFirmly connectedActive releaseProgramme-controlled manipulatorGripping headsShaped beamThree stage

The invention discloses a symmetric spatial three-dimensional micro manipulator with a three-stage motion amplifying mechanism. The micro manipulator is small in size, compact in structure, stable andreliable in clamping force and high in movement precision. The micro manipulator is composed of a base and a plurality of amplification clamping modules, wherein each amplification clamping module comprises a piezoelectric ceramic driver, a bridge type displacement amplification mechanism, two lever displacement amplification mechanisms, a Z-shaped beam displacement amplification mechanism, two flexible guide mechanisms and a clamping jaw; the piezoelectric ceramic driver is arranged between the base and the movable end of the bridge type displacement amplification mechanism; and the piezoelectric ceramic driver drives the movable end of the bridge type displacement amplification mechanism, the output end of the bridge type displacement amplification mechanism drives the input ends of thelever displacement amplification mechanisms, the output end of each lever displacement amplification mechanism drives the input end of the Z-shaped beam displacement amplification mechanism, and theoutput end of the Z-shaped beam displacement amplification mechanism is fixedly connected with the clamping jaw. The micro manipulator is compact in structure, stable and reliable in clamping force, low in cost and high in movement precision.

Owner:TIANJIN UNIV

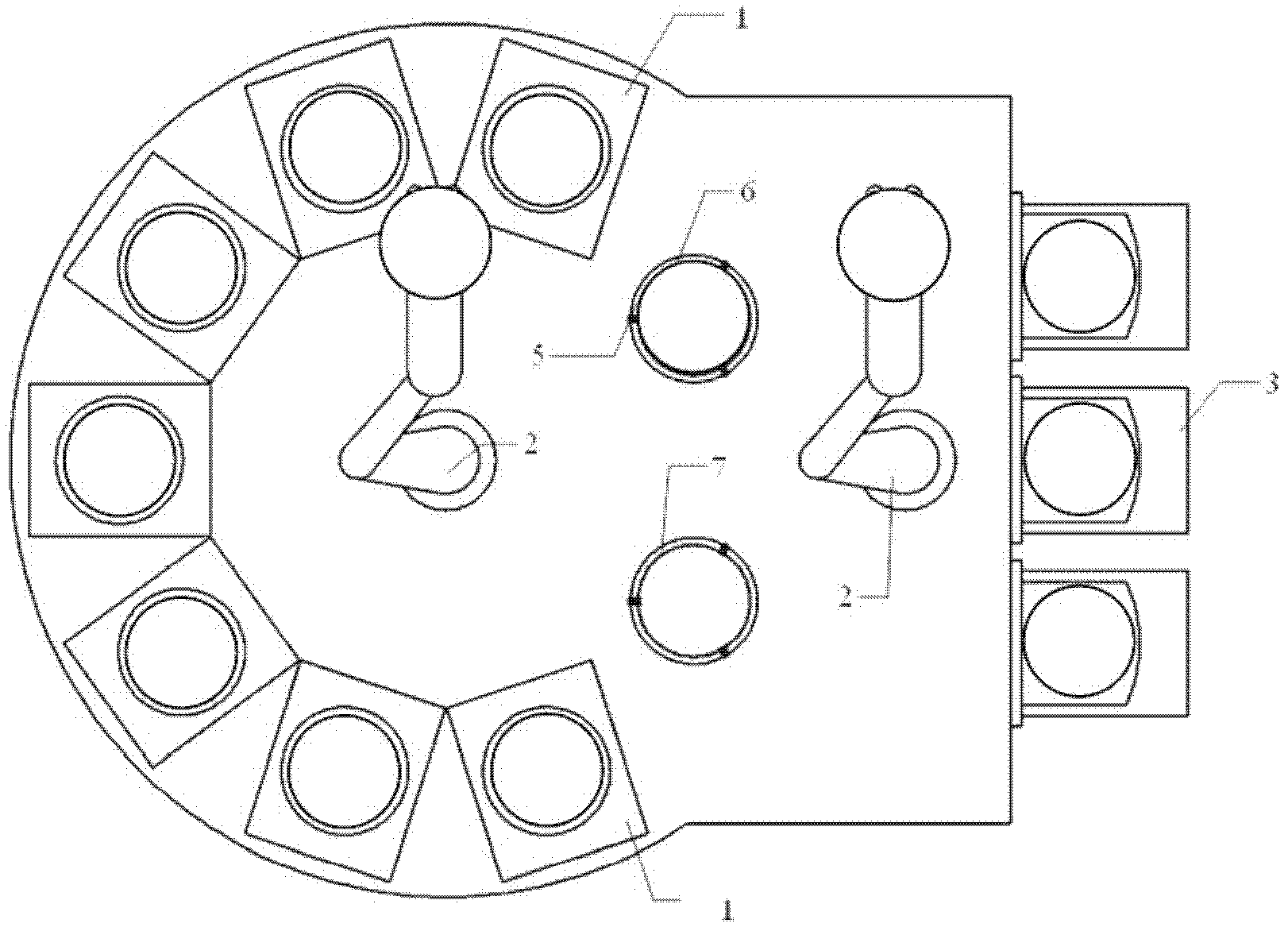

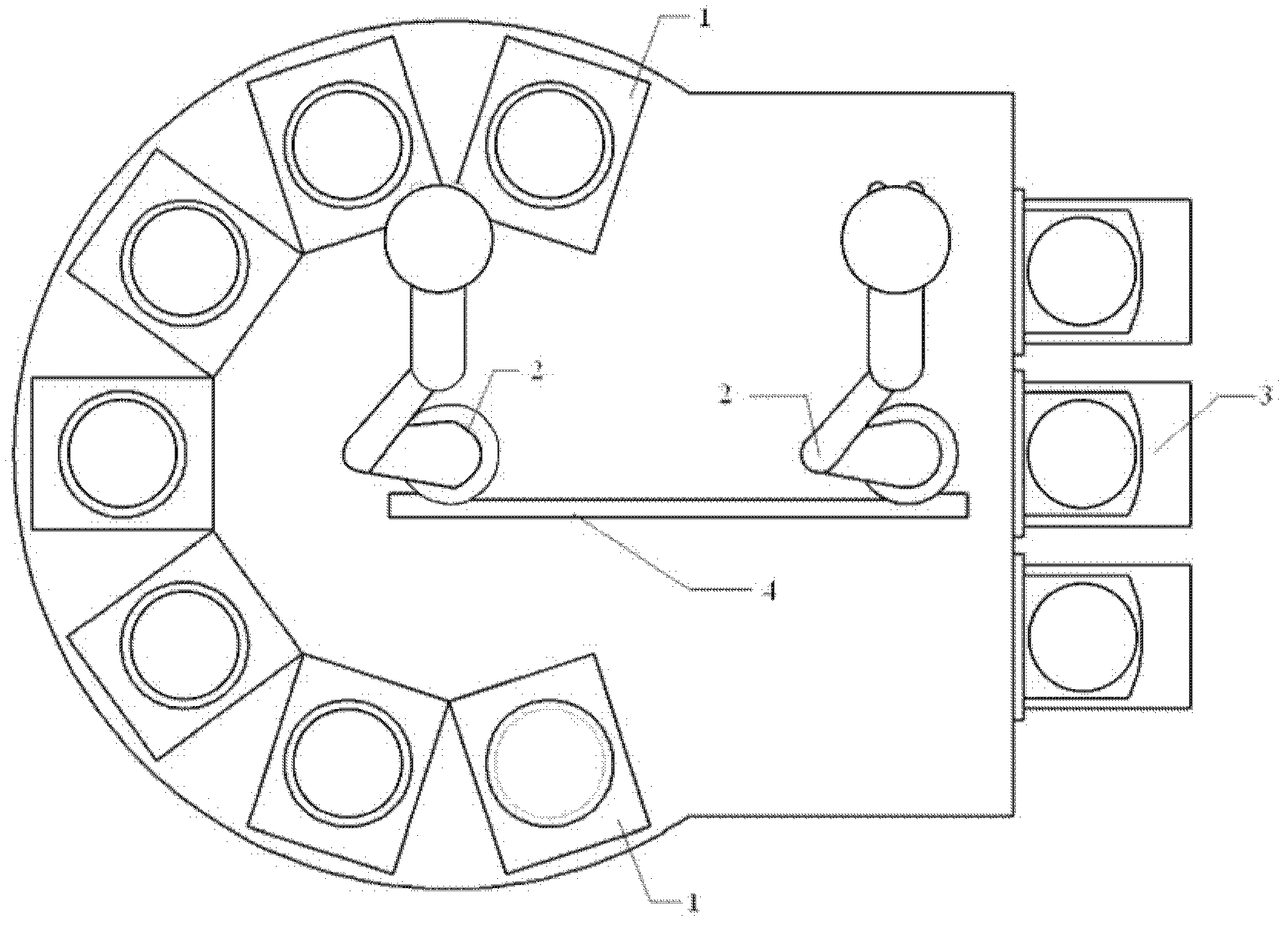

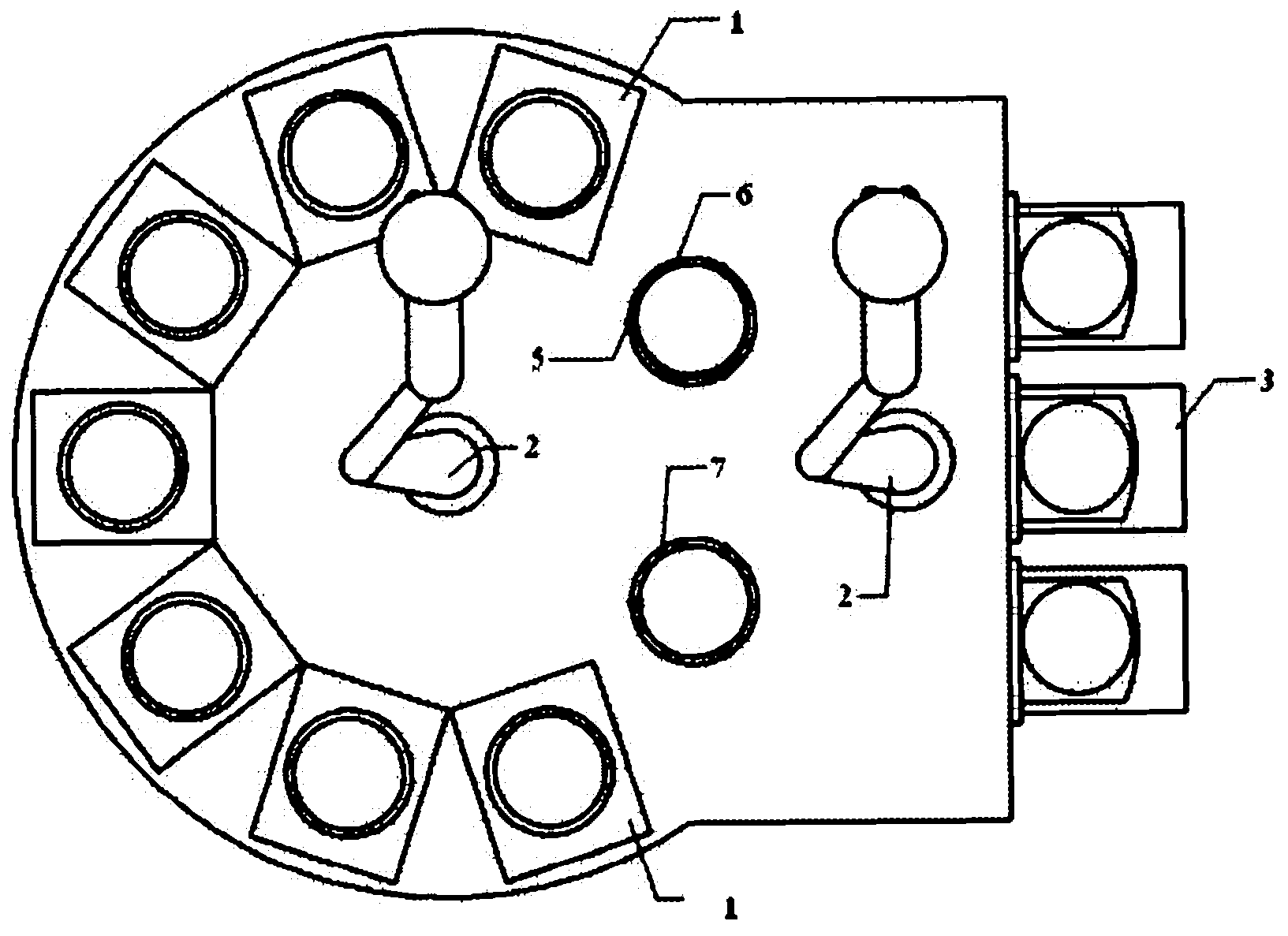

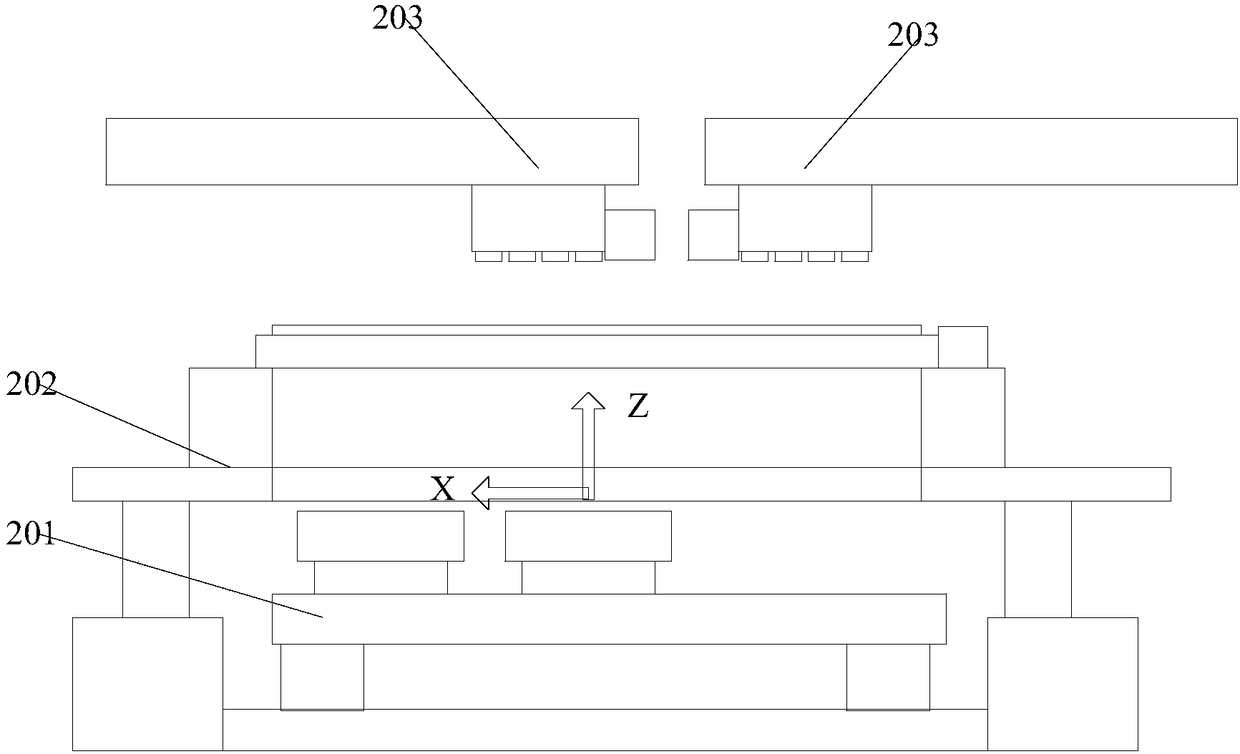

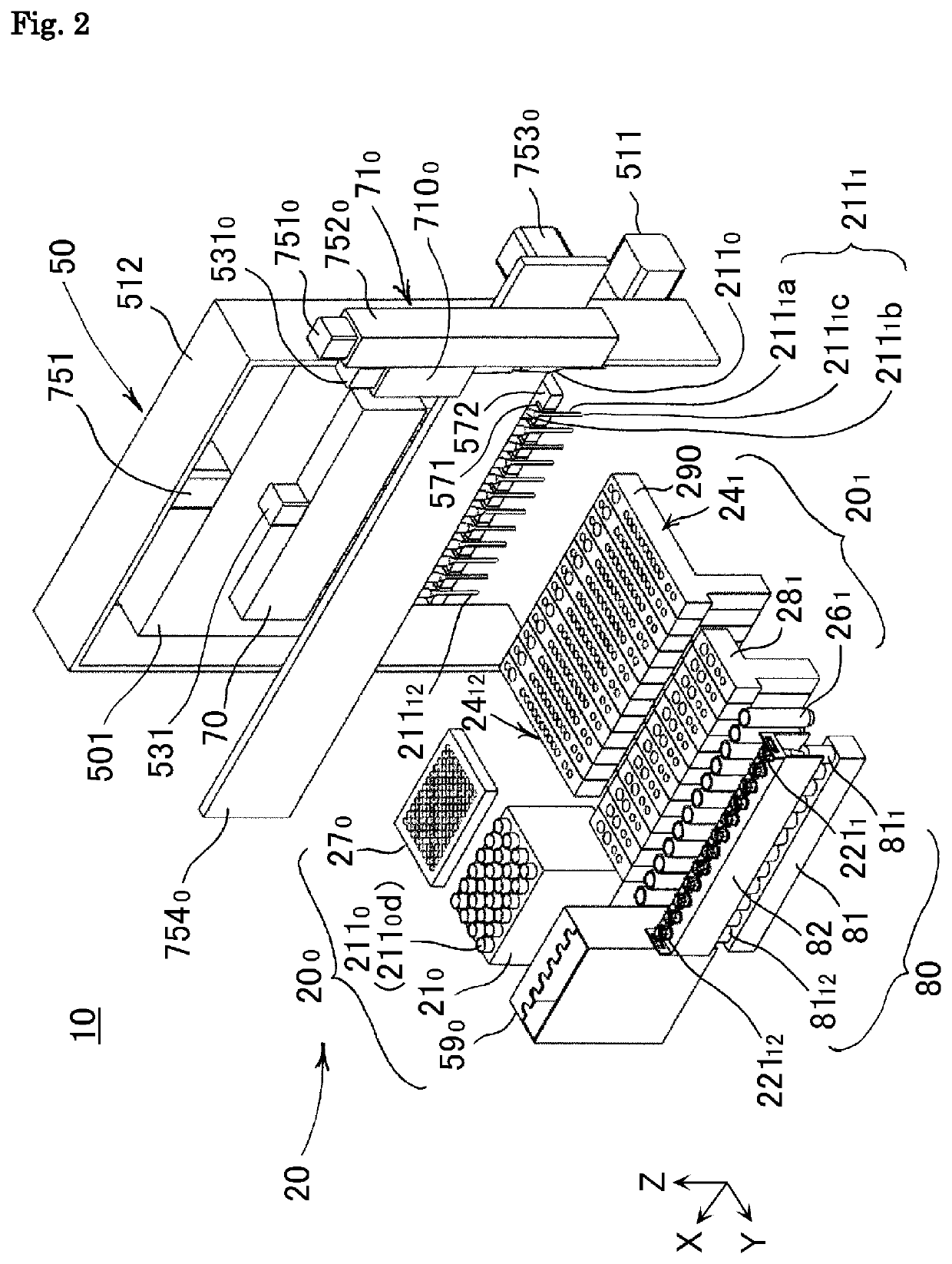

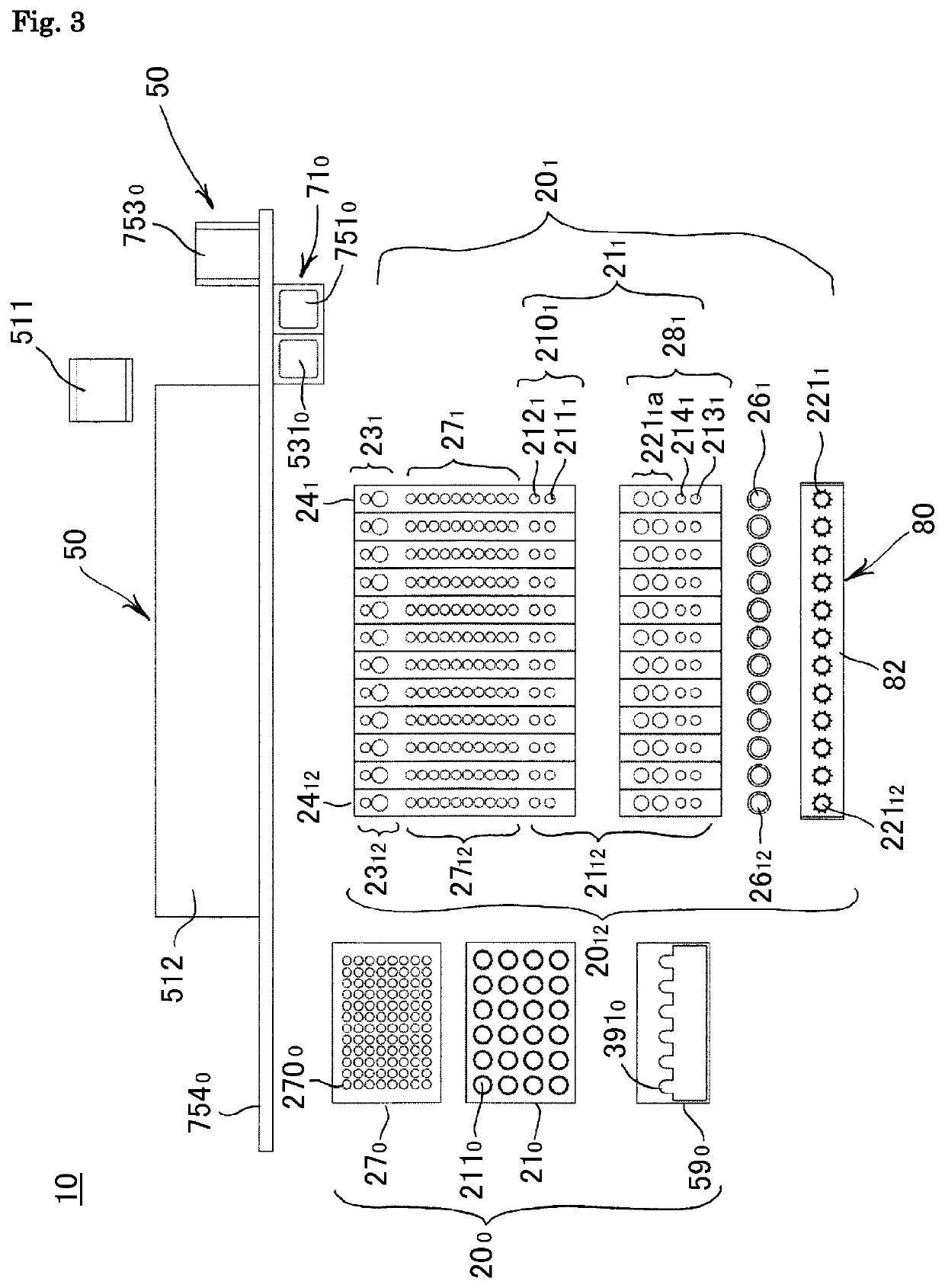

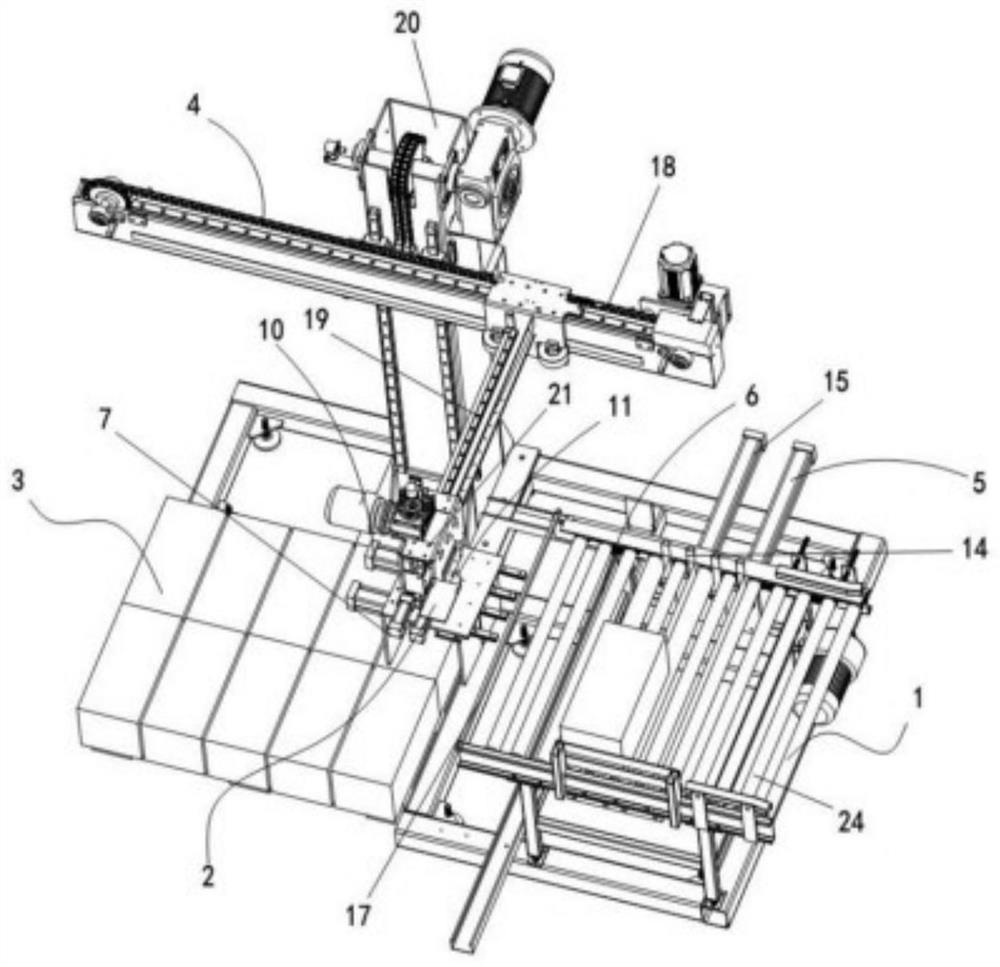

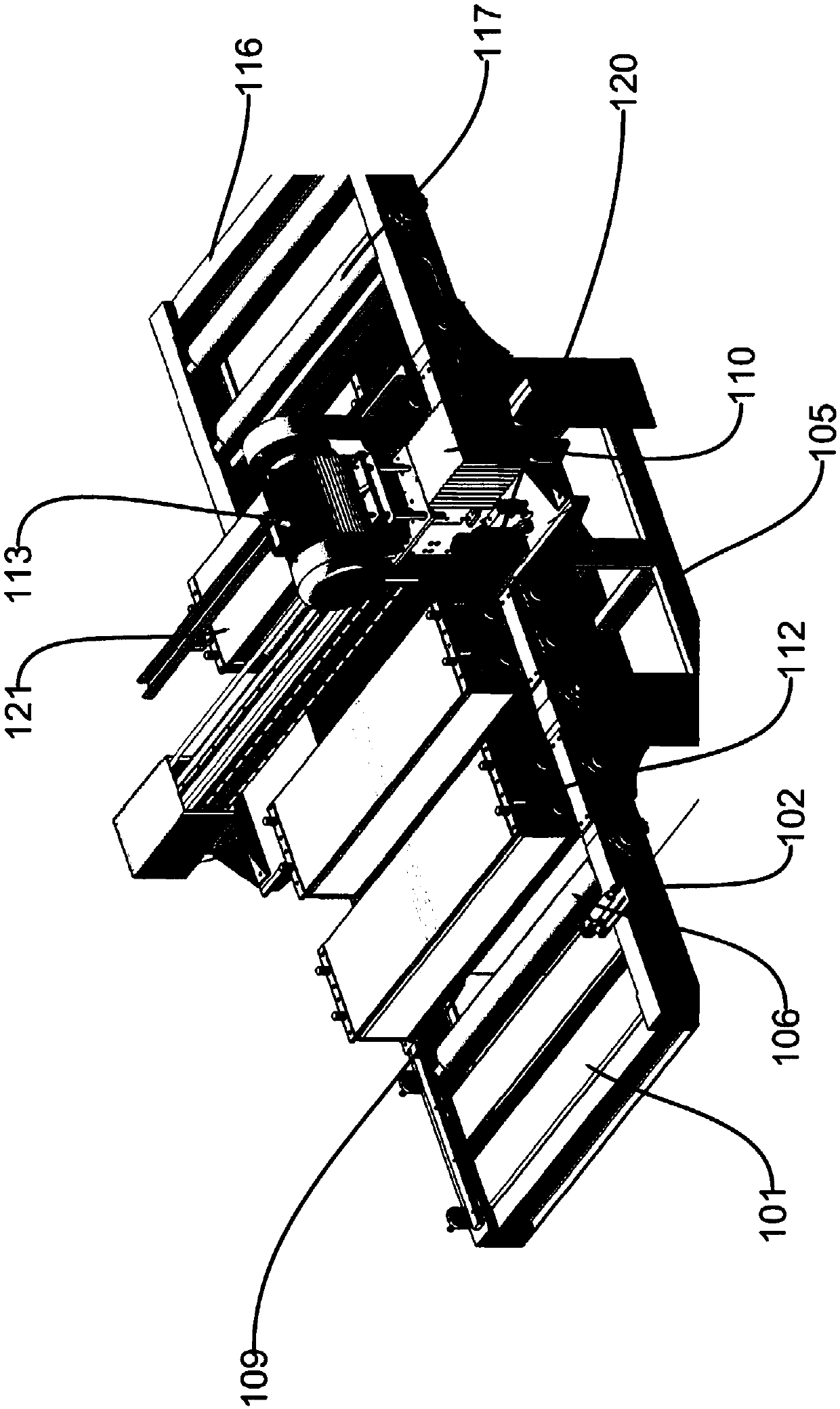

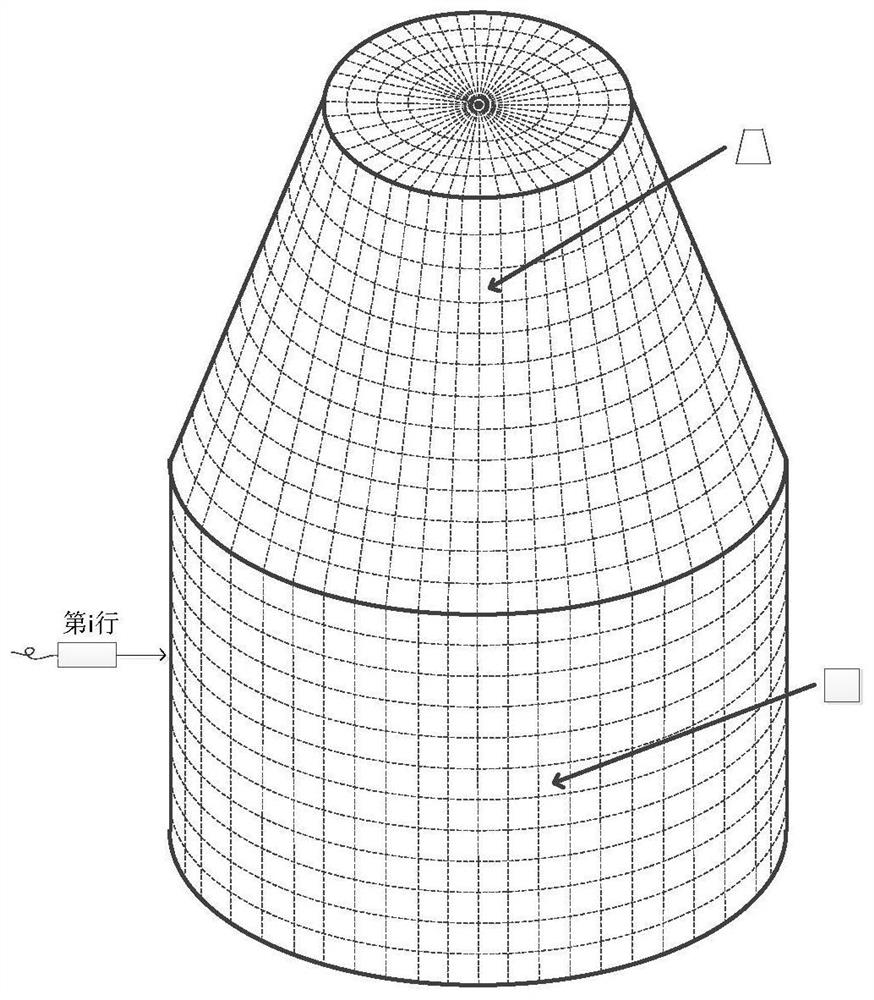

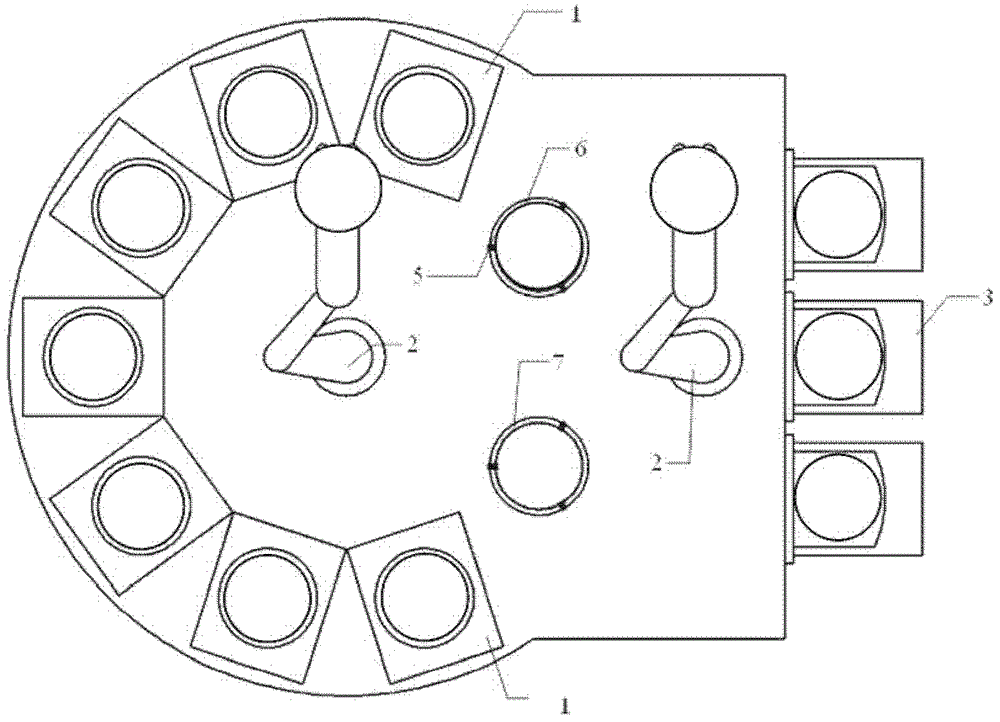

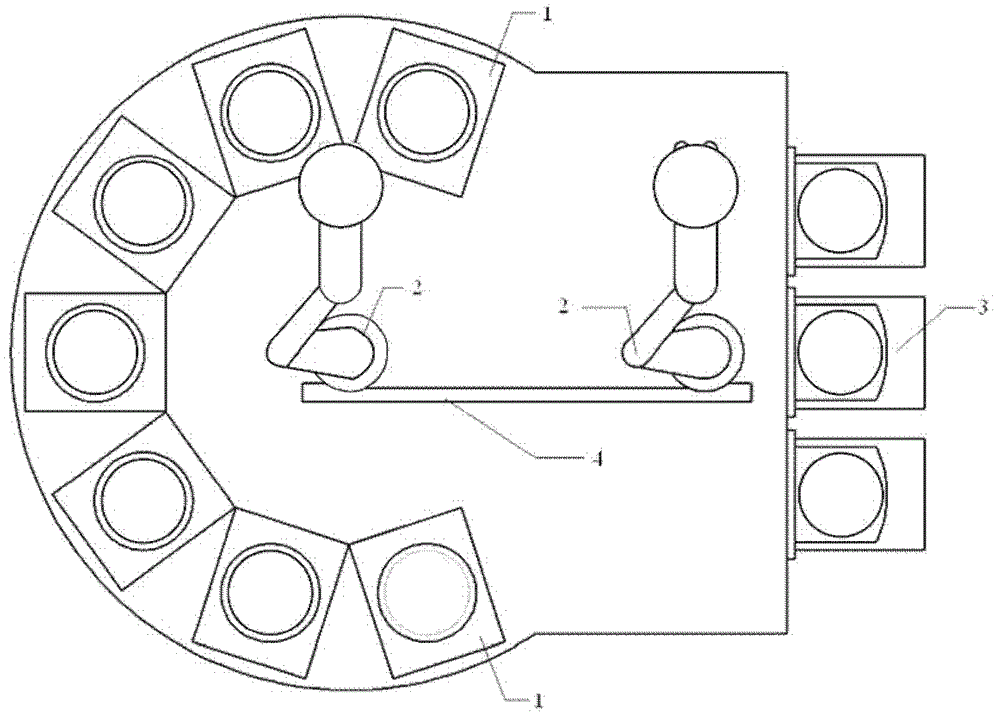

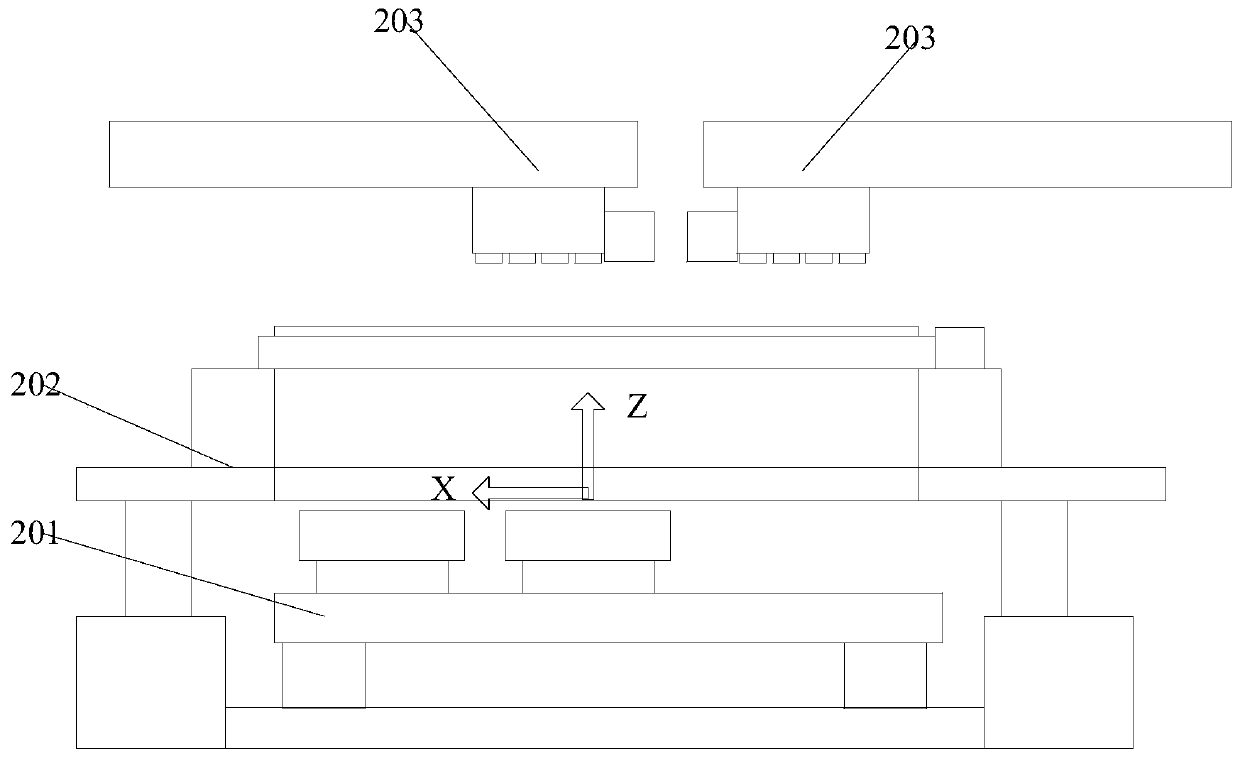

Conveying system for wafer-shaped object

ActiveCN102502253ASimplify motion pathFast and reliable accessConveyor partsManufacturing technologyEngineering

The invention discloses a conveying system for a wafer-shaped object, which belongs to the technical field of semiconductor wafer manufacture. The conveying system comprises at least two processing units (1) and mechanical hands (2), wherein, the distances between the mechanical hands (2) and the processing units (1) are equivalent, and the mechanical hands (2) are used for placing the wafer-shaped object to be processed in the processing units (1) and taking out the wafer-shaped object that is processed. The conveying system can store and take out the wafer-shaped object through the self-rotation and the lifting of the two mechanical hands by enabling the distances between the mechanical hands (2) and the processing units (1) to be equivalent, and can adopt a temporary storage platform to transit so as to achieve one wafer transition process or directly convey wafers to processing unit areas with the help of the movement of the mechanical hands on guiding rails after taking wafers from cassette areas by adopting the mechanical hands provided with the guiding rails; the two manners achieve simple motion path and are rapid and reliable to store and take out; and meanwhile, the conveying system can effectively reduce the occupied track area by compared with the same type of equipment.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

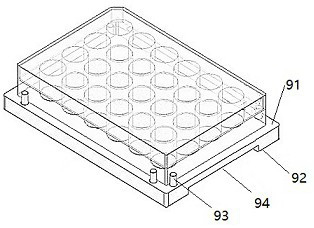

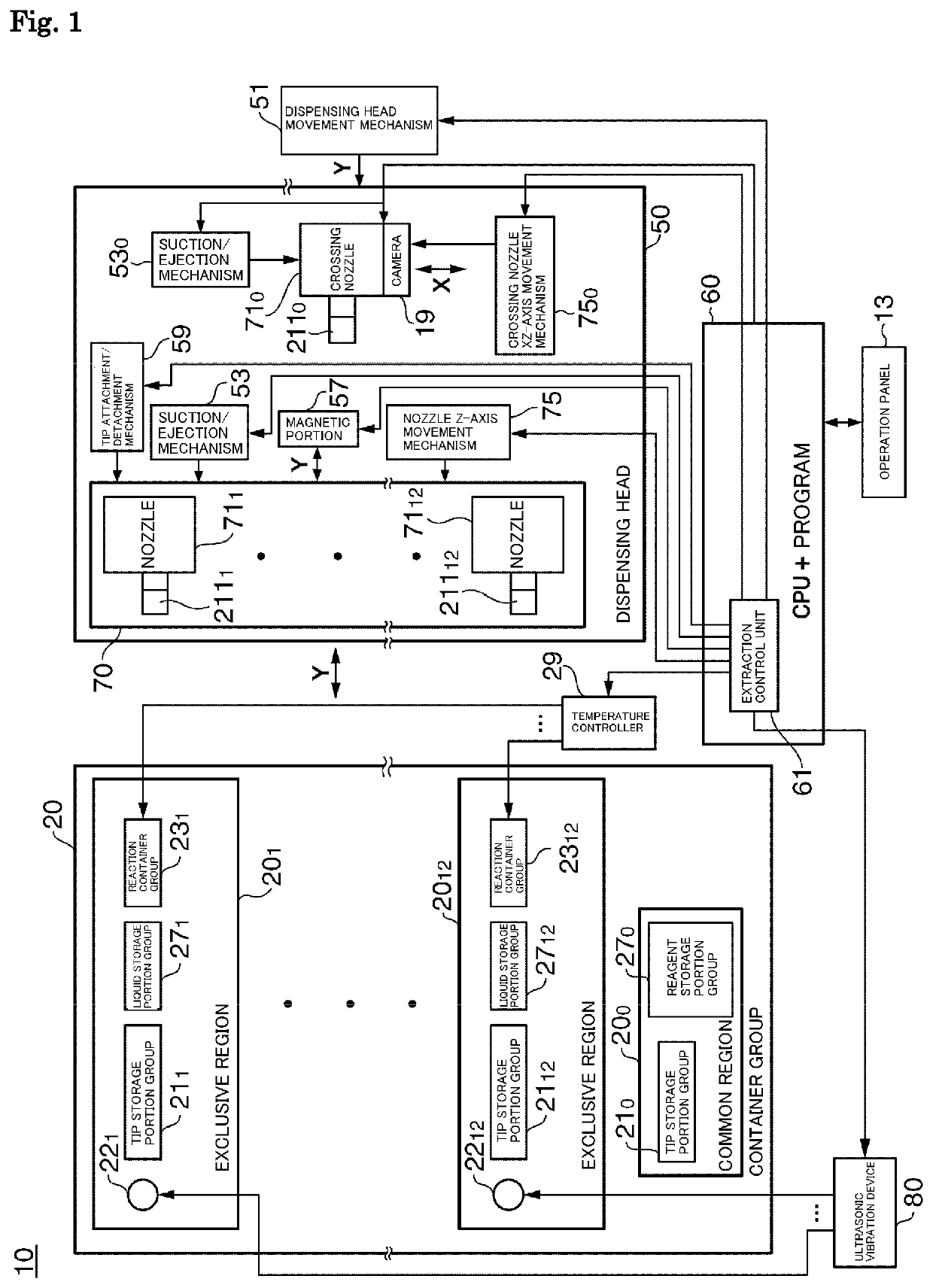

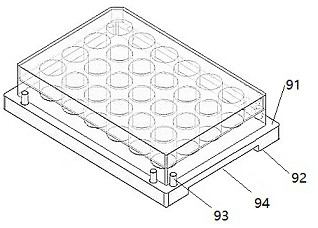

Linear movement type reaction treatment apparatus and method thereof

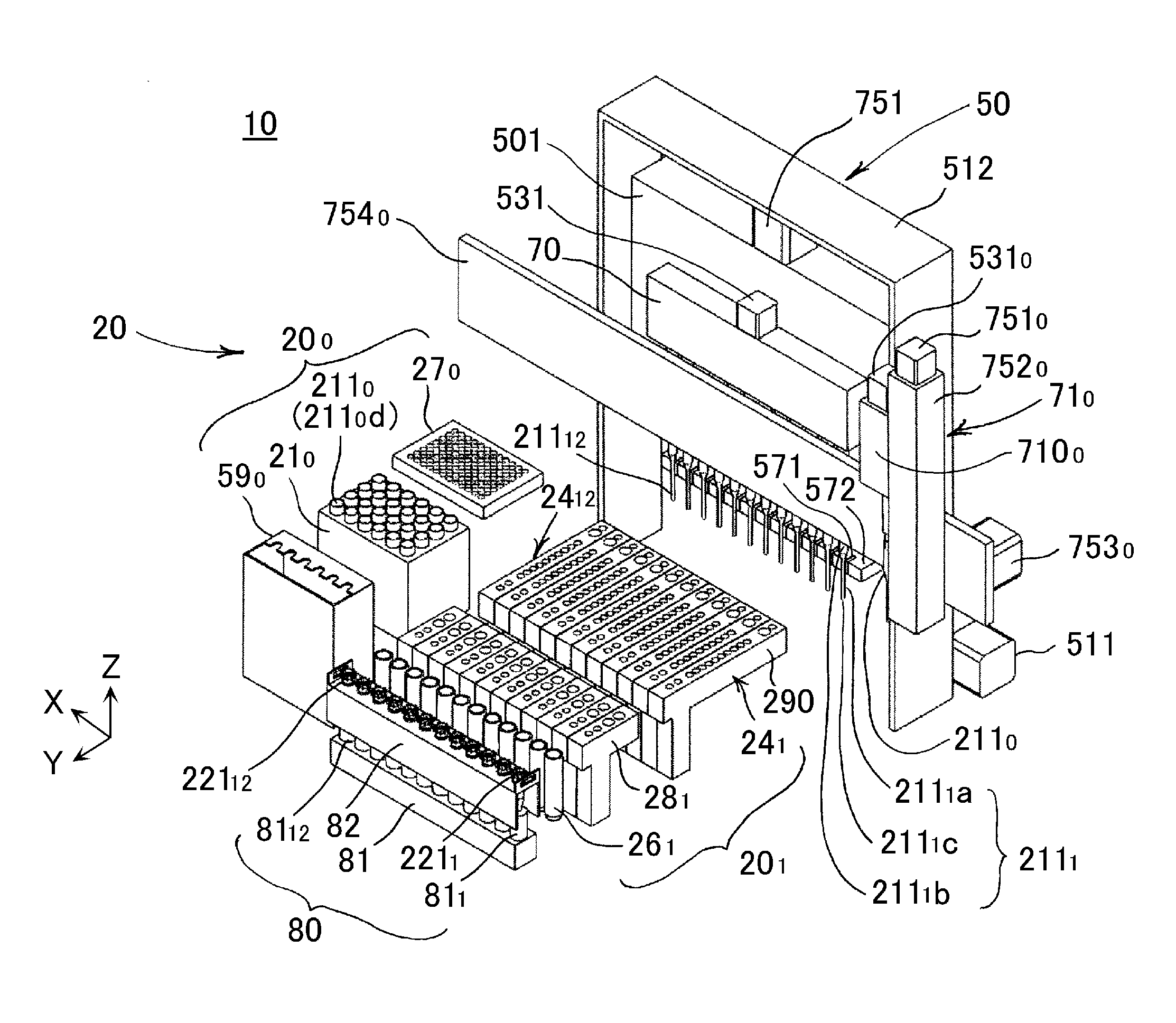

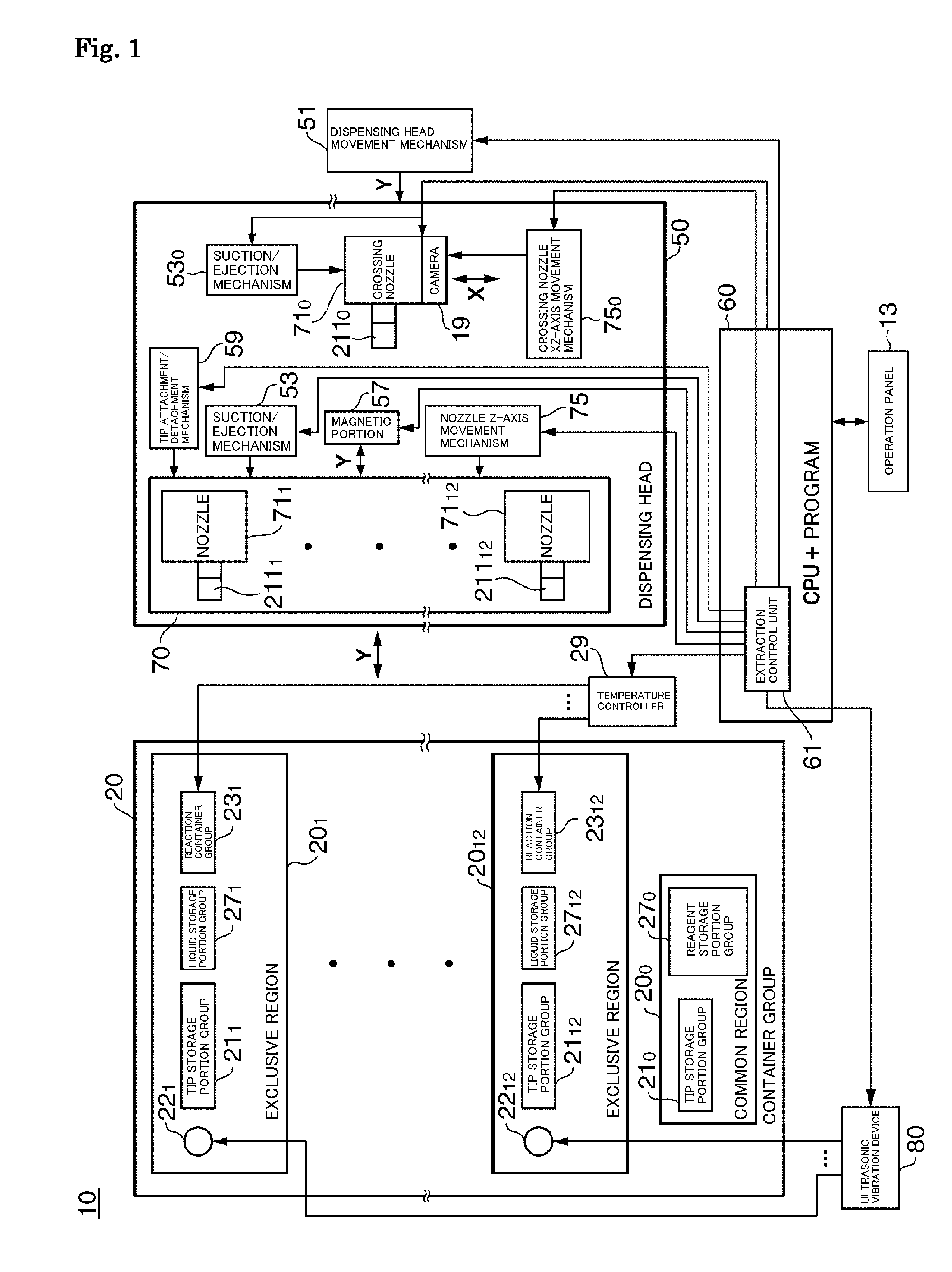

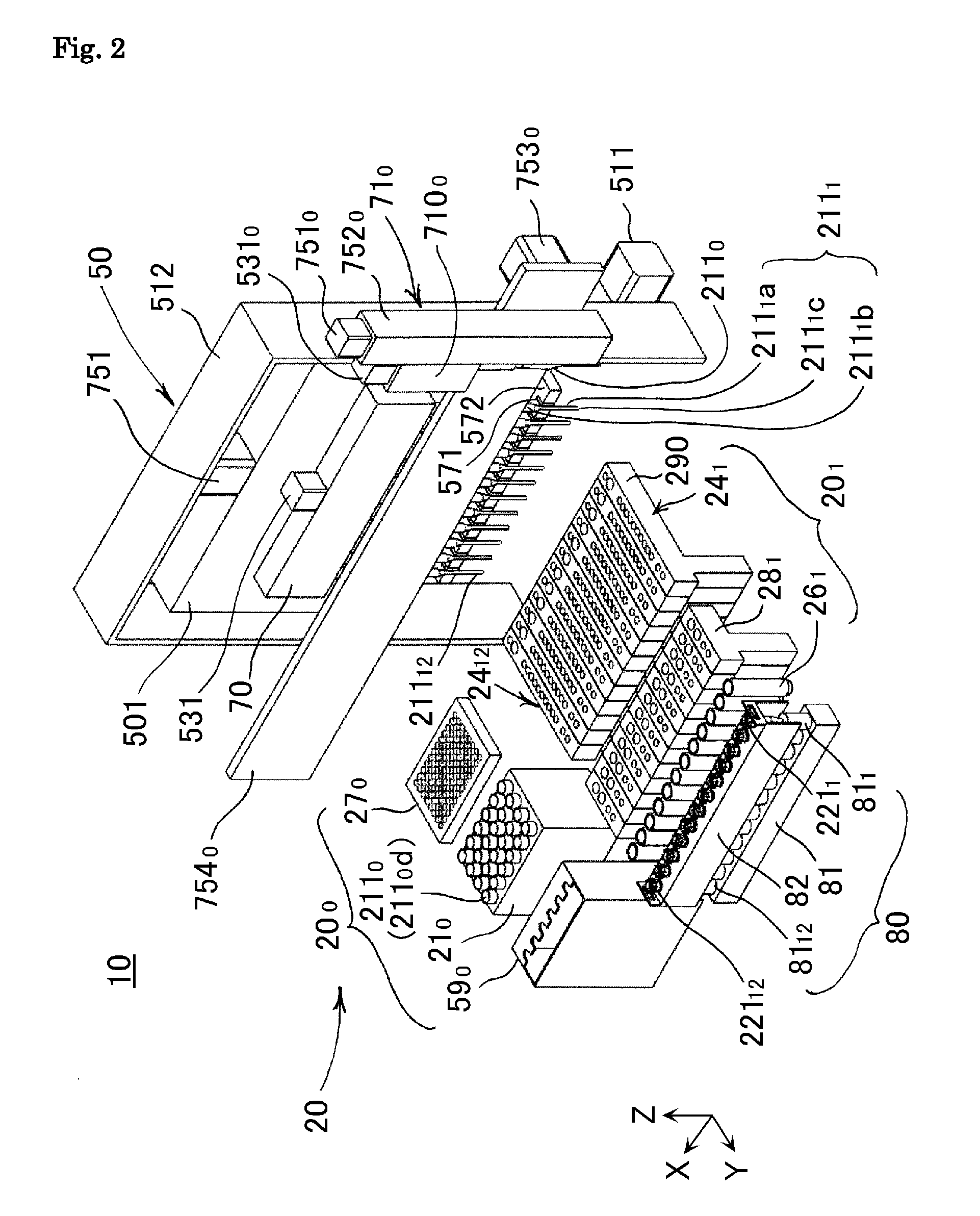

ActiveUS20150309059A1Simplify motion pathEasy to controlBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringUltrasonic vibration

The invention relates to a linear movement type reaction treatment apparatus and a method thereof, and an object thereof is to reliably prevent cross-contamination and to decrease a working time or a working space involved with reaction treatment.A linear movement type reaction treatment apparatus includes: a container group in which one or two or more reaction containers and two or more liquid storage portions are arranged in at least one linear shape; a dispensing head to which one or two or more dispensing tips are detachably attached and which is relatively movable between the dispensing tip and the container group; a magnetic portion which is capable of separating magnetic particles contained in a solution inside each dispensing tip; and an ultrasonic vibration device which applies an ultrasonic vibration to a sample storage portion, as sample storage portion at least one of the liquid storage portions are selected.

Owner:UNIVERSAL BIO RESEARCH CO LTD

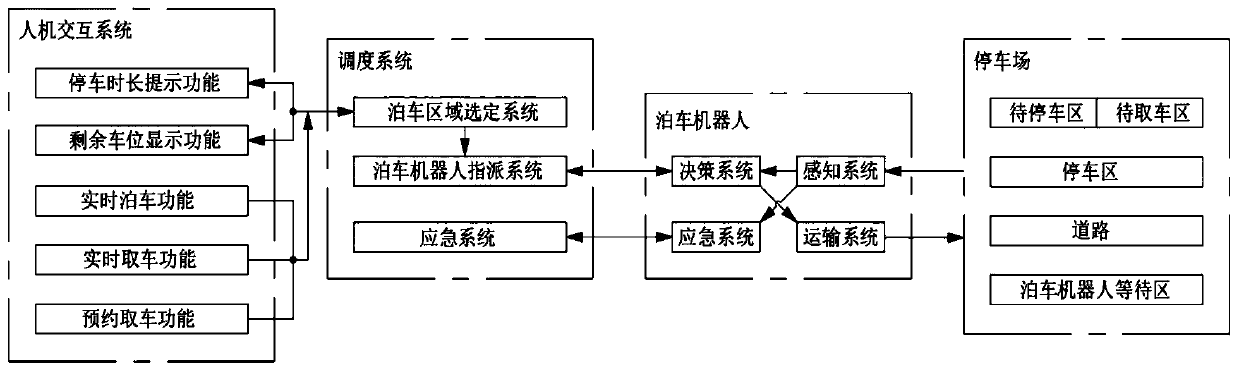

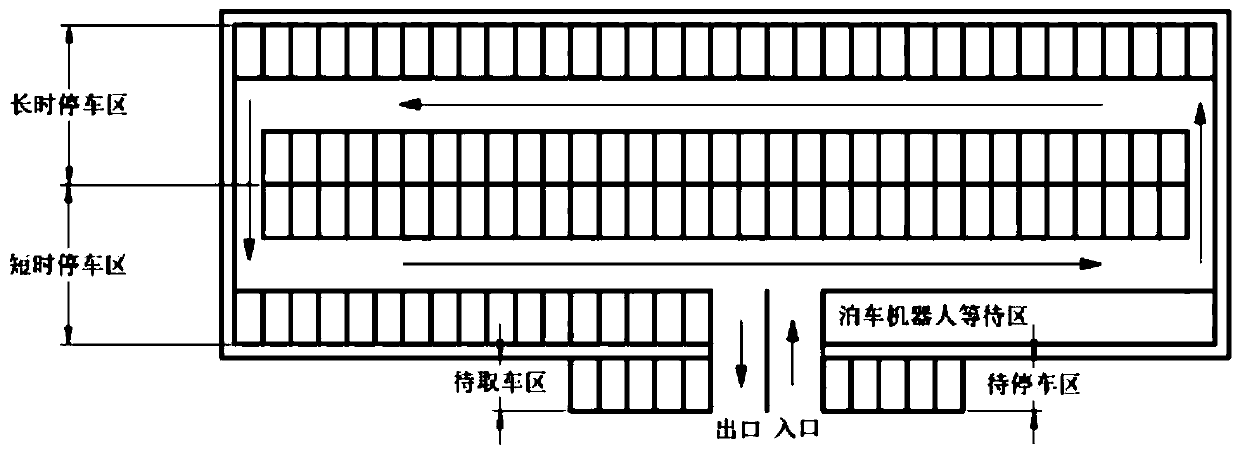

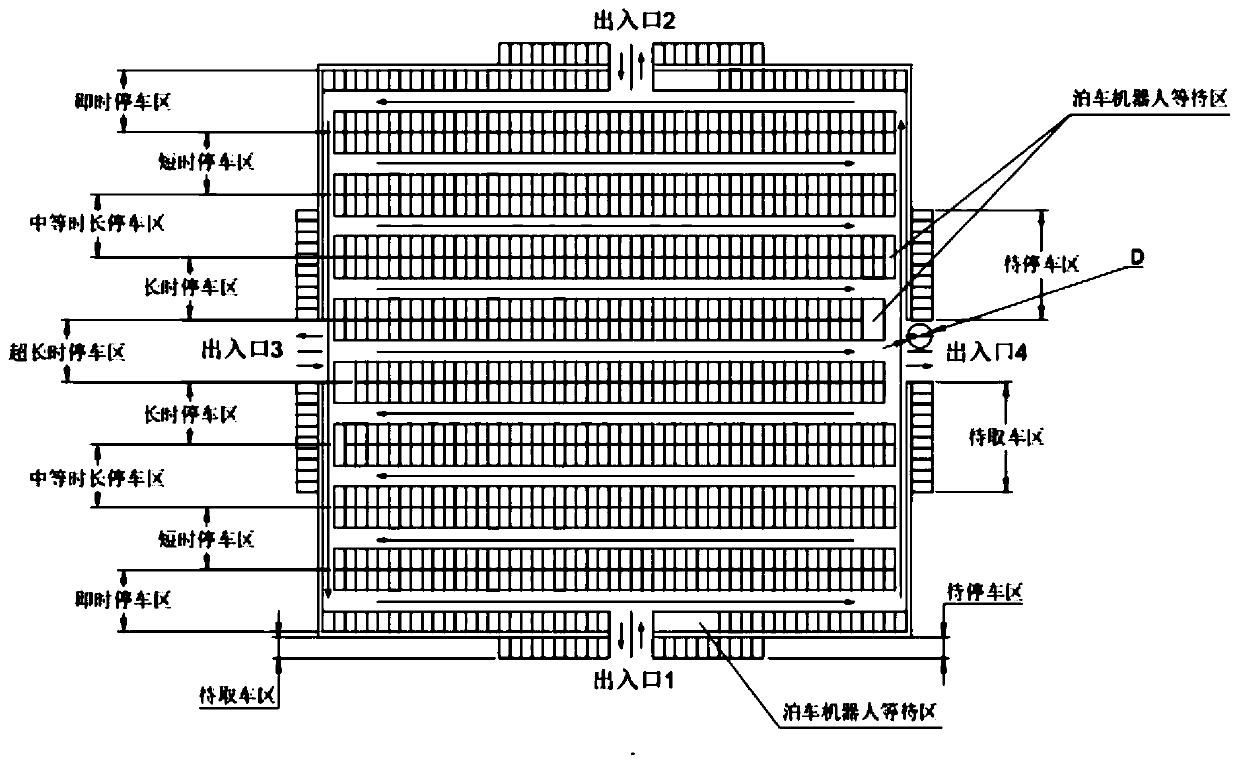

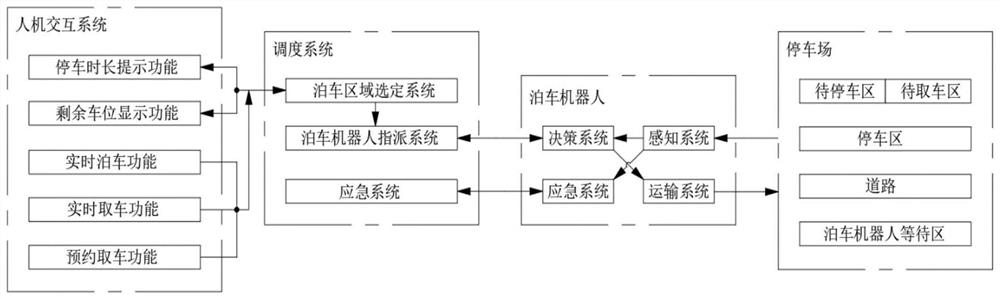

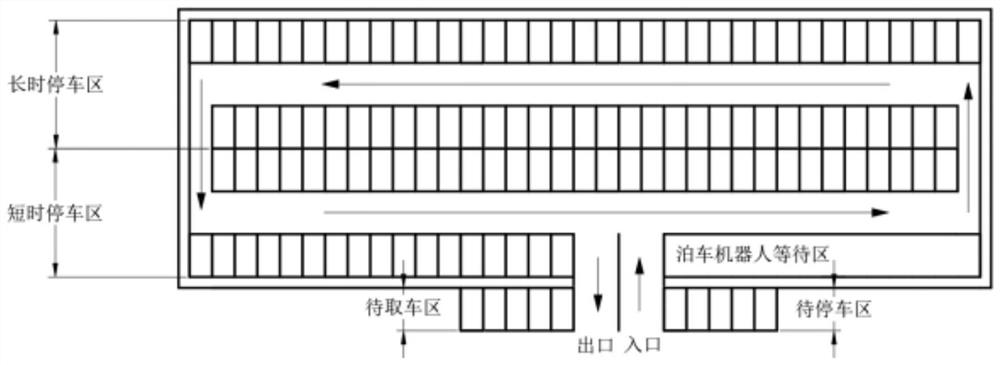

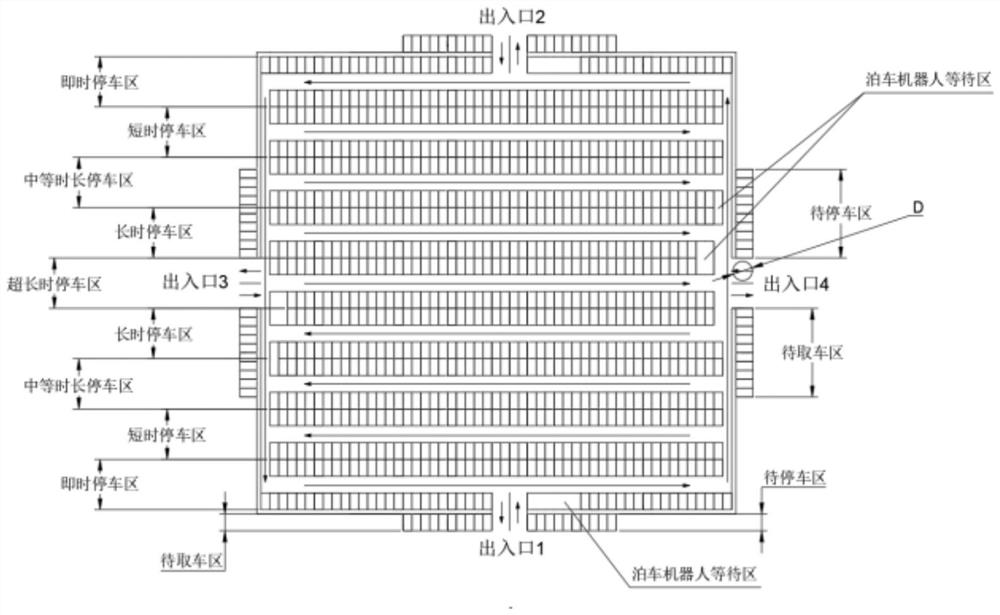

Automatic parking system based on parking robots and operation method thereof

ActiveCN110952815AImprove space utilizationEasy to maintainResourcesParkingsAutomotive engineeringReal-time computing

The invention discloses an automatic parking system based on parking robots. The automatic parking system comprises a parking lot, a human-machine interaction system, a parking zone selecting system,a parking robot assignment system, the plurality of parking robots, a decision making system of the parking robots, a transportation system and an emergency dispatching system. The plurality of parking robots can move in a parking lot and are provided with moving type clamping mechanisms and lifting mechanisms, and can receive instruction information sent by the parking robot assignment system tocarry a to-be-parked vehicle into a parking area. The transportation system is capable of executing a movement instruction generated by the decision making system of the parking robots, so that the parking robots can transport the vehicle according to an expected path in the parking lot. An emergency plan is stored in the emergency dispatching system, and the emergency dispatching system can inform parking lot staff of going to an accident site. The invention further discloses an automatic parking system operation method based on the parking robots.

Owner:JILIN UNIV

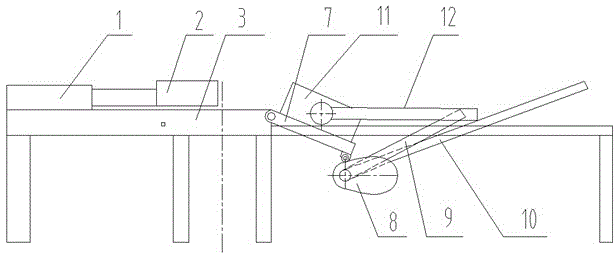

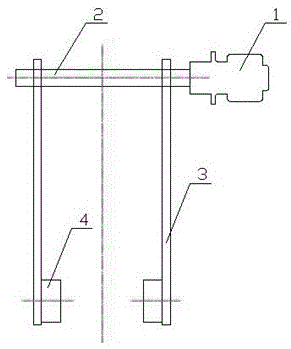

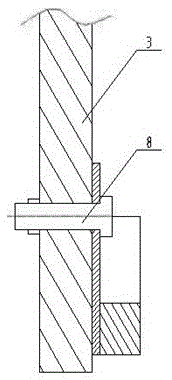

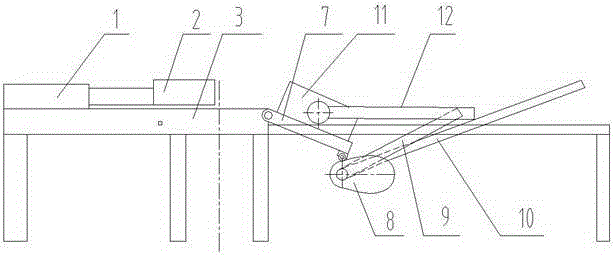

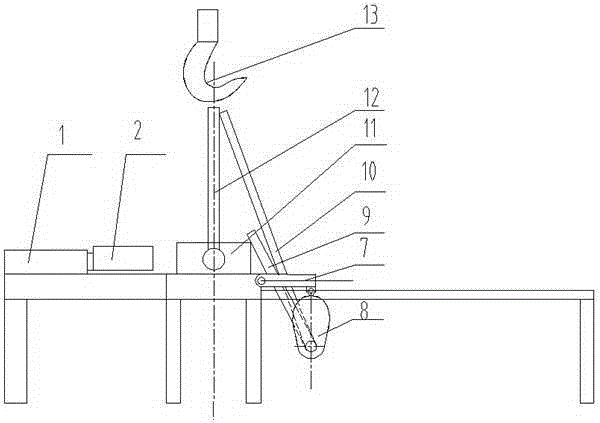

Well mouth assembling and disassembling method of mechanical workover treatment intelligent elevator

ActiveCN104453740AReduce labor intensityReduce security risksDrilling rodsDrilling casingsWellheadPetroleum

The invention discloses a well mouth assembling and disassembling method of a mechanical workover treatment intelligent elevator. The method comprises the steps that a well mouth platform of a frame structure is installed on a well mouth; an elevator disassembling device is installed on the left side of the well mouth platform, an elevator on the well mouth platform over the well mouth is disassembled to the right side of the well mouth through stretching and retraction movement of the elevator disassembling device, a connecting plate tilting in the lower right direction is hinged to the right side of the well mouth, the elevator is pushed by the elevator disassembling device to the connecting plate, and a suspension ring tilts rightwards due to the gravity center; a support is arranged on the right side, opposite to the left side provided with the elevator disassembling device, of the well mouth platform, the support is provided with an elevator assembling device, the elevator assembling device rotates to jack up the connecting plate where the elevator is placed, push the elevator to the well mouth and push the suspension ring to a large hook, and finally the elevator is assembled and disassembled on the well mouth. According to the mouth assembling and disassembling method of the mechanical workover treatment intelligent elevator, mechanical petroleum string tripping operation can be achieved when no operator exists on the well mouth, the labor intensity of workers is lowered, and potential safety hazards are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

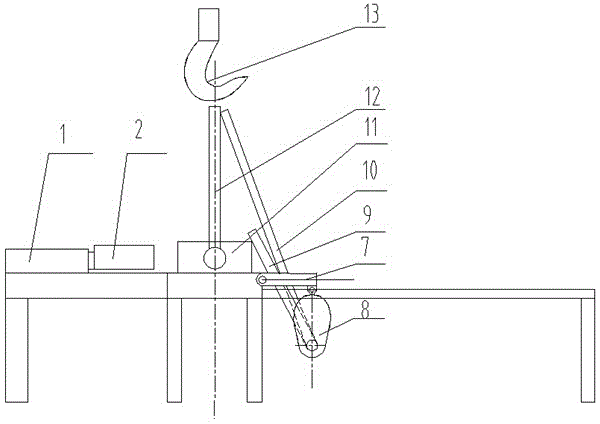

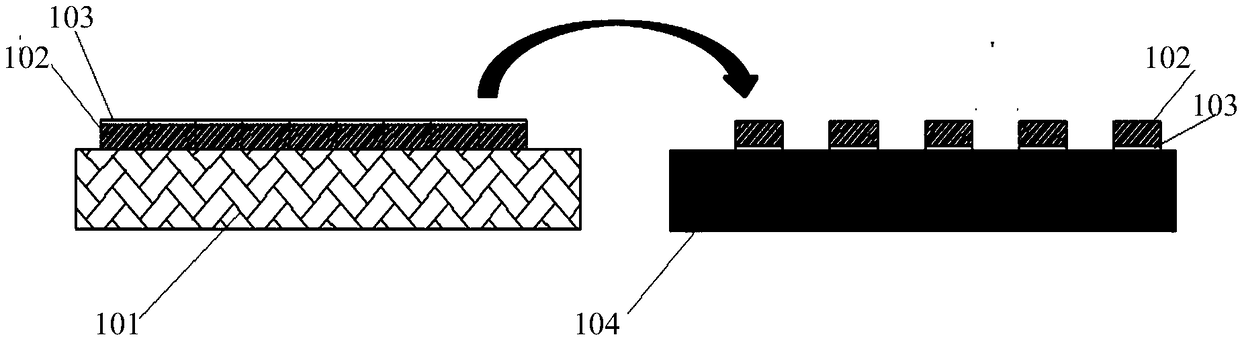

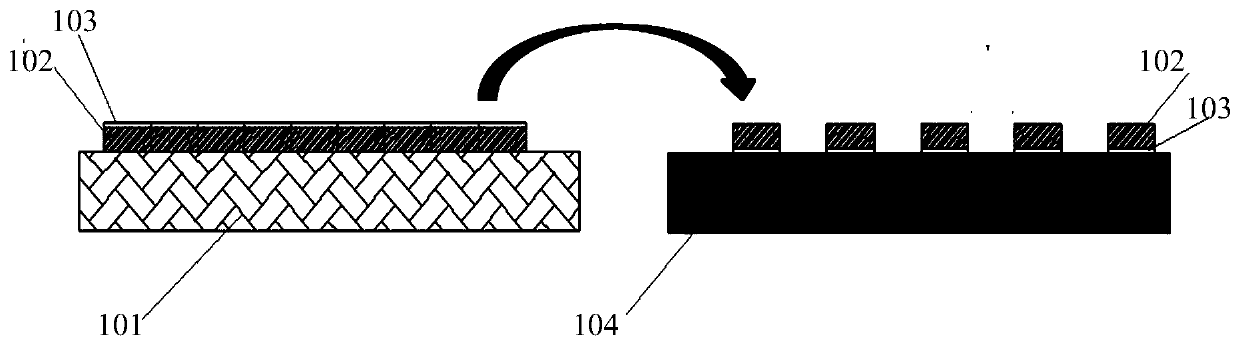

Chip bonding device and chip bonding method

ActiveCN108122787ASimplify motion pathSimple stepsSemiconductor/solid-state device manufacturingDie bondingElectrical and Electronics engineering

The invention provides a chip bonding device and a chip bonding method. The chip bonding device comprises a plurality of groups of batch chip transmission parts, a base bearing part and a bonding force output part from top to bottom. In the chip bonding device and the chip bonding method provided in the invention, the batch chip transmission part can bond several chips at one time, the chips are bonded to a base borne by the base bearing part at the same time; in the case of bonding, a bonding ejection mechanism only needs to be used to eject the base bearing part until the base on the base bearing part is bonded with a plurality of chips, that is, only one mechanism is needed to perform a vertical movement in the case of bonding, the movement path and steps are simplified, the productionefficiency is improved, the time is saved, and mass production demands can be met.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

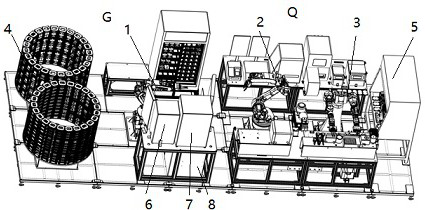

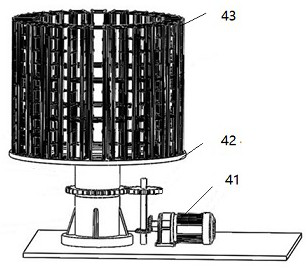

Full-automatic quality control system

ActiveCN113298975AFully automatedGuaranteed sterilityRegistering/indicating quality control systemsRegistering/indicating during manufacturing processRobotic armQuality control system

The invention relates to the technical field of biology, in particular to a full-automatic quality control system which comprises a goods storage area, a quality inspection area and a control system which are arranged in a positive pressure environment, and the control system is internally provided with a set of a plurality of control processes of a robotic arm and a set of control site image groups formed according to time streams corresponding to the control processes of the robotic arm A; and meanwhile, an image verification unit is arranged in the control system and used for comparing a real-time video stream, obtained by the camera system, of a certain control process of the robotic arm with a control image group of the corresponding control process according to time points. According to the technical scheme, comprehensive automatic detection in the cell production process is achieved, and the quality stability in the cell batch production process is effectively guaranteed.

Owner:HELP STEM CELL INNOVATIONS CO LTD

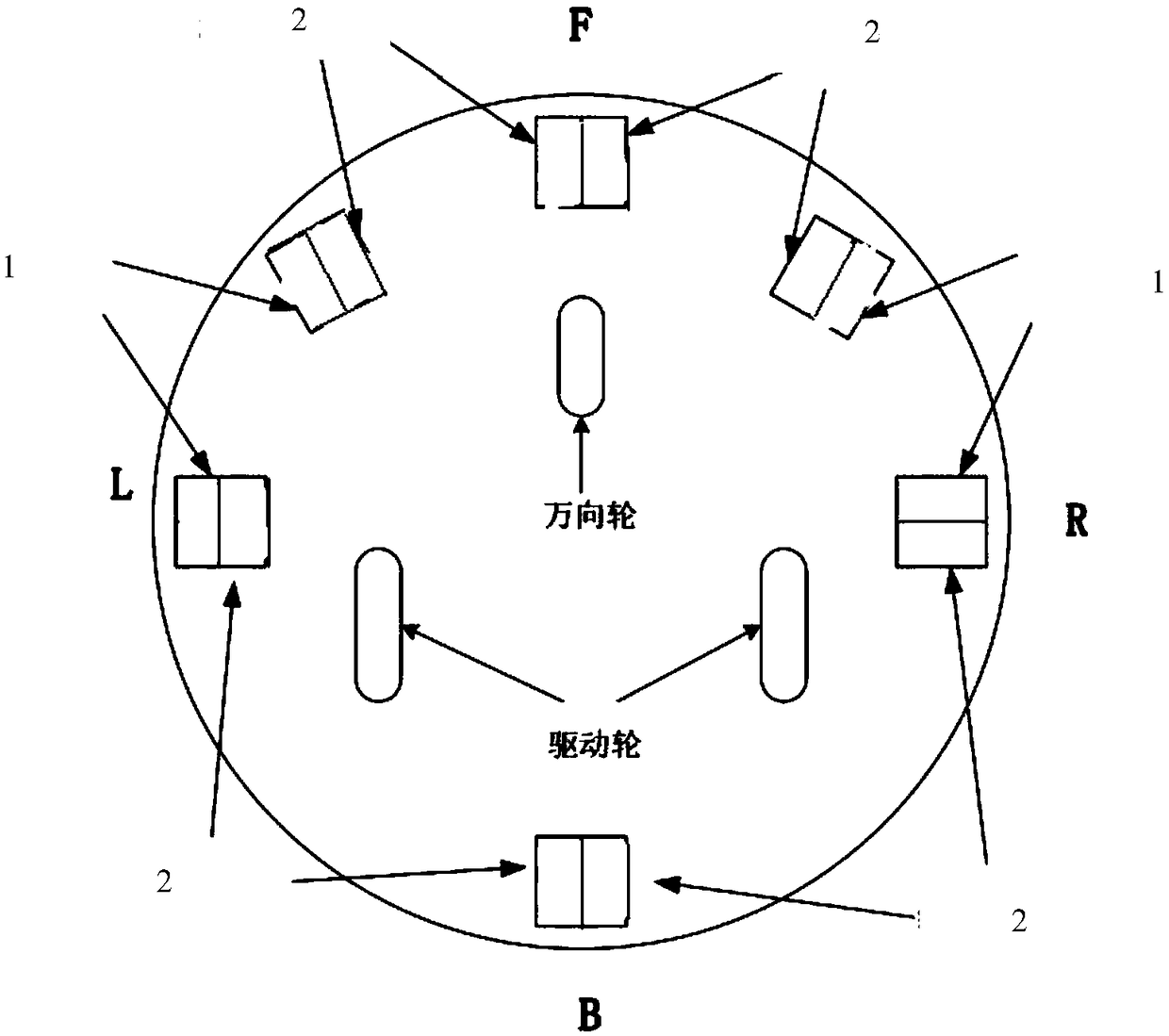

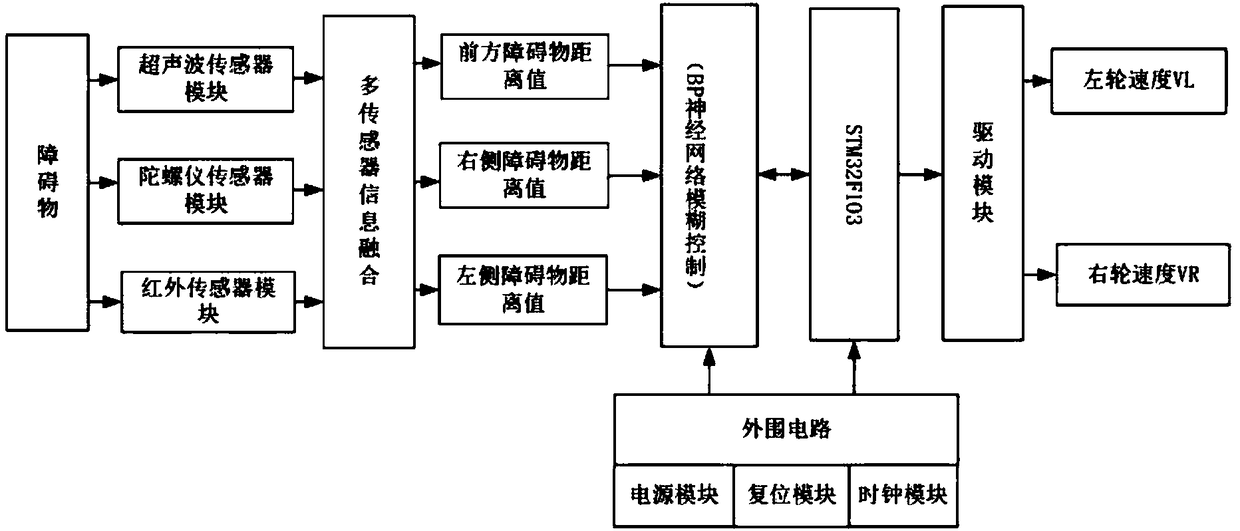

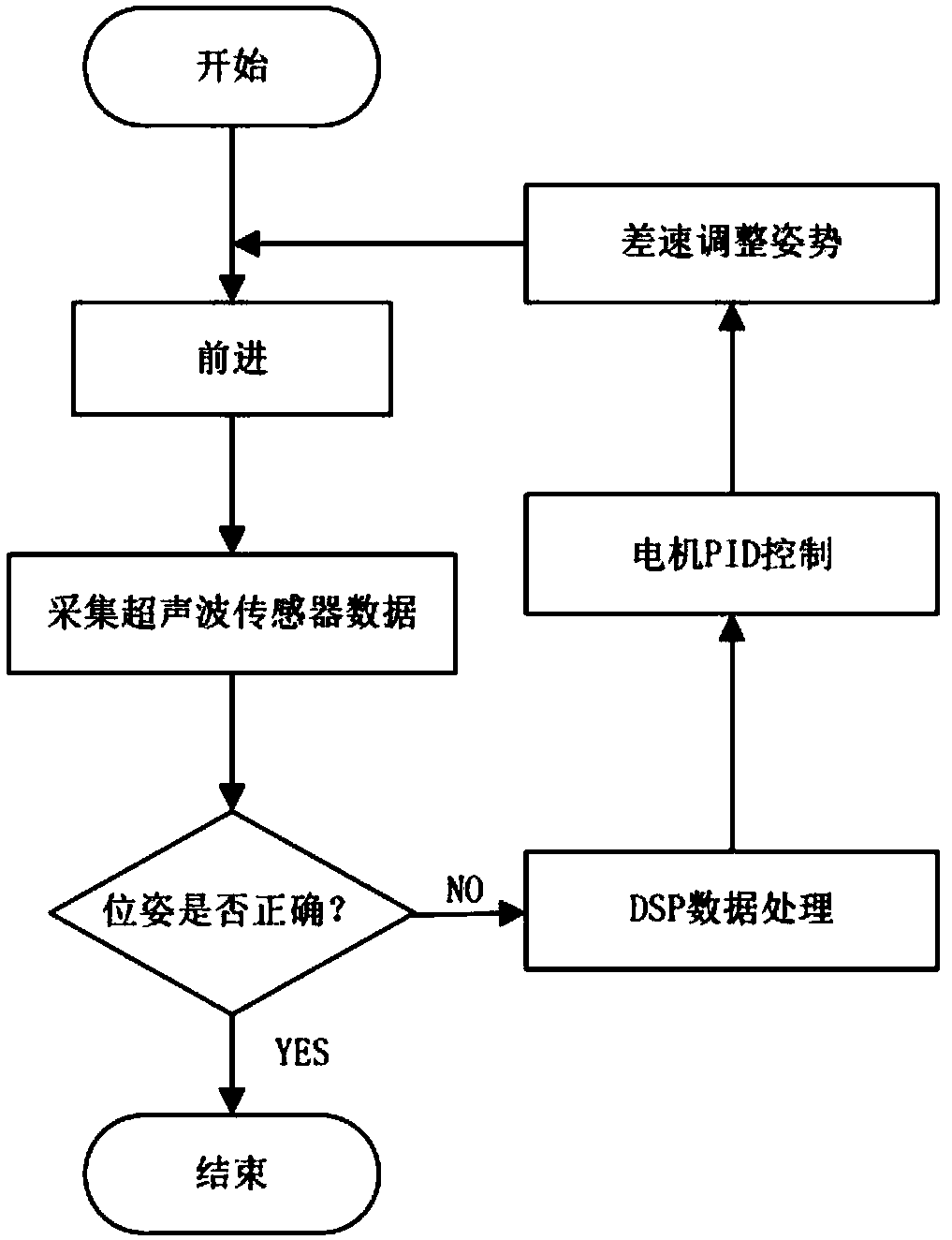

Device for automatically recharging robot by using multi-path external environment detection modules

InactiveCN108303981AGuaranteed mutual levelGuaranteed parallelPosition/course control in two dimensionsVehiclesEngineeringInformation integration

The invention discloses a device for automatically recharging a robot by using multi-path external environment detection modules. The device comprises a charging base having a plurality of signal transmitting modules, a robot base plate, a multi-path information fusion module, and a driving module. A state information detection module and a plurality of external environment detection modules are installed at the robot base plate; and each external environment detection module is arranged at the bottom of the robot base plate in an a circular array manner and is used for receiving a signal. Themulti-path information fusion module receives information from the state information detection module and the external environment detection modules. The driving module is installed on the robot baseplate.

Owner:SHANGHAI XPARTNER ROBOTICS +1

Linear movement type reaction treatment apparatus and method thereof

ActiveUS10775397B2Simplify motion pathEasy to controlHeating or cooling apparatusLaboratory glasswaresEngineeringUltrasonic vibration

Owner:UNIVERSAL BIO RESEARCH CO LTD

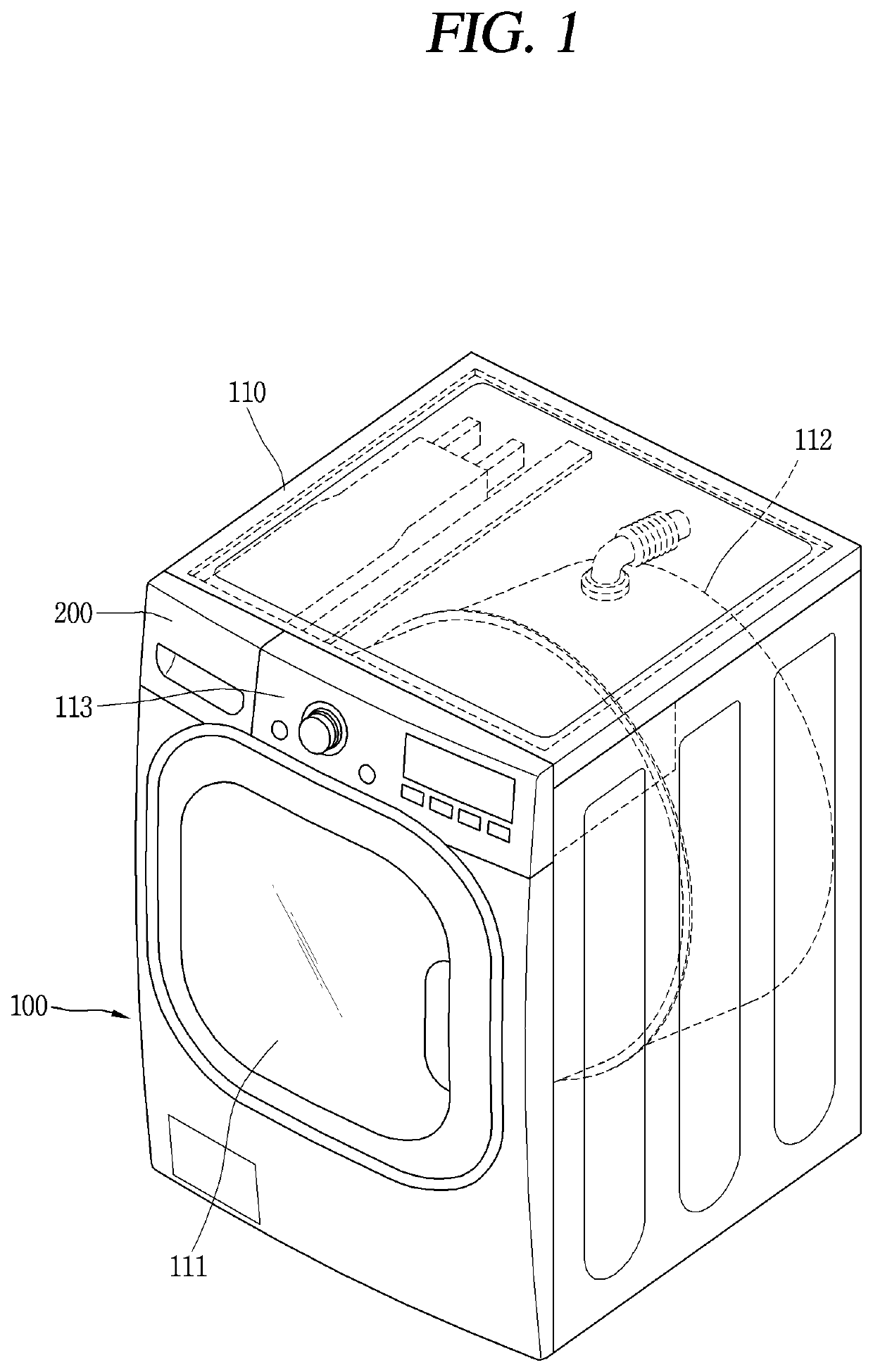

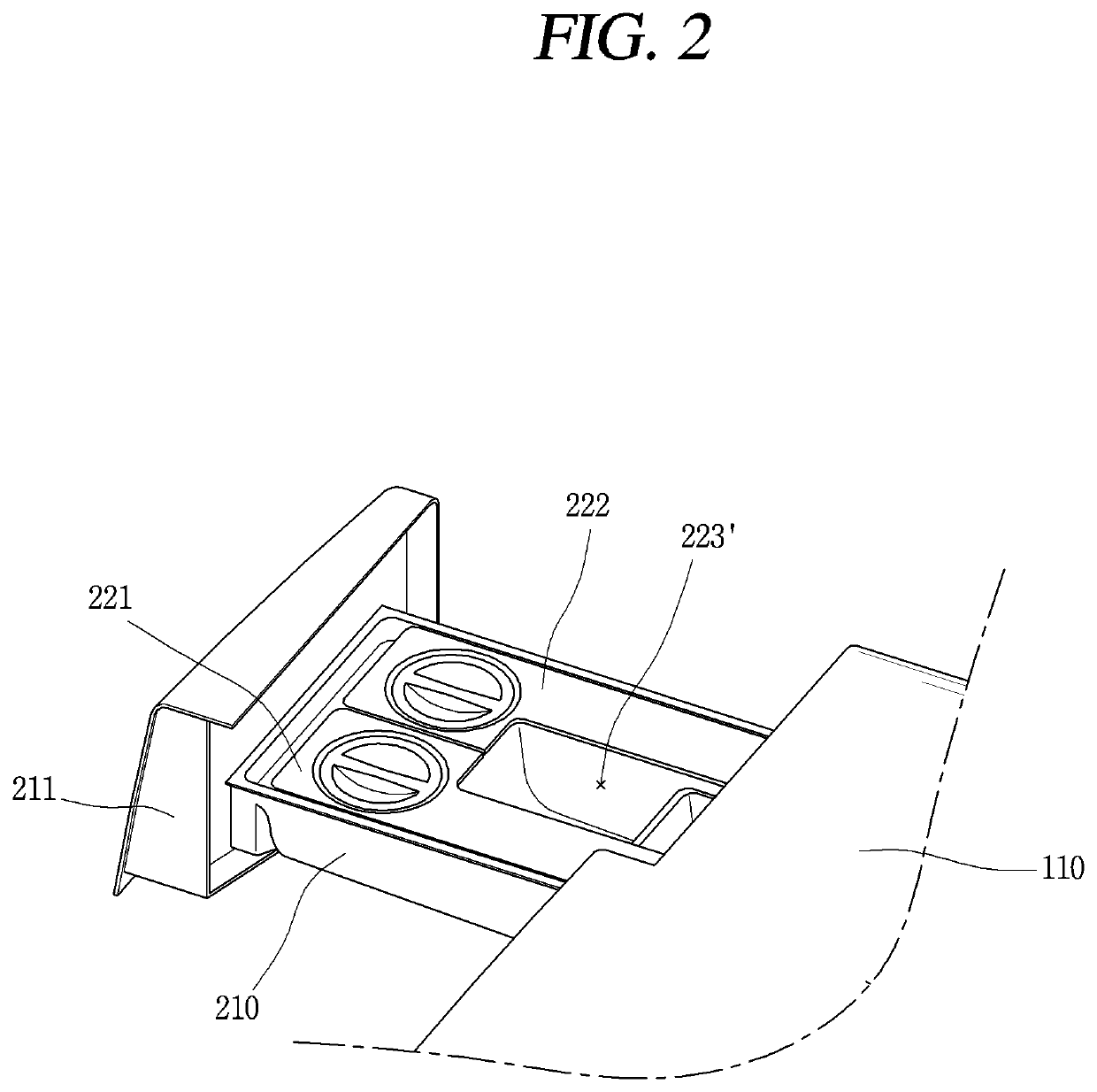

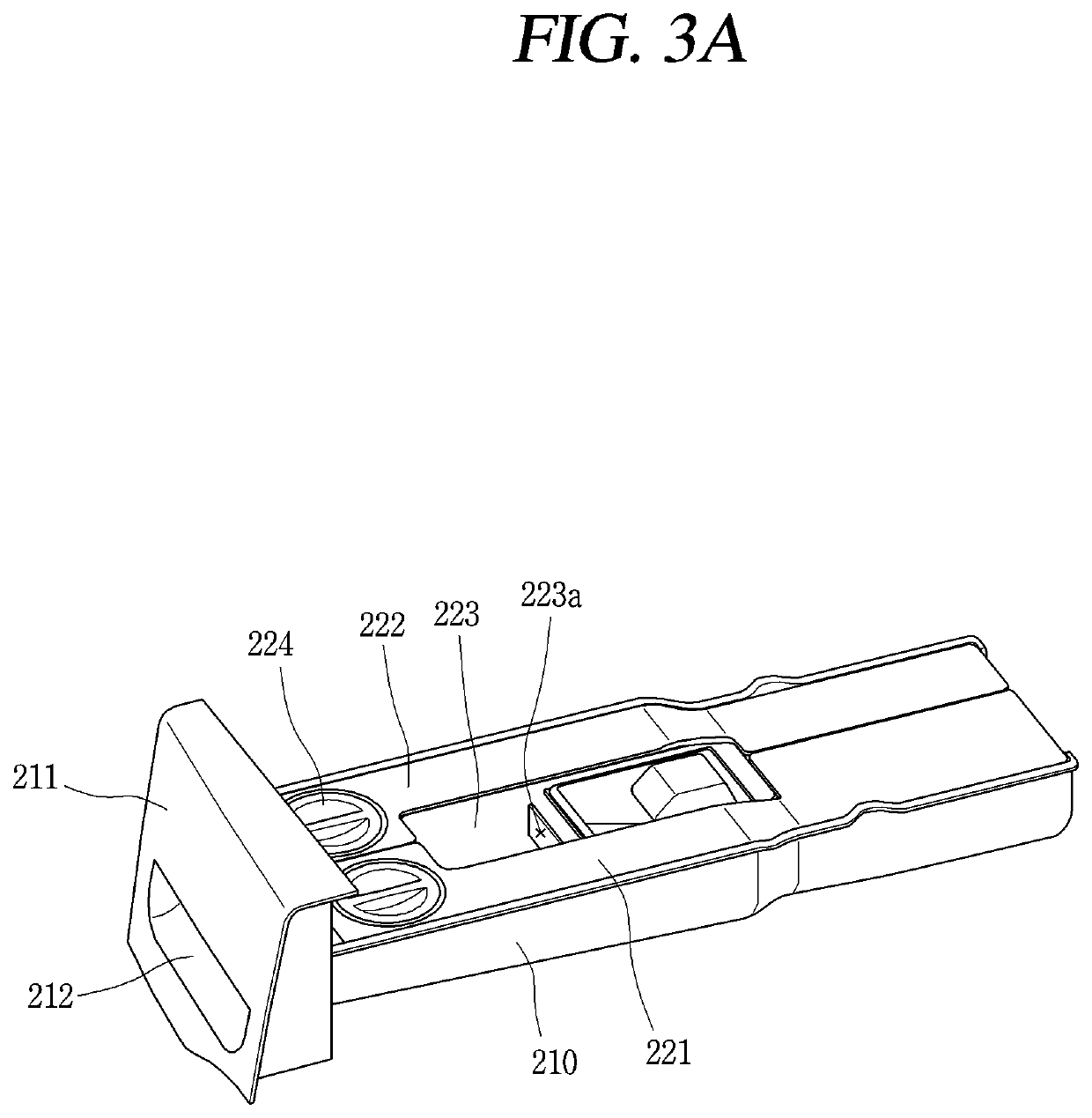

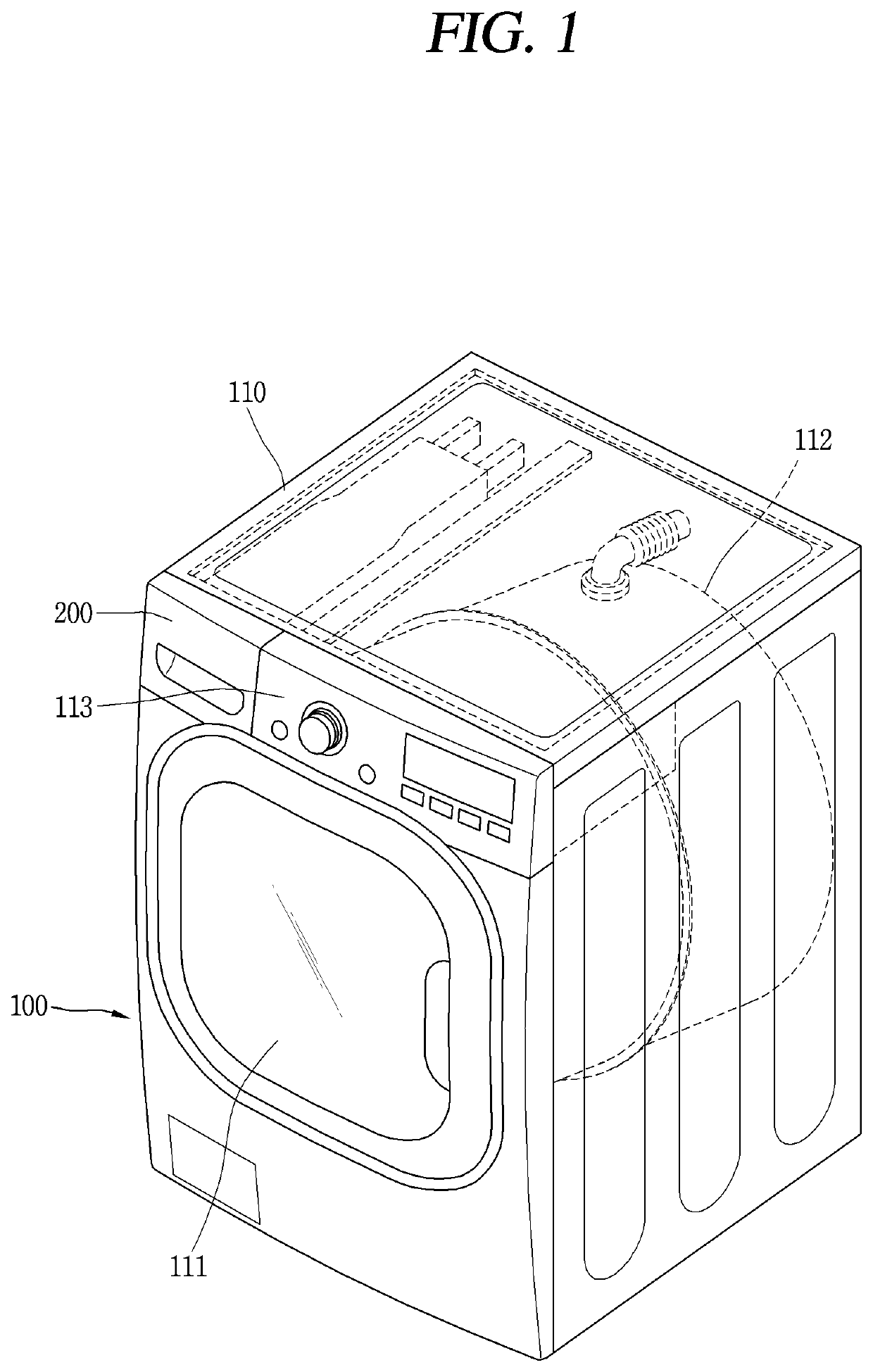

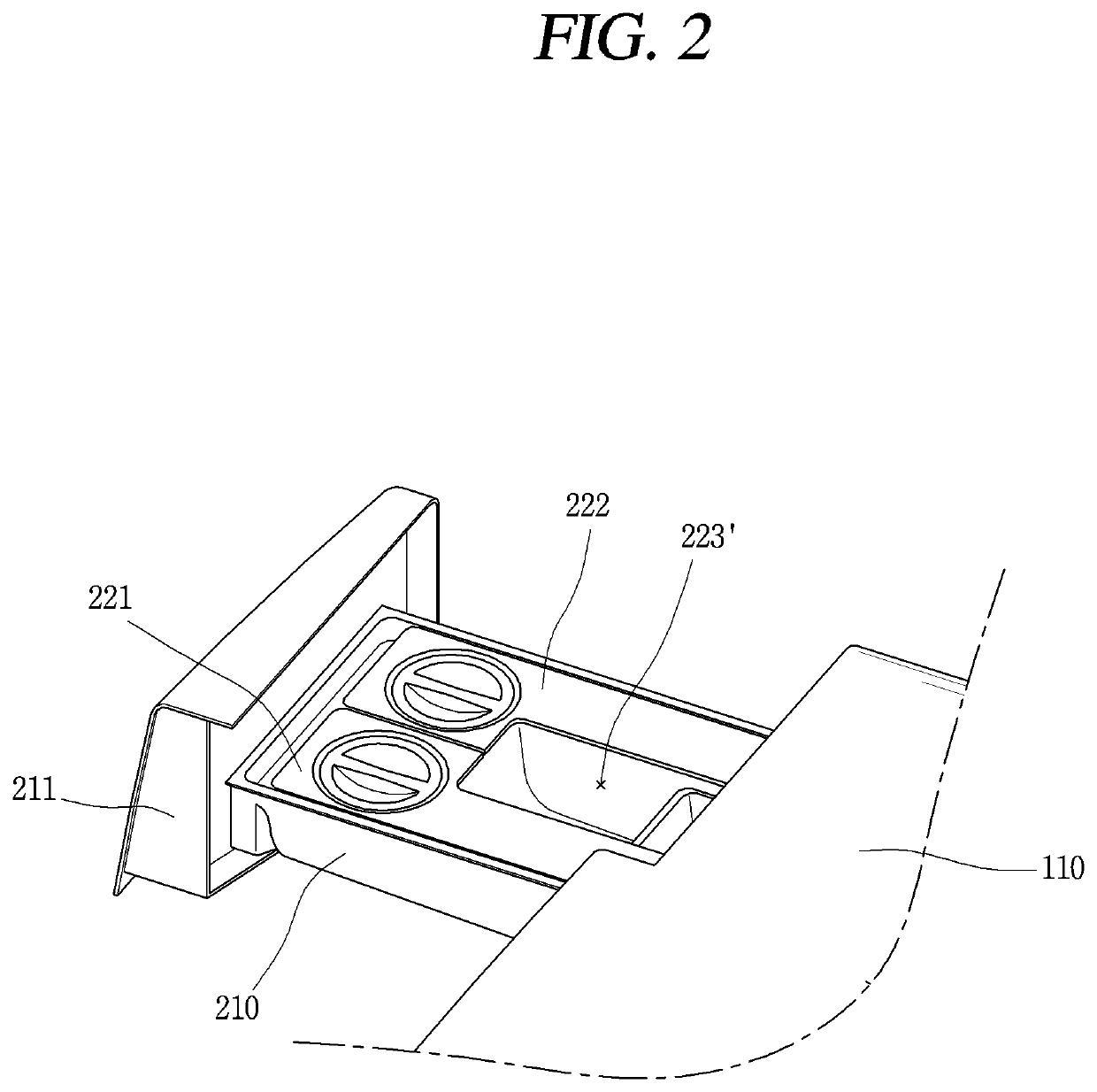

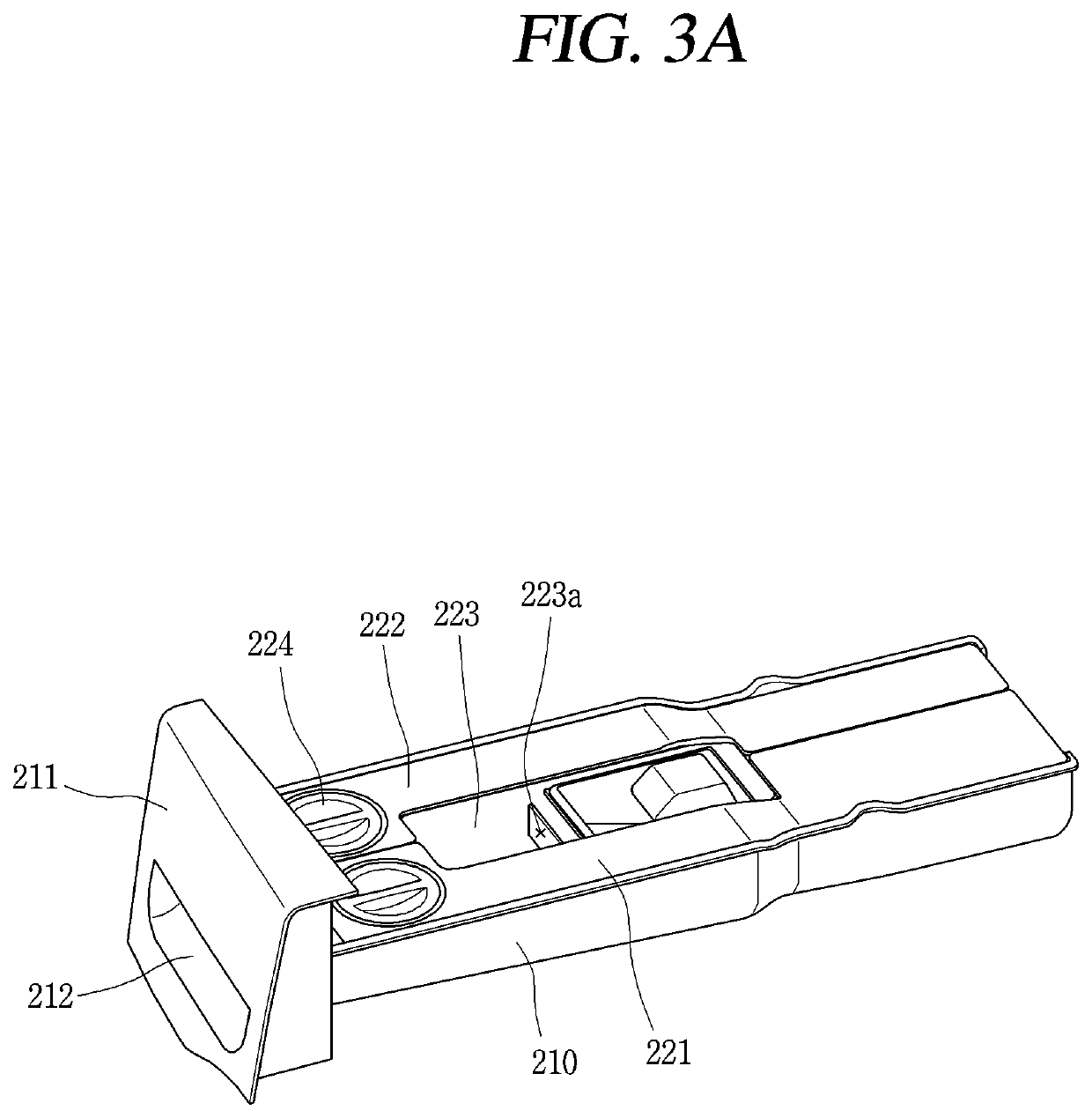

Laundry treating apparatus

ActiveUS20200232147A1Easy to useShorten the lengthOther washing machinesControl devices for washing apparatusProcess engineeringLaundry

The present disclosure relates to a laundry treating apparatus, including a tub provided inside a main body and a drum rotatably provided inside the tub; and a detergent supply apparatus configured to supply laundry detergent to the tub, and provided to be inserted into or withdrawn from a front surface of the main body, wherein the detergent supply apparatus includes a housing defining an outer appearance; a storage container disposed to extend in a front-rear direction of the main body to store the laundry detergent, and mounted to the housing; and a laundry detergent pump provided at one side of the storage container, and configured to suck laundry detergent stored in the storage container, and then to discharge the laundry detergent to a lower side of the housing.

Owner:LG ELECTRONICS INC

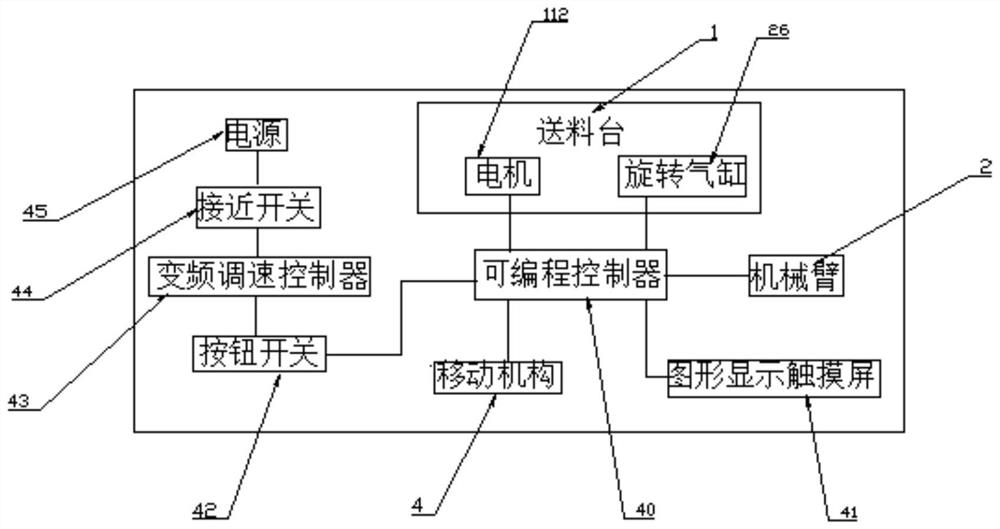

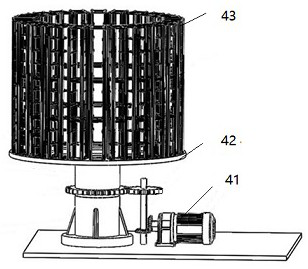

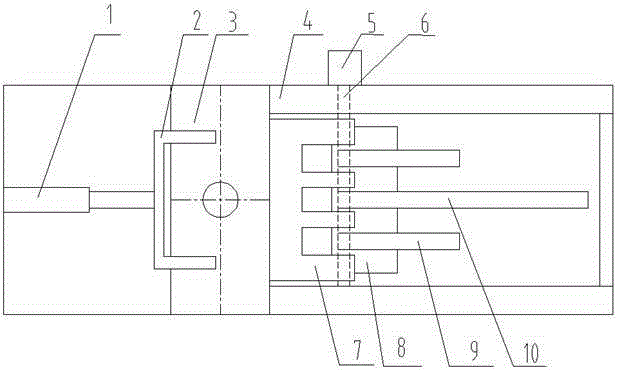

Industrial control system of stacker crane

PendingCN112783077ASimplify motion pathFull range of mobilityProgramme control in sequence/logic controllersGraphicsControl engineering

The invention discloses an industrial control system of a stacker crane. A variable-frequency speed regulation controller is sequentially connected with a proximity switch and a programmable controller; ports of the programmable controller are externally connected with a motor and a rotating air cylinder of a feeding table for conveying materials, a mechanical arm for clamping the materials, a moving mechanism for moving the mechanical arm in all directions, a driving mechanism of a claw head, a rotating mechanism and a graphic display touch screen of the stacker crane through wiring terminals respectively. The graphic display touch screen is provided with an operation interface and controls the programmable controller to execute instructions. According to the invention, the materials are continuously conveyed to the designated position in the same mode through the feeding table, the action path of the mechanical arm is simplified, meanwhile, the mechanical arm moves in all directions through the multiple sets of guide rails, the stacking efficiency is greatly improved through cooperation with the rotatable claw head, the service life of equipment is prolonged, the maintenance cost is reduced, and practicability and economical efficiency are achieved.

Owner:杭州承致智能装备有限公司

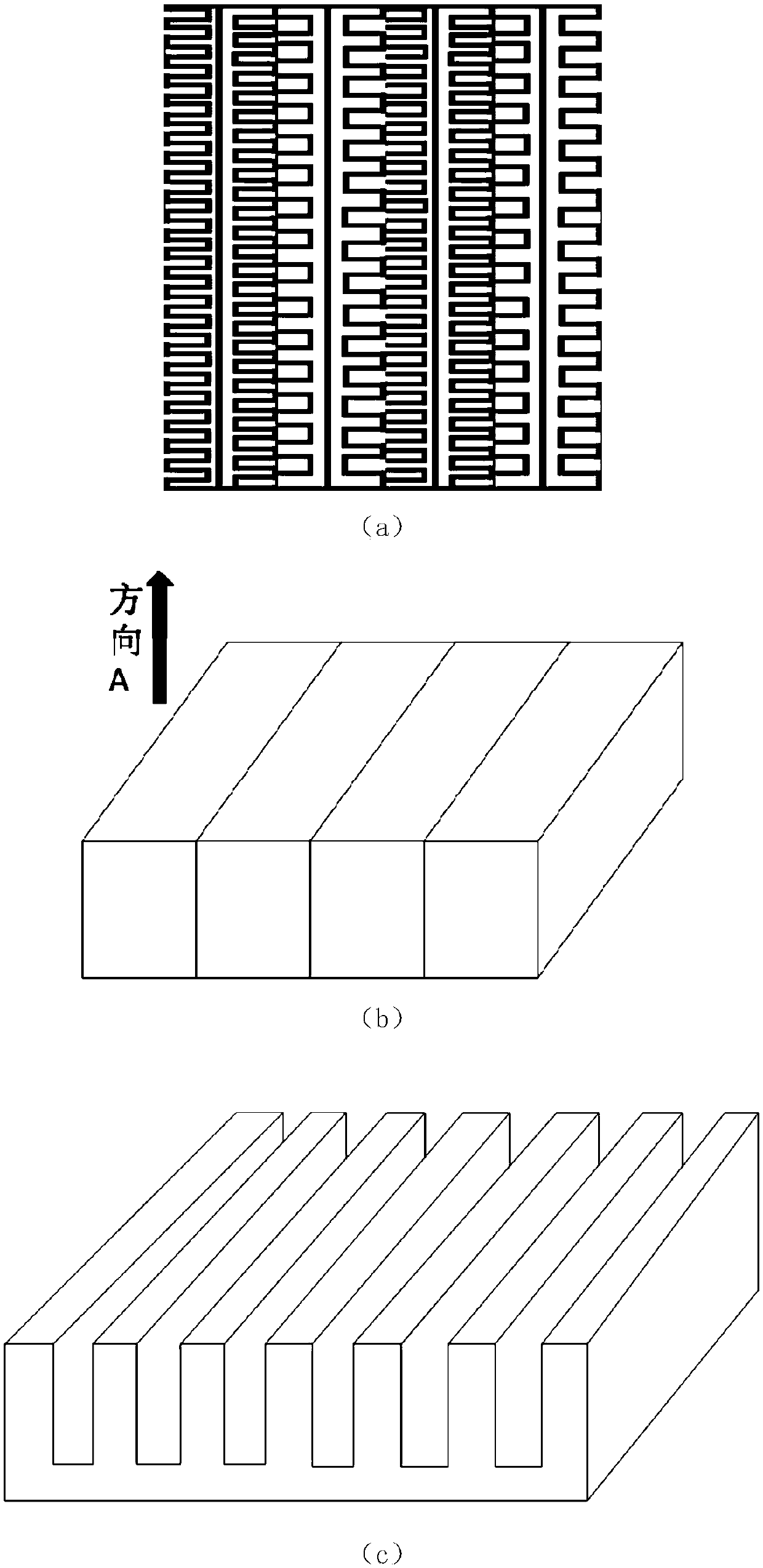

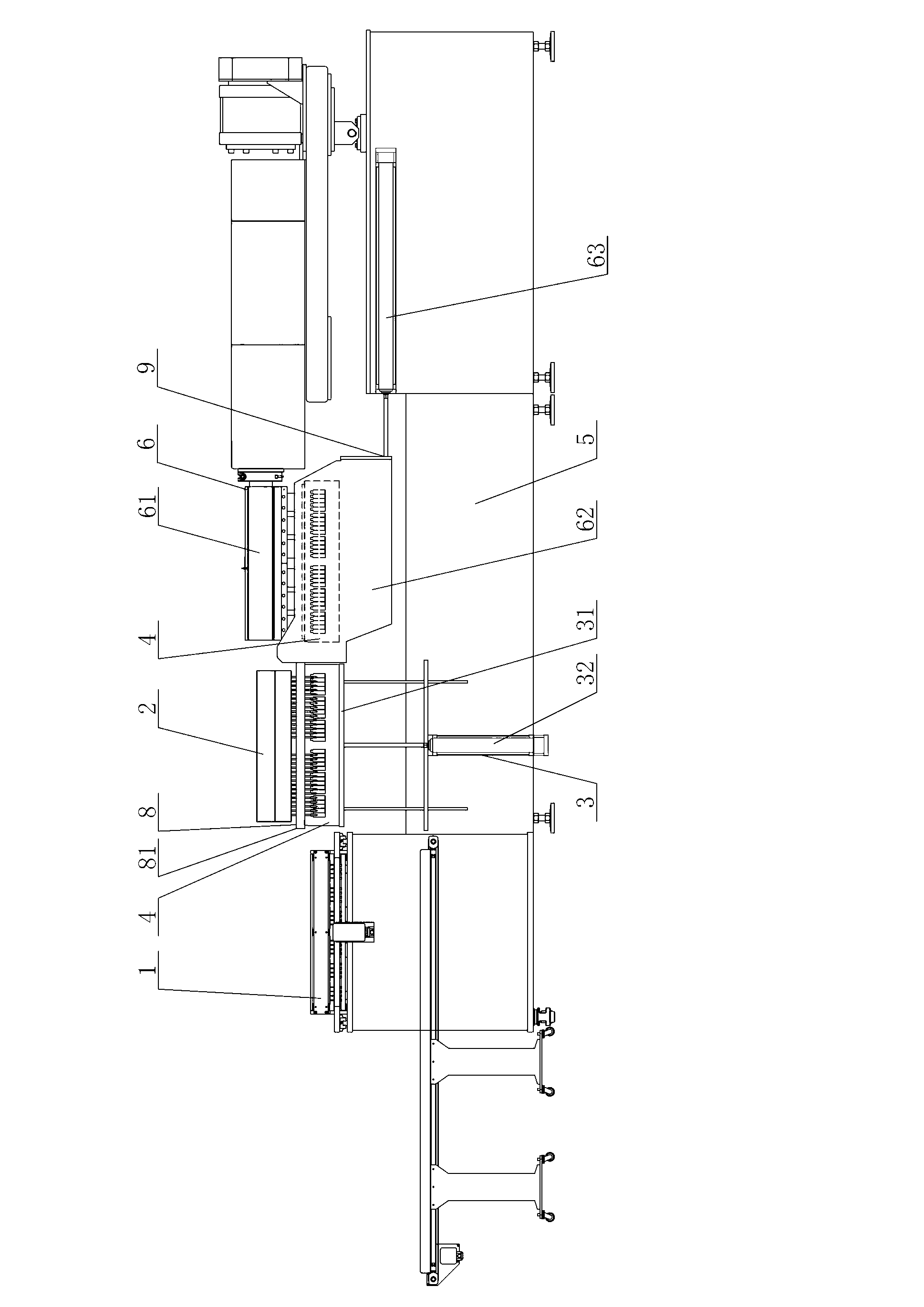

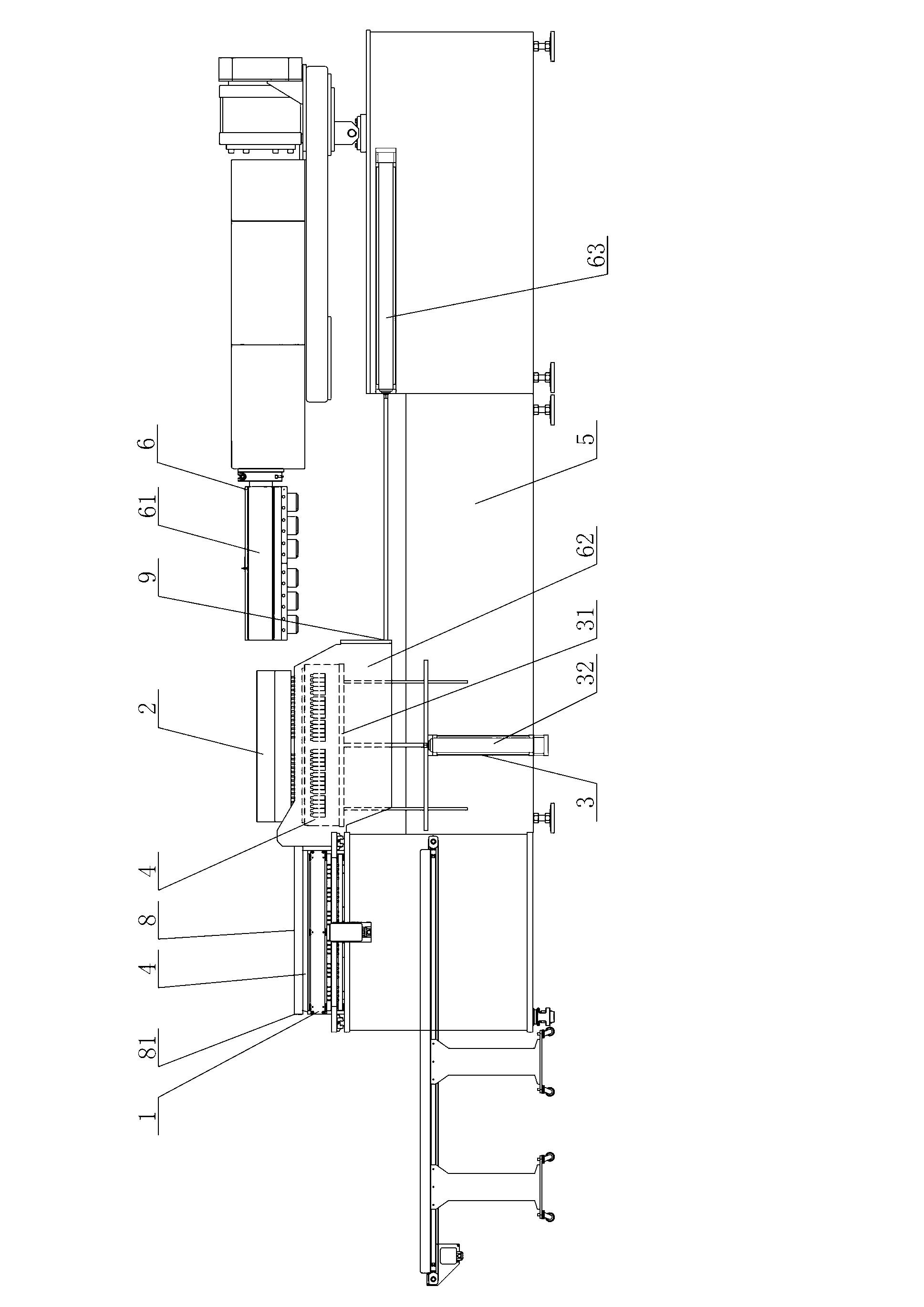

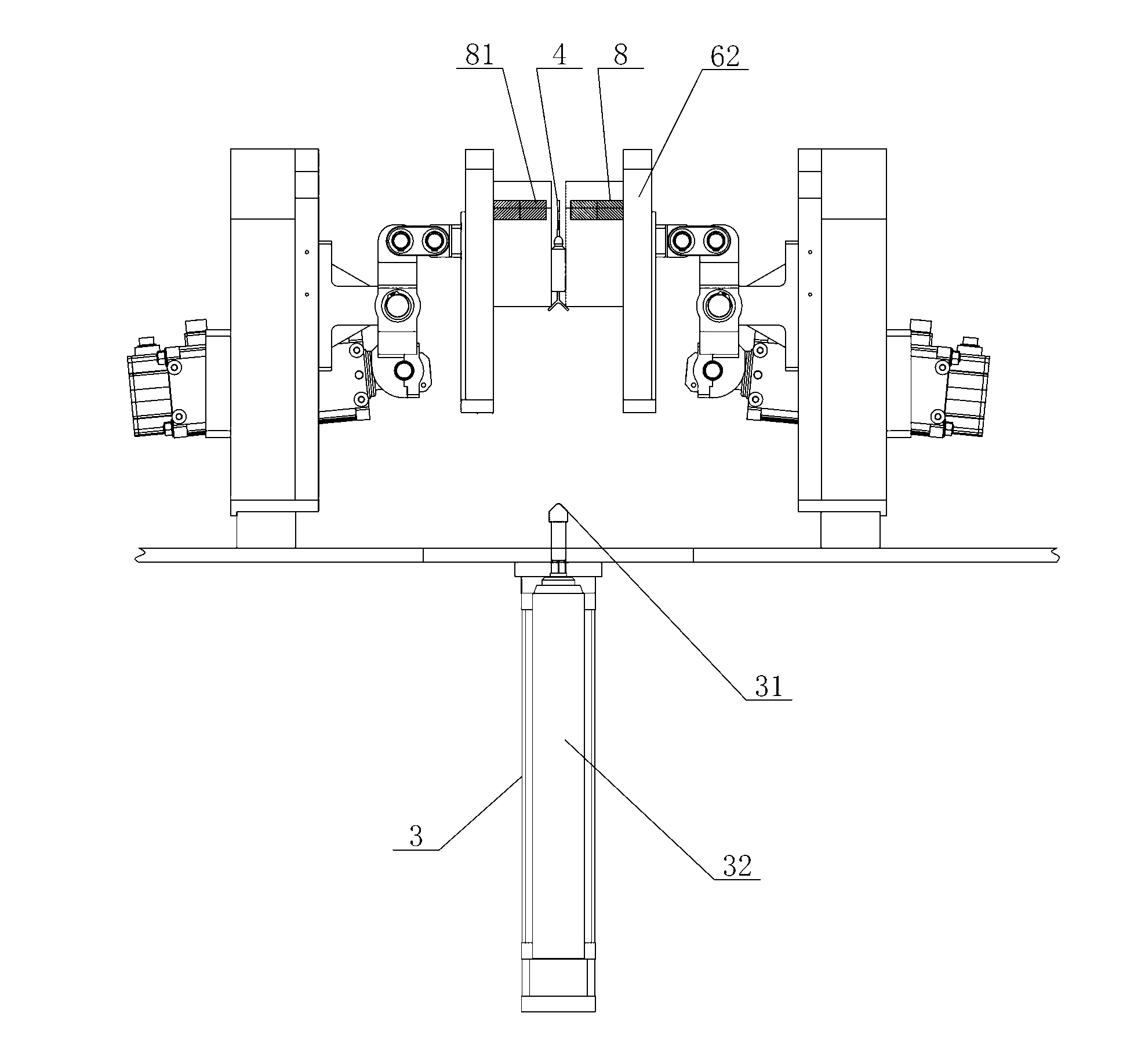

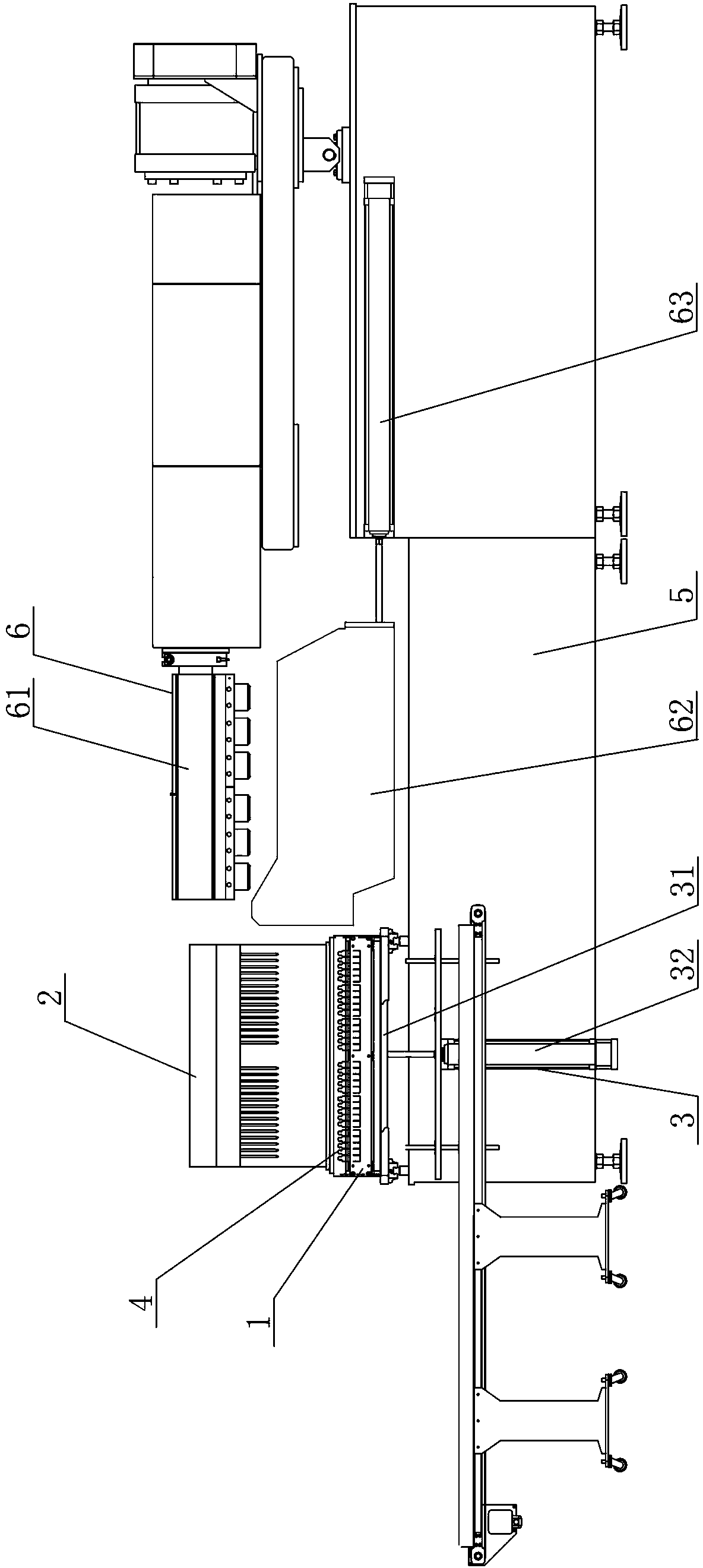

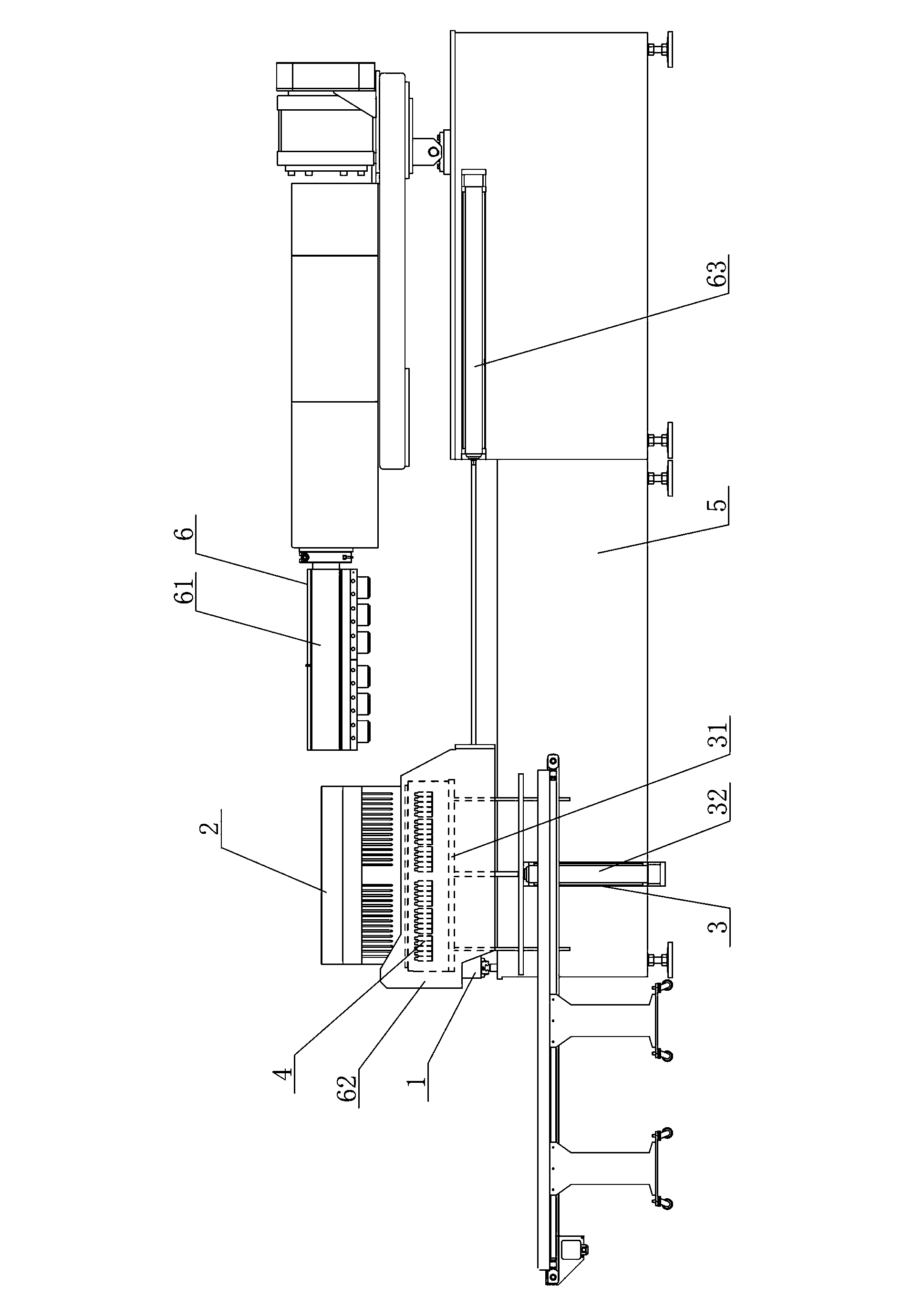

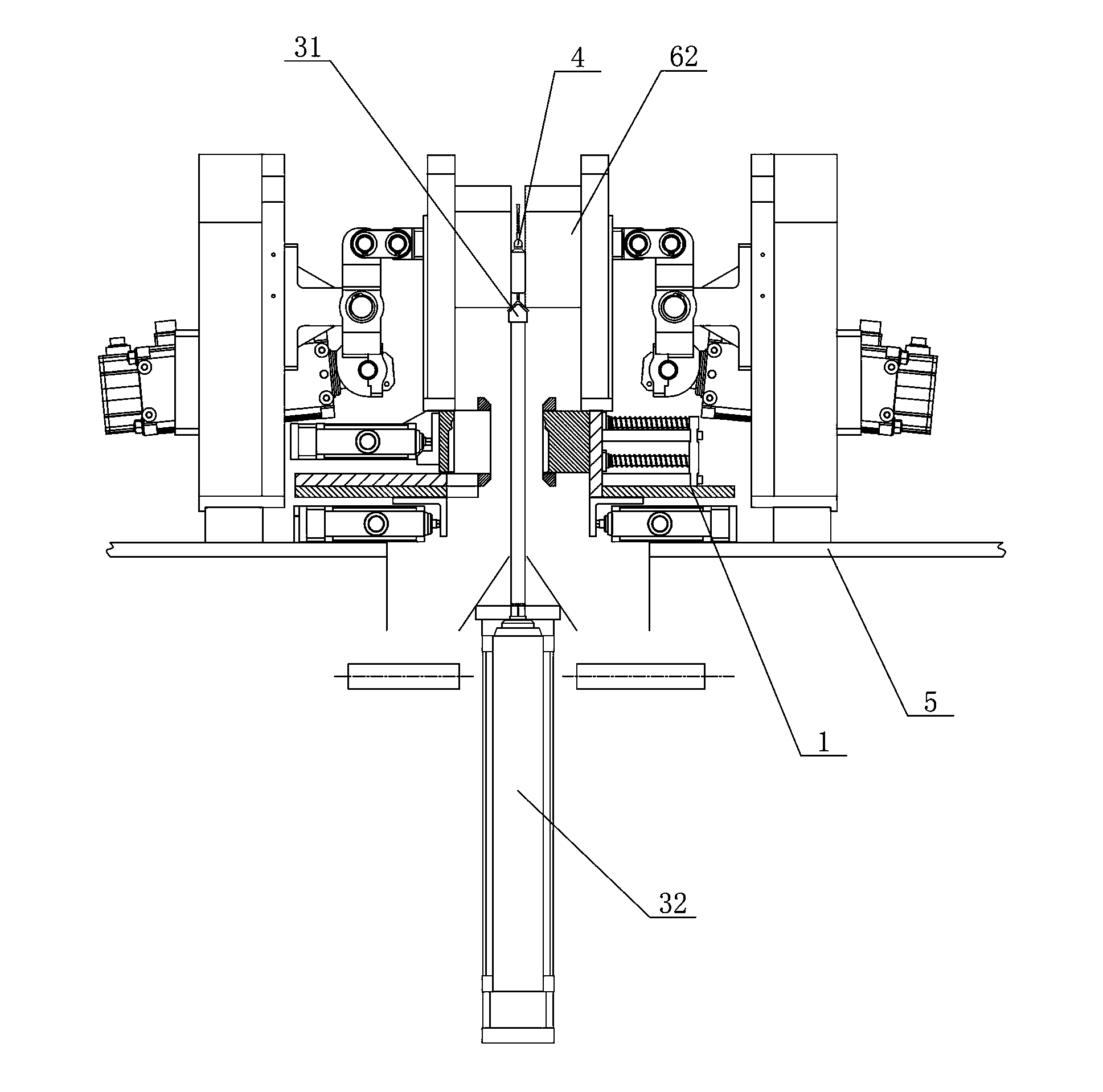

Automatic plate grooving device and plate grooving machining method thereof

ActiveCN110450244AControl rotation speedPrecise control of rotation speedWood mortising machinesBark-zones/chip/dust/waste removalControl systemEngineering

The invention provides a full-automatic plate grooving device and a plate grooving machining method thereof. The full-automatic plate grooving device comprises a workbench, a grooving assembly and a PLC control system, the workbench is provided with a conveying assembly, a first driving device and a positioning module, the grooving assembly comprises a groove saw portal frame, a second driving device and a saw blade, and the second driving device at least can drive the saw blade to move. The PLC control system controls the first driving device, the second driving device and the positioning module to realize full-automatic grooving of the plate. The technical scheme is suitable for plate grooving with low bonding strength, the depth and the width of a groove are adjustable, liquid does notneed to be used for cooling the saw blade in the grooving process, and the full-automatic accurate grooving of the plate can be realized fast.

Owner:ZHENJIANG SUNSIER DENDRO TECH CO LTD

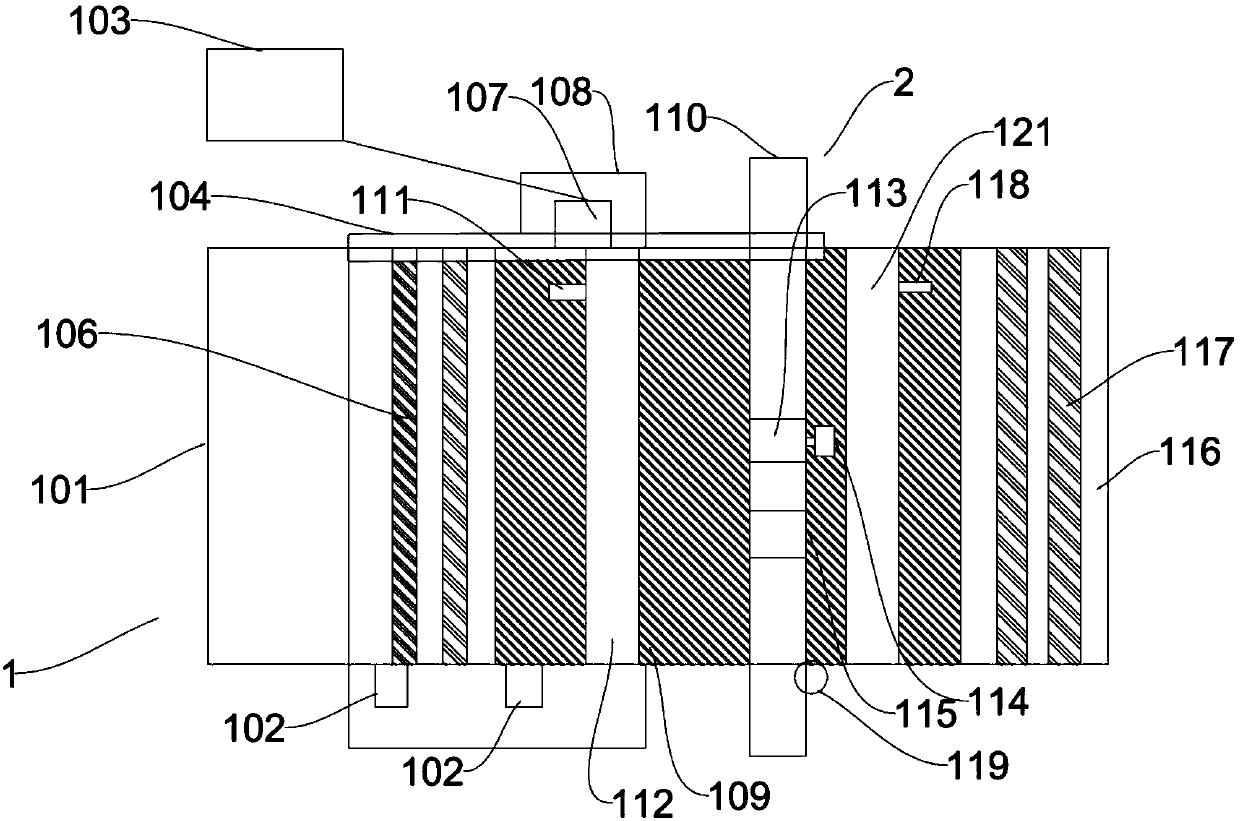

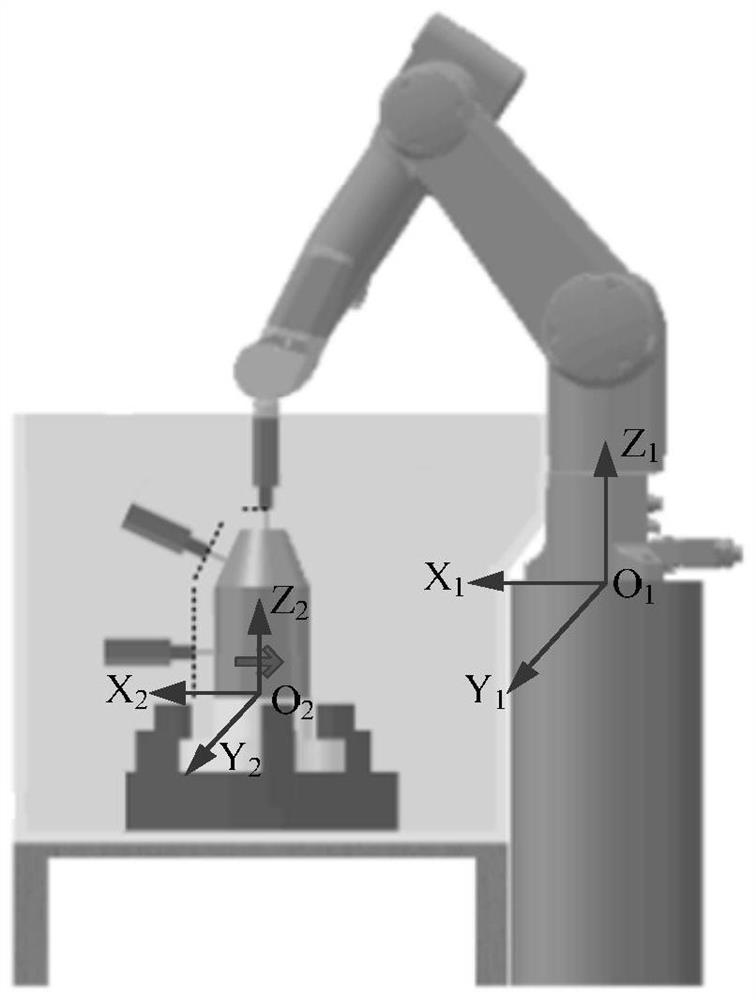

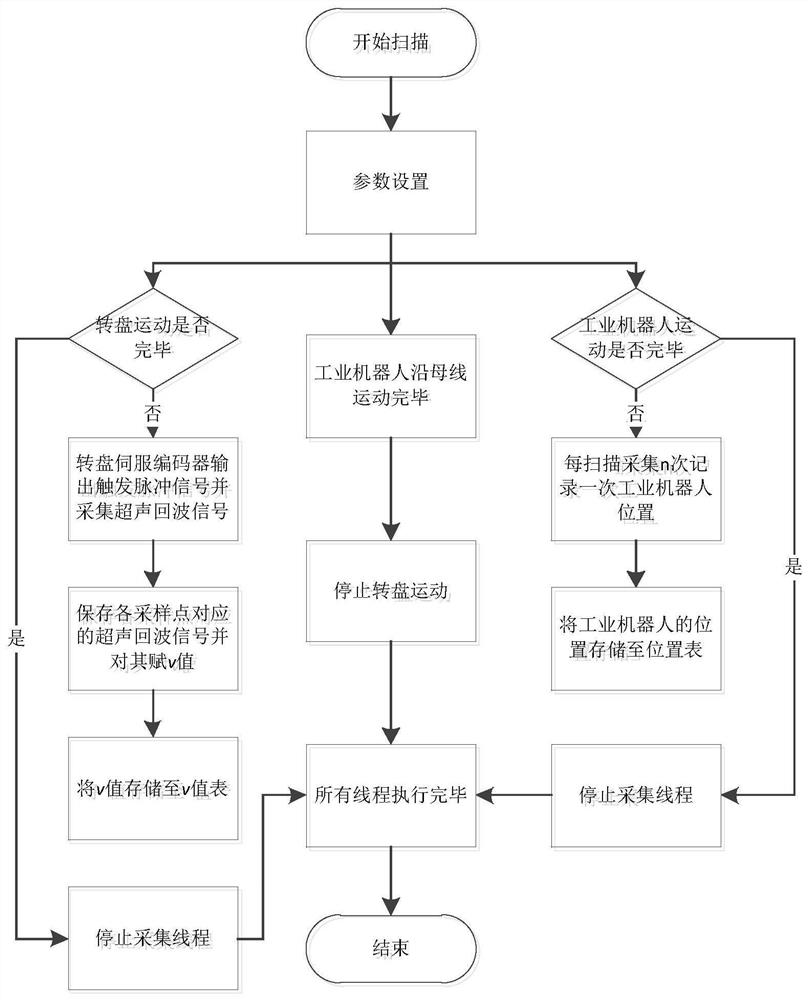

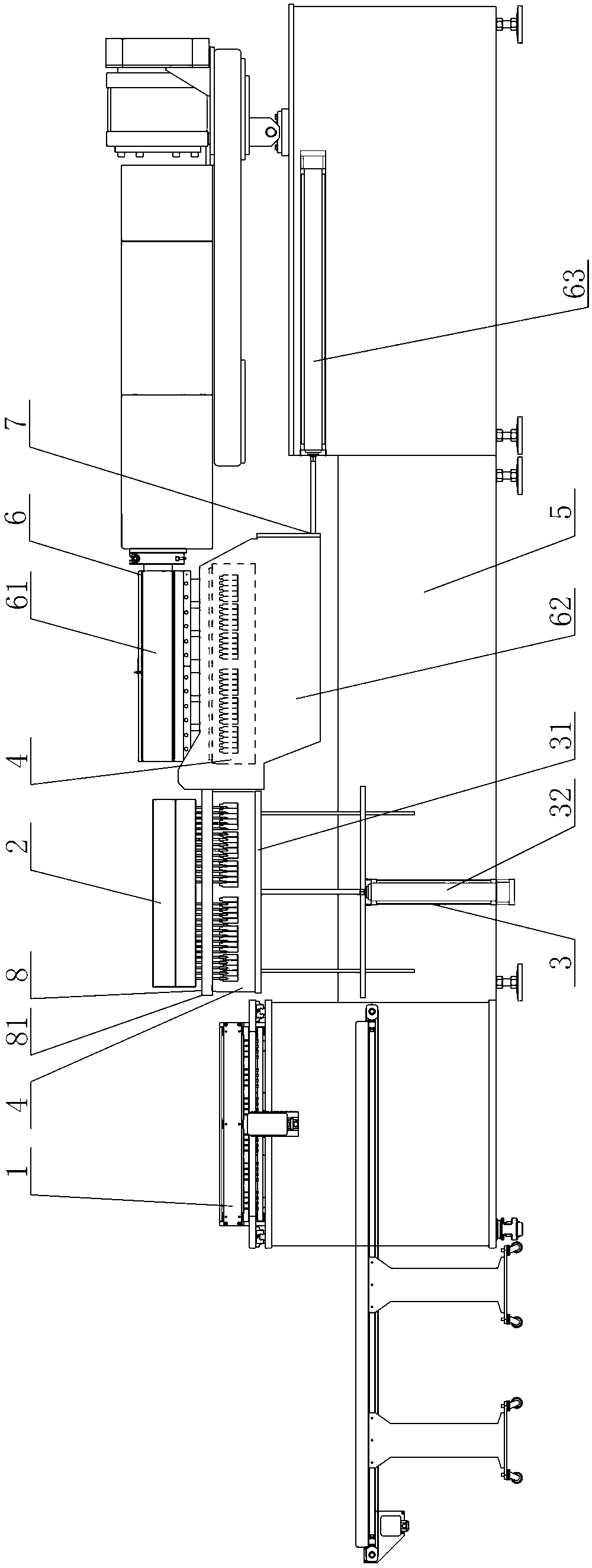

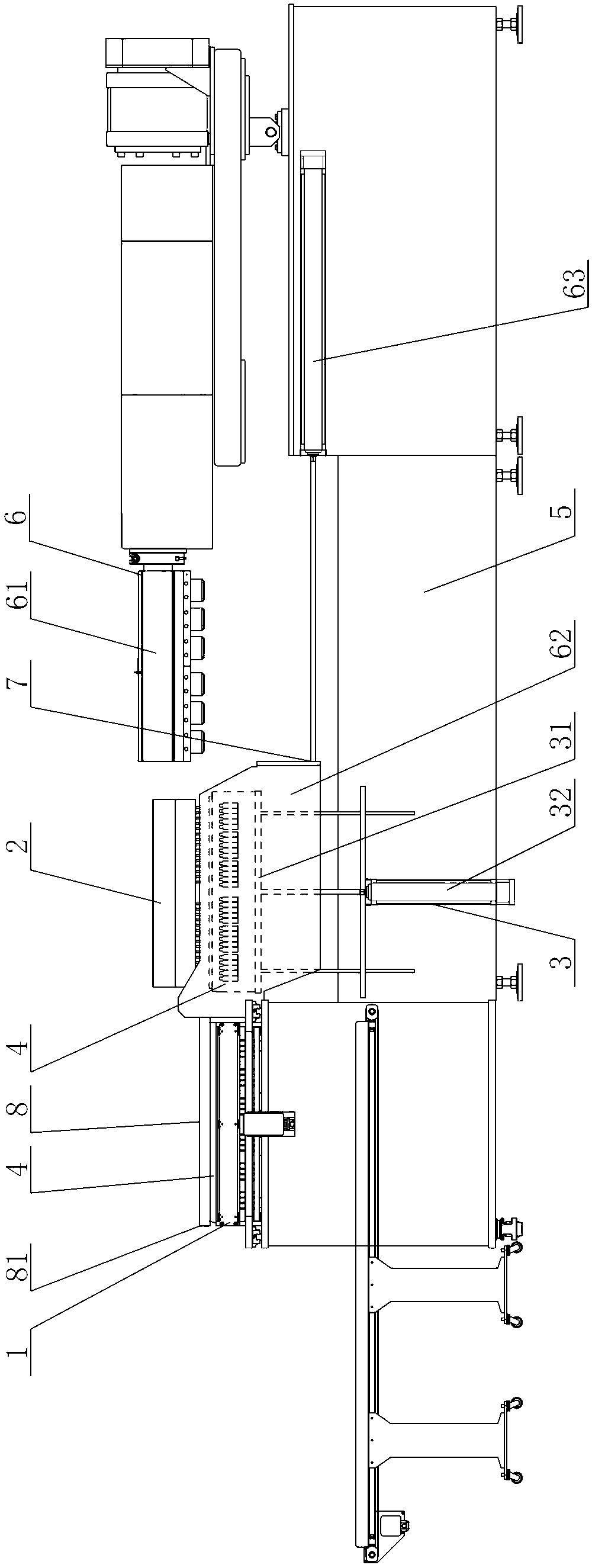

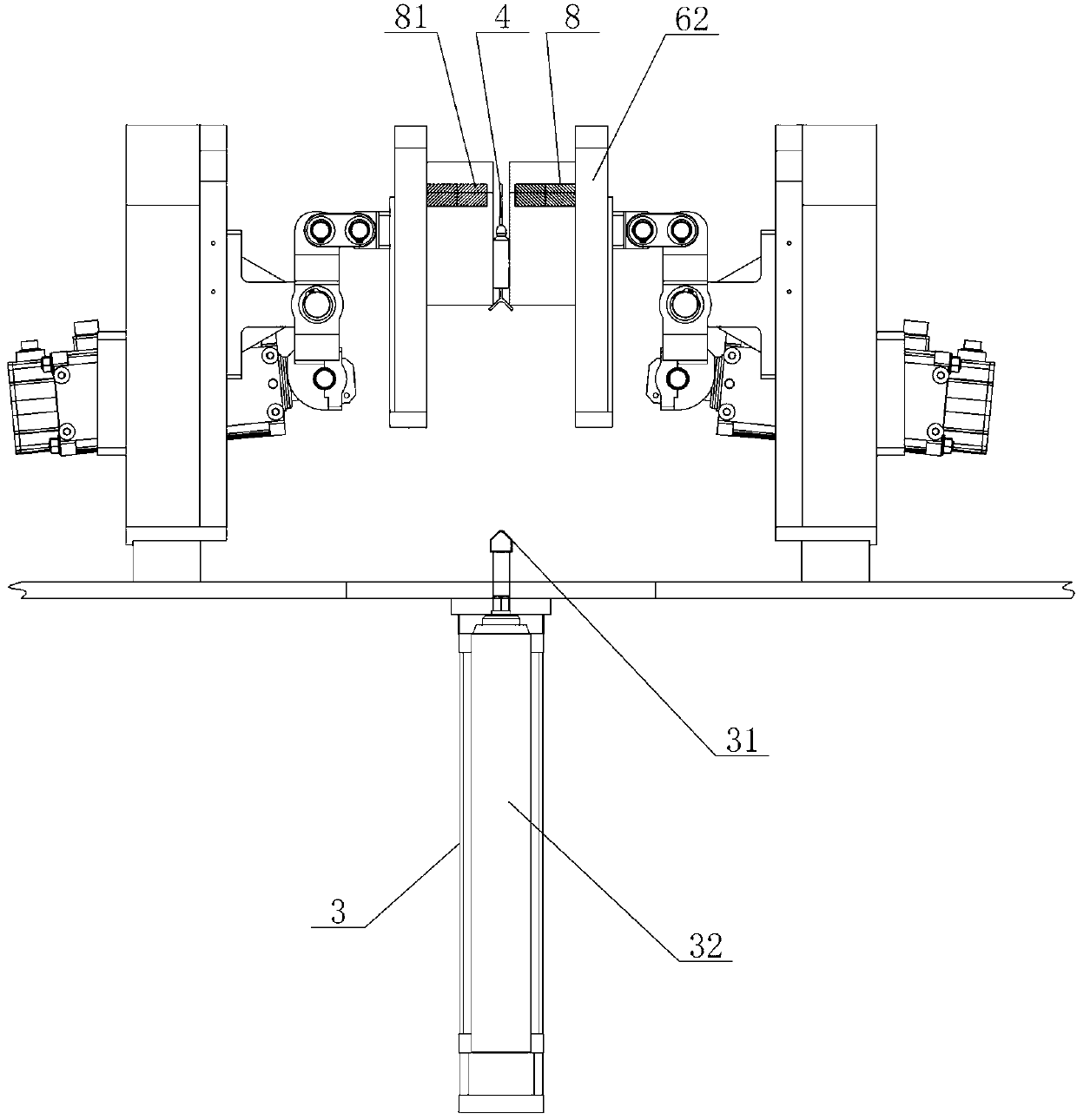

An automatic detection method of ultrasonic c-scanning based on industrial robot

ActiveCN109946382BImprove detection accuracySolving the Problem of Precise AlignmentAnalysing solids using sonic/ultrasonic/infrasonic wavesPattern recognitionTransceiver

An ultrasonic C-scan automatic detection method, comprising S1, placing a workpiece at the center of a turntable, and teaching a world coordinate system and a reference coordinate system; S2, establishing a three-dimensional imaging model according to the actual size of the workpiece, and dividing sampling points; S3, Obtain the coordinate values of the key points on the bus of the imaging model in the reference coordinate system, and calculate the position value of the industrial robot at the key points; S4, the turntable drives the workpiece to rotate, and the pulse signal is provided by the turntable servo encoder as an ultrasonic transceiver and The external trigger source of the data acquisition card, the industrial robot triggers and collects the workpiece according to each sampling point and the ultrasonic echo signal, so that the ultrasonic echo signal of each sampling point corresponds to the spatial position of the imaging model; S5, data processing , and through the color palette, the feature values of different sampling points correspond to different color values and are mapped to the C-scan image. The detection method greatly simplifies the motion path of the industrial robot and ensures high detection efficiency and detection accuracy.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Blowing encapsulation all-in-one machine for plastic ampoule

ActiveCN102431947BSolve the large amount of deformationEnsure positioning reliabilityBottle-handling machinesMetal working apparatusSmall footprintEngineering

The invention discloses a blowing encapsulation all-in-one machine for a plastic ampoule. The machine comprises a frame, and an extrusion bottle making device, an encapsulation device and a die cutting device which are arranged on the frame and are sequentially distributed along the horizontal direction according to a process, wherein an encapsulation positioning component is arranged below an encapsulation station on the encapsulation device; the extrusion bottle making device is connected with the encapsulation device through a first conveying component so as to convey bottle clamps; and the encapsulation device is connected with the die cutting device through a second conveying component so as to convey the encapsulated bottle clamps. The machine has the advantages of simple and compact structure, low cost, small occupied area, short material conveying time and the like, is conveniently and quickly positioned and is easy to control and debug.

Owner:TRUKING TECH LTD

a cnc machine tool

ActiveCN106363448BHigh degree of automationReduce labor costsProgramme-controlled manipulatorGripping headsNumerical controlManipulator

The invention discloses a CNC (computer numerical control) machine tool, which comprises a machine tool body and a protection door arranged on the machine tool body. The CNC machine tool is characterized by also comprising a material taking system, wherein the material taking system comprises a mechanical hand device and a material cabin; the mechanical hand device is arranged in front of the protection door and is used for feeding and material taking; the material cabin is arranged at one side of the machine tool body and is sued for putting and conveying processing parts. The CNC machine tool has the advantages that the structure is simple; the automation degree is high; the feeding and material taking of the processing parts can be automatically performed.

Owner:广州市新滘热处理厂

A fully automatic quality control system

ActiveCN113298975BFully automatedGuaranteed sterilityRegistering/indicating quality control systemsRegistering/indicating during manufacturing processQuality control systemMachine

The present invention relates to the field of biotechnology, and relates to a fully automatic quality control system, including a product storage area, a quality inspection area and a control system arranged in a positive pressure environment. The control system has a collection of several control processes of a robotic arm, A set of image groups of each manipulation site formed according to the corresponding time axis of each manipulation process of the robotic arm A; at the same time, an image verification unit is built into the control system for converting the robotic arm captured by the camera system The real-time video stream of a certain control process is compared with the control image group corresponding to the control process according to time points. The technical scheme of the present application realizes comprehensive automatic detection in the cell production process, and effectively ensures the quality stability in the mass production process of cells.

Owner:HELP STEM CELL INNOVATIONS CO LTD

Blowing, filling and sealing integrated machine for plastic ampoule

ActiveCN102381673BSolve the large amount of deformationEnsure positioning reliabilityBottle-handling machinesMetal working apparatusSmall footprintBottle

The invention discloses a blowing, filling and sealing integrated machine for a plastic ampoule, which comprises a machine frame, and an extrusion bottle making device, a filling and sealing device and a die cutting device which are sequentially arranged according to procedures in the horizontal direction, a filling and sealing positioning component is arranged below a filling and sealing stationon the filling and sealing device, the extrusion bottle making device is connected with the filling and sealing device through a first conveying component so as to accomplish the conveying to bottle clamps, the filling and sealing device is connected with the die cutting device through a second conveying component so as to accomplish the conveying to the bottle clamps after filling and sealing, and a slot cutting component is mounted on the die cutting device. The blowing, filling and sealing integrated machine disclosed by the invention has the advantages of simple and compact structure, lowcost, small occupied area, short material conveying time, convenience and fastness in positioning, and easiness in control and debugging, and the like.

Owner:TRUKING TECH LTD

Plastic ampoule blowing, filling and sealing all-in-one machine

ActiveCN102515071BSolve the large amount of deformationEnsure positioning reliabilityBottle-handling machinesMetal working apparatusSmall footprintMechanical engineering

The invention discloses a plastic ampoule blowing, filling and sealing all-in-one machine comprising a frame, and a filling and sealing device, a die cutting device, an extrusion ampoule manufacturing device and a positioning component which are arranged on the frame; the die cutting device is arranged right below the filling and sealing device; the positioning component is arranged below the filling and sealing device and can take an ampoule clip to reach a die cutting station or a filling and sealing station through lifting motion; and a slotted component is arranged on the die cutting device. The plastic ampoule blowing, filling and sealing all-in-one machine has the advantages of simple and compact structure, low cost, small occupied area, short conveying time, convenient and quick positioning, easiness in control and debugging and the like.

Owner:TRUKING TECH LTD

Conveying system for wafer-shaped object

ActiveCN102502253BSimplify motion pathFast and reliable accessConveyor partsManufacturing technologyEngineering

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

Laundry treating apparatus

ActiveUS11332873B2Easy to useShorten the lengthOther washing machinesControl devices for washing apparatusProcess engineeringLaundry

The present disclosure relates to a laundry treating apparatus, including a tub provided inside a main body and a drum rotatably provided inside the tub; and a detergent supply apparatus configured to supply laundry detergent to the tub, and provided to be inserted into or withdrawn from a front surface of the main body, wherein the detergent supply apparatus includes a housing defining an outer appearance; a storage container disposed to extend in a front-rear direction of the main body to store the laundry detergent, and mounted to the housing; and a laundry detergent pump provided at one side of the storage container, and configured to suck laundry detergent stored in the storage container, and then to discharge the laundry detergent to a lower side of the housing.

Owner:LG ELECTRONICS INC

Symmetrical three-dimensional micromanipulator with three-stage motion amplification mechanism

ActiveCN109909976BFirmly connectedActive releaseProgramme-controlled manipulatorGripping headsMicromachineryManipulator

Owner:TIANJIN UNIV

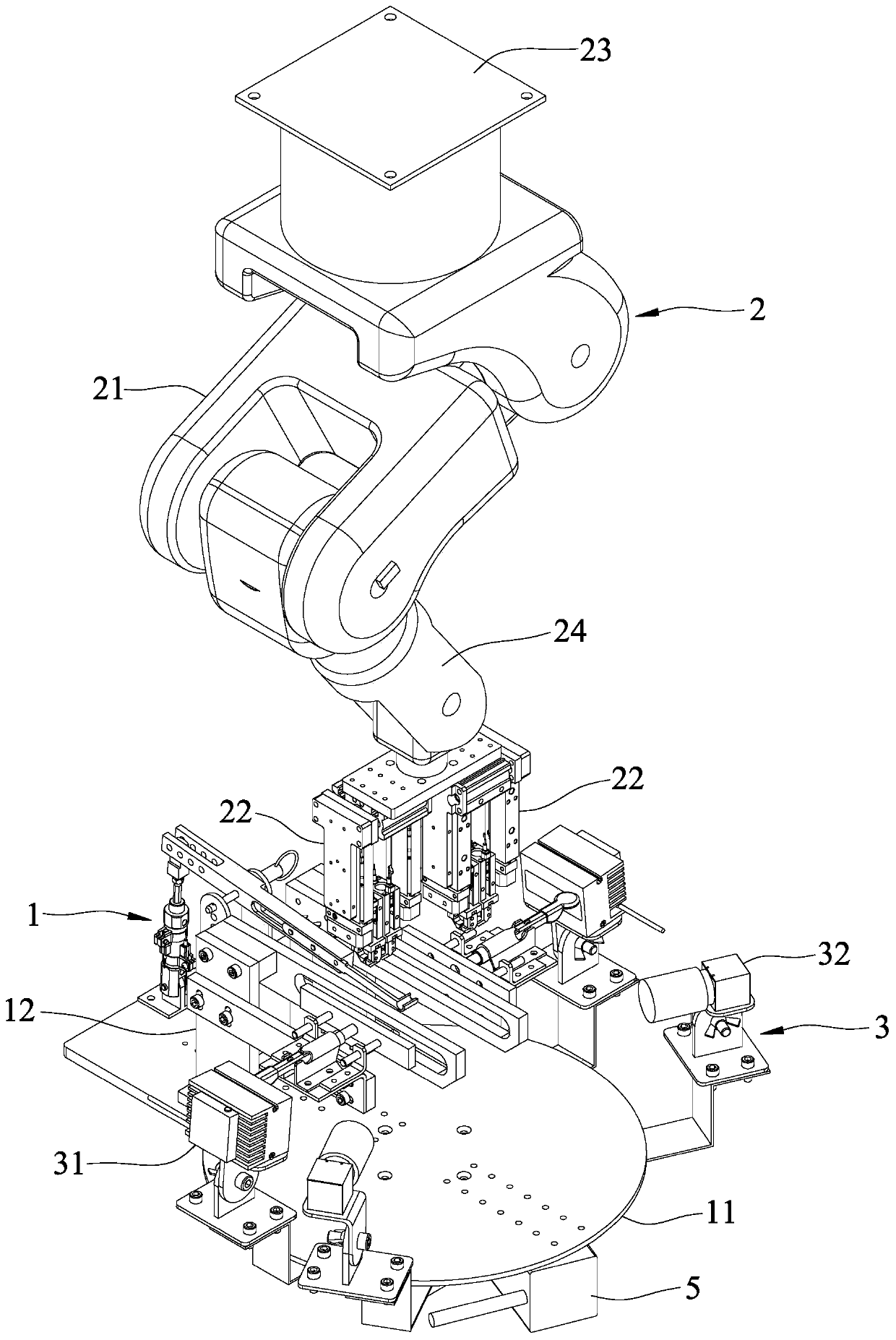

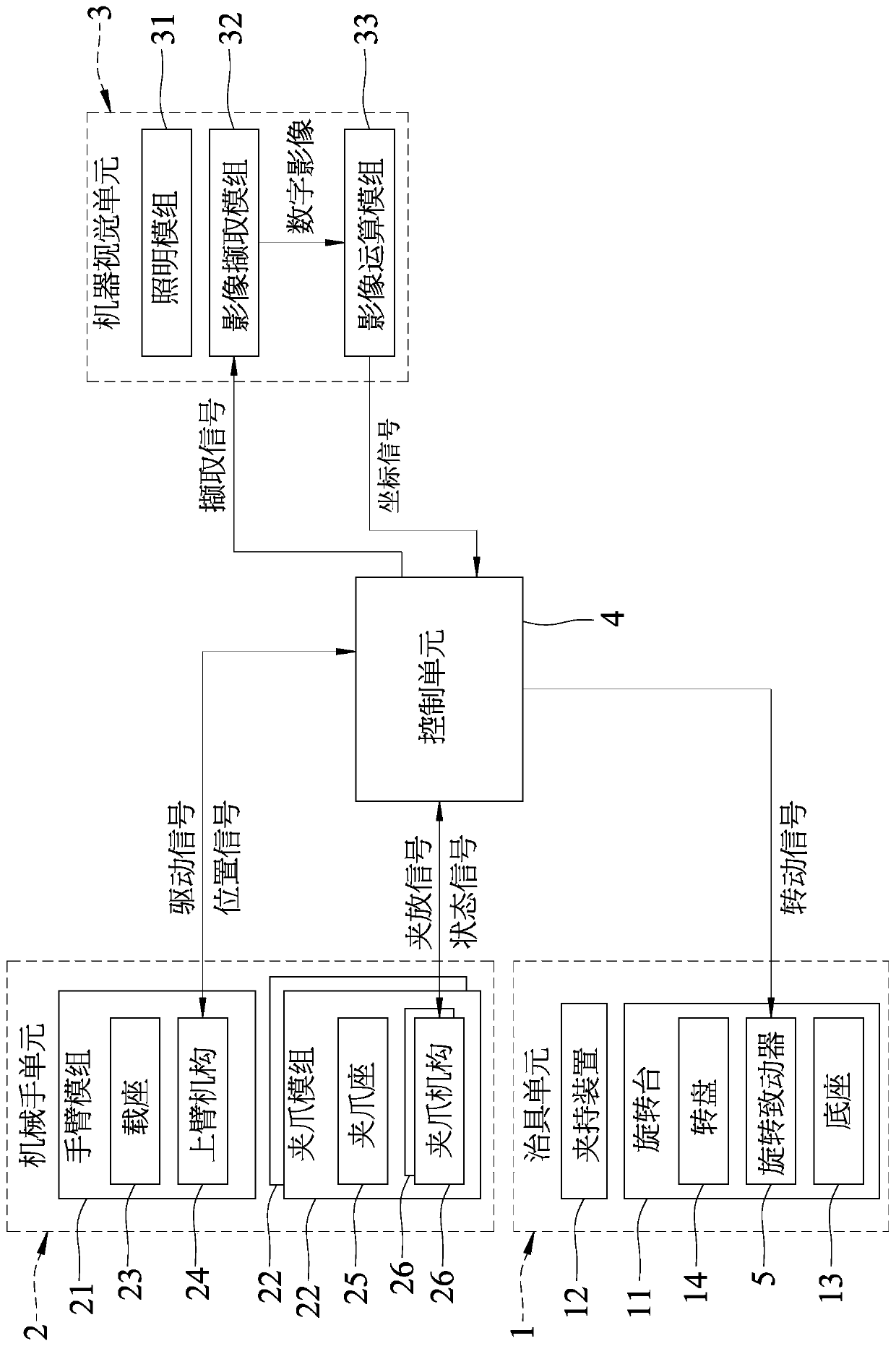

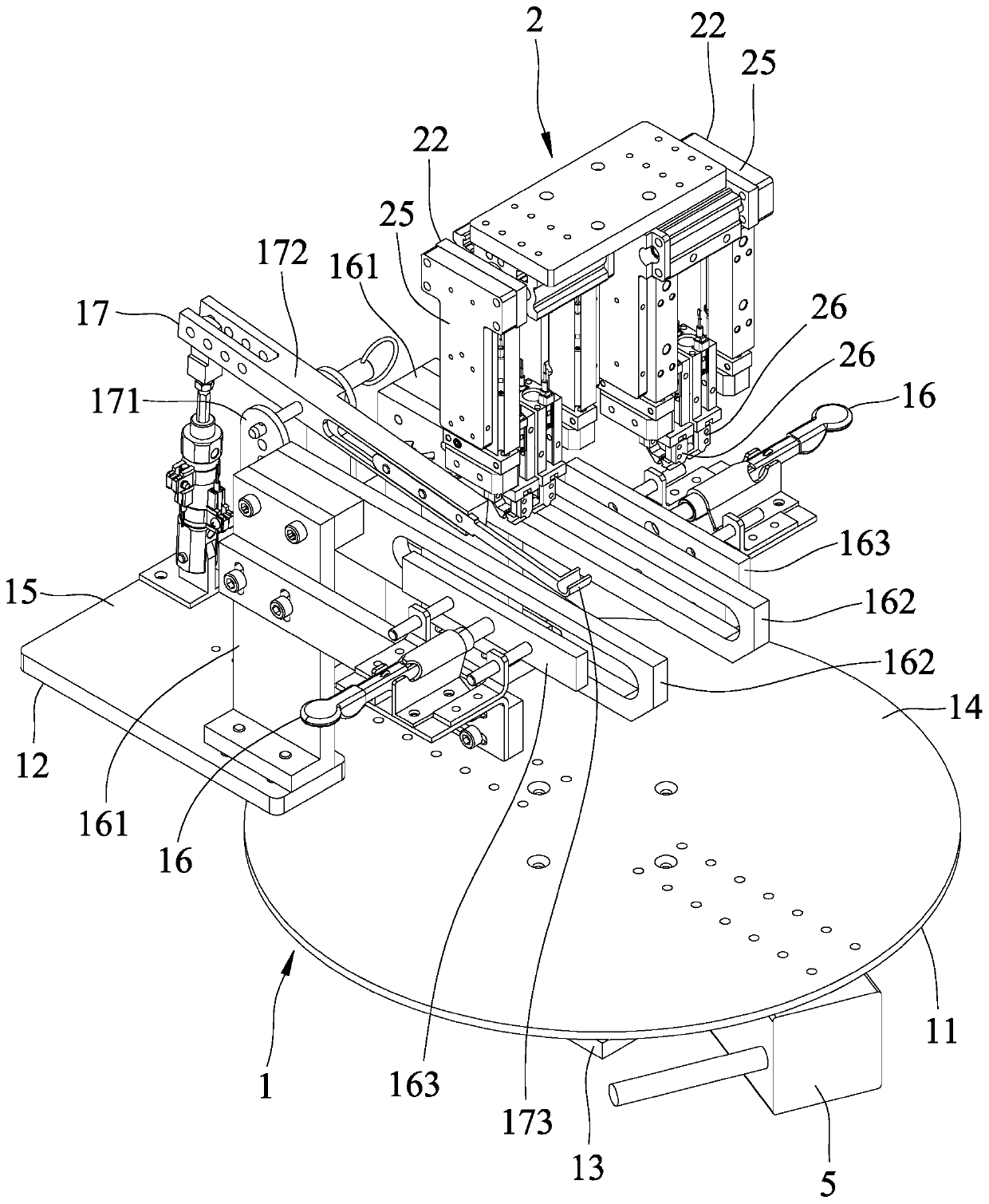

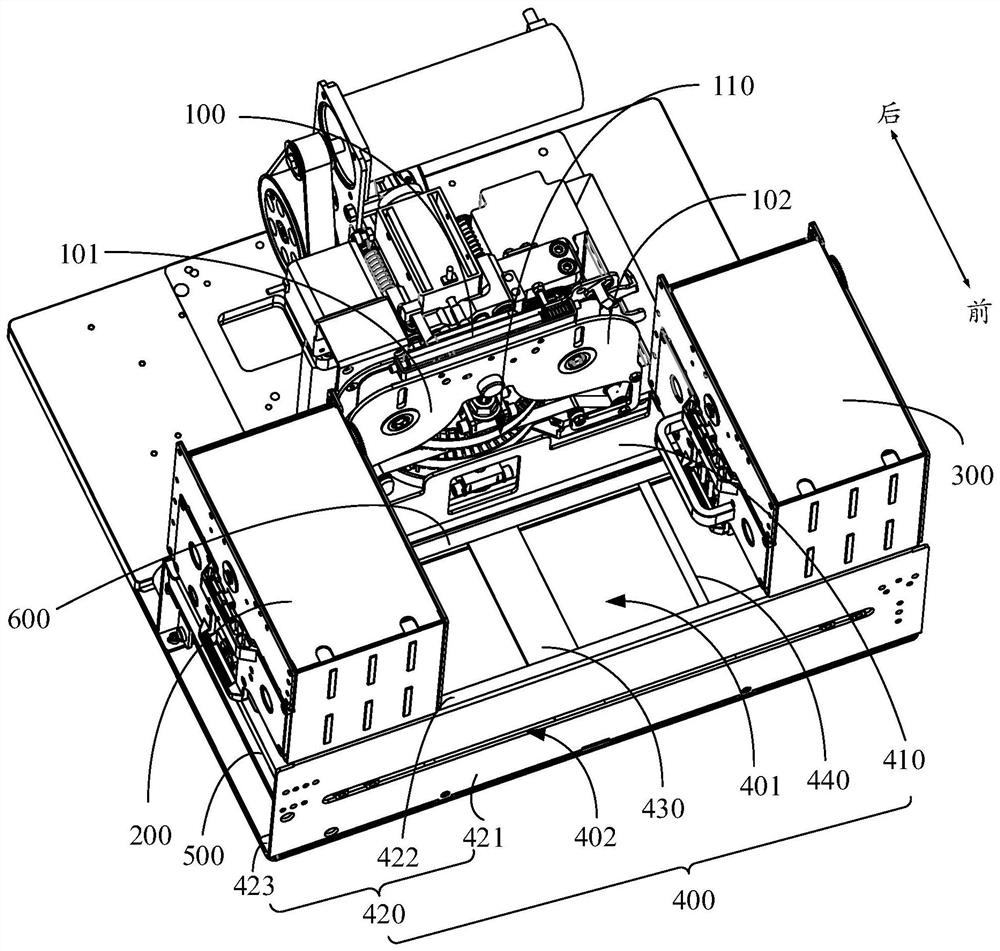

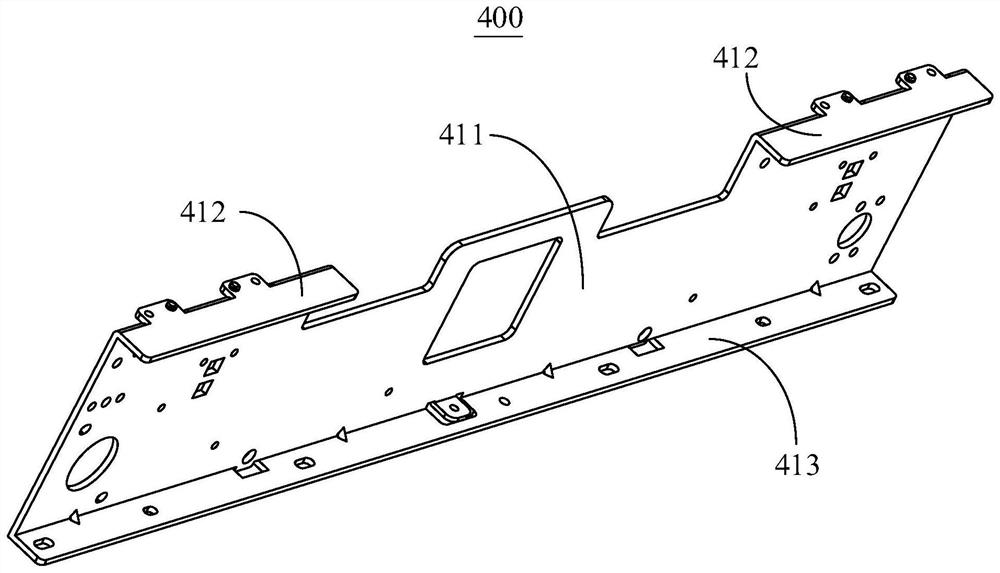

Automatic shoelace machine and shoe upper processing method

ActiveCN108567200BSimplify motion pathSimplified range of movementShoemaking devicesMachine visionShoe laces

The invention provides an automatic shoelace tying machine and a vamp processing method. According to the automatic shoelace tying machine, a shoelace can penetrate into a vamp part. The shoelace comprises two end coating parts and a flexible section. The vamp part comprises two eyelet pieces with multiple shoelace holes. The automatic shoelace tying machine comprises a jig unit, a mechanical handunit, a machine vision unit and a control unit. The jig unit is arranged on the vamp part. The mechanical hand unit can clamp or release the end coating parts at the same time and enable the end coating parts to sequentially penetrate through the shoelace holes. The machine vision unit can detect the positions of the shoelace holes and output a coordinate signal related to the position of one ofthe shoelace holes. The control unit receives the coordinate signal and outputs a drive signal for controlling the mechanical hand unit to act. By means of the automatic shoelace tying machine, the processing time of automatic shoelace tying can be shortened, and the acting complexity of the mechanical hand unit can be reduced.

Owner:POU CHEN CORPORATION

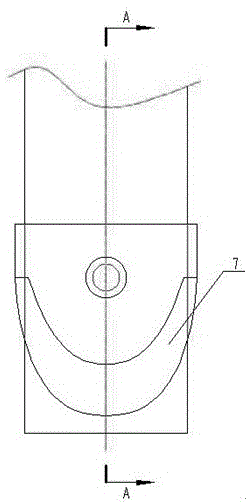

A two-degree-of-freedom folding and unfolding three-dimensional micromanipulator with a three-stage amplifying mechanism

ActiveCN111546312BSimplify motion pathFirmly connectedProgramme-controlled manipulatorGripping headsBridge typeManipulator

The invention discloses a two-degree-of-freedom folding and unfolding three-dimensional micro-manipulator with a three-stage amplifying mechanism, which is composed of two sets of identical three-stage amplifying mechanisms folded along a symmetrical axis; the three-stage amplifying mechanism includes a lever displacement amplifying mechanism I, a half-bridge displacement Amplifying mechanism, lever displacement amplifying mechanism II, parallelogram guiding mechanism and base body; the base body is located at the bottom, lever displacement amplifying mechanism II and half-bridge type displacement amplifying mechanism are vertically arranged above the base body in turn from outside to inside, and the half-bridge type displacement amplifying mechanism The top end is connected with the lever displacement amplifying mechanism I, and the parallelogram guiding mechanism is integrated in the lever displacement amplifying mechanism II; a piezoelectric ceramic driver is arranged between the base body and the lever mechanism I, and the lever mechanism II is provided with an output end and an input end; half The output end of the bridge amplifying mechanism is connected with the input end of the lever displacement amplifying mechanism II through the connecting rod and the flexible hinge; the output end of the lever displacement amplifying mechanism II is connected with the clamping jaw.

Owner:TIANJIN UNIV

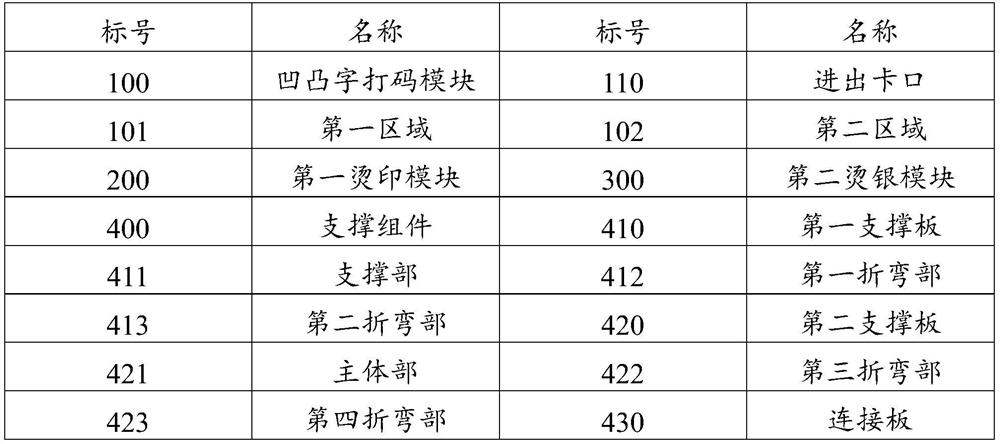

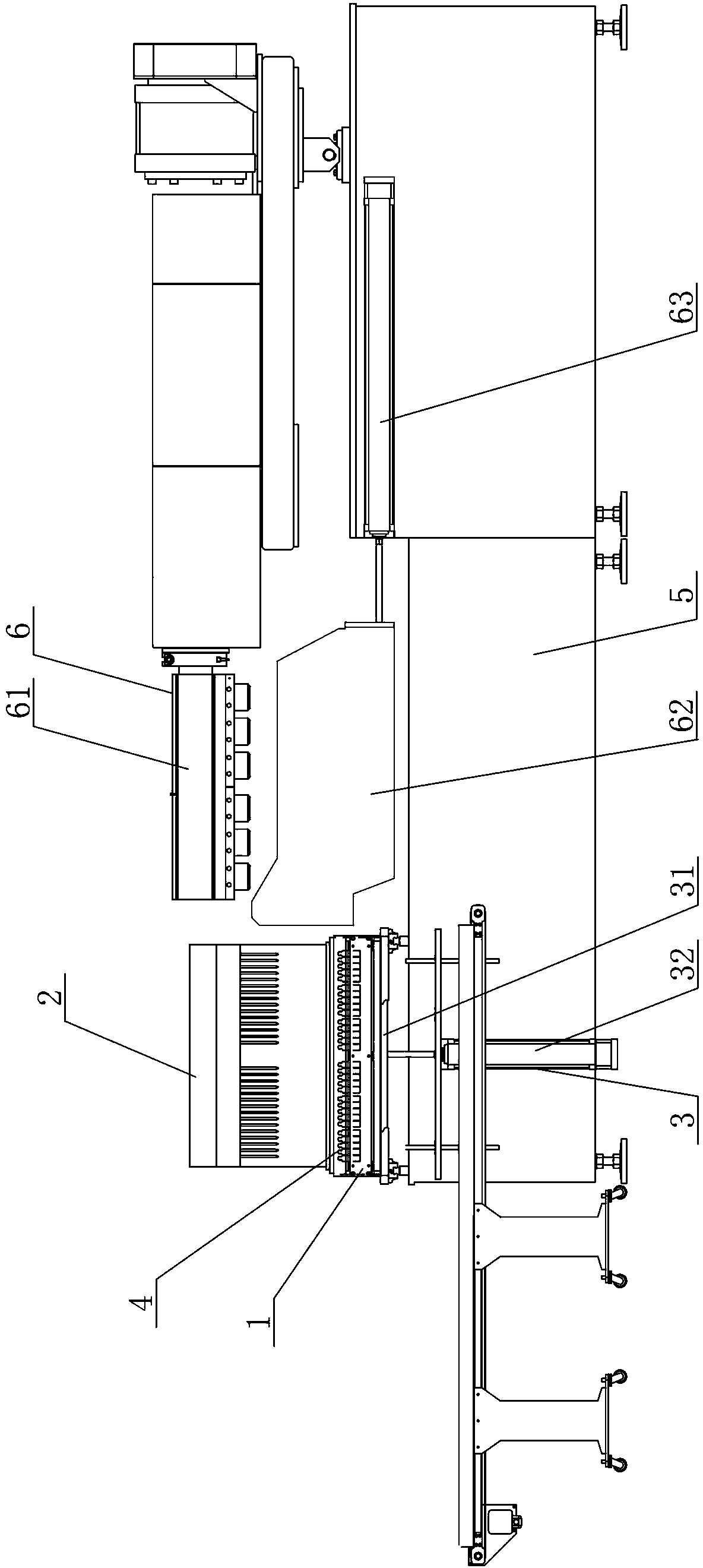

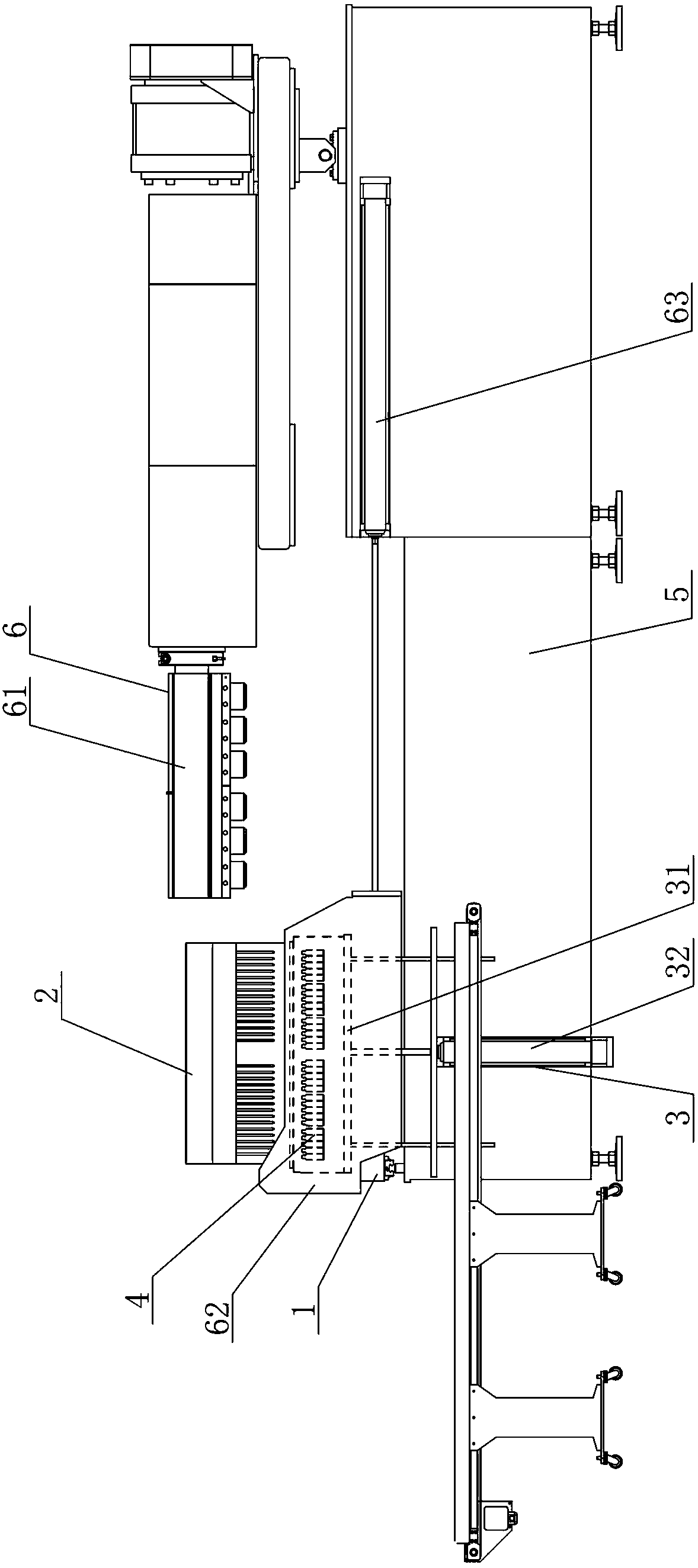

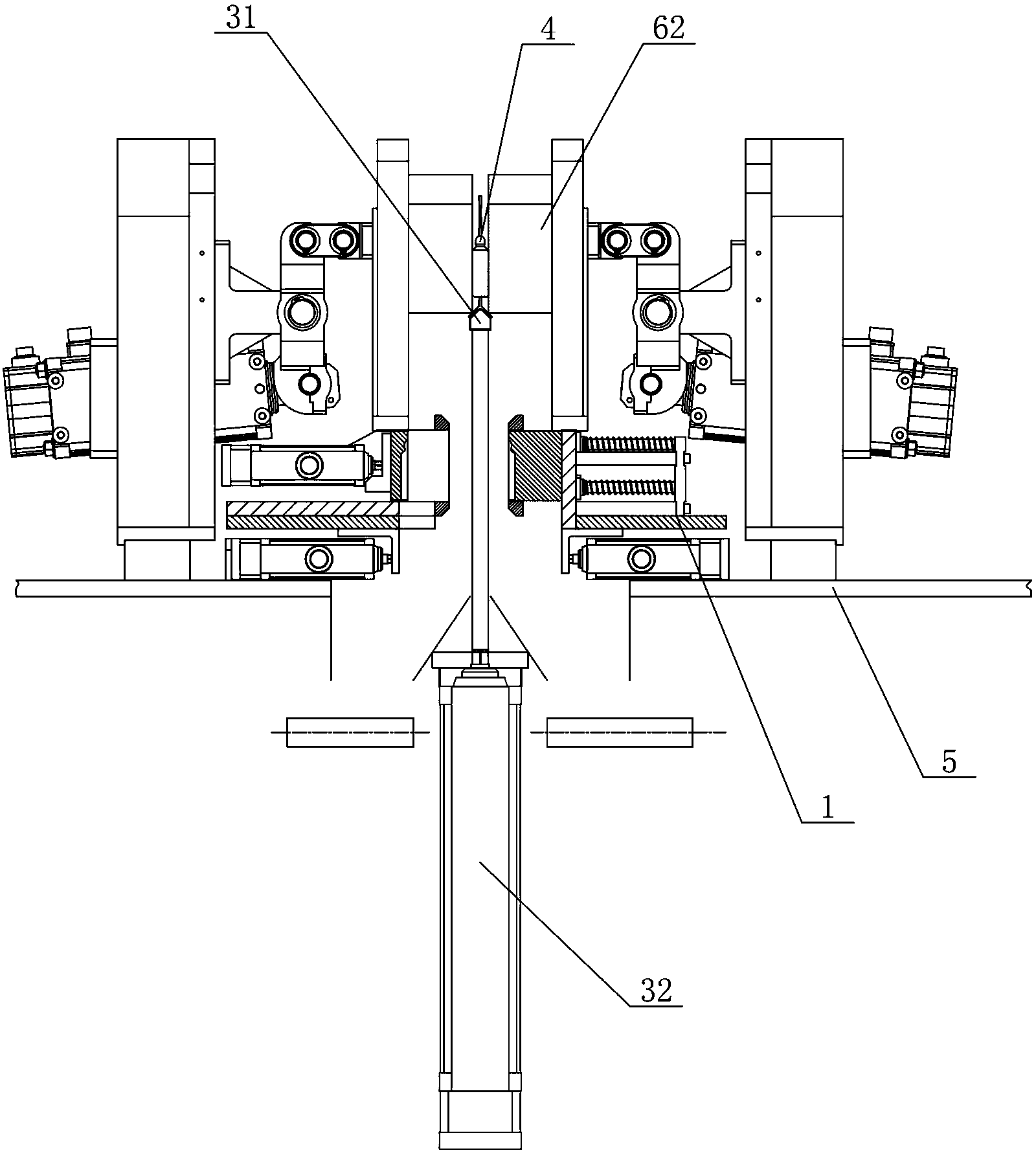

Card making equipment

InactiveCN113183619AImprove transmission efficiencyIncrease productivityRotary pressesCode moduleHot stamping

The invention discloses card making equipment which comprises a concave-convex character coding module, a first hot stamping module and a second hot stamping module, wherein the concave-convex character coding module comprises a first area and a second area which are opposite, the concave-convex character coding module is provided with a card inlet and outlet opening located between the first area and the second area, and the direction from the first area to the second area is perpendicular to the card inlet and outlet direction of the card inlet and outlet opening; the first hot stamping module is arranged in front of the concave-convex character coding module and corresponds to the first area or corresponds to the side, away from the second area, of the first area; the second hot stamping module is arranged in front of the concave-convex character coding module and corresponds to the second area or corresponds to the side, away from the first area, of the second area. According to the technical scheme, after the card is sent out from the card inlet and outlet, one of the two opposite directions can be selected to move so as to enter the first hot stamping module or the second hot stamping module, and thus, the movement path is simplified, and the occupied space of the card making equipment is saved.

Owner:CREATOR CHINA TCH CO

Plastic ampoule blowing-filing and sealing integrated machine

ActiveCN102431946BSolve the large amount of deformationEnsure positioning reliabilityBottle-handling machinesMetal working apparatusSmall footprintBottle

The invention discloses a plastic ampoule blowing-filing and sealing integrated machine, comprising a frame, and a filling and sealing device, a die cutting device, an extrusion bottle-making device and a locating component which are all arranged on the frame. The die cutting device is directly below the filling and sealing device, and the locating component is located under the filing and sealing device and can take a bottle lock to a die cutting work station or a filling and sealing work station by lifting motion. The plastic ampoule blowing-filing and sealing integrated machine has the advantages of simple and compact structure, low cost, small footprint, short material conveying time, convenient and quick location work, easy control and debugging work, and the like.

Owner:TRUKING TECH LTD

An automatic parking system based on a parking robot and its operation method

ActiveCN110952815BImprove space utilizationImprove versatilityResourcesParkingsParking areaEmergency plan

Owner:JILIN UNIV

Chip bonding apparatus and chip bonding method

ActiveCN108122787BSimplify motion pathSimple stepsSemiconductor/solid-state device manufacturingDie bondingBond Force

The invention provides a chip bonding device and a chip bonding method. The chip bonding device comprises a plurality of groups of batch chip transmission parts, a base bearing part and a bonding force output part from top to bottom. In the chip bonding device and the chip bonding method provided in the invention, the batch chip transmission part can bond several chips at one time, the chips are bonded to a base borne by the base bearing part at the same time; in the case of bonding, a bonding ejection mechanism only needs to be used to eject the base bearing part until the base on the base bearing part is bonded with a plurality of chips, that is, only one mechanism is needed to perform a vertical movement in the case of bonding, the movement path and steps are simplified, the productionefficiency is improved, the time is saved, and mass production demands can be met.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Elevator transfer method for mechanized workover operation

ActiveCN104453741BRealize unmanned transportationReduce labor intensityDrilling rodsDrilling casingsHydraulic motorUltimate tensile strength

The invention discloses a mechanical workover treatment elevator transportation method. An elevator transportation mechanism is located on one side of a well mouth axis, two transportation hands are symmetrical about the well mouth axis, and the transportation hands are used for hooking suspension rings of an intelligent elevator to drive the intelligent elevator to rotate along with a transportation frame, so that elevator transportation is achieved. In the transportation process, the transportation hands can hook the elevator all the time, and therefore elevator falling accidents are completely eradicated. The mechanical workover treatment elevator transportation mechanism is composed of a hydraulic motor, a rotary mandrel, the transportation frame, hinge shafts and transportation hand bodies, wherein the hinge shafts and the transportation hand bodies form the transportation hands used for transporting the intelligent elevator. According to the mechanical workover treatment elevator transportation method, mechanical elevator transportation during workover treatment can be achieved, the space of the well mouth axis is not occupied in the transportation process, the mechanical degree of the workover treatment is improved, the worker labor intensity is lowered, and meanwhile workover treatment efficiency is not affected.

Owner:CHINA PETROLEUM & CHEM CORP +1

A wellhead loading and unloading method for intelligent elevators in mechanized workover operations

ActiveCN104453740BReduce labor intensityReduce security risksDrilling rodsDrilling casingsGravity centerPetroleum

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com