Conveying system for wafer-shaped object

A technology of conveying system and objects, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of complex motion precision design, complex movement path of accessing wafers, affecting the speed of accessing wafers, etc., to achieve fast and reliable access, The effect of reducing footprint area and simple motion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

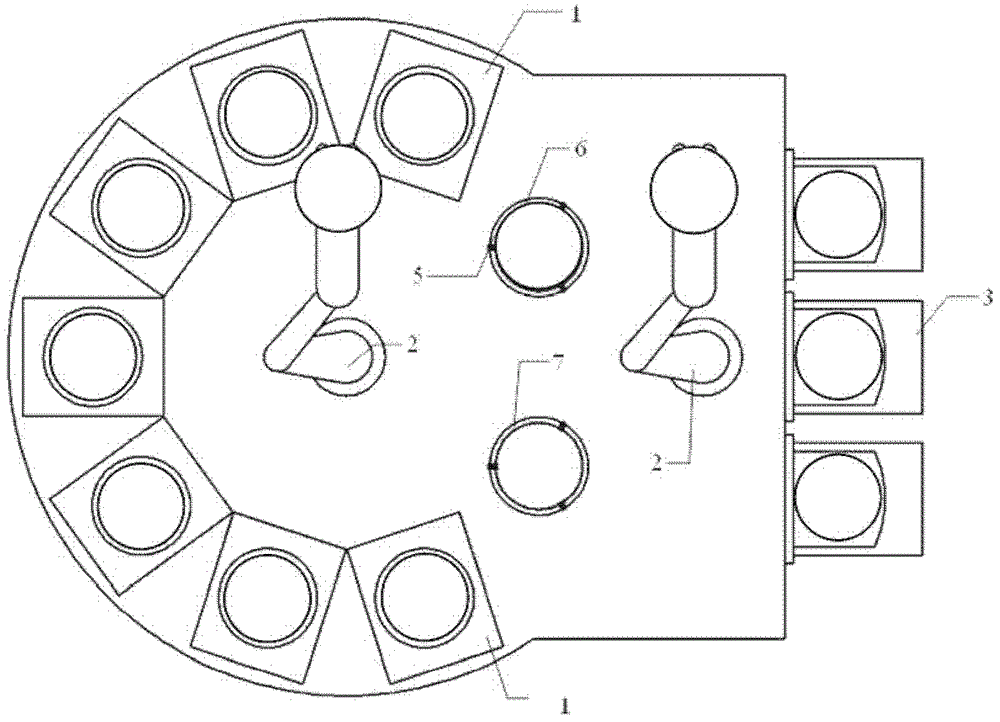

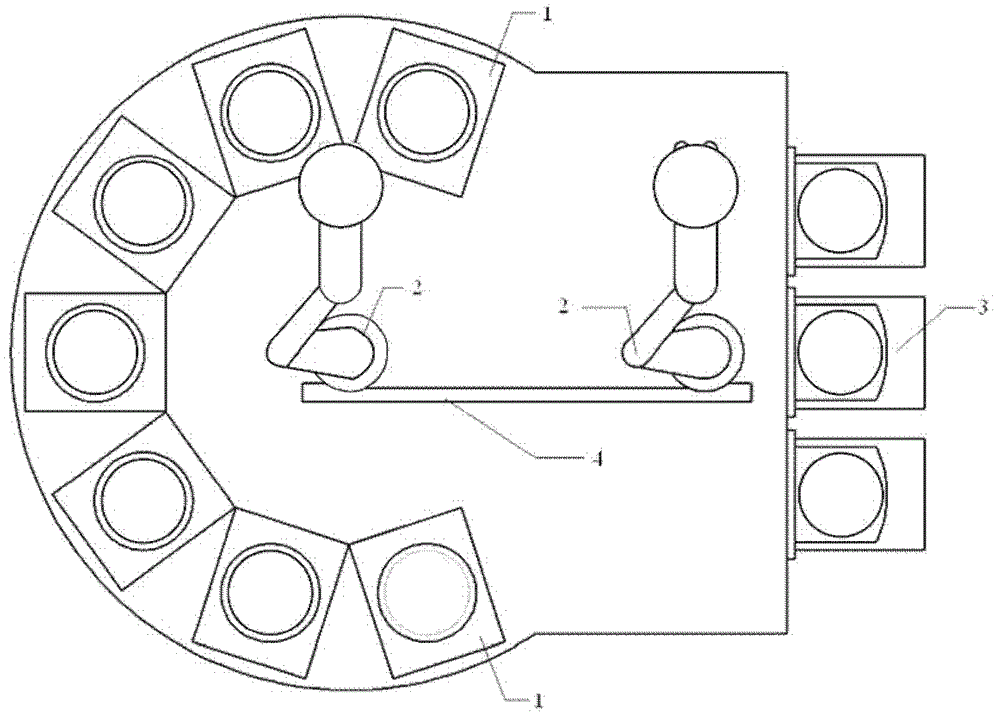

[0018] like Figure 1-2 As shown, the conveying system for wafer-shaped objects according to the present invention includes at least two processing units 1 and manipulators 2. The distance between the manipulators 2 and each processing unit 1 is equal, and is used to transport wafer-shaped objects to be processed placed in the processing unit 1, and the processed wafer-shaped object is taken out. The distance between the center of the access arm of the manipulator 2 and the processing center of each processing unit is equal.

[0019] Preferably, the processing units 1 are arranged in a circular or regular polygonal array.

[0020] Preferably, at least one cassette 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com