Chip bonding apparatus and chip bonding method

A chip bonding and chip technology, which is applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., and can solve problems such as time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

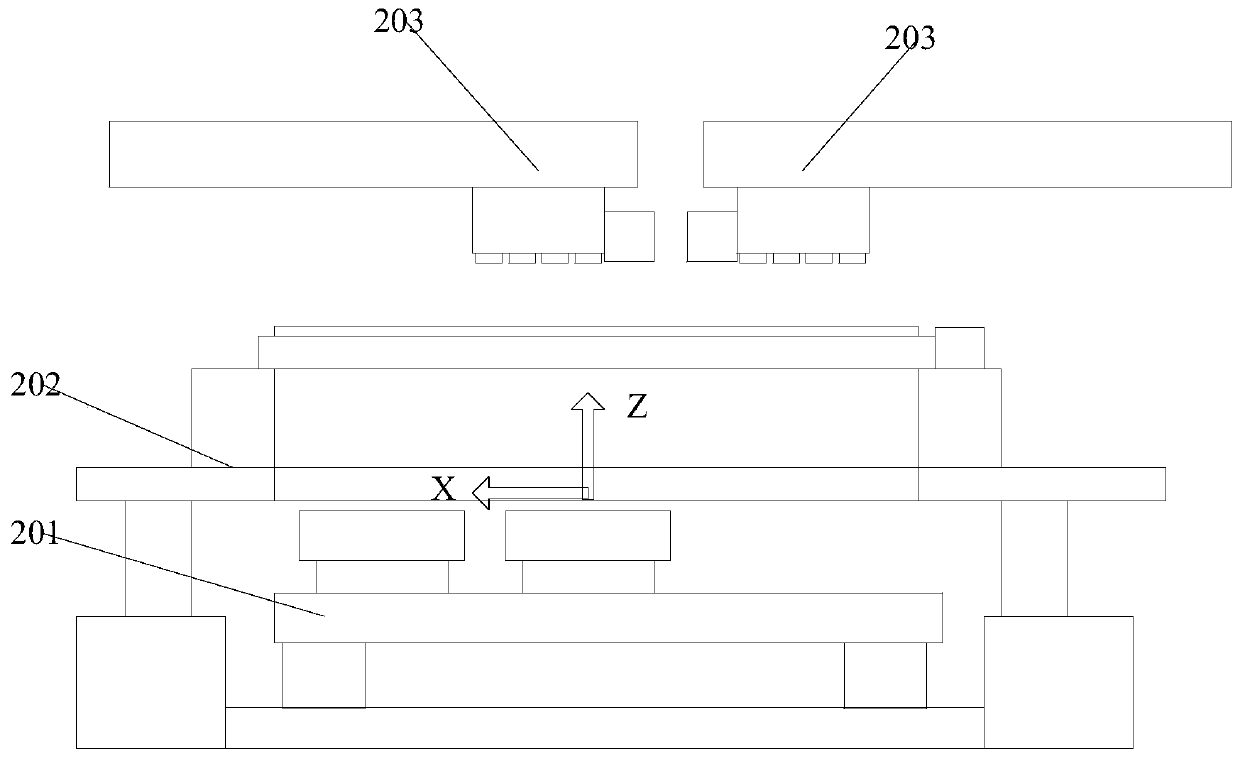

[0049] Please refer to image 3 , with the horizontal direction as the X direction, the vertical direction perpendicular to the horizontal plane as the Z direction, and the plane formed perpendicular to the X and Z directions as the Y direction, an XYZ three-dimensional coordinate system is established. The invention provides a chip bonding device, which includes from top to bottom

[0050] There are several batches of chip transfer parts 203 , substrate carrying parts 202 and bonding force output parts 201 .

[0051] Specifically, several groups of batch chip transfer components 203 are arranged in six groups in this embodiment, forming two columns respectively, as Figure 5 As shown, the first to third batches of chip transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com