Patents

Literature

49results about How to "Ensure positioning reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

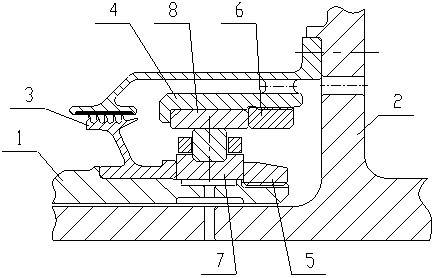

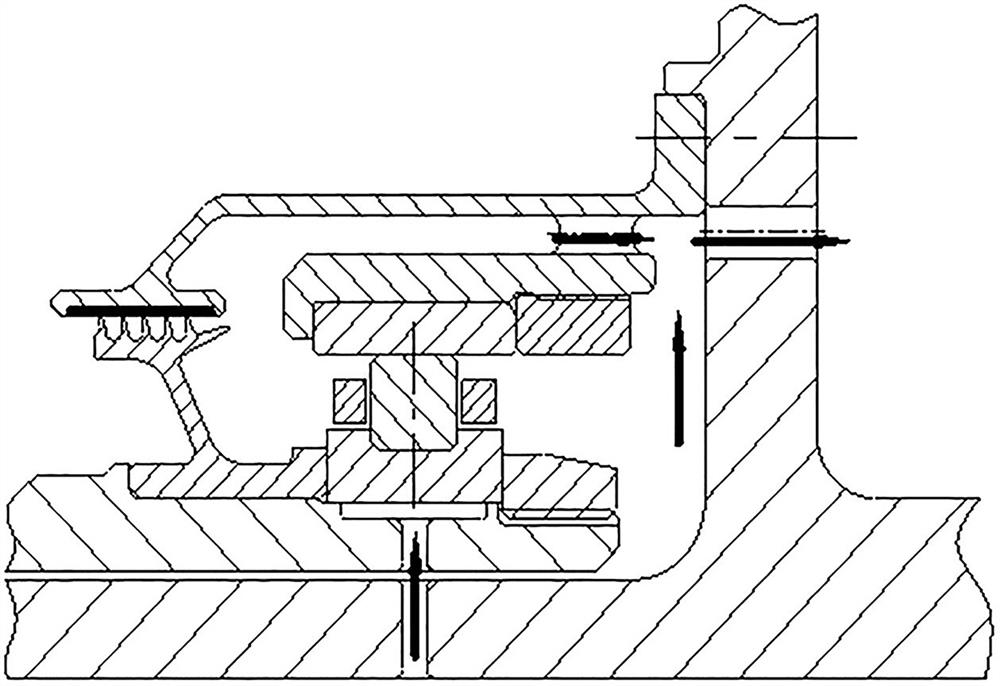

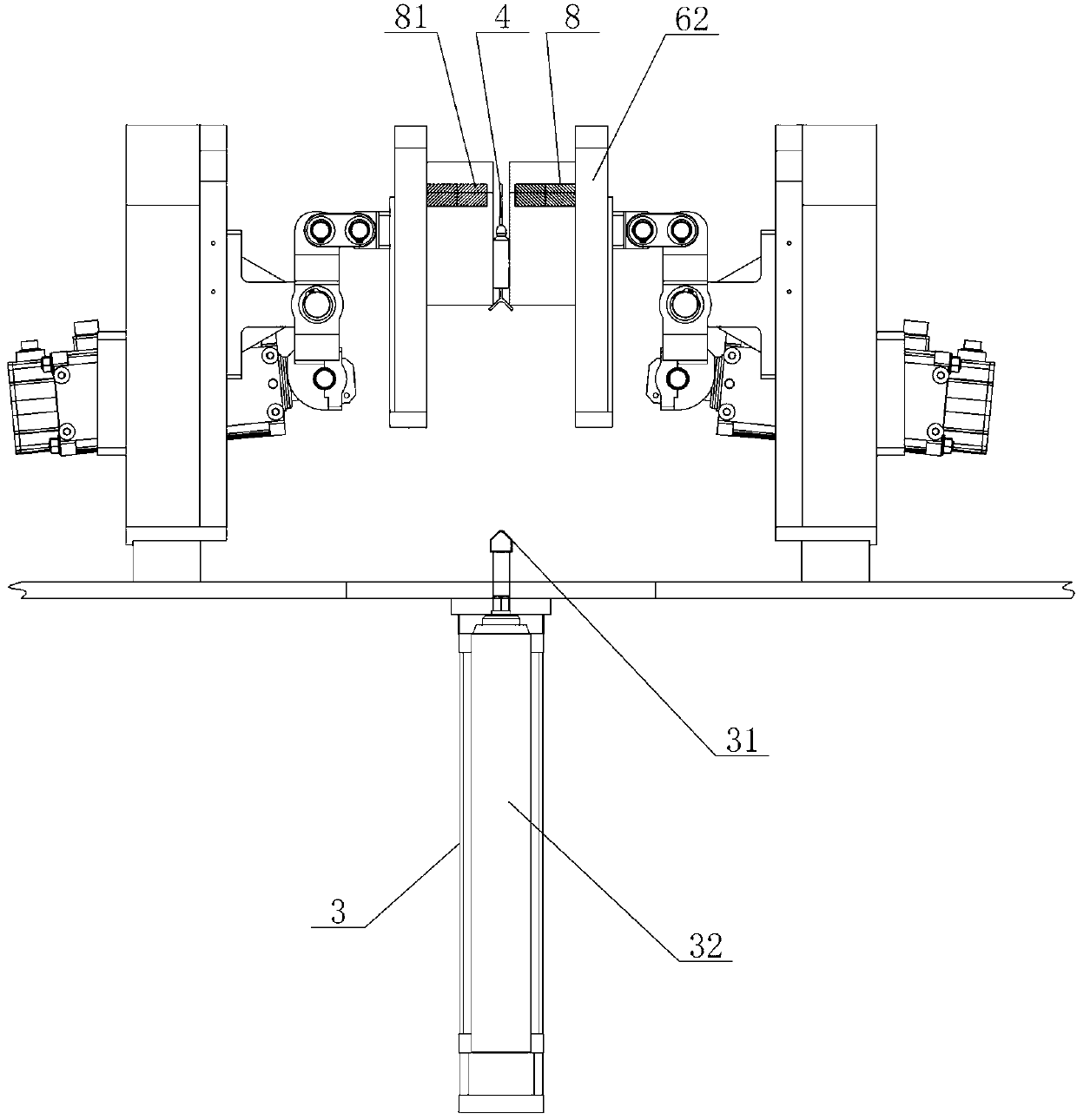

Fixture used for milling and boring support

ActiveCN103862309AHigh precisionUniform force distributionWork clamping meansPositioning apparatusWork supportDouble row

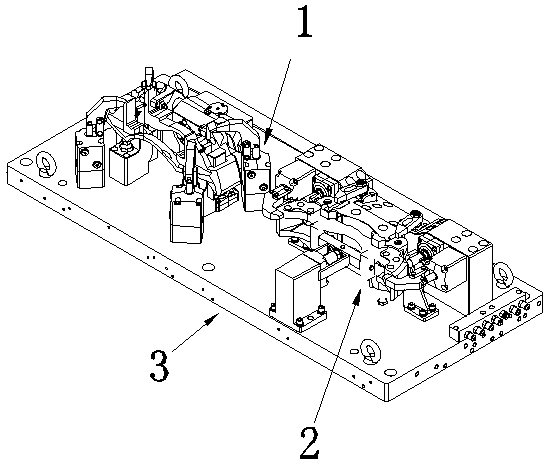

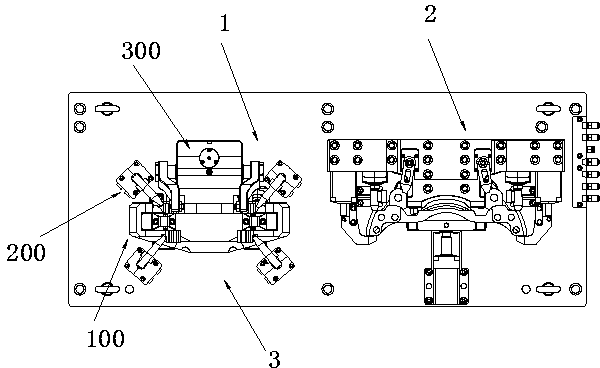

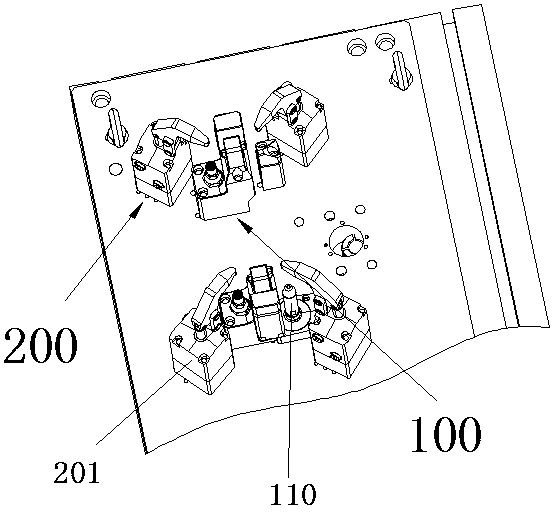

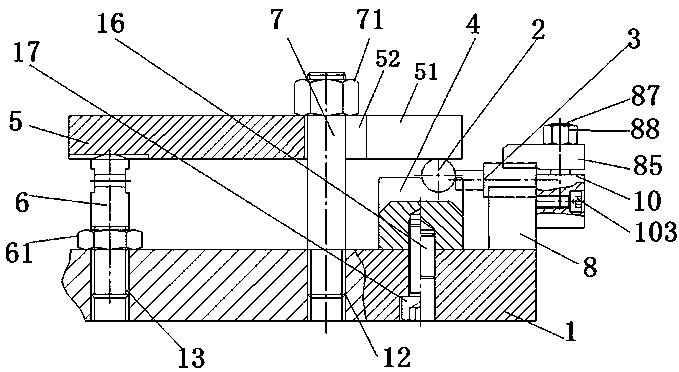

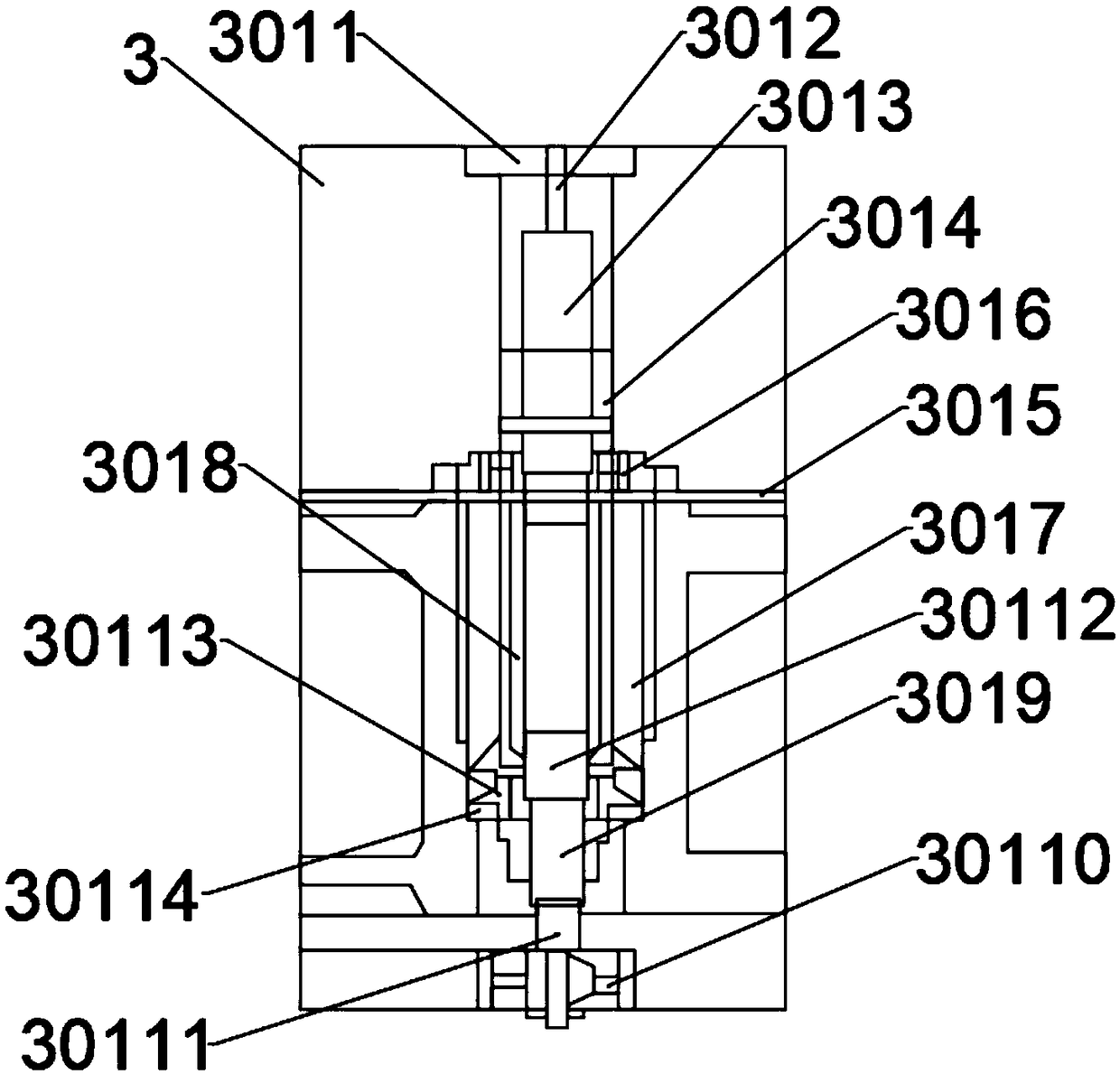

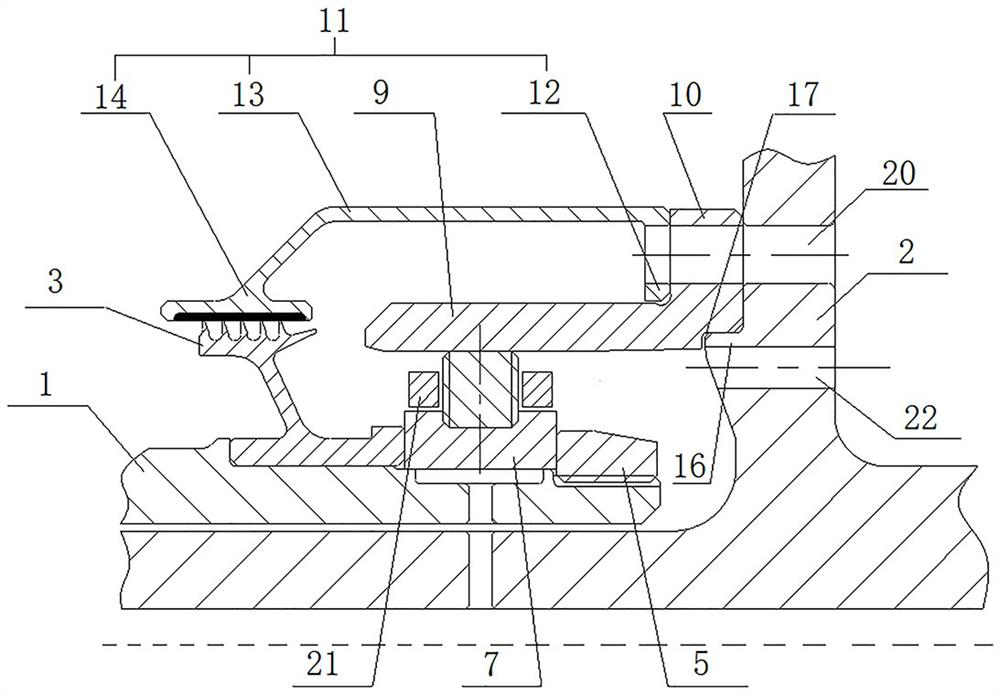

The invention discloses a fixture used for milling and boring a support. The fixture comprises a station I fixture body, a station II fixture body and a bottom plate, wherein the station I fixture body comprises a first positioning mechanism, a first clamping mechanism and a center positioning mechanism for strutting a workpiece outwards; the center positioning mechanism comprises a supporting seat, two pressing plates I, an angle pole, a guide screw and a driving device, wherein the two pressing plates I are symmetrically arranged at both ends of the supporting seat; the driving device comprises a gear mechanism and a driving oil cylinder; the gear mechanism comprises a double-row rack, gears II and a single-row rack, wherein the gears II are respectively meshed with the double-row rack, and the single-row rack is meshed with the gear II; one end of the angle pole is connected with the pressing plates I; the other end of the angle pole is connected with the single-row rack. According to the fixture disclosed by the invention, clamping can be performed rapidly, and is steady; the work support is not easy to deform, and therefore, the machining precision is improved; moreover, when the support of a symmetrical structure is milled, the center of the support can be rapidly and accurately positioned; moreover, the fixture can be suitable for volume production.

Owner:杭州钰友精密机械有限公司

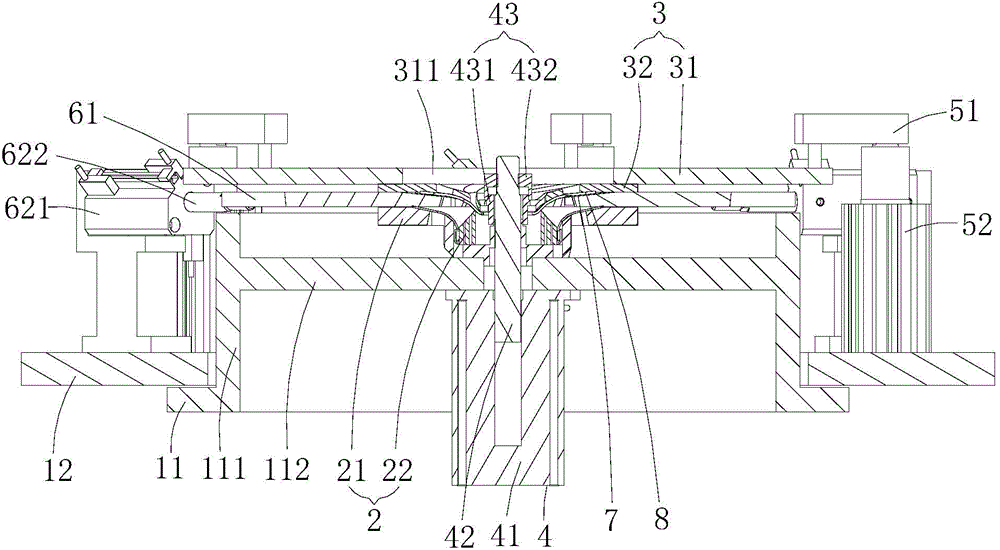

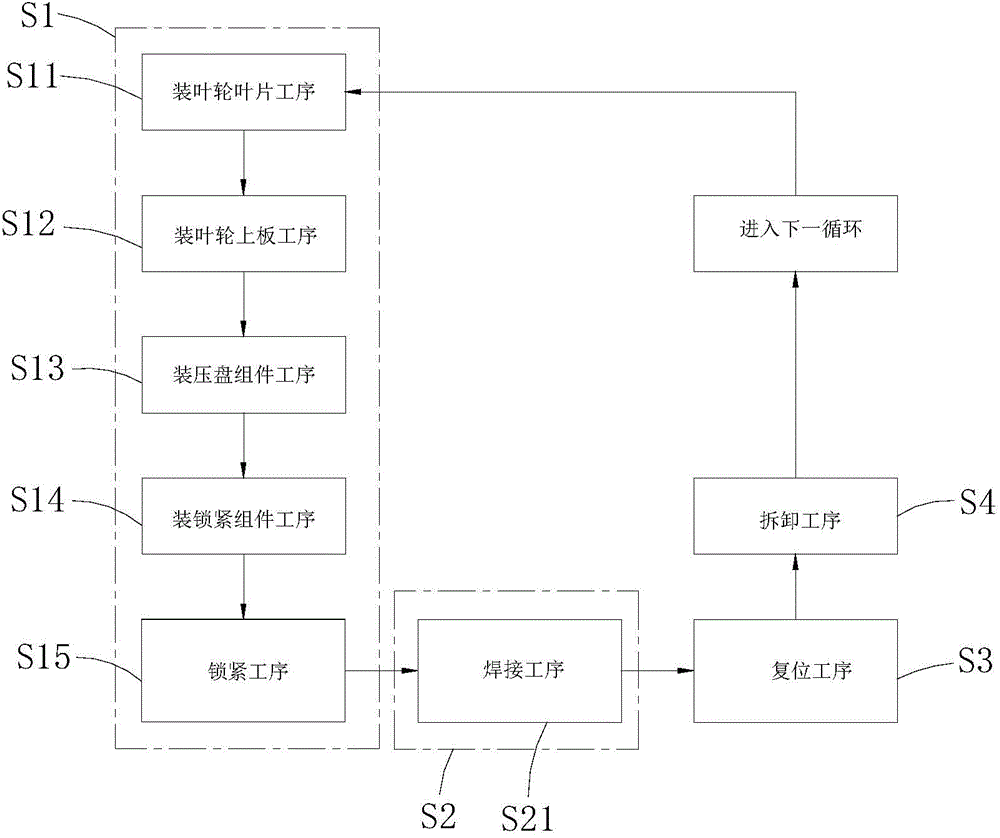

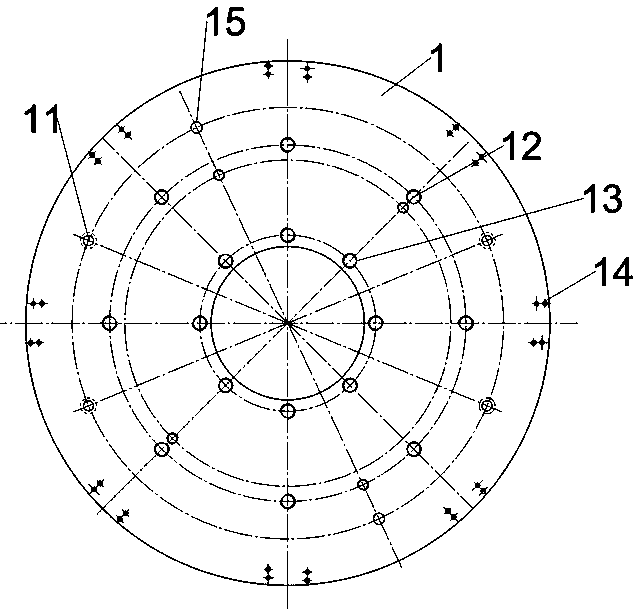

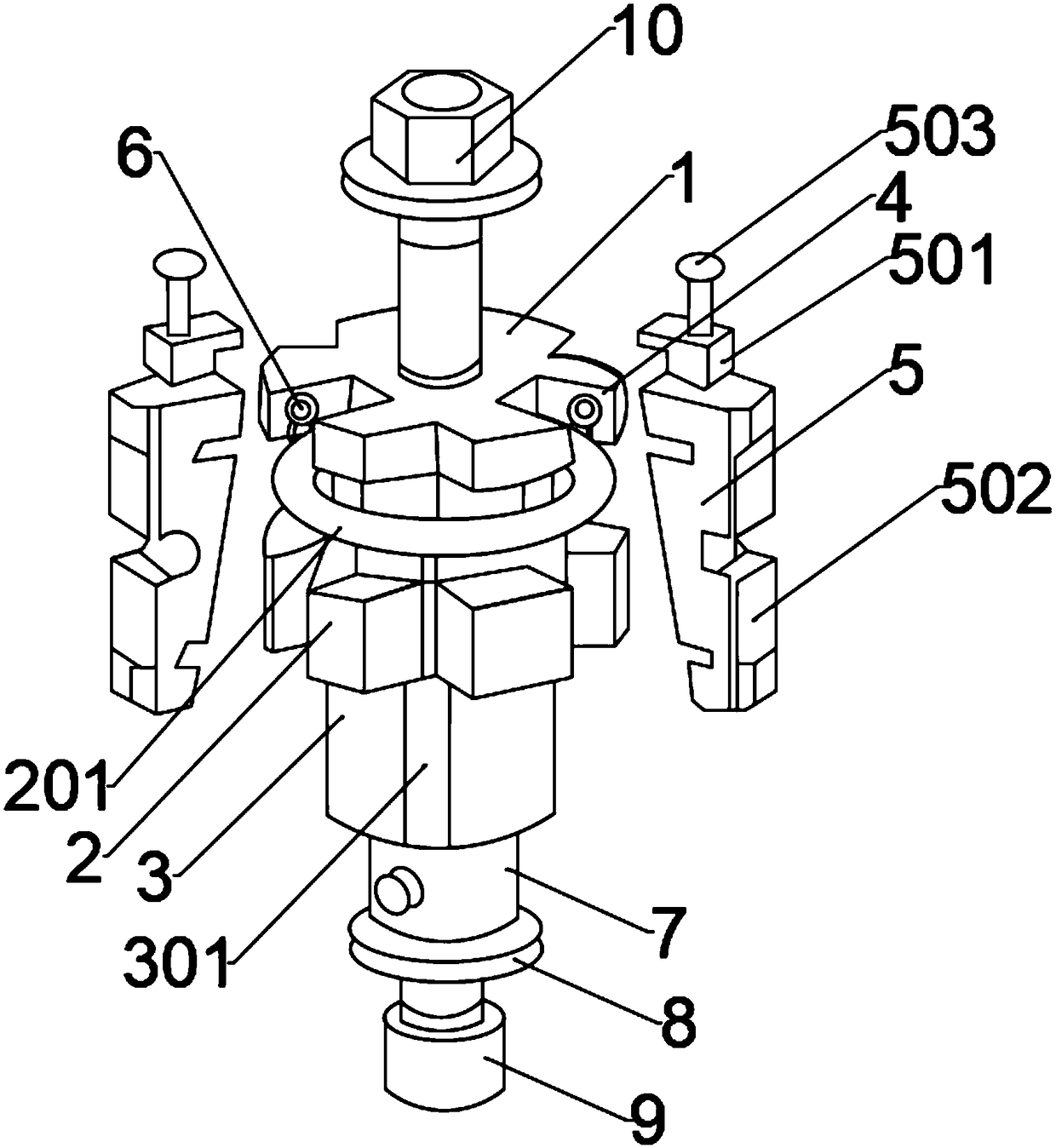

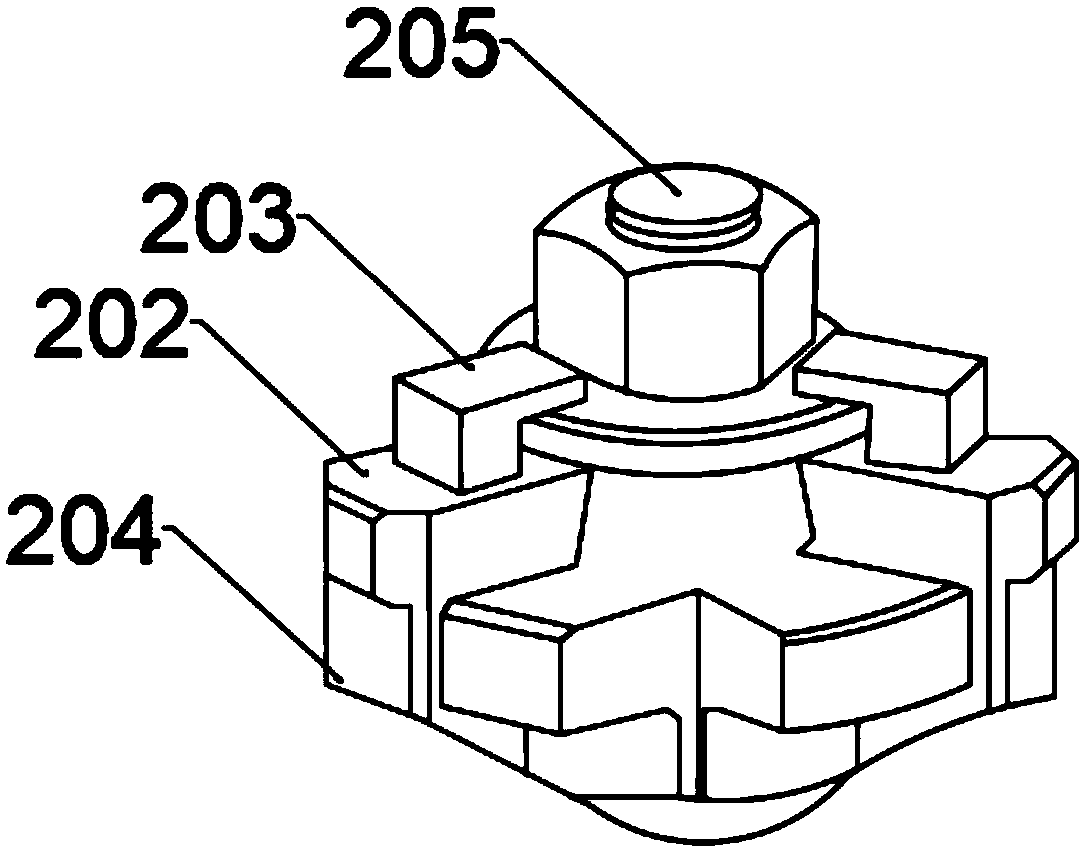

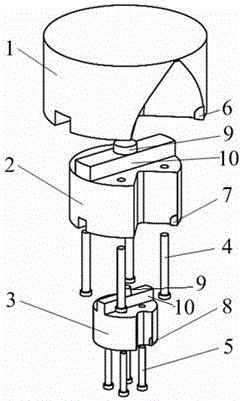

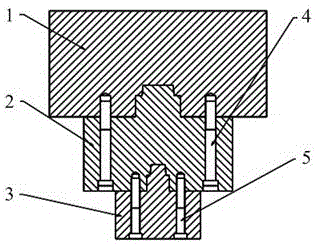

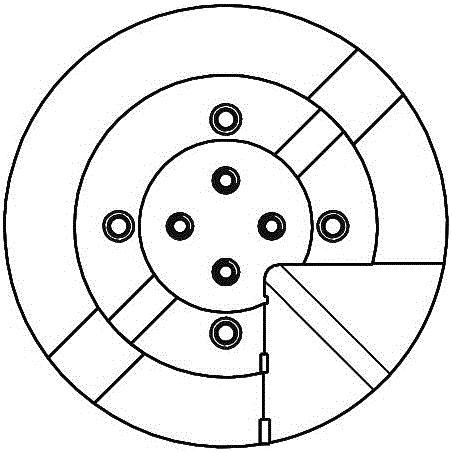

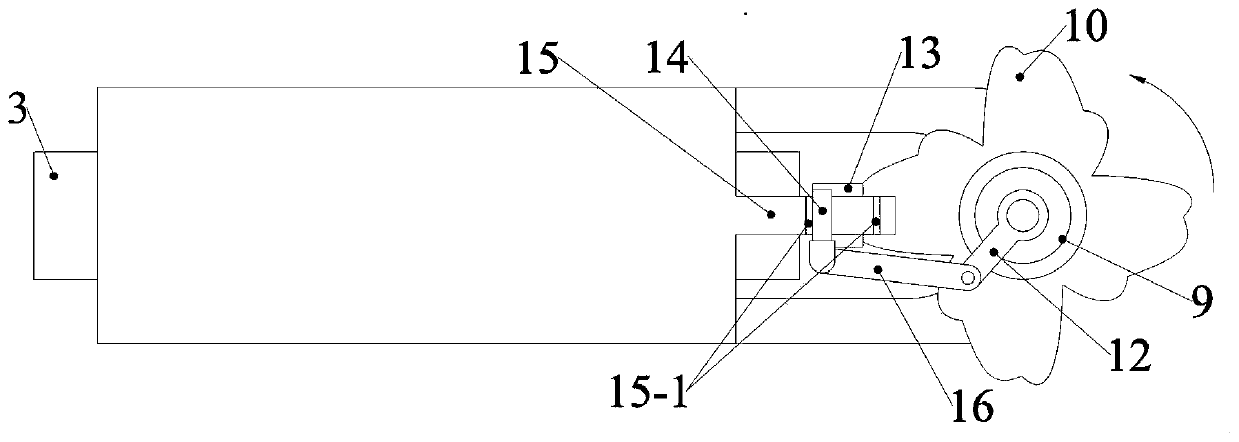

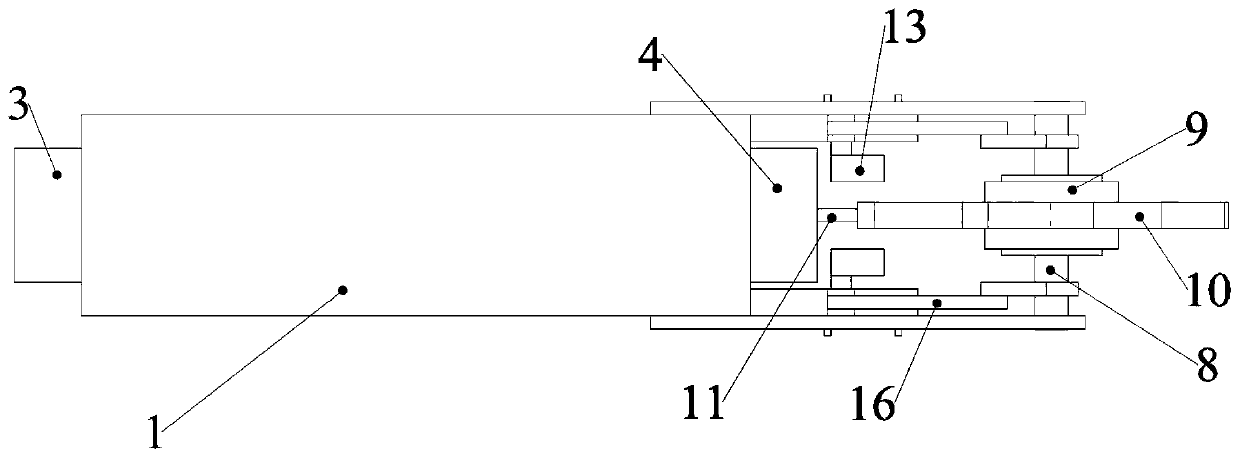

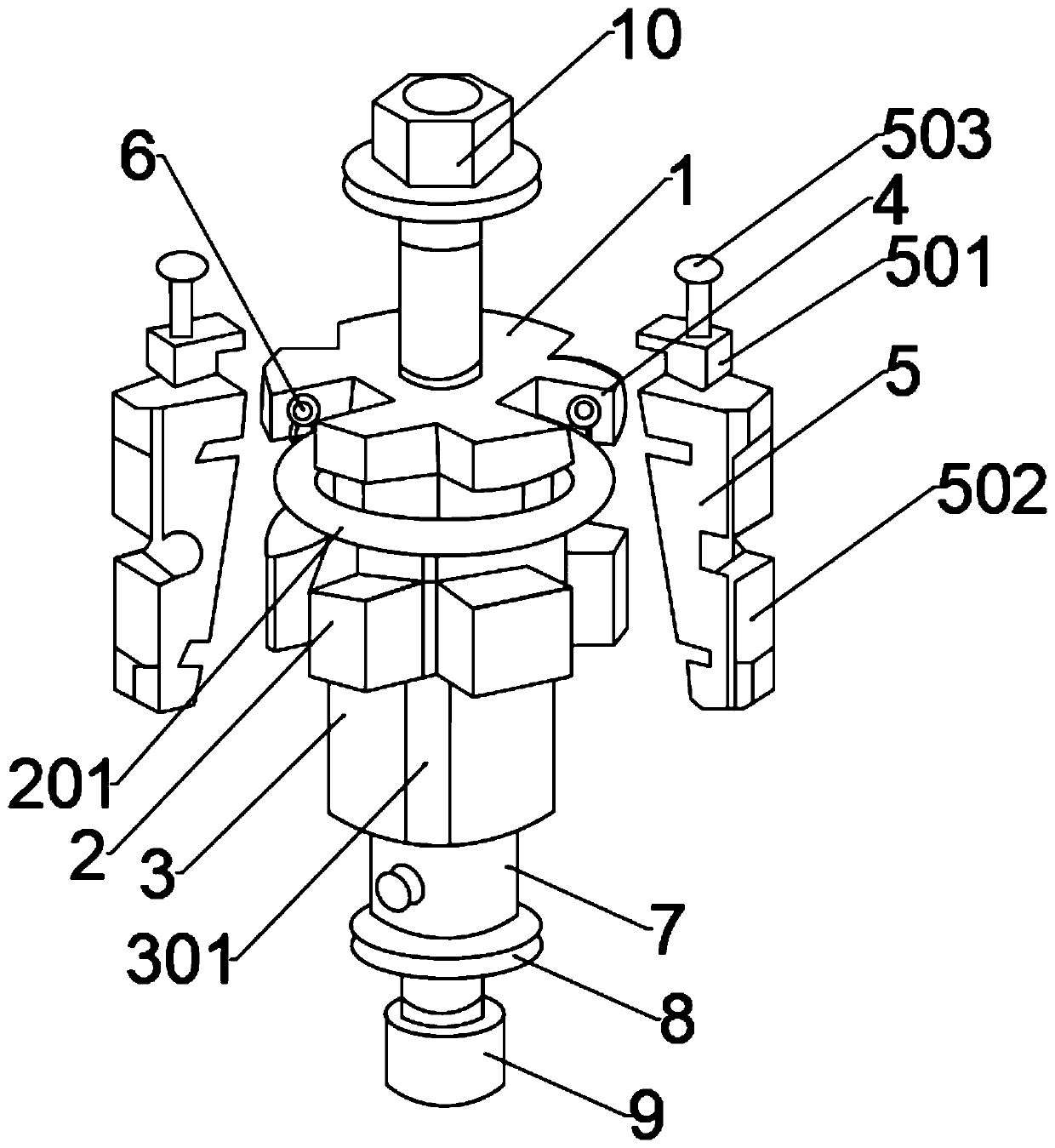

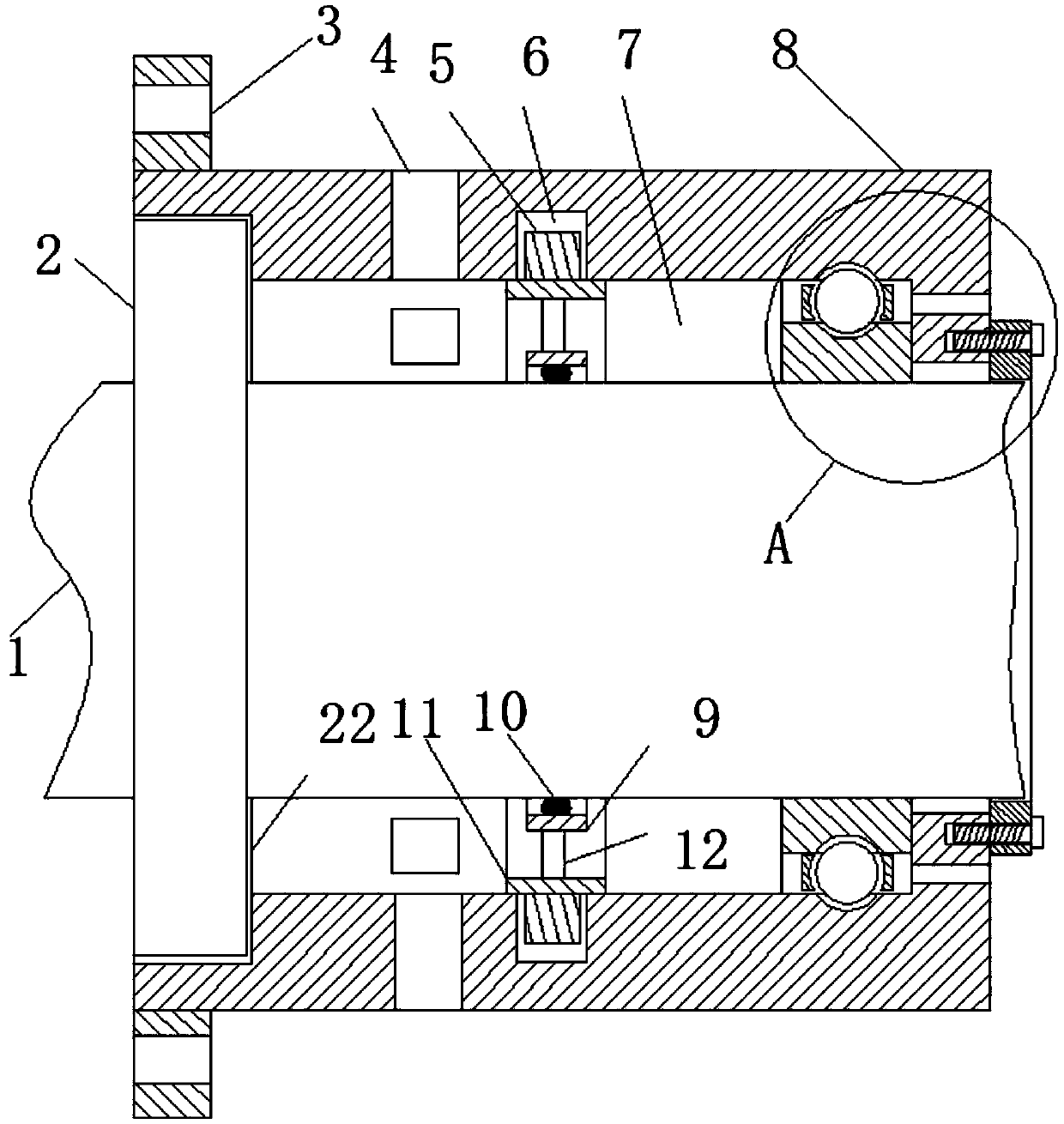

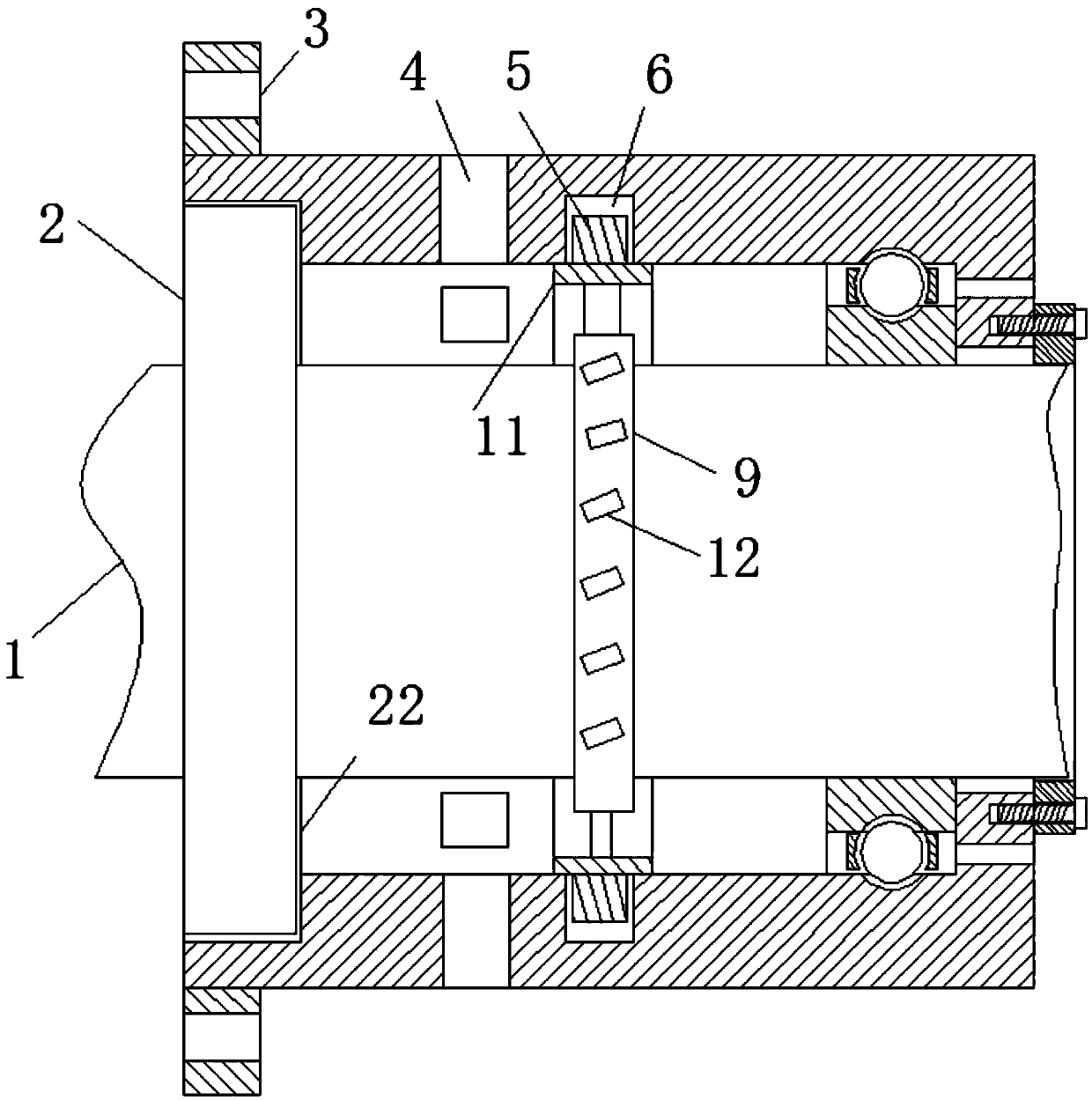

Impeller blade and impeller upper plate laser welding method and clamping method and jig

ActiveCN104384804AGuaranteed reliabilityEnsure positioning reliabilityTurbinesWelding/cutting auxillary devicesImpellerEngineering

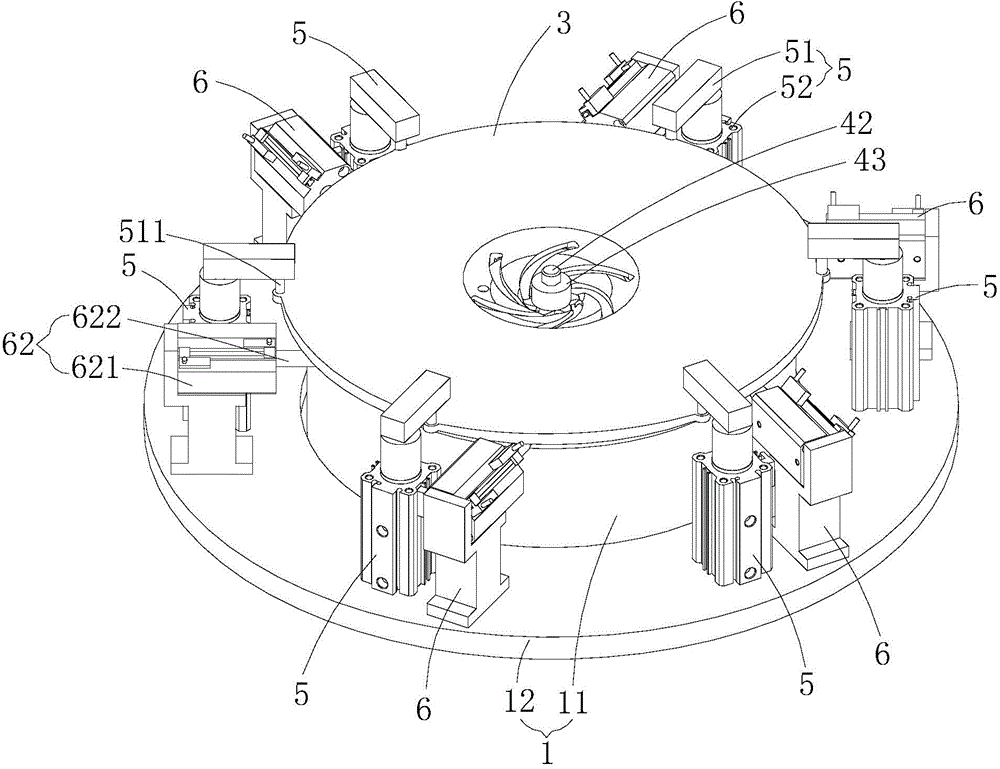

The invention is applicable to the field of impeller laser welding and discloses an impeller blade and impeller upper plate laser welding jig, an impeller blade and impeller upper plate clamping method with the jig and an impeller blade and impeller upper plate laser welding method through the clamping method. The impeller blade and impeller upper plate laser welding jig comprises a base assembly, a support assembly mounted on the base assembly for placing and positioning an impeller blade and an impeller upper plate, a pressing plate assembly arranged above the support assembly for pressing the impeller blade and the impeller upper plate to the support assembly, a first telescoping assembly mounted on the base assembly for pressing the pressing plate assembly in the axial direction of the base assembly, a plurality of peripheral pressing structures mounted on the base assembly, and a plurality of lateral positioning structures mounted on the base assembly. The impeller blade and impeller upper plate laser welding jig, the impeller blade and impeller upper plate clamping method with the jig and the impeller blade and impeller upper plate laser welding method through the clamping method solve the technical problems of poor versatility, clamping difficulty and low clamping efficiency, clamping positioning reliability and automation degree of existing impeller laser welding jigs.

Owner:HANS LASER TECH IND GRP CO LTD

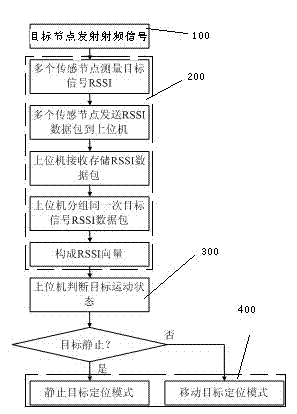

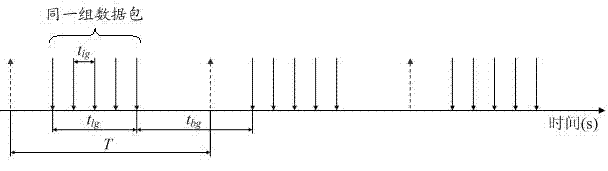

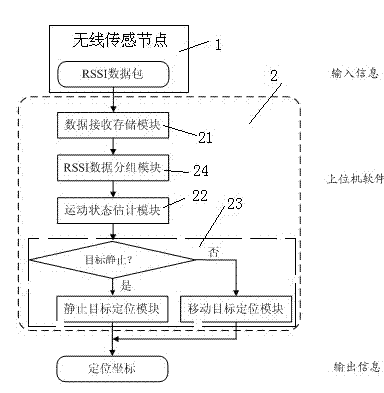

Wireless sensor network target location method and system used for online estimation of motion states

ActiveCN103200518AHigh positioning accuracyEnsure positioning reliabilityNetwork topologiesTransmission monitoringWireless sensor networkingRadio frequency signal

The invention relates to a wireless sensor network target location method and system used for online estimation of motion states. The wireless sensor network target location method and system used for the online estimation of the motion states comprises a goal node, a plurality of wireless sensing nodes and an upper computer, wherein the goal node transmits radio-frequency signals, the plurality of wireless sensing nodes receive the signals of the goal node, and the upper computer receives information of the wireless sensing nodes. The wireless sensor network target location method and system used for the online estimation of the motion states includes the steps that the goal node transmits the radio-frequency signals; the wireless sensing nodes receive the signals and upload the signals to the upper computer; the motion states of the goal node is judged; and the goal node is located. According to the wireless sensor network target location method and system used for the online estimation of the motion states, the goal motion states can be judged online, location precision is improved by averaging through coordinate location under a goal motionless state, and location reliability can be guaranteed only by utilization of cycle measuring data location under a goal mobile state.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

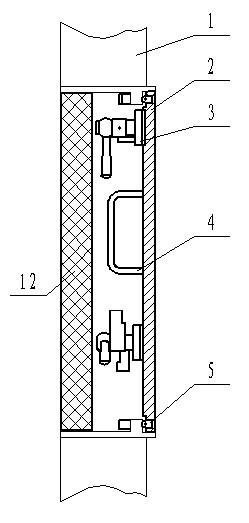

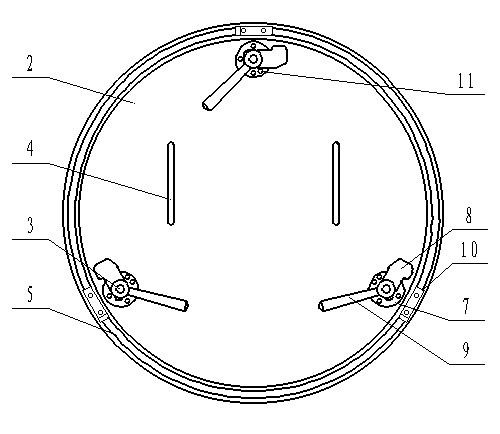

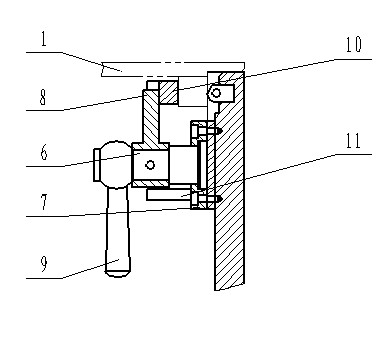

Movable type escape capsule emergency escape door for mine

ActiveCN102635298AEnsure positioning reliabilityGuaranteed sealing reliabilityGasproof doorsConstruction fastening devicesMovable typeEngineering

The invention provides a movable type escape capsule emergency escape door for a mine and belongs to the technical field of escape capsule equipment for the mine. Aiming to the solve the technical problem, the invention provides the movable type escape capsule emergency escape door for the mine, which has the advantages of reliability in sealing, simplicity in operation, strong anti-knocking and anti-impacting performance and high-temperature resistance and is convenient for people in a capsule to use when the people actively go out of the capsule. The technical scheme disclosed by the invention is as follows: a circumferential edge of the door is uniformly provided with three manual locking devices and the door is mounted on the capsule body through the manual locking devices; a handle is arranged at the inner side of the door; a sealing strip is arranged on the circumference on which the door is contacted with the capsule body; and the capsule body in the door is provided with a heat-preservation and heat-insulating cover. The invention provides the emergency escape door for the mine escape capsule.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

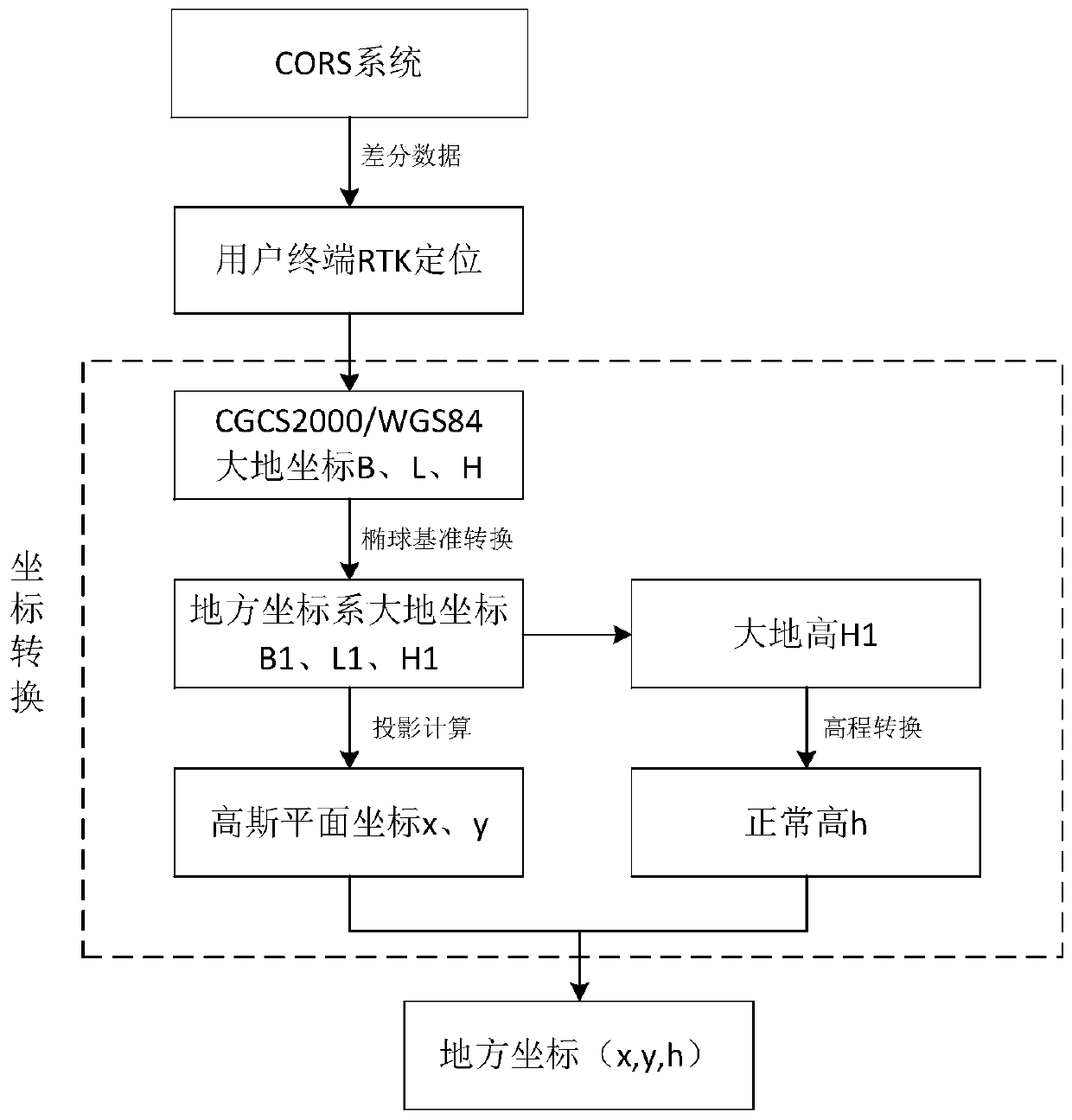

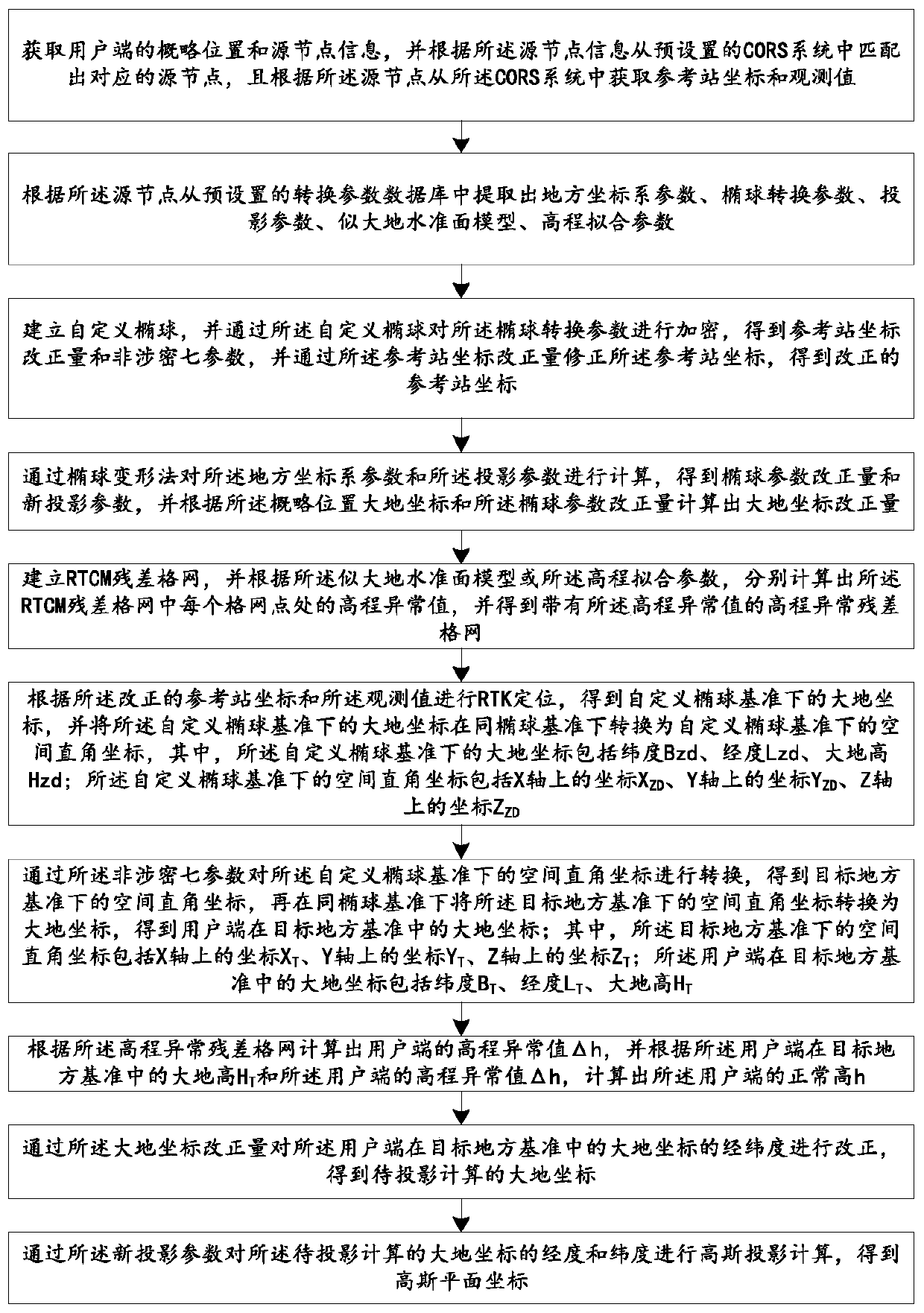

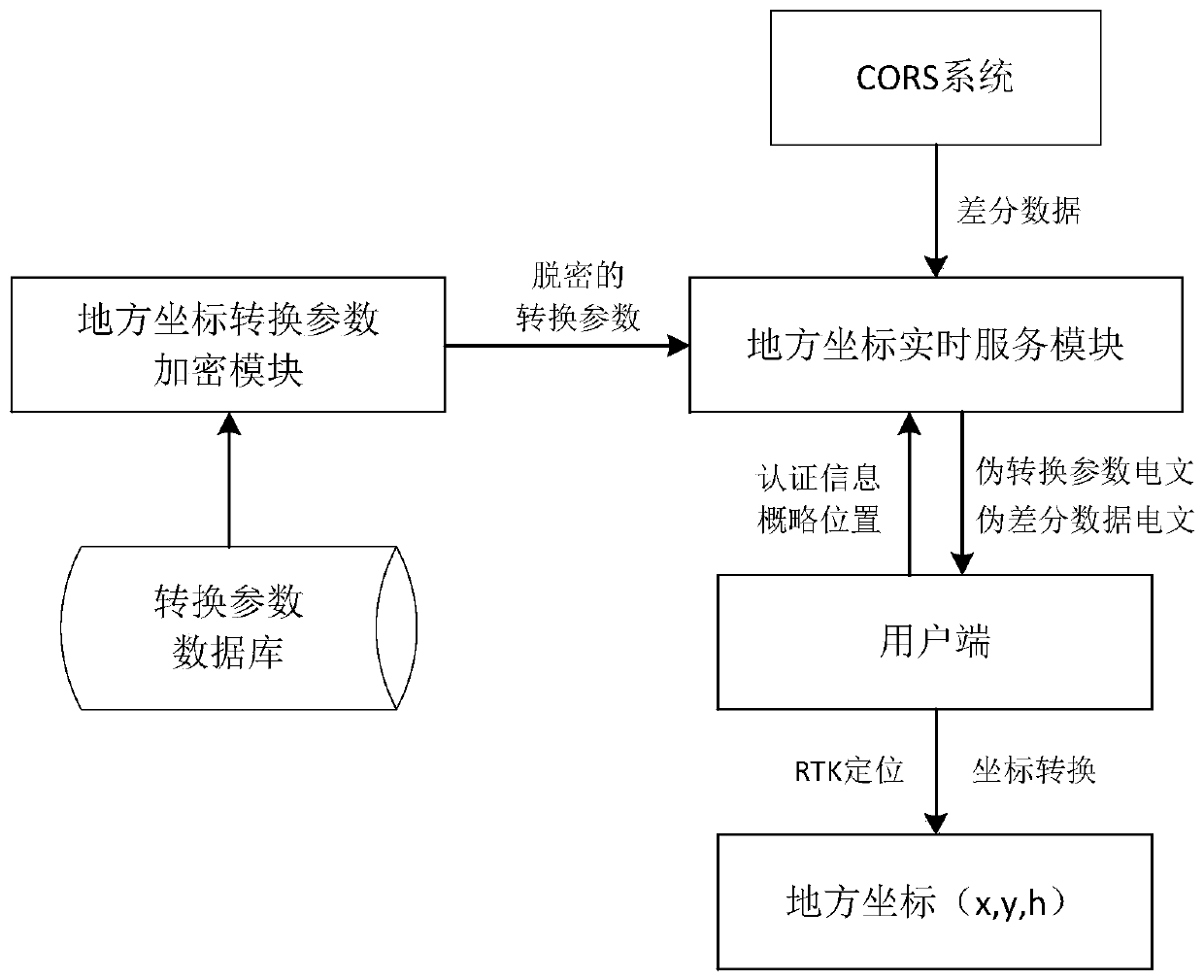

CORS (Continuously Operating Reference Stations) system-based real-time positioning service method for local coordinates

ActiveCN109884676ASolve security and confidentiality issuesImplement encryptionPublic key for secure communicationSatellite radio beaconingReal Time KinematicNormal height

The invention relates to a CORS (Continuously Operating Reference Stations) system-based real-time positioning service method for local coordinates. The method has the beneficial effects that the encryption of seven real ellipsoid conversion parameters is realized by adopting a custom ellipsoid encryption method and the influence of the encryption method on RTK (Real-Time Kinematic) positioning istaken into account to strictly control the offset at the same time; the ellipsoid parameters are converted by adopting an ellipsoid deformation method, thereby eliminating the projection high parameters and solving the contradiction that the projection high parameters cannot be broadcasted in RTCM (Radio Technical Commission for Maritime services) message; generating a grid around a user positionby using the user position as the center, interpolating elevation abnormal values of grid points by using an existing elevation conversion model, generating RTCM residual grid message and broadcasting to the user end, thereby obtaining the normal height of the user end, solving the elevation conversion problem and not affecting the RTK baseline solution at the same time; and by implementing the method disclosed by the invention, after the user terminal receives pseudo conversion parameter message, the Gaussian plane coordinates and the normal height can be directly obtained with no need for configuring any parameters, thereby guaranteeing the security, the real-time performance and the universality of the local coordinate positioning.

Owner:自然资源部第三大地测量队

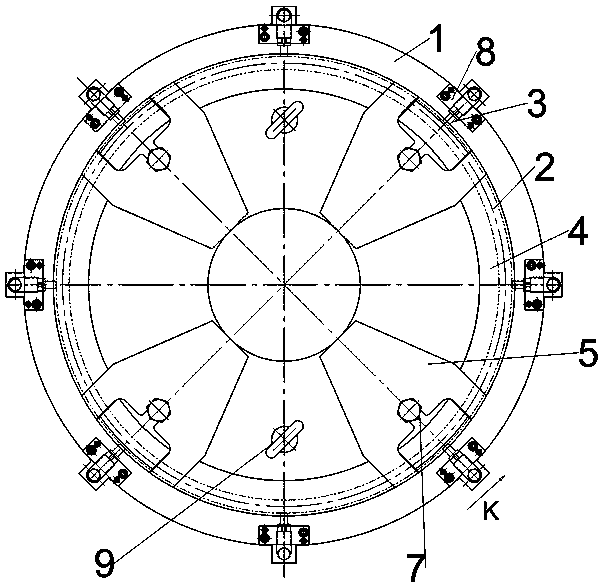

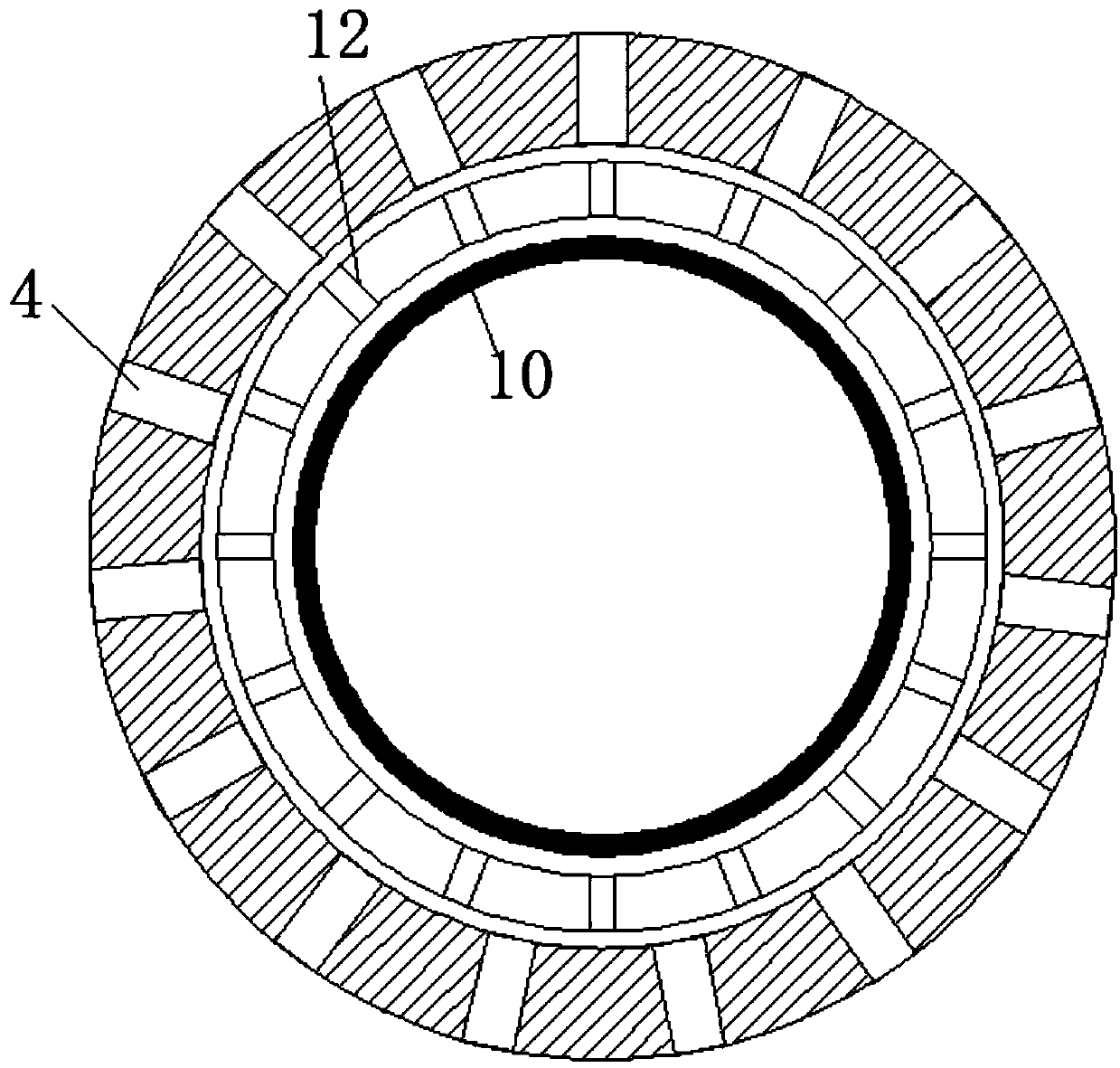

Positioning fixture for welding shielding ring and insert

ActiveCN109773391APrecise positioningHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringContact position

The invention relates to a positioning fixture for welding a shielding ring and an insert. The positioning fixture for welding the shielding ring and the insert comprises a supporting seat with a central axis and an insert positioning seat; the positioning fixture is provided with a set datum plane which is perpendicular to the central axis; a positioning groove which is used for placing the shielding ring is formed in the supporting seat; the positioning groove is provided with a positioning groove wall and a notch; the centre circle of the cross section of the shielding ring at a set position is perpendicular to the central axis; the centre of the centre circle of the cross section is positioned in the central axis; a set distance is reserved between the centre circle of the cross section and the datum plane; more than two pressing plate components are uniformly distributed in the circumferential direction around the central axis of the supporting seat at intervals; each pressing plate component comprises a pressing plate, a compressing mechanism and a stop positioning piece; a contact position between the shielding ring and each pressing plate is taken as a supporting point; anda reverse torque is respectively applied to each pressing plate by the corresponding compressing mechanism and the corresponding stop positioning piece. The positioning precision and the positioningreliability between the shielding ring and the insert are ensured.

Owner:STATE GRID CORP OF CHINA +1

USB Type-C connector and fabrication process thereof

PendingCN108808416AGuaranteed positional stabilityReduce generationContact member manufacturingContact member assembly/disassemblyMetal stripsComputer module

The invention discloses a USB Type-C connector and a fabrication process thereof. The fabrication process comprises the steps of 1, preparing a first metal strip, a second metal strip and a third metal strip, wherein a first group of terminal and a second group of terminal are arranged on the first metal strip, a first fixed piece and a second fixed piece are arranged on the third metal strip, andan intermediate shielding piece is arranged on the third metal strip; 2, placing the three metal strips in a first injection molding die in a lamination way, and obtaining a first terminal insulationbody and a second terminal insulation body after injection molding; 3, cutting a first terminal module and a second terminal module; 4, laminating the first terminal module and the second terminal module to form a terminal core module; and 5, assembly a metal shell outside the terminal core module. By the fabrication process, the stamping process, the operation process and the injection molding die number are simplified, the production efficiency is improved, the strip waste is reduced, the resource is saved, the die design and development cost is reduced, the process of assembling an upper fixed piece, a lower fixed piece and the metal intermediate shielding piece is omitted, the manual assembly cost is reduced, the production efficiency is further improved, and meanwhile, the product quality is improved.

Owner:东莞市良拓电子科技有限公司

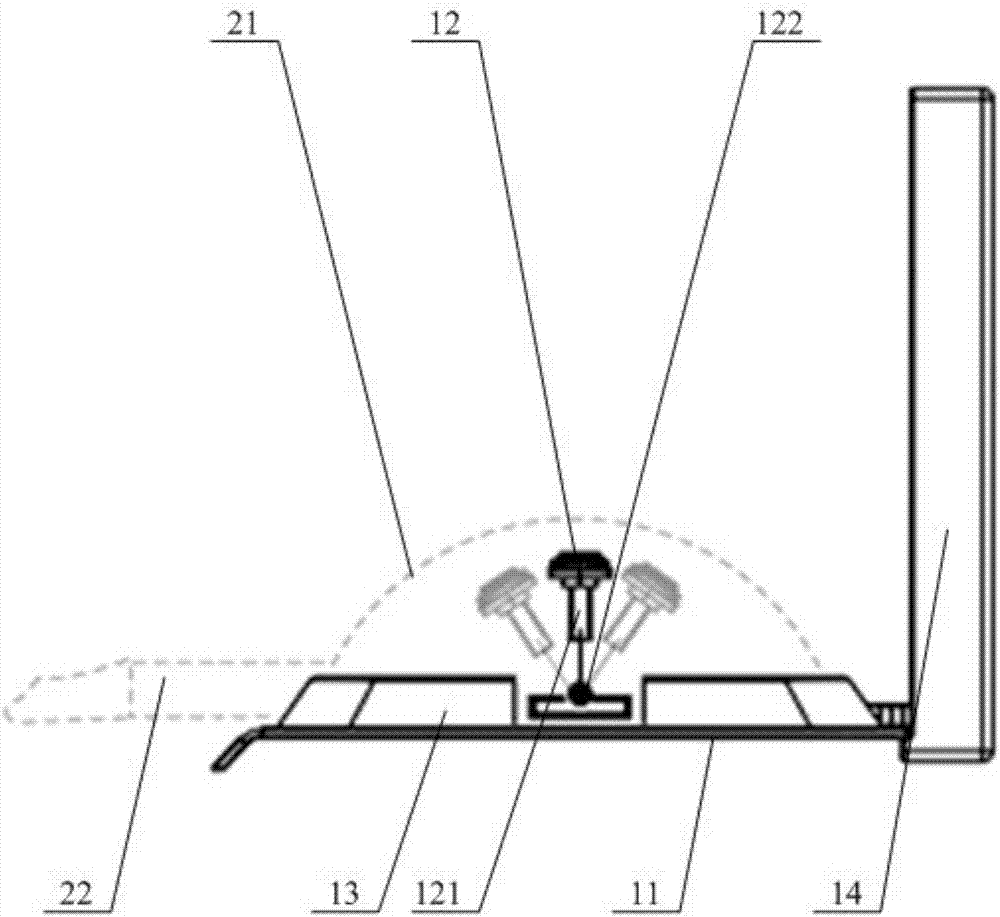

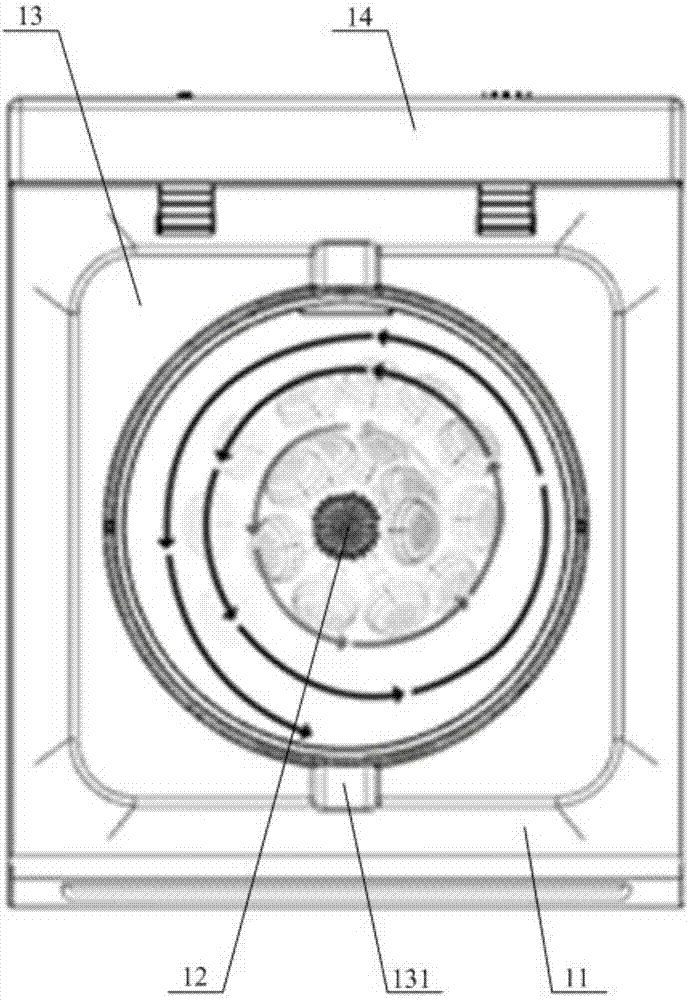

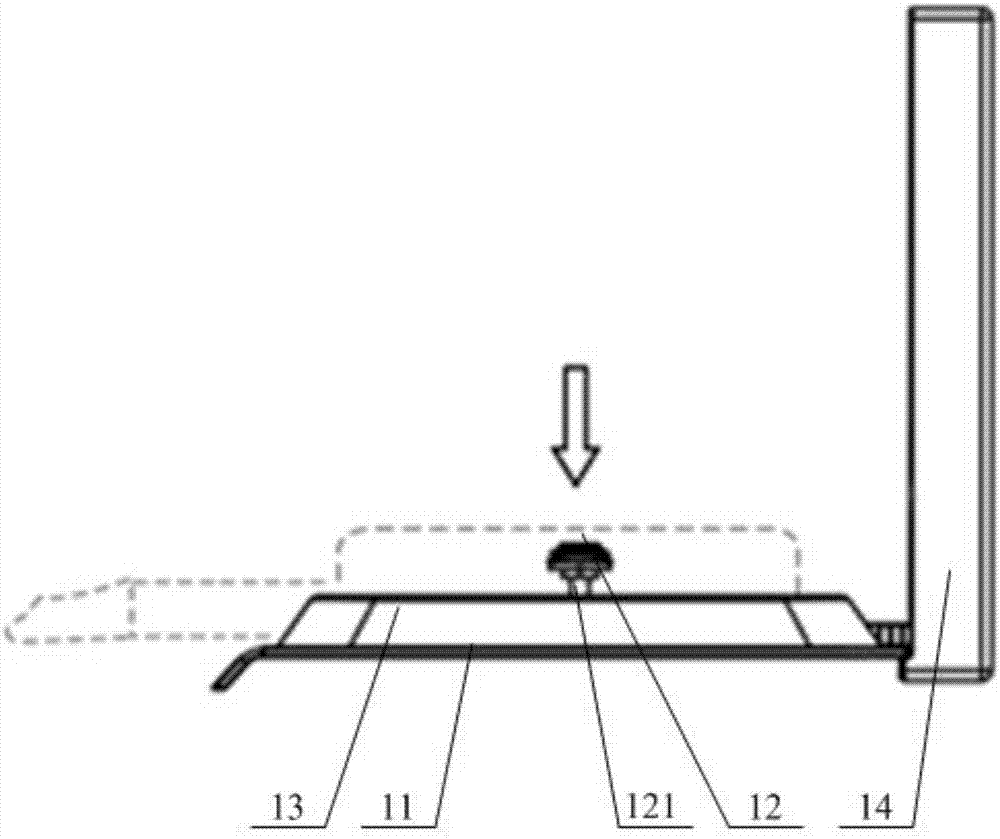

Pot washing machine

PendingCN107997720ACompact structureGuaranteed cleaning effectTableware washing/rinsing machine detailsCleaning equipmentCleansing AgentsWater spray

The invention discloses a pot washing machine which comprises a base and a brush. A guide shaft is arranged at the bottom of the brush in an axially telescopic manner and connected to the middle of the base through a spherical pair, and the brush is provided with a plurality of water spraying holes. In a use process of the pot washing machine, a pot is put on the base in an upside down manner to enable the brush to be positioned in the pot and contact with the inner wall of the pot; in an operating process of the pot washing machine, the brush is capable of realizing large-angle spiral brushing operation through the spherical pair to completely clean the inner wall of the pot; in a cleaning process, clean water or a detergent can be sprayed through the water spraying holes so as to make itconvenient to flush off greasy dirt in a brushing process. In addition, the guide shaft with an axial telescopic structure is capable of guaranteeing complete fitting of the brush and pots in different depths to guarantee cleaning effects of the pot washing machine. The pot washing machine is integrally compact and delicate in structure, capable of efficiently cleaning single pots in the cleaningprocess, low in power consumption and water consumption and simple, convenient and feasible in an the operating process.

Owner:GUANGDONG UNIV OF TECH

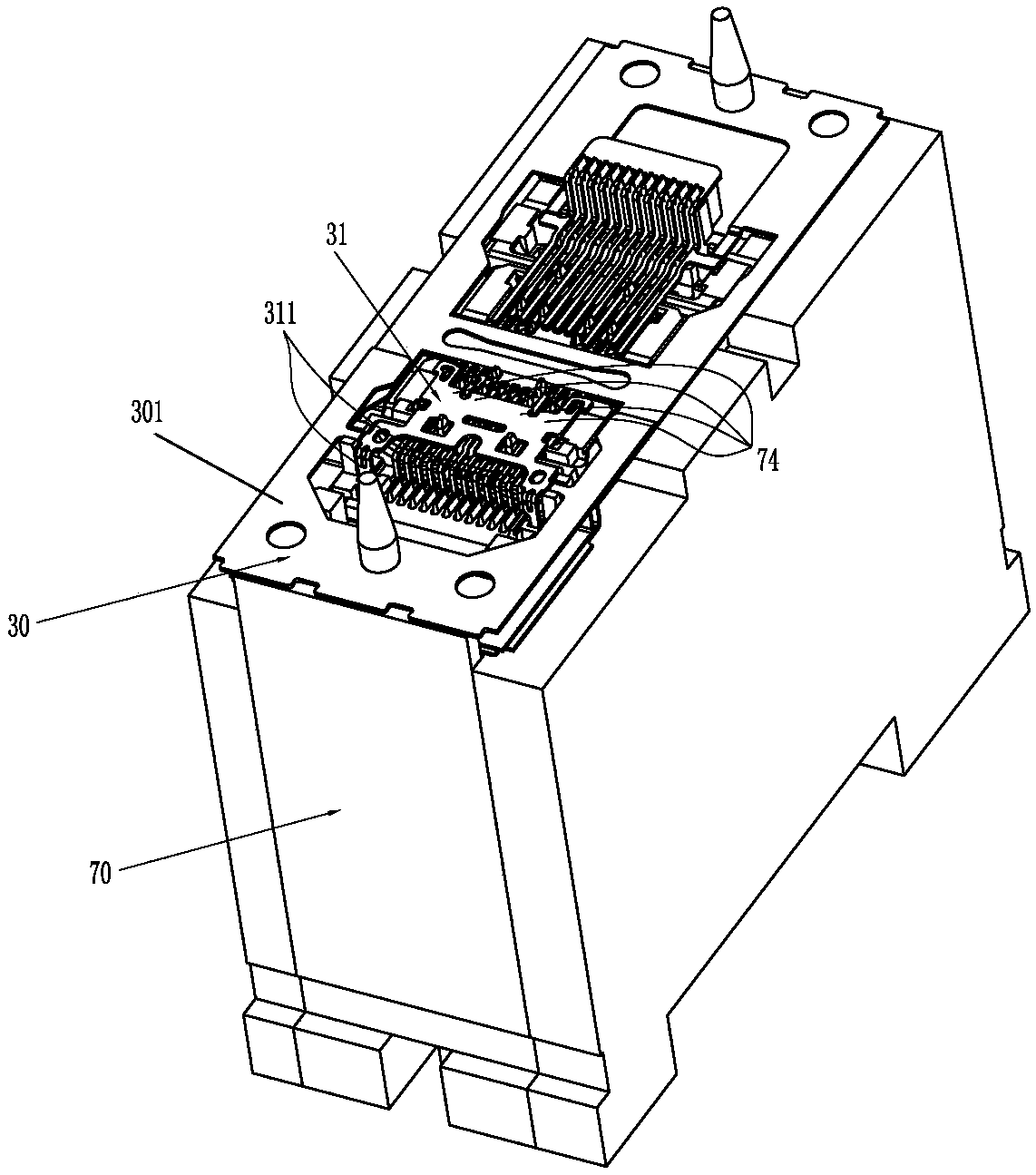

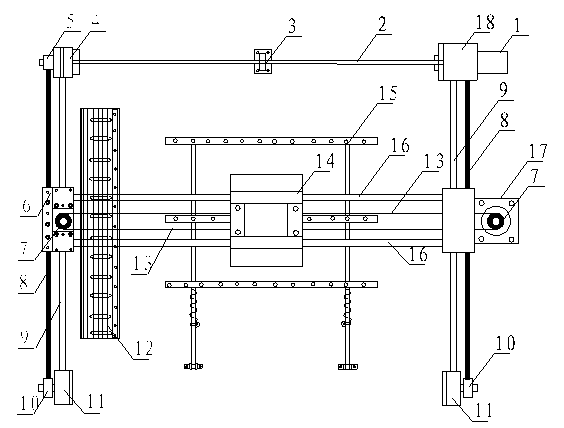

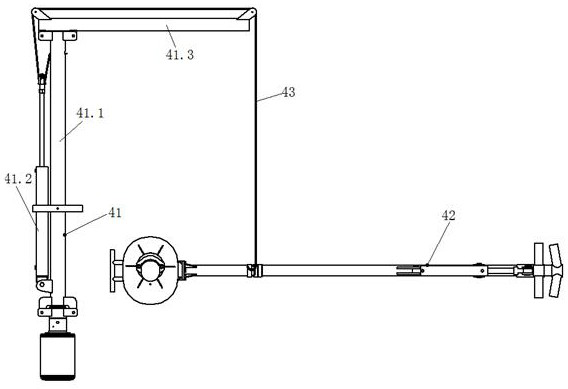

X-Y movement device for simple chip mounter

InactiveCN103140045ACompact structureReduce weightPrinted circuit assemblingElectric machineEngineering

Disclosed is an X-Y movement device for a simple chip mounter. A Y-axis driving motor is arranged on the outer side of a pedestal, the inner side of the pedestal is connected with a Y-axis light bar fixing base through a light bar, the Y-axis light bar fixing base is connected with a fixing pedestal through a Y-direction light bar, a Y-direction gear is arranged on the outer side of the Y-axis light bar fixing base, a gear is arranged on the outer side of the fixing pedestal, a synchronous toothed belt is arranged between the Y-direction gear and the gear and connected with a second fixing pedestal, the second fixing pedestal is slidably connected with the Y-direction light bar, an X-direction gear and an X-direction light bar are arranged on the second fixing pedestal, an X-direction toothed belt is arranged on the X-direction gear 7, a chip mounting head pedestal is arranged on the X-direction light bar, a PCB (printed circuit board) fixing support is arranged below the chip mounting head pedestal, a feed chute is connected with the PCB fixing support, the motor drives the gear to drive the synchronous toothed belt to linearly reciprocate within a certain range, and the synchronous toothed belt moves to drive a linear bearing fixed on a shaft pedestal to realize linkage movement in an X-Y axis direction. The X-Y movement device has the advantages of simple structure and low maintenance cost.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

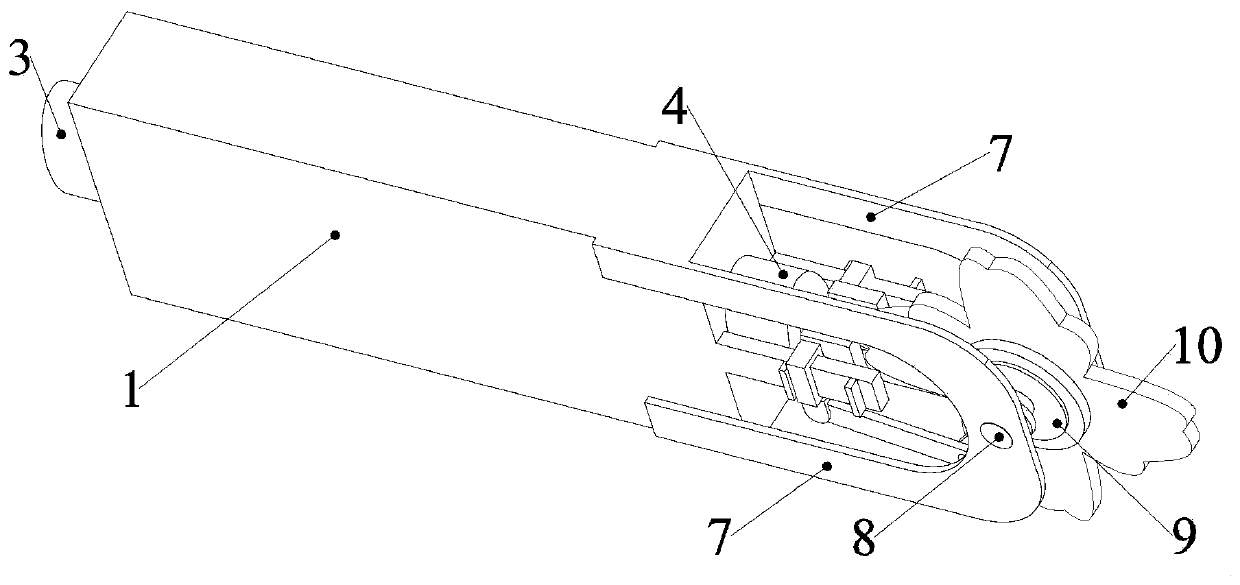

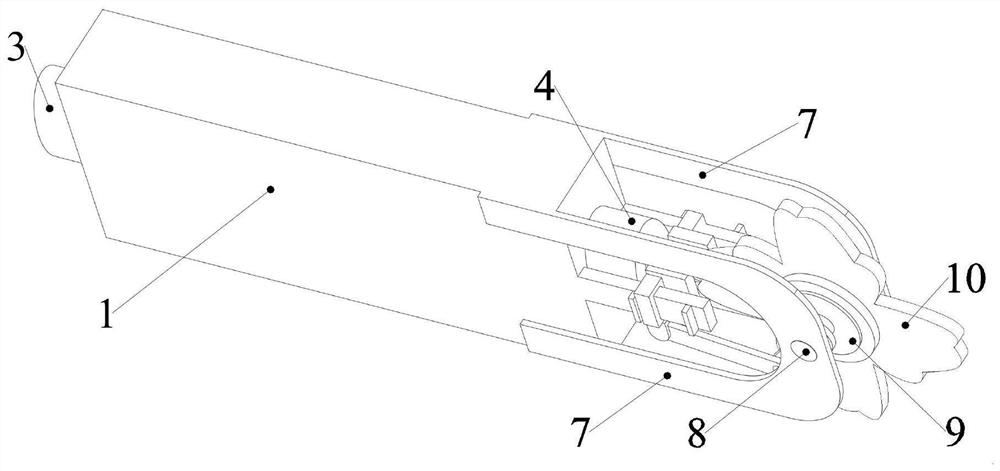

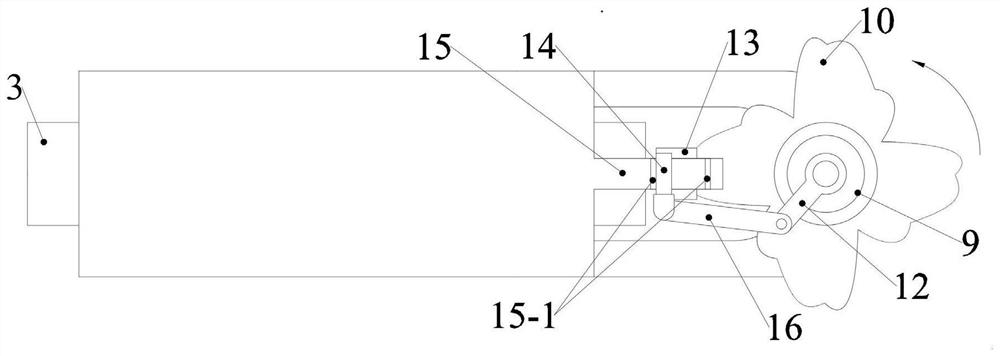

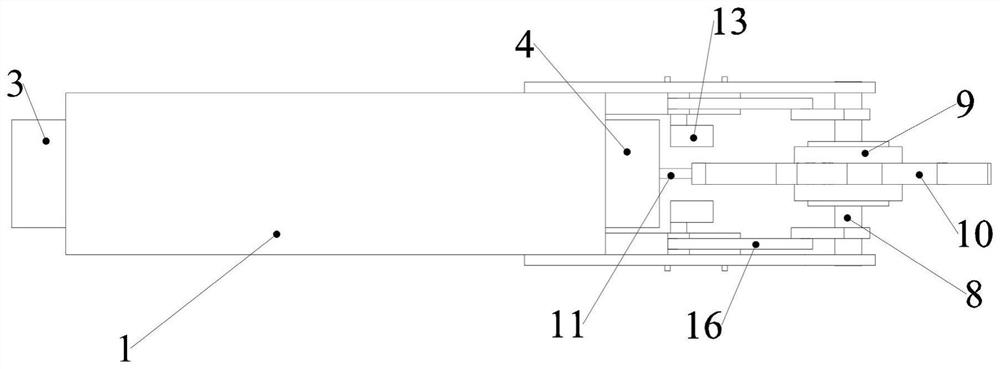

Cable wire stripping mechanism

InactiveCN108075404AEnsure positioning reliabilityEasy to processBasic electric elementsApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention discloses a cable wire stripping mechanism. According to the cable wire stripping mechanism, a structure is simple, the operation is convenient, and the working efficiency is improved. The cable wire stripping mechanism comprises a worktable, wherein a wire releasing roller, a wire stripping assembly and a wire collection assembly are set on the worktable in sequence. The wire stripping assembly comprises a bushing, a pair of brackets and a pair of cutters. The busing is set on the pair of brackets. The pair of brackets are set on the worktable. Penetration holes are set at two ends of the bushing. The pair of cutters are located in the penetration holes. The outer sides of the cutters are connected with cylinders. The wire collection assembly comprises a wire winding roller.The wire winding roller is driven by a motor. The cable wire stripping mechanism is convenient for processing and operation.

Owner:YANGZHOU HUALIAN COATING MACHINERY

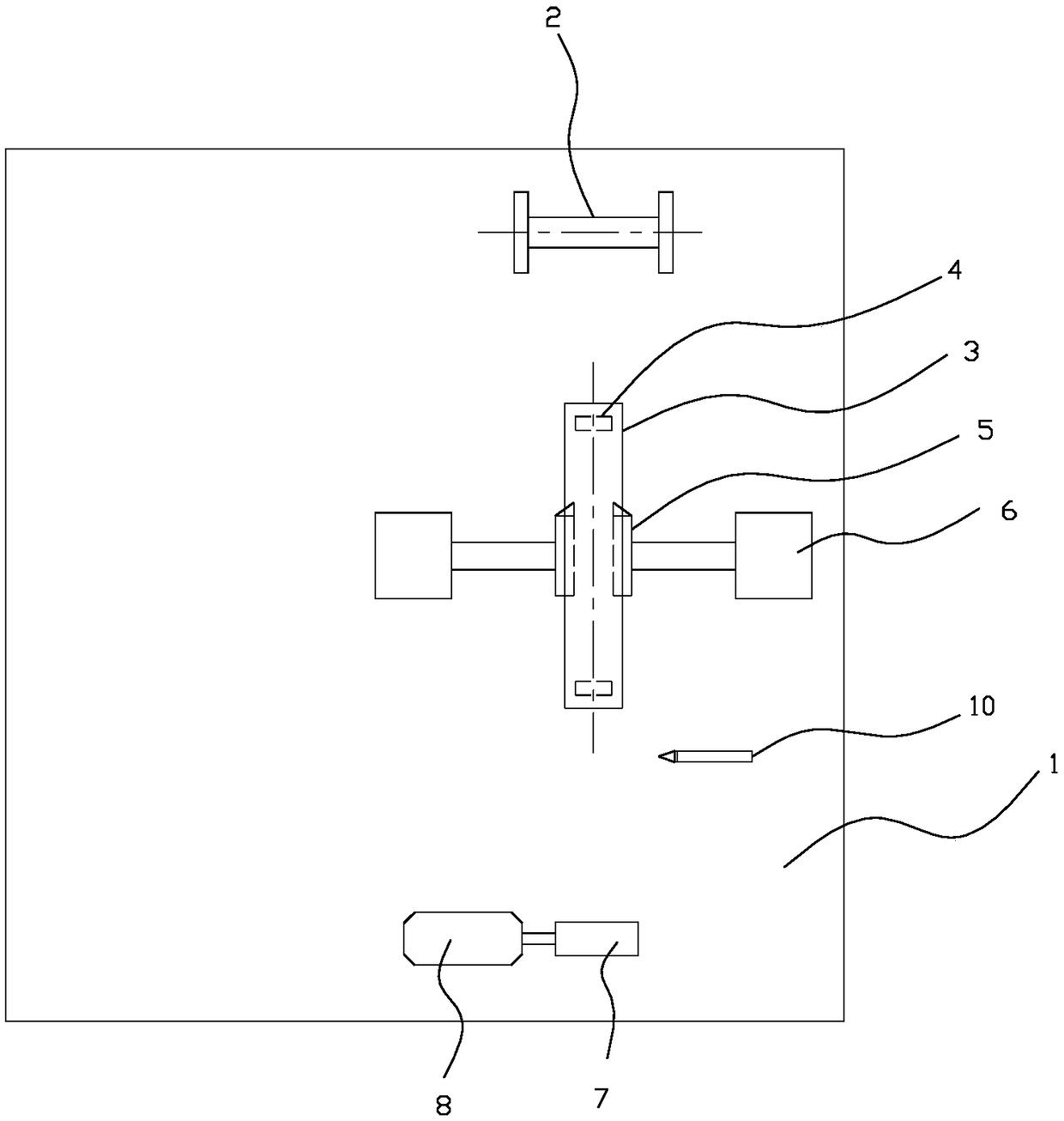

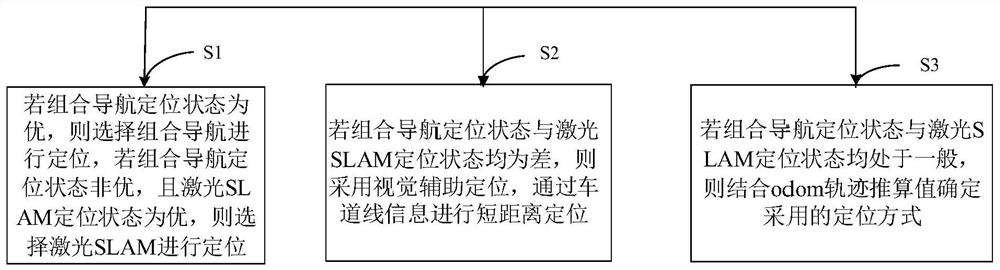

Positioning system and method for automatic driving vehicle

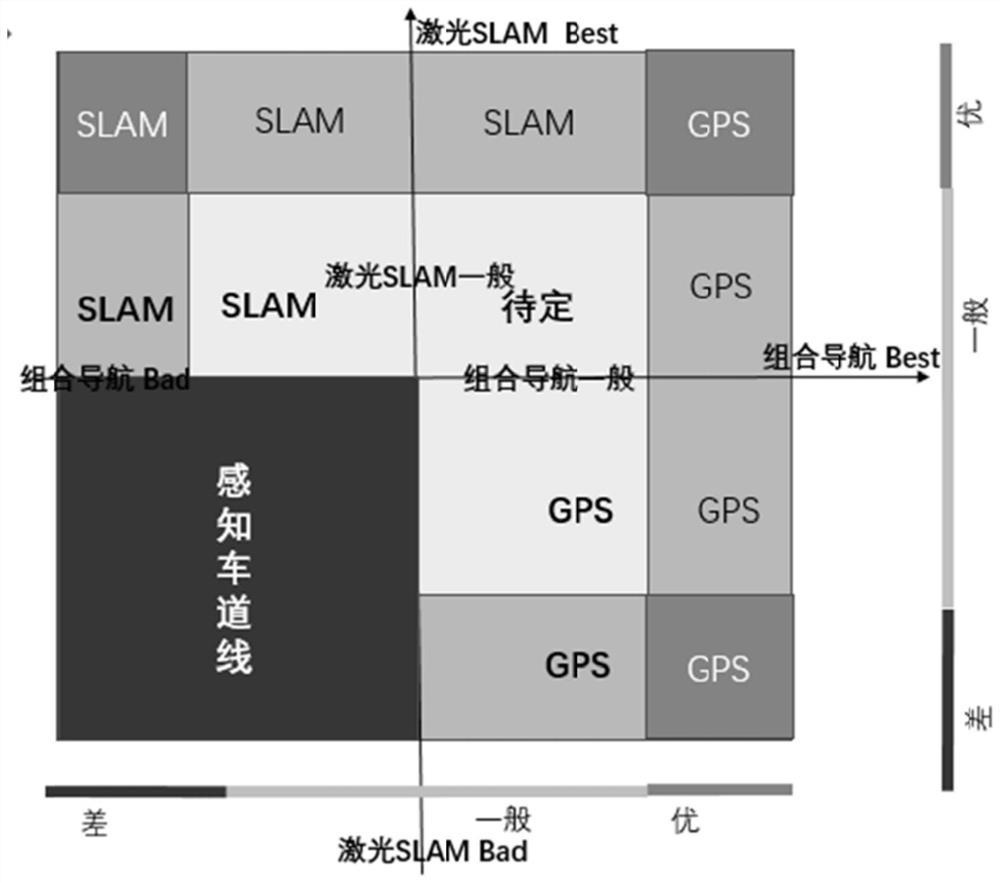

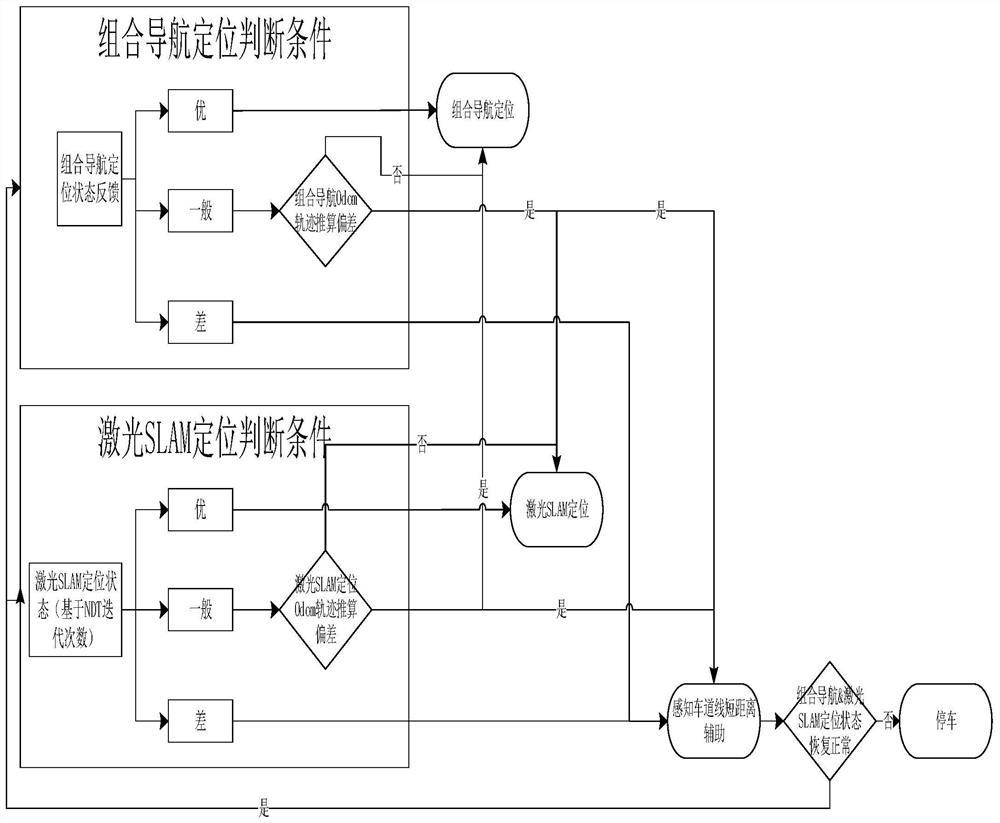

ActiveCN112558087AAvoid frequent switchingGuaranteed driving comfortInternal combustion piston enginesNavigation by speed/acceleration measurementsRadarPositioning system

The invention discloses a positioning system and method for an automatic driving vehicle, belongs to the technical field of automatic driving of automobiles, and aims to provide a vehicle positioningresult by using an integrated navigation module in a place with a good GPS signal so as to ensure that the vehicle can normally run along a preset track. When the integrated navigation state is not good, a multi-angle coverage laser radar SLAM positioning algorithm is used for providing vehicle state information; when the method is used in a scene with poor integrated navigation and laser SLAM states, short-distance positioning is carried out through lane line information obtained through current data; three positioning schemes are adopted for safety redundancy, and vehicle positioning safetyand positioning reliability are fully guaranteed.

Owner:DONGFENG MOTOR CORP HUBEI

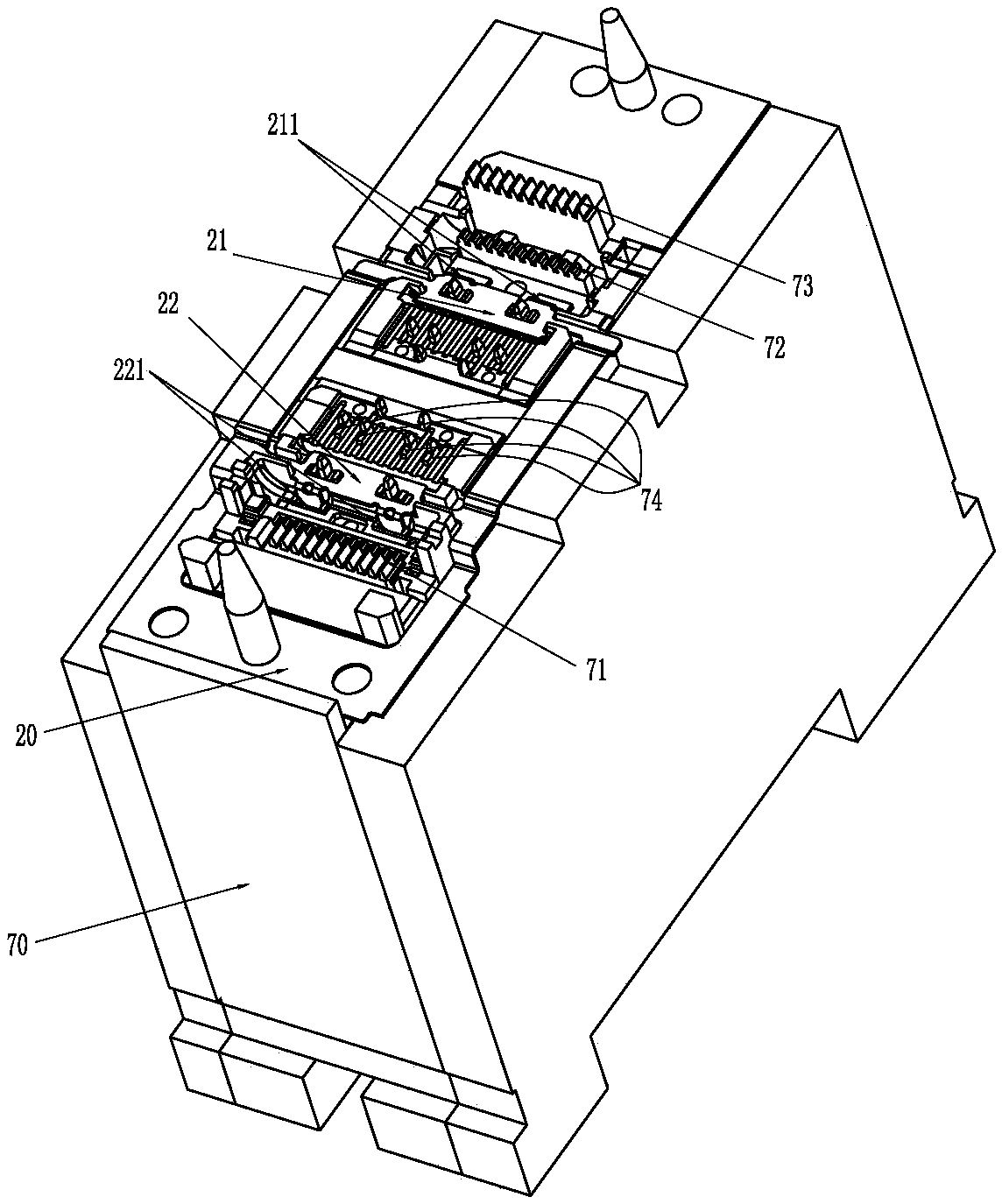

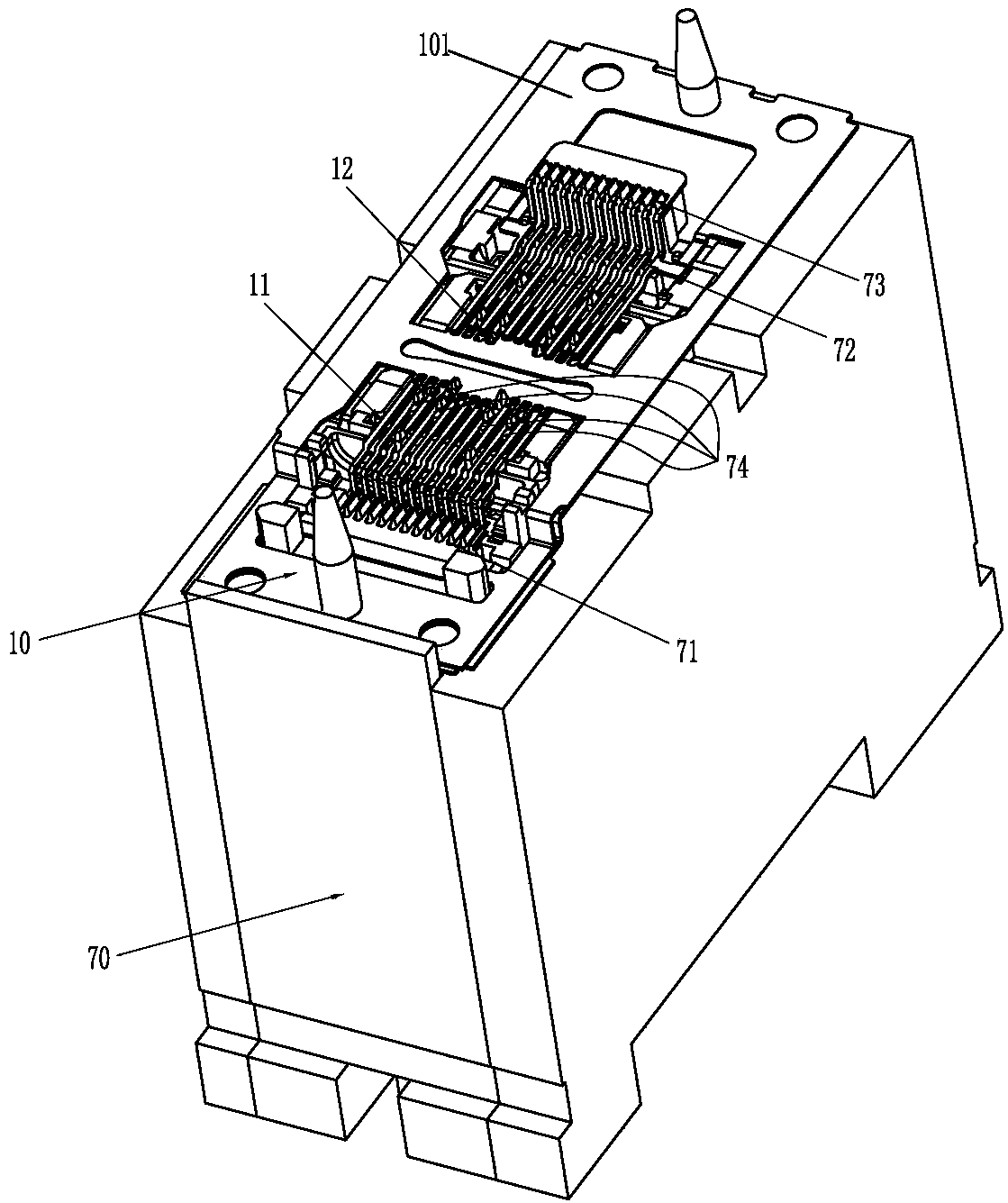

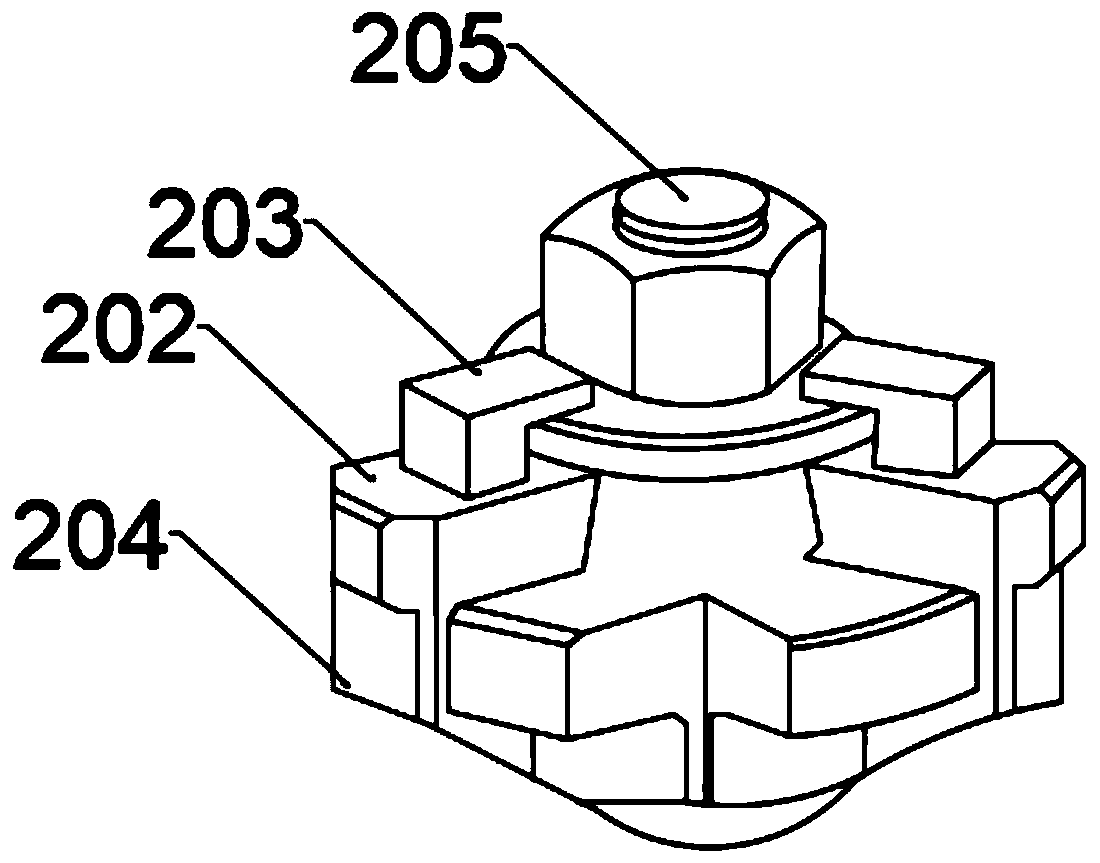

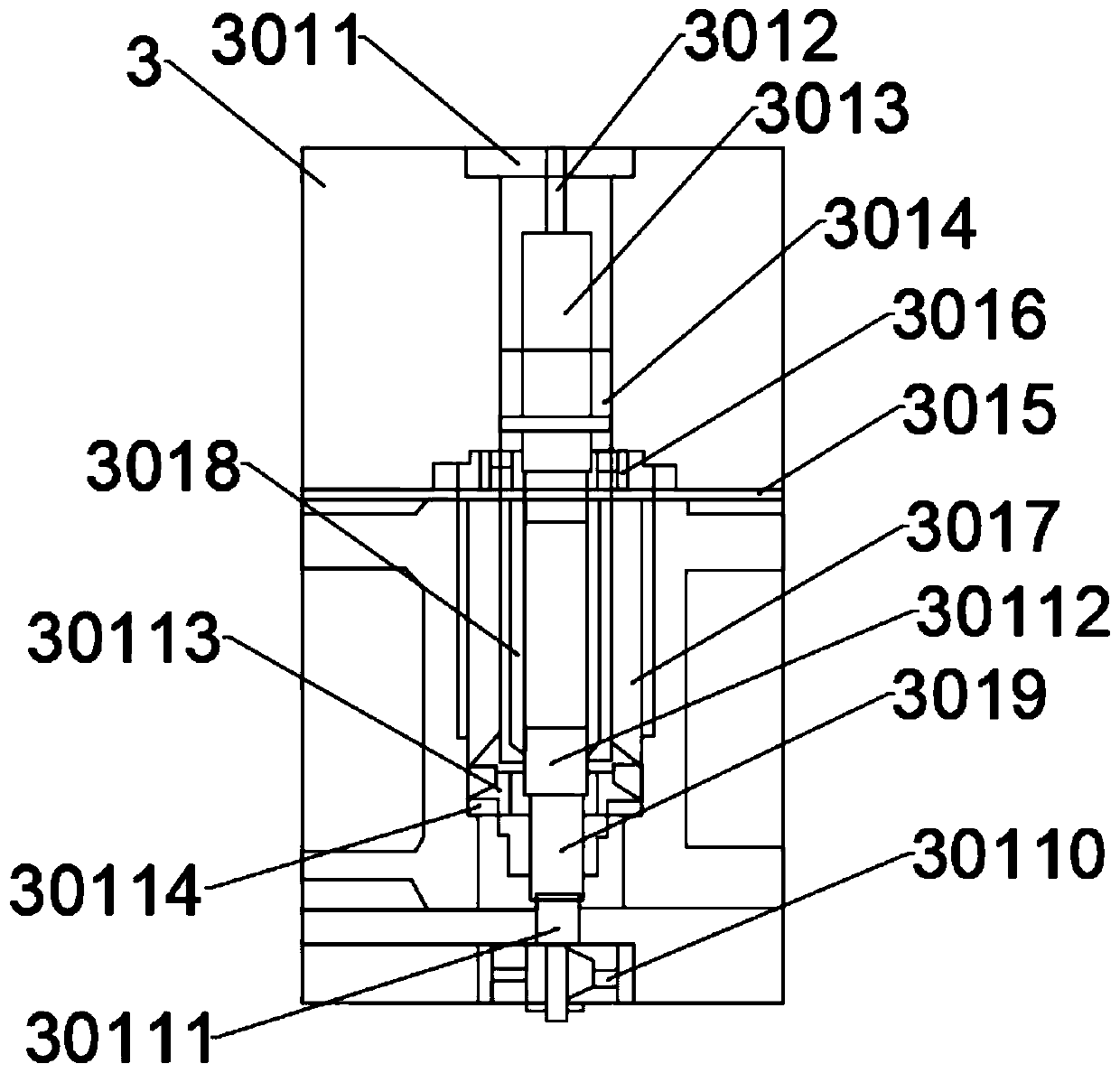

Multifunctional positioning fixture used for production of radar slotted waveguide antennas

ActiveCN108788802AGuaranteed positioning accuracyAvoid large gapsPositioning apparatusMetal-working holdersSlotted waveguideRadar

The invention discloses a multifunctional positioning fixture used for production of radar slotted waveguide antennas. The multifunctional positioning fixture comprises a tapered groove mandrel, a pressing mechanism and a central shaft. A tapered groove is formed in the outer surface of the tapered groove mandrel. An adjustment nut is connected to the upper portion of the tapered groove mandrel ina threaded mode. The pressing mechanism is connected to the lower portion of the tapered groove mandrel in the axial direction. The central shaft is connected to the lower portion of the pressing mechanism in the axial direction. A central shaft correction mechanism is arranged in the central shaft. A positioning pin is connected to the lower output end of the central shaft correction mechanism in the axial direction. A bolt is connected to the lower portion of the positioning pin in the axial direction through a washer. The whole multifunctional positioning fixture has the advantage of central shaft positioning and overcomes the defects of large gaps and low machining precision in the mandrel positioning process, the position precision of a shaft hole relative to main machining faces such as the upper and lower surfaces of a shaft body and a main bearing hole is effectively ensured, the center of the shaft hole is used for positioning to achieve machining, and thus, the positioning precision is improved.

Owner:中安锐达(北京)电子科技有限公司

Integrated navigation positioning method and device based on short base line

PendingCN113551669AEasy to moveGuaranteed positioning accuracyNavigational calculation instrumentsNavigation by speed/acceleration measurementsEngineeringPosition fixing

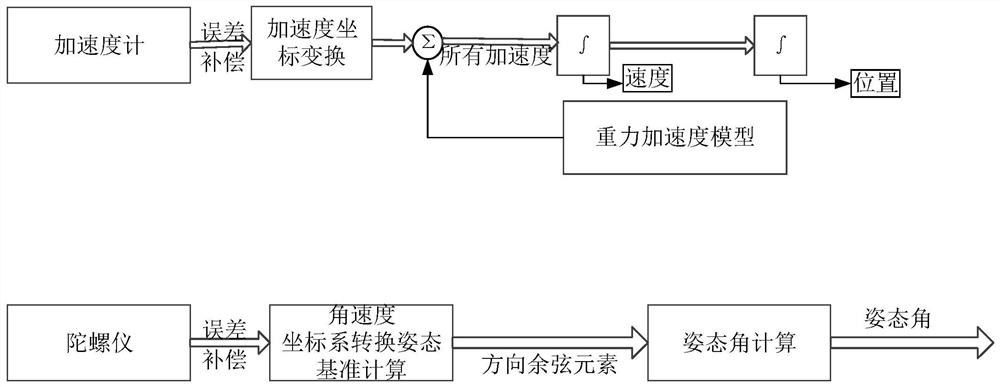

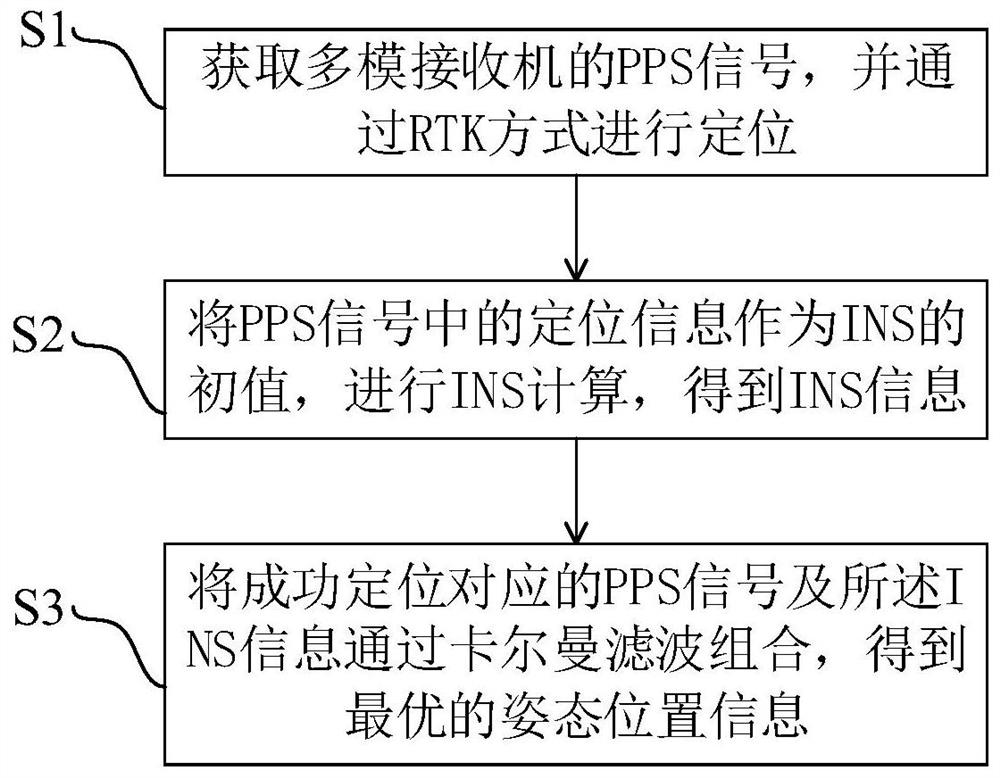

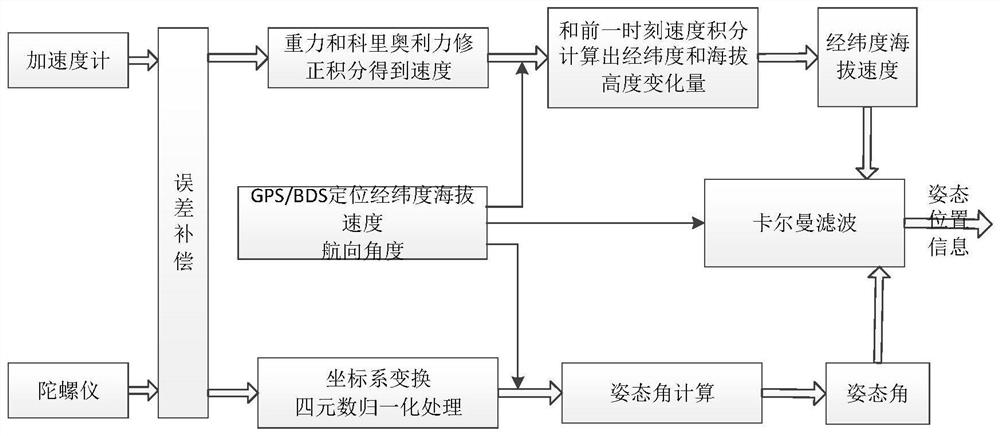

The invention provides an integrated navigation positioning method and device based on a short base line. The method comprises the steps of obtaining a PPS signal of a multimode receiver, and carrying out the positioning through an RTK mode, taking positioning information in the PPS signal as an initial value of INS, conducting INS calculation, and acquiring INS information, and combining the successfully positioned PPS signal and the INS information through Kalman filtering to obtain optimal attitude position information. A short base line is adopted, the length of the base line is only 320 mm, two receiving antennas are arranged, the weight is only 5 kg, the device is small and exquisite, movement is convenient, GNSS and INS combined navigation is achieved, fast positioning can be achieved through the INS when a carrier is shielded, a high-precision INS inertial element is adopted, meanwhile, errors of the inertial element are optimized through Kalman filtering, deviation of the INS inertial element can be corrected through positioning information of the GNSS, and the positioning precision and reliability of the system are ensured.

Owner:山东泉清通信有限责任公司

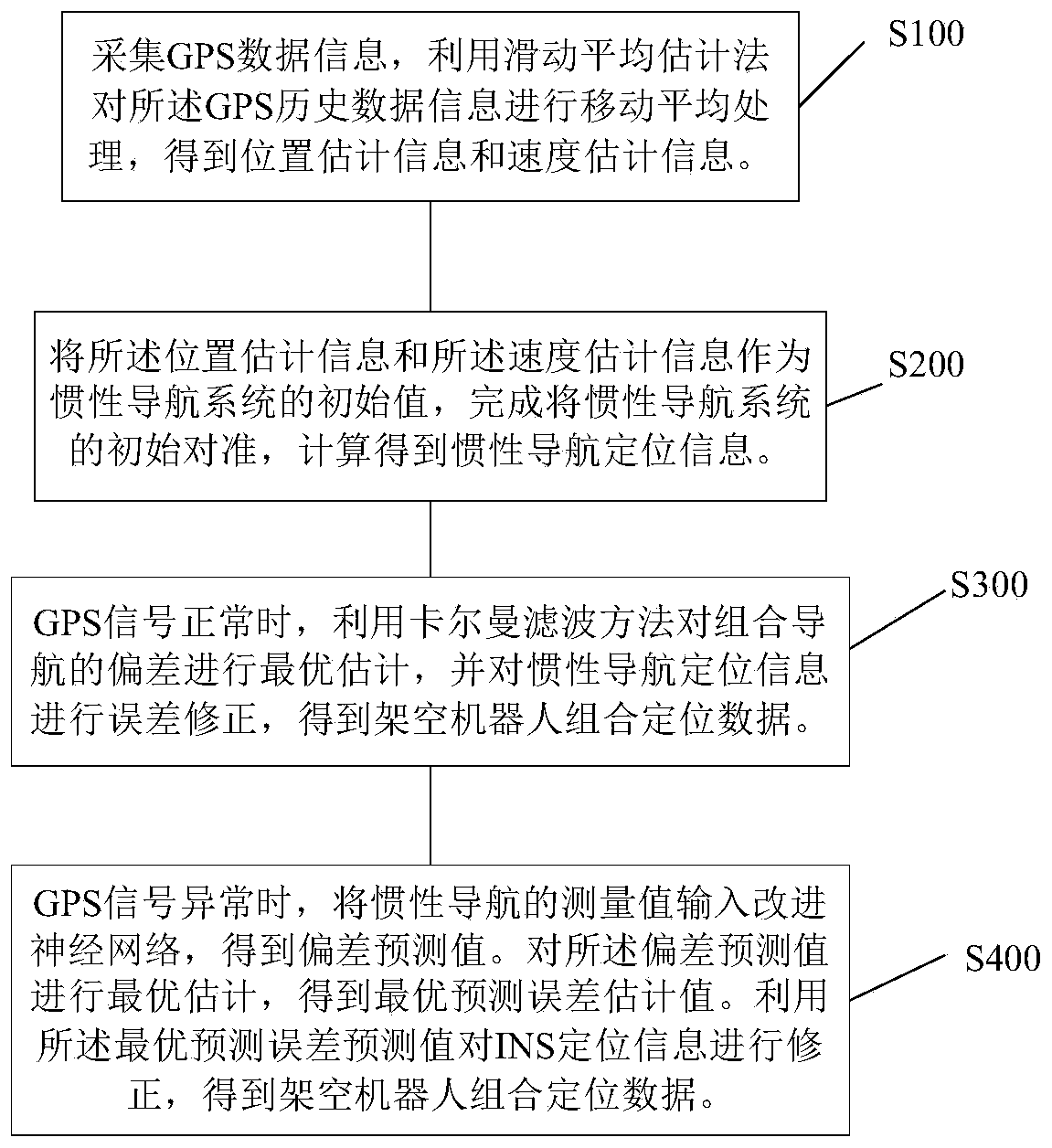

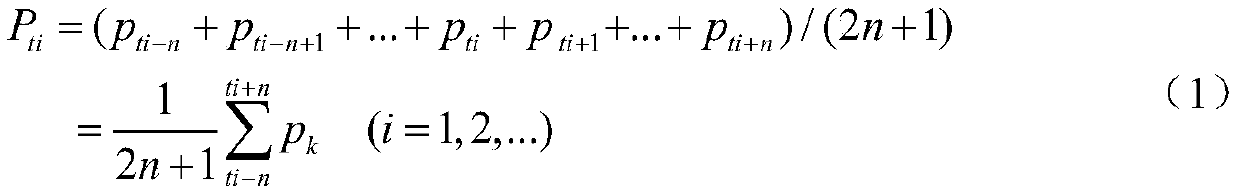

Aerial robot combined positioning method

PendingCN111288988ATroubleshoot inaccurate technical issuesGuaranteed positioning accuracyNavigation by speed/acceleration measurementsSatellite radio beaconingKaiman filterEngineering

The application discloses an aerial robot integrated positioning method. Data fusion is carried out on GPS and inertial navigation positioning information of an aerial maintenance robot by adopting aKalman filter and optimal estimation is performed on positioning errors, so that correction of integrated navigation errors is realized, and the positioning precision is improved. Meanwhile, an improved neural network is introduced, and a problem that the positioning precision of the overhead maintenance robot becomes poor under the condition that GPS signal receiving is abnormal is solved. When aGPS signal is shielded, the navigation error is predicted by improving the neural network, so that the positioning precision and reliability of the maintenance robot when the GPS signal is unavailable are ensured, and a technical problem that the positioning information of the aerial robot is inaccurate when the GPS signal is abnormal is solved.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Intermediate fulcrum outer ring supporting structure of engine

ActiveCN114575930AEnsure safetyEnsure positioning reliabilityInternal combustion piston enginesBlade accessoriesEngineeringBolt connection

The invention belongs to the field of intermediate case design, and relates to an engine intermediate fulcrum outer ring supporting structure which comprises a bearing, a low-pressure rotor, a high-pressure rotor and a sealing ring. The outer ring of the second bearing is axially compressed and positioned by arranging the mounting side plate to be in bolted connection with the sealing ring and the low-pressure rotor, a bearing seat and a first compression nut in a traditional structure are omitted, and the mounting side plate is arranged between the sealing ring and the low-pressure rotor, so that the outer ring of the second bearing is axially compressed and positioned at the same temperature. Thermal barrier deformation on the sealing ring and the low-pressure rotor can only be transmitted to the mounting side plate, the outer ring of the second bearing cannot be influenced by the sealing ring and the low-pressure rotor, the bearing cannot be loosened, the problems of vibration of the whole machine, damage to the bearing and the like cannot be caused, and the safety of the engine can be guaranteed; and the relative positions of the sealing ring, the mounting side plate and the low-pressure rotor are not changed, so that the mounting side plate, namely the reliable axial and radial positioning of the bearing, is realized, and the positioning reliability of the intermediate fulcrum outer ring is ensured.

Owner:AECC SHENYANG ENGINE RES INST

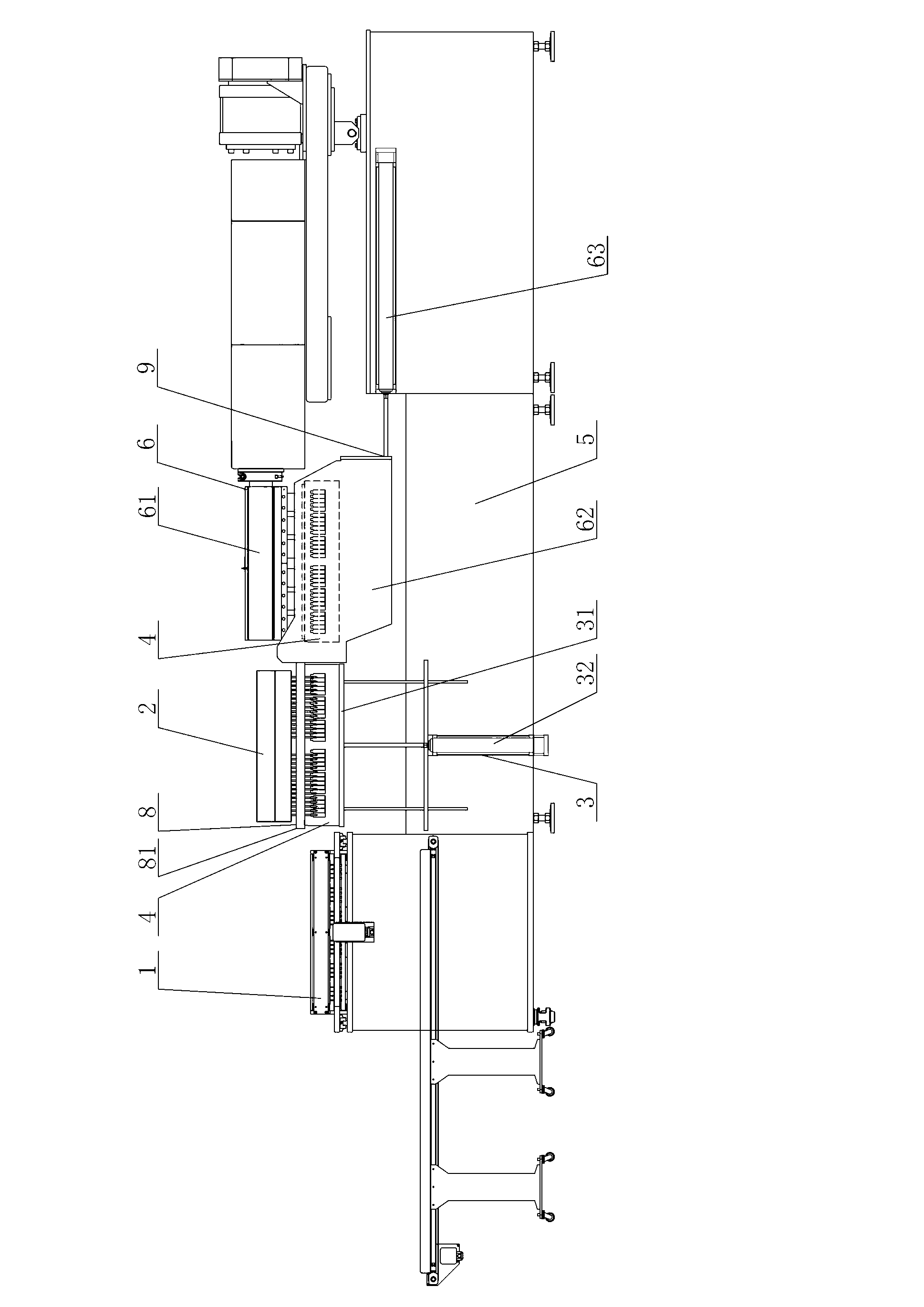

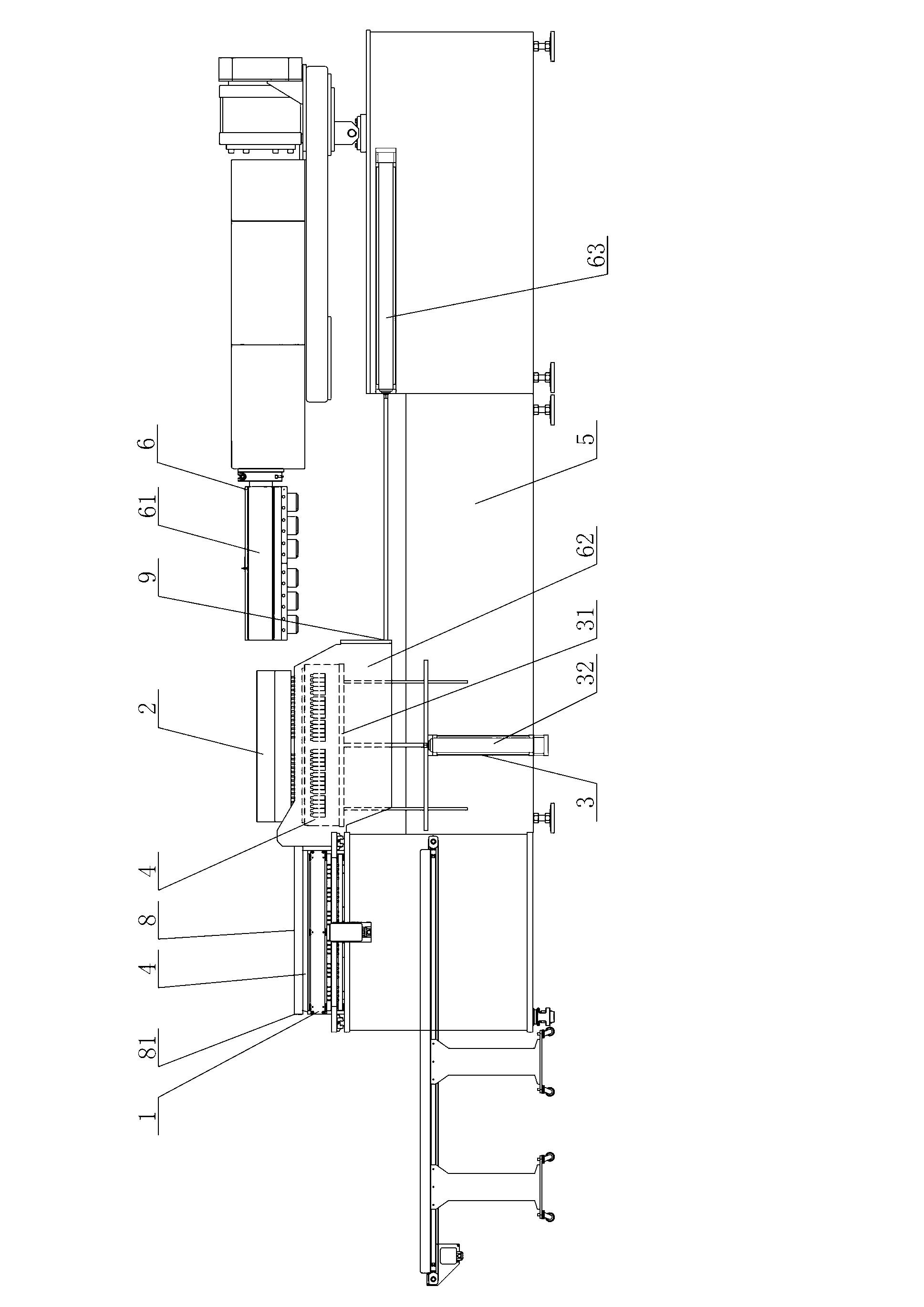

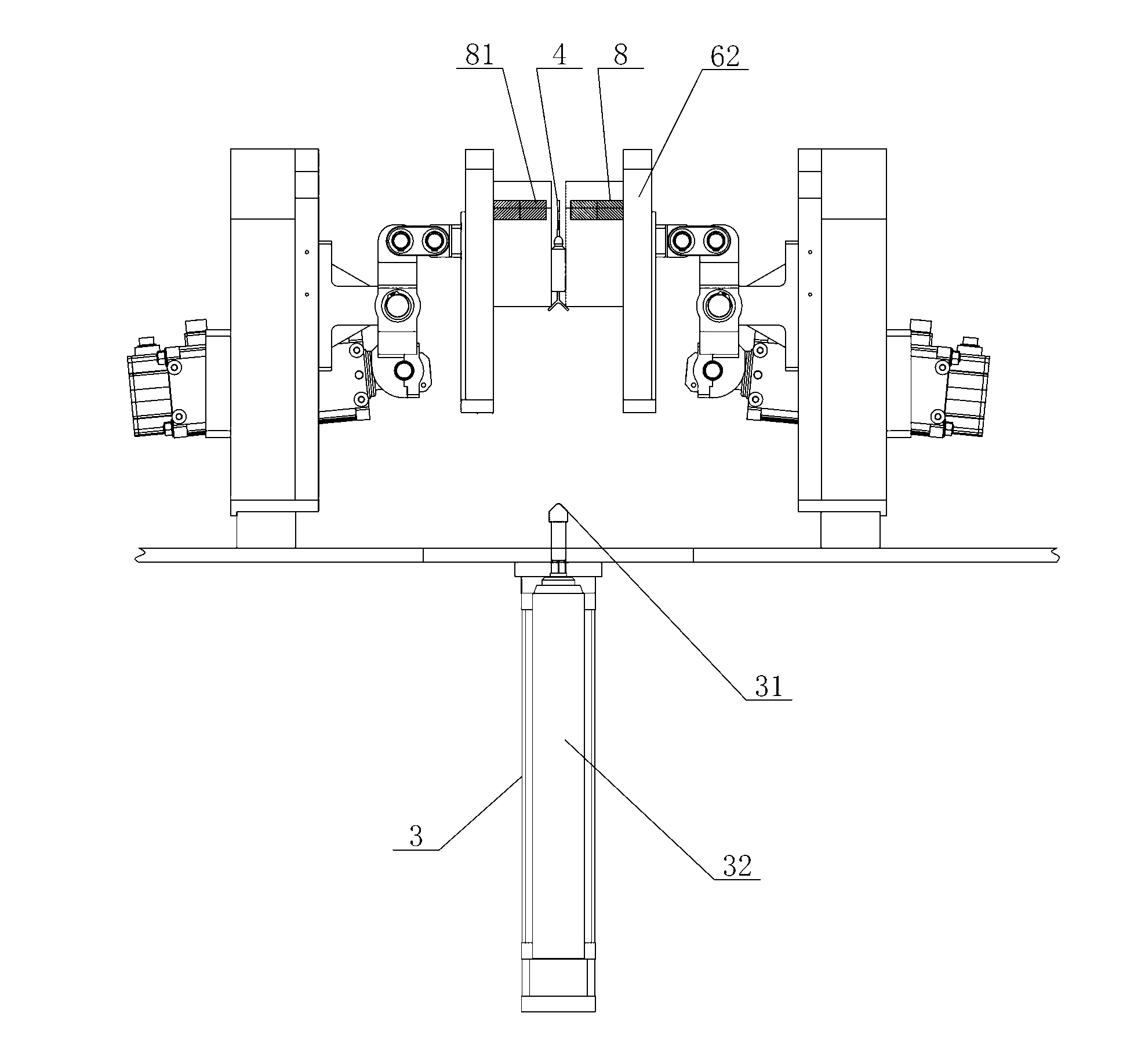

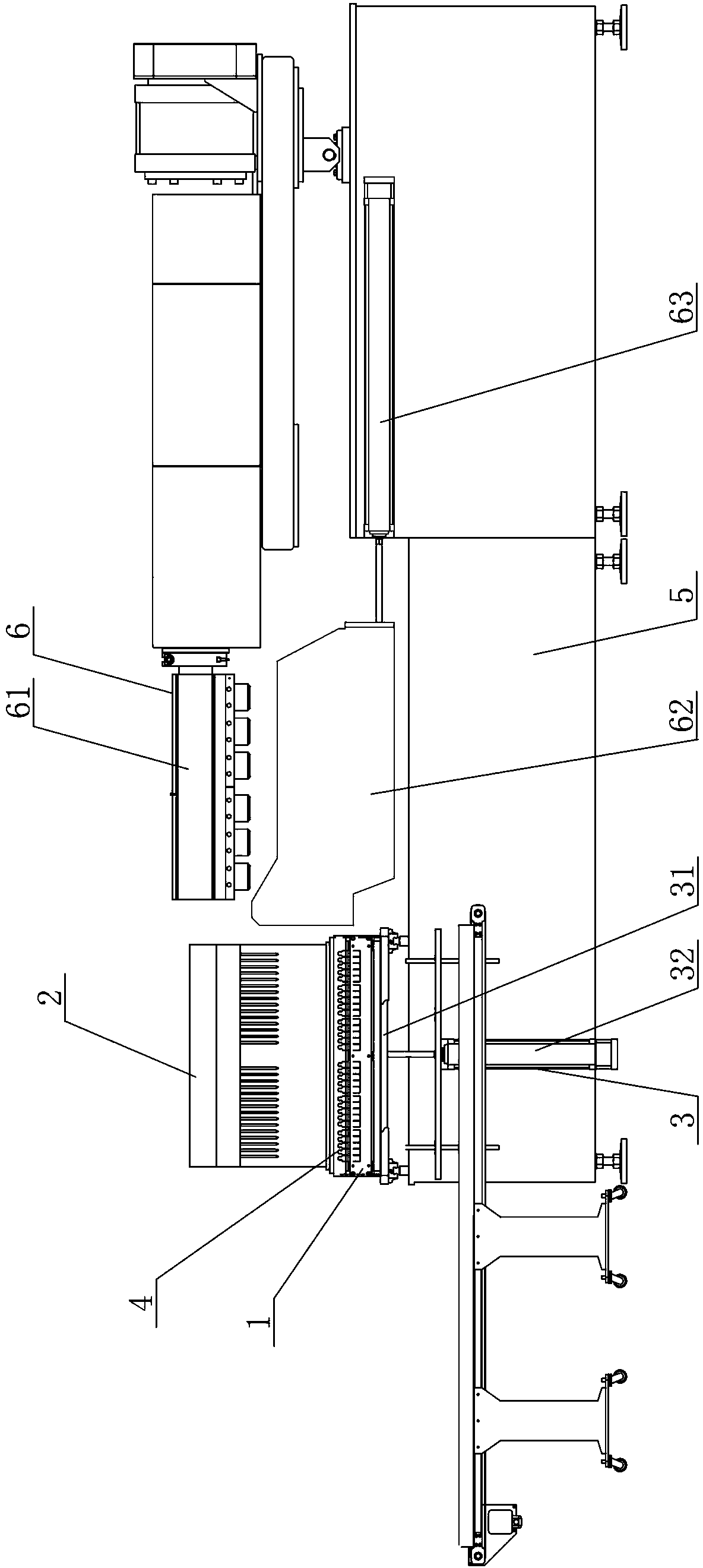

Cutting device for angle steel

InactiveCN105234478ASmall vibrationUnlikelyNibbling shearing machinesShearing machine accessoriesMechanical engineeringEngineering

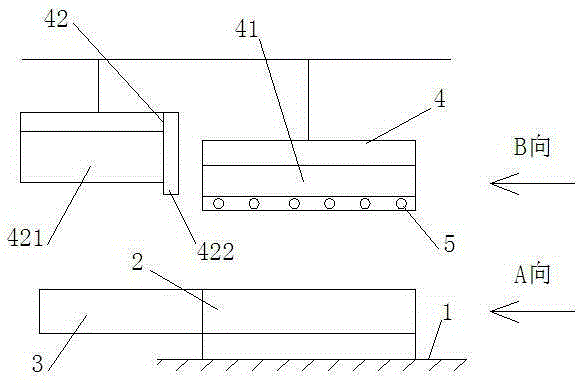

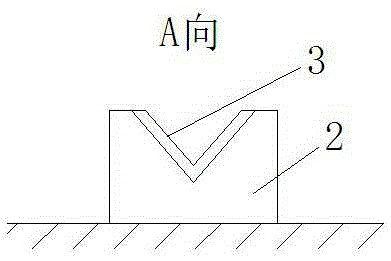

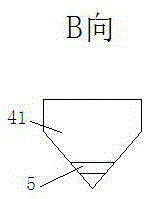

The invention relates to a cutting device for angle steel. The cutting device comprises a rack (1) and a V-shaped positioning block (2) arranged on the rack (1). The angle steel (3) is placed in the V-shaped positioning block (2). A cutter (4) which is located at the upper portion of the V-shaped positioning block (2) and corresponds to the V-shaped positioning block (2) is arranged on the rack (1). The cutter (4) comprises a positioning block (41) and a cutting knife (42). The section of the positioning block (41) is in a V shape, and corresponds to the inner wall of the angle steel (3) to position the angle steel (3). The section of the cutting knife (42) is in a V shape. The cutting knife (42) comprises a knife body (421) and a blade (422). The blade (422) is arranged on one side of the knife body (421) and protrudes out of the knife body (421). The positioning block (41) is lower than the cutting knife (42). The cutting device for the angle steel is simple in structure, and can well cut the angle steel.

Owner:扬州市邗江科达涂装有限公司

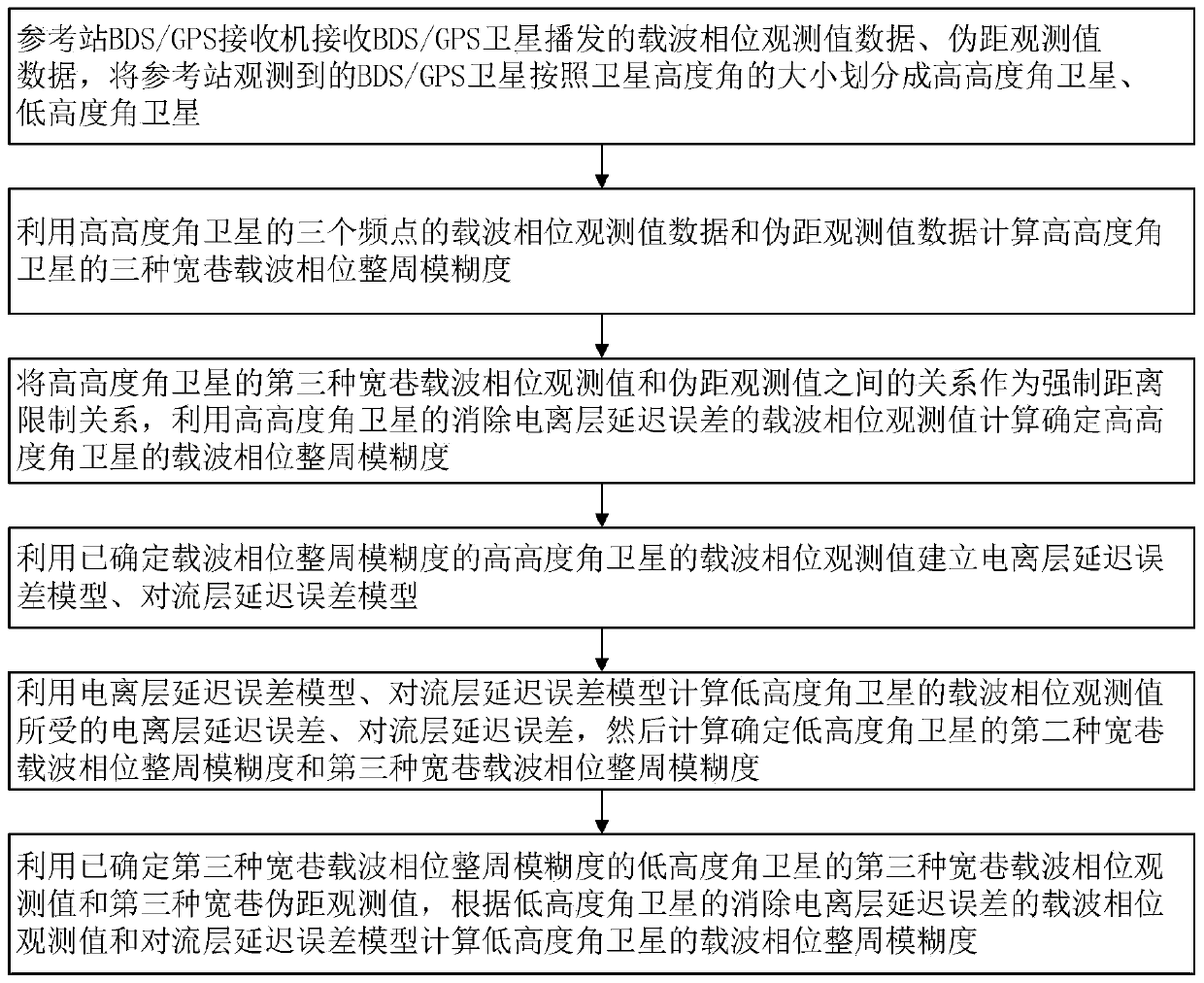

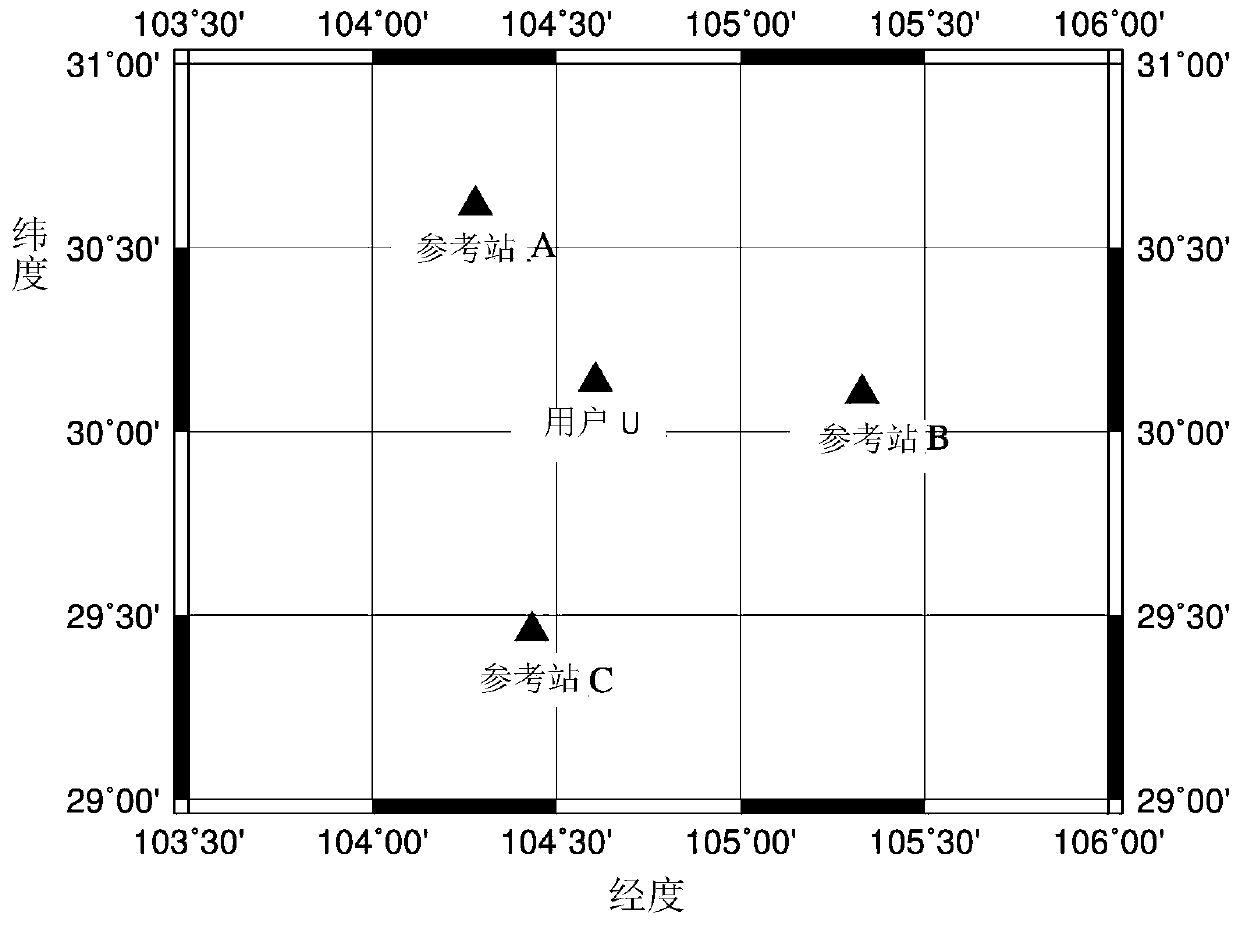

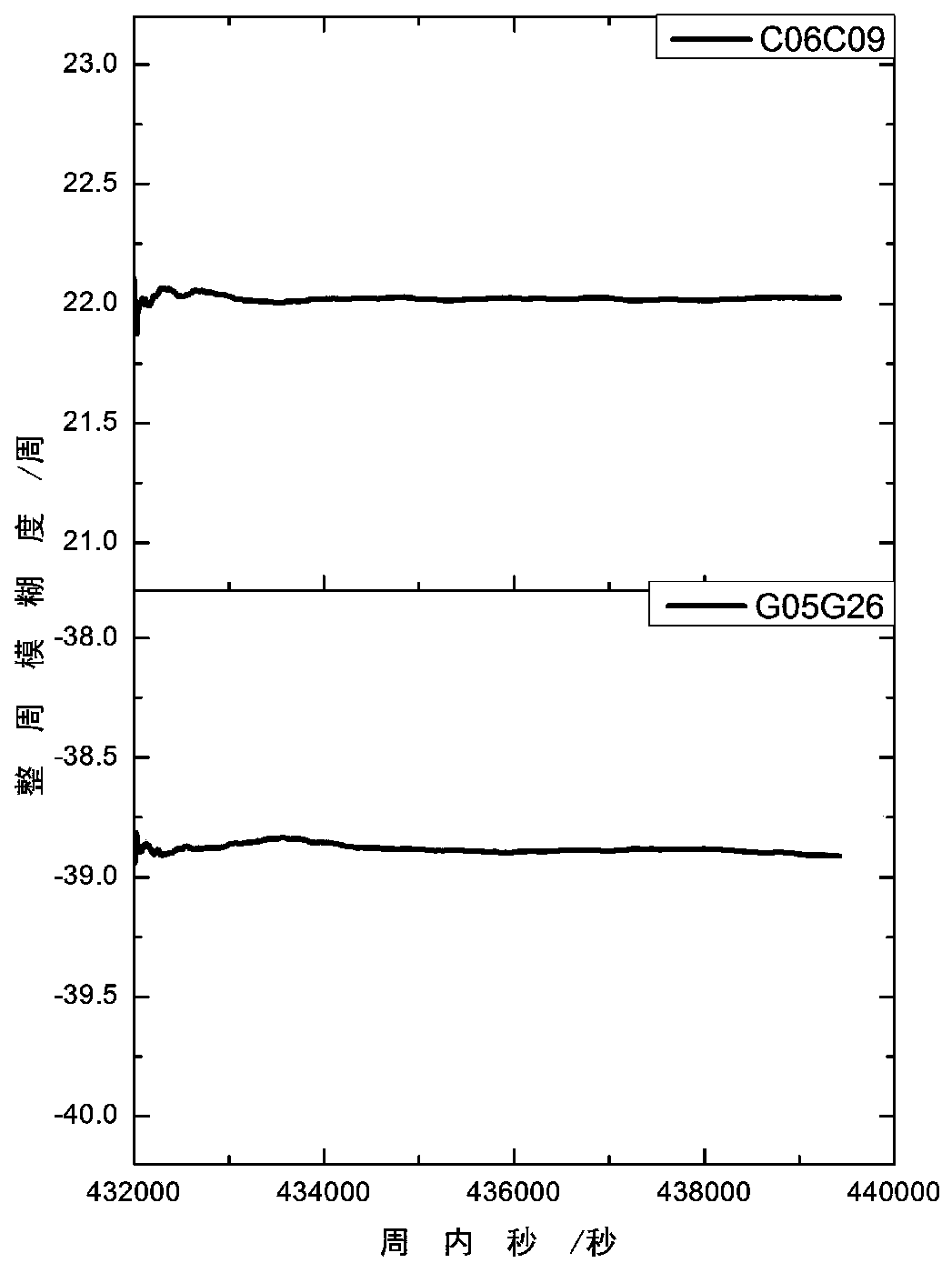

BDS/GPS reference station low altitude angle satellite integer ambiguity determination method

ActiveCN111551975AReduce ambiguityIncrease profitSatellite radio beaconingICT adaptationObservation dataCarrier signal

The invention relates to the technical field of satellite positioning systems and positioning measurement, and provides a BDS / GPS reference station low altitude angle satellite integer ambiguity determination method. The method comprises the following steps: dividing BDS / GPS high altitude angle and low altitude angle satellites; calculating three kinds of wide lane carrier phase integer ambiguityby using a high altitude angle satellite three-frequency carrier phase observation value and a pseudo-range observation value; calculating the carrier phase integer ambiguity by utilizing the carrierphase observation value for eliminating the ionospheric delay error based on the forced distance limiting relation, and establishing ionospheric and tropospheric delay error models by utilizing the carrier phase observation value; calculating a delay error corresponding to the low altitude angle satellite and the second and third wide lane carrier phase integer ambiguity, and calculating the carrier phase integer ambiguity by using the third wide lane observation data according to the carrier phase observation value for eliminating the ionospheric delay error and a tropospheric delay error model. According to the method, the precision of determining the BDS / GPS low altitude angle satellite carrier phase integer ambiguity can be improved.

Owner:LIAONING TECHNICAL UNIVERSITY

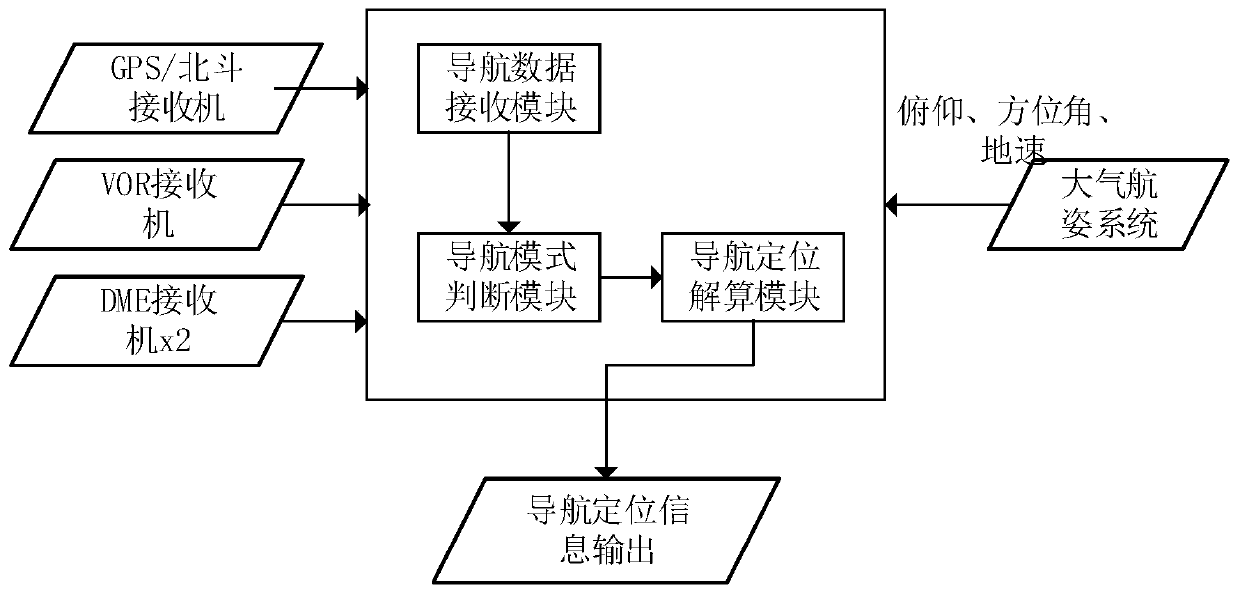

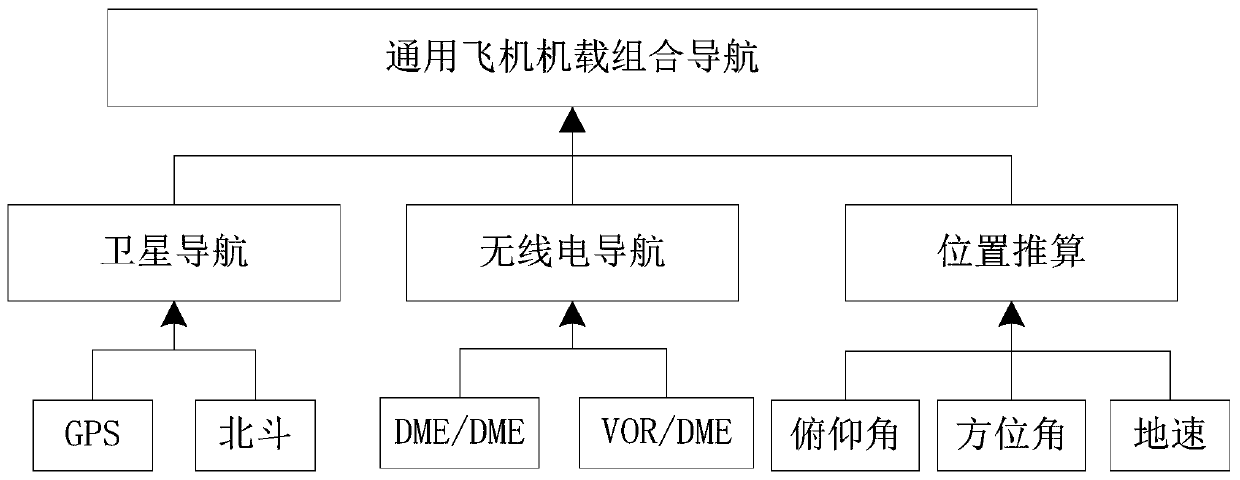

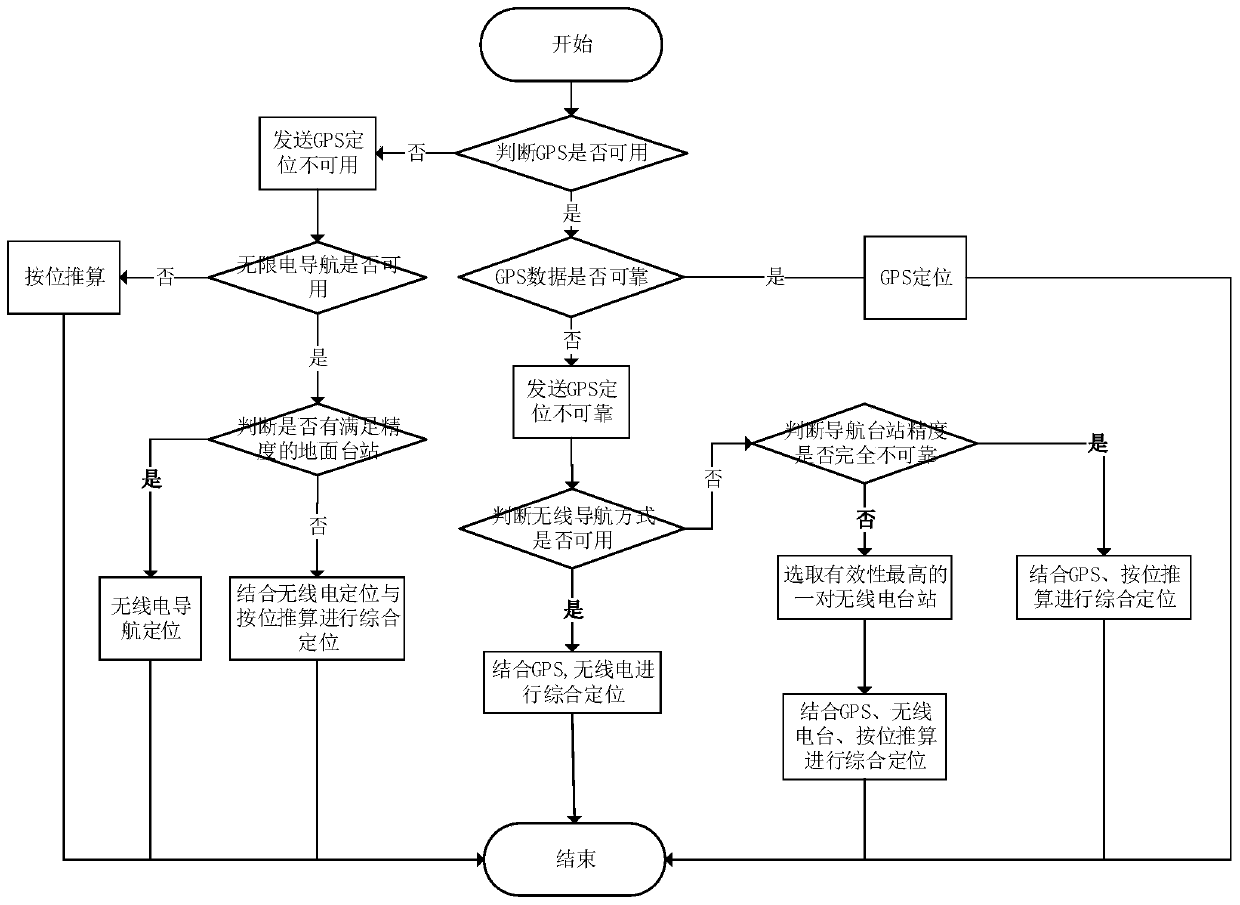

Universal aircraft airborne integrated navigation system and method

InactiveCN111007555AEnsure positioning reliabilityLow reliabilityNavigation by speed/acceleration measurementsSatellite radio beaconingTime informationEngineering

The invention relates to a universal aircraft airborne integrated navigation system and method, and solves the problems of single navigation mode, low navigation precision and reliability and incapability of realizing an autonomous navigation function of the existing universal aircrafts. The system comprises a navigation data receiving module, a navigation mode judging module and a navigation positioning resolving module; the navigation data receiving module is used for receiving real-time information sent by airborne receiving equipment, and the airborne receiving equipment comprises a GPS / Beidou satellite receiver, a VOR receiver, a DME receiver and an atmospheric navigation attitude system; the navigation mode judgment module is used for judging which navigation mode is adopted for comprehensive positioning, and the navigation modes comprise a GPS / Beidou satellite navigation mode, a radio DME / DME navigation mode, a radio VOR / DME navigation mode and a bitwise reckoning navigation mode; and the navigation positioning resolving module is used for calculating position information of a current airplane according to the selected navigation mode.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

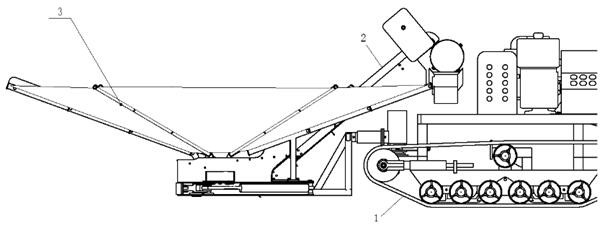

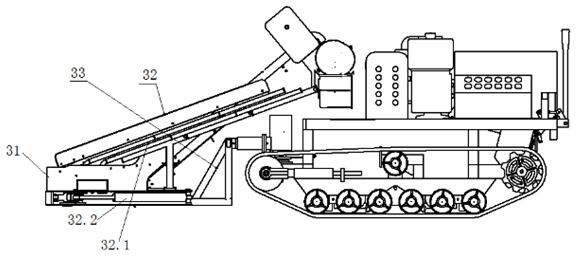

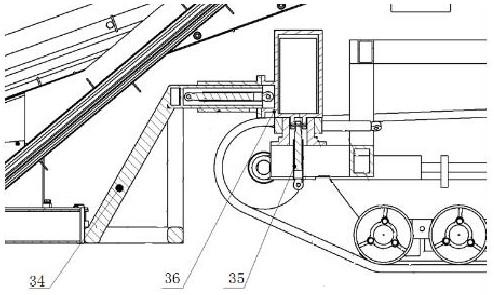

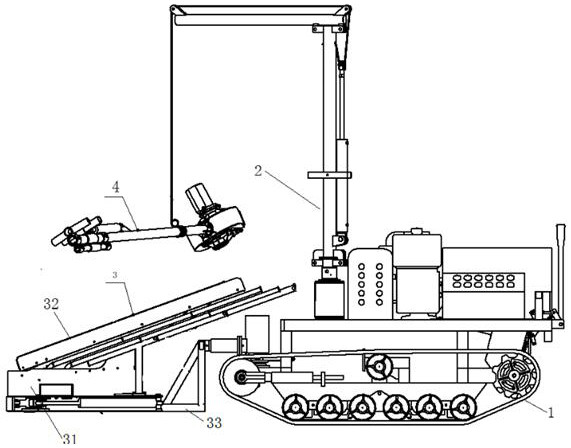

Forest fruit vibrating picking collection vehicle

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

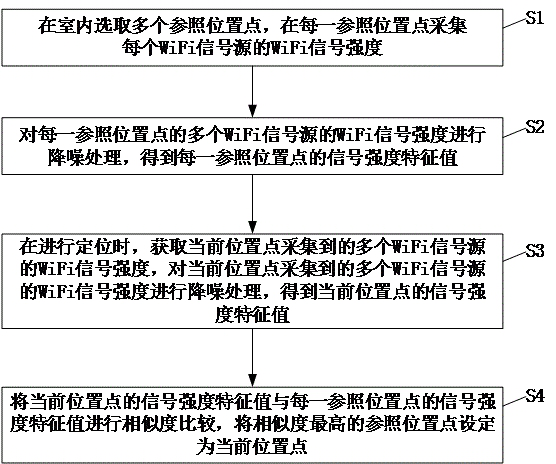

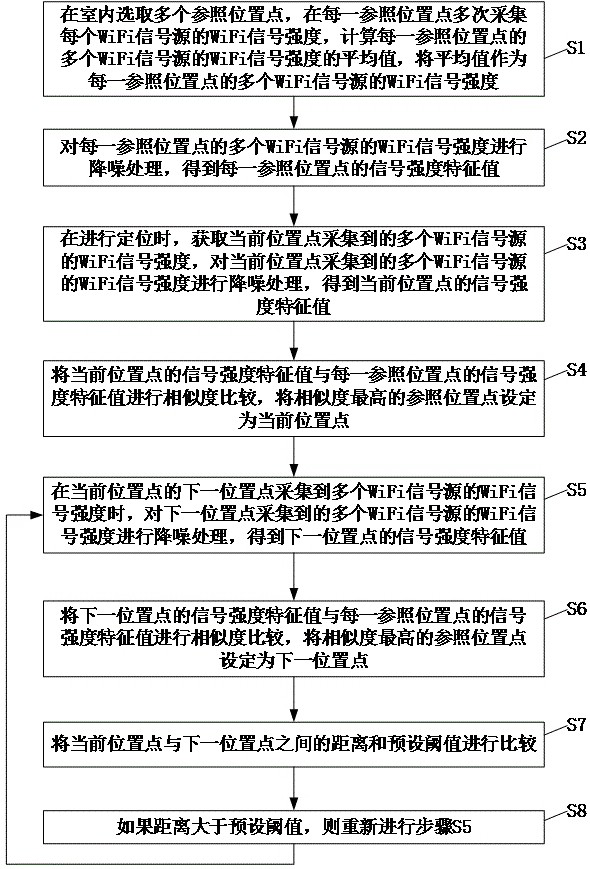

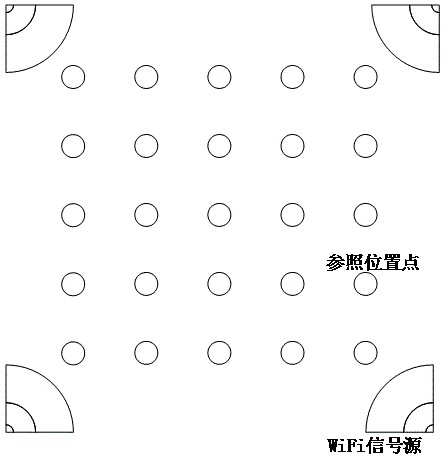

Indoor positioning method based on WiFi

ActiveCN112689237AHigh precisionWide signal rangeParticular environment based servicesLocation information based servicePublic placeEngineering

The invention discloses an indoor positioning method based on WiFi, and the method comprises the steps: selecting a plurality of reference position points indoors, and collecting the WiFi signal intensity of each WiFi signal source at each reference position point; performing noise reduction processing on the WiFi signal intensities of the plurality of WiFi signal sources of each reference position point to obtain a signal intensity characteristic value of each reference position point; when positioning is carried out, acquiring WiFi signal intensities of a plurality of WiFi signal sources collected by a current position point, and carrying out noise reduction processing to obtain a signal intensity characteristic value of the current position point; and performing similarity comparison on the signal intensity characteristic value of the current position point and the signal intensity characteristic value of each reference position point, and setting the reference position point with the highest similarity as the current position point. The problems that in the prior art, positioning interference is large, positioning precision is poor, and equipment needs to be rearranged for public places with different indoor patterns can be solved.

Owner:四川山高聚慧物联网科技有限公司

Composite hole machining cutter capable of being spliced and combined

The invention discloses a composite hole machining cutter capable of being spliced and combined. The composite hole machining cutter capable of being spliced and combined comprises a first cutter body and the like; the first cutter body is fixed above a second cutter body which is fixed above a third cutter body; an upper fastening screw is located on the second cutter body; a lower fastening screw is located on the third cutter body; an outer blade is installed on one side of the first cutter body; an auxiliary blade is installed on one side of the second cutter body; an inner blade is installed on one side of the third cutter body; a square table is arranged on the upper portion of the second blade body; a square table is arranged on the upper portion of the third cutter body; a conical table is fixed to each square table; a protective edge is fixed to the first cutter body; a protective edge is fixed to the second cutter body; a protective edge of fixed to the third cutter body; conical grooves are located above square grooves and located below the square tables; the first cutter body, the second cutter body and the third cutter body are each provided with a step hole; and threaded holes are located in the left sides of the step holes. The composite hole machining cutter capable of being spliced and combined is simple in structure, reliable in performance and capable of being used under the heavy load condition, the cutter utilizing rate is increased, and cost is saved.

Owner:SHANGHAI UNIV

Cam-type multi-stable reversing valve and working position switching method thereof

ActiveCN111156218AExtended service lifeReduce use costOperating means/releasing devices for valvesServomotor componentsEngineeringCam

The invention discloses a cam-type multi-stable reversing valve and a working position switching method thereof. In existing electromagnetic valves, only multi-stable electromagnetic elastic valves have two stable working positions. The cam-type multi-stable reversing valve comprises a valve seat, a valve element, a first electromagnet, a second electromagnet, a movable permanent magnet and a working position switching mechanism; the first electromagnet and the second electromagnet both adopt power-lossing type electromagnets; the working position switching mechanism comprises a support, a rotation shaft, a one-way bearing, a torsional spring, a cam, a pushing rod and a transmission assembly; and the transmission assembly comprises a driven iron block, a sliding block, a connecting rod anda rocking rod. According to the cam-type multi-stable reversing valve and the working position switching method thereof, the valve element of the reversing valve is driven by a cam mechanism, therefore, electric energy does not need to be consumed when the reversing valve is located at all the working positions, and the using cost of the electromagnetic valve is greatly reduced; and in addition,the defect that in an existing electromagnetic reversing valve, due to the fact that electromagnets need to be electrified for a long time, the electromagnets are prone to being damaged is overcome, and the service life of the reversing valve is prolonged.

Owner:SHANGHAI HAILUFENG MARINE VALVE

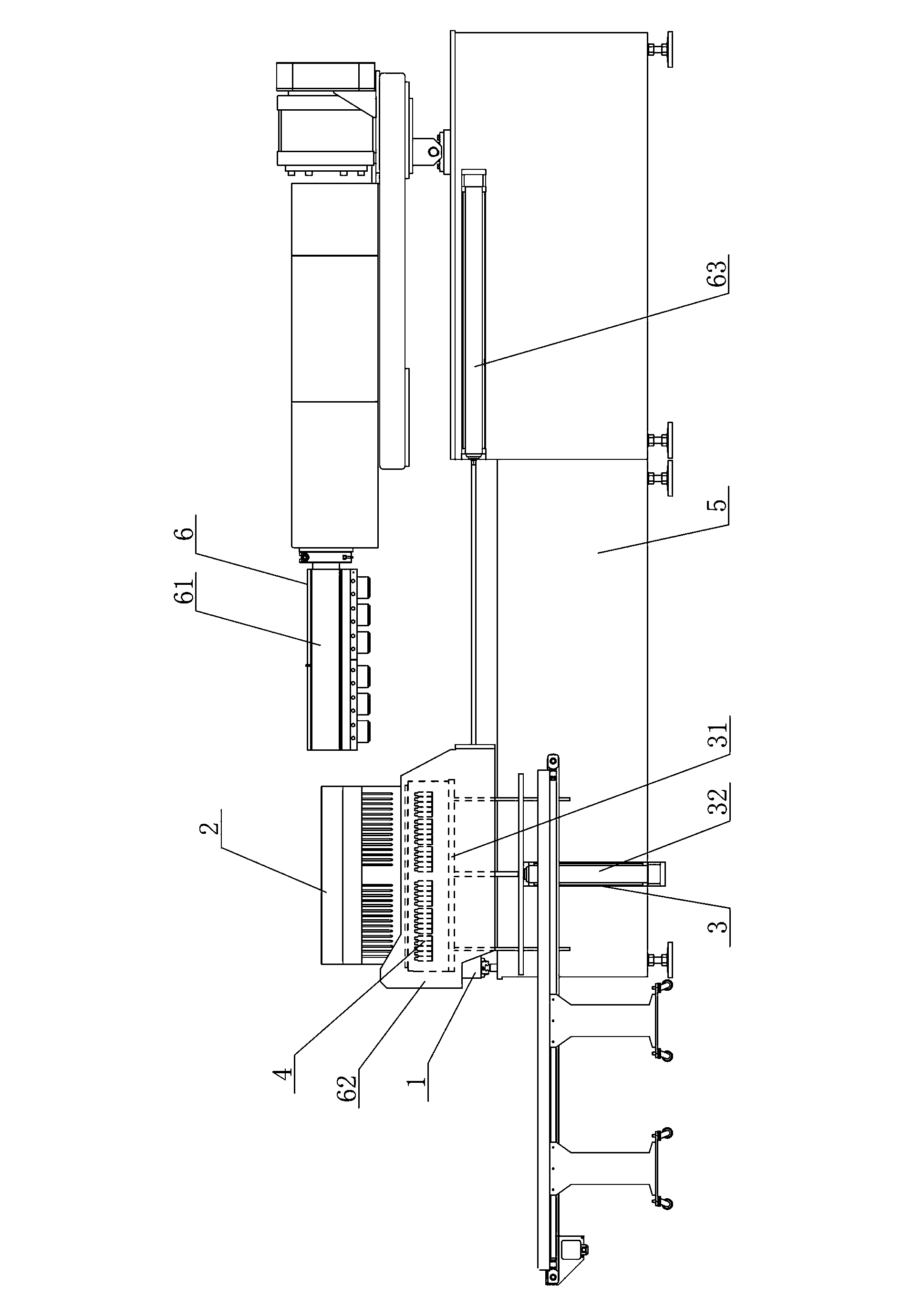

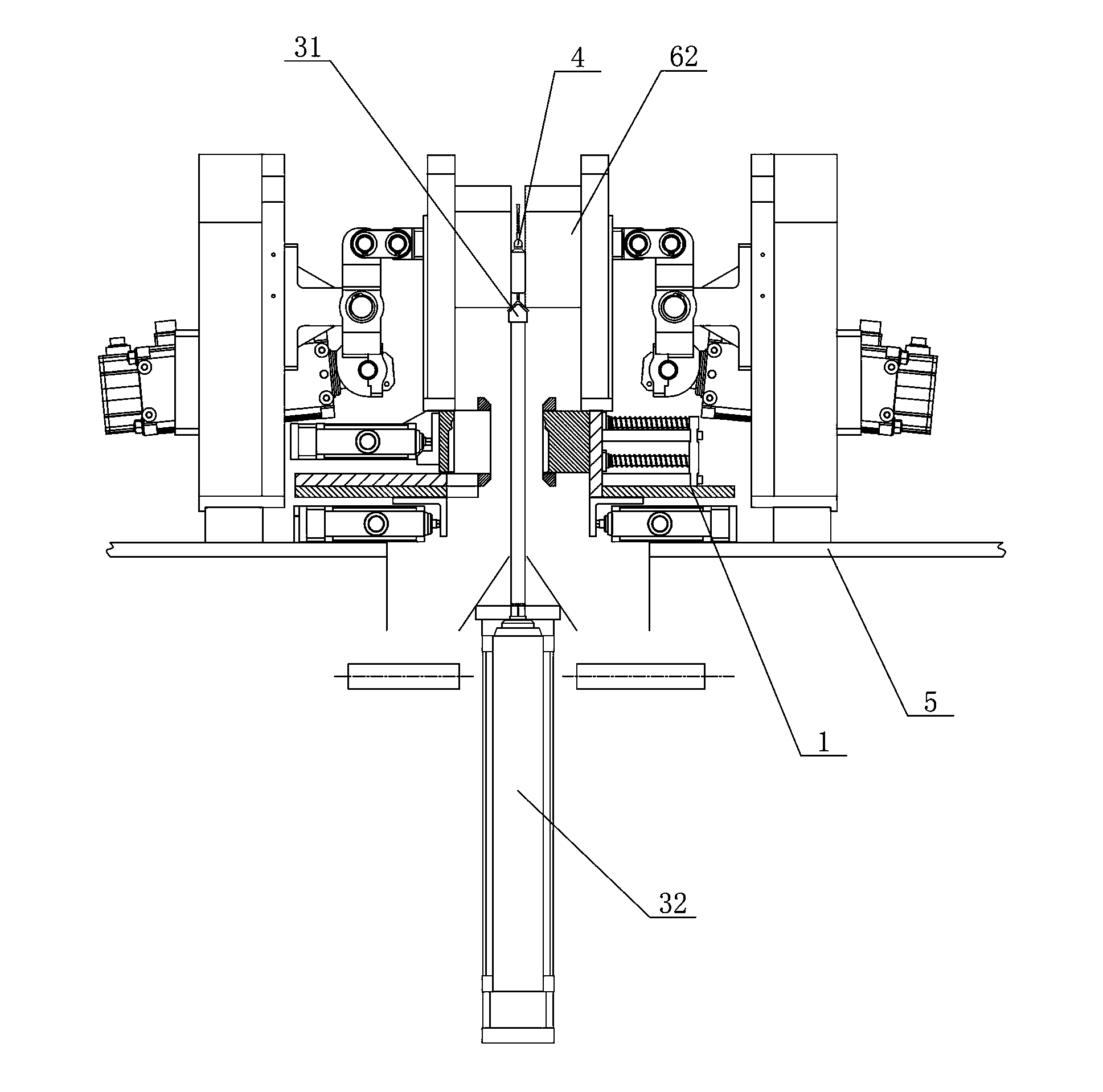

Blowing encapsulation all-in-one machine for plastic ampoule

ActiveCN102431947BSolve the large amount of deformationEnsure positioning reliabilityBottle-handling machinesMetal working apparatusSmall footprintEngineering

The invention discloses a blowing encapsulation all-in-one machine for a plastic ampoule. The machine comprises a frame, and an extrusion bottle making device, an encapsulation device and a die cutting device which are arranged on the frame and are sequentially distributed along the horizontal direction according to a process, wherein an encapsulation positioning component is arranged below an encapsulation station on the encapsulation device; the extrusion bottle making device is connected with the encapsulation device through a first conveying component so as to convey bottle clamps; and the encapsulation device is connected with the die cutting device through a second conveying component so as to convey the encapsulated bottle clamps. The machine has the advantages of simple and compact structure, low cost, small occupied area, short material conveying time and the like, is conveniently and quickly positioned and is easy to control and debug.

Owner:TRUKING TECH LTD

A multifunctional positioning fixture for the production of radar slit waveguide antenna

ActiveCN108788802BGuaranteed positioning accuracyImprove machining accuracyPositioning apparatusMetal-working holdersSlotted waveguideSlot-waveguide

The invention discloses a multifunctional positioning fixture used for production of radar slotted waveguide antennas. The multifunctional positioning fixture comprises a tapered groove mandrel, a pressing mechanism and a central shaft. A tapered groove is formed in the outer surface of the tapered groove mandrel. An adjustment nut is connected to the upper portion of the tapered groove mandrel ina threaded mode. The pressing mechanism is connected to the lower portion of the tapered groove mandrel in the axial direction. The central shaft is connected to the lower portion of the pressing mechanism in the axial direction. A central shaft correction mechanism is arranged in the central shaft. A positioning pin is connected to the lower output end of the central shaft correction mechanism in the axial direction. A bolt is connected to the lower portion of the positioning pin in the axial direction through a washer. The whole multifunctional positioning fixture has the advantage of central shaft positioning and overcomes the defects of large gaps and low machining precision in the mandrel positioning process, the position precision of a shaft hole relative to main machining faces such as the upper and lower surfaces of a shaft body and a main bearing hole is effectively ensured, the center of the shaft hole is used for positioning to achieve machining, and thus, the positioning precision is improved.

Owner:中安锐达(北京)电子科技有限公司

A cam type multi-stable reversing valve and its working position switching method

ActiveCN111156218BExtended service lifeReduce use costOperating means/releasing devices for valvesServomotor componentsSolenoid valveEngineering

The invention discloses a cam type multi-stable reversing valve and a working position switching method thereof. Among the existing electromagnetic valves, only the bistable electromagnetic energizing valve can have two stable working positions; the present invention is a cam type multi-stable reversing valve, which comprises a valve seat, a valve core, a first electromagnet, a second Electromagnet, moving permanent magnet and working position switching mechanism. Both the first electromagnet and the second electromagnet are de-energized electromagnets; the working position switching mechanism includes a bracket, a rotating shaft, a one-way bearing, a torsion spring, a cam, a push rod and a transmission assembly. The transmission assembly includes a driven iron block, a slider, a connecting rod and a rocker. The invention drives the spool of the reversing valve through the cam mechanism, so that the reversing valve does not need to consume electric energy when it is in each working position, which greatly reduces the use cost of the solenoid valve; The defect that iron needs to be kept energized for a long time is prone to damage, which improves the service life of the reversing valve.

Owner:SHANGHAI HAILUFENG MARINE VALVE

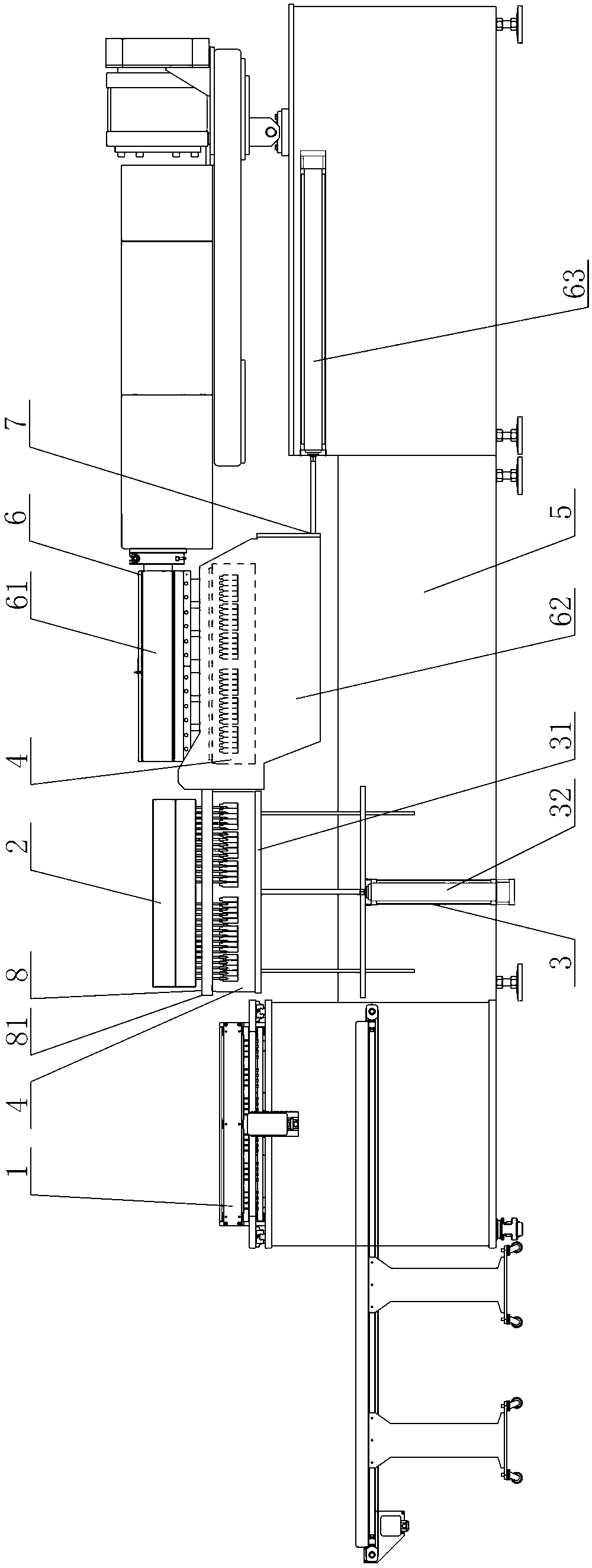

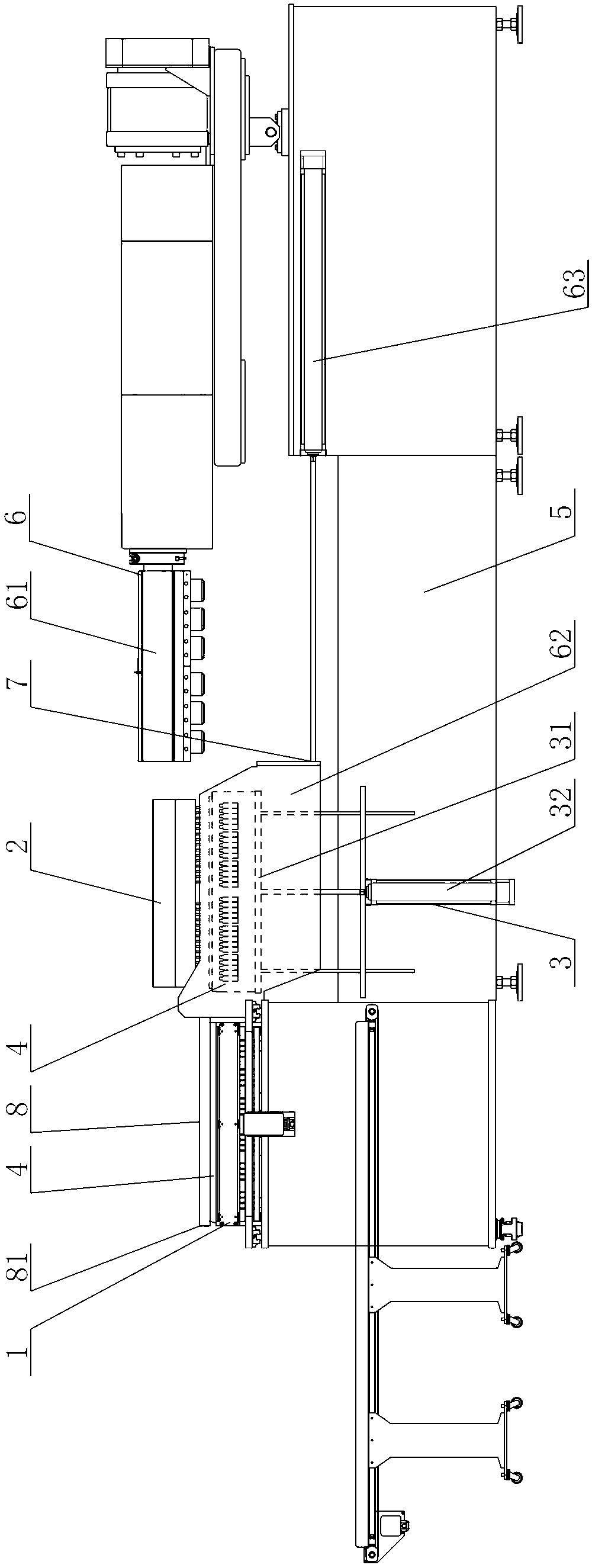

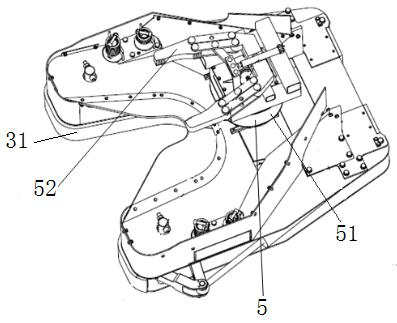

Double Vibration Fruit Picking Vehicle

ActiveCN110959383BEasy to pickEasy to collectAgricultural undercarriagesPicking devicesFruit treeTree trunk

Double-vibration fruit picking vehicle, including a crawler-type running mechanism, a vibrating mechanism that clamps the trunk to vibrate the fruit, and a receiving mechanism for catching the shaken fruit. The receiving mechanism is installed at the front end of the running mechanism and can The outer circumference is opened or folded in an umbrella shape. The vibration mechanism includes the auxiliary vibration element suspended directly above the receiving mechanism and the main vibration element installed on the receiving mechanism. The main vibration element is located below the auxiliary vibration element. The main vibration element and the auxiliary vibration element The tree trunks are respectively clamped and vibrations are transmitted, and the clamping positions of the main vibrating part and the auxiliary vibrating part on the tree trunks are all adjustable. In the present invention, the clamping positions of the main vibrating part and the auxiliary vibrating part can be adjusted according to the trunk position, thickness and fruit distribution, so as to meet the picking requirements of different fruit trees, improve the picking rate, and realize the integrated automatic operation from picking to collecting , making fruit picking and collection more convenient, greatly improving work efficiency, and meeting the needs of vibration picking and vibration collection of forest fruits in uneven mountains and hills.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

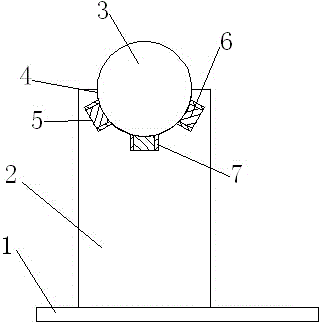

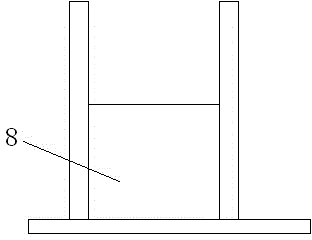

Mould frame used for pipe welding

InactiveCN105618996AGuarantee processing qualityEnsure positioning reliabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPipe welding

The invention discloses a mould frame used for pipe welding. The mould frame comprises a base (1) fixed to a fixing object, wherein at least two positioning frames (2) are arranged on the base (1); the upper part of each positioning frame (2) is provided with a semicircular groove (4) which is fitted with a pipe (3) in shape; and the semicircular grooves (4) are located on the same horizontal plane. According to the mould frame, the pipes are positioned by the semicircular grooves which are fitted with the pipes, so that the pipes are welded in a pipe welding process, and therefore, the pipe processing quality is ensured; and small grooves are arranged in the semicircular grooves, and magnetic substances are arranged in the small grooves for attracting the pipes, so that the positioning reliability of the pipes is further ensured; and the mould frame is simple in structure.

Owner:JIANGSU WEICHUANG RADIATOR MFG

Blowing, filling and sealing integrated machine for plastic ampoule

ActiveCN102381673BSolve the large amount of deformationEnsure positioning reliabilityBottle-handling machinesMetal working apparatusSmall footprintBottle

The invention discloses a blowing, filling and sealing integrated machine for a plastic ampoule, which comprises a machine frame, and an extrusion bottle making device, a filling and sealing device and a die cutting device which are sequentially arranged according to procedures in the horizontal direction, a filling and sealing positioning component is arranged below a filling and sealing stationon the filling and sealing device, the extrusion bottle making device is connected with the filling and sealing device through a first conveying component so as to accomplish the conveying to bottle clamps, the filling and sealing device is connected with the die cutting device through a second conveying component so as to accomplish the conveying to the bottle clamps after filling and sealing, and a slot cutting component is mounted on the die cutting device. The blowing, filling and sealing integrated machine disclosed by the invention has the advantages of simple and compact structure, lowcost, small occupied area, short material conveying time, convenience and fastness in positioning, and easiness in control and debugging, and the like.

Owner:TRUKING TECH LTD

Plastic ampoule blowing, filling and sealing all-in-one machine

ActiveCN102515071BSolve the large amount of deformationEnsure positioning reliabilityBottle-handling machinesMetal working apparatusSmall footprintMechanical engineering

The invention discloses a plastic ampoule blowing, filling and sealing all-in-one machine comprising a frame, and a filling and sealing device, a die cutting device, an extrusion ampoule manufacturing device and a positioning component which are arranged on the frame; the die cutting device is arranged right below the filling and sealing device; the positioning component is arranged below the filling and sealing device and can take an ampoule clip to reach a die cutting station or a filling and sealing station through lifting motion; and a slotted component is arranged on the die cutting device. The plastic ampoule blowing, filling and sealing all-in-one machine has the advantages of simple and compact structure, low cost, small occupied area, short conveying time, convenient and quick positioning, easiness in control and debugging and the like.

Owner:TRUKING TECH LTD

Squirrel-cage elastic support bearing capable of improving installation accuracy

ActiveCN109538636AImprove fitting accuracyEnsure positioning reliabilityBall bearingsBearing coolingInterference fitArchitectural engineering

The invention relates to the technical field of squirrel-cage elastic support bearings, and discloses a squirrel-cage elastic support bearing capable of improving installation accuracy. The squirrel-cage elastic support bearing comprises mounting blocks and a rotor, cylindrical grooves are transversely formed in the left sides of the mounting blocks, round holes are formed in one sides, far away from the groove openings, of the cylindrical grooves, the right end of the rotor penetrates through the cylindrical grooves and the round holes and extends to the outside of the mounting blocks, fixedrings are arranged in the cylindrical grooves, the inner sides of the fixed rings are in interference fit with the side wall of the rotor, the side walls of the fixed rings are movably connected withretainers in a sleeved mode, a plurality of uniformly distributed rollers are slidably connected in the retainers, and annular mounting grooves are formed in the outer sides of the fixed rings. The squirrel-cage elastic support bearing capable of improving installation accuracy can reduce installed parts and reduce installation error between matched components, ensures the positioning reliabilityof a bearing outer ring and a squirrel-cage elastic support, effectively lubricates and cools the squirrel-cage elastic support bearing to prevent faults such as bearing locking can be prevented.

Owner:GUIZHOU TIANMA HONGSHAN BEARING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com