Mould frame used for pipe welding

A technology for pipe fitting welding and formwork, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of deviation in the angle of the finished product, unguaranteed coaxiality, low work efficiency, etc. The effect of ensuring the processing quality, improving the service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

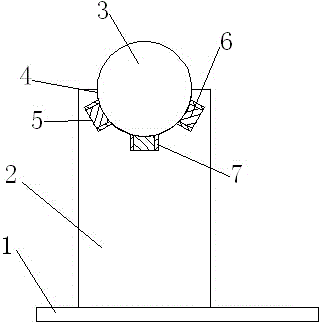

[0013] The present invention includes a base 1 fixed on a fixed object, the base 1 is provided with at least two positioning frames 2, the upper part of the positioning frame 2 is provided with a semicircular groove 4 matching the shape of the pipe fitting 3, and the semicircular Shaped groove 4 is on the same level.

[0014] The semicircular groove 4 is provided with several small grooves 5 along the radial direction, and the magnetic bodies 6 are arranged in the small grooves 5 .

[0015] A spacer magnet 7 is arranged between the inner wall of the small groove 4 and the magnetic body 6 .

[0016] The magnetic bodies 6 slightly protrude from the small groove 4, and the magnetic bodies 7 are on the same circumference.

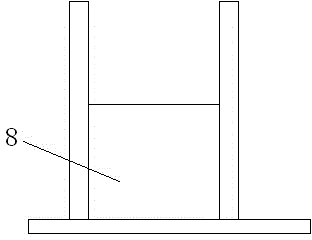

[0017] A connecting plate 8 is arranged between the adjacent positioning frames 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com