X-Y movement device for simple chip mounter

A motion device and placement machine technology, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of backward placement machine technology, high maintenance costs, and complex structure, and achieve compact structure, weight reduction, and inertial load reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

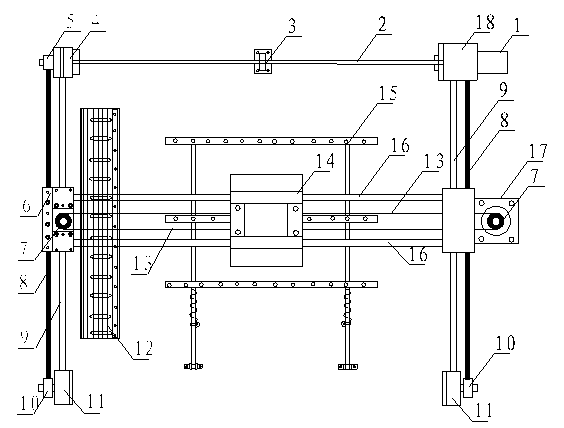

[0013] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0014] Referring to the accompanying drawings, a simple X-Y movement device of a placement machine includes a base 18, which is characterized in that the outside of the base 18 is provided with a Y-axis drive motor 1, and the inside of the base 18 passes through the light rod 2 and the Y-axis light rod. The fixed base 4 is connected, the Y-axis optical rod fixed base 4 is connected with the fixed base 11 through the Y-direction optical rod 9, the Y-axis optical rod fixed base 4 is provided with a Y-direction gear 5, and the fixed base 11 is provided with a gear 10 outside. A synchronous toothed belt 8 is arranged between the Y direction gear 5 and the gear 10, the synchronous toothed belt 8 links to each other with the second fixed base 6, the second fixed base 6 is slidingly connected with the Y direction ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com