Composite hole machining cutter capable of being spliced and combined

A hole machining and compound technology, applied in the direction of tools, manufacturing tools, metal processing equipment for lathes, etc., can solve the problems that the utilization rate of tools cannot be maximized, it is not suitable to promote the use of combined tools, and the reliability is not enough. To achieve the effect of simple structure, reduced cycle, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

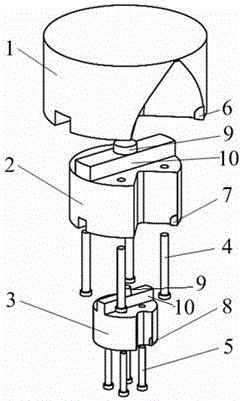

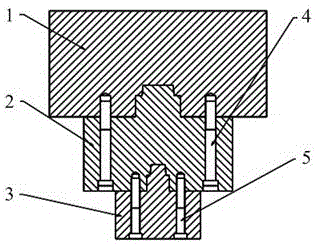

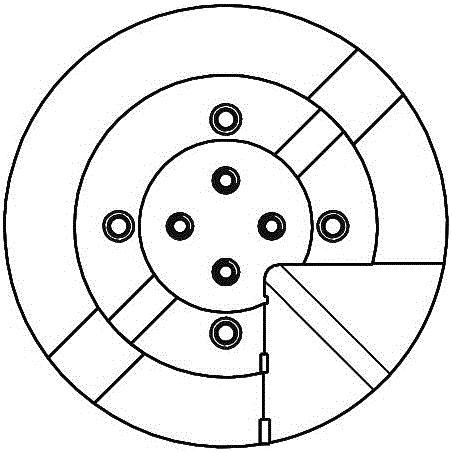

[0018] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0019] Such as Figure 1 to Figure 8 As shown, the present invention can be spliced and combined compound hole machining tool comprising a first cutter body 1, a second cutter body 2, a third cutter body 3, an upper fastening screw 4, a lower fastening screw 5, an outer blade 6, an auxiliary Blade 7, inner blade 8, tapered platform 9, square platform 10, edge protection 11, tapered groove 12, square groove 13, threaded hole 14, stepped hole 15, the first cutter body 1 is fixed on the second cutter body 2 Above, the second cutter body 2 is fixed above the third cutter body 3, the upper fastening screw 4 is located on the second cutter body 2, the lower fastening screw 5 is located on the third cutter body 3, and the outer blade 6 is installed on the first cutter body Body 1 side, auxil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com