Blowing, filling and sealing integrated machine for plastic ampoule

A blow-fill-seal and all-in-one machine technology, which is applied in pharmaceutical packaging machinery and food fields, can solve problems such as unfavorable production automation, long production cycle, and low production efficiency, and achieve shortened transmission distance and transmission time, convenient production control, and land occupation. small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

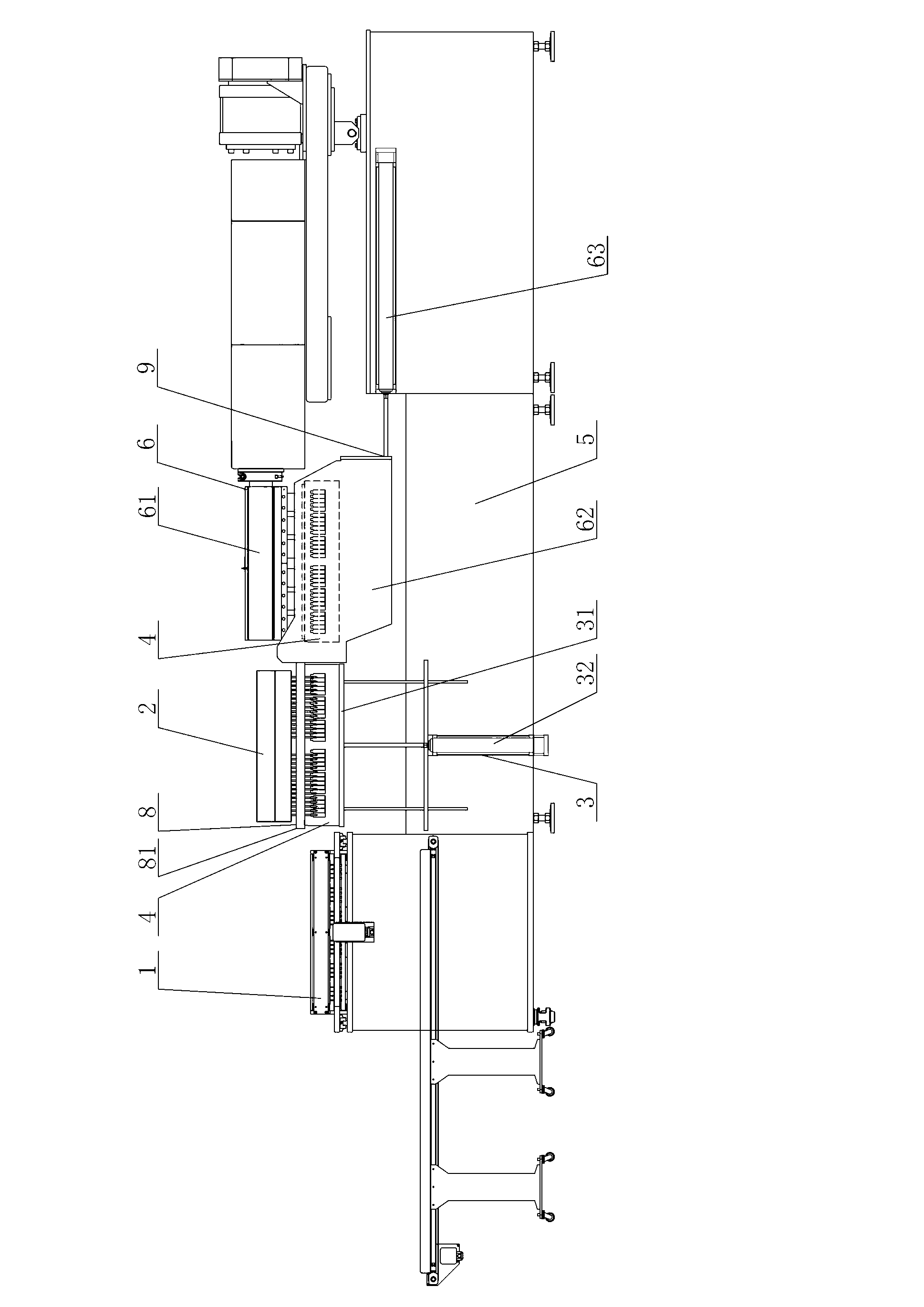

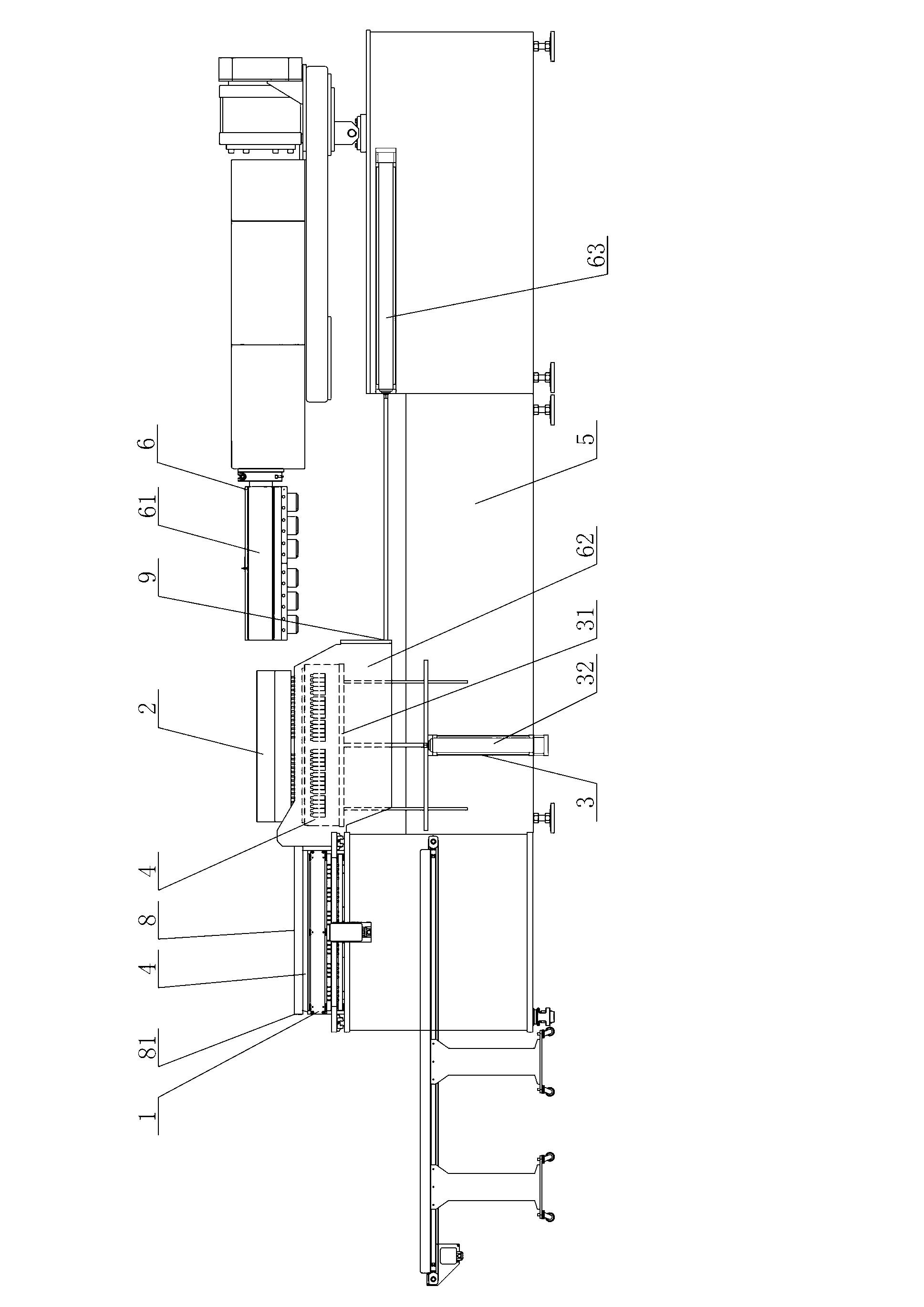

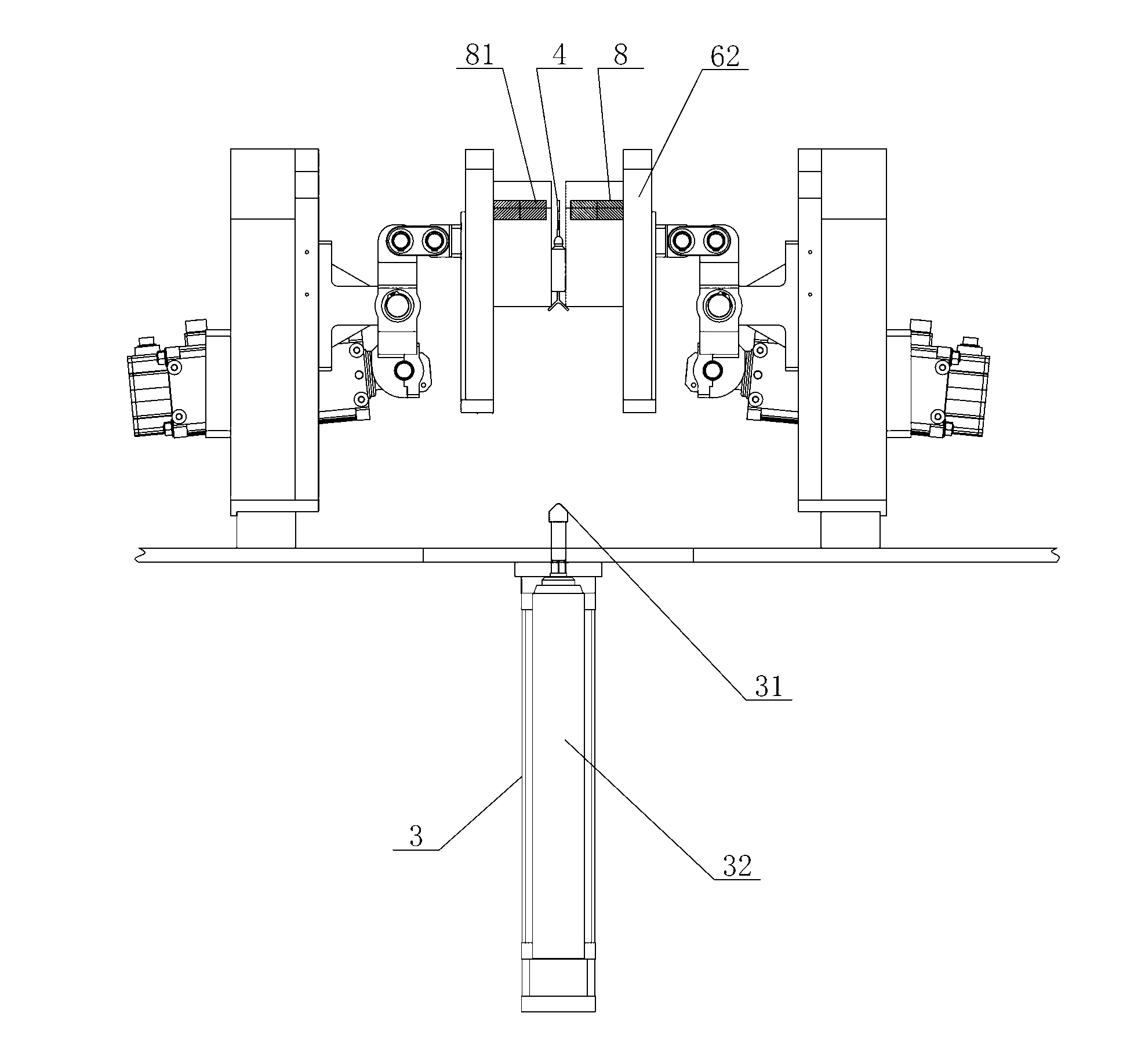

[0045] Figure 1 to Figure 5 It shows an embodiment of the combined mechanism of the present invention for plastic ampoule blow-fill-seal integrated machine, including a frame 5 and an extrusion bottle making device 6 arranged on the frame 5 and arranged in sequence along the horizontal direction according to the process, Potting device 2, die-cutting device 1, a potting positioning assembly 3 is provided below the potting station on the potting device 2, and the extrusion bottle making device 6 is connected with the potting device 2 through the first conveying assembly 9 to complete the bottle. For the transmission of the card 4, the filling and sealing device 2 is connected with the die-cutting device 1 through the second conveying assembly 8 to complete the transmission of the bottle card 4 after filling, and the die-cutting device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com