Method for selecting longitudinal mounting position of split casing

A technology of longitudinally installing the edge and opening the case, which is applied in the direction of measuring devices, metal processing machinery parts, measuring/indicating equipment, etc., which can solve the problems of unguaranteed accuracy of parts, difficulty in controlling part deformation, inconsistent deformation of parts, etc. To achieve the effect of ensuring accuracy, controlling deformation and reducing scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

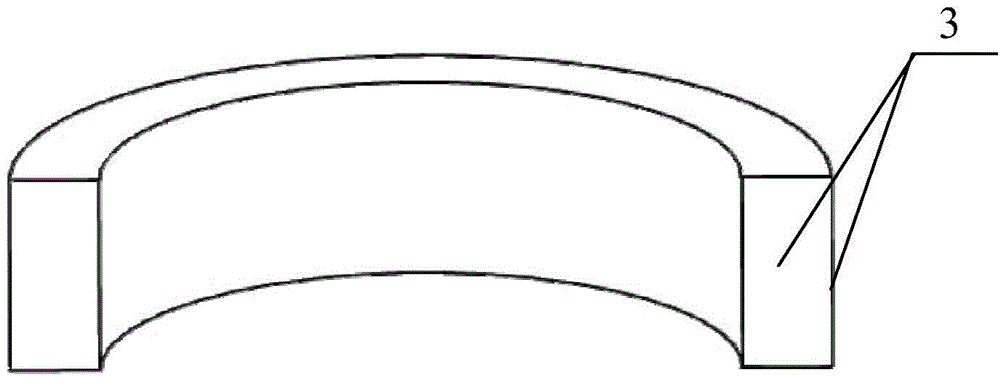

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] A method for selecting the position of the longitudinal installation side of the opening case, comprising the following steps:

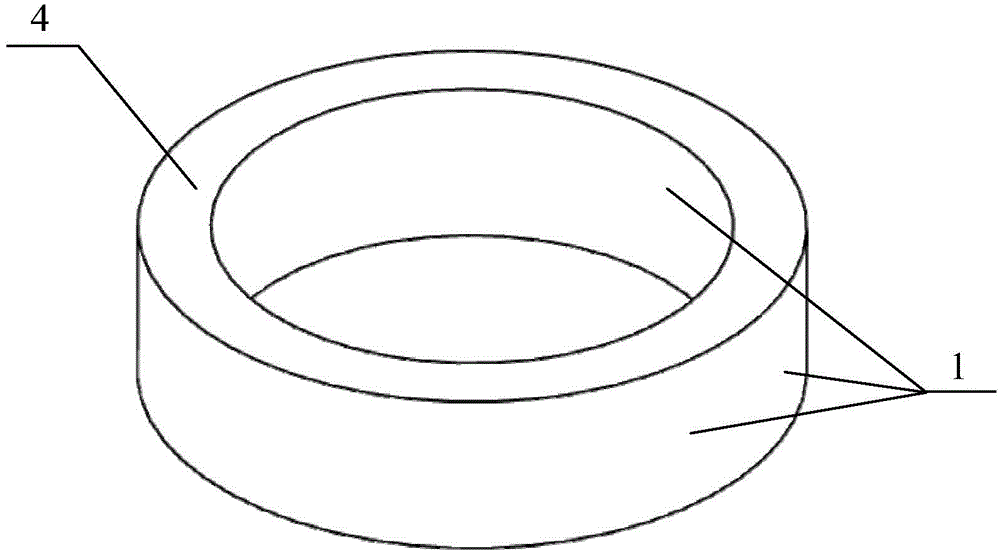

[0018] Step 1: Determining the stress measurement point 1 of the ring blank 4;

[0019] According to the shape characteristics of the ring blank 4, the stress measurement points 1 of the present embodiment are respectively arranged at 16 places along the inner and outer circumferential surfaces of the ring blank 4, and are evenly distributed along the circumferential direction, as figure 1 shown;

[0020] Step 2: Use the blind hole method to measure the stress at the stress measurement point 1 determined in Step 1;

[0021] Use punching equipment, stress strain gauges and stress measuring instruments to measure stress;

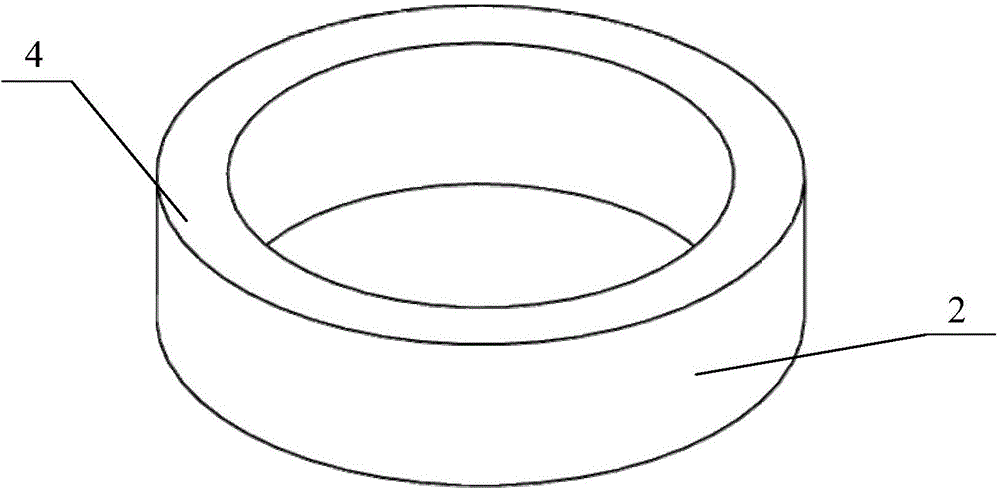

[0022] Step 3: Select the point 2 with the maximum stress value as the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com