Battery gas-discharging equipment and use method thereof

A technology for degassing equipment and batteries, which is applied to electrical components, battery pack components, circuits, etc., can solve the problems of failure to prevent battery rupture and waste, and achieve the effect of facilitating overall assembly and reducing battery scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

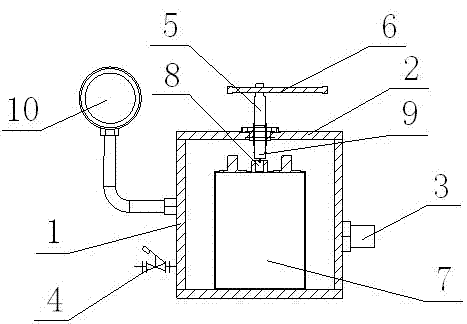

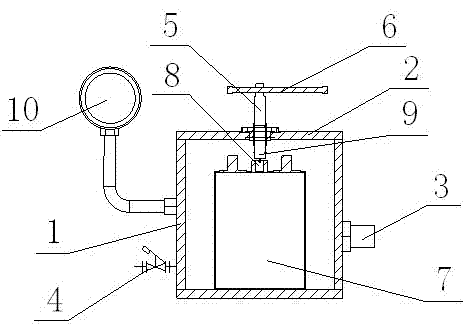

[0020] Such as figure 1 As shown, the battery deflation device of this embodiment includes a box body 1, and the box body 1 is movably installed with a box cover 2, which forms a seal with the box body 1 after the box cover 2 is closed; the box body 1 is equipped with a vacuum tube connecting the inside and outside of the box body The tank body 1 is connected with a vacuuming device through the vacuuming pipeline interface 3, and the box cover 2 is installed with a rotatable rotating shaft 5 through a dynamic sealing method. The top of the rotating shaft 5 is provided with a handle 6, and the bottom The end is provided with a matching part 9 that cooperates with the safety valve 8 of the battery 7 (the vacuum device is not shown in the figure).

[0021] Further, in order to monitor the air pressure inside the box body 1 conveniently, the box body 1 is equipped with a pressure gauge 10 for detecting the air pressure inside the box body.

[0022] Further, in order to facilitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com