Method for coating photoresist and method for forming photolithography pattern

A coating method and photoresist technology, applied in the direction of photo-engraving process coating equipment, etc., can solve the problems affecting the line width of the exposure process, etching or ion implantation, photolithography pattern defects, etc., to eliminate defects and improve good quality. The effect of low gas rate and gas cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

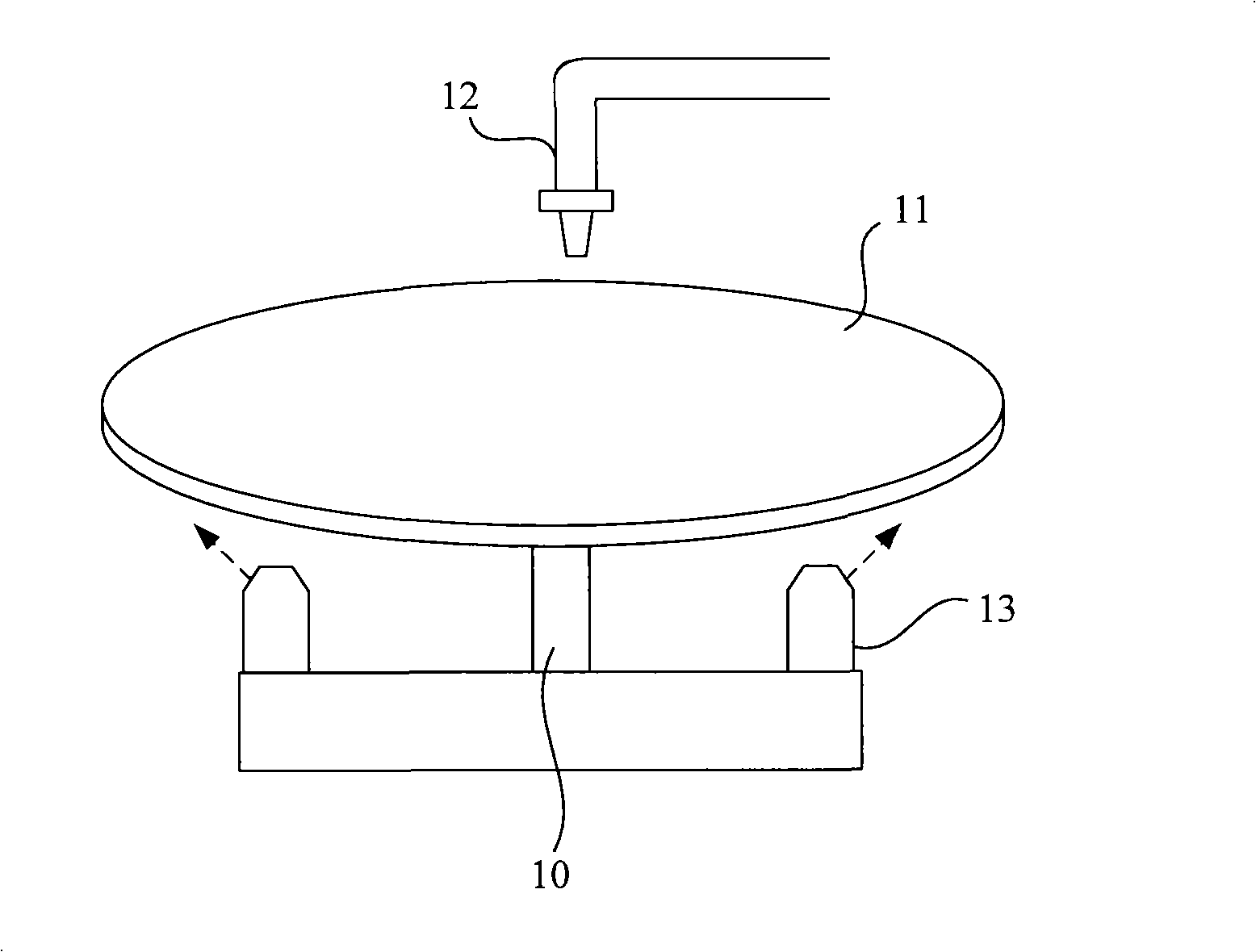

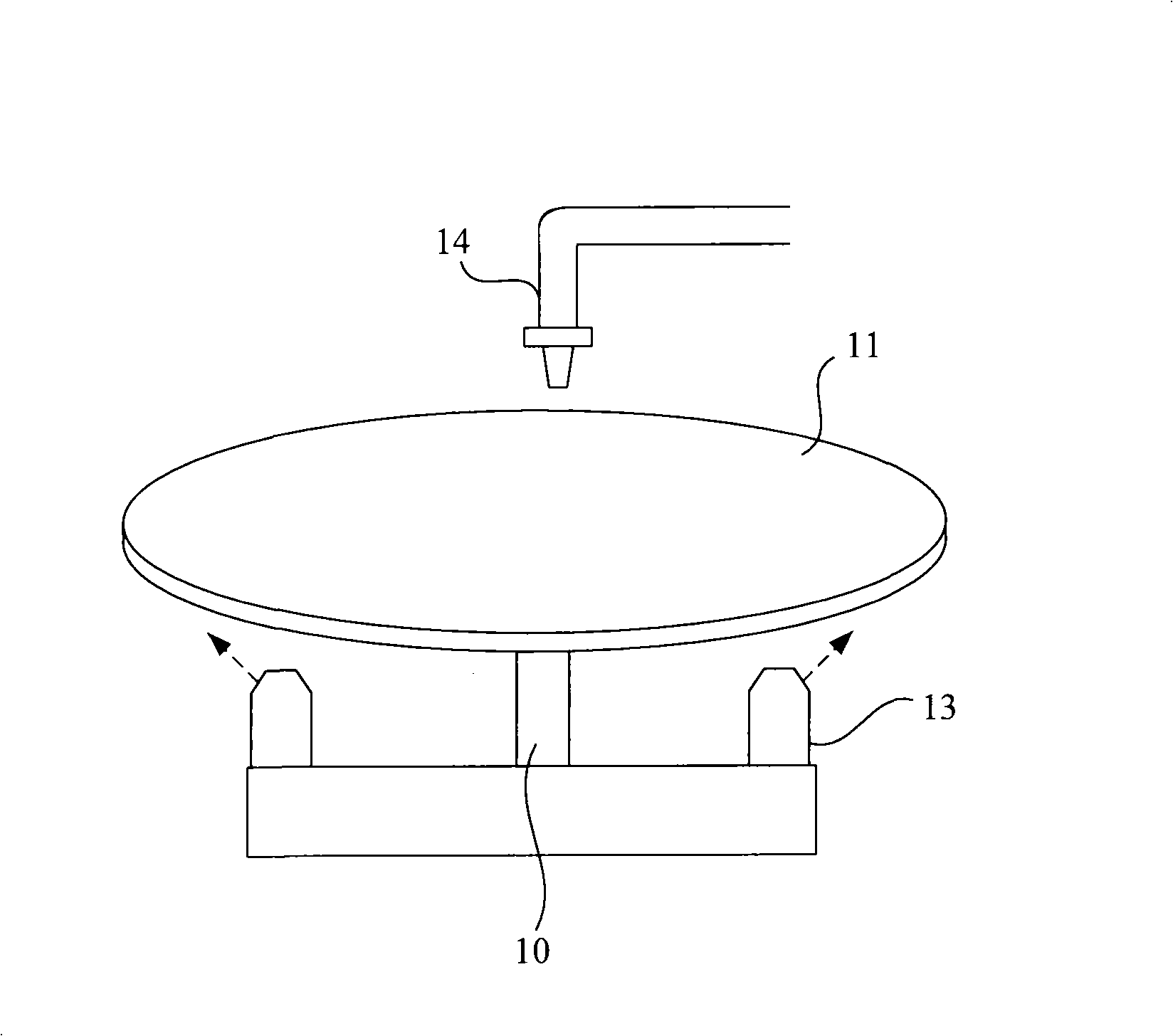

[0057] In the photoresist coating process, in order to prevent the photoresist from flowing to the back side along the edge of the semiconductor wafer and causing pollution, it is necessary to spray a cleaning solution on the back of the semiconductor wafer for cleaning; however, the cleaning process of the cleaning solution is accompanied by the cleaning of the semiconductor wafer. Rotate, so that the cleaning solution sprayed on the back of the semiconductor wafer is thrown to the side wall of the spin coating device, and is splashed back to the surface of the photoresist layer, causing defects. The invention provides a coating method for photoresist, which The method can avoid the occurrence of said defects.

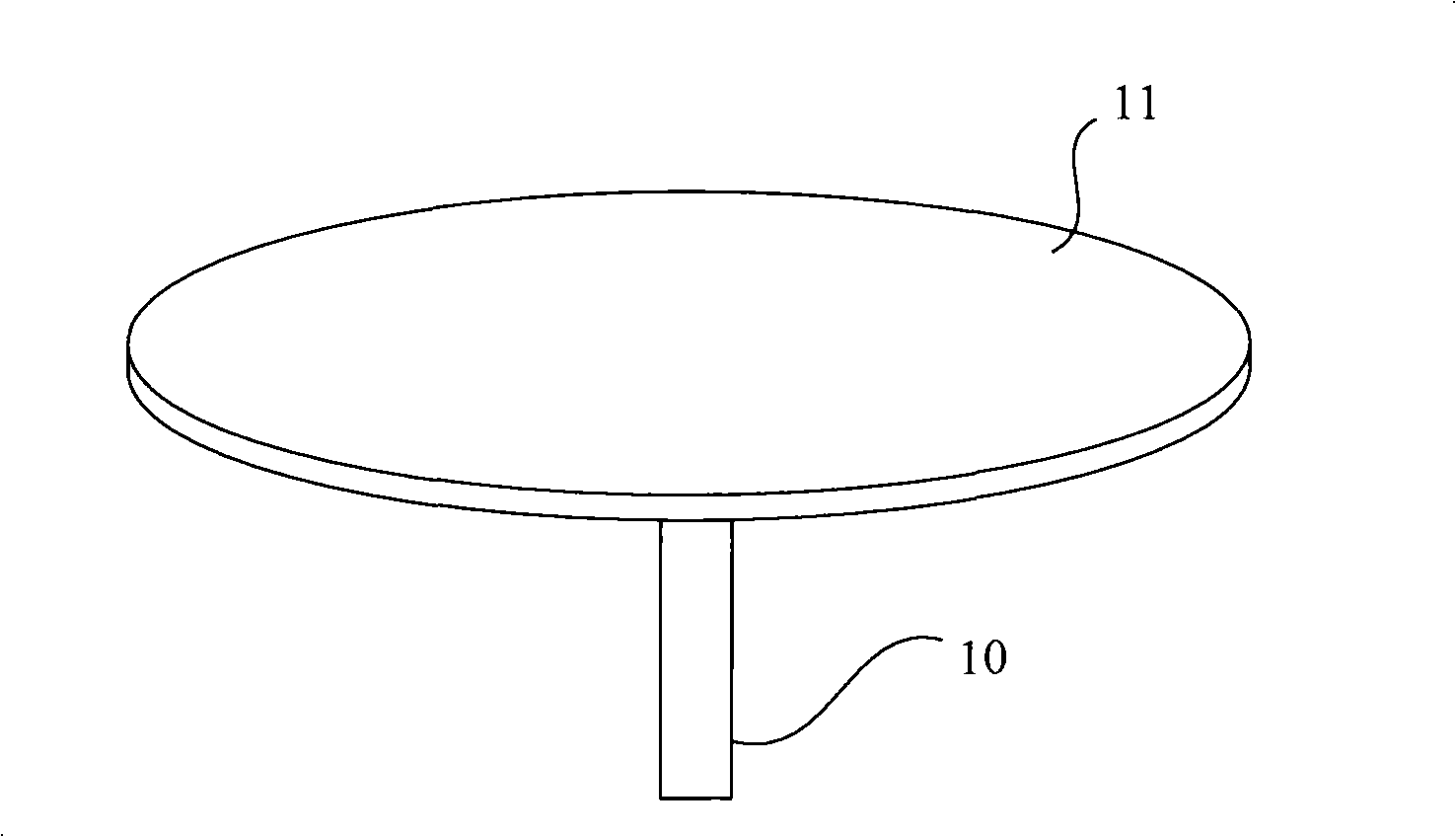

[0058] The step of the coating method of photoresist of the present invention is as follows: first, provide the semiconductor wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com