Unitary sorbent canister with thin end wall

A technology of adsorbent and granular adsorbent, which is applied in the direction of adsorption, gas treatment, household appliances, etc., and can solve problems such as contamination of food or medicine, overflow of contents, and permeability of containers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

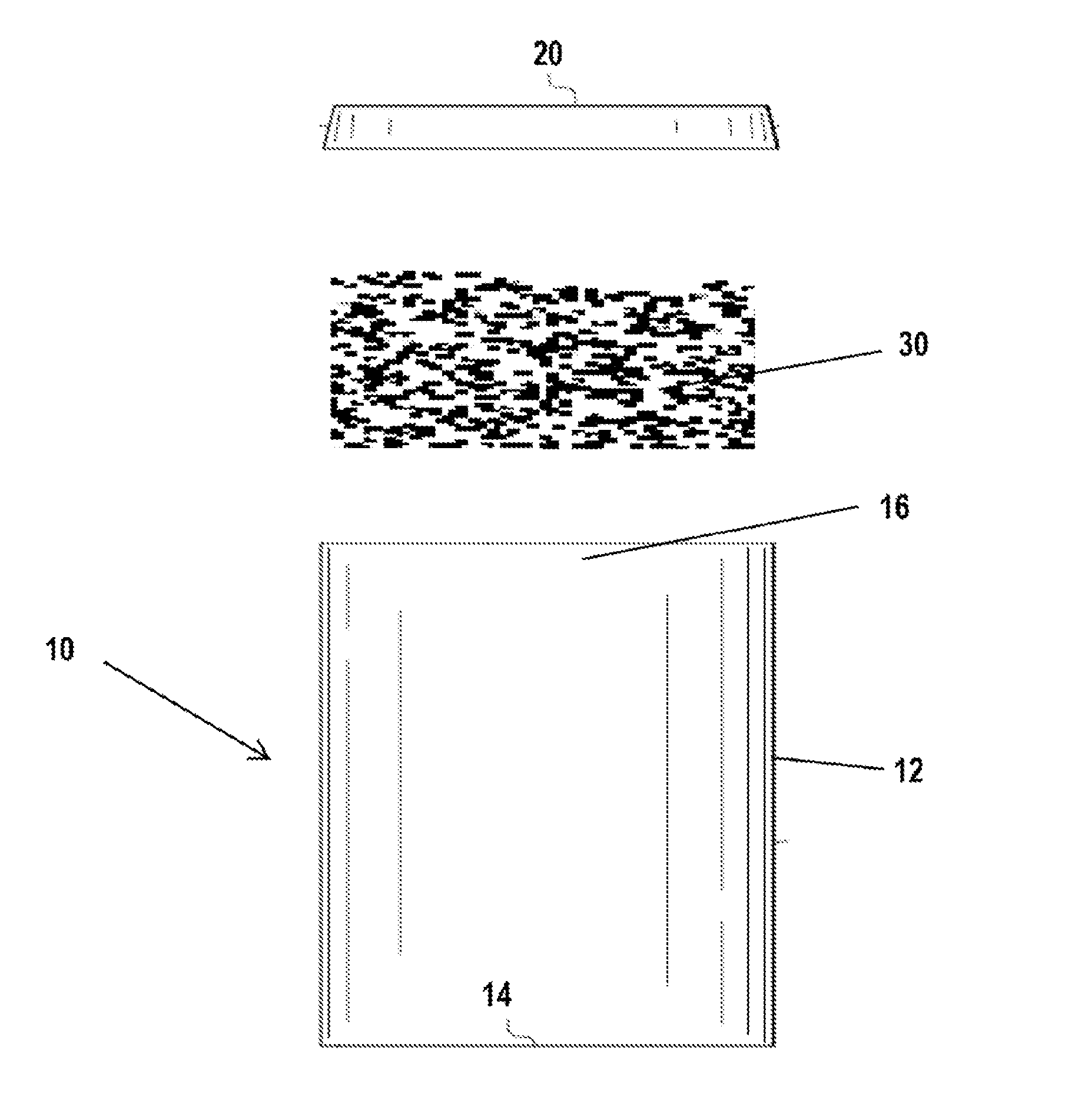

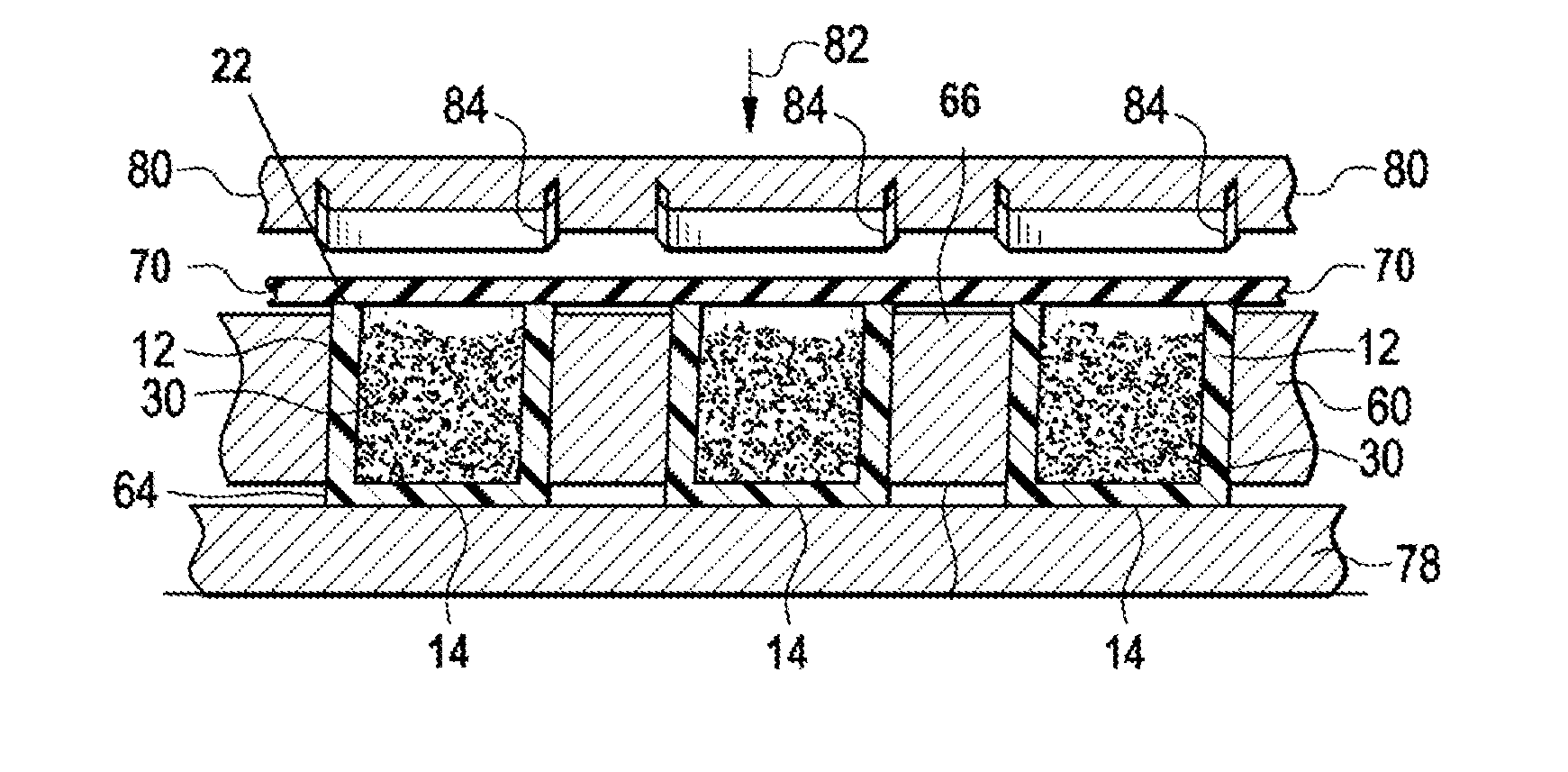

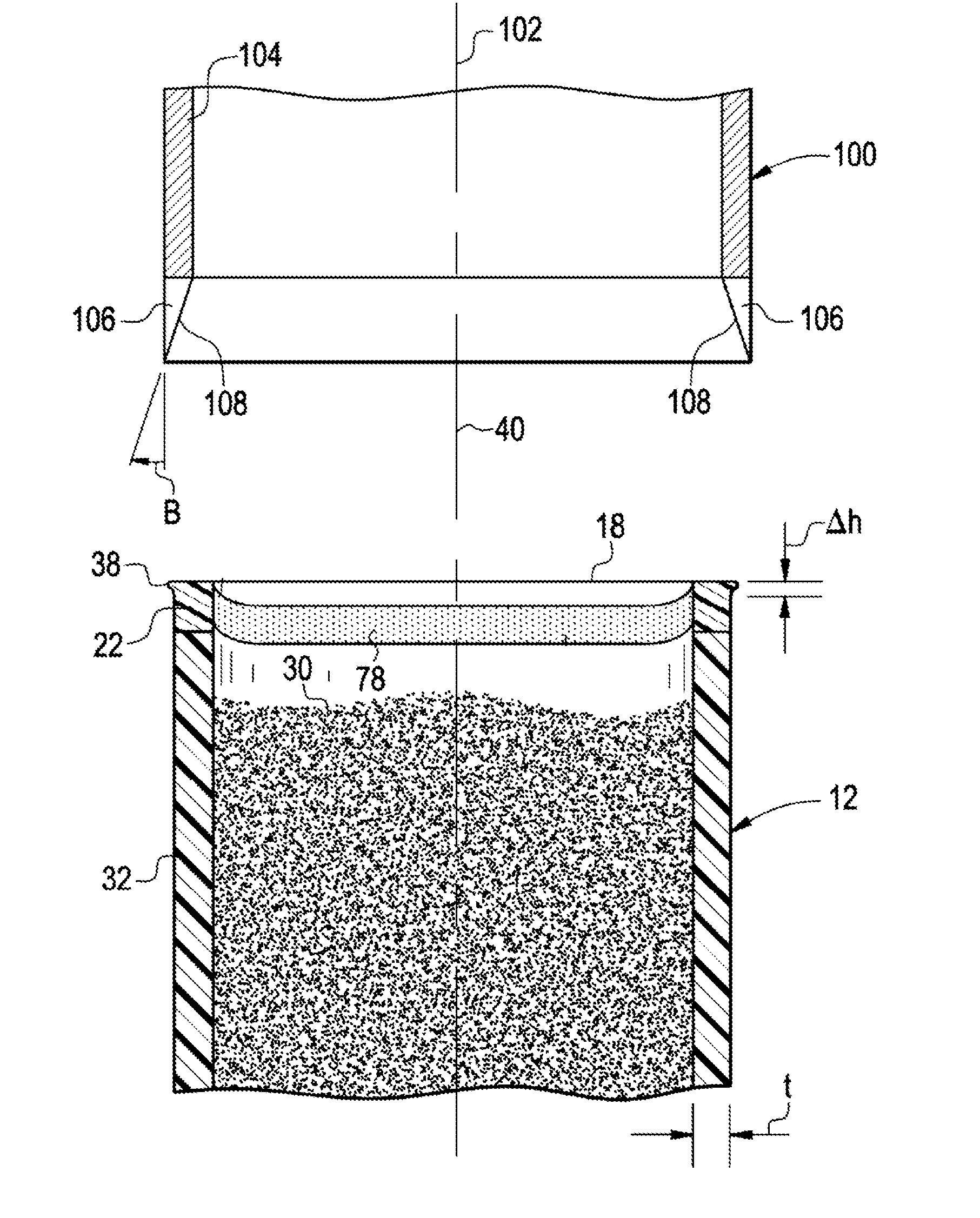

[0020] Referring now to Figures 1 and 2, there is shown a sorbent canister in accordance with the present invention. As shown in Figure 2, the sorbent canister 2 includes a container 10 and a cover 20 that may be secured to the container 10 to form a unitary structure. Container 10 is preferably, but not necessarily, cylindrical for ease of manufacture. Container 10 includes side walls 12 and end walls 14 . A side wall 12 extends from an end wall 14 and defines an opening 16 opposite the end wall. End wall 14 is shown as relatively flat, but may be concave or convex as desired. Preferably, the container 10 is at least partly made of a material that the sorbent tank 2 is designed to be permeable to the absorbed gas, and more preferably the entire container 10 is formed of such a permeable material. Examples of materials from which container 10 may be formed include thermoplastic materials including, but not limited to, polyethylene terephthalate, polyolefins, HPMC or HDPE. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com