Tunable laser

A technology for tuning lasers and tuning units, applied to lasers, laser components, semiconductor lasers, etc., to achieve reliable, high reliability, and easy manufacturing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described based on the drawings.

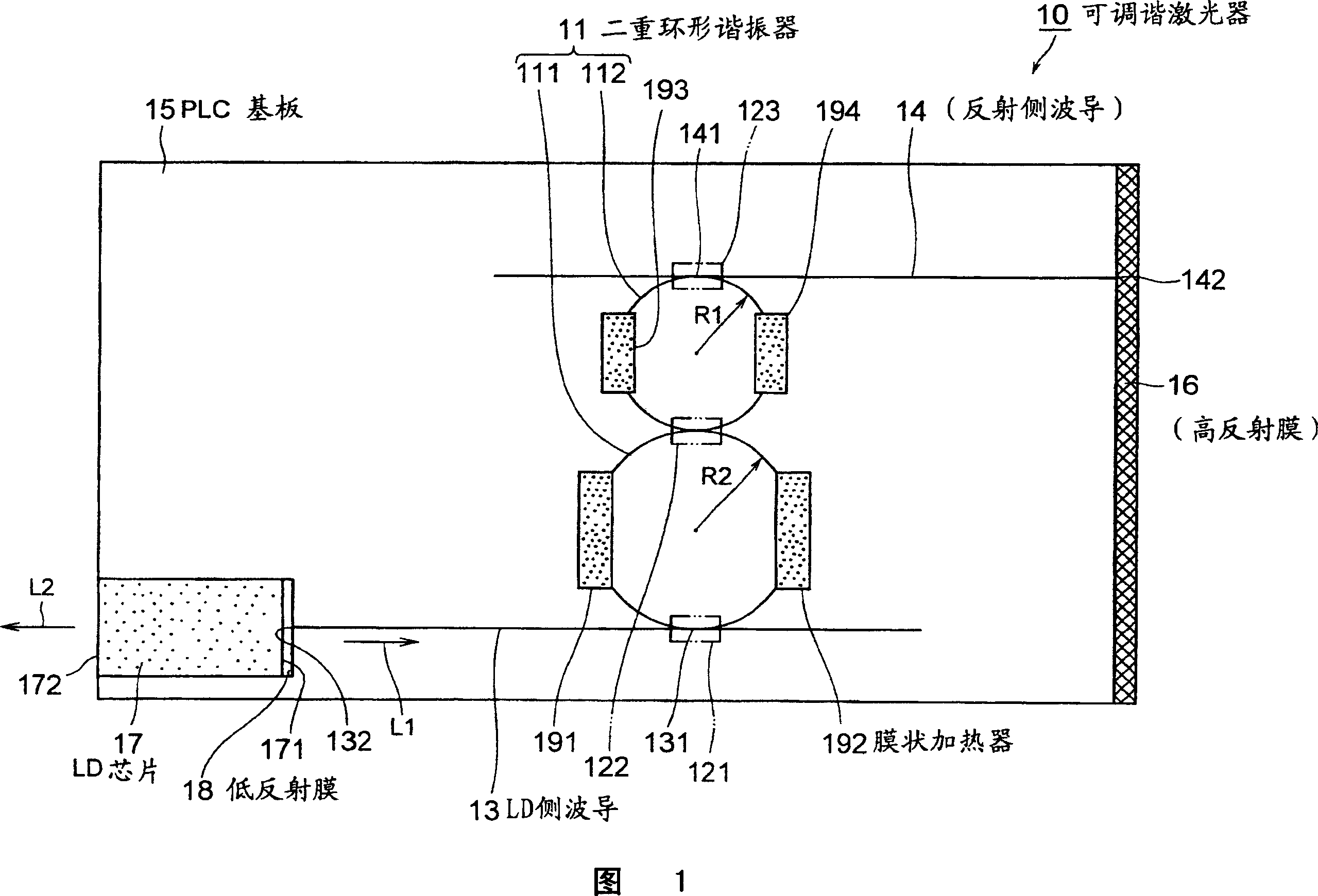

[0037] FIG. 1 is a plan view showing a first embodiment of a tunable laser according to the present invention. Hereinafter, it demonstrates based on this figure.

[0038] The tunable laser 10 of this embodiment includes: a double ring resonator 11, ring resonators 111 and 112 composed of ring waveguides with different optical paths from each other, connected through a directional coupler 122; LD side waveguide 13, through a directional A coupler 122, one end 131 is connected to the ring resonator 111; the reflection side waveguide 14 is connected to the ring resonator 112 through a directional coupler 123, and one end 141 is connected to the ring resonator 112; a PLC substrate 15 is formed with ring resonators 111, 112, LD The side waveguide 13 and the reflective side waveguide 14; the high reflection film 16 is arranged on the other end 142 of the reflective side waveguide 14;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com