Hot tapping plugging construction method of long natural gas delivery pipeline

A technology for natural gas pipelines and pressurized drilling, which is applied to pipe elements, pipe cutting devices, manufacturing tools, etc., can solve problems such as slow plugging, and achieve the effects of cost saving, short construction period and light labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

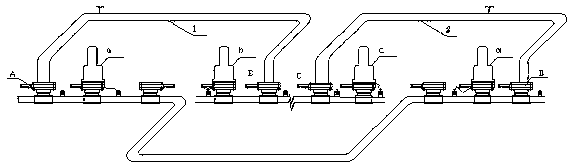

[0039] Embodiment: The construction method of the long-distance natural gas pipeline of the present invention is to open holes under pressure to install instruments, valves and other equipment under the allowable highest sealing pressure that does not affect the needs of downstream pipeline users; at the same time, for equipment pipelines In the case of blockage, damage or even fracture, which seriously affects the medium transportation, holes can be opened under pressure in the intact parts and sections on both sides of the damaged pipe section, bypass tee holes can be opened before and after the plugging point, and the bypass pipe can be installed and pressure tested. Replace with nitrogen, so that the medium to be transported is temporarily transported through the bypass branch, and the damaged or need to be replaced pipe section is blocked. After the hole is opened, the plugging device is installed to start the plugging operation. To block the downstream, use the balance va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com