Herbst bremer goldschlaegerei

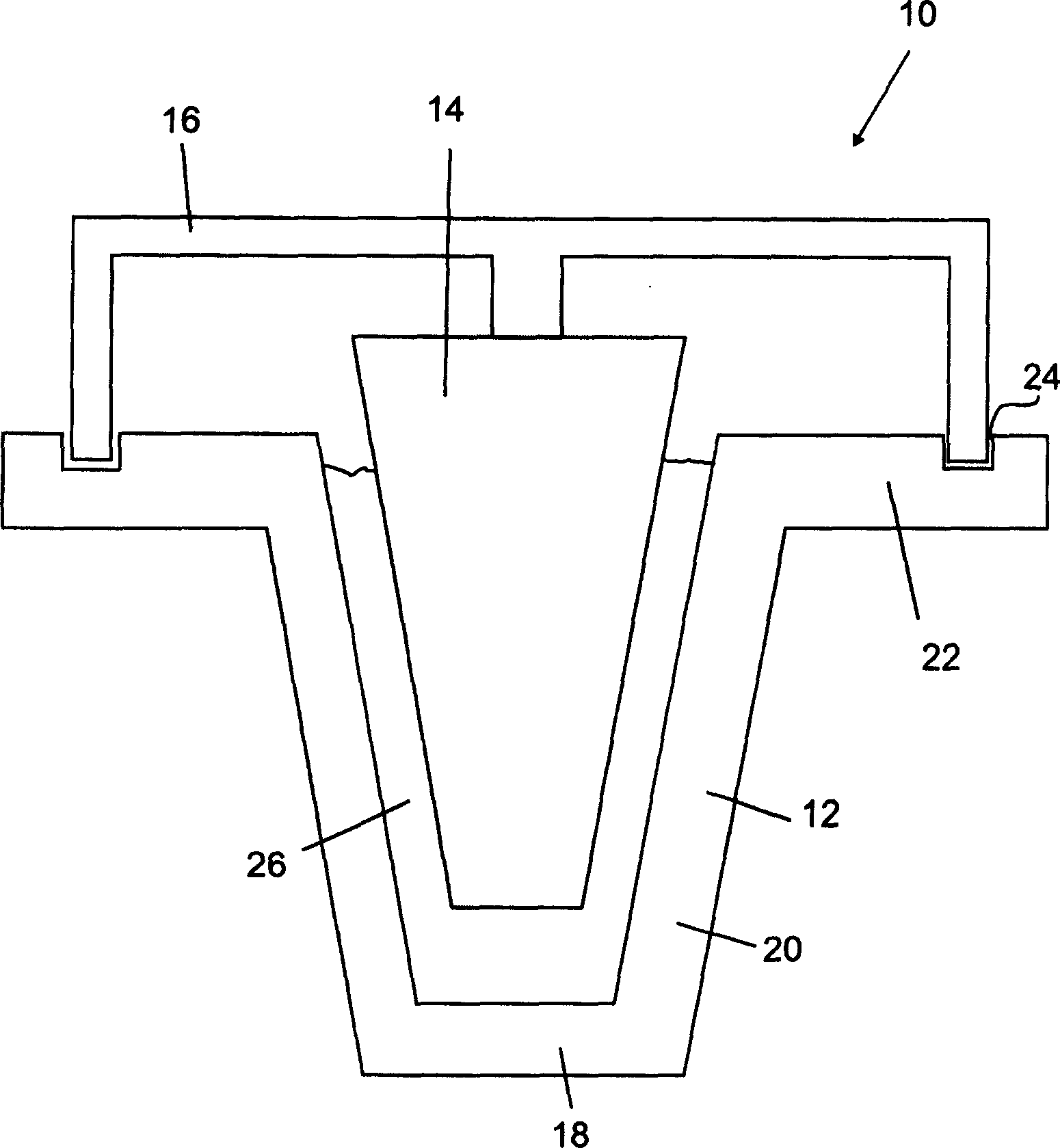

A technology of ceramic crucible and ceramics, which is applied to the equipment for implementing the production method of ceramic crucibles, and the field of preparing ceramic crucibles, can solve the problems not mentioned in the production of ceramic crucibles, and achieve good processing and operation characteristics, precise geometry, and good resistance to metal melting The effect of bulk chemical corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] A method of preparing a ceramic crucible according to an embodiment of the present invention is described below. Mix silica hydrosol with alumina powder and mullite powder by stirring, and add glycerin.

[0102] SiO in hydrated silica 2 The median diameter of particle diameter distribution (d 50) is 8nm. The diameter of the alumina powder particles is less than 10 μm, and the diameter of the mullite powder particles is less than 80 μm. Such a sol is industrially produced, for example, by acidifying a sodium silicate solution, passing the solution through a cation exchanger and basifying the obtained sol. Such sols are sold by CWK.

[0103] Material

g

weight%

100

50.9

Aluminum oxide

45

22.9

SiO 2 sol

50

25.4

1.5

0.8

total

196.5

100.0

[0104] This mixture is a freeze-castable slurry, that is, a special settable slurry. The ...

Embodiment 2

[0111] Another embodiment of the method according to the invention is described below. SiO 2 The hydrosol is mixed with alumina, mullite, and Nb powder by stirring, and glycerol is added. Alumina, mullite, and SiO 2 The diameters of the particles were the same as those described in Example 1. The diameter of the Nb particles is less than 40 μm.

[0112] Material

[0113] The slurry prepared in this way was poured into metal casting molds as in Example 1 and frozen in a freezer at -40°C. The obtained preform body was demoulded, and then dried in a drying room with a relative humidity of 30%, a pressure of 1013 hPa, and a temperature of 60°C. The preform was then sintered in air at 1200°C for 3 hours. During sintering, the niobium powder oxidizes (due to the presence of oxygen in the air) to form niobium pentoxide which results in an increase in volume.

Embodiment 3

[0116] The slurry prepared in this way was poured into a metal casting mold as in Example 1 and frozen at -40° C. using a cryostat. The obtained preform body was demoulded, and then dried in a drying room with a relative humidity of 30%, a pressure of 1013 hPa, and a temperature of 60°C. Then, the preform body is first heated to 600° C. to 700° C. for 2 hours, and then sintered at 1200° C. in air for 3 hours. When the temperature of the preform body is between 600°C and 800°C, the AlMg5 powder is liquefied and oxidized to produce alumina, magnesia, and spinel, and the volume increases at the same time. This alternative embodiment of the method results in a particularly low porosity.

[0117] In both alternative embodiments, the volume increase that occurs compensates for the sintering shrinkage of the other components such that the sintered preform dimensions deviate by less than 1% from the pre-sintered preform dimensions.

[0118] The above-described methods accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com