Front and rear edge profile redesign method for adaptive processing

A front and back edge redesign technology, applied in computing, image data processing, 3D modeling, etc., to improve algorithm efficiency, reduce machining allowance shortage, and narrow search range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0031] As shown in the figure, a method for redesigning the shape of the leading and trailing edges of blade parts oriented to adaptive processing in the present invention is characterized in that it includes the following steps:

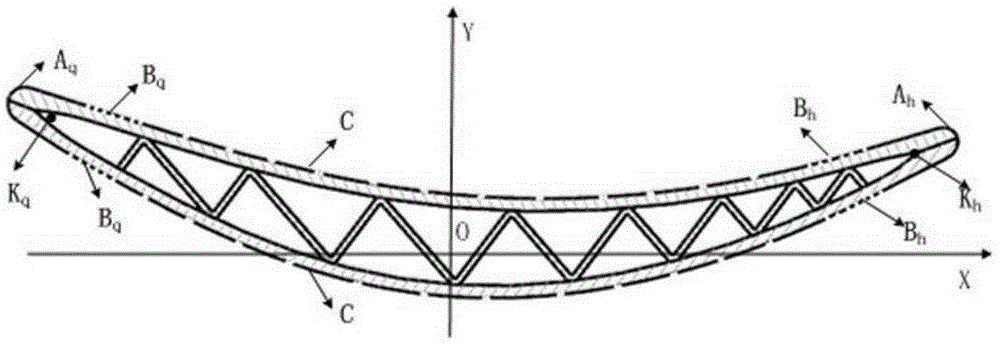

[0032] A. Airfoil section line division

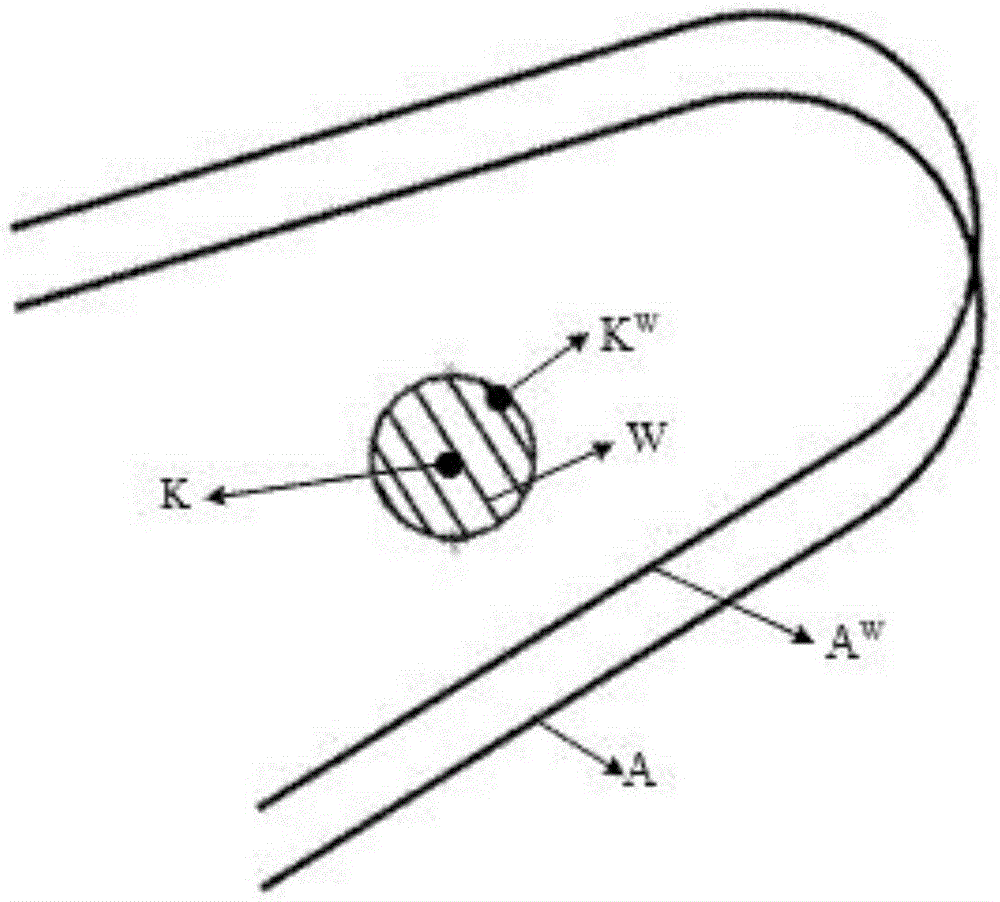

[0033] Extract the section line of the airfoil, divide the section line into the proximal area A, the transition area B and the blade body area C, and take the midpoint on the arc segment of the proximal area as the centroid K. The leading edge of the proximal region is denoted as A q , and the proximal region of the trailing edge is denoted as A h , similarly with leading edge / trailing edge transition (B q / B h ) and leading / trailing centroid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com