Fixture used for milling and boring support

A face milling and drilling technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems affecting the processing quality of workpieces, unfavorable batch production, workpiece deformation, etc., so as to achieve not easy deformation, improve processing efficiency, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

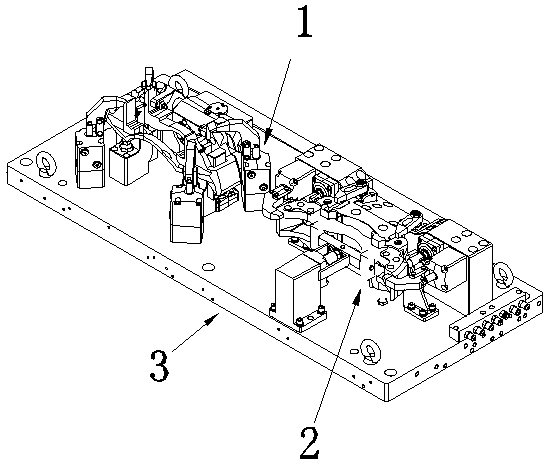

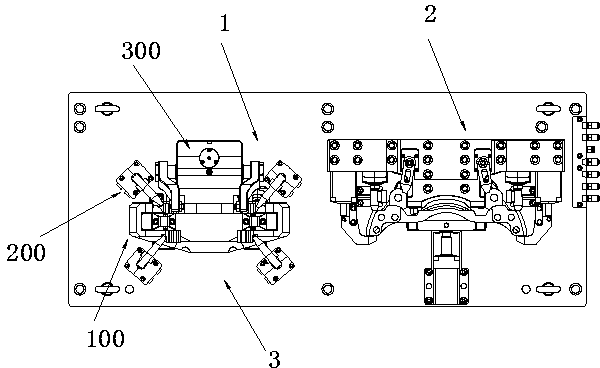

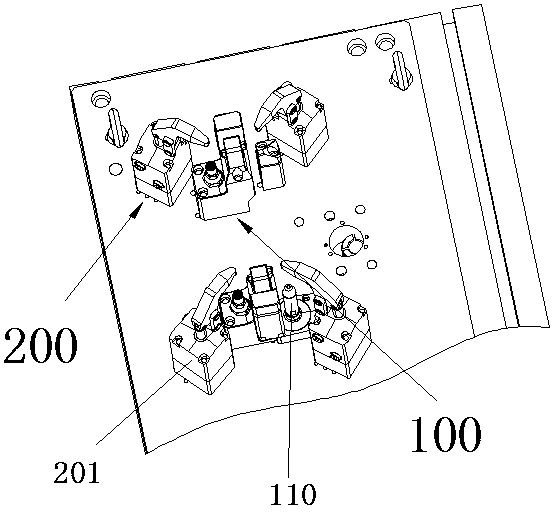

[0040] Such as Figure 1-3 As shown, as an embodiment of the present invention, a fixture for processing bracket milling and drilling includes a station-jack body 1 for milling the end face of the bracket, and station two for milling the side of the bracket and drilling The clamp body 2 and the base plate 3, the clamp body 1 of the first station and the clamp body 2 of the second station are arranged on the base plate 3, the clamp of the present invention combines the two stations of the processing bracket on one clamp, saving the research and development of the clamp Cost and production time are also saved in the number of equipment. In this embodiment, the station-clamp body 1 includes a first positioning mechanism 100 for positioning the workpiece, a first clamping mechanism 200 for clamping the workpiece, and a centering mechanism 300 for spreading the workpiece outward, so as to perform positioning and clamping, come right as Figure 14 The shown workpiece support end f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com