Cutting device for angle steel

A technology of cutting device and angle steel, which is applied in the direction of shearing device, device for cutting with nibbling action, and accessory device of shearing machine, etc. It can solve the problems of operator's physical injury, large cutting volume of angle steel, and damage to the blade, etc., and guarantees Stability and consistency, ensure positioning reliability, and ensure the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

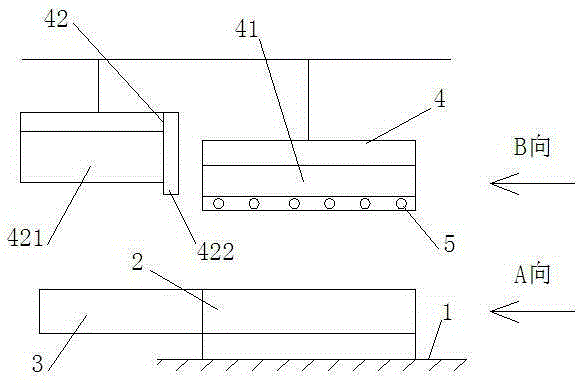

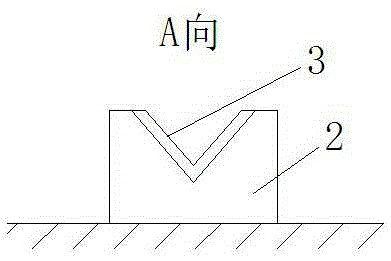

[0024] The present invention includes a frame 1 and a V-shaped positioning block 2 arranged on the frame 1, and the angle steel 3 is placed in the V-shaped positioning block 2;

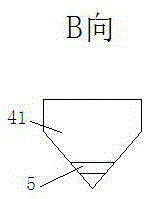

[0025] The frame 1 is provided with a cutter 4 corresponding to the V-shaped positioning block 2 on the top of the V-shaped positioning block 2, and the cutter 4 includes a positioning block 41 and a cutting knife 42;

[0026] The section of the positioning block 41 is V-shaped, corresponding to the inner wall of the angle steel 3 to form the positioning of the angle steel 3;

[0027] The section of the cutting knife 42 is V-shaped, the cutting knife 42 includes a knife body 421 and a blade 422, and the blade 422 is arranged on one side of the knife body 421 and protrudes from the knife body 421;

[0028] The positioning block 41 is arranged lower than the cutting knife 42 .

[0029] The part where the positioning block 2 contacts with the angle steel 3 is provided with an elastic layer.

[0030] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com