All-round verifying device for pressure instrument equipment

A technology of pressure instruments and verification devices, which is applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of insufficient system stability, low degree of automation, and bulky volume, so as to improve detection accuracy, use flexibly, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

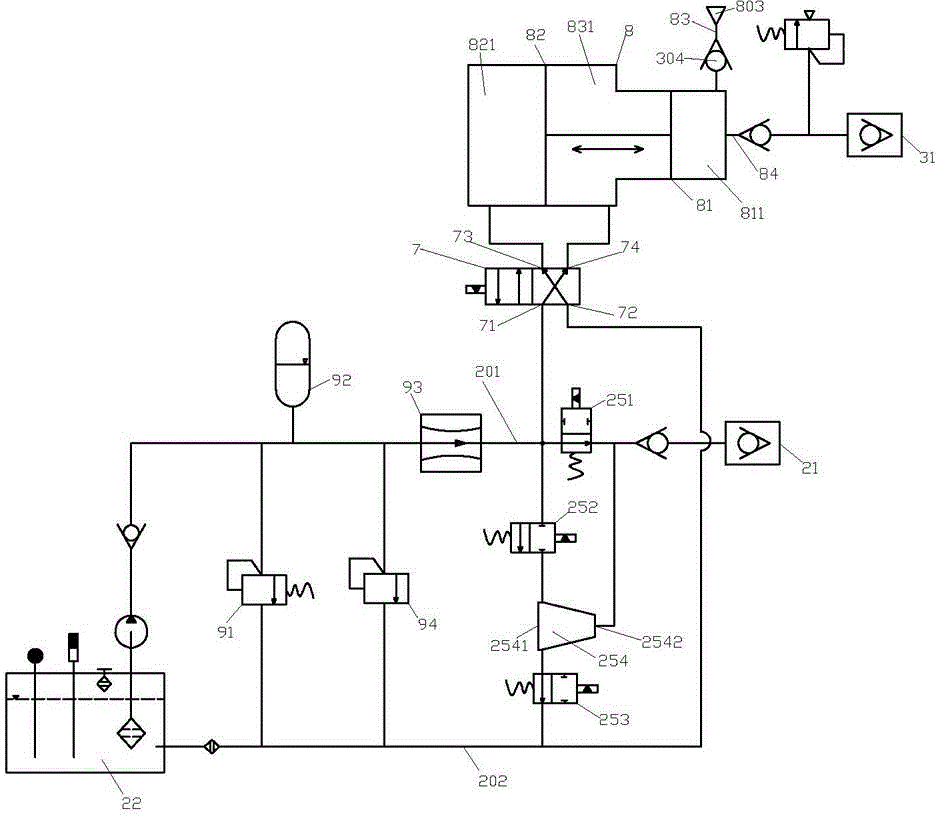

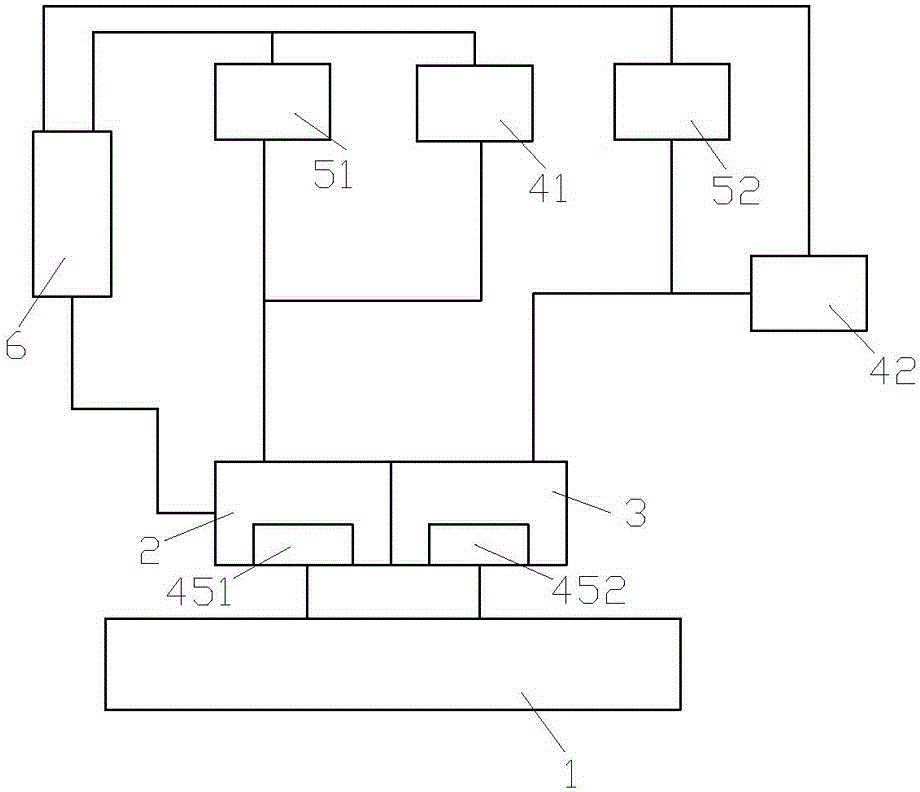

[0033] Example 1, such as figure 1 , 2As shown in the figure, an all-round verification device for pressure instrument equipment. It has an integrated platform 1, and the integrated platform 1 is respectively equipped with a hydraulic and pneumatic integrated supply and delivery device, a hydraulic standard device 41, a hydraulic pressure instrument connector 51 to be tested, a pneumatic standard device 42, a pneumatic pressure instrument connector 52 to be tested and Data processing module 6 for electrical control. There are hydraulic pressure source 2 and air pressure source 3 in the hydraulic and air pressure integrated supply and delivery device. The hydraulic pressure outlet 21 of the hydraulic pressure source 2 is synchronously connected to the hydraulic standard device 41 and the connector 51 of the hydraulic pressure instrument to be tested. The air pressure outlet 31 of the air pressure source 3 is synchronously connected to the air pressure standard. A one-way valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com