Transmission gear of automobile instrument motor

A technology for transmission gears and automotive instruments, which is applied in the field of tooth profile structure, can solve the problems of large structural size, vibration and noise, and inconstant reduction ratio of the reduction transmission system, and achieve small structure, low vibration and noise, and large transmission speed ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

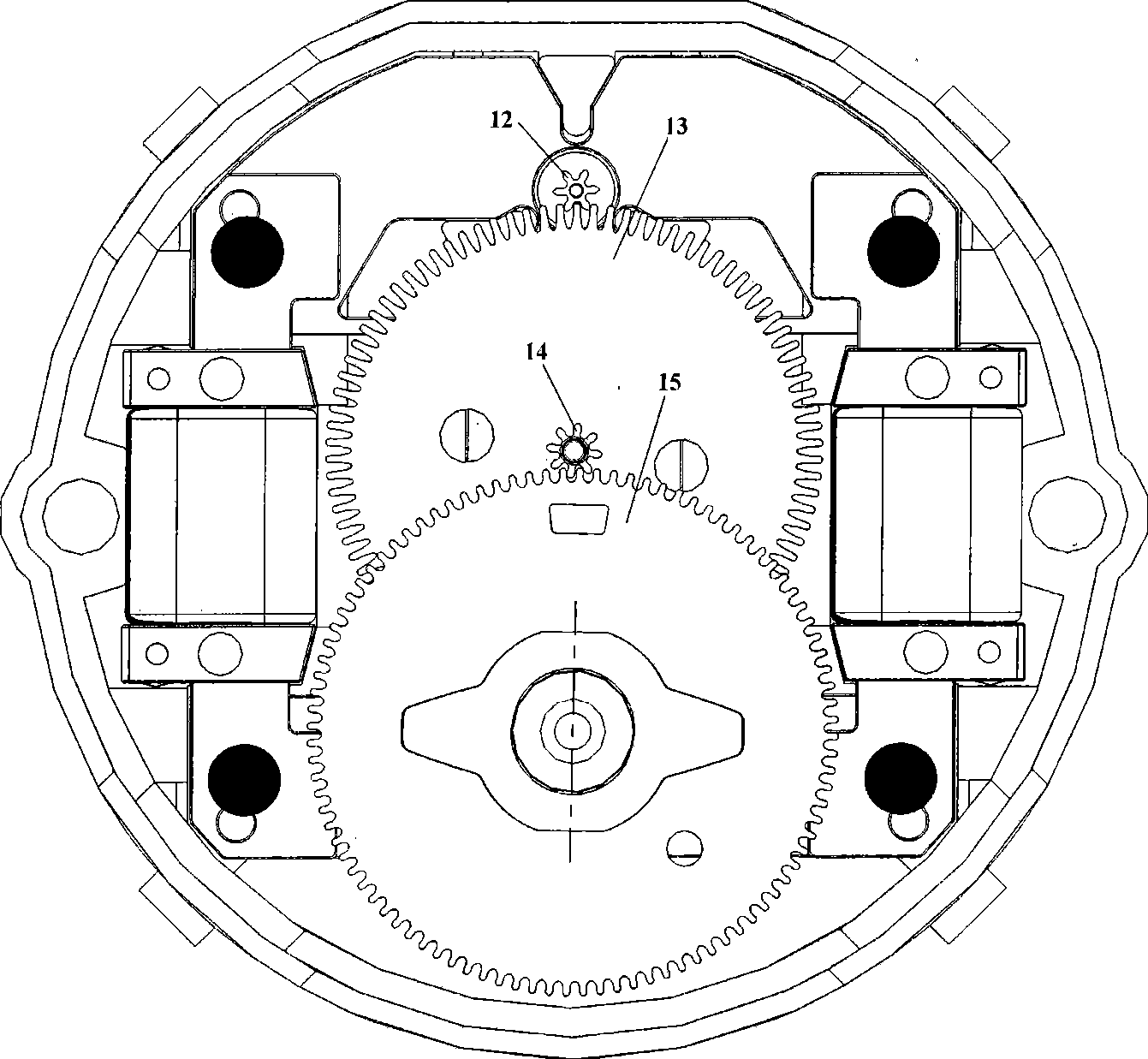

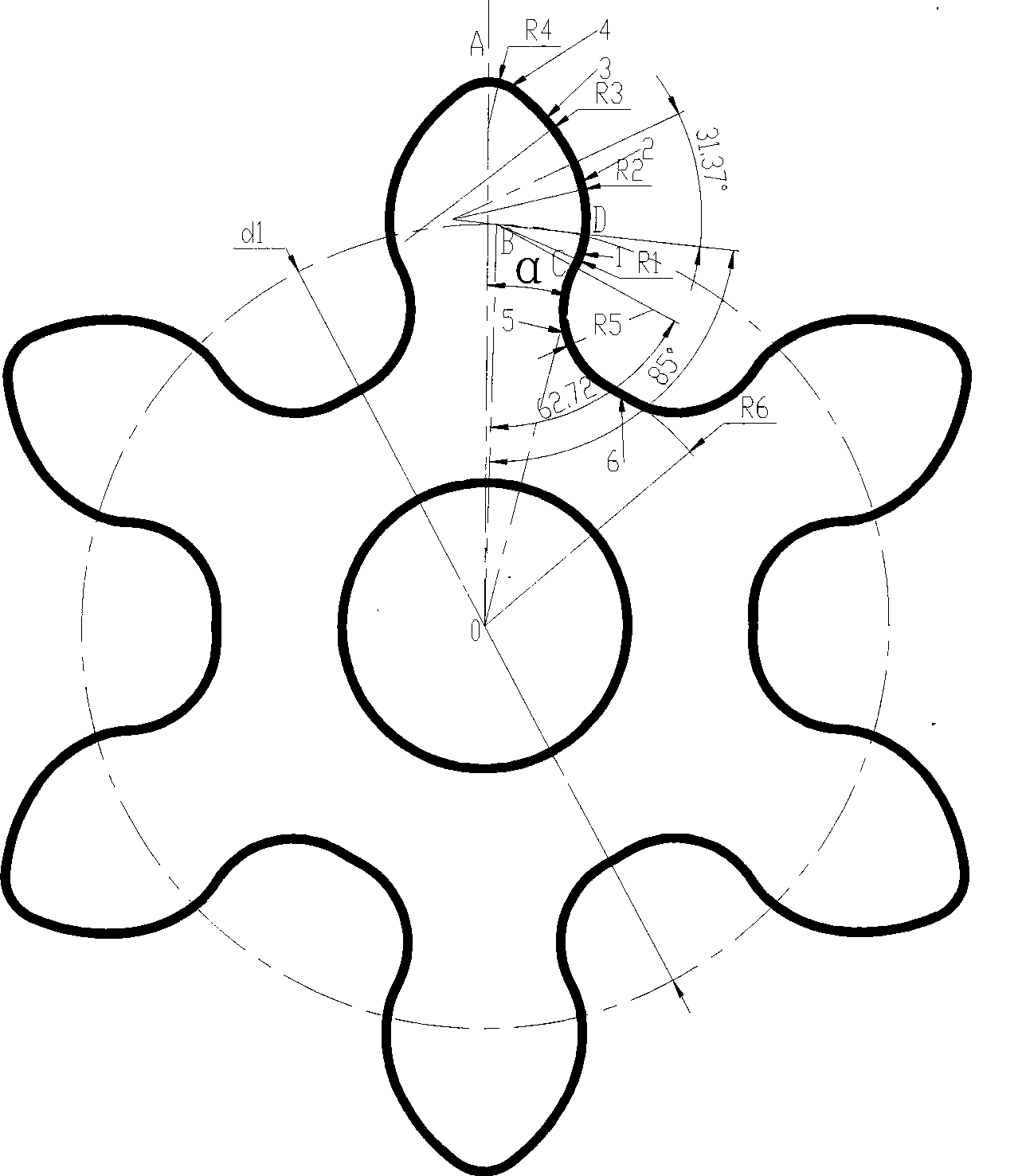

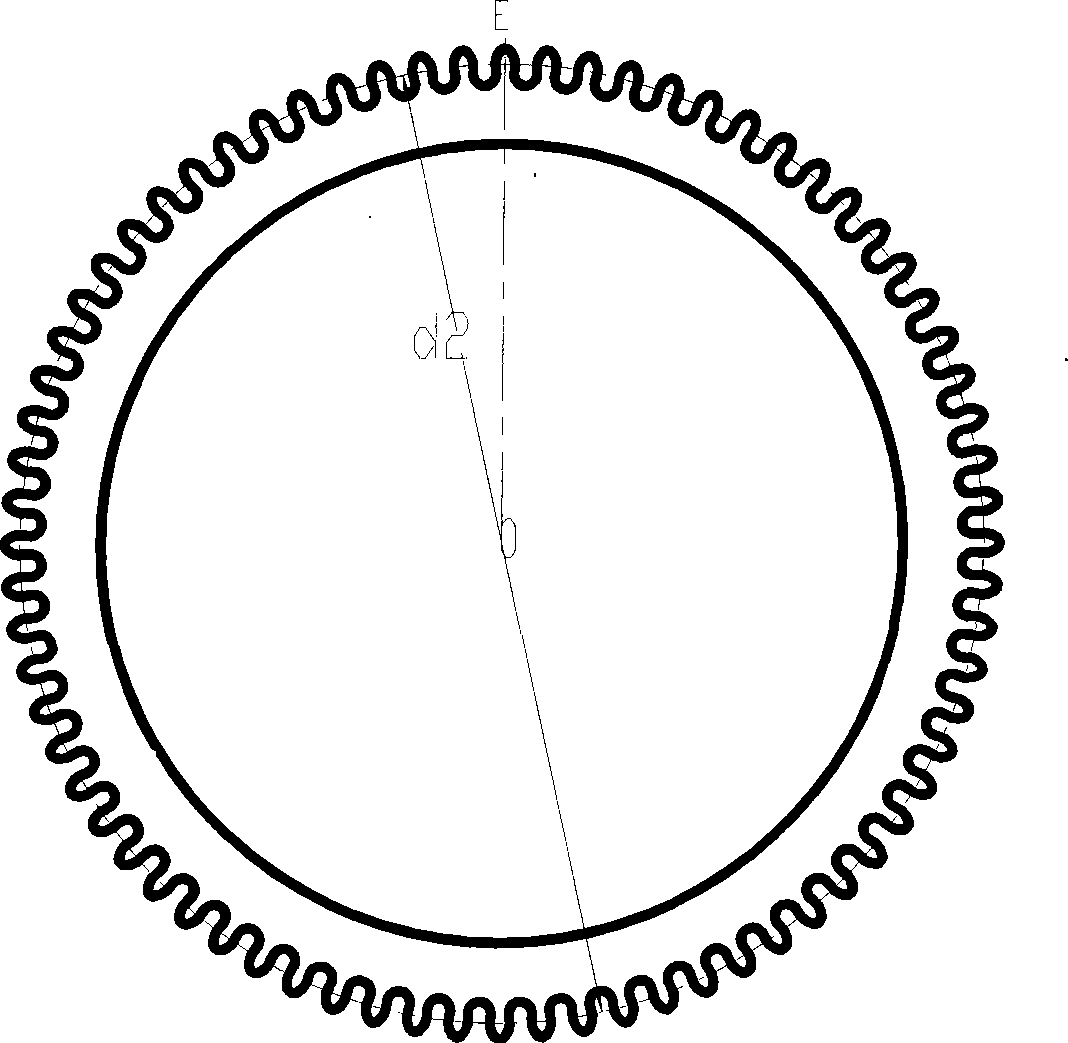

[0011] combine figure 1 , figure 2 and Figure 4 , the transmission gear of the automobile instrument motor of the present invention comprises a motor drive pinion 12, a middle bull gear 13, a middle pinion 14 and an output bull gear 15, the middle bull gear 13 and the middle pinion 14 are coaxial gears, and the drive pinion 12 It meshes with the middle bull gear 13, and the middle pinion gear 14 meshes with the output bull gear 15. The tooth profile structure of the driving pinion 12 and the middle pinion gear 14 is the same, collectively referred to as the pinion, the middle bull gear 13 and the output bull gear 15 The tooth profile structure is the same, collectively referred to as the bull gear, and the tooth profile of the pinion is a symmetrical curve along the axis OA, which is composed of the first to sixth arcs 1, 2, 3, 4, 5, and 6 that are tangent. The tooth profile of the relatively meshing bull gear is a symmetrical curve along the axis OE, which is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com