Uni-axial screw pump

A screw pump, single-shaft technology, applied in the field of motors with large output, can solve the problems of complex manufacturing process and heavy weight, and achieve the effect of small vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

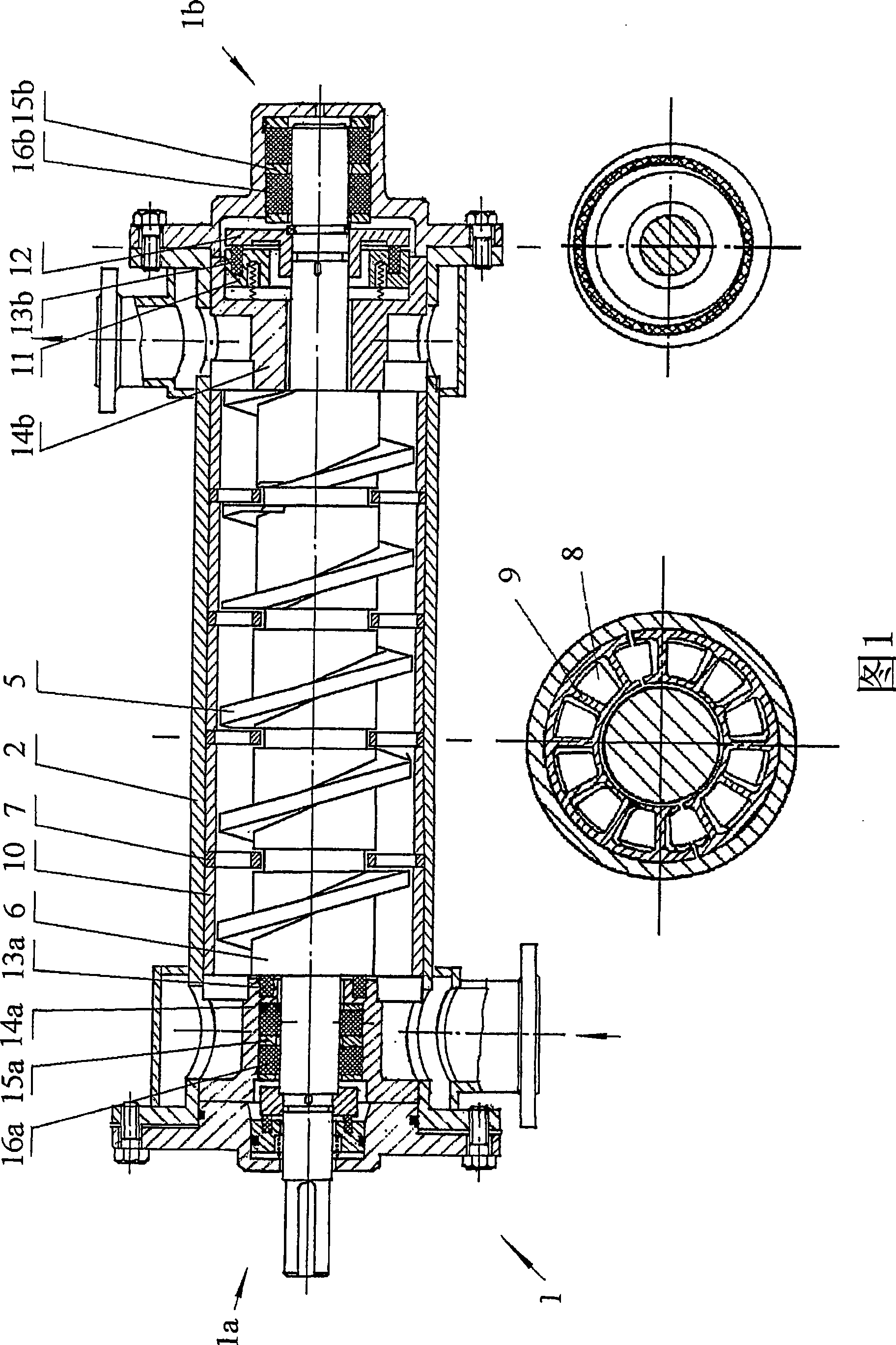

[0037] Referring now to Figure 1, there is shown a screw pump 1 made in accordance with the invention comprising an outer cylindrical housing 2 having an inlet end 1a and a discharge end 1b.

[0038] The threaded rotor 3 is a molded or welded component that is directly connected to the motor 4 and is rotatably mounted inside said outer casing 2 .

[0039]The threads 5 extending on the threaded rotor 3 are broken at pitch intervals to form as many thread portions 5 as there are pitches. The threaded shaft 6 is not broken, and as a result, when the rotor 3 rotates, a plurality of annular spaces are formed between said broken threaded portions 5 .

[0040] A plurality of annular restraints 7 fitted in said annular space are inserted therein. When the screw rotor 3 rotates, said means 7 restrain the conveyed fluid from moving in a direction around the axis 6 and force the fluid to move axially towards the discharge end 1b. An annular restraint 7 is arranged at the beginning of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com