Rotary-cylinder rotor engine

A rotary engine and rotary cylinder technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of increased fuel and engine oil consumption, the inability to use compression ignition, high cost, etc., and achieve improved intake and exhaust Superposition angle, improved intake and exhaust angle, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

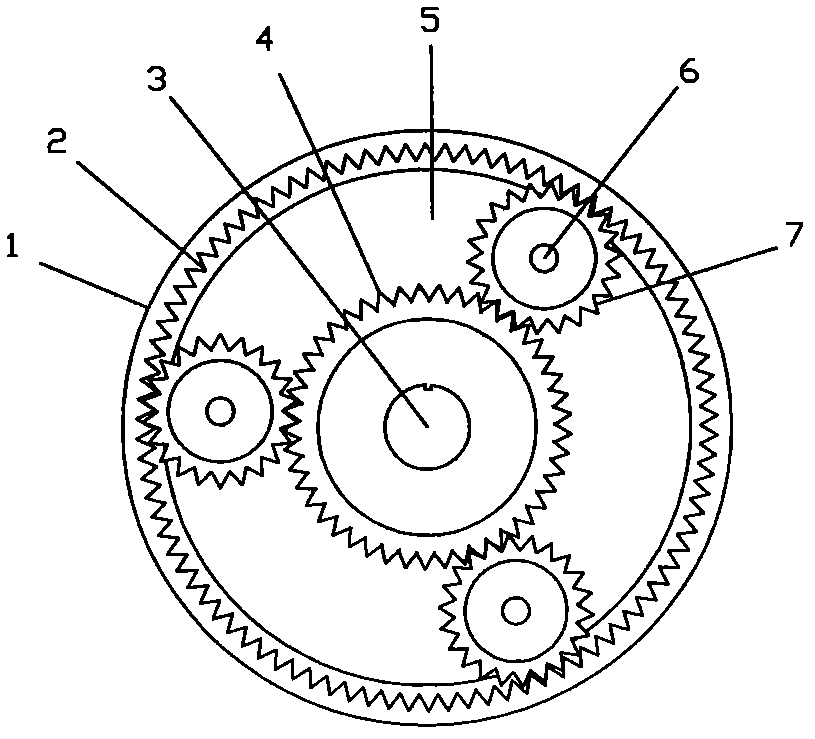

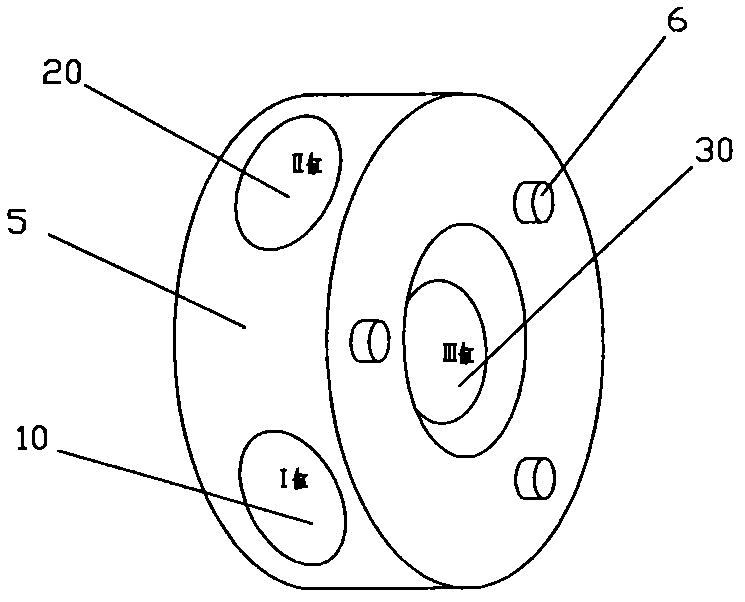

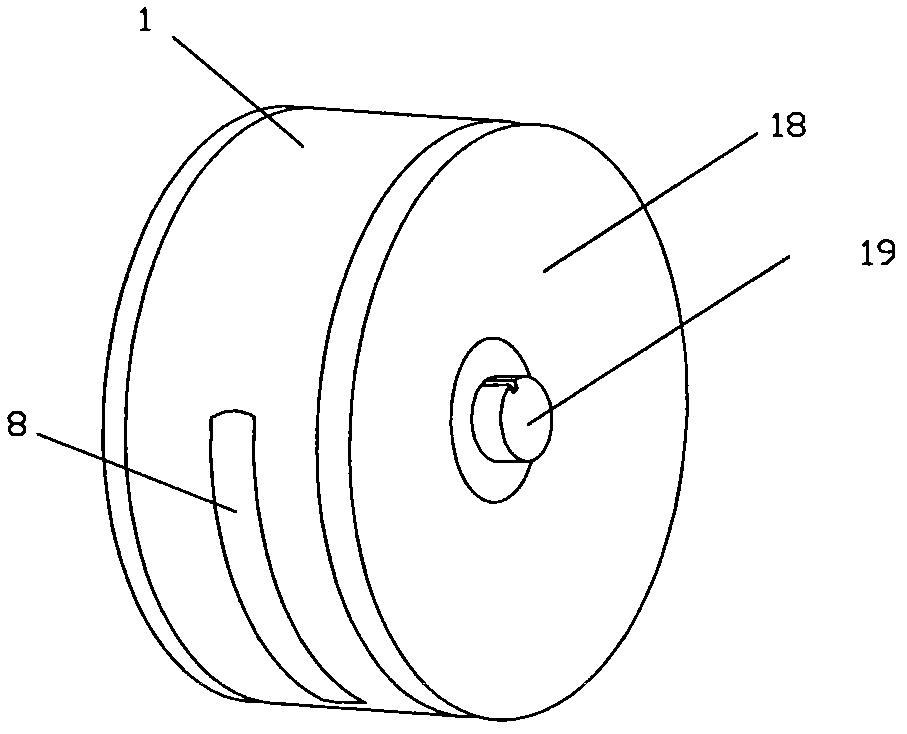

[0018] Such as Figure 1 to Figure 7 As shown, the present invention includes a housing 1 and a rotor 5. The inner wall of the housing 1 is circular, and the housing 1 is provided with an air intake slot 8 and an exhaust slot 15 with a radian of 80° to 100° along the circumferential direction. , the intake notch 8 is adjacent to the exhaust notch 15, and the inner wall of the opposite housing 1 at the adjacent place is provided with a hole for installing the spark plug 16, the intake notch 8 is connected with the carburetor 9, and the exhaust notch 15 Connected with the exhaust pipe, the inner wall of the housing 1 or the end cover is provided with an inner ring gear 2; the rotor 5 is a circular structure, and the rotor 5 is provided with three cylinders 10, 20, 30. There is a piston 11 in the cylinder, a crankshaft 14 and a connecting rod 12 mechanism are installed in the center of the rotor 5, and the crankshaft 14 is installed on the central axis 3 in the center of the roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com