Patents

Literature

63results about How to "Slow rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

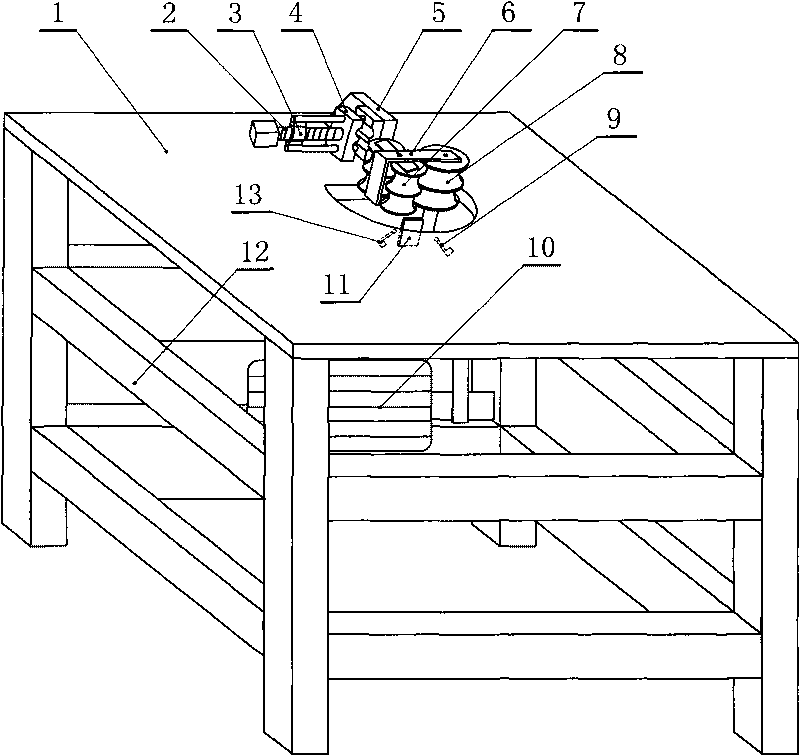

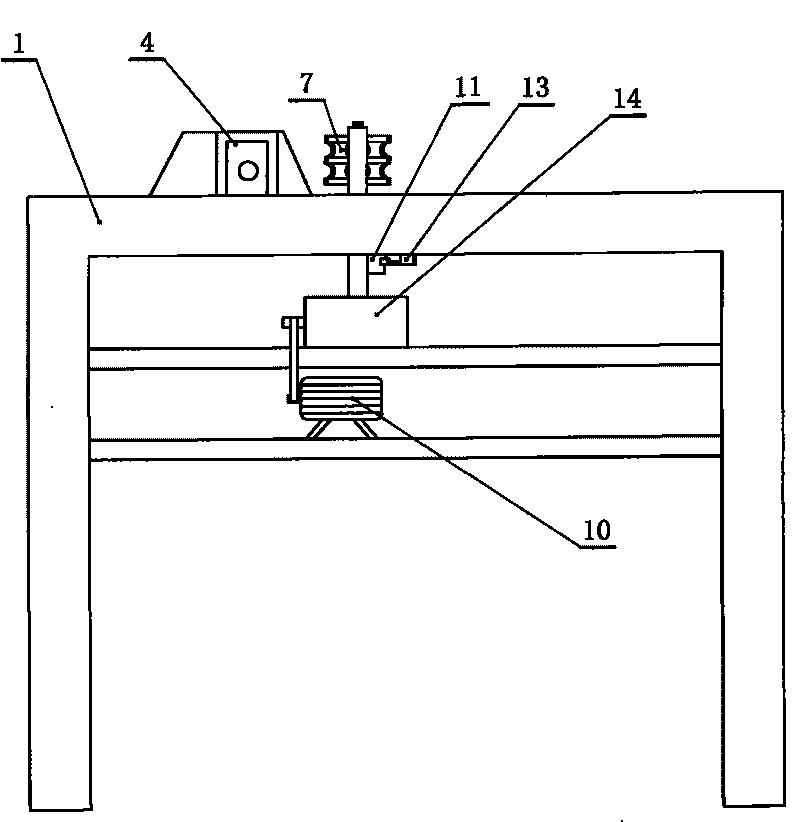

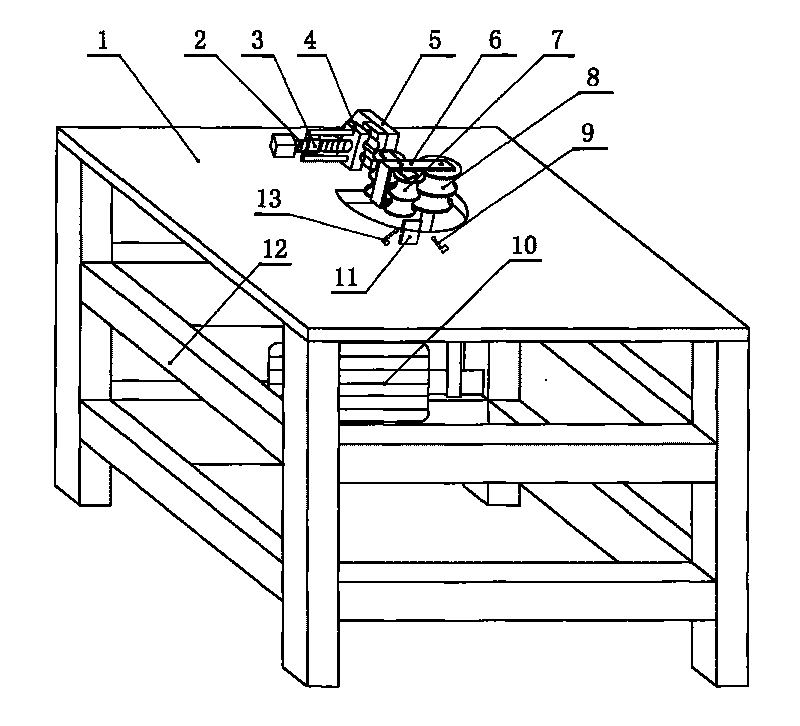

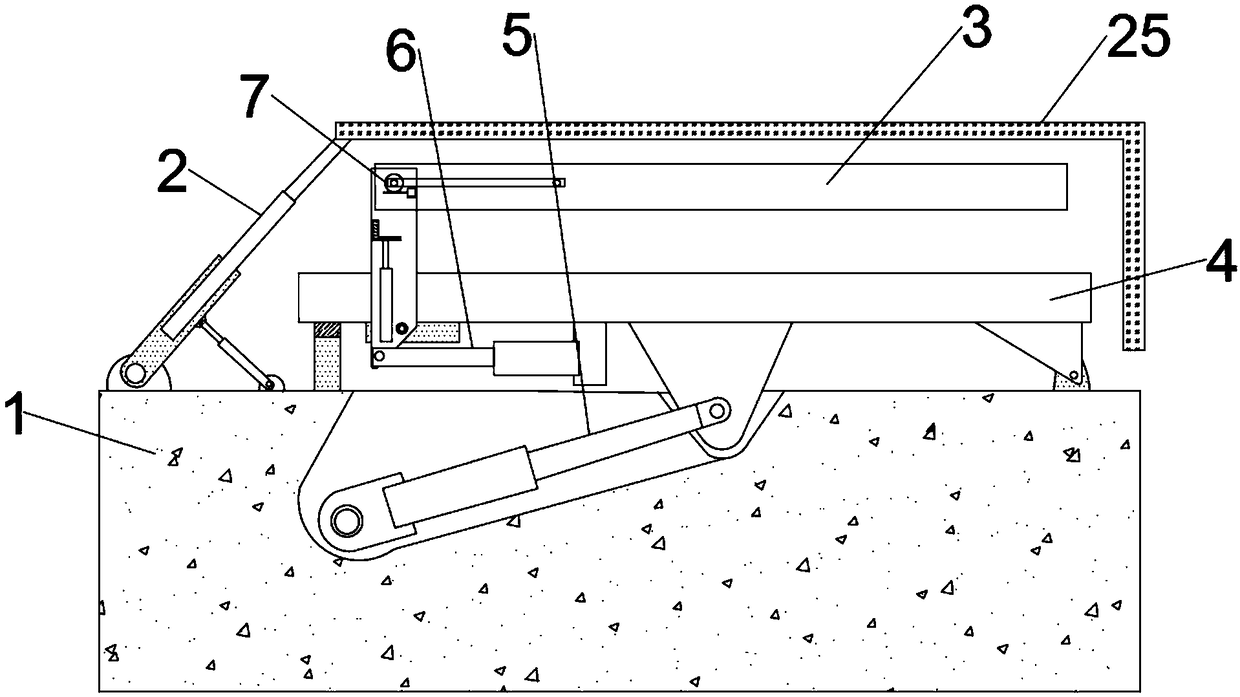

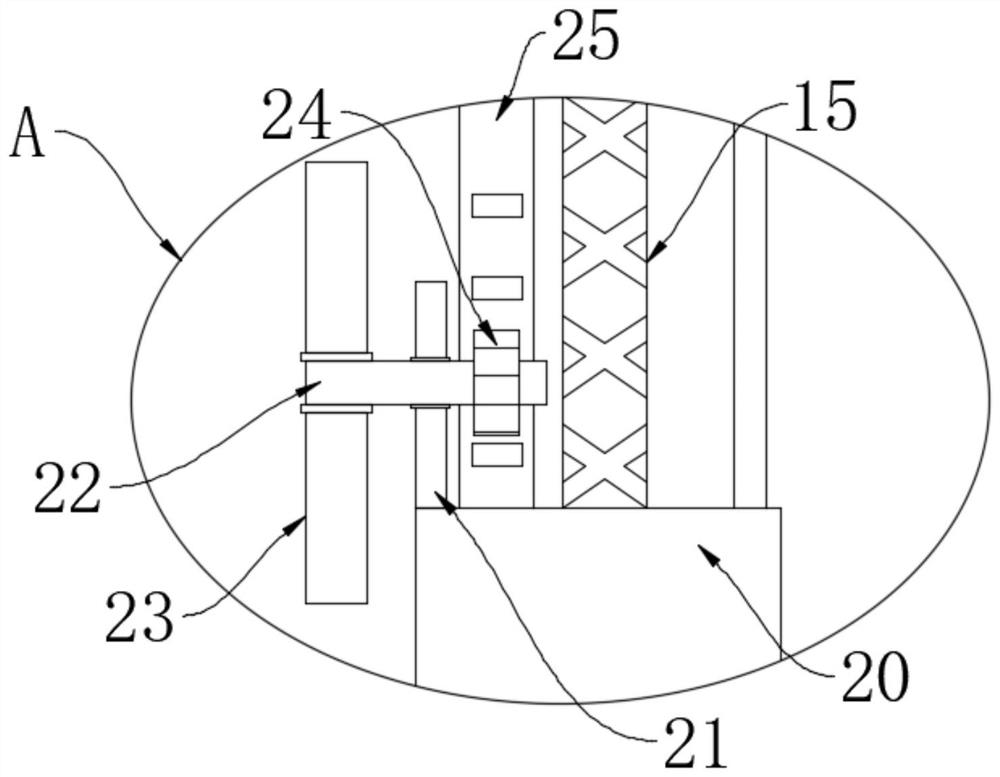

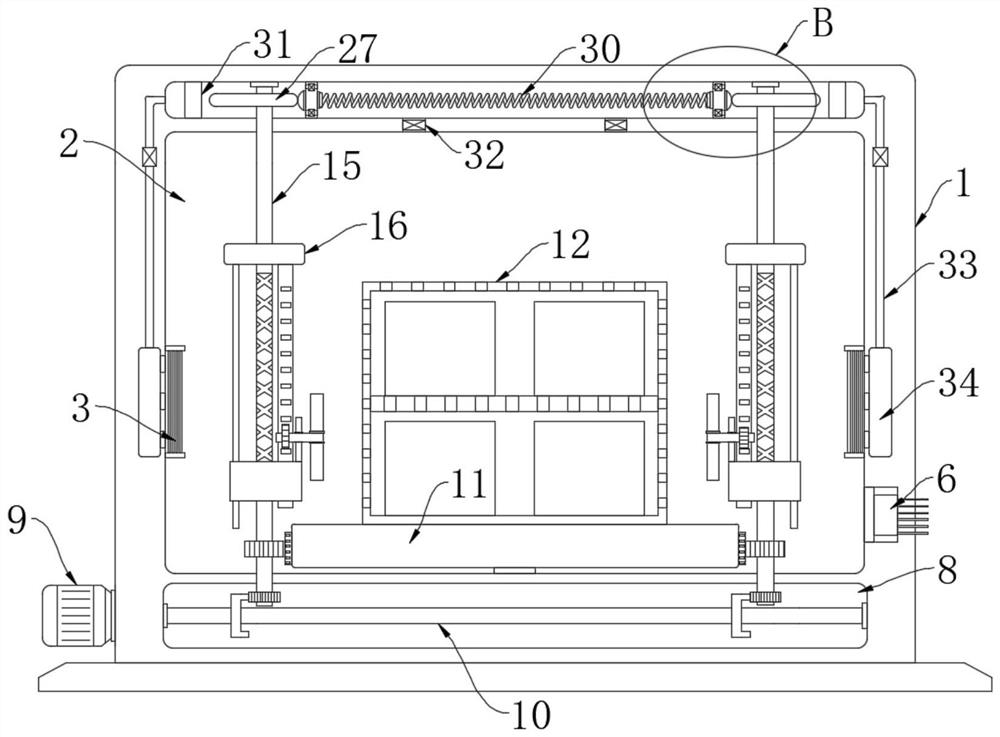

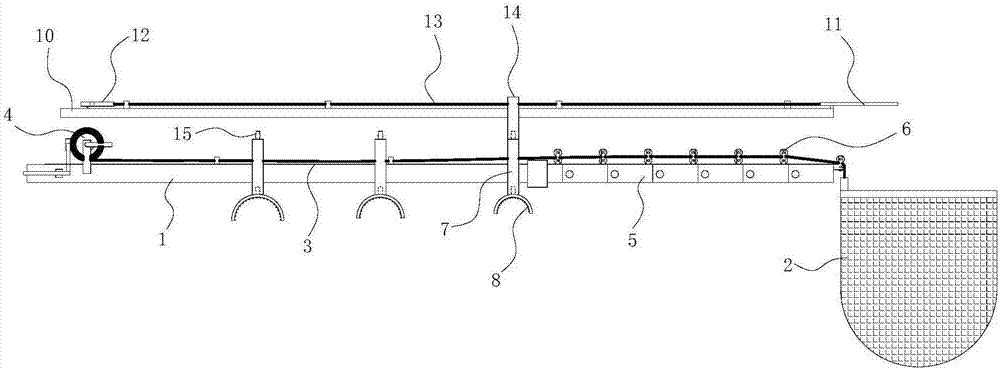

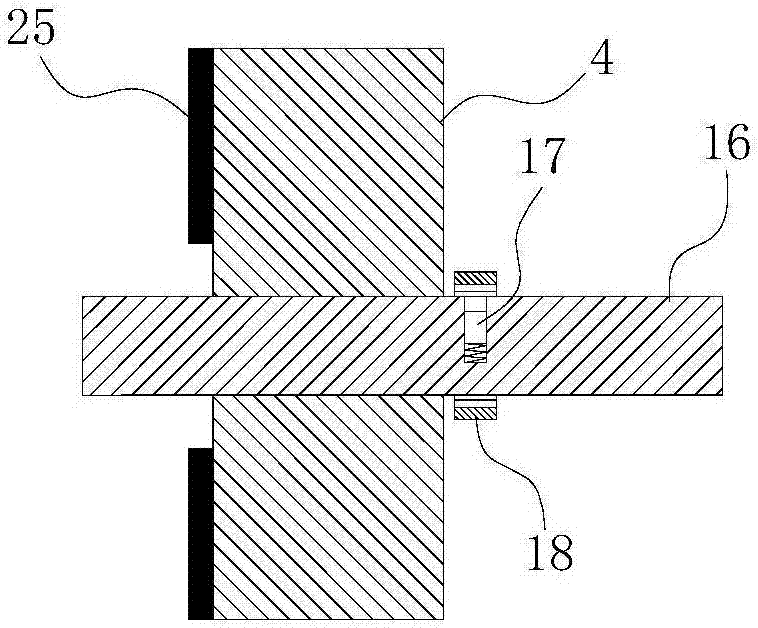

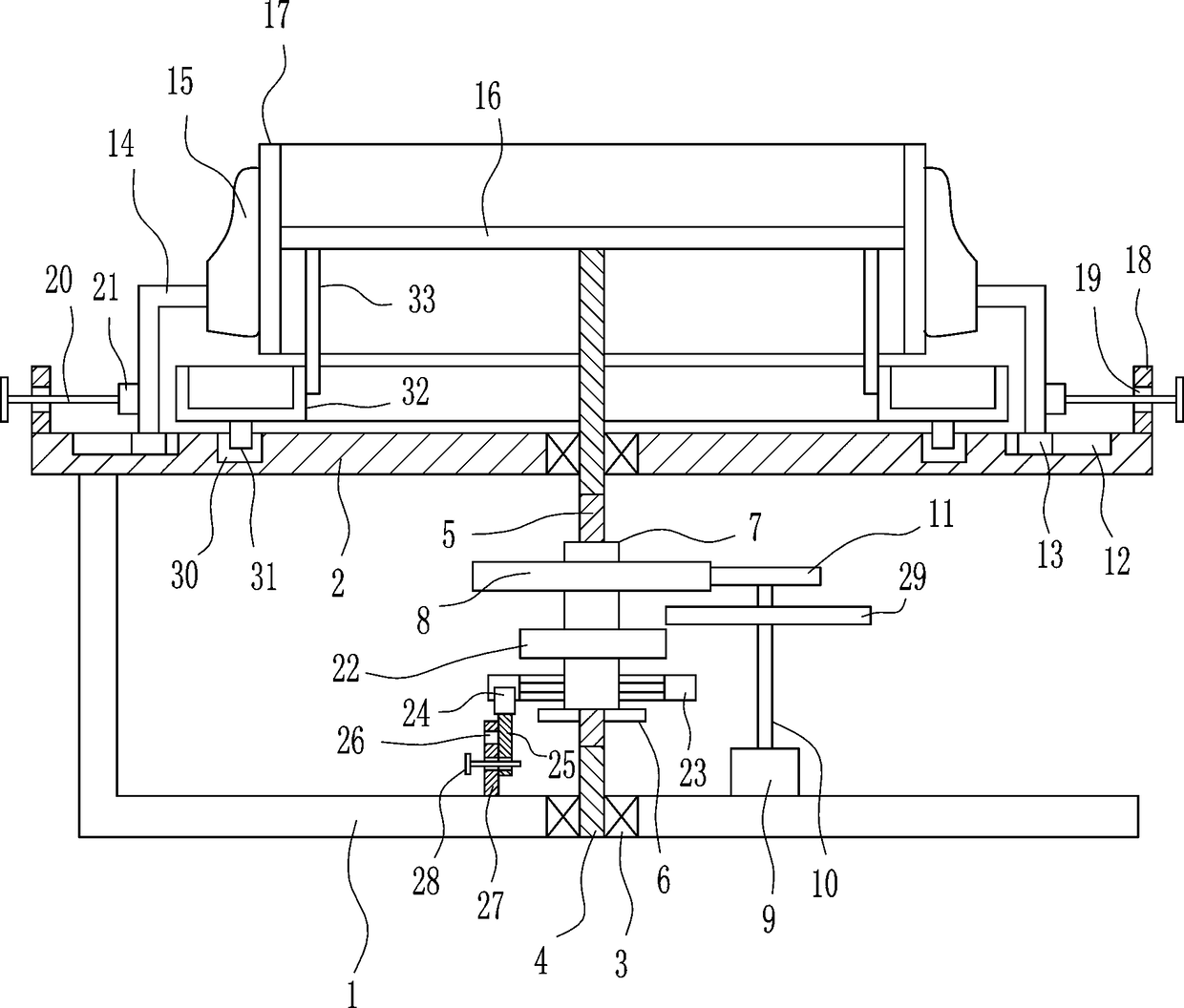

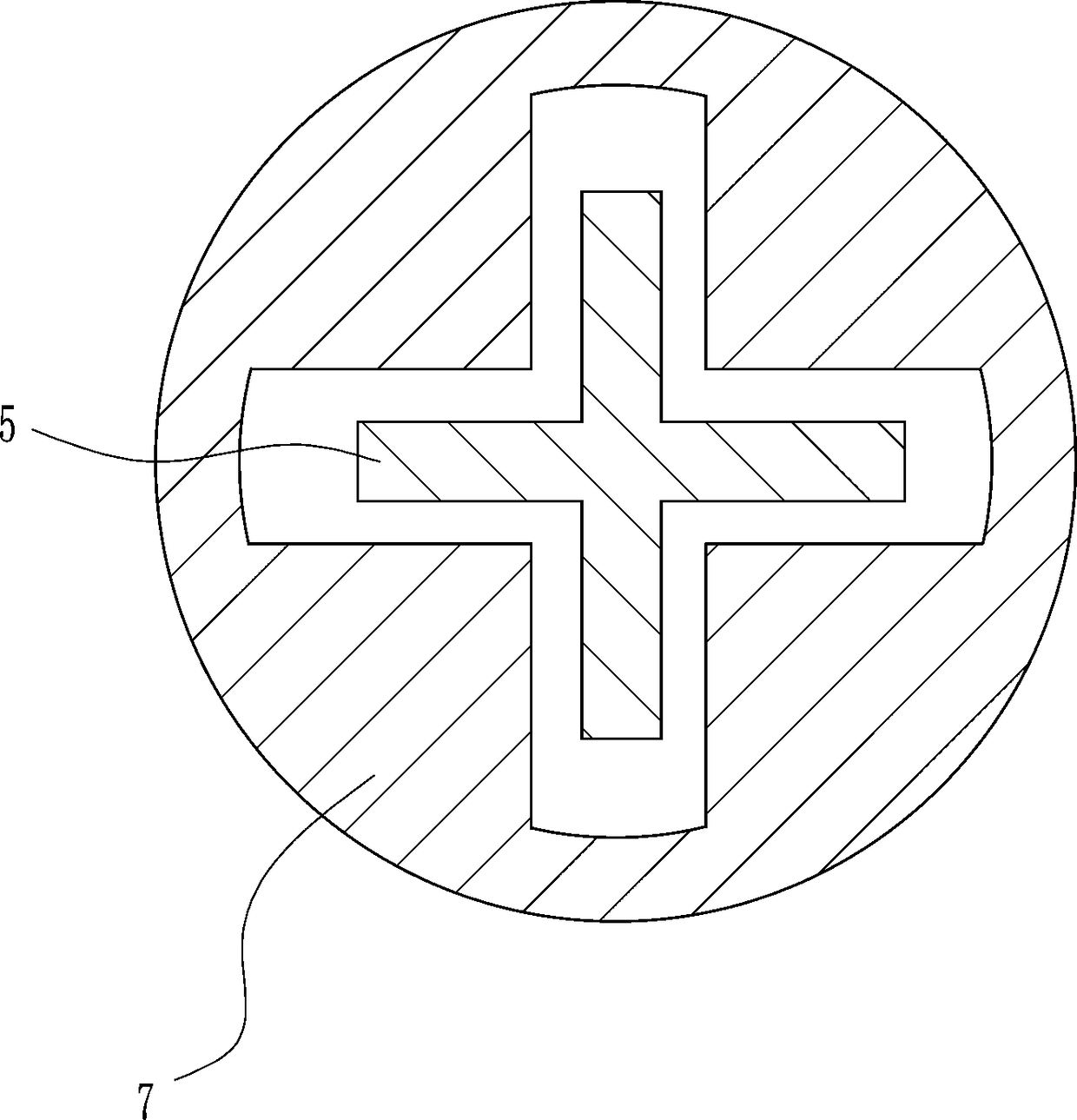

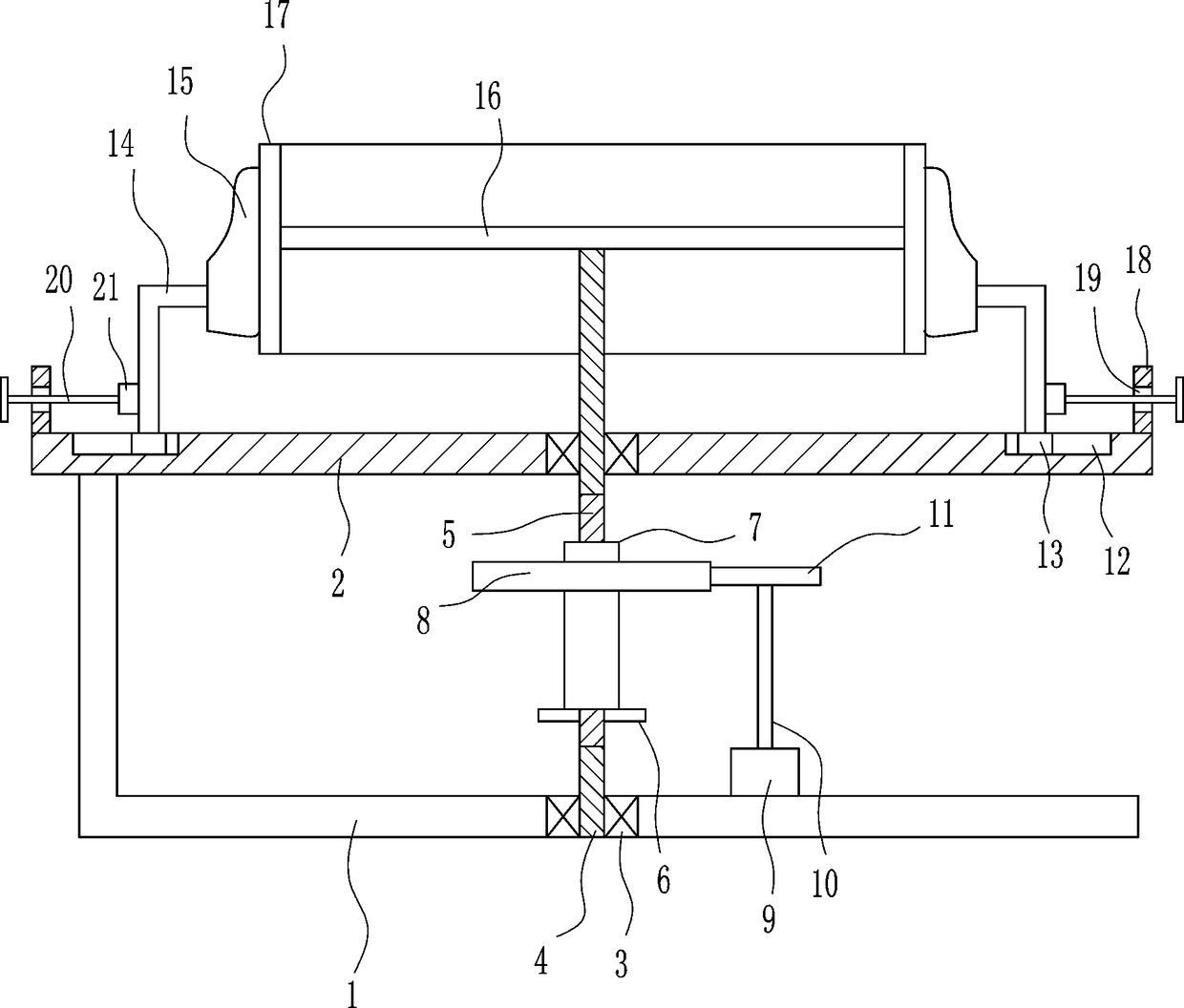

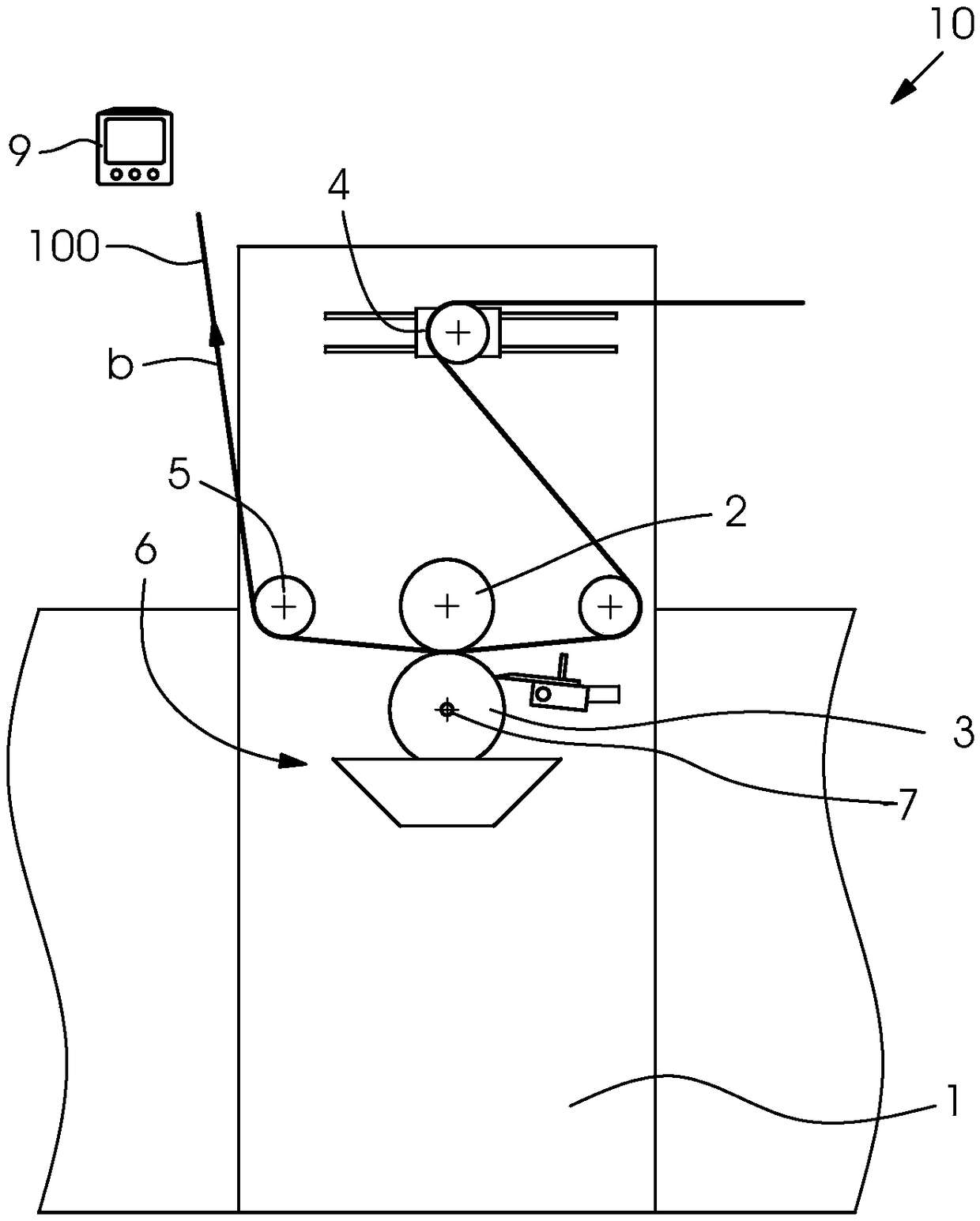

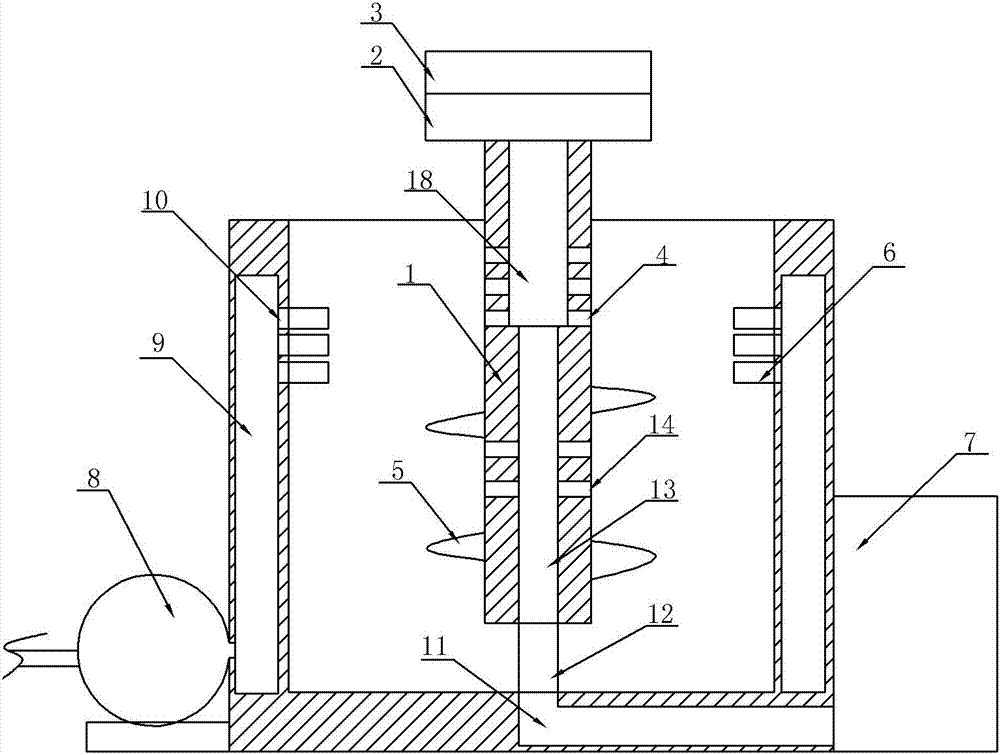

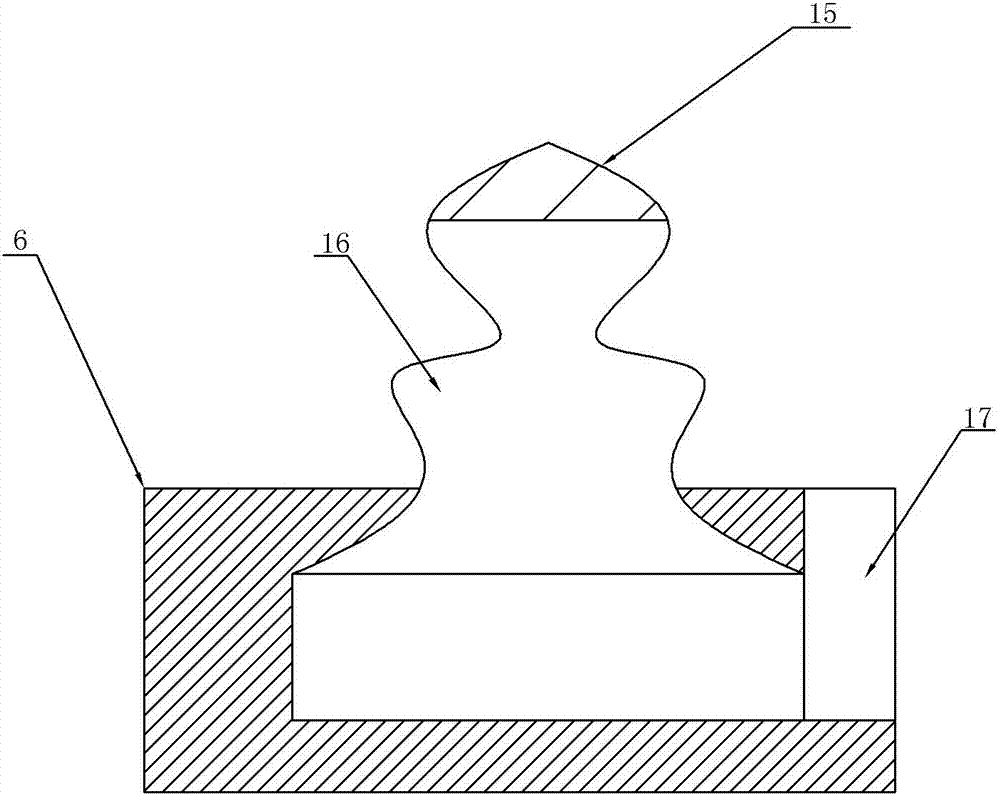

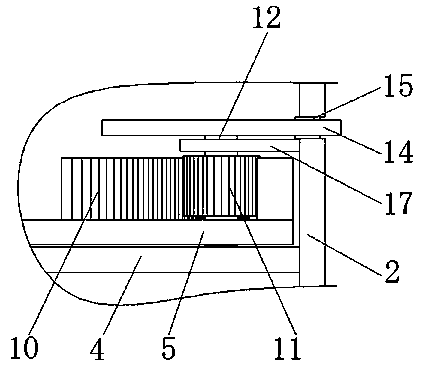

Electric pipe bending machine

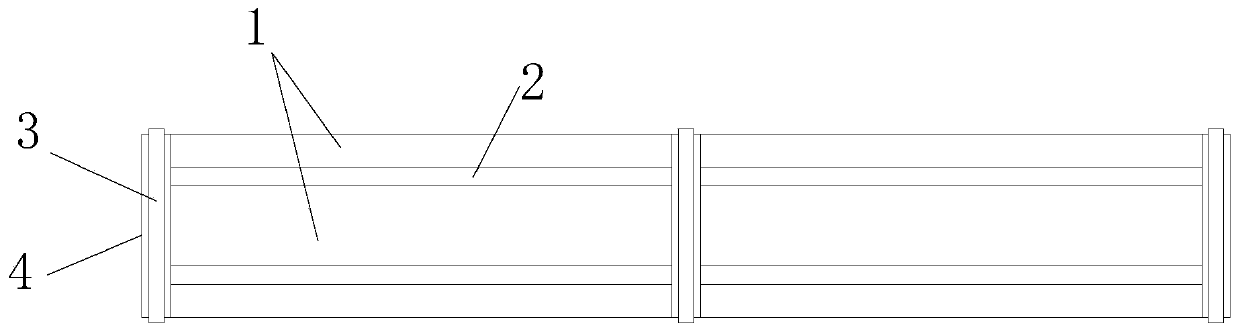

The invention relates to an electric pipe bending machine which comprises a frame. An operation platform is arranged on the frame, and a bending pipe fixing frame is fixedly installed on the operation platform. The bending pipe fixing frame comprises a fixed press block, wherein the fixed press block is fixedly installed on the operation platform, and the inner side of the fixed press block is provided with a groove; a screw rod frame is fixedly installed on the operation platform, and a screw rod is installed on the screw rod frame; one end of the screw rod is connected with a moving press block, and the inner side of the moving press block is provided with a groove; the operation platform is provided with an opening, and a motor is arranged under the operation platform; the motor is connected with a reduction box, and an output shaft of the reduction box passes upwards through the opening on the operation platform vertically to be connected with a main wheel of a bending pipe; a bending pipe U-shaped bracket is fixedly connected to the main wheel of the bending pipe, and two bending pipe secondary wheels are connected between the inner side of the bending pipe U-shaped bracket and the main wheel of the bending pipe by pins; a travel switch baffle plate is fixedly connected to the output shaft of the reduction box, and an arriving sensor and a return sensor are installed under the operation platform. The invention has the characteristics of low rotating speed, small inertia, low power requirement of the motor and low cost.

Owner:王克启

Fireproof composite cable

ActiveCN110111940AQuick breakQuickly turn offInsulated cablesInsulated conductorsHeat conductingSlow rotation

The invention discloses a fireproof composite cable, which comprises a cable body formed by splicing more than one outer sheath layer and more than one connecting pieces, wherein the connecting piecesare arranged between adjacent outer sheath layers; each outer sheath layer is in fixed contact with the end surfaces of the corresponding connecting pieces; more than one cavity is disposed on the outer sheath layer and surround the outer sheath layer; each cavity is filled with an expansion body; each expansion body is filled with an inert gas; the bottom of each expansion body is provided witha bottom plate layer; more than one compression spring is arranged at the bottom of each bottom plate layer; the bottom of each compression spring is fixedly connected with the bottom surface of the cavity; and the outer end side of each expansion body is provided with a heat conducting piece. The fireproof composite cable, by using a method of thermal expansion, jets out the inert gas and a partof a fire extinguishing agent when there is a fire source in order to quickly extinguish the flame on the outer sheath layer and the surrounding flame, and can achieve one-side jet to realize slow rotation in order to well stay away from the fire source and well extinguish the fire.

Owner:江西美园电缆集团有限公司

Folding device for onboard high-mobility large antenna array radar

ActiveCN108832258AReduce shakingExtended service lifeCollapsable antennas meansAntenna supports/mountingsRadarScratching

The invention discloses a folding device for an onboard high-mobility large antenna array radar. The folding device comprises an antenna base. A support protection device is arranged on the left end of the antenna base. A lower array antenna frame is installed on the top of the antenna base through a hinge seat. The left side of the top of the lower array antenna frame is connected to the antennabase by an overturning pitch mechanism. The top of the lower array antenna frame is connected with an upper array antenna frame through a folding rotating mechanism. The support protection device canprotect a radar in transit against the scratching by foreign objects. An L-shaped protective support plate can support the back of a radar array antenna when the radar is unfolded to operate, therebyreducing the shaking of the radar and improving the stability of a radar transmission signal. By an angle rotation mechanism, the upper array antenna can be automatically fixed when rotating to an appropriate position to operate or folded to an appropriate angle to contract. The upper array antenna has a slow and stable rotation speed and high angle adjustment precision.

Owner:嘉兴市恒泰化工科技有限公司

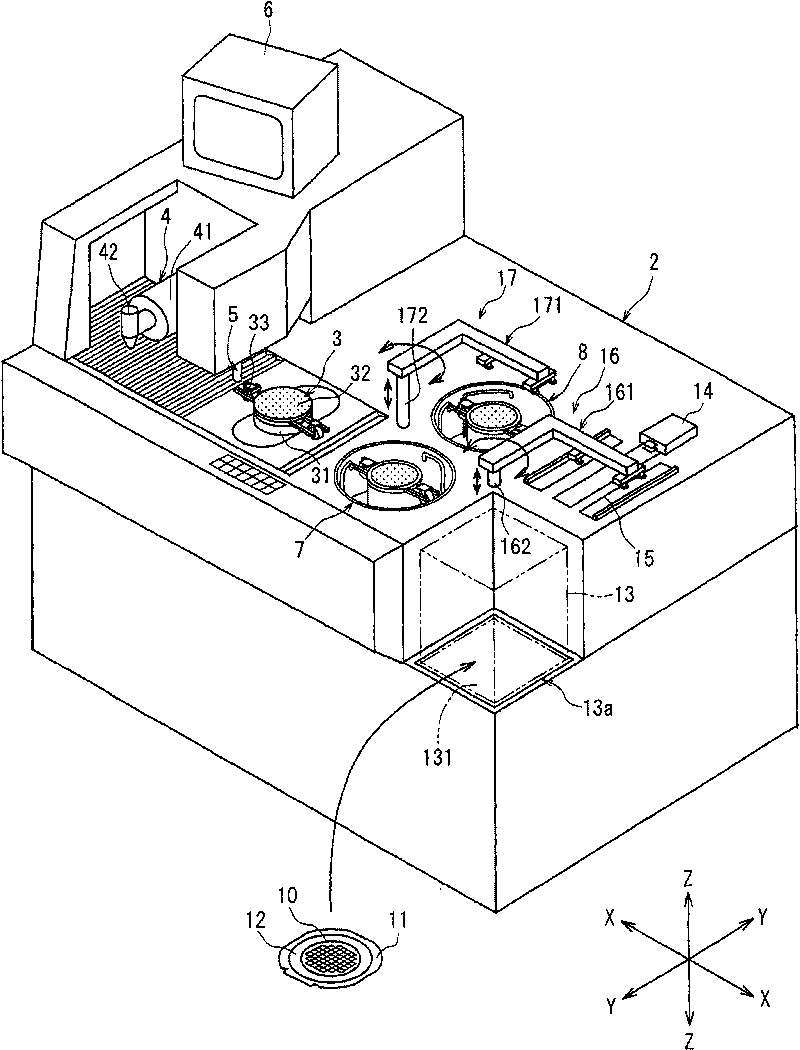

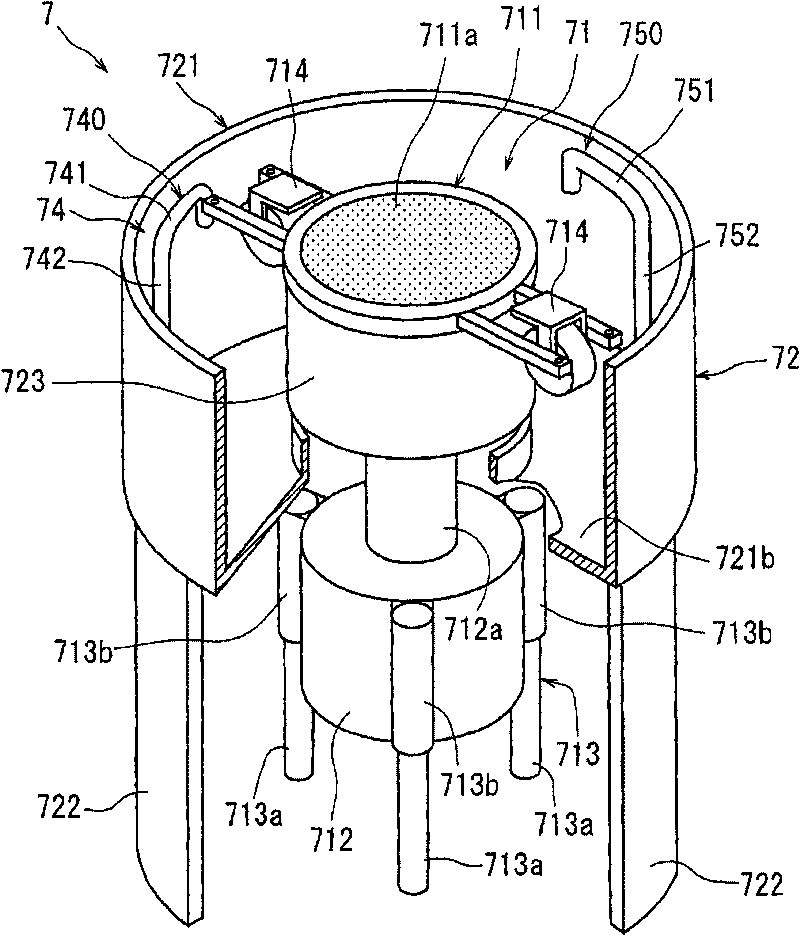

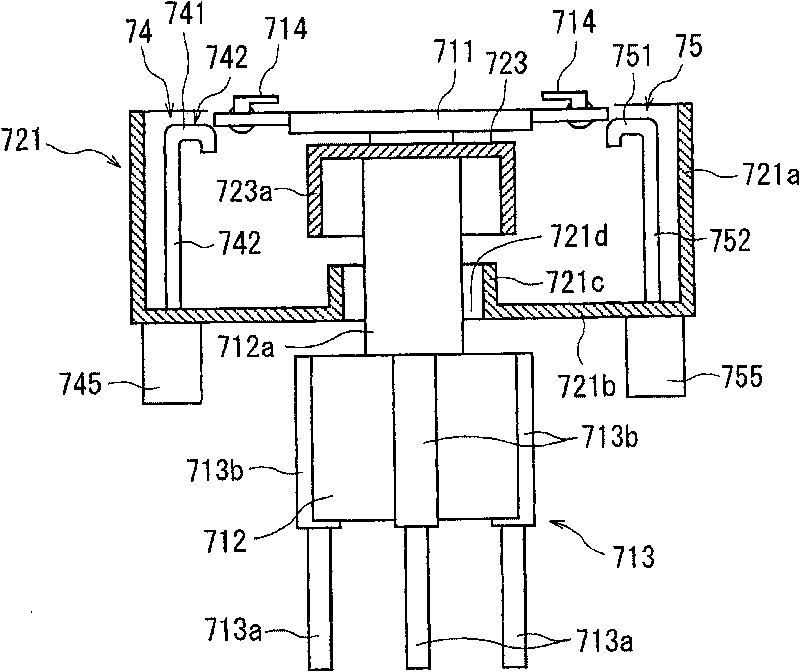

Protective film forming method and apparatus

ActiveCN101740419ARaise the ratioReduce usageLiquid surface applicatorsSemiconductor/solid-state device manufacturingTectorial membraneLiquid state

A protective film forming method for forming a protective film of resin on a work surface of a wafer. The protective film forming method includes a wafer holding step of holding the wafer on a spinner table in the condition where the work surface is oriented upward, a spray coating step of spraying first liquid resin onto the work surface of the wafer as rotating the spinner table at a first rotational speed after performing the wafer holding step, a liquid resin supplying step of dropping a predetermined amount of second liquid resin onto a central area of the work surface of the wafer as rotating the spinner table at a second rotational speed lower than the first rotational speed after performing the spray coating step, and a spin coating step of rotating the spinner table at a third rotational speed higher than the first rotational speed after performing the liquid resin supplying step to thereby spread the second liquid resin dropped onto the central area of the work surface of the wafer, thus forming the protective film on the work surface of the wafer.

Owner:DISCO CORP

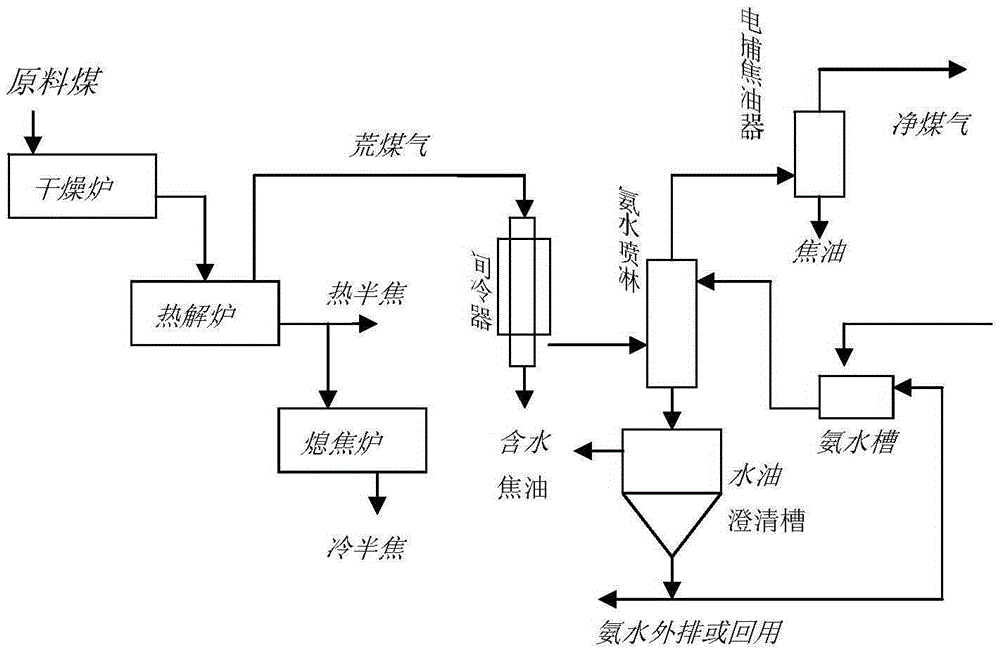

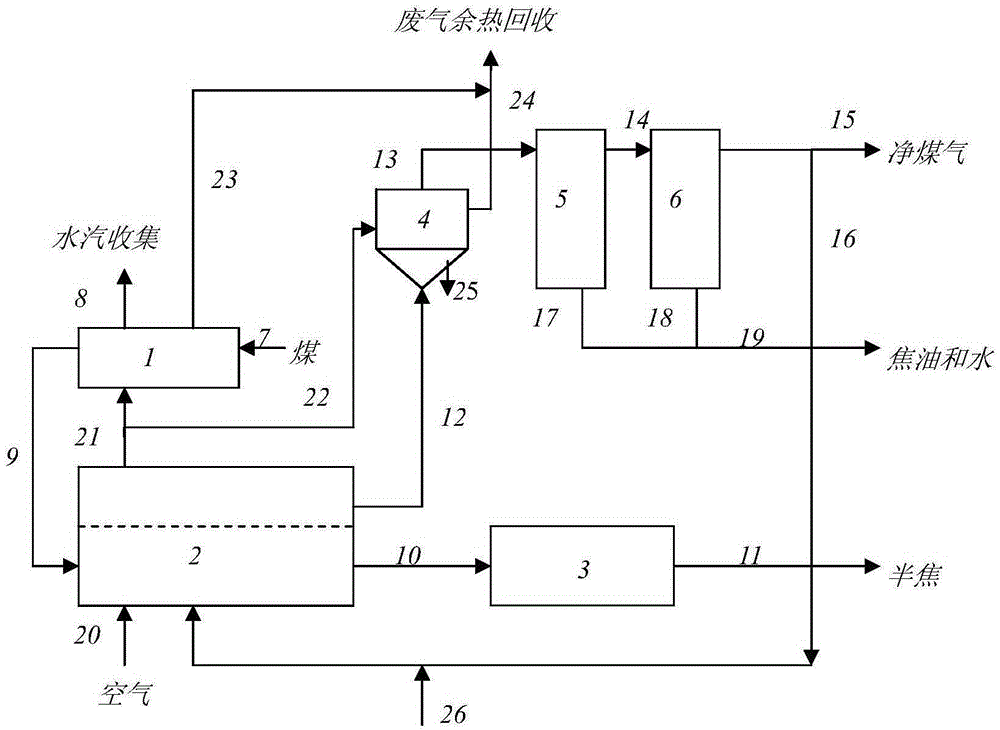

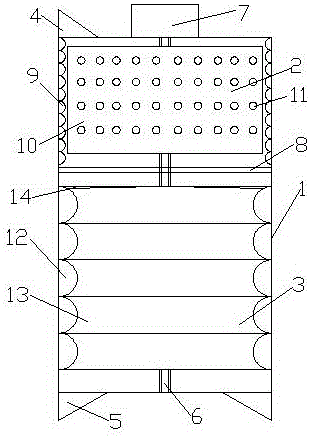

Small-particle-size low-rank coal pyrolysis technology and equipment coupling multi-stage dust reducing

ActiveCN105273733AImprove heat transfer efficiencySuppress entrainmentCoke quenchingChemical industryHeat conductingProcess engineering

The invention provides a pyrolysis furnace, small-particle-size low-rank coal pyrolysis equipment coupling multi-stage dust reducing and containing the pyrolysis furnace and a small-particle-size low-rank coal pyrolysis technology coupling multi-stage dust reducing and applying the equipment. The heat conducting efficiency of out heating pyrolysis can be improved; granular dust in the pyrolysis process is inhibited, and a raw coke oven gas dust carrying zone is minimized; high-temperature oil-dust separation is performed on dust in the raw coke oven gas carrying zone, and the tar quality is improved.

Owner:CCTEG CHINA COAL RES INST

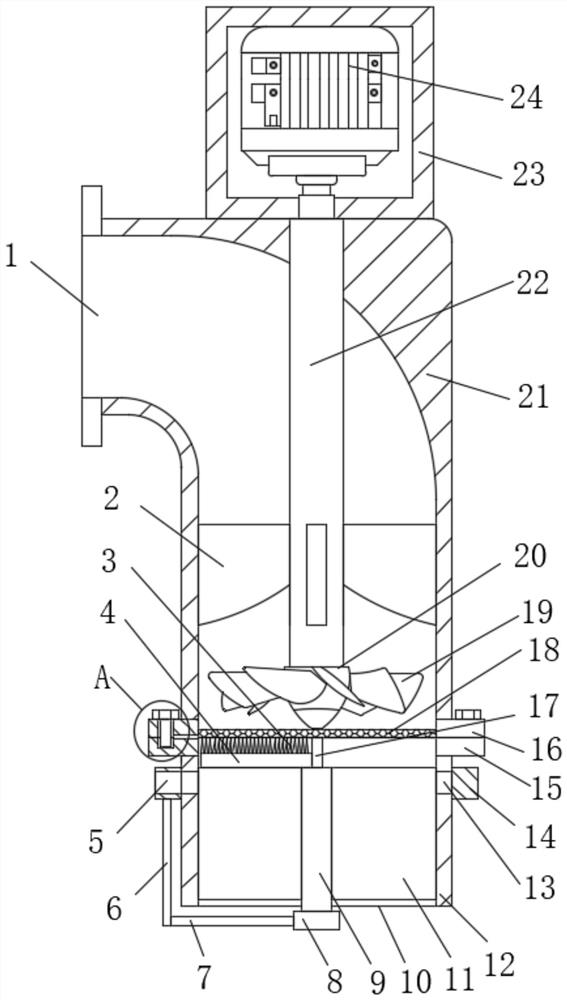

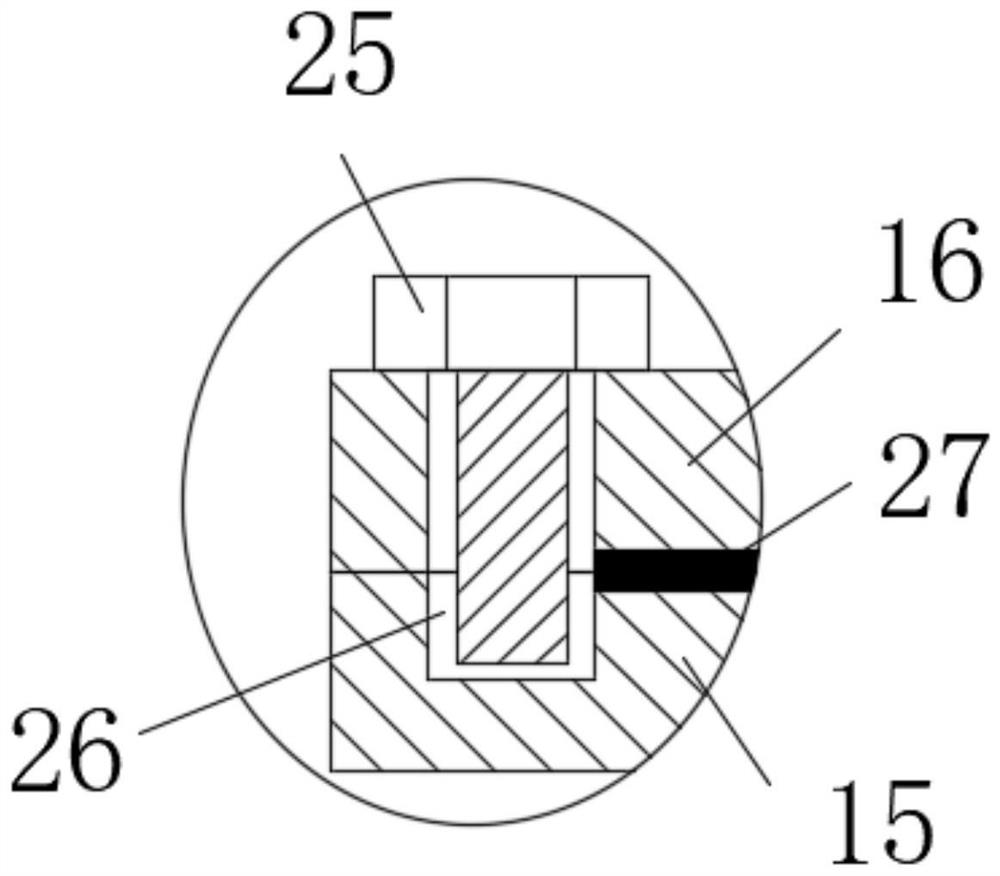

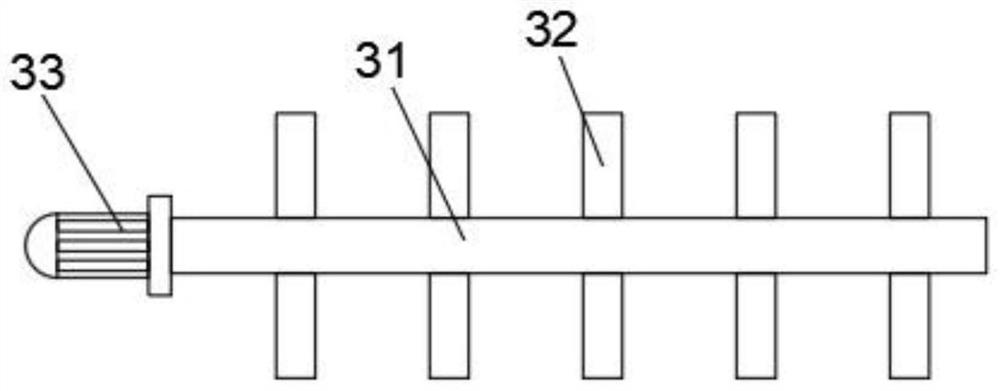

Crushing and grinding device

InactiveCN106607171AShorten the timeNo human intervention requiredGrain treatmentsEngineeringMechanical engineering

The invention provides a crushing and grinding device. The crushing and grinding device comprises a tank body, a crushing structure and a grinding structure. A shaft is arranged in the middle of the interior of the tank. The crushing structure is arranged on the upper portion of the interior of the tank, the grinding structure is arranged on the lower portion of the interior of the tank, and a filtering interlayer is arranged in the middle of the interior of the tank. The crushing structure is fixedly connected with the shaft. A crushing tank is arranged outside the crushing structure. Blades are arranged at the bottom of the interior of the crushing tank. Sieve pores are distributed in the crushing tank at equal intervals. The grinding structure comprises convex wheels fixed to the inner side of the tank and concave wheels arranged on the shaft. The concave wheels are connected with the shaft through a shaft sleeve. A spiral material tank which extends outwards with the shaft as the center is arranged above the concave wheels. According to the crushing and grinding device, the interior of the tank is divided into two portions with the filtering interlayer as the boundary, the crushing structure is arranged on the upper portion and mainly used for collecting materials and then dividing the materials, and the grinding structure is arranged on the lower portion and used for grinding the materials divided into small blocks by the upper portion into powder; and the two functions are achieved in sequence, more time is saved, the crushing effect is good, manual intervention is not needed, and the crushing and grinding device is simpler.

Owner:SUZHOU GUTESI ELECTRONICS TECH

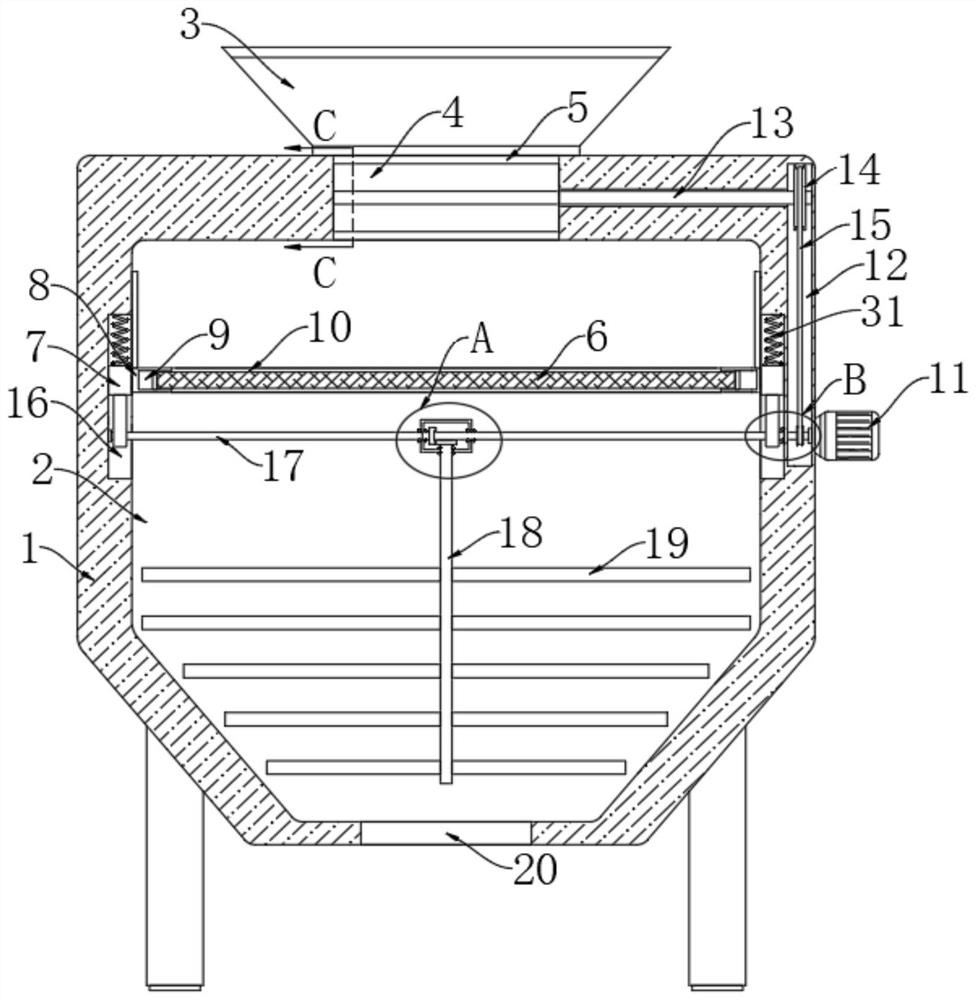

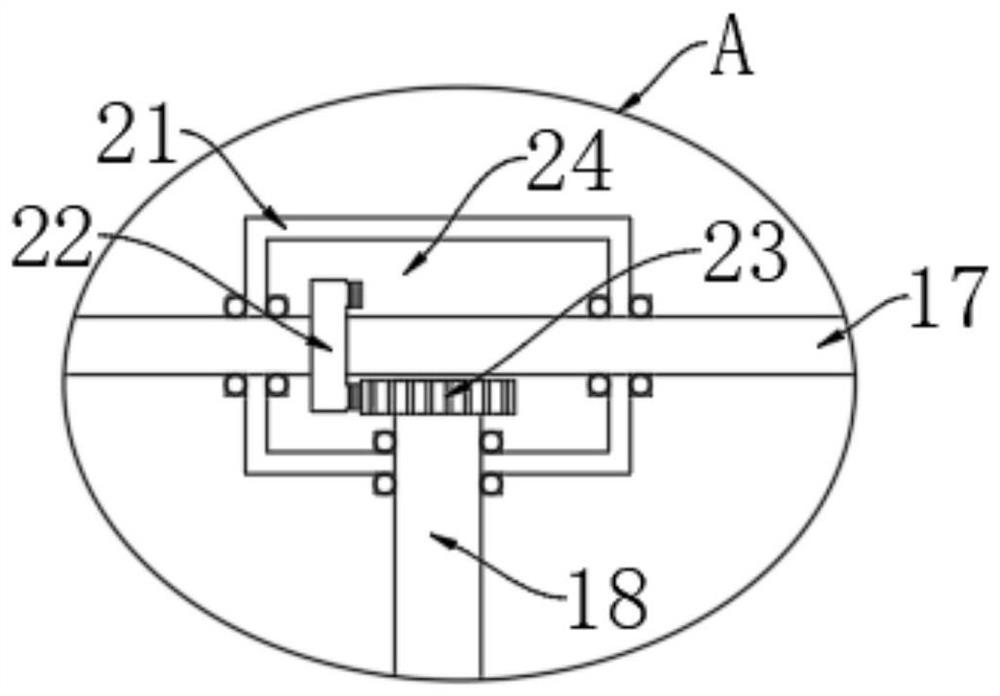

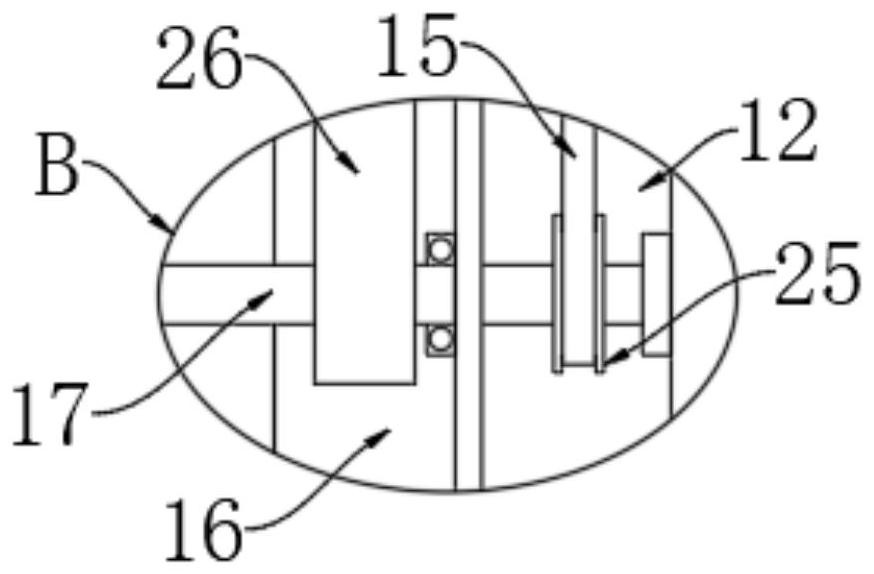

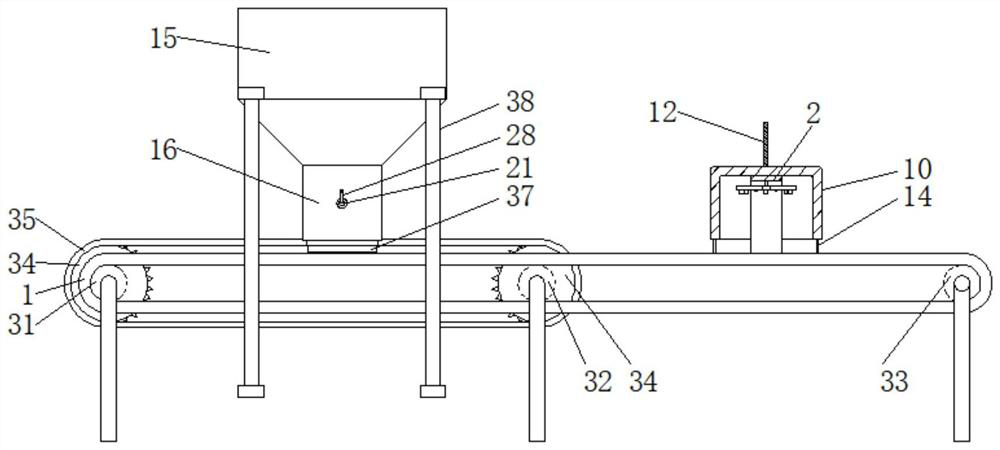

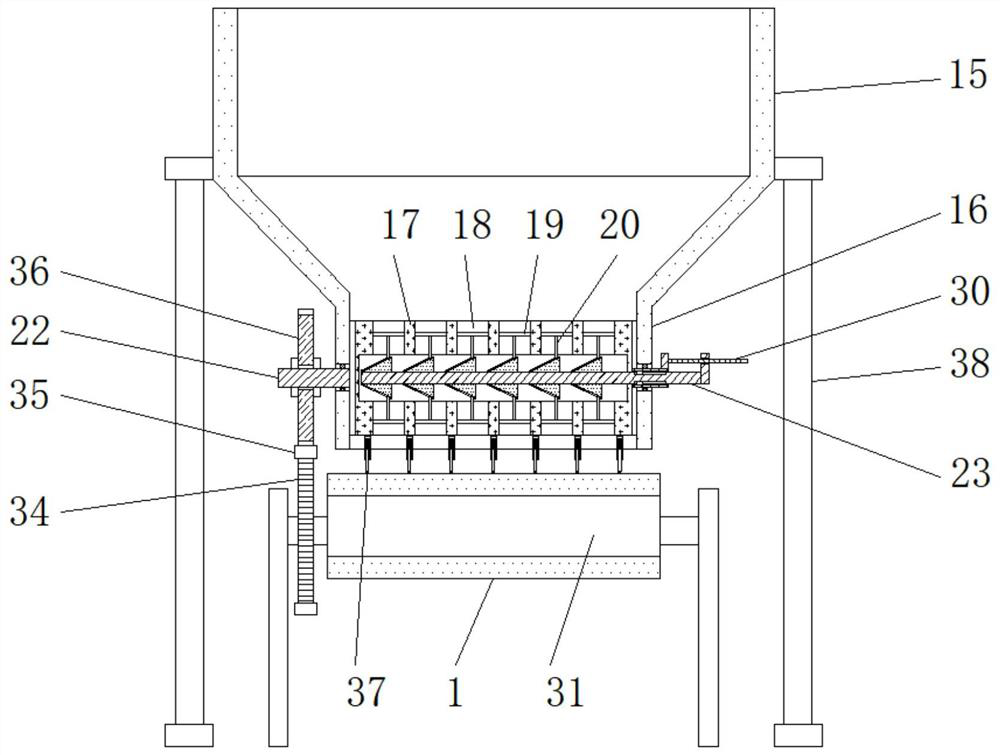

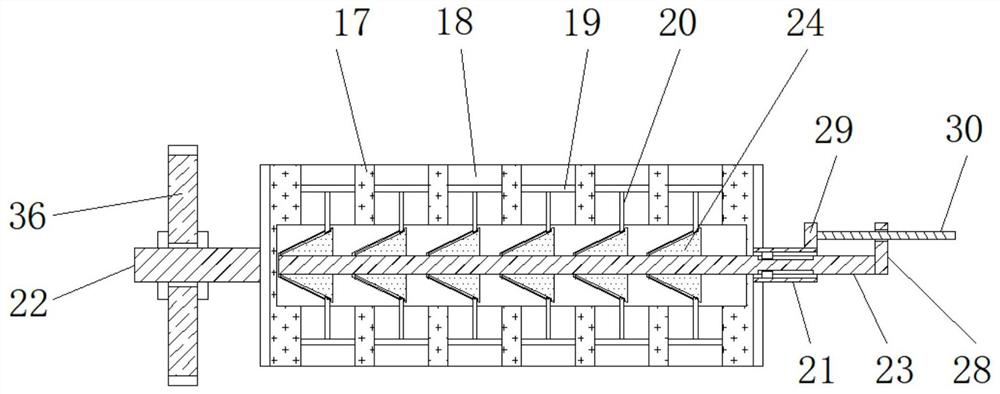

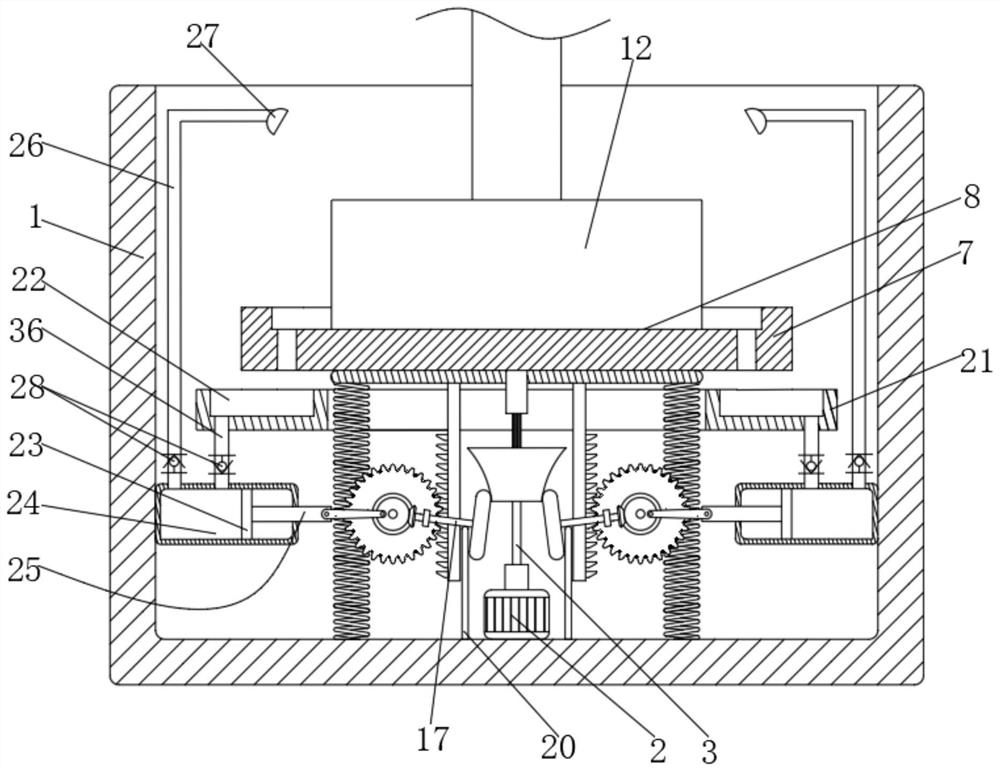

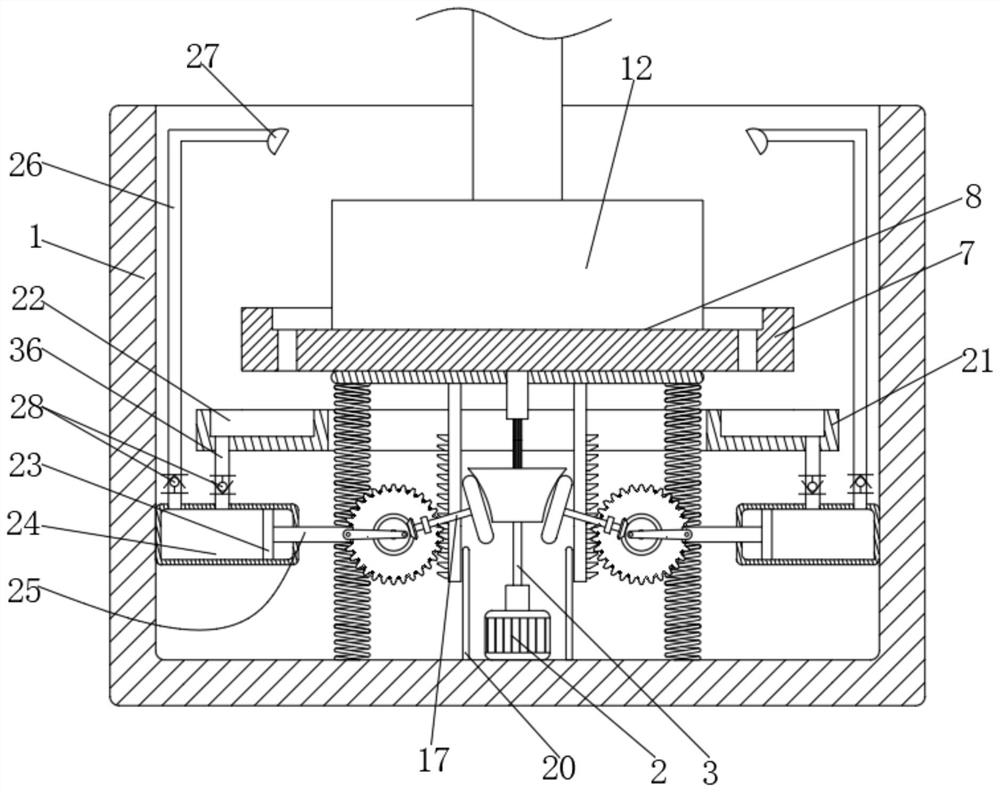

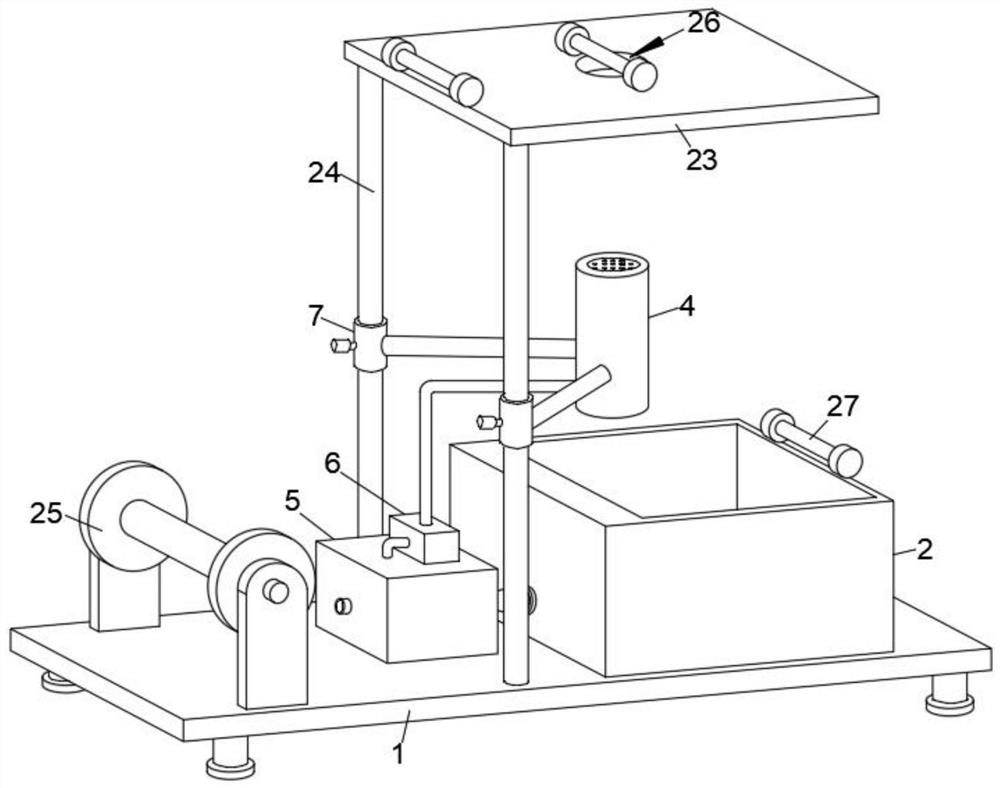

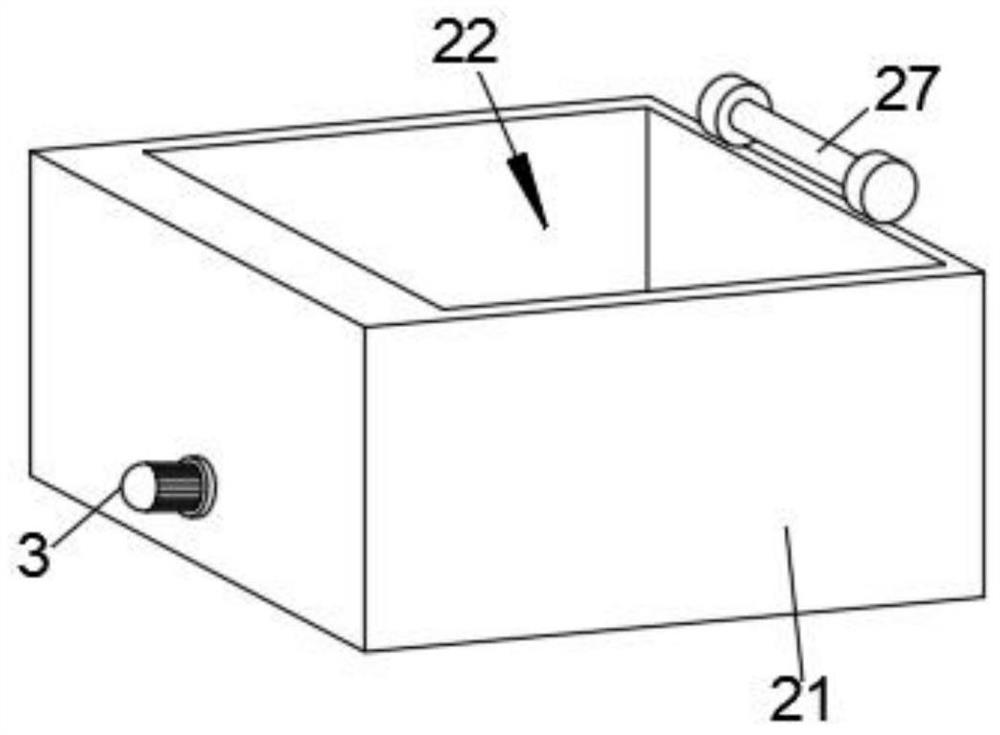

Soil screening equipment for soil remediation

InactiveCN112893428ASmall screening pressureReduce rotation speedSievingScreeningVertical vibrationSoil remediation

The inventio discloses soil screening equipment for soil remediation, and the equipment comprises: a shell, in which a treatment chamber is arranged, wherein a discharging opening is formed in the inner bottom of the treatment chamber, a feeding opening is formed in the inner top of the treatment chamber, a feeding hopper is installed at the upper end of the shell and is communicated with the upper end of the feeding opening, a columnar cavity is formed in the shell, and the columnar cavity is positioned above the treatment chamber; and a vibration screening mechanism, which comprises a driving motor installed on the right side of the shell, wherein the tail end of an output shaft of the driving motor extends into the treatment chamber and is fixedly connected with a first rotating rod, and sliding grooves are formed in the inner walls of the two sides of the treatment chamber. When the screening equipment is used, only one motor is needed for driving, in the soil screening process, vertical vibration and transverse vibration can be conducted at the same time, an intermittent feeding structure is arranged, and the screening pressure of a screen can be reduced.

Owner:李海慧

Condensate water preventing type efficient kit drying device

InactiveCN112460961AReduce consumptionEasy to dryDrying gas arrangementsDrying chambers/containersPhysical chemistryEnvironmental engineering

The invention discloses a condensate water preventing type efficient kit drying device. The condensate water preventing type efficient kit drying device comprises a drying box and an electrifying mechanism, wherein a drying chamber and a rotating cavity are formed in the drying box, the rotating cavity is located below the drying chamber, heating resistance wires are installed on the inner walls of the two sides of the drying chamber, a containing frame is arranged in the drying chamber, the containing frame is composed of a plurality of porous plates, a plurality of kits are placed in the containing frame, and the electrifying mechanism comprises a power generation groove formed in the inner wall of one side of the drying chamber. When the condensate water preventing type efficient kit drying device is used for drying the kits, heat generated by the heating resistance wires can be quickly dispersed in the drying chamber, humid air formed by water evaporation is treated at the same time, and therefore the kits can be quickly dried.

Owner:李银玲

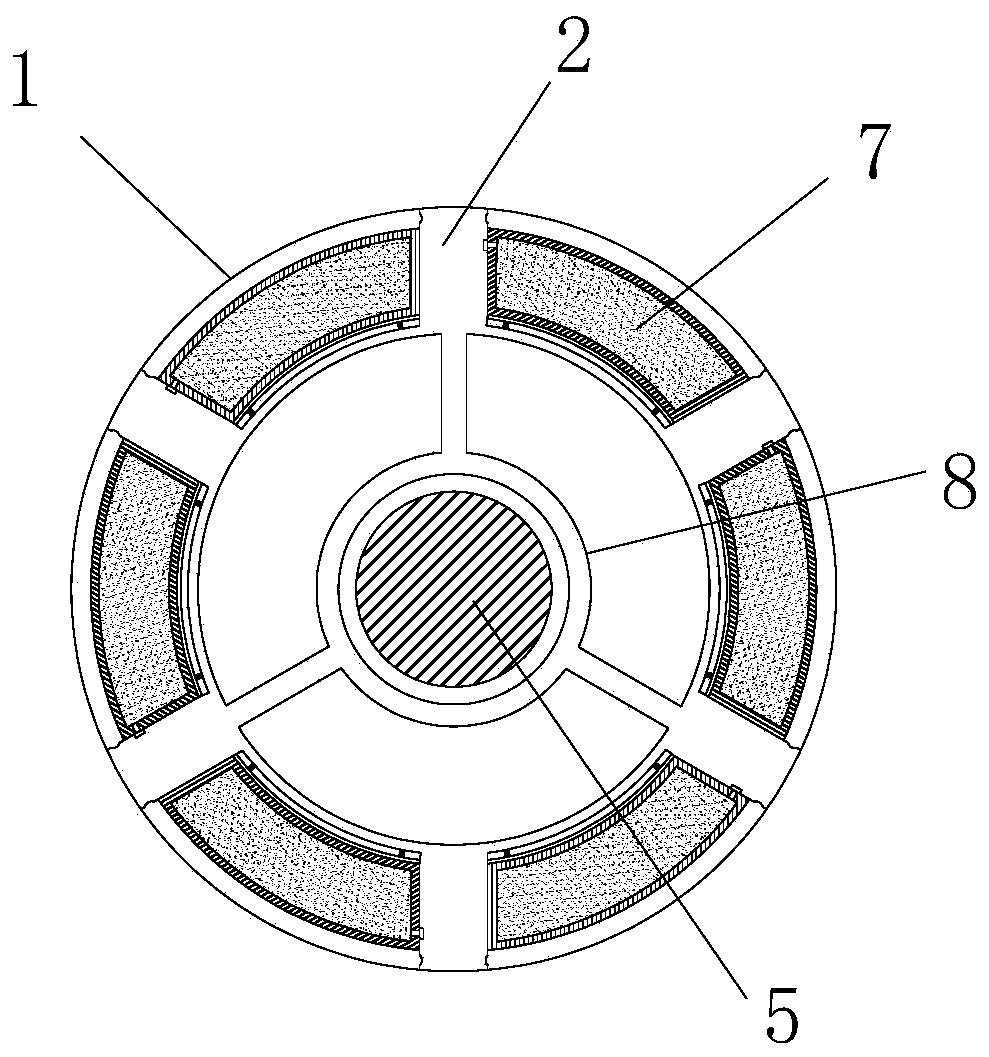

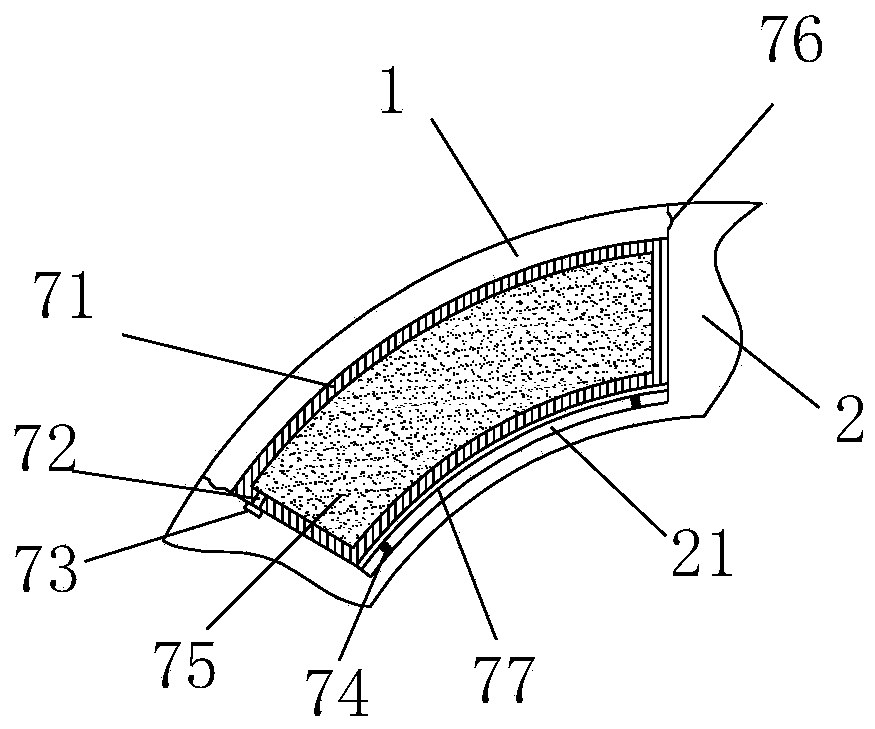

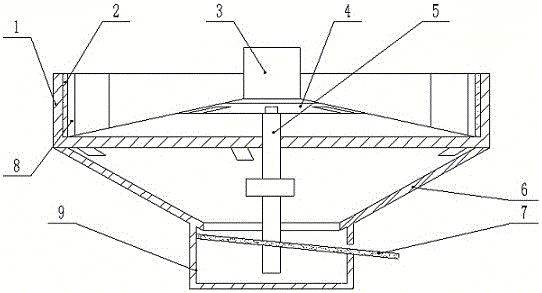

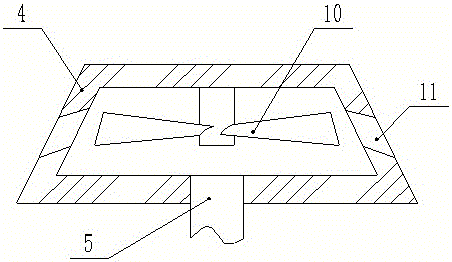

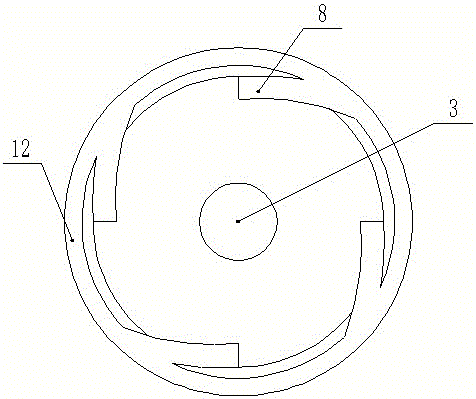

Rotary-cylinder rotor engine

InactiveCN102536447AHelpful in solving lift problemsSolve the lift problemInternal combustion piston enginesEngineeringCylinder block

The invention relates to an engine and discloses a rotary-cylinder rotor engine, which comprises a shell and a rotor, and is characterized in that: the inner wall of the shell is round, an air-inlet notch and an air-discharging notch are arranged on the shell along a circumferential direction, the inner wall of the shell is provided a hole for installing a spark plug, and an inner gear ring is arranged in an end cover on the lateral surface of the shell; the rotor is of an annular structure, three cylinder bodies which are in star-shaped uniform distribution at an angle of 120 degrees are arranged in the rotor, a piston is arranged in each cylinder body, a crankshaft connecting-rod mechanism is installed at the center of the rotor, one ends of three connecting rods are installed on a connecting-rod pin on a crankshaft, and the other ends of the three connecting rods are respectively connected with the three pistons in the rotor; and the rotor is driven to rotate along the same direction by the crankshaft through a transmission mechanism. The rotary-cylinder rotor engine has the advantages of simple and reliable structure, intensity work doing, high power, small size, low oil consumption, small noise and small vibration and can be used for replacing ordinary reciprocating-type engines and rotor engines.

Owner:马驰成

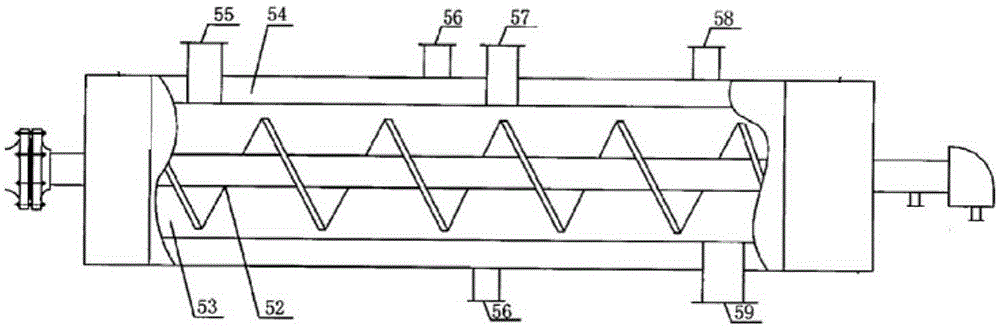

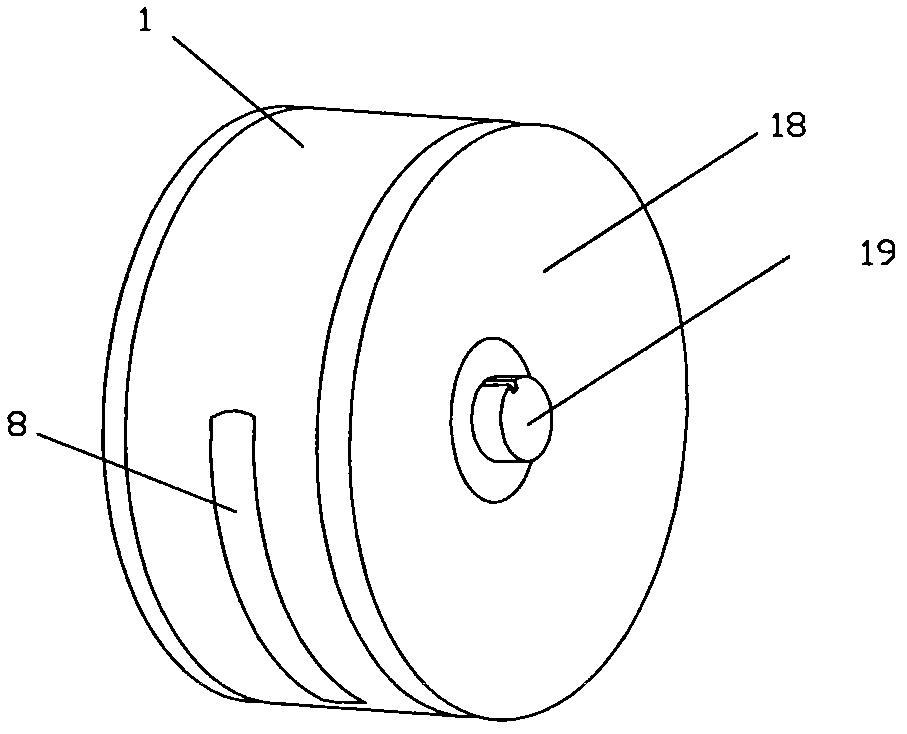

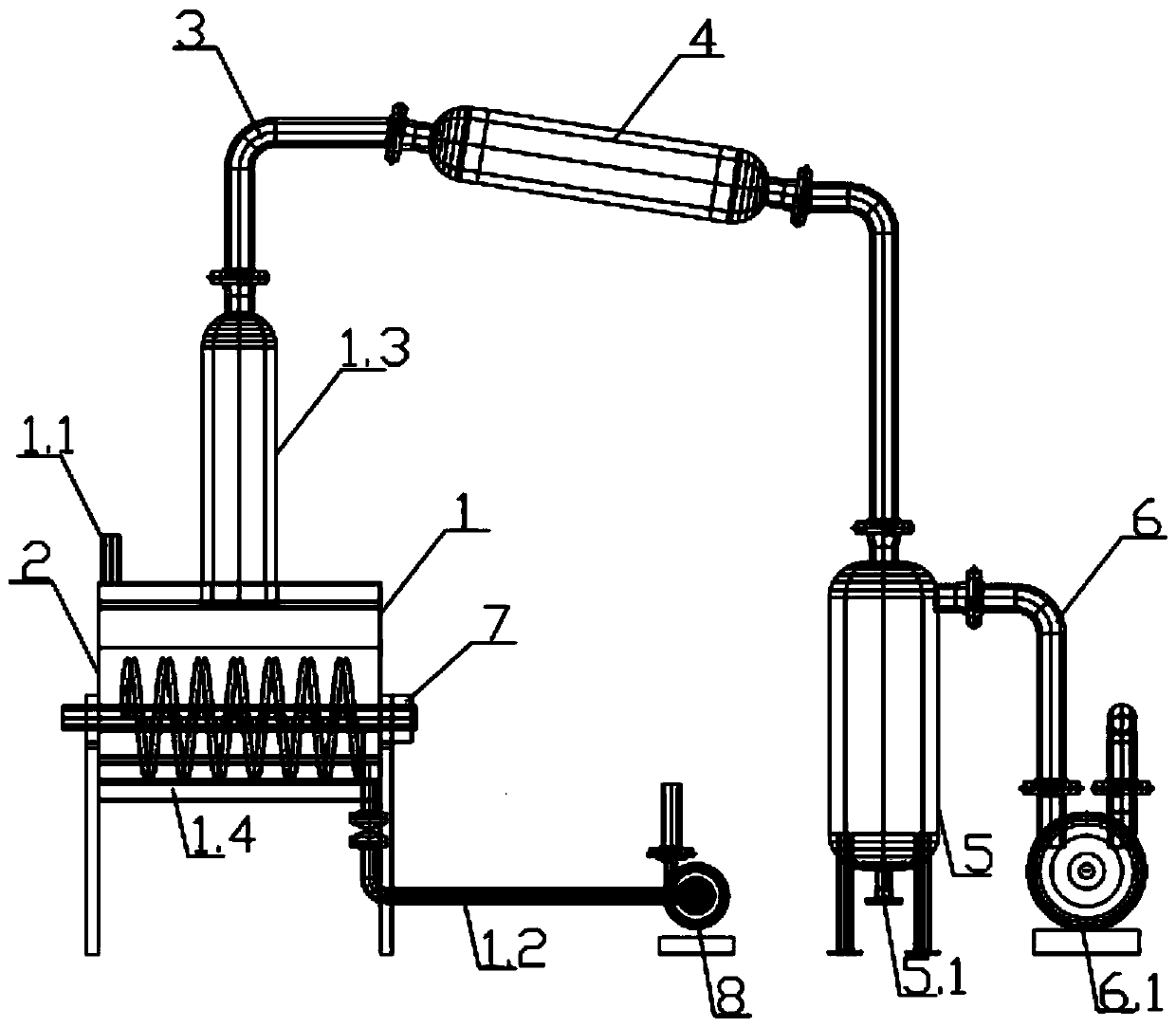

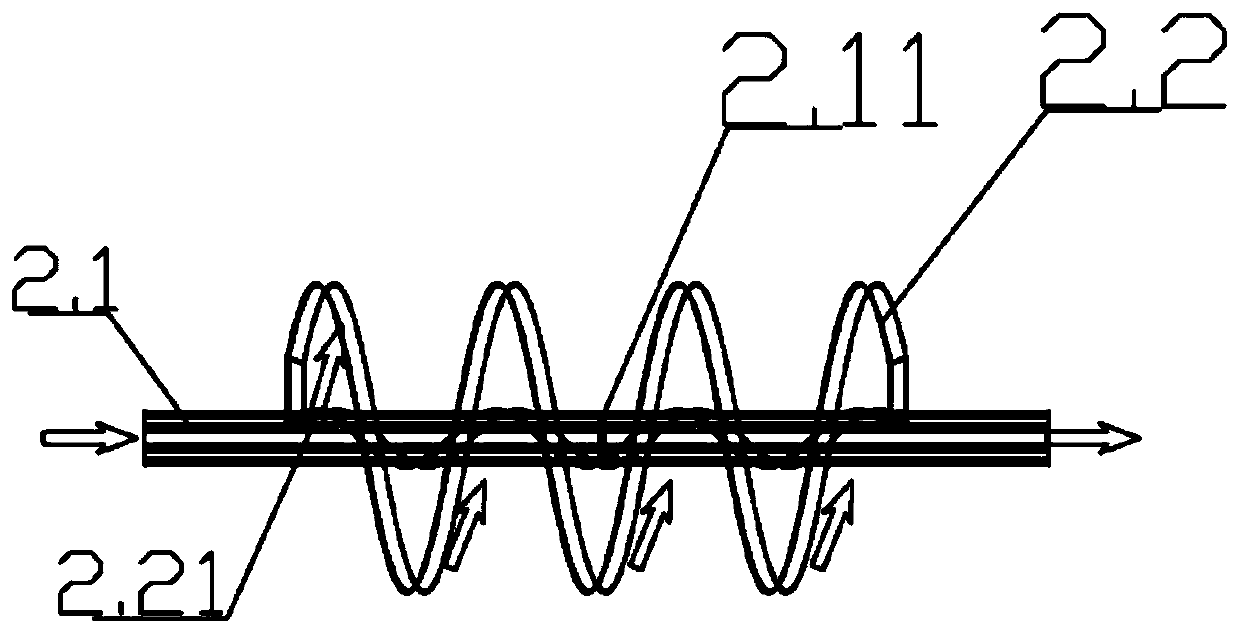

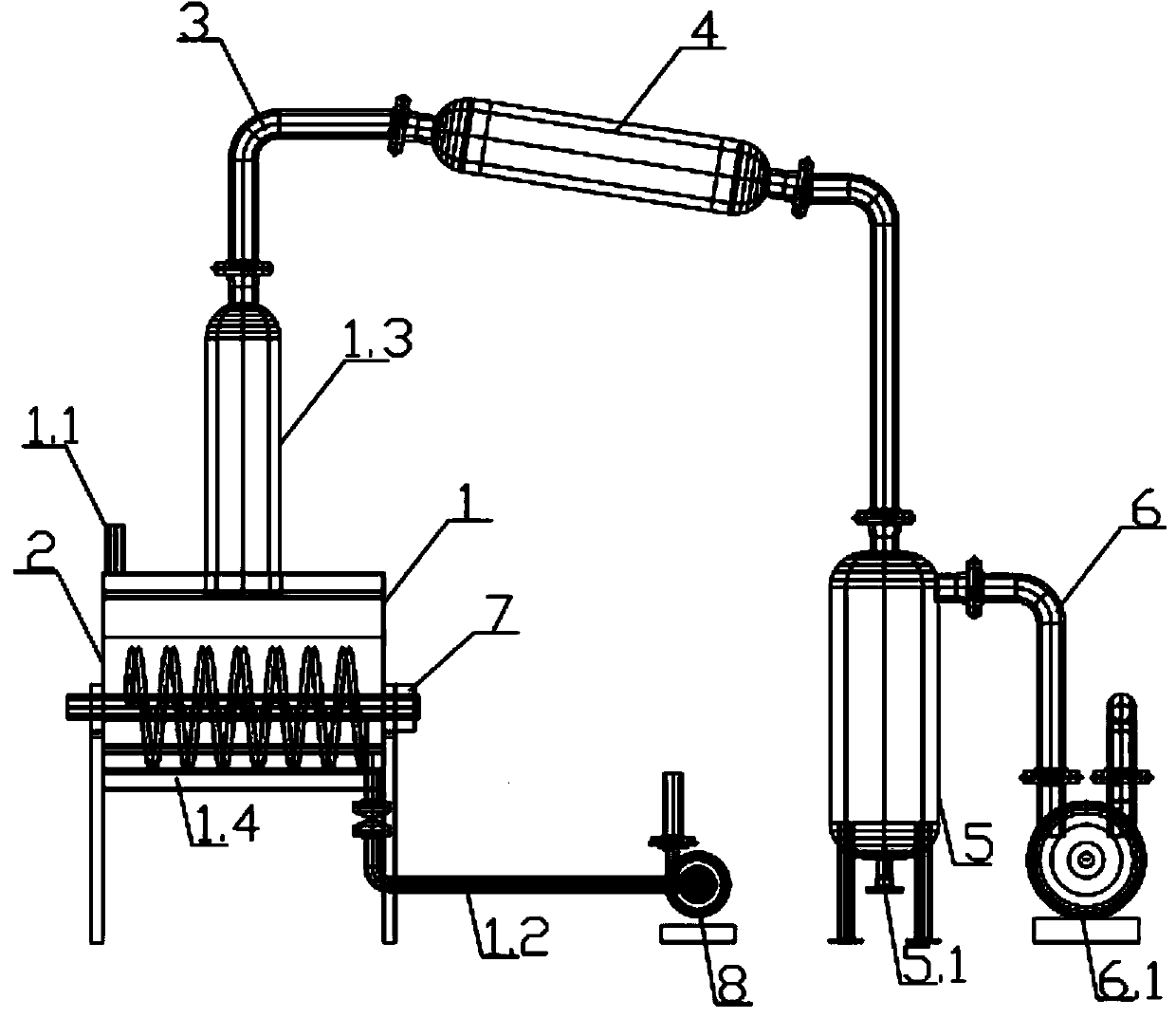

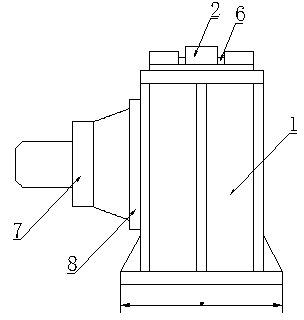

Hollow spiral-blade heating thin-film evaporator and evaporation method

PendingCN109701290AAvoid accumulation and foulingAvoid high concentrationsEvaporator accessoriesHeat transfer efficiencyEvaporator

The invention discloses a hollow spiral-blade heating thin-film evaporator and an evaporation method. The hollow spiral-blade heating thin-film evaporator comprises a heating evaporation tank; a feeding pipe is arranged on the upper tank wall of the heating evaporation tank; a discharging pipe is arranged under the lower tank wall of the heating evaporation tank; a hollow spiral-blade heating device is arranged in the heating evaporation tank; the hollow spiral-blade heating device comprises a hollow rotary shaft tube arranged at two ends of the heating evaporation tank through bearing blocks;the transmission end of the hollow rotary shaft tube is provided with a speed reducing motor; an intercepting plate is arranged in the middle of the hollow rotary shaft tube; the outer wall of the hollow rotary shaft tube is provided with a hollow and continuous spiral blade; and two end openings of the spiral blade are respectively arranged at two ends of the intercepting plate and communicate with the hollow rotary shaft tube. Ultralow-temperature evaporation and high-viscosity evaporation are realized through a method of carrying out liquid ultralow-temperature evaporation and high-viscosity evaporation by utilizing the hollow spiral-blade heating thin-film evaporator, and the characteristics of high heat transfer efficiency and good material uniformity are achieved.

Owner:WUHAN MEIWEIYUAN BIOLOGICAL ENG LTD

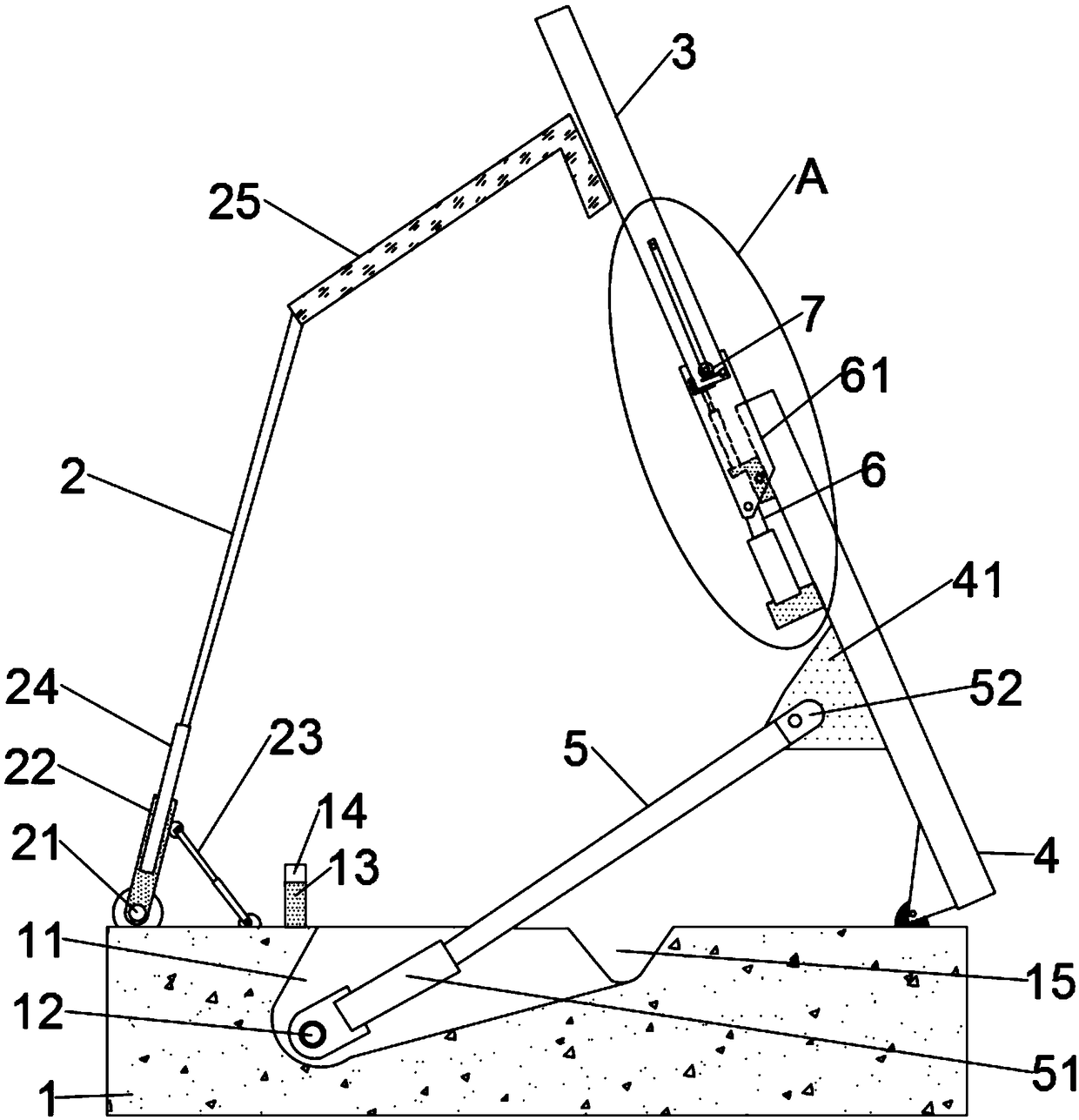

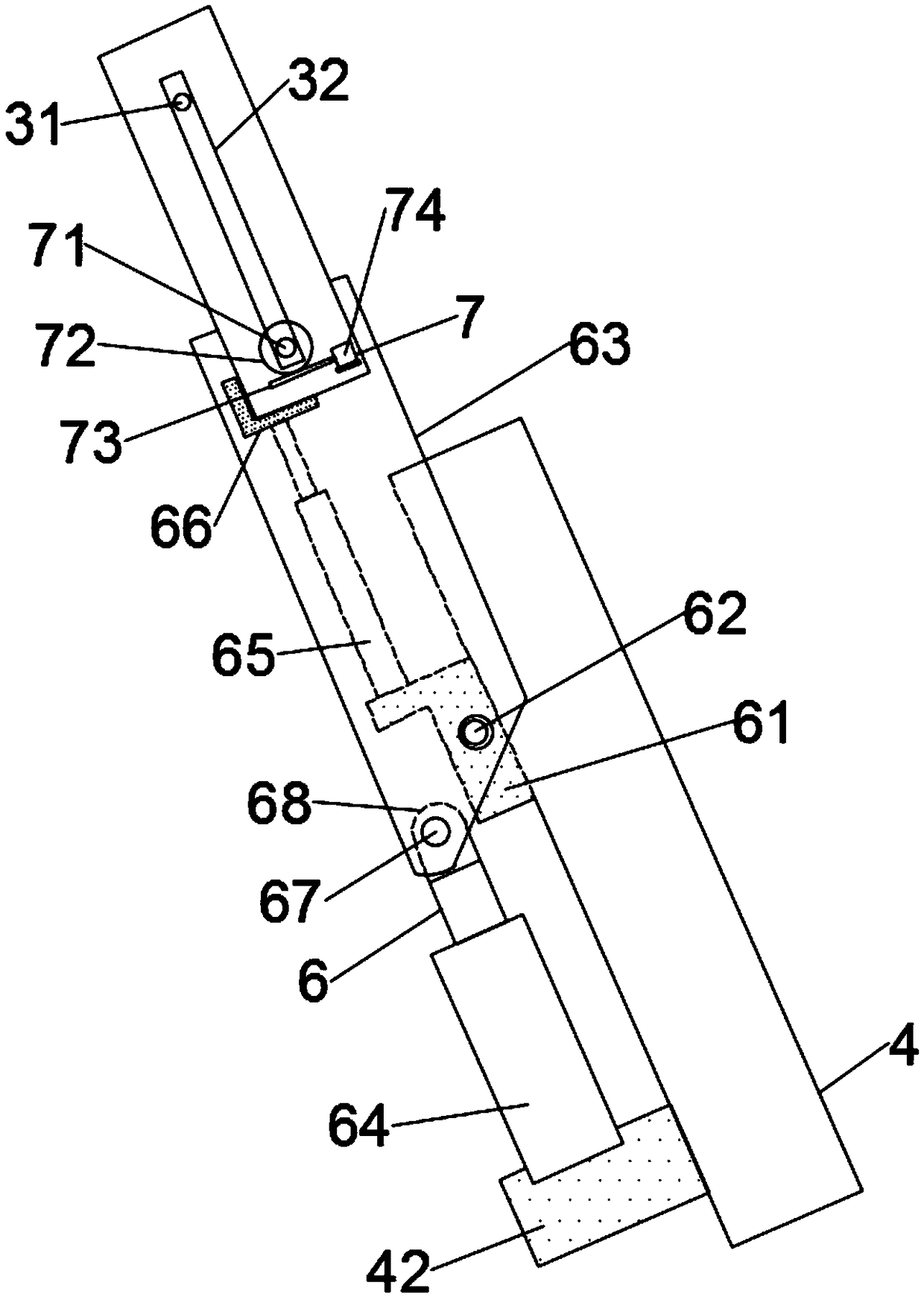

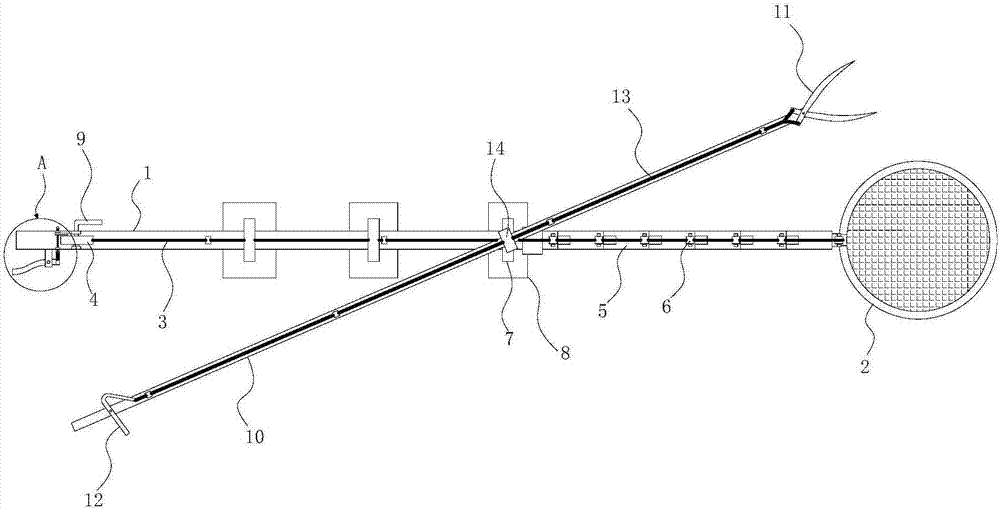

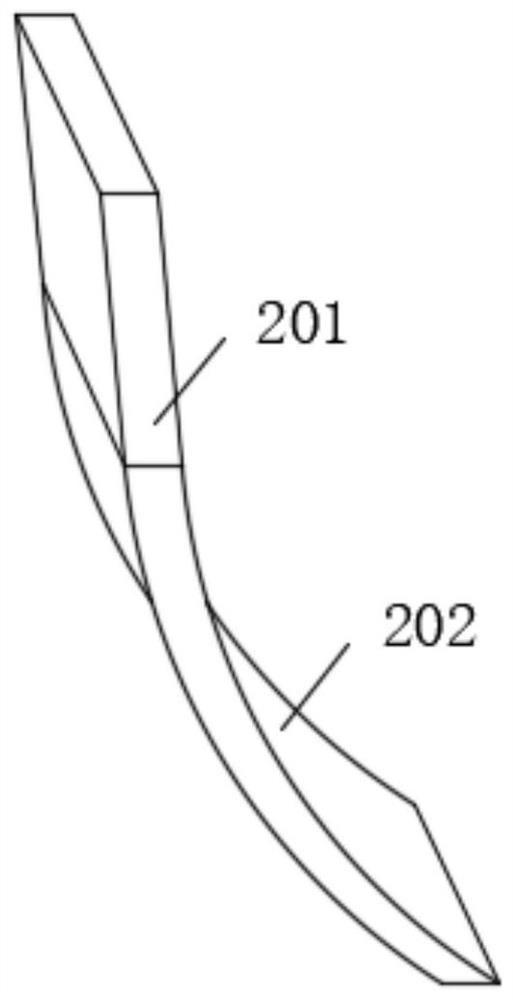

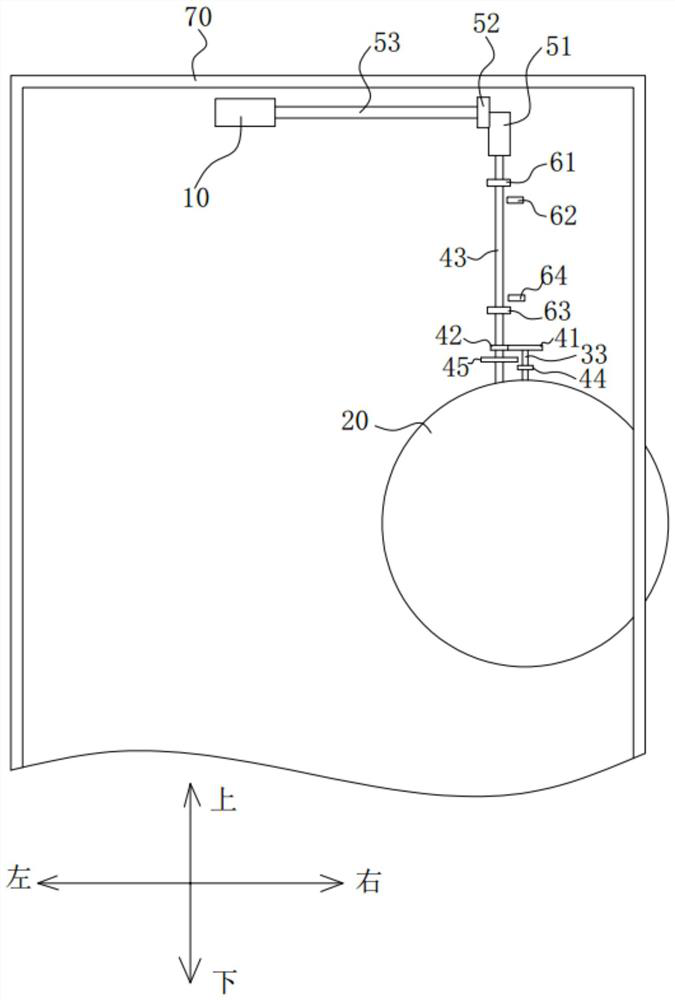

High-level jack fruit picking device

The invention relates to a high-level jack fruit picking device which comprises a net bag rod and a shear rod, wherein the net bag rod and the shear rod are respectively connected with a net bag rod supporting plate and a shear rod supporting rod in a sliding manner; the shear rod supporting rod is rotationally connected with the net bag rod supporting plate; the net bag rod supporting plate is rotationally connected with a fixing sleeve; a reel is arranged at one end of the net bag rod; a multi-section hinged rod is arranged at the other end of the net bag rod; a hinge of the hinged rod is aspring hinge; a net bag is arranged outside the hinged rod; a net bag rope is connected between the net bag and the reel; two ends of the shear rod are respectively hinged with a shear and a drive handle; and the shear and the drive handle are connected by a shear connecting line. One end of the high-level jack fruit picking device is erected on branches of a jack fruit tree by the picking staff,and the other end of the device is operated on the ground, so that jack fruits can be picked. The device disclosed by the invention is simple in structure, convenient to operate and low in cost, and is particularly suitable to be used by a family with one or two jack fruit trees.

Owner:柳州市金升汽车配件有限公司

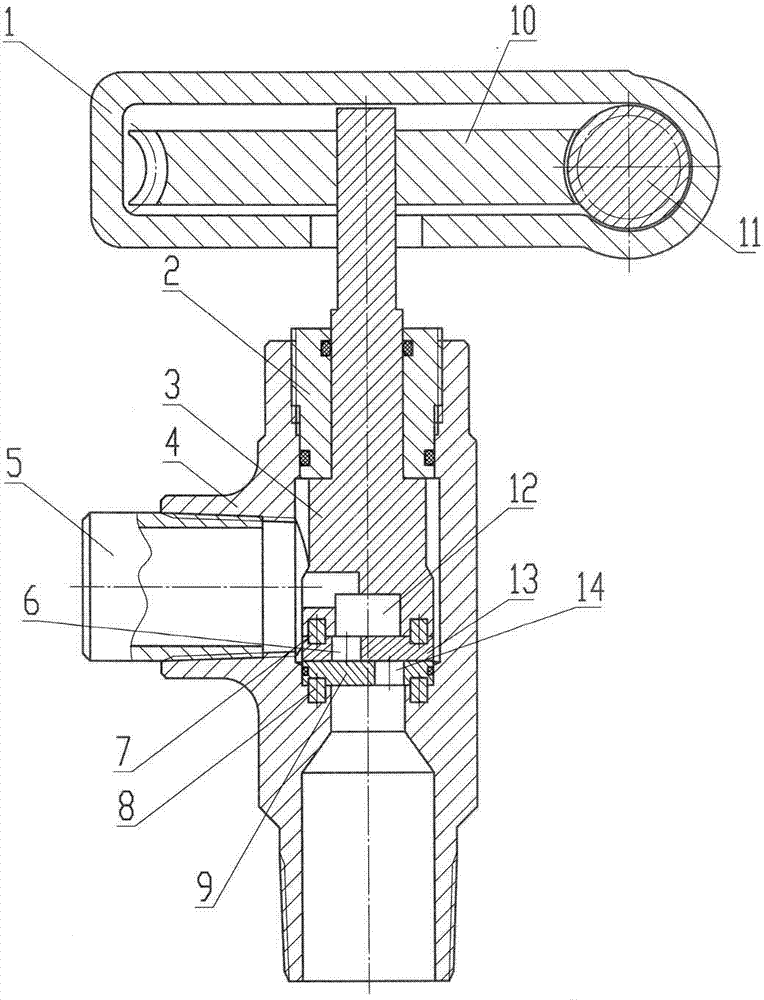

Flow control valve for test of electric submersible centrifugal oil pump units

ActiveCN103115176ASlow rotationRotates slowly and saves effortOperating means/releasing devices for valvesEqualizing valvesEconomic benefitsControl valves

Owner:CHINA PETROLEUM & CHEM CORP +1

Traditional Chinese medicine composition for control of laying hen fatty liver syndrome and preparation method thereof

InactiveCN104800746ASlow rotationWon't happenOrganic active ingredientsDigestive systemFatty liverBetaine

The invention relates to a composition for control of laying hen fatty liver syndrome and a preparation method thereof. The composition comprises the following components by weight: 20 parts of Alisma, 5-40 parts of the root of red-rooted salvia, 5-25 parts of radix bupleuri, 5-10 parts of turmeric, 1-2 parts of vitamin E and 1-2 parts of betaine. The composition provided by the invention has significant effects of promoting fat metabolism, inhibiting fat accumulation in the liver and increasing bile excretion, can effectively alleviate and reduce the incidence of fatty liver syndrome and improve egg production efficiency of laying hens.

Owner:TIANJIN JIACHUANG BIO TECH

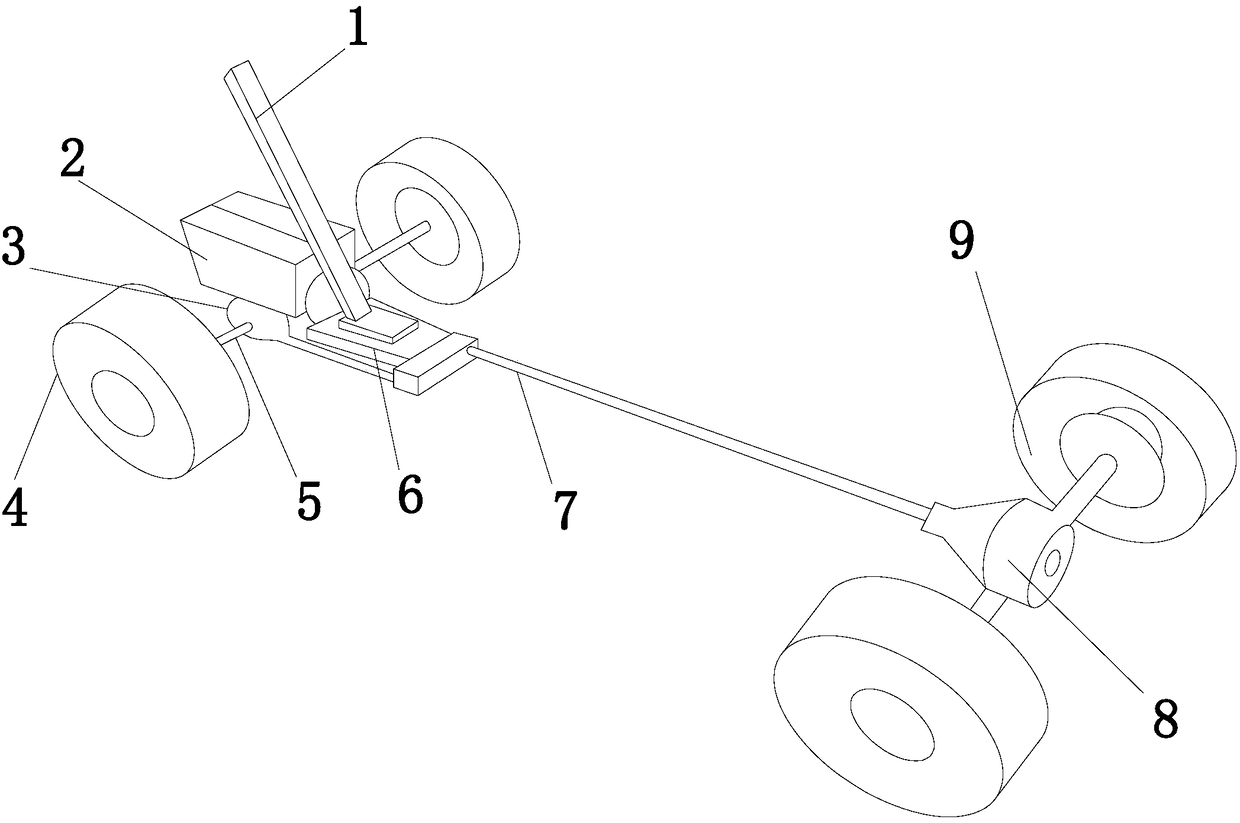

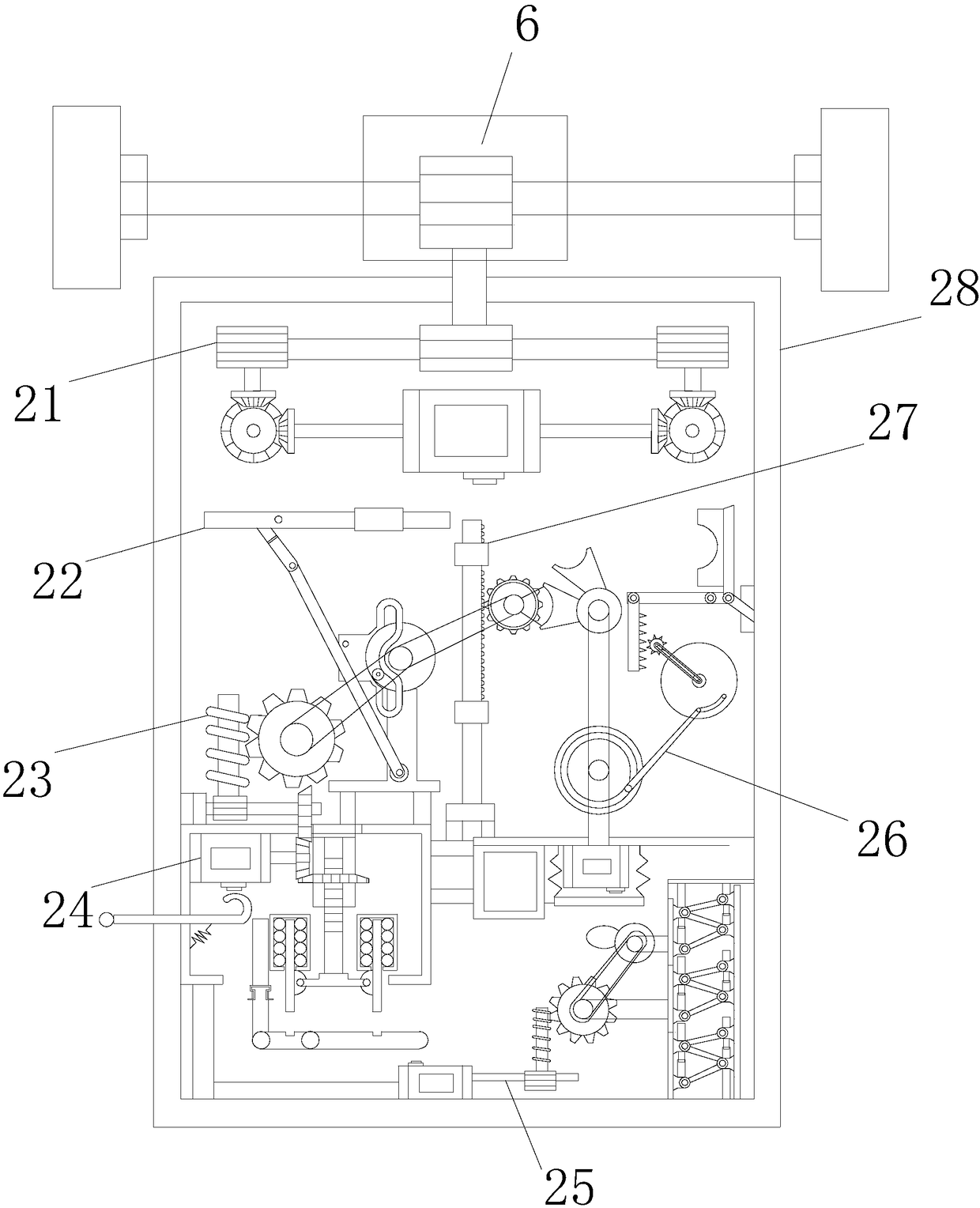

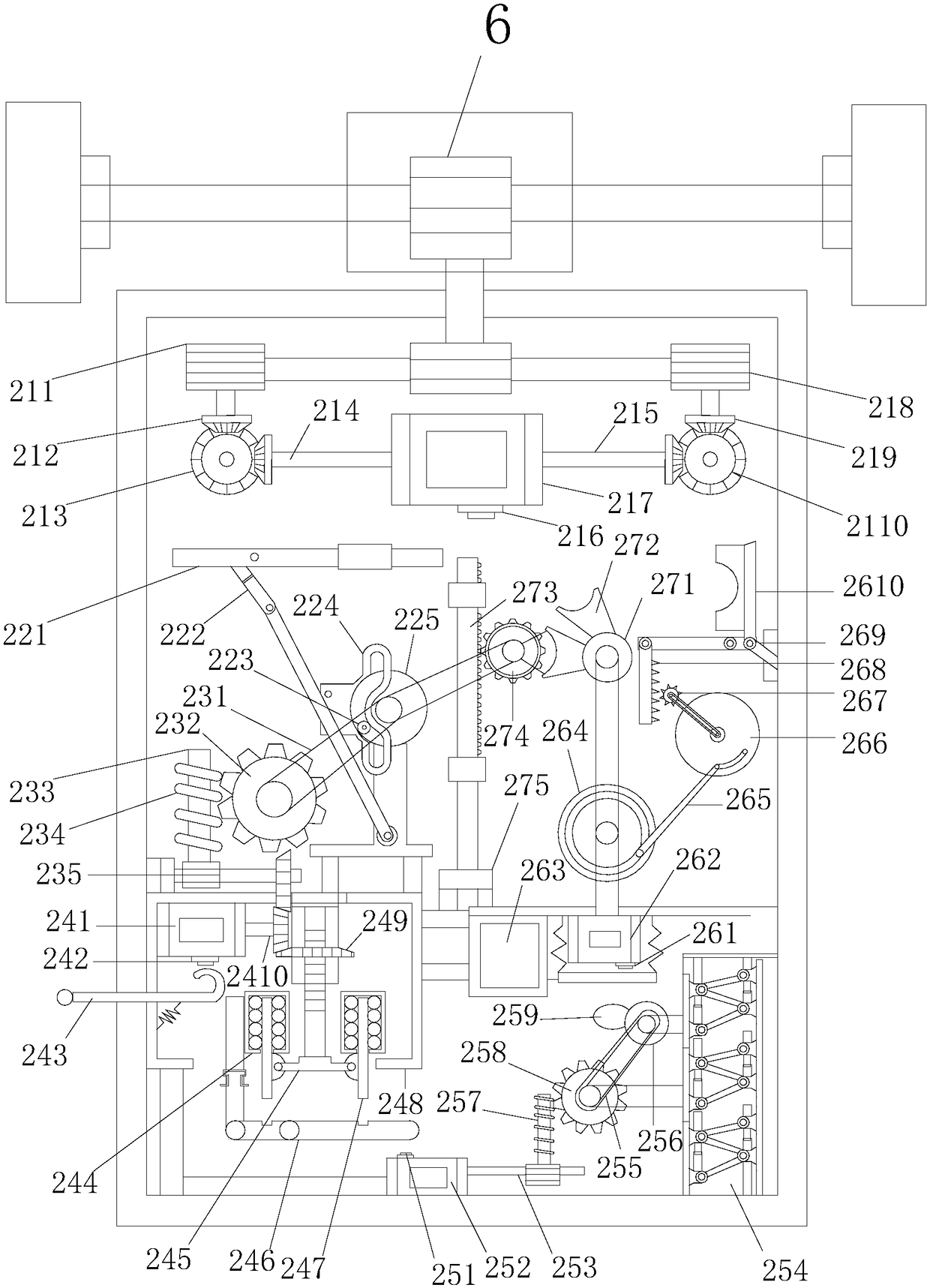

Idling driving force adjusting device

The invention discloses an idling driving force adjusting device, which structurally comprises an adjusting rod, a driving force controlling mechanism, a front differential mechanism, a front runningwheel, a connecting bearing, a front driving shaft, a rear driving shaft, a rear differential mechanism and a rear running wheel; the adjusting rod is fixed above the front driving shaft through a screw, the front driving shaft is fixed at the left side of the rear driving shaft through a screw rod, the front differential mechanism is mechanically connected to the left side of the front driving shaft, the driving force controlling mechanism comprises a gear mechanism, a sliding bar mechanism, a driving mechanism, a start mechanism, a linking mechanism, a transmission mechanism, an ejection mechanism and a metal outer frame; the idling driving force adjusting device has the beneficial effects that through the arranged driving force controlling mechanism, the driving force can be reduced bythe driving force controlling mechanism when the device is accelerating or when the speed difference of the driving wheel and the non-driving wheel is too large, so as to reduce the slippage rate of the driving wheel, the device can stably start and accelerate, peril incident of cars caused by slipping of the driving wheel can be avoided, and the safety and practicability of the idling driving force adjusting device are improved.

Owner:莆田市超逸贸易有限公司

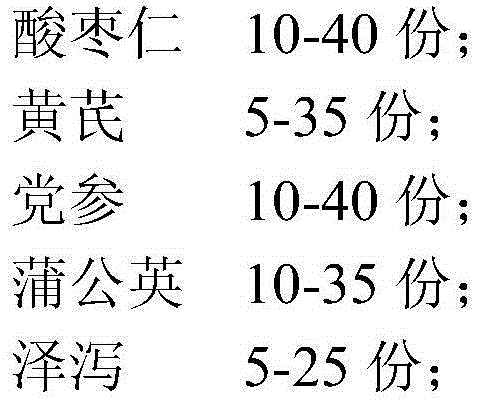

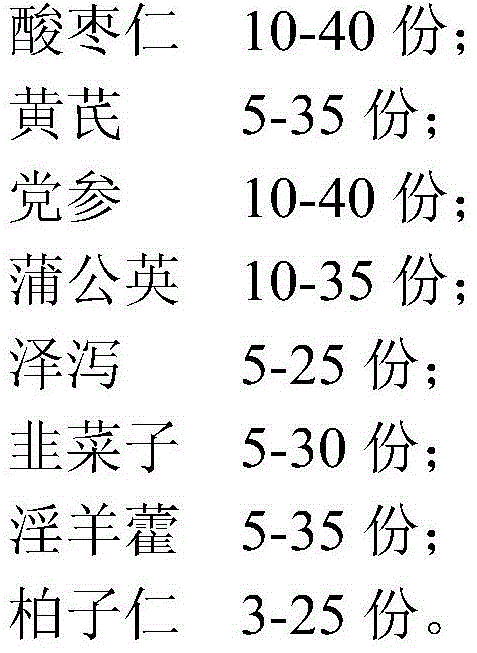

Traditional Chinese medicine composition for enhancing poultry immunity and preparation method of traditional Chinese medicine composition

InactiveCN104666790ASlow rotationWon't happenImmunological disordersPlant ingredientsSide effectCodonopsis pilosula

The invention relates to a traditional Chinese medicine composition for enhancing poultry immunity and a preparation method of the traditional Chinese medicine composition. The traditional Chinese medicine composition is prepared by carrying out superfine grinding treatment on the following raw materials: spina date seeds, astragalus membranaceus, codonopsis pilosula, dandelion, rhizoma alismatis, tuber onion seeds, herba epimedii and platycladi seeds in a heavy-load grinding manner. The particles of the traditional Chinese medicine composition are uniform in fineness; the medicinal materials are high in availability; and the traditional Chinese medicine composition is reasonable in formula, environmentally friendly, safe, and free of a toxic or side effect and medicine residue.

Owner:TIANJIN ZHONGAO BIOTECH

Axial-flow pump with anti-blocking function

ActiveCN113357161AEliminates rotational motionReduce lossesGeneral water supply conservationPump componentsAxial-flow pumpImpeller

The invention belongs to the field of axial-flow pumps, particularly relates to an axial-flow pump with an anti-blocking function, and provides the following scheme to solve the problems that existing axial-flow pumps are prone to jamming, part of the axial-flow pumps are internally provided with filter screens, but impurities under the filter screens are more and more and cannot be discharged, and then the water pumping efficiency is reduced. The axial-flow pump comprises a pump body and a connecting pipe, the connecting pipe is located below the pump body, connecting assemblies used for connection are arranged at the connecting pipe and the water inlet end of the pump body, a water inlet is formed in the bottom of the connecting pipe, and a water outlet is formed in one side of the pump body. According to the axial-flow pump, the water suction process is realized through an impeller; through arrangement of a first filter screen and a second filter screen, the filtering quality can be improved, and the pump is prevented from being blocked; through arrangement of an ash discharging port, impurities below the second filter screen can be continuously discharged, and the pump is prevented from being blocked; a guide vane can eliminate the rotating motion of water flow, and the water pumping efficiency is improved.

Owner:浙江理工泵业有限公司

Sole rotary type grinding equipment for producing shoes

ActiveCN108378471AHigh degree of polishingIncrease rotation speedGrinding carriagesShoemaking devicesFixed frameEngineering

The invention relates to grinding equipment, in particular to sole rotary type grinding equipment for producing shoes. For solving the technical problems, the invention provides the sole rotary type grinding equipment for producing the shoes, which can grind pairs of shoes without need of one pair by one pair manual operation and has higher grinding efficiency. The sole rotary type grinding equipment for producing the shoes comprises a mounting frame, a circular fixed frame, first bearing blocks, first rotating rods, a cross pole, stop levers, a sleeve, a first gear, a slowdown motor and the like; the circular fixed plate is arranged at the top of the mounting frame; the first bearing blocks are in embedded connection with the middle part of the circular fixed plate and the middle part ofthe mounting frame. According to the sole rotary type grinding equipment disclosed by the invention, the effects of grinding multiple pairs of shoes at a time without need of one pair by one pair manual operation and achieving higher grinding efficiency can be realized; an annular grinding stone and a plurality of shoe trees can be used for grinding more shoes and further the effect of improving the grinding efficiency is realized.

Owner:温州仪格制鞋机械有限公司

Steel shot quenching and collecting device

ActiveCN106755829ARealize automatic collectionSmooth rotationFurnace typesHeat treatment furnacesDraining tubeQuenching

The invention relates to the technical field of production of steel shots, in particular to a steel shot quenching and collecting device. The device comprises a quenching bath and a funnel cavity, wherein a centrifugal machine is positioned in the middle of the quenching bath; the top of the funnel cavity is fixedly connected with the bottom of the quenching bath; a frustum which is projected upwards is arranged on the bottom surface of the quenching bath; a sprinkler capable of rotating is mounted on the top of the frustum; a layer of magnets are arranged on the inner wall of the quenching bath; the bottom of the quenching bath is connected with a plurality of water draining tubes; water inlet ends of the water draining tubes are inclined in the same direction and are attached to the inner wall of the quenching bath; water outlet ends of the water draining tubes communicate with the funnel cavity; the bottom of the funnel cavity is connected with a water tank; a discharging opening is formed in a side wall of the water tank; a screen which is inclined and is abutted to the side wall of the water tank is arranged on the discharging opening; the bottom of the water tank communicates with a return pipe; a water outlet end of the return pipe communicates with the sprinkler; and a water pump is mounted on the return pipe. By the scheme, the steel shots can be collected automatically even if the centrifugal machine works continuously, and water is recycled.

Owner:南通壹选智能科技有限公司

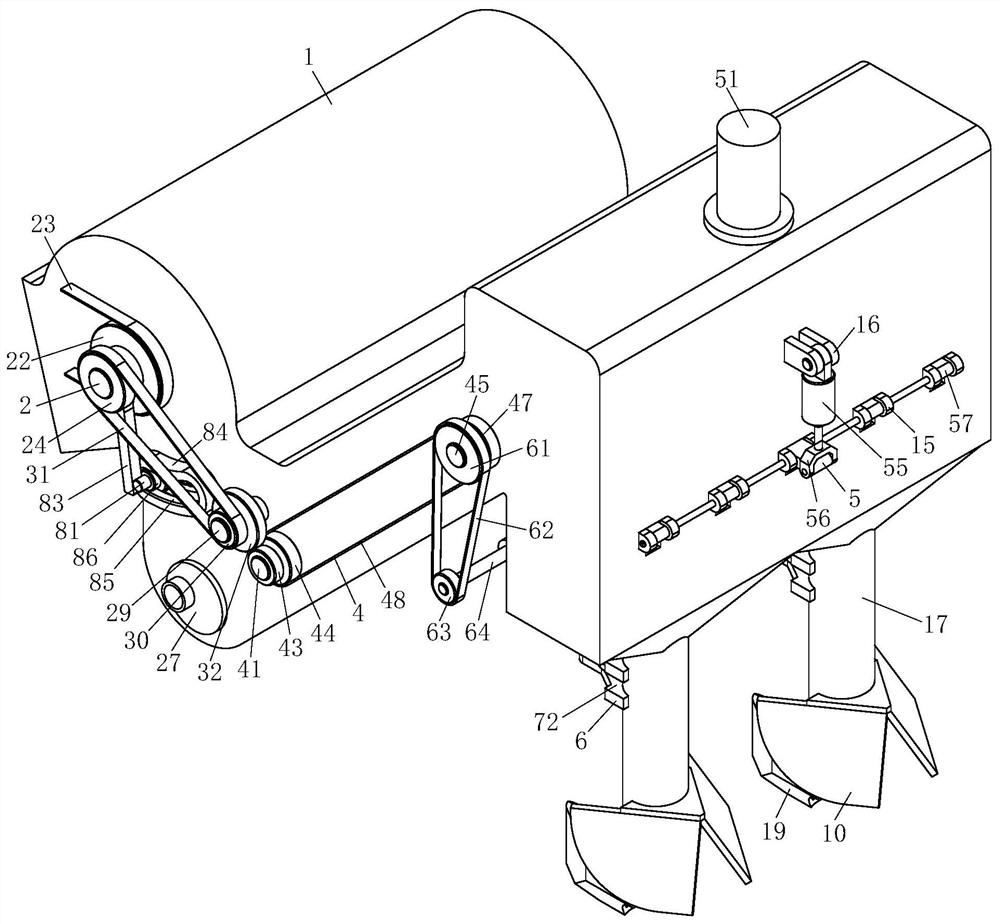

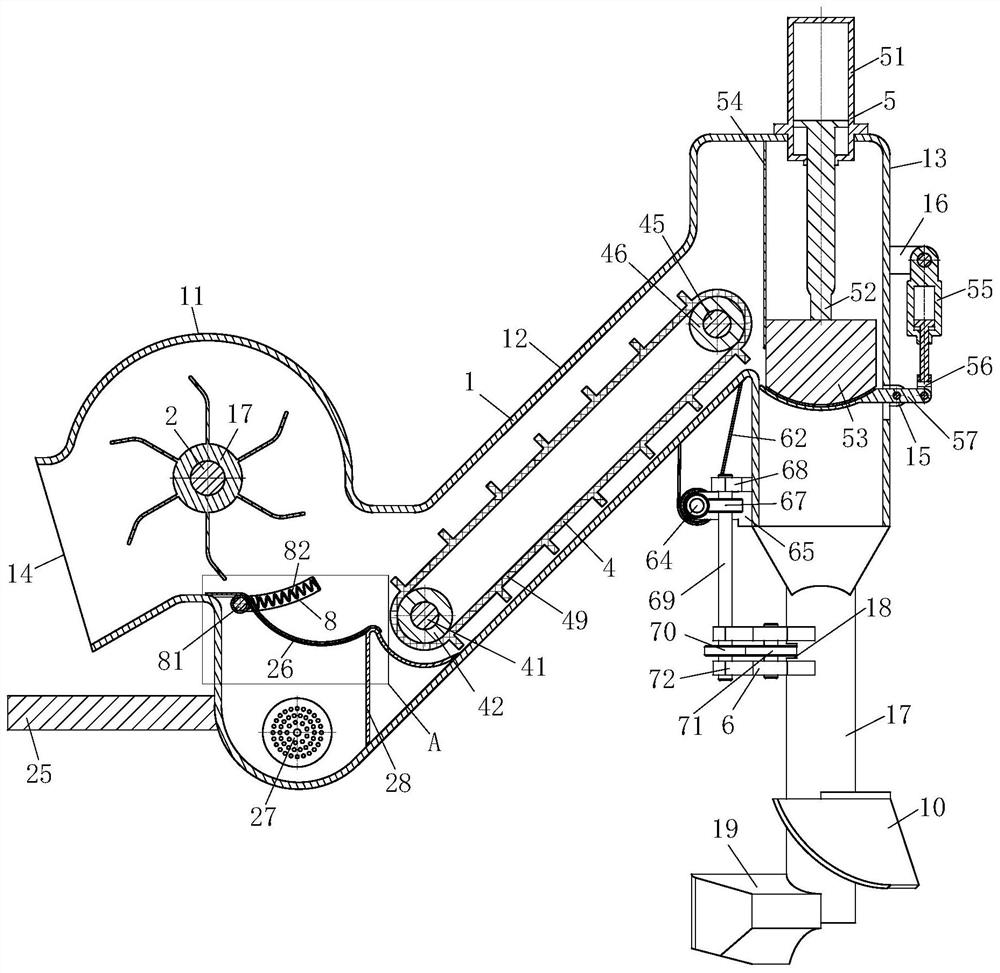

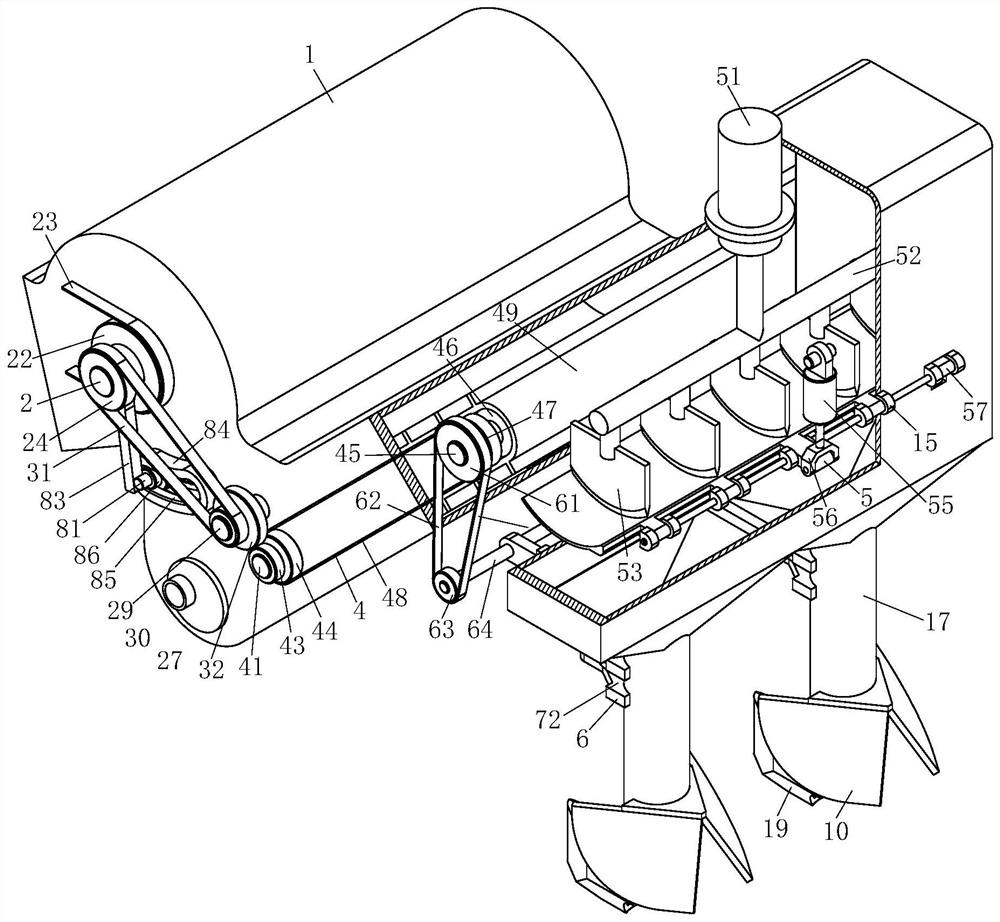

Crushing and landfilling device for floating straws of irrigated field

The invention belongs to the technical field of farm machinery and particularly relates to a crushing and landfilling device for floating straws of an irrigated field. The crushing and landfilling device comprises an enclosure, a rotating shaft I, an impeller, a belt pulley I, a belt I, a belt pulley II, a connecting rod, an elastic metallic filter screen, a water pump, a filter screen bracket, arotating shaft II, a belt pulley III, a belt II, a gear I, a conveying mechanism, a crushing mechanism and a landfilling mechanism. According to the crushing and landfilling device, the straws floating in the irrigated field can be collected, conveyed and crushed through the crushing and landfilling device, then, the crushed straws are filled underground the irrigated field in situ by using the landfilling mechanism, then, young seedlings in the irrigated field are prevented from being buried by the straws, and then, normal growth of the young seedlings is protected; and meanwhile, the strawscan be changed into a fertilizer of the young seedlings, and then, sufficient nutrients are provided for growth of the young seedlings.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

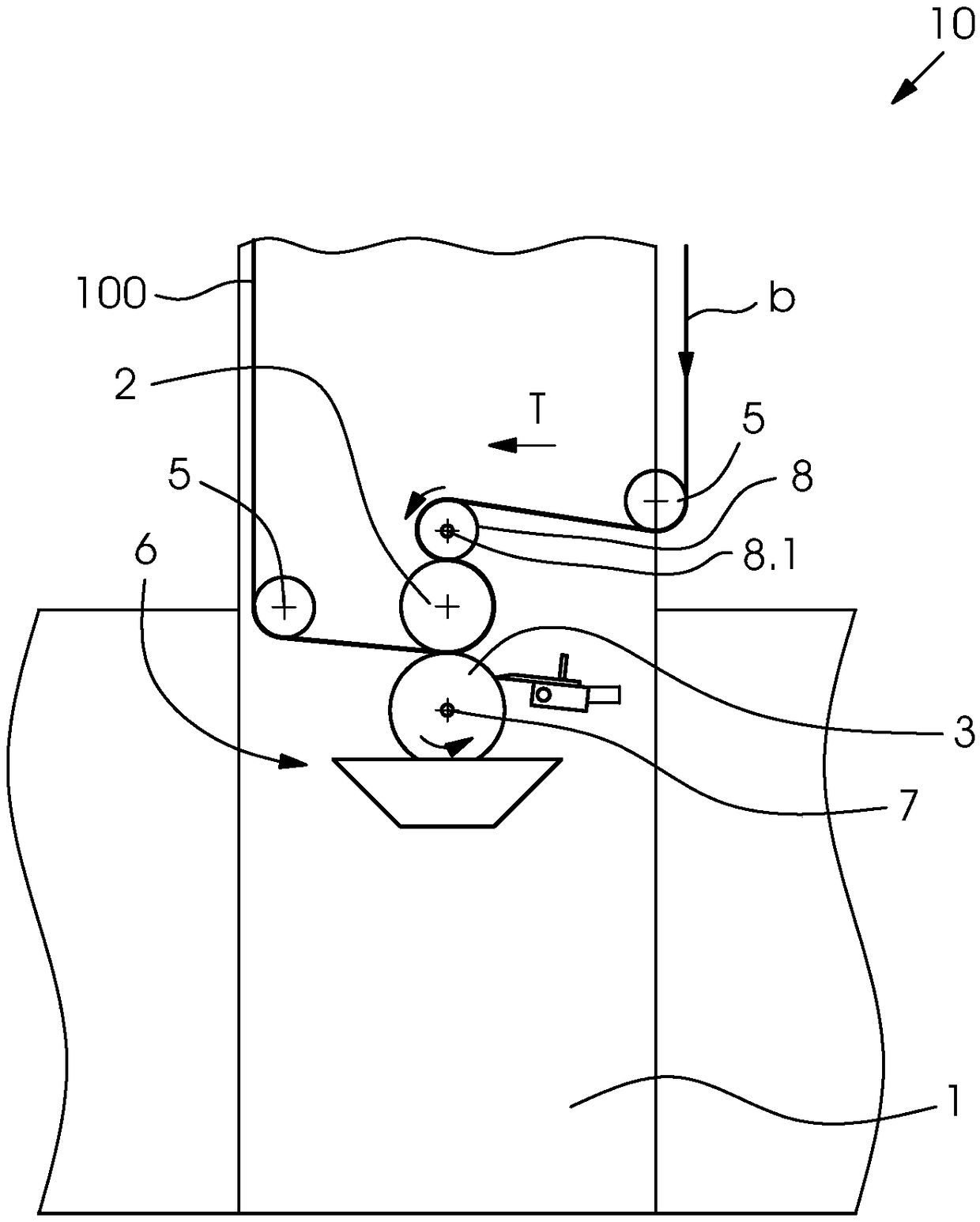

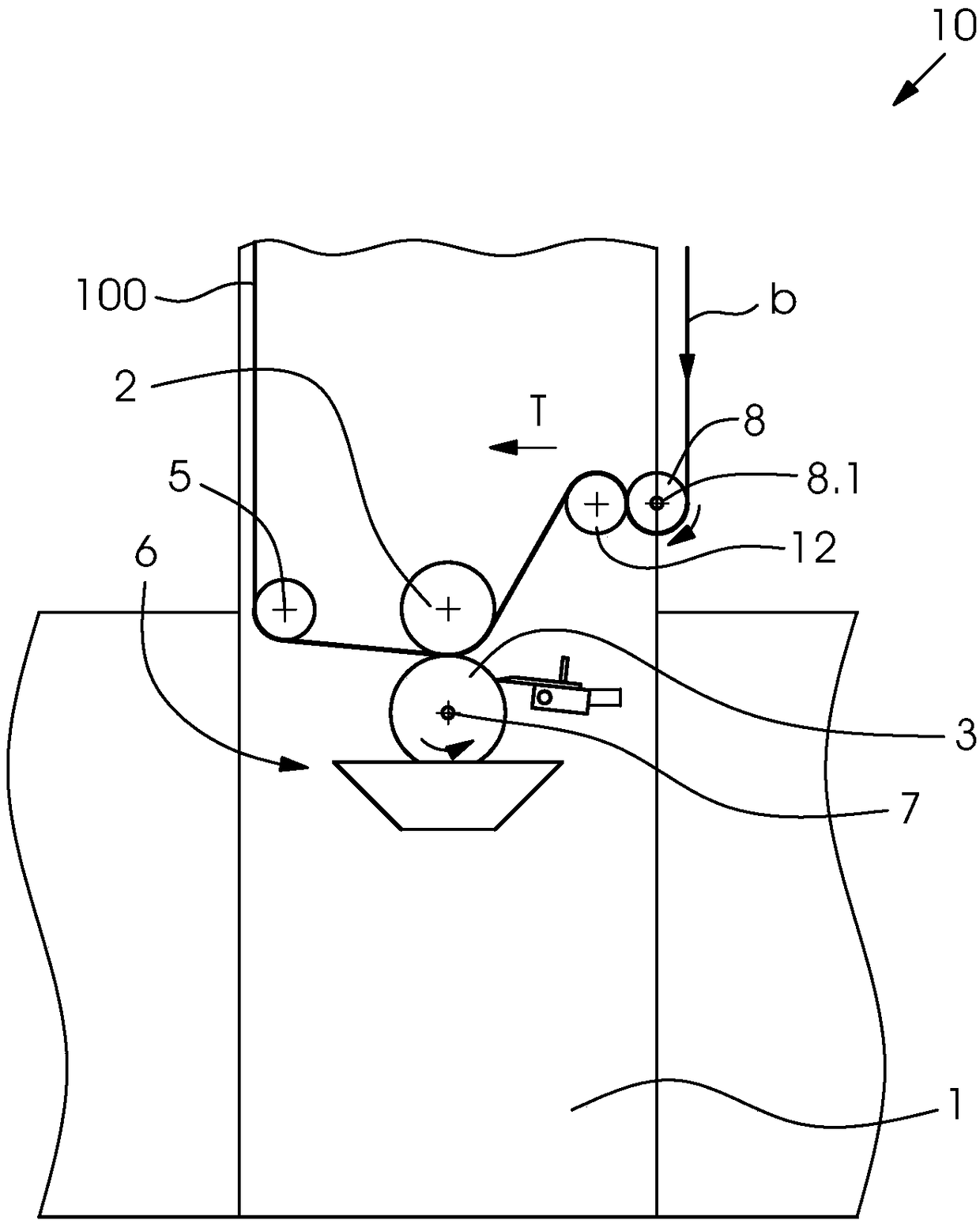

Rotogravure with snubber roll

InactiveCN109130455AEasy to adjustGood registration accuracyRotary intaglio printing pressOther printing apparatusWaste productSnubber

Owner:HEIDELBERGER DRUCKMASCHINEN AG

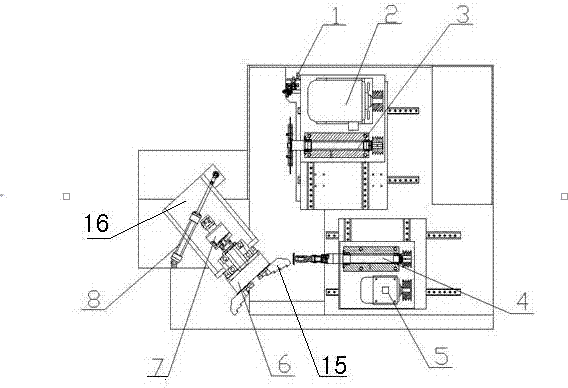

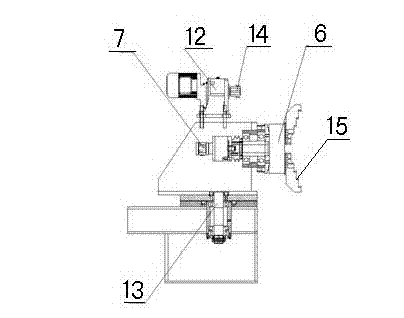

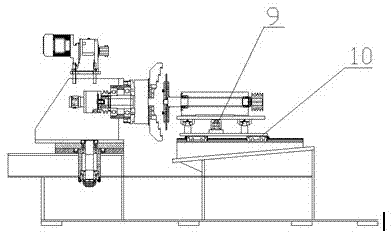

Horizontal gravity casting hub dedicated riser cutting machine

A horizontal gravity casting hub dedicated riser cutting machine comprises a fixture part, a large cutter main shaft part and a small cutter main shaft part. The horizontal gravity casting hub dedicated riser cutting machine is characterized in that the large cutter main shaft part and the small cutter main shaft part are arranged horizontally in a machine tool, the fixture part is provided with a hub, the fixture part clamps and swings or rotates the hub on the fixture part, and cutters on the large cutter main shaft part and cutters on the small cutter main shaft part respectively cut the hub according to setting. According to the horizontal gravity casting hub dedicated riser cutting machine, the double shafts adopts the design of large knives and small knives, the small knives machine hub central risers, and the large knives machine hub excircle risers. A machine tool fixture has the rotating function. The fixture rotates 40 degrees at machining time, and the fixture is made to rotate outward, so that an operator can detach the hub conveniently. The machine tool fixture rotates slowly at machining time, and is small in inertia to hub excircle risers. Moreover, a riser ring is incapable of flying out to damage the operator due to inertia when the riser ring is cut off. The defects of machine tools of other forms are eliminated.

Owner:江苏天宏智能装备有限公司

Stirring process based on solder paste production

ActiveCN107537371AFull contact timeSlow rotationRotary stirring mixersMixer accessoriesSolder pasteEngineering

The invention relates to the technical field of solder paste production and processing, and discloses a stirring process based on solder paste production. The stirring process is carried out by a solder paste stirring device which comprises a stirring barrel, a stirring shaft, a discharging box, a rack and a motor, wherein the stirring barrel is fixedly mounted on the rack; the stirring shaft is mounted in the stirring barrel; the discharging box is located above the stirring barrel and is fixedly connected with a lower part of the motor; the motor is fixedly mounted on the rack; an airbag isarranged on one side of the stirring barrel; an air cavity communicated with the airbag is formed in the stirring barrel; a dispersing mechanism is arranged on a side wall of the stirring barrel; thedispersing mechanism comprises a fixed base, a rubber bag and an extruding part; an inner cavity communicated with the air cavity is formed in the fixed base; an air outlet check valve with an air outlet toward the stirring shaft is arranged on the fixed base; the extruding part is fixedly mounted on the rubber bag; the rubber bag is communicated with the inner cavity; a material cavity communicated with the discharging box is formed in the upper part of the stirring shaft; a discharge hole is formed in the side wall of the material cavity. The stirring process provided by the invention has agood stirring effect and reduces production of bubbles of solder paste.

Owner:广东天高科技有限公司

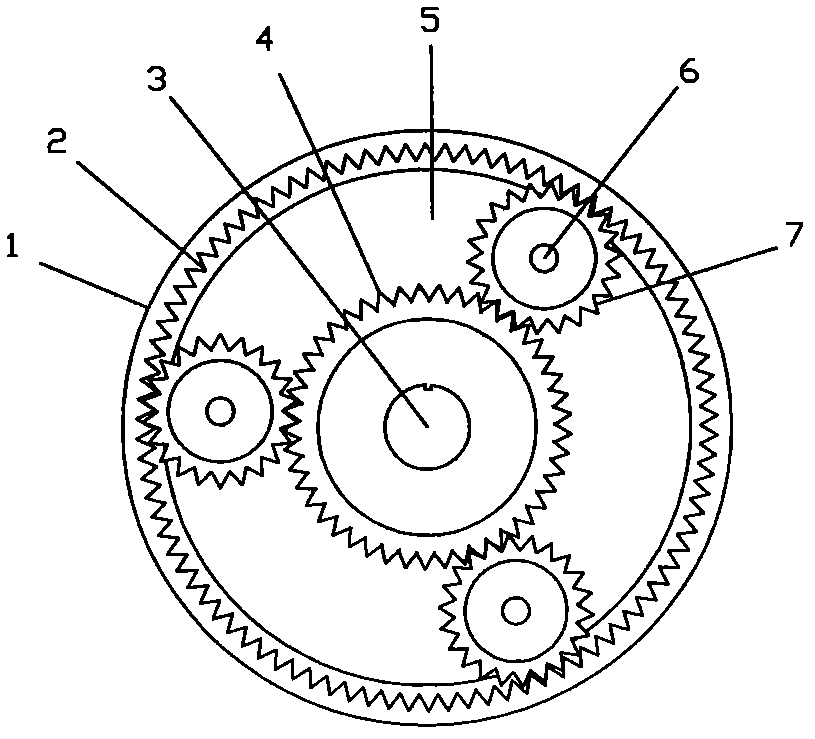

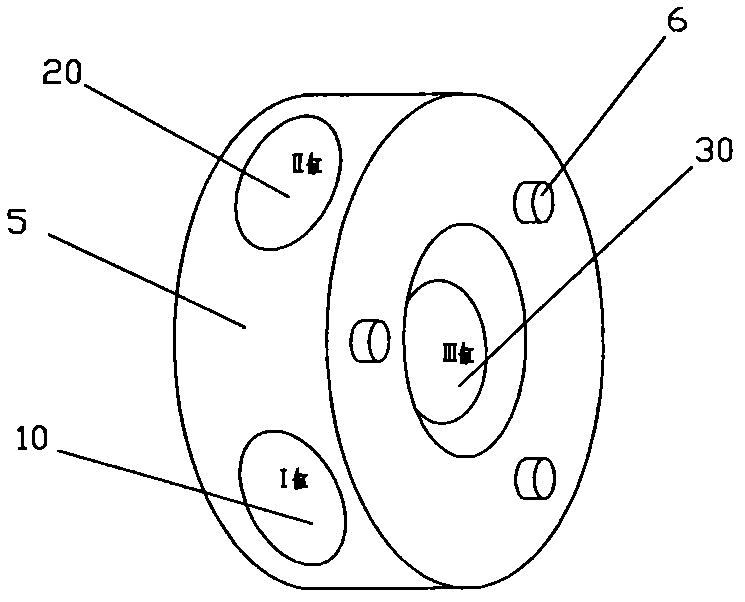

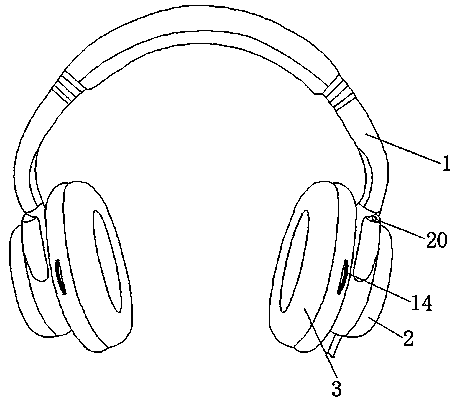

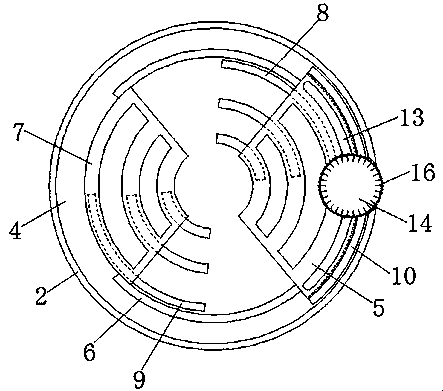

A headset that changes the frequency response parameters of the headset at low frequencies

ActiveCN109068224AChanging the frequency response parameterAdjustable frequency response parametersMicrophonesLoudspeakersEngineeringHeadphones

The invention discloses an earphone which can change the frequency response parameter of low frequency of the earphone,the earphone includes earphone connecting rings,headphone housing and cushion. The number of earphone housings is two, both ends of the earphone connecting ring are fixedly connected with the surface of the earphone housing, the inner part of the earphone connecting ring is fixedly connected with a partition plate, one side of the partition plate is slidably connected with a driving stopper ring, both ends of the driving stopper ring are fixedly connected with a connecting rod, and one end of the connecting rod far away from the driving stopper ring is fixedly connected with a driven stopper ring, which relates to the earphone technical field. The earphone can change the frequency response parameter of low frequency of the earphone, as the drive retain ring and the driven retain ring are arranged, the frequency response parameters of the low frequency of the earphone can be adjusted by controlling the shielding range, and the speed of the driving stopper ring and the driven stopper ring can be adjusted more slowly by using the transmission ratio of the gear ring and the tooth column when the rotating tooth plate is used for adjustment, thereby achieving the effect of fine adjustment and fine control.

Owner:惠州市克林声学有限公司

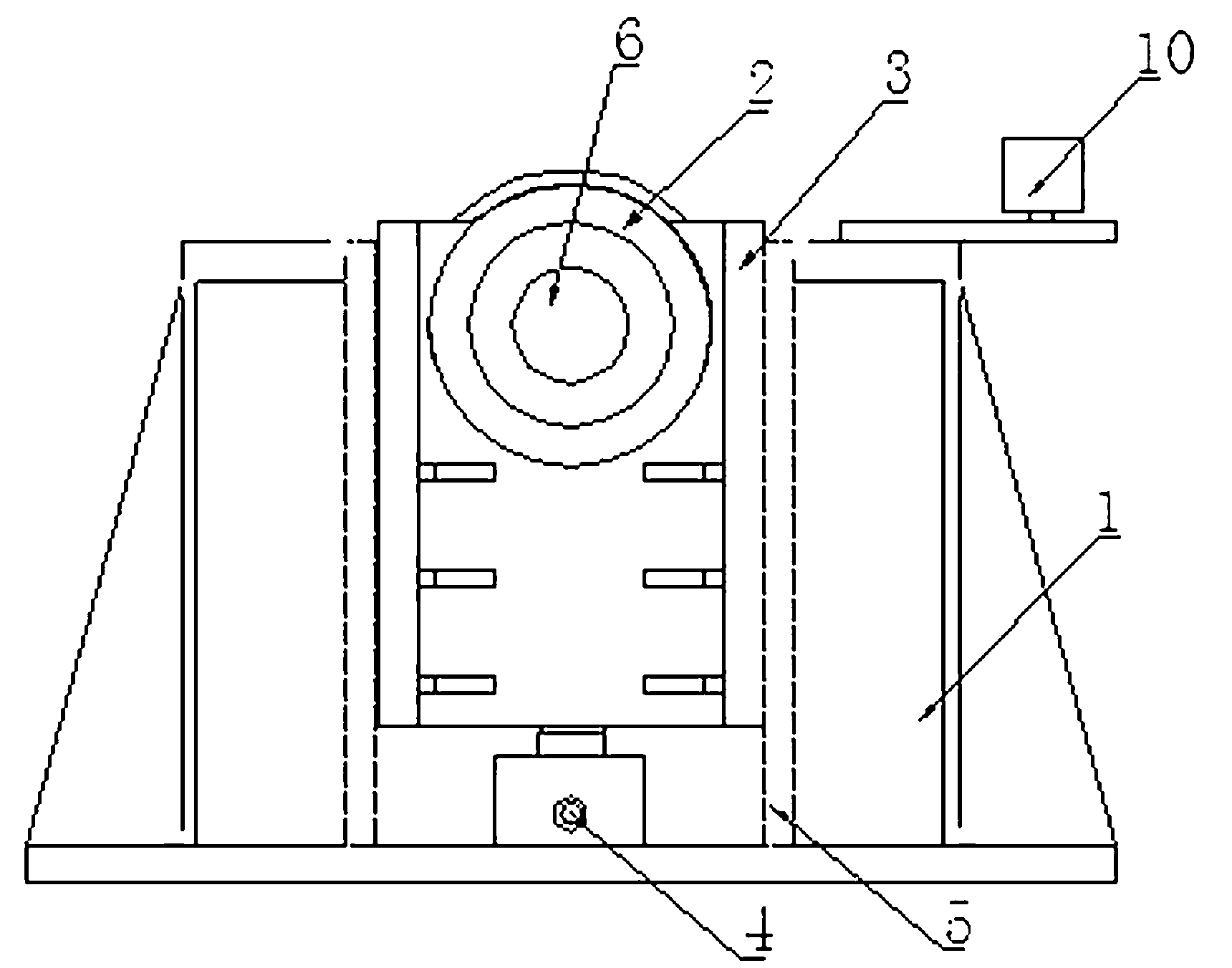

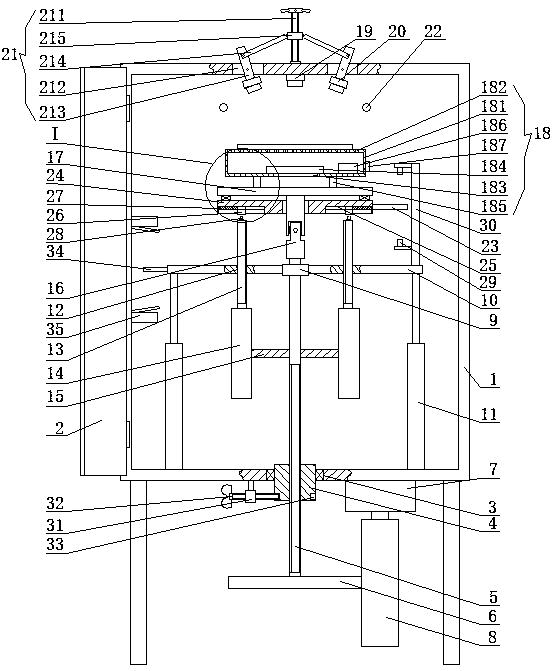

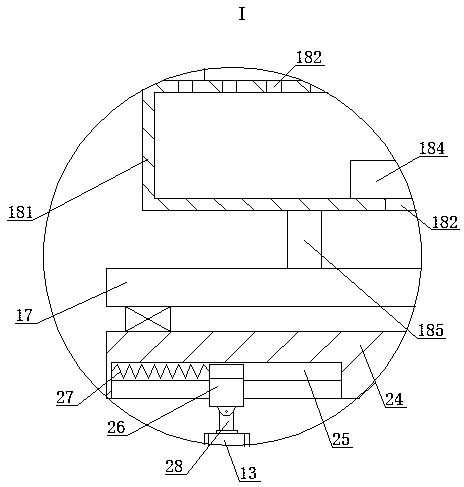

Heavy rotary supporting roller frame

ActiveCN103009134ASlow rotationSimple structurePositioning apparatusMetal-working holdersSelf lockingPulp and paper industry

The invention discloses a heavy rotary supporting roller frame. The heavy rotary supporting roller frame comprises a seat body, a speed-reducing motor, a supporting roller and a supporting roller support frame, wherein a groove is formed in the seat body; a self-locking jack is fixedly arranged at the bottom of the groove; the self-locking jack is fixedly connected with the bottom of the supporting roller support frame; the supporting roller support frame is arranged in the groove in a sliding way; the supporting roller is movably connected with the supporting roller support frame; the working supporting surface of the supporting roller is higher than the supporting roller supporting frame; and the power output shaft of the speed-reducing motor is connected with the supporting roller. By using the heavy rotary supporting roller frame, the bearing capacity is high; the safety is high; the position of a metal piece can be adjusted conveniently in a machining process, so that the machining is facilitated; the heavy rotary supporting roller frame can be arranged on a platform flexibly and can be detached quickly after the machining is finished; the working position of equipment is not occupied; and the utilization rate of the equipment is improved.

Owner:四川德建机械有限公司

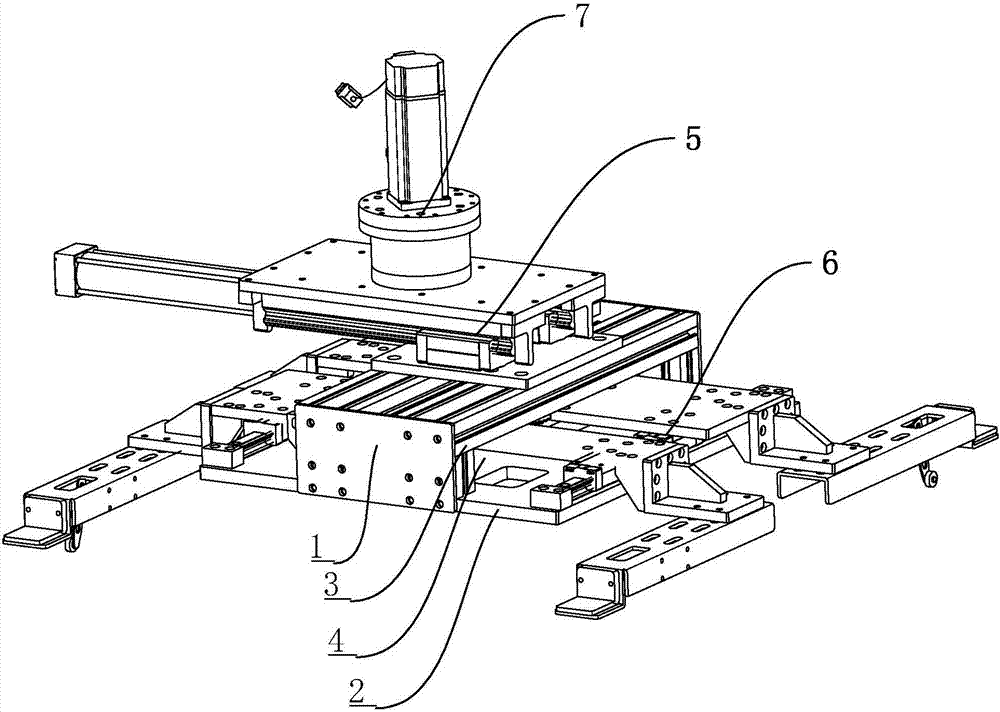

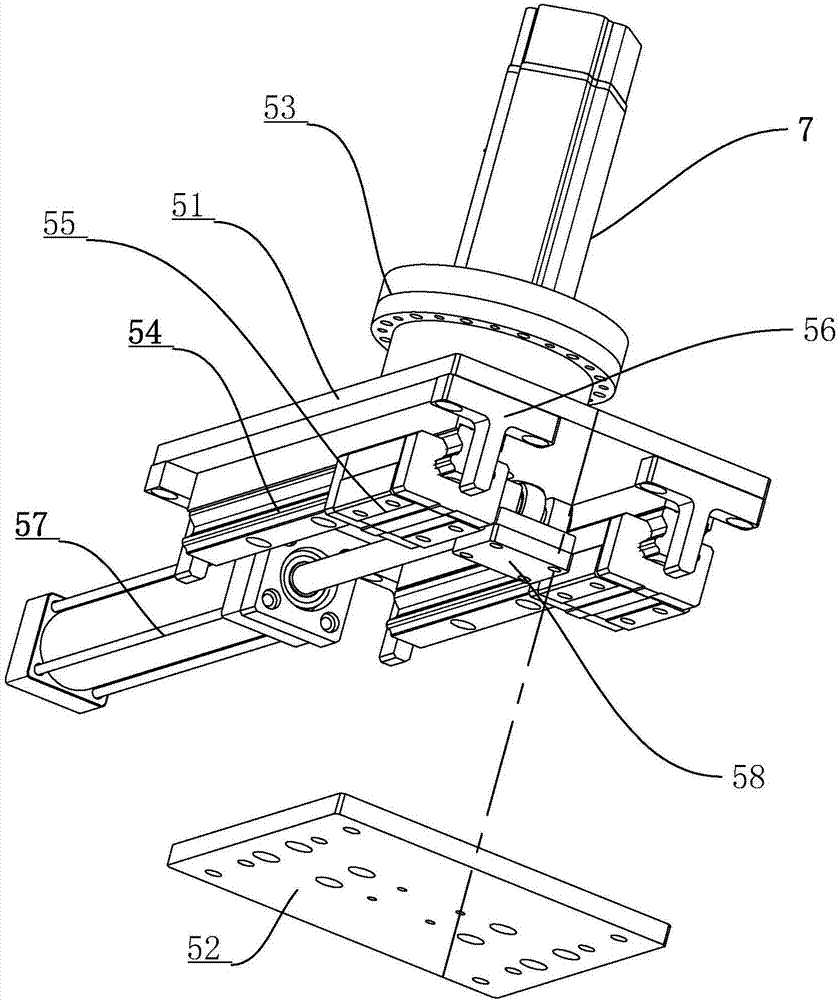

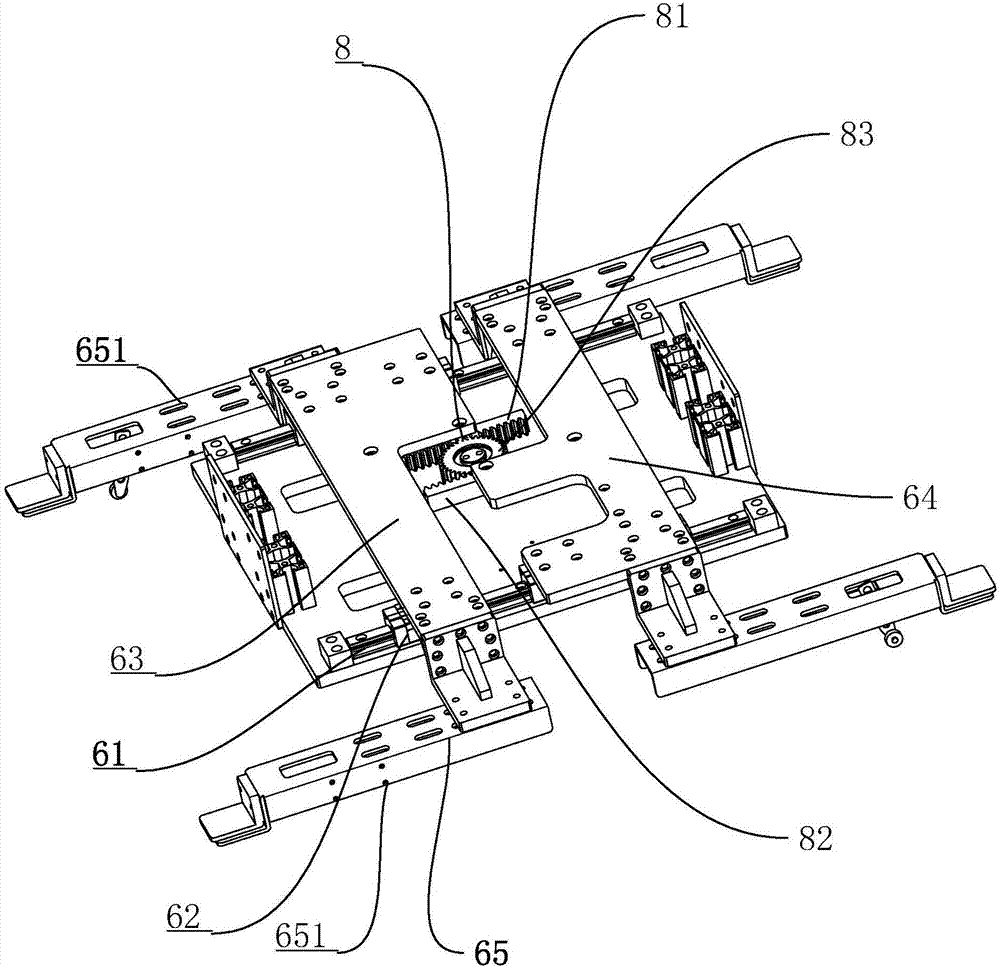

Rotating transferring mechanism and lifting transferring machine with same

The invention discloses a rotating transferring mechanism and a lifting transferring machine with the same. According to the technical scheme, the rotating transferring mechanism comprises multiple sucking disc sets, a rotating mechanism, an installation rack, an X-axis reciprocating mechanism and a Y-axis reciprocating mechanism, wherein the rotating mechanism enables the multiple sucking disc sets to rotate together in a linked manner along the Z axis, the installation rack is arranged between the sucking disc sets and the rotating mechanism and is rotated through the rotating mechanism in a linked manner, the X-axis reciprocating mechanism is linked with the rotating mechanism and pushes the installation rack to achieve horizontal reciprocating movement, and the Y-axis reciprocating mechanism is arranged in the installation rack and linked with the sucking disc sets for horizontal reciprocating movement. By means of the technical scheme, the sucking disc sets can achieve two-axis movement on the horizontal plane according to the X-axis reciprocating mechanism and the Y-axis reciprocating mechanism, and then the sucking disc sets are rotated through the rotating mechanism; and circumferential rotation of workpieces on sucking discs can be achieved according to the rotation point of the rotating mechanism, the rotation radius of the workpieces can be adjusted after rotation, and therefore the radial length from each workpiece to the rotation point can be adjusted so as to adapt to a needed position after the transferring process.

Owner:江苏艾伯赛精密机械有限公司

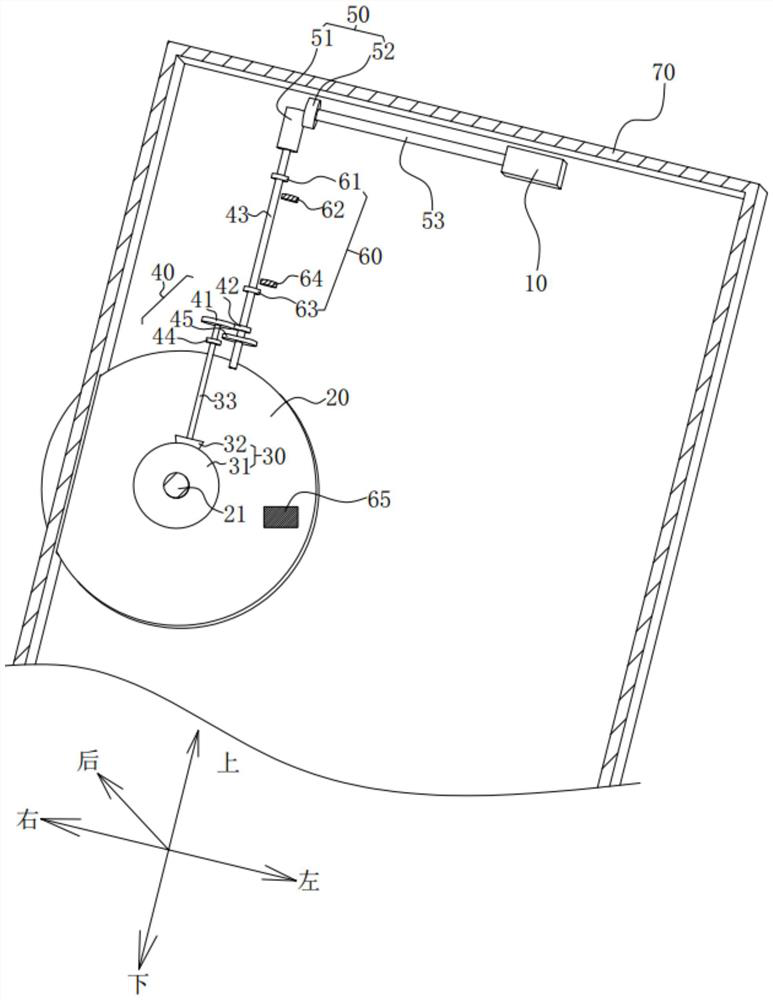

Roller rotation camera assembly, mobile terminal and control method

ActiveCN113810526AReduce in quantityFast rotationTelevision system detailsColor television detailsCamera moduleControl theory

The invention discloses a roller rotation camera assembly, a mobile terminal and a control method, and the assembly comprises a roller which is rotatably arranged; a first transmission assembly which is connected with the roller and converts shifting of the roller into rotation in the vertical direction; a variable speed transmission assembly which is connected with the first transmission assembly and used for changing the rotating speed of the first transmission assembly; a second transmission assembly which is connected to the variable speed transmission assembly and converts the rotation direction of the variable speed transmission assembly into rotation in the left-right direction; and a camera module which is connected to the second transmission assembly and is driven by the second transmission assembly to rotate in the left-right direction. The problem that the shooting angle is difficult to grasp due to the fact that the camera angle cannot be adjusted in the prior art is solved.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

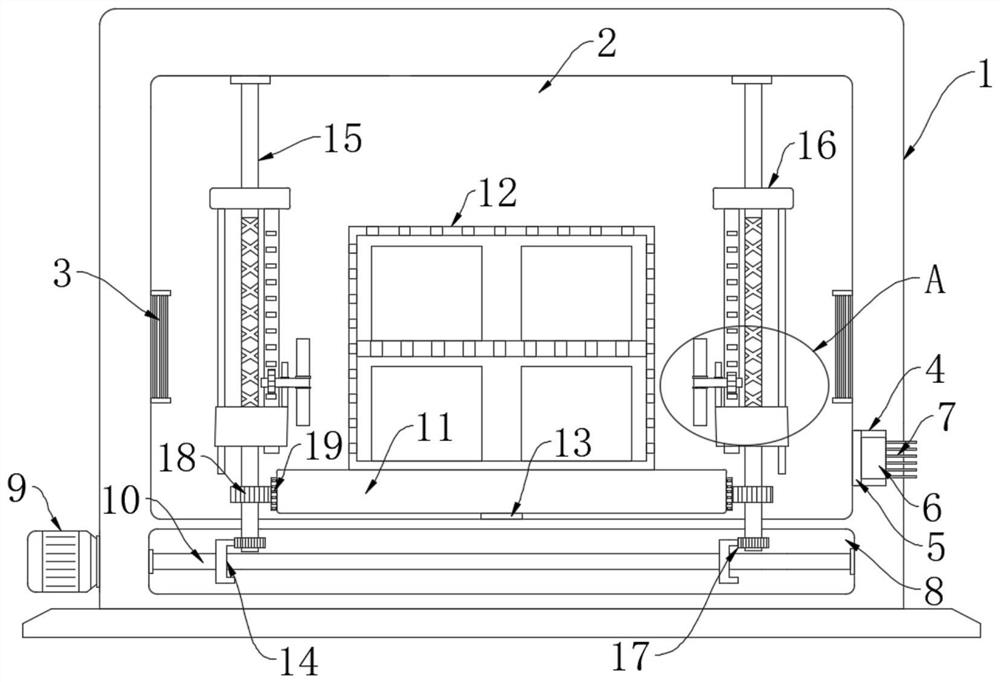

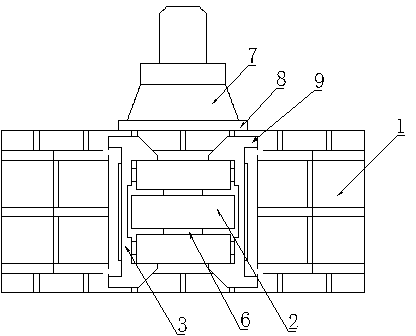

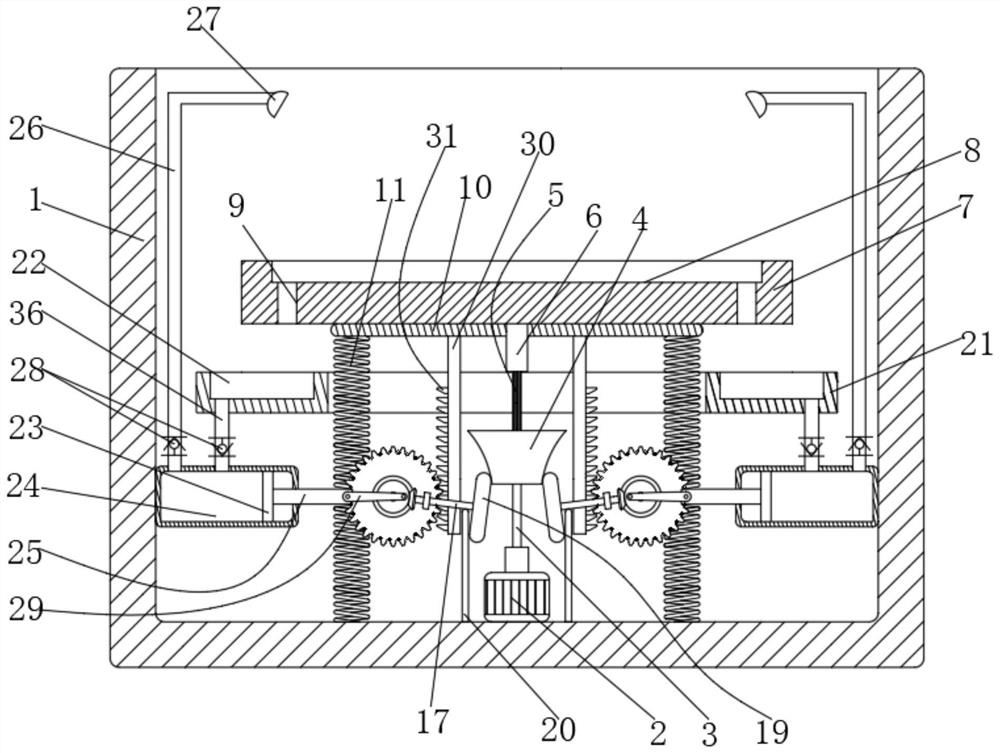

Quality detection device for embossing printed matter

InactiveCN110455796AChange distanceEasy to detectMaterial analysis by optical meansSlow rotationEngineering

The invention relates to a quality detection device for an embossing printed matter. The quality detection device comprises a box body, wherein a box door is arranged at a front side opening of the box body, a through hole is opened in the middle of the bottom side of the box body, a nut is arranged in the through hole, a lead screw is arranged in the nut in a threaded manner, a first gear is fixedly mounted on the lower end of the lead screw, a motor is fixedly mounted on one side of the bottom side of the box body, a coaxial gear column is fixedly mounted on the lower end of a motor rotatingshaft, the first gear meshes with the gear column, an upper end bearing of the periphery of the lead screw is provided with a coaxial fixing ring, the left side and the right side of the fixing ringare separately provided with horizontal plates, the outer side of the bottom side of each horizontal plate is fixedly connected to the upper end of a telescopic rod, respectively, and the lower end ofeach telescopic rod is fixedly connected with the bottom of the box body respectively. The device of the invention has the advantages of simple structure and ingenious design, and realizes the lifting and lowering adjustment of the printed matter, the change of angles between the top side of the printed matter and the horizontal plane, and the slow rotation of the printed matter by one motor; andthe lifting and lowering of the printed matter can change the distance between the printed matter and a camera.

Owner:CHANGSHA NORMAL UNIV

Aggregate angularity on-site real-time monitoring device

ActiveCN113933216ARealize deliverySmooth releaseSolid waste managementMaterial analysisEngineeringStructural engineering

The invention discloses an aggregate angularity on-site real-time monitoring device, and belongs to the technical field of aggregate angularity detection. A material distribution mechanism which is erected on two sides of a fixed bracket and can uniformly and stably distribute aggregate on a conveying belt is arranged right above the conveying belt; an image acquisition mechanism for shooting the dispersed aggregate is mounted on the fixed bracket; a covering mechanism for shading the shot aggregate is arranged on the image acquisition mechanism; a detection mechanism for testing the shot material is arranged under the advancing tail end of the conveying belt; and a sampling mechanism for receiving the shot aggregate and conveying the shot aggregate to the inner side of the detection mechanism is arranged under the advancing tail end of the conveying belt. Through continuous rotation of the discharging roller, aggregate in each notch is released to the upper end face of the conveying belt at a certain distance in a spaced manner, so that the aggregate is uniformly and independently distributed on the conveying belt, and favorable conditions are provided for subsequent photographing of the aggregate by the image acquisition mechanism.

Owner:CHANGAN UNIV

Indoor automatic watering machine based on Internet of Things

InactiveCN113179926AEasy to viewPromote growthWater treatment parameter controlMicroorganismsThe InternetEnvironmental engineering

The invention discloses an indoor automatic watering machine based on the Internet of Things, and relates to the technical field of watering machines. A first reset spring is jointly and fixedly connected with the opposite sides of a connecting block and a barrel, two spraying mechanisms capable of adaptively increasing the spraying amount when water in basin bodies is reduced are arranged on the inner wall of the barrel body, and two adjusting mechanisms capable of being adaptive to basin bodies with different masses are arranged on the inner wall of the barrel body. According to the indoor automatic watering machine based on the Internet of Things, reduction of the water content of a plant is converted into reduction of gravity mass, the spraying amount is increased in a self-adaptive mode through the spraying mechanisms, and after the water content of the plant is within a certain range, the original water spraying amount is restored; and by arranging the adjusting mechanisms, after the basin bodies with different masses are placed into the device, the initial water spraying amount is the same, so that the indoor automatic watering machine adapts to the basin bodies with different masses, and the indoor automatic watering machine has the effect of better practicability.

Owner:谢维宁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com