Protective film forming method and apparatus

A technology of covering device and film, which is applied in the manufacture of devices, electrical components, and semiconductor/solid-state devices that apply liquid to the surface. The amount of use, good affinity, and the effect of increasing the ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, preferred embodiments of the protective film covering method and protective film covering apparatus according to the present invention will be described in detail with reference to the accompanying drawings.

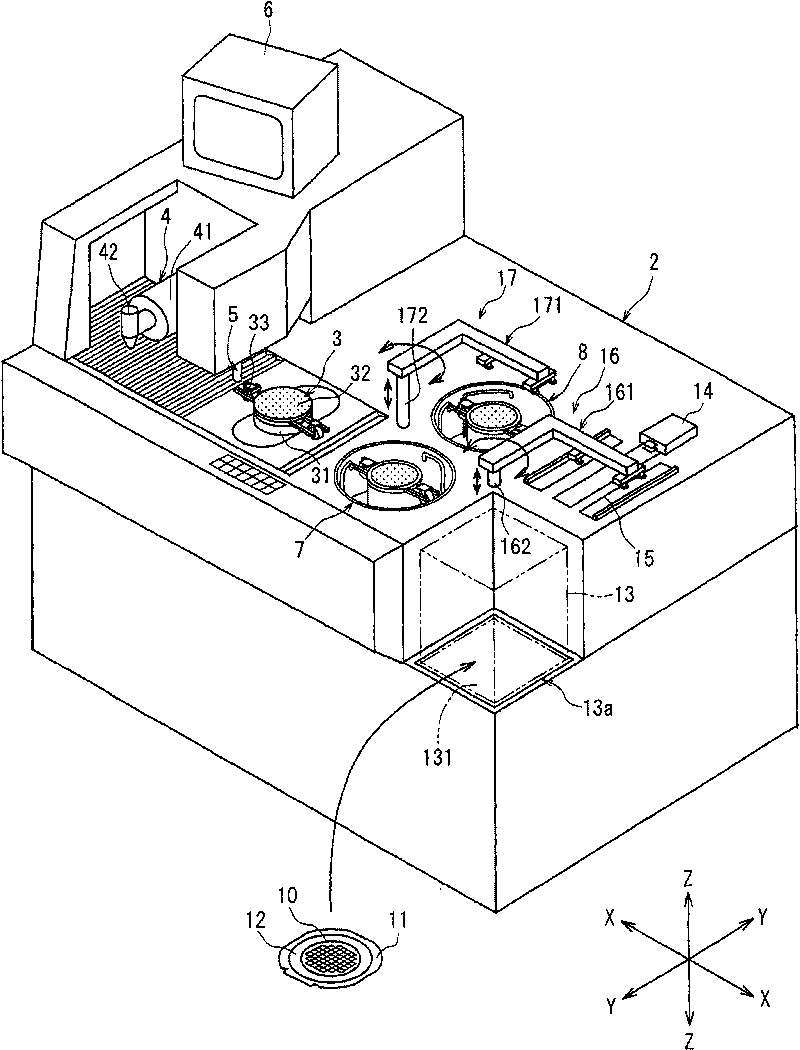

[0033] exist figure 1 , shows a perspective view of a laser processing machine equipped with a protective film covering device according to the present invention.

[0034] figure 1 The laser processing machine shown has an approximately cuboid housing 2 . In the casing 2 of this device, a chuck table 3 as a workpiece holding unit for holding a workpiece is disposed so as to be movable in a direction indicated by an arrow X which is a machining feeding direction. The chuck table 3 has a suction chuck support base 31 and a suction chuck 32 mounted on the suction chuck support base 31, and sucks, for example, a disc-shaped semiconductor to be processed by a suction unit not shown. The wafer is held on the surface of the suction chuck 32 , that is, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com