Patents

Literature

87results about How to "Stable rotation speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

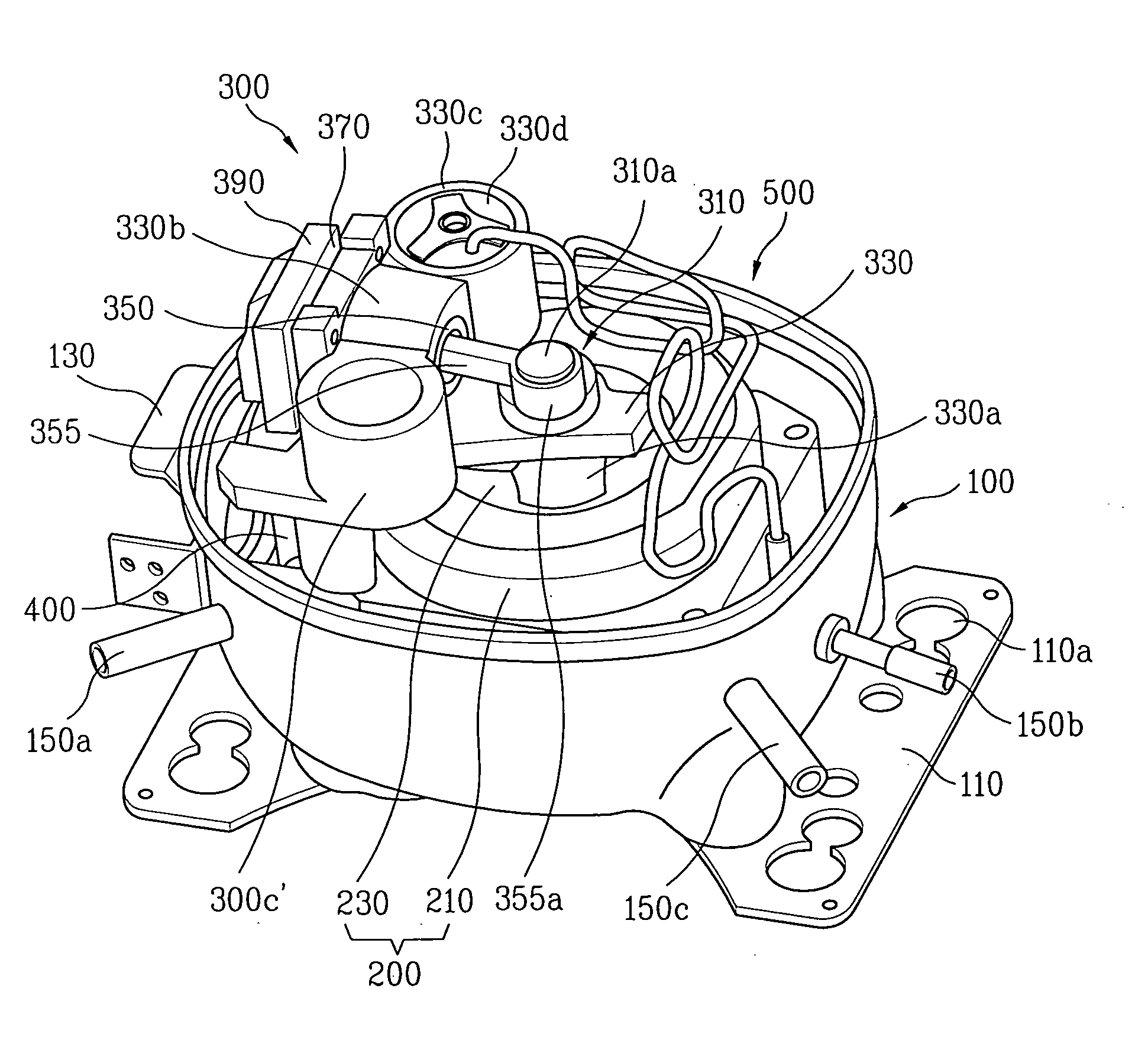

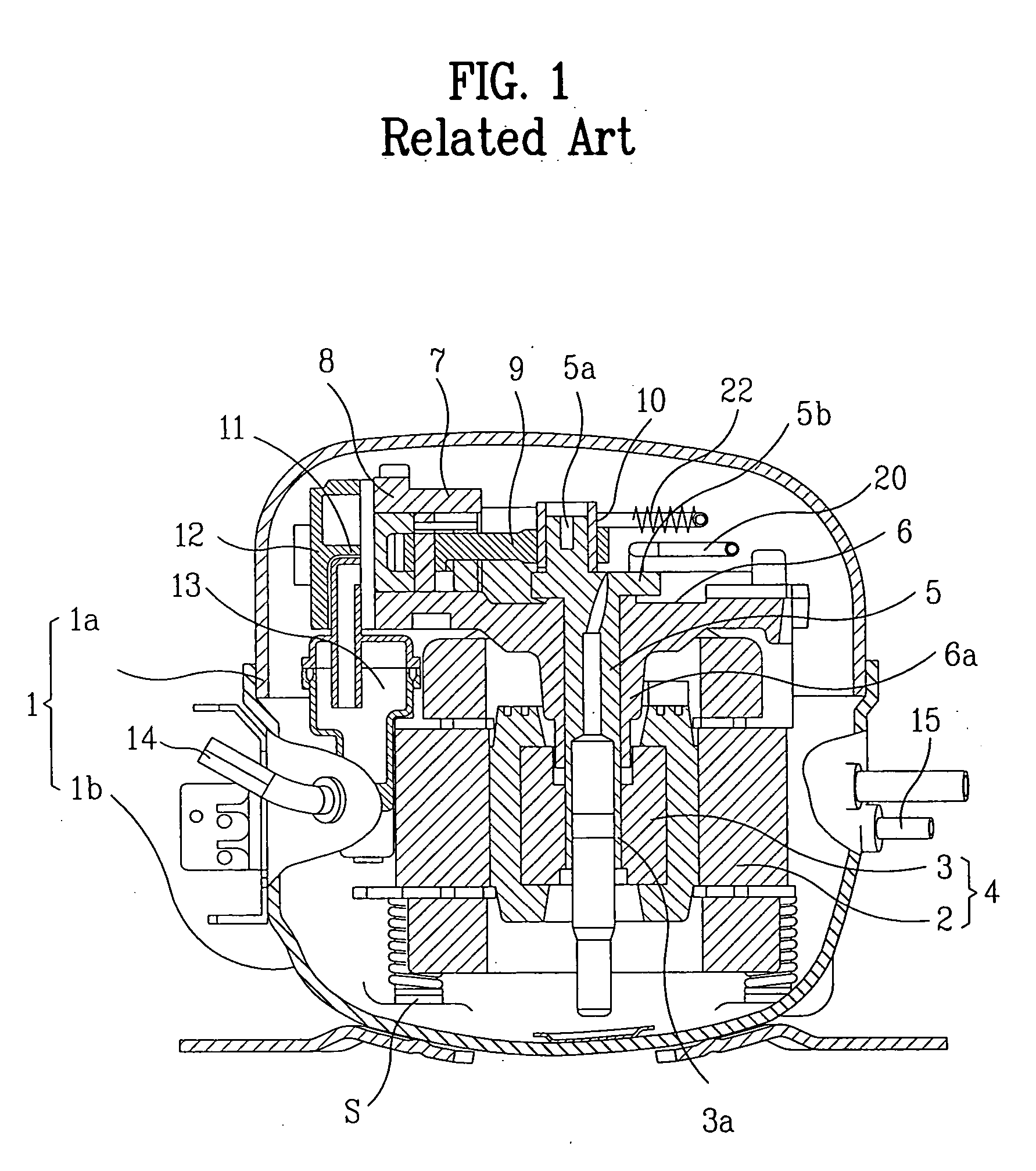

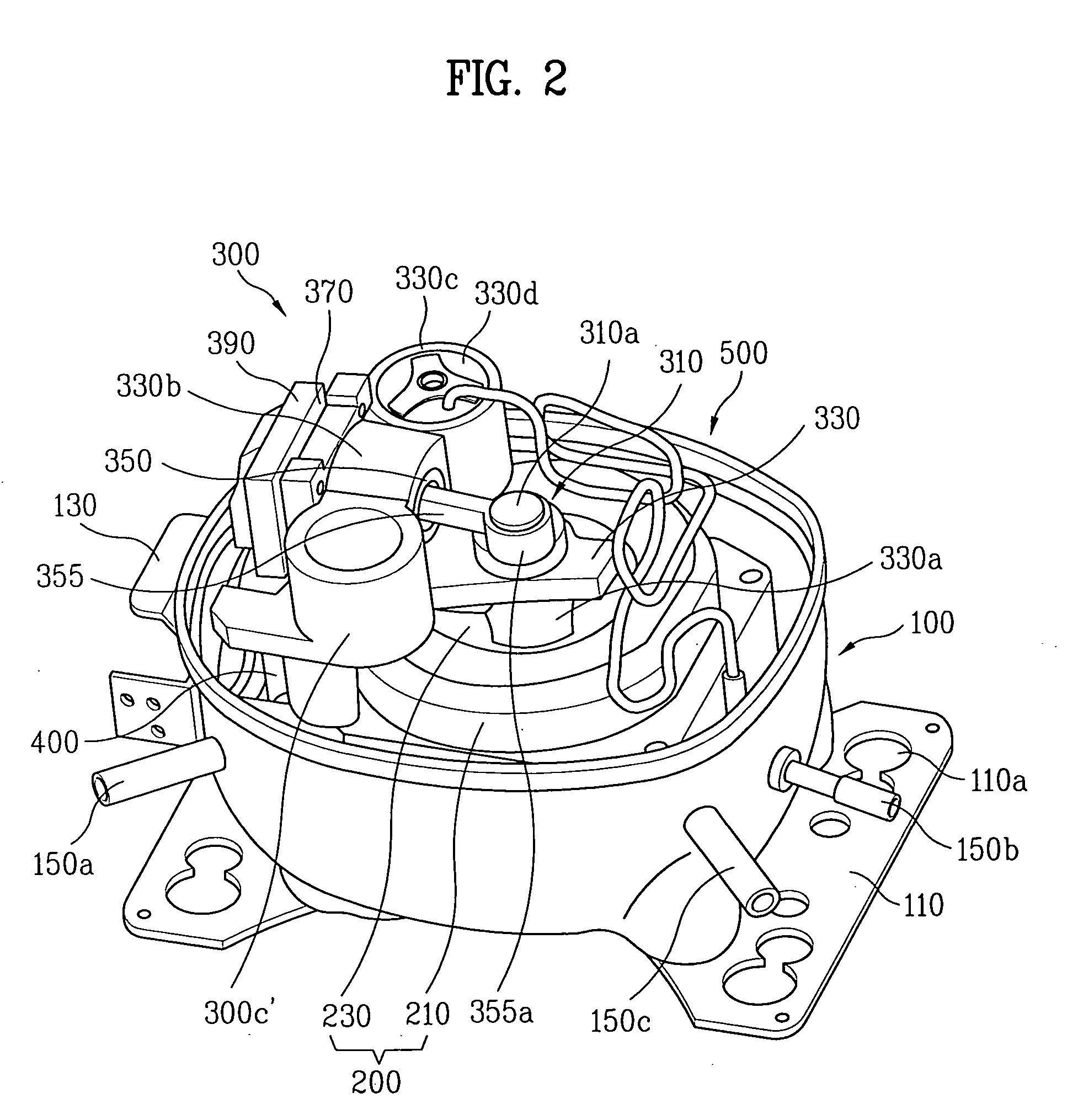

Hermetic compressor

InactiveUS20050106037A1Eliminate the problemStable rotation speedRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsEngineeringHigh pressure

Hermetic compressor including a hermetic container having an enclosed space therein, a motor part in the hermetic container for converting an electric energy into a kinetic energy, a compression part connected to the motor part for compressing low temperature, low pressure refrigerant into high temperature, high pressure refrigerant, a discharge muffler adjacent to the compression part for attenuating noise of the refrigerant compressed into high temperature and high pressure, a discharge pipe passed through one side of the hermetic container for discharging the refrigerant to an outside of the compressor, and a loop pie of a synthetic resin between the discharge muffler and the discharge pipe.

Owner:LG ELECTRONICS INC

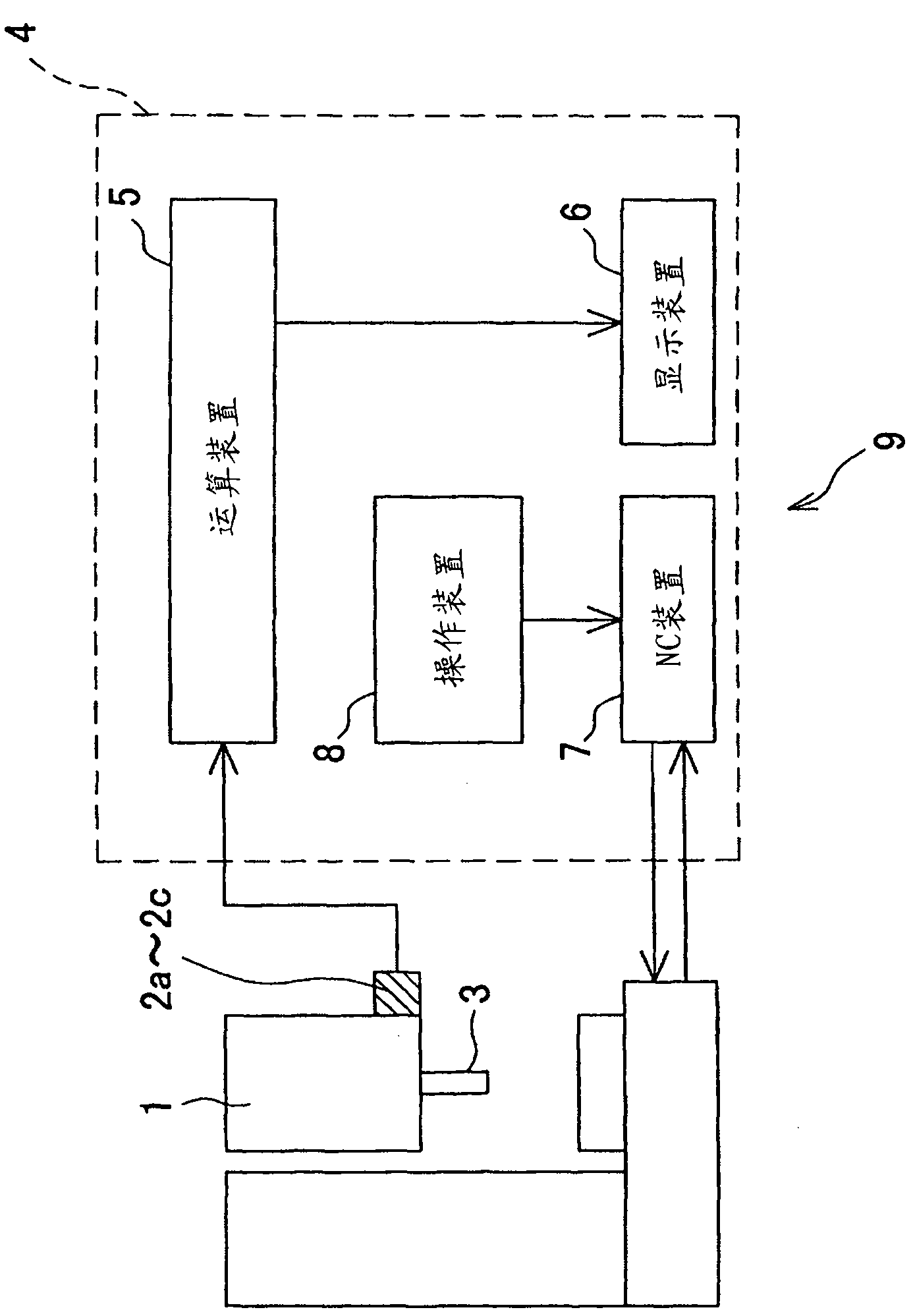

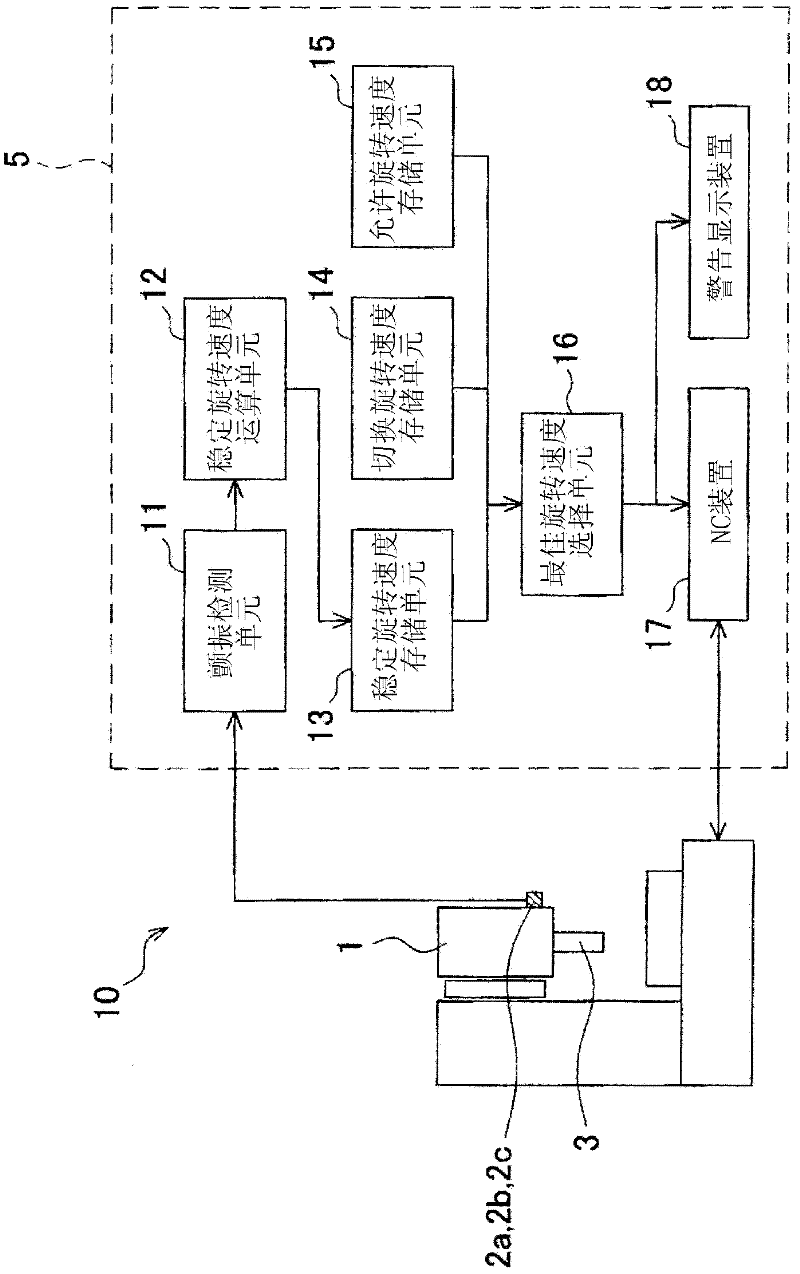

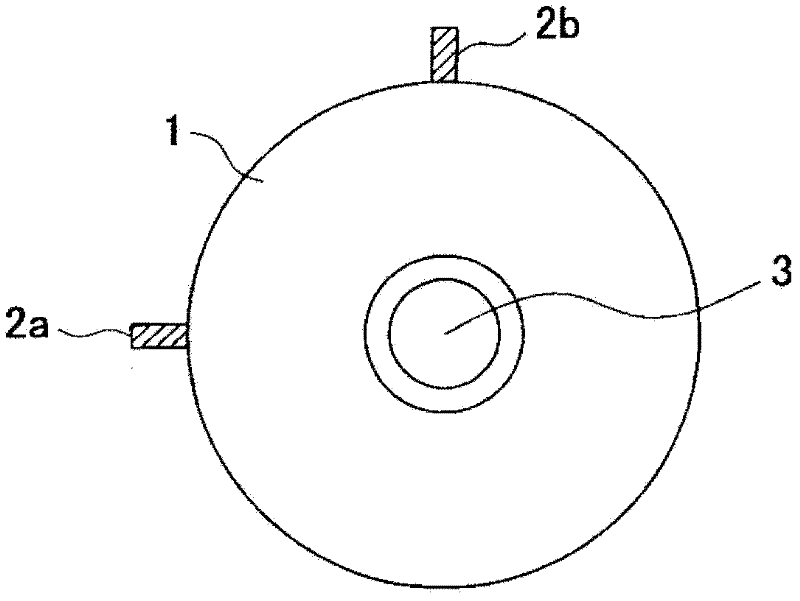

Vibration suppression device

InactiveCN102029546ASuppress chatterAvoid breakingMeasurement/indication equipmentsMetal working apparatusVibration accelerationEngineering

The invention provides a vibration suppression device, which can reliably and quickly suppress the flutter and realize the precision increase of processing surfaces, long service life of tools and high efficiency of processing.Vibration acceleration detected by vibration sensors (2a - 2c) is momentarily analyzed and the operation based on the analyzed result is carried out by an arithmetic unit (5).The analyzed result and the operation result are displayed on a display unit (6) in real time.When "flutter" is suppressed, operators can operate an operating means (8) while referring to the display unit (6) to change the rotation speed.Compared with the prior art, wherein the rotation speed is changed based on experiences of operators, the device can suppress "flutter" more accurately and more quickly.

Owner:OKUMA CORP

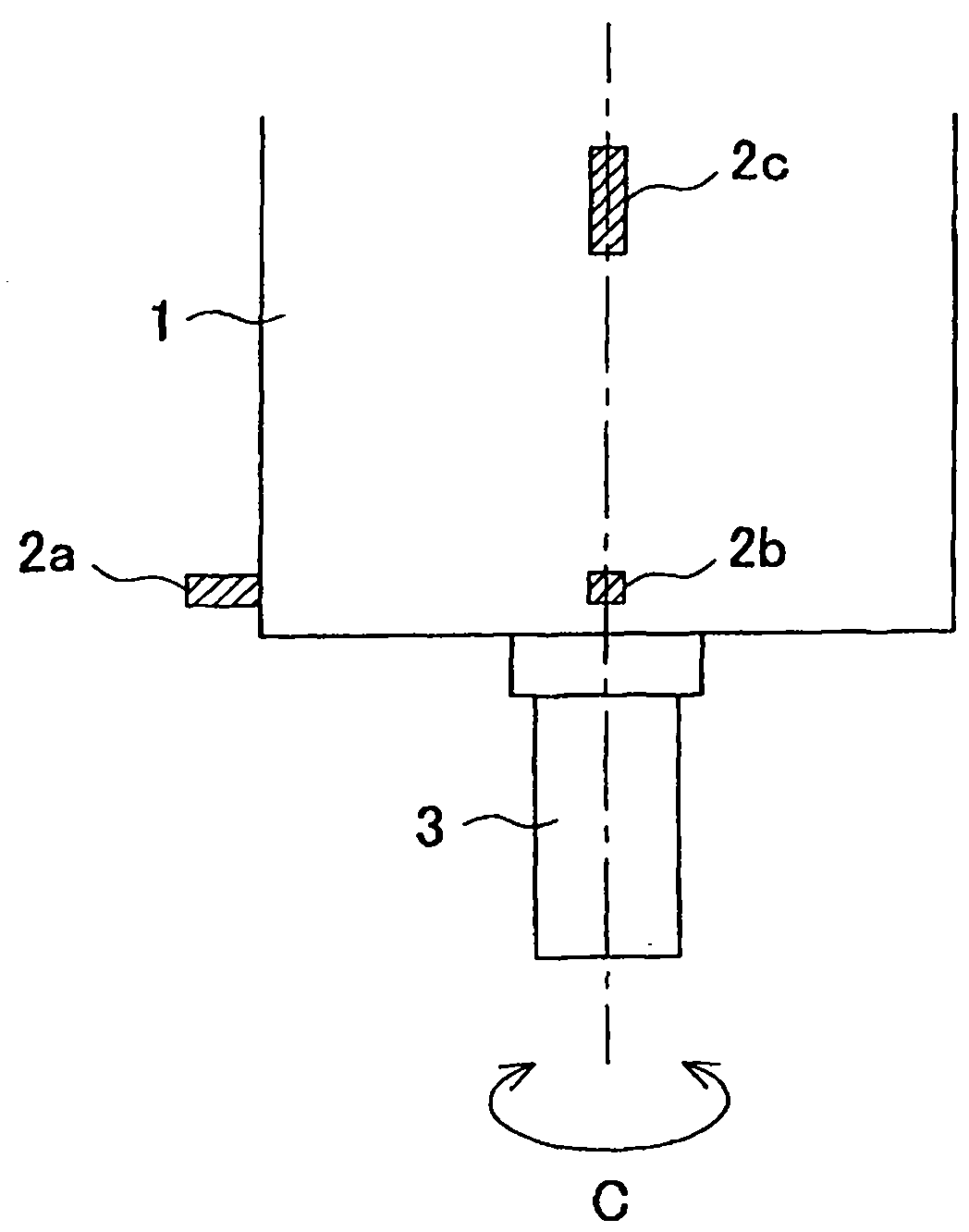

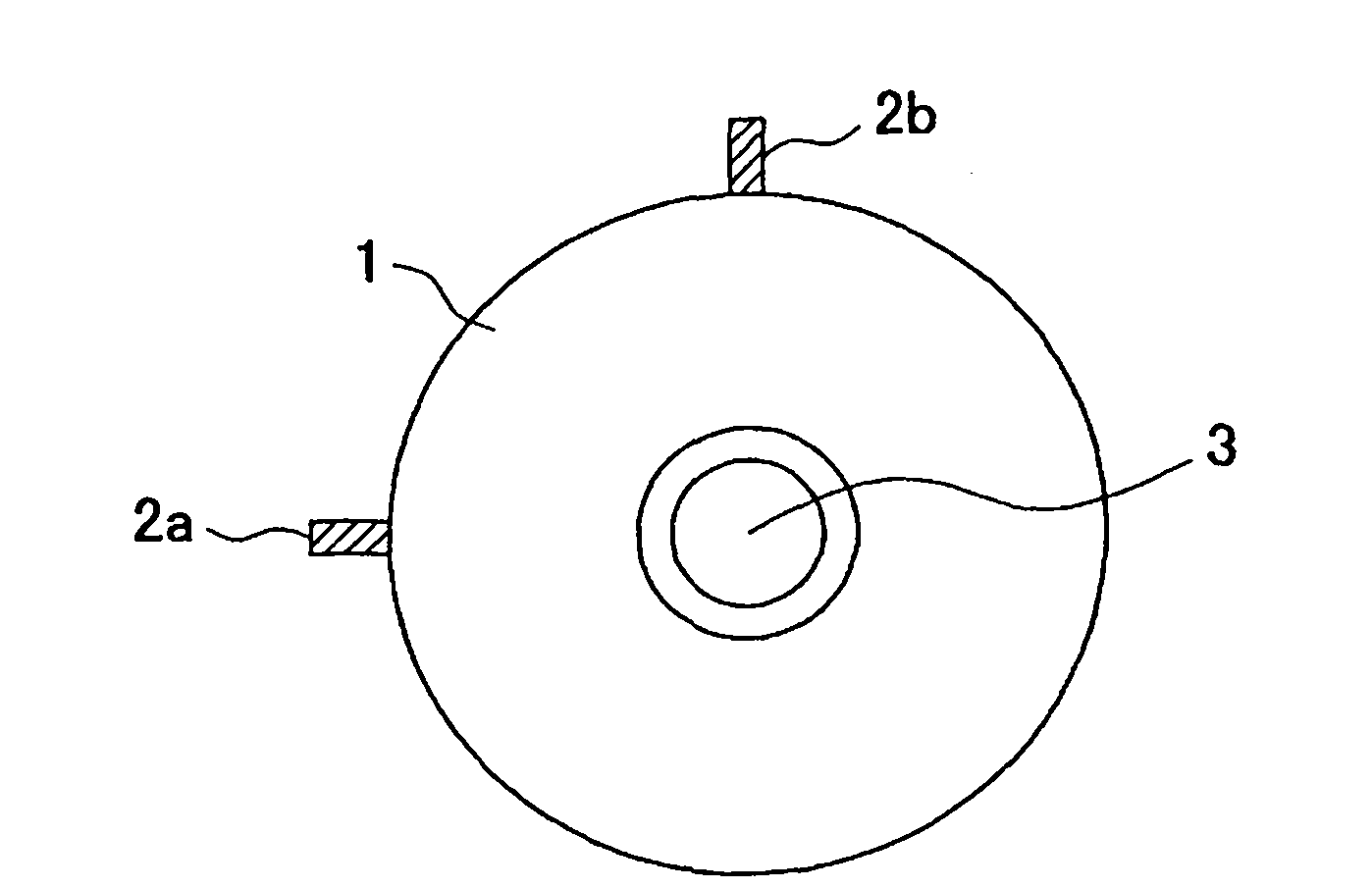

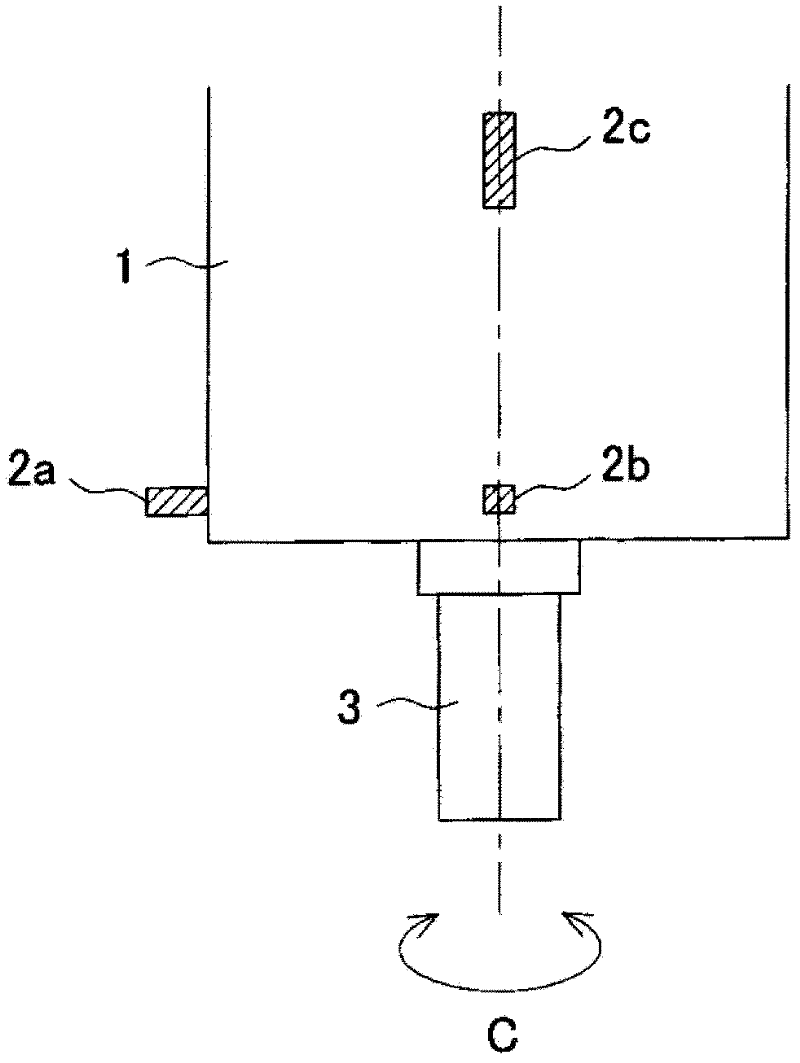

Vibration suppressing method and vibration suppressing device for use in machine tool

ActiveCN102554685ASuppressing "flutterSuppress chatterProgramme controlAutomatic control devicesChatter vibrationRotation velocity

The present invention aims to provide a vibration suppressing method and a vibration suppressing device in which an adequate stable rotation speed can be selected from the obtained stable rotation speeds without changing the dynamic characteristics so that chatter vibrations can be suppressed without fail. With the vibration suppressing method and vibration suppressing device as described above, a maximum rotation speed of the main spindle (3) and a switching rotation speed across which a dynamic characteristic of the main spindle (3) system changes are stored, then an optimum rotation speed that is a rotation speed which is not higher than the maximum rotation speed of the main spindle (3) and to which the rotation of speed of the main spindle (3) is changeable without crossing the switching rotation speed is selected from the stable rotation speeds, and the rotation speed of the main spindle (3) is changed to the optimum rotation speed selected. Accordingly, the possibilities of changing the rotation speed of the main spindle (3) to a rotation speed which cannot be attained or a rotation speed such that change of the rotation speed to that speed changes the dynamic characteristic of the main spindle (3) and thus makes it impossible to suppress ''chatter vibrations'' can be eliminated, so that the ''chatter vibrations'' can be suppressed more effectively than any existing methods.

Owner:OKUMA CORP

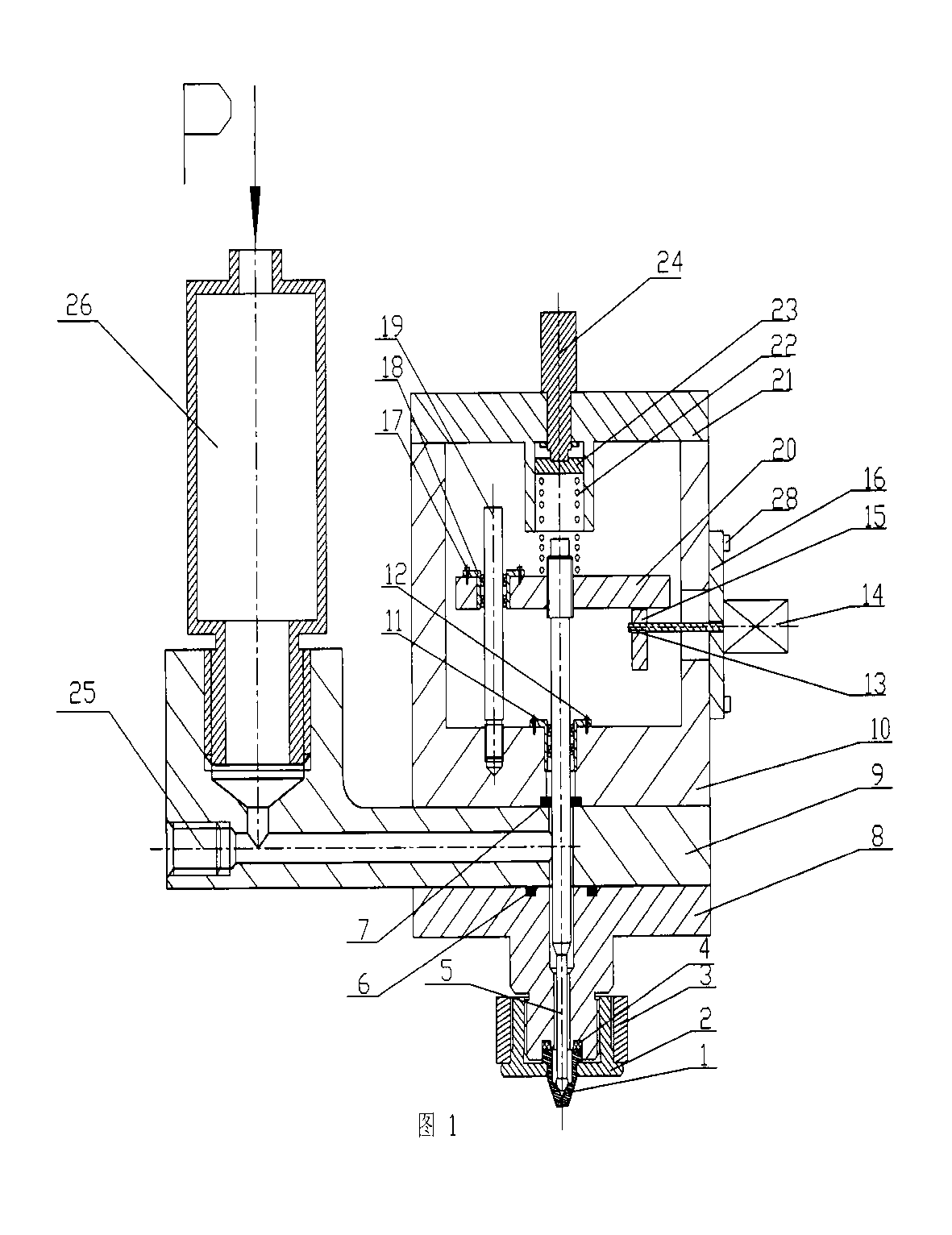

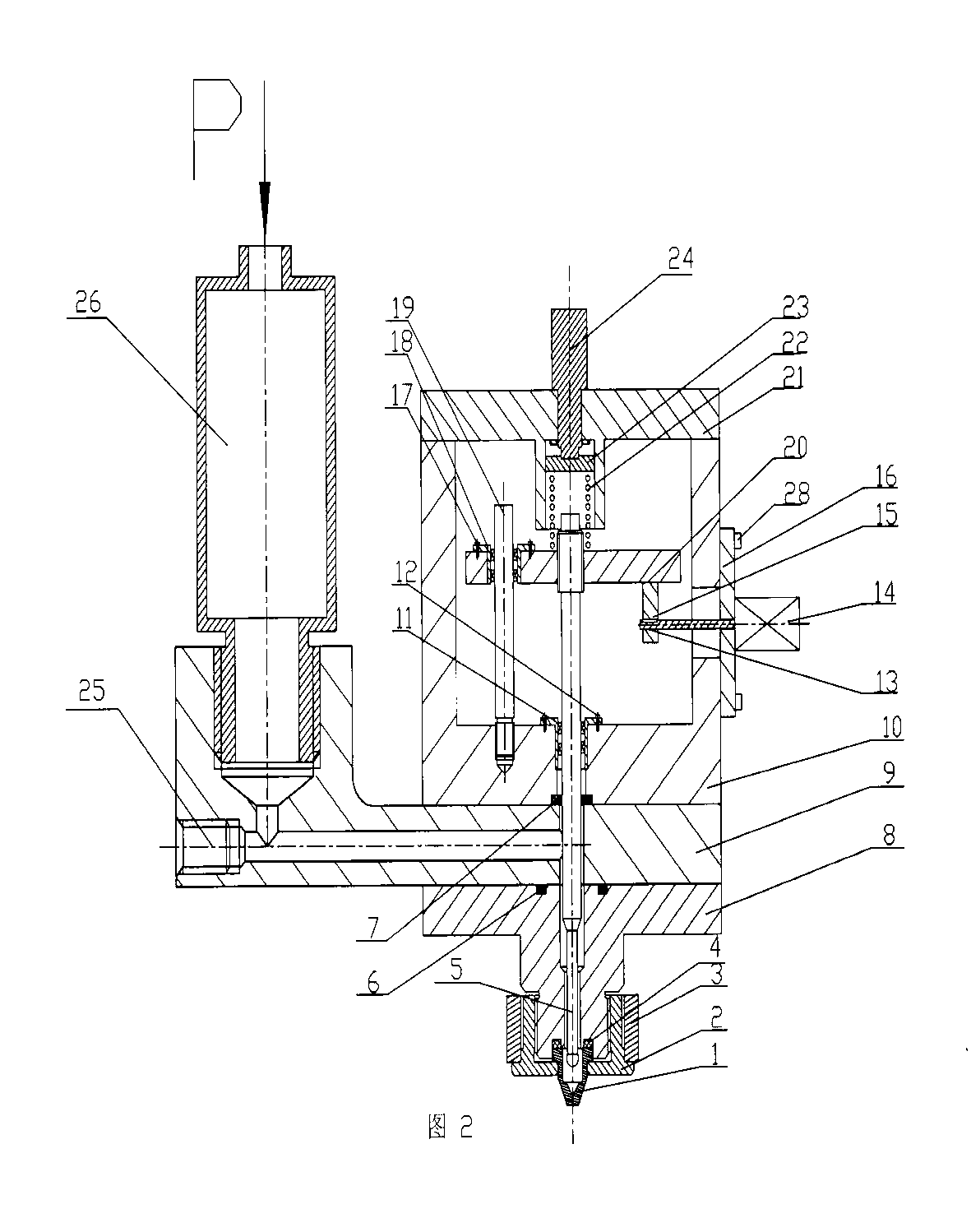

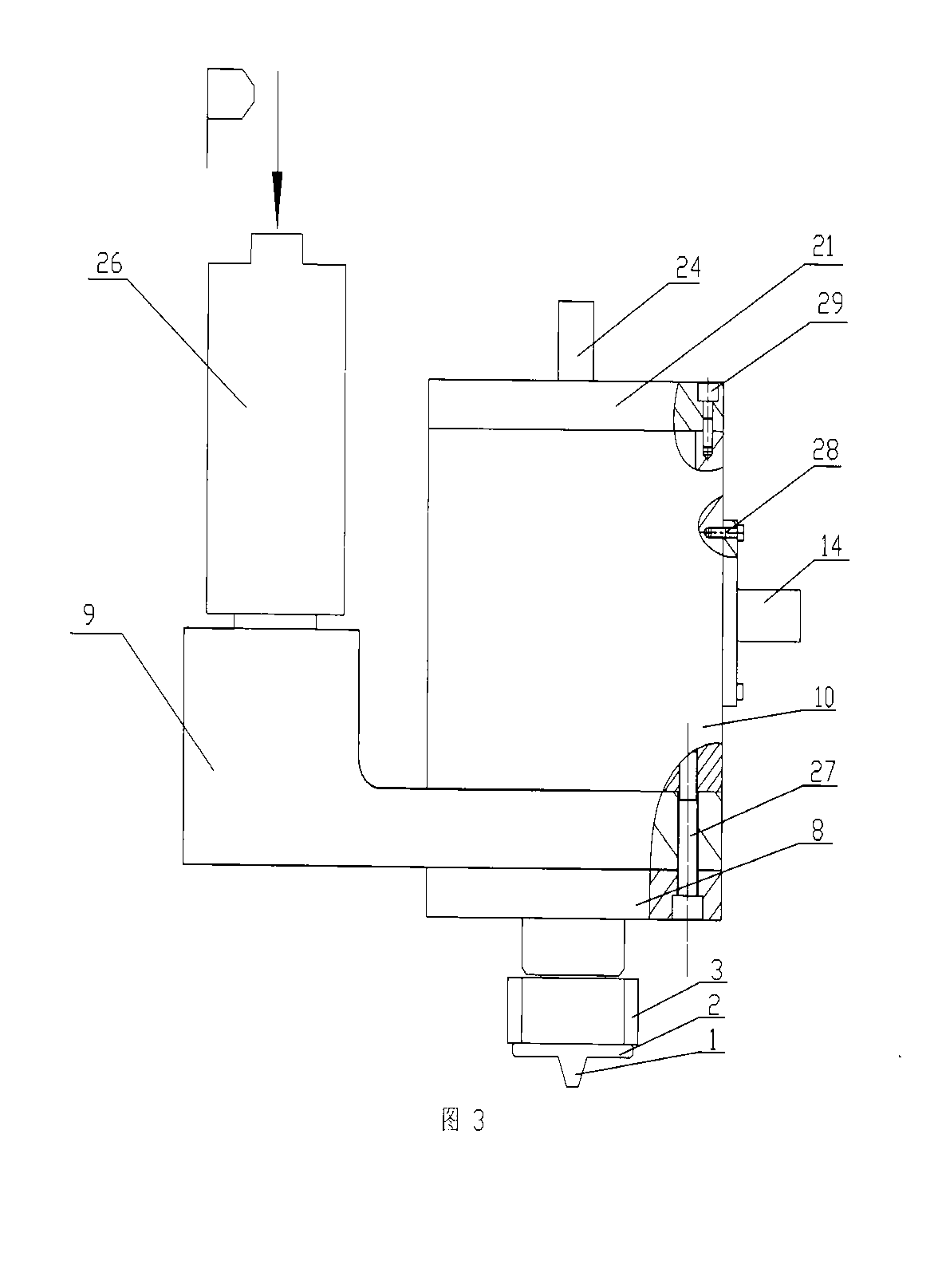

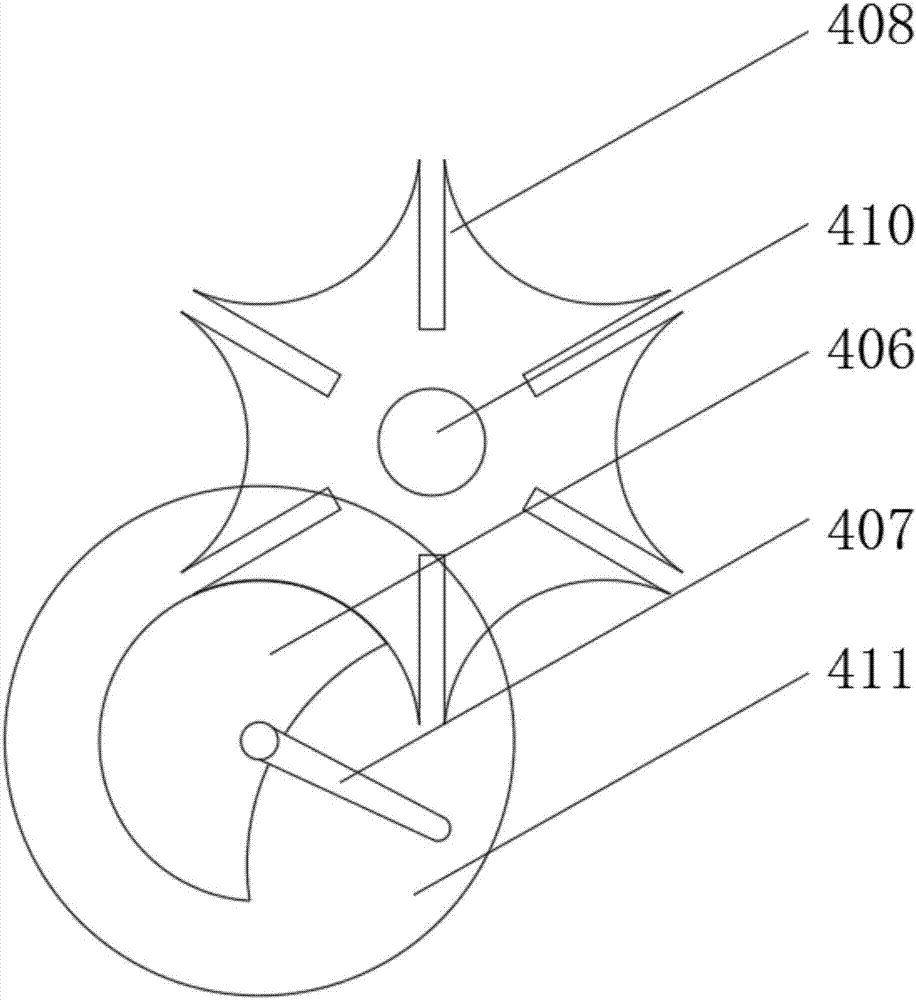

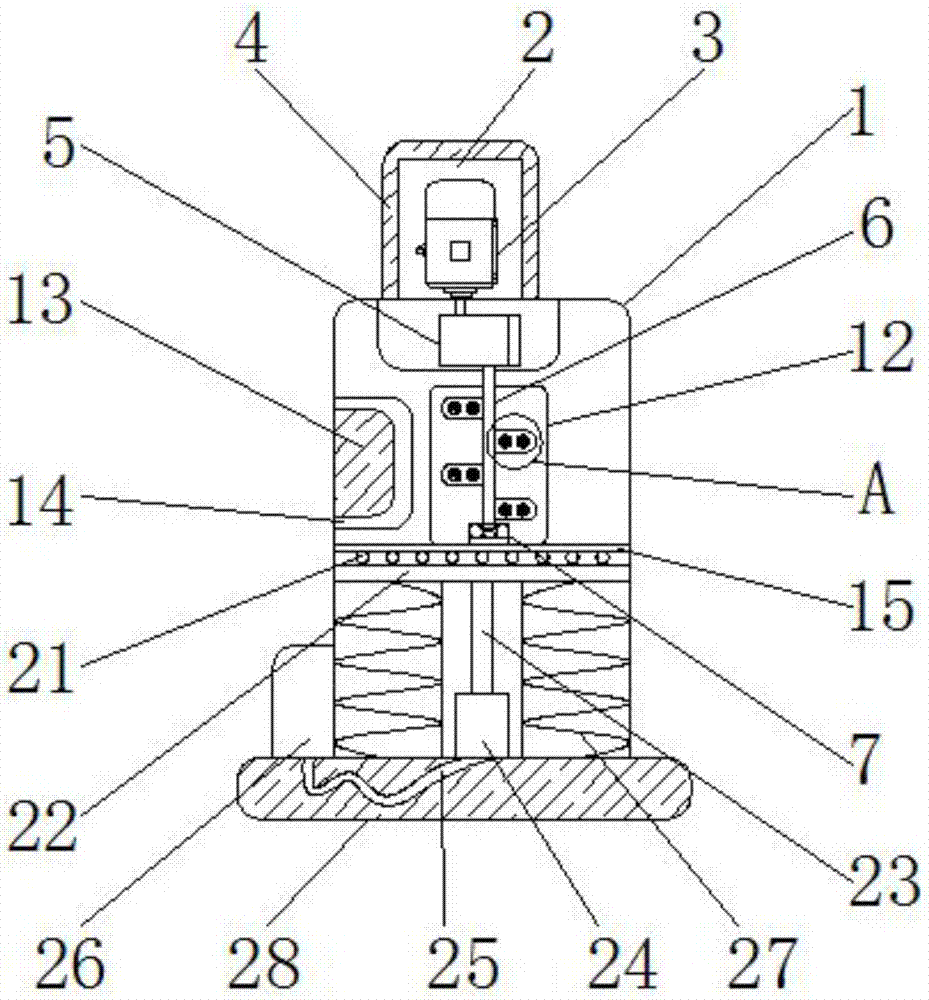

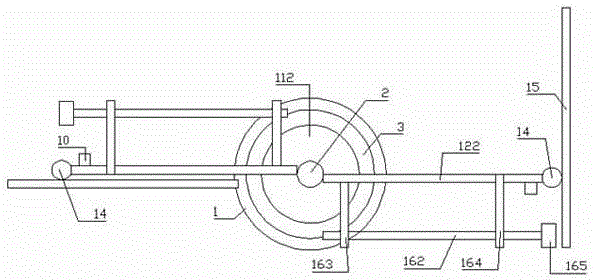

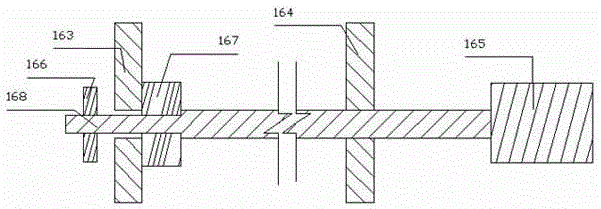

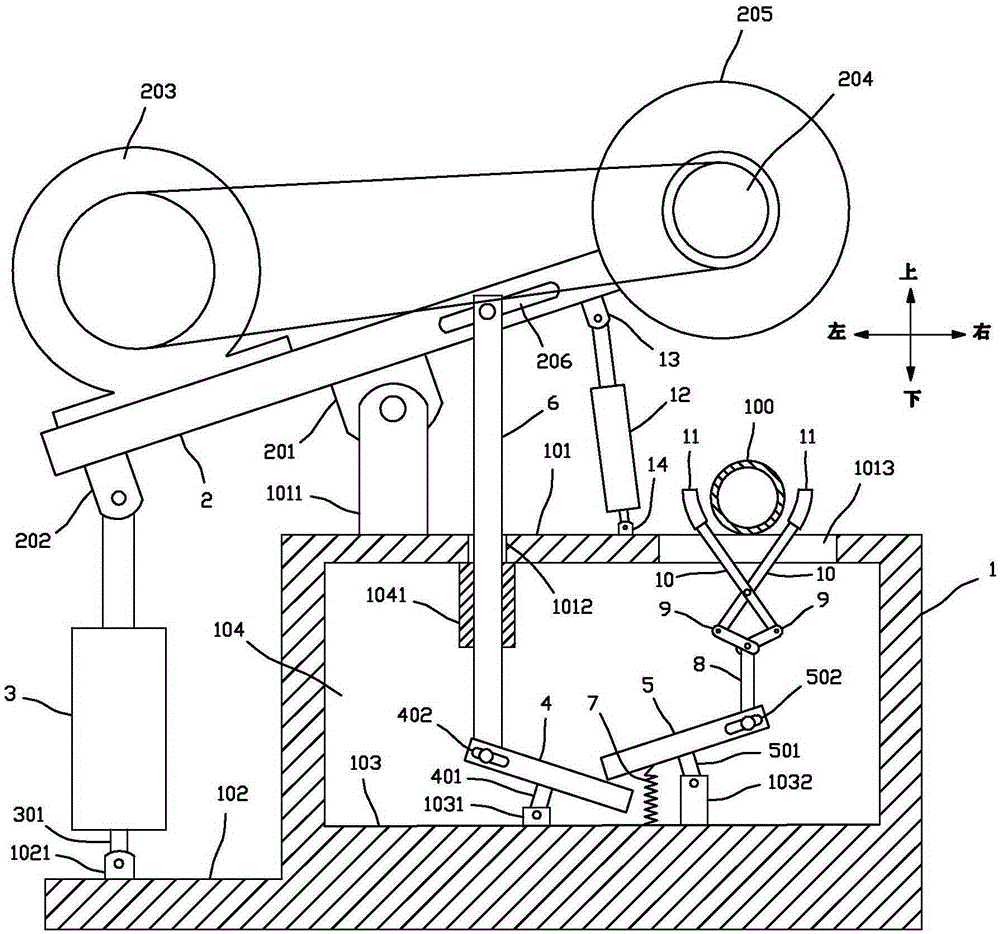

Cam jet dispensing device

InactiveCN103223395AUp and down fastStable rotation speedLiquid surface applicatorsCoatingsElectric machineryEngineering

The invention discloses a cam jet dispensing device mainly composed of a servo nozzle 1, a firing pin 5, a servo motor 14, a cam 15, a movement arm 20, a micrometer head 24, a pressing plate 23, and a spring 22. The firing pin 5 is arranged on the movement arm 20, such that a movement part is formed. The firing pin 5, the movement arm 20, and the cam 15 form a cam mechanism. The servo motor 14 drives the cam mechanism to rotate. The cam mechanism drives the firing pin 5 to move up and down, such that the closing and opening of the firing pin 5 and the nozzle 1 are realized. High-pressure glue at the nozzle 1 is jet through the nozzle 1. The device has the main characteristics that: (1) power of the device used for driving the firing pin is provided by the cam rotated by the servo motor; the rotation speed of the servo motor is stable; firing pin moves fast up and down; and jet frequency is high; and (2) firing pin movement speed of the device is determined by motor rotation speed; the amount of coupling coefficients is low, and controlling is convenient.

Owner:JILIN UNIV

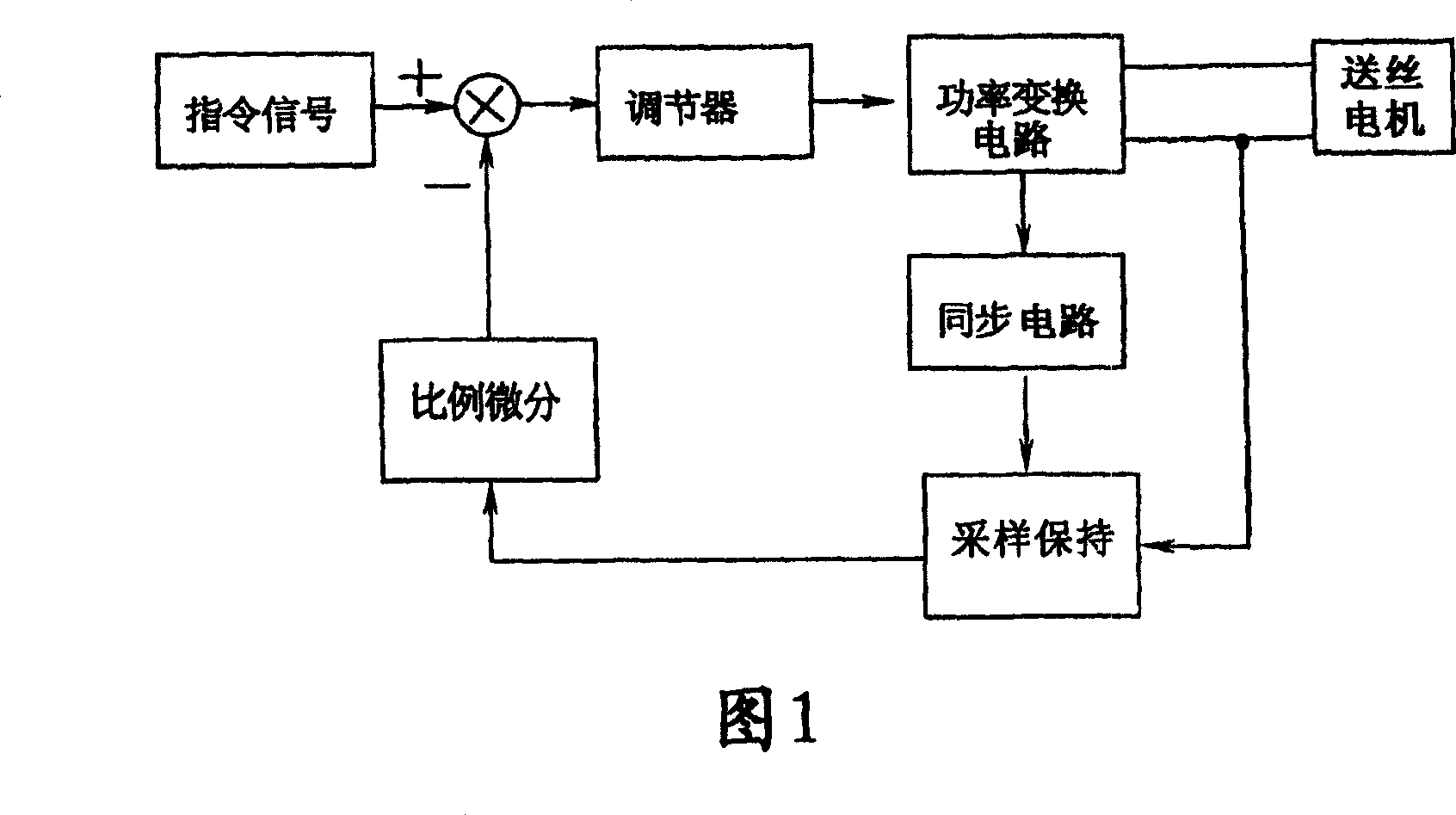

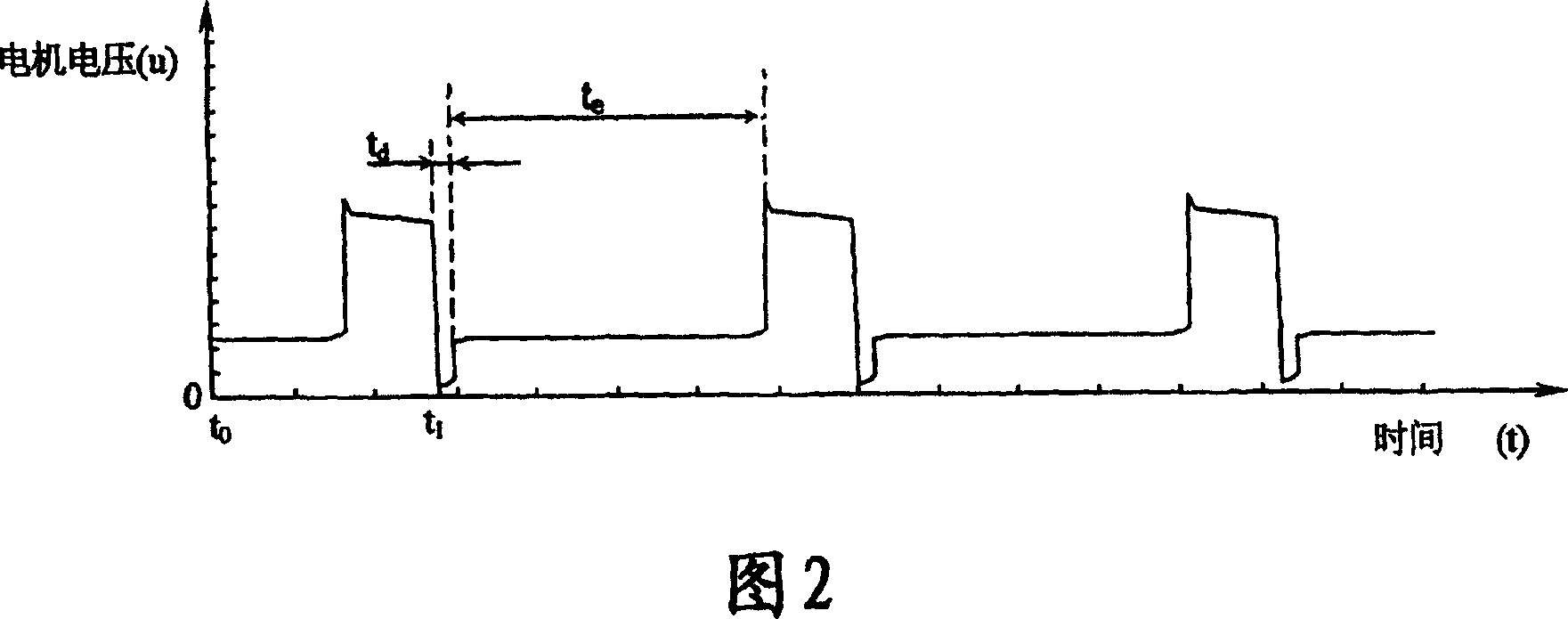

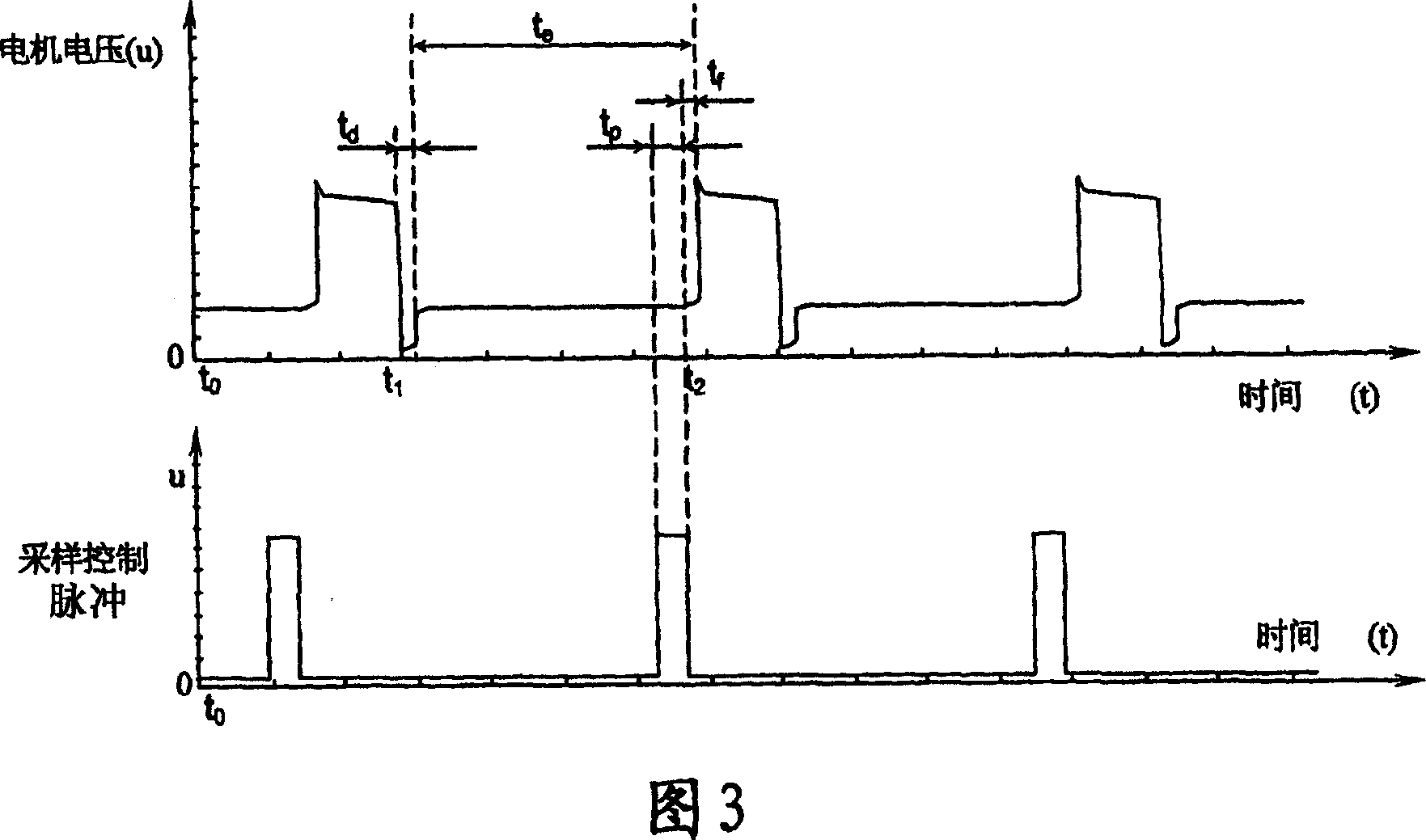

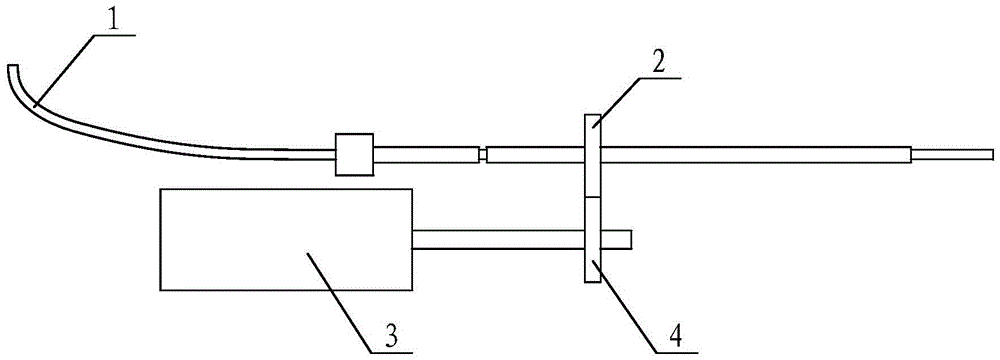

Method and system for regulating feeding wire speed

ActiveCN101051808AAccurately reflect the rotation speedRotation speed adjustmentField or armature current controlArc welding apparatusWire speedEngineering

The system includes following parts: when sampling control device outputs control pulse, the sample and hold device is in use for sampling and holding the sampled signals; regulating device is in use for magnifying error of instruction signal and the said sampled and held signal; modulation device is in use for outputting signal of pulse width modulation, and the said signal is in use for controlling output from the drive unit based on signal outputted from the regulating device; the drive unit is in use for revolving driving the motor for delivering wire based on pulse signal outputted from the modulation device; the sample and control device is in use for outputting sample and control pulse signal before the moment when the drive unit provides energy to the motor for delivering wire; starting device is in use for controlling operating states of the modulation device and the drive unit.

Owner:PANASONIC WELDING SYST TANGSHAN

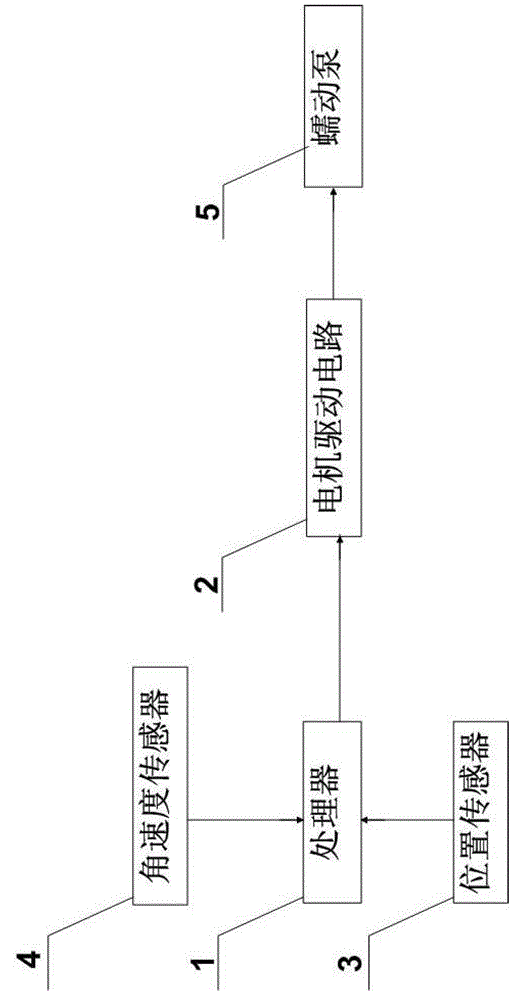

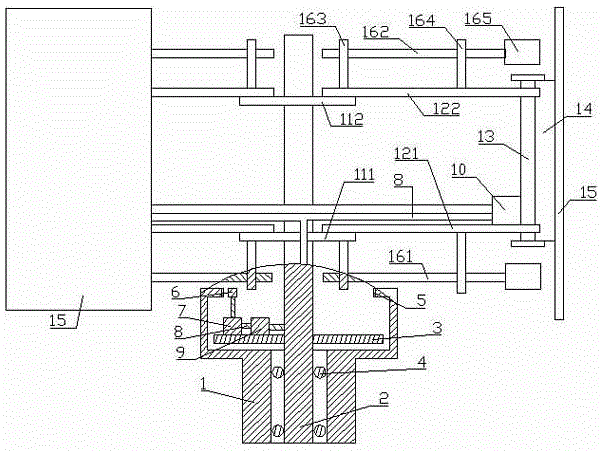

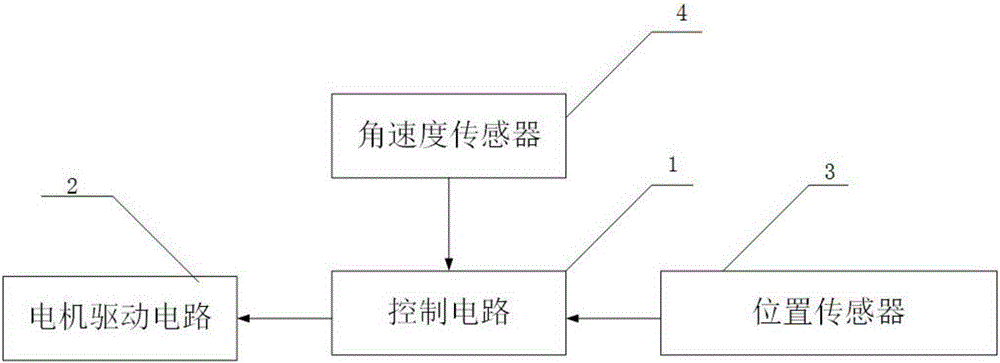

Peristaltic pump control system for purifying blood and method thereof

ActiveCN102743803AQuickly adjust the rotation speedSmooth rotationDialysis systemsBlood pumpsPeristaltic pumpControl system

The invention discloses a peristaltic pump control system for purifying blood and a method thereof, which relate to a haemodialysis machine component. The peristaltic pump control system comprises a control circuit and a motor driving circuit, wherein the output end of the control circuit is connected with the input end of the motor driving circuit; the first input end of the control circuit is connected with the signal output end of a position sensor; and the second input end of the control circuit is connected with the signal output end of an angular speed sensor. The rotating speed of a peristaltic pump can be adjusted rapidly, so that the rotating speed of the peristaltic pump is stable, and the phenomenon of reflowing during use is avoided; the rotating speed of the peristaltic pump is kept stable, so that loss of the peristaltic pump is reduced, and the service life of the peristaltic pump is prolonged; and moreover, the peristaltic pump control system further has the characteristics of freeness from pollution, high accuracy, high sealing property and the like.

Owner:SWS HEMODIALYSIS CARE CO LTD

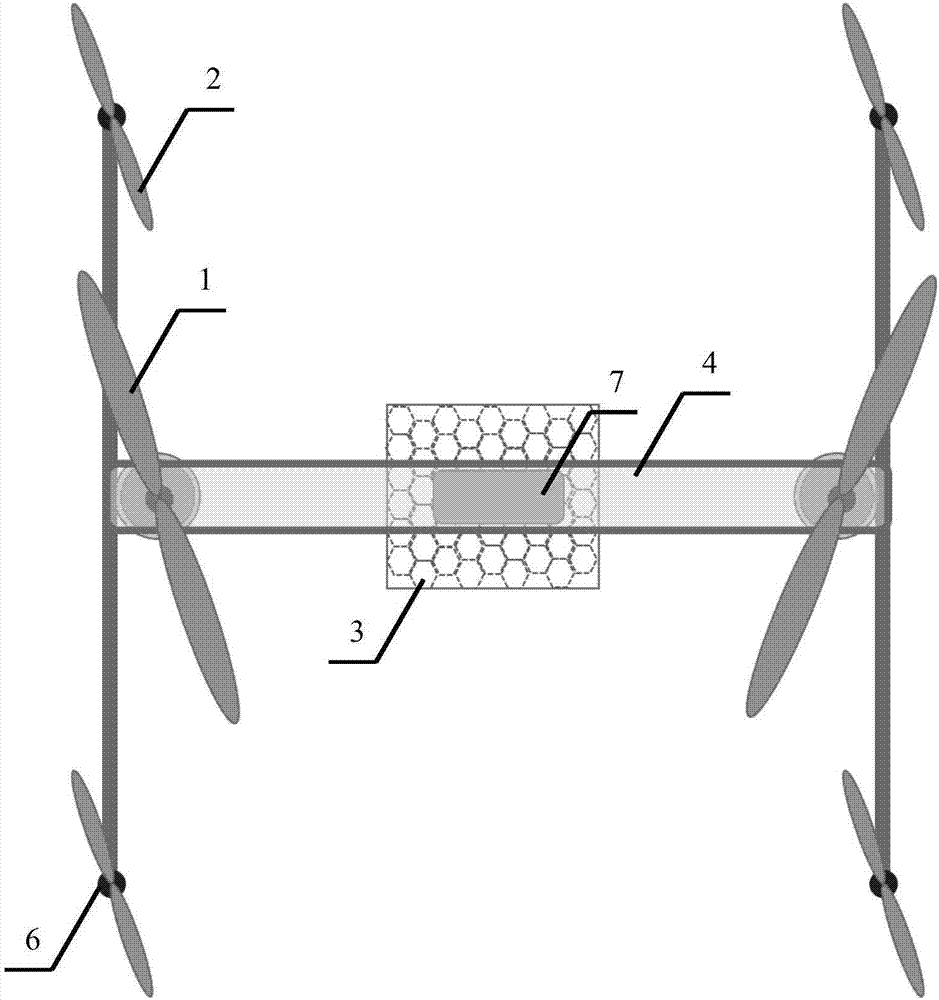

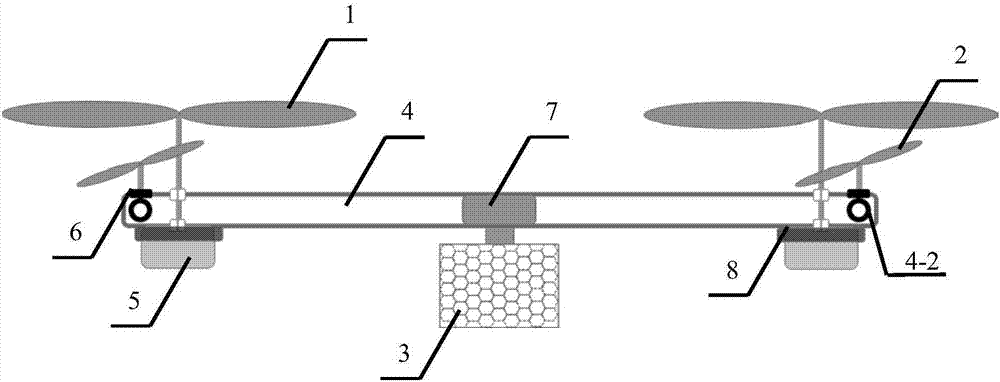

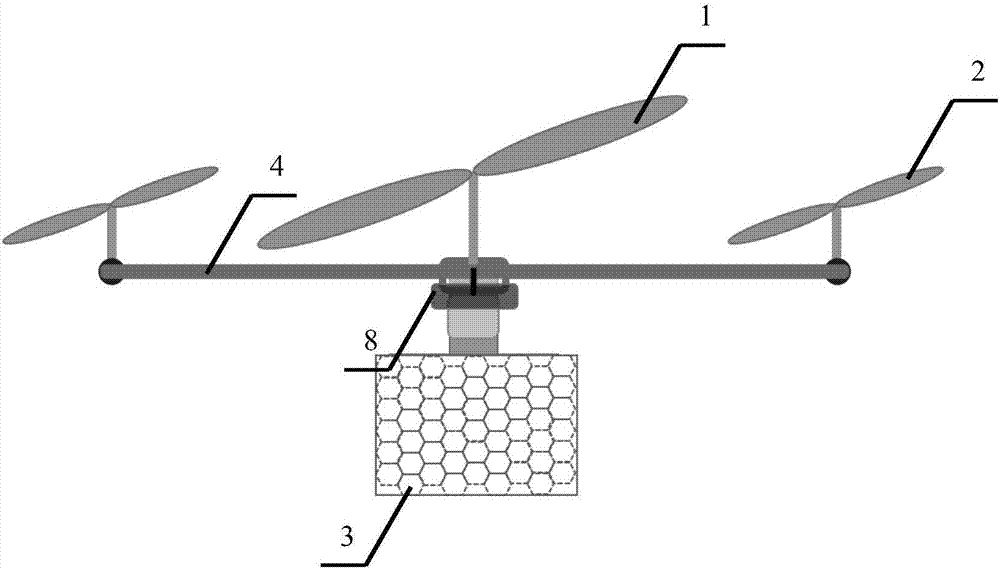

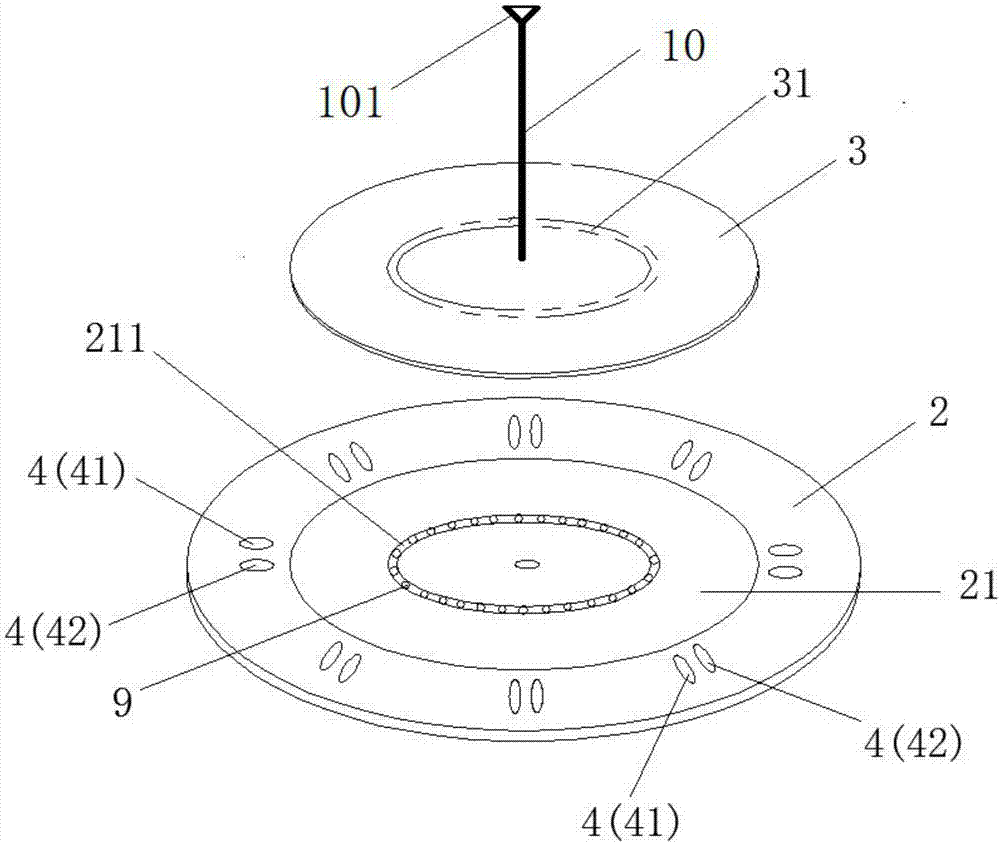

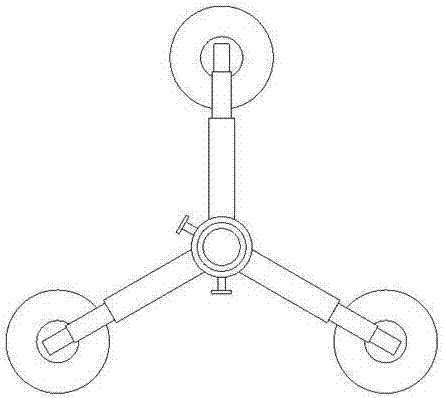

Hybrid power unmanned aerial vehicle

InactiveCN107140192AEasy loadingImprove utilization efficiencyPower plant typeRotocraftFlight vehicleUncrewed vehicle

The invention relates to a hybrid power unmanned aerial vehicle. The hybrid power unmanned aerial vehicle is characterized by comprising at least two lifting rotors, control rotors, a load frame and a rack, wherein the lifting rotors, the control rotors and the load frame are all mounted on the rack; the lifting rotors are symmetrically arranged in pairs and are arranged on two sides of the central axis of the unmanned aerial vehicle, and the rotor faces of the lifting rotors are perpendicular to the central axis of the unmanned aerial vehicle; and the lifting rotors are driven by fuel motors, and the control rotors are driven by motors. According to the hybrid power unmanned aerial vehicle, the lifting rotors provide the main lifting force; the control rotors keep the attitude of an aircraft; during advancement, retreatment and selective movement in a plane, the control rotors are accelerated or decelerated to change the attitude of the aircraft; the control algorithm of the unmanned aerial vehicle is similar to that of the multiple rotors, and a matched control structure of a helicopter is omitted, so that the structure and the control algorithm are greatly simplified, and further, the stability, the load, the flight duration and the controllability of the aircraft are improved.

Owner:陶霖密

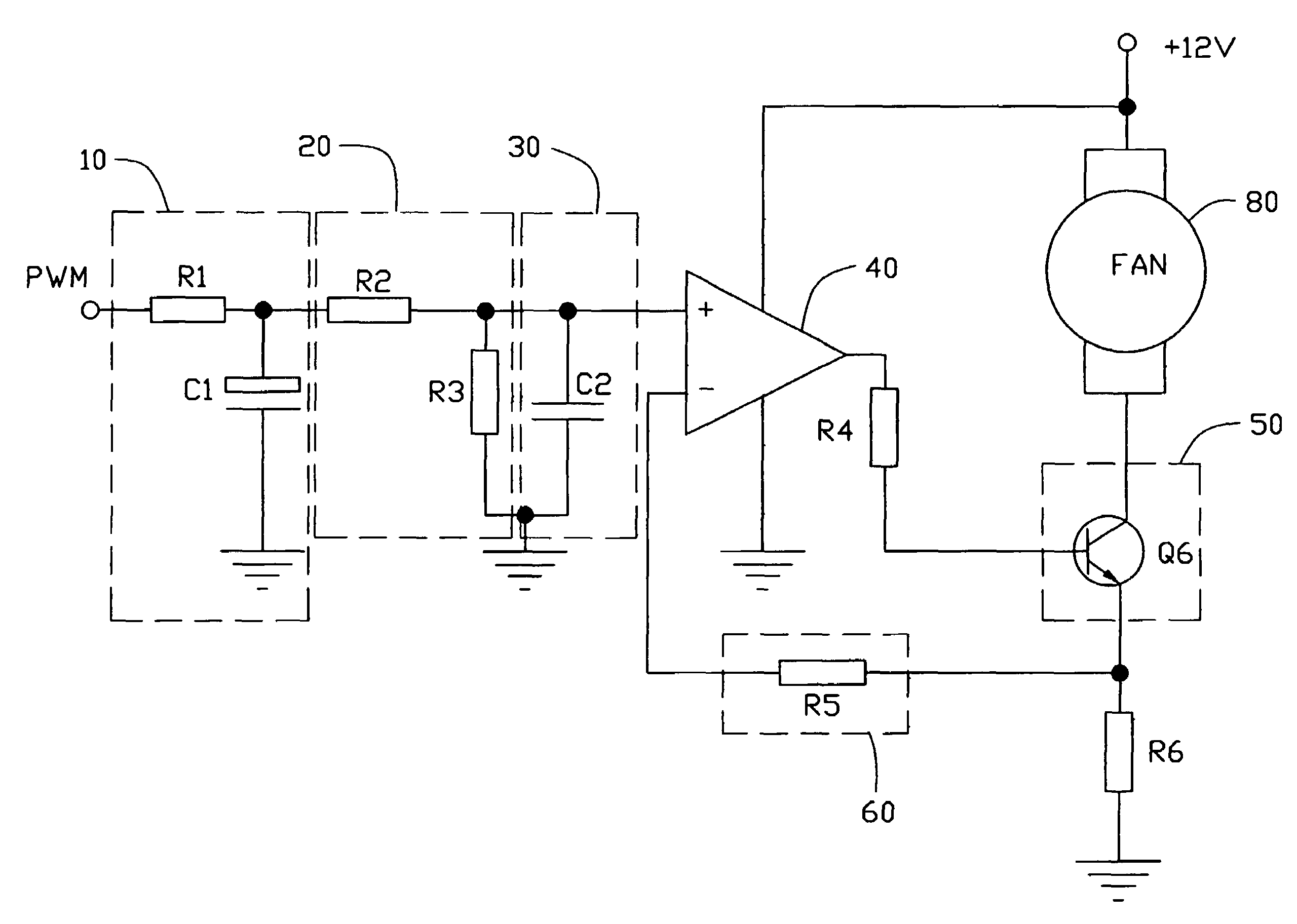

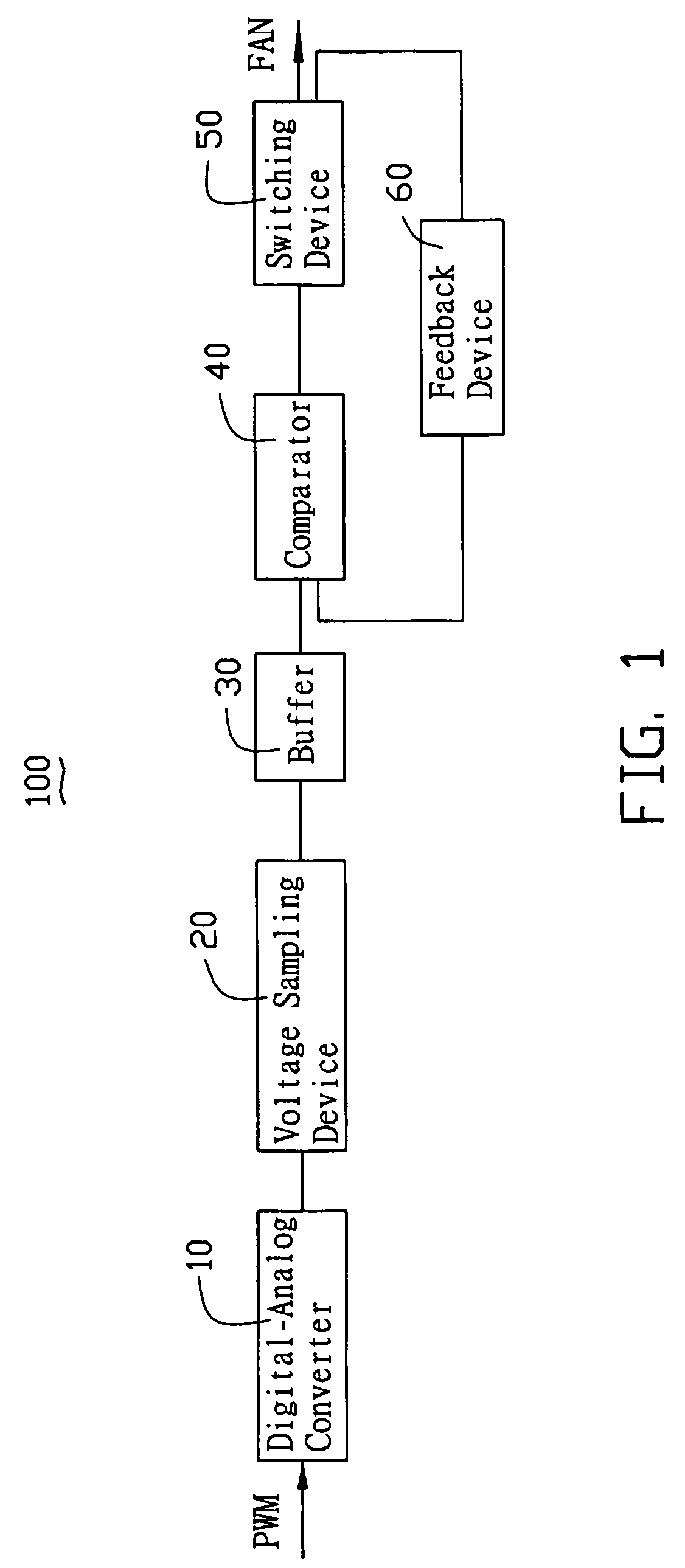

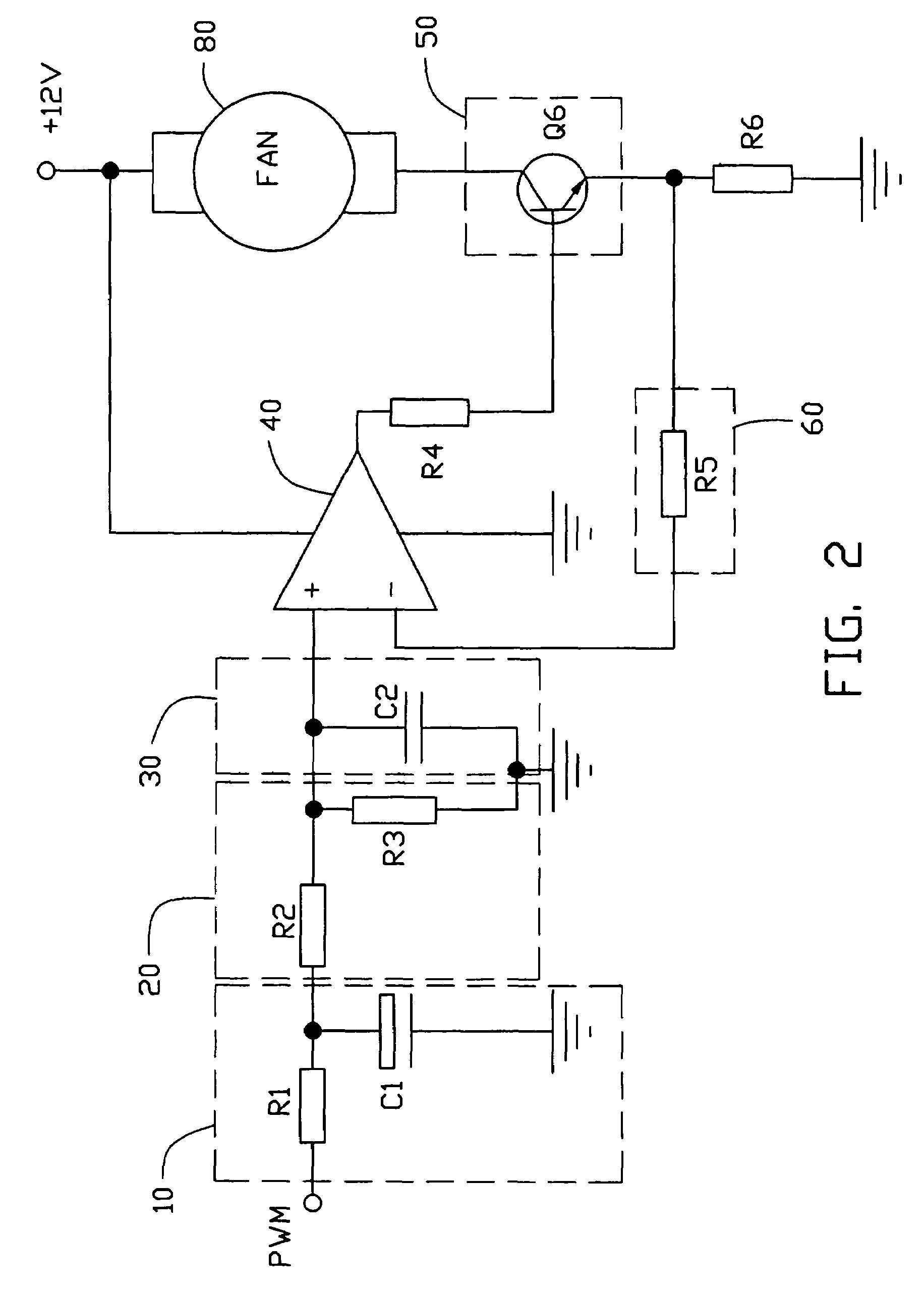

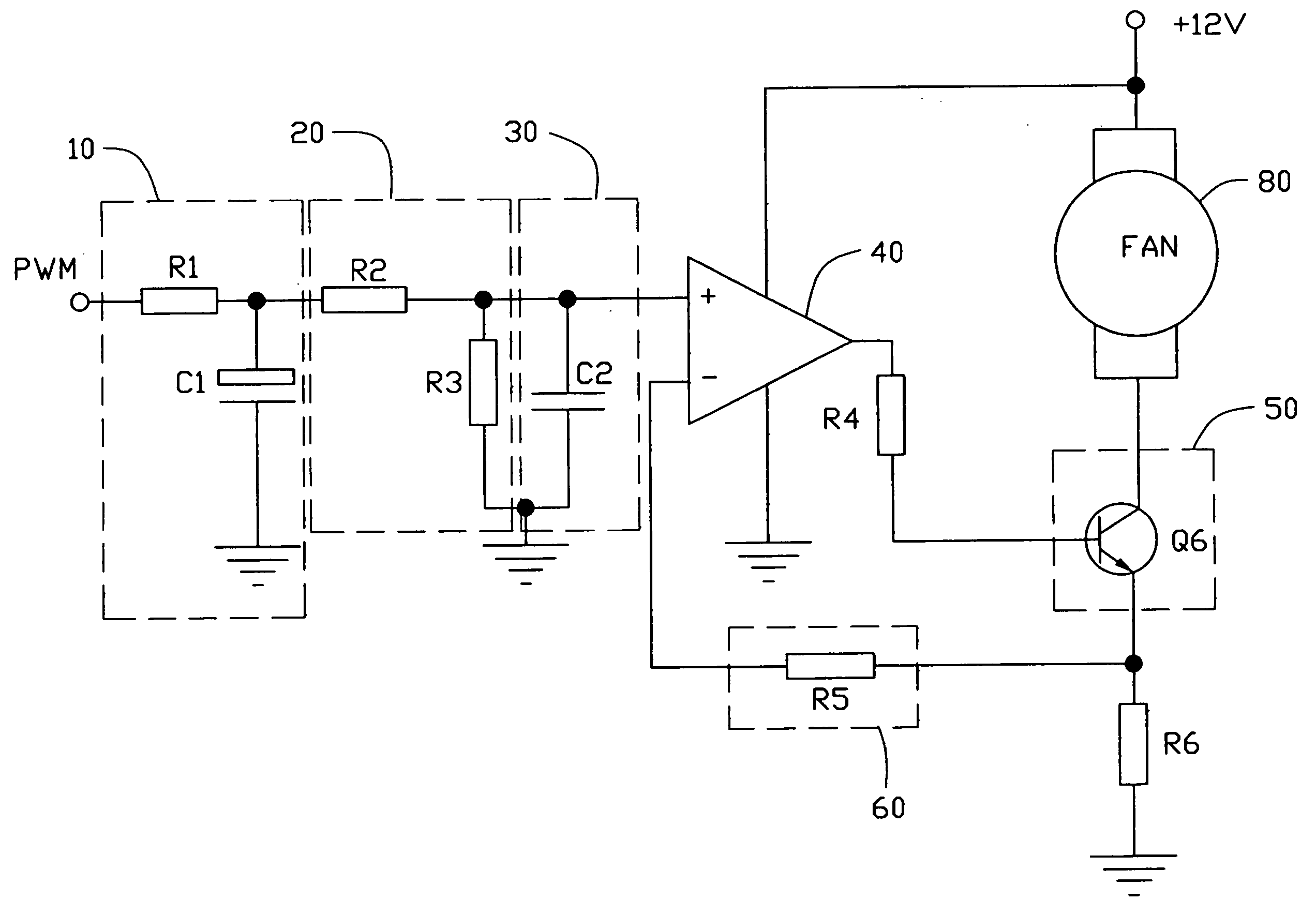

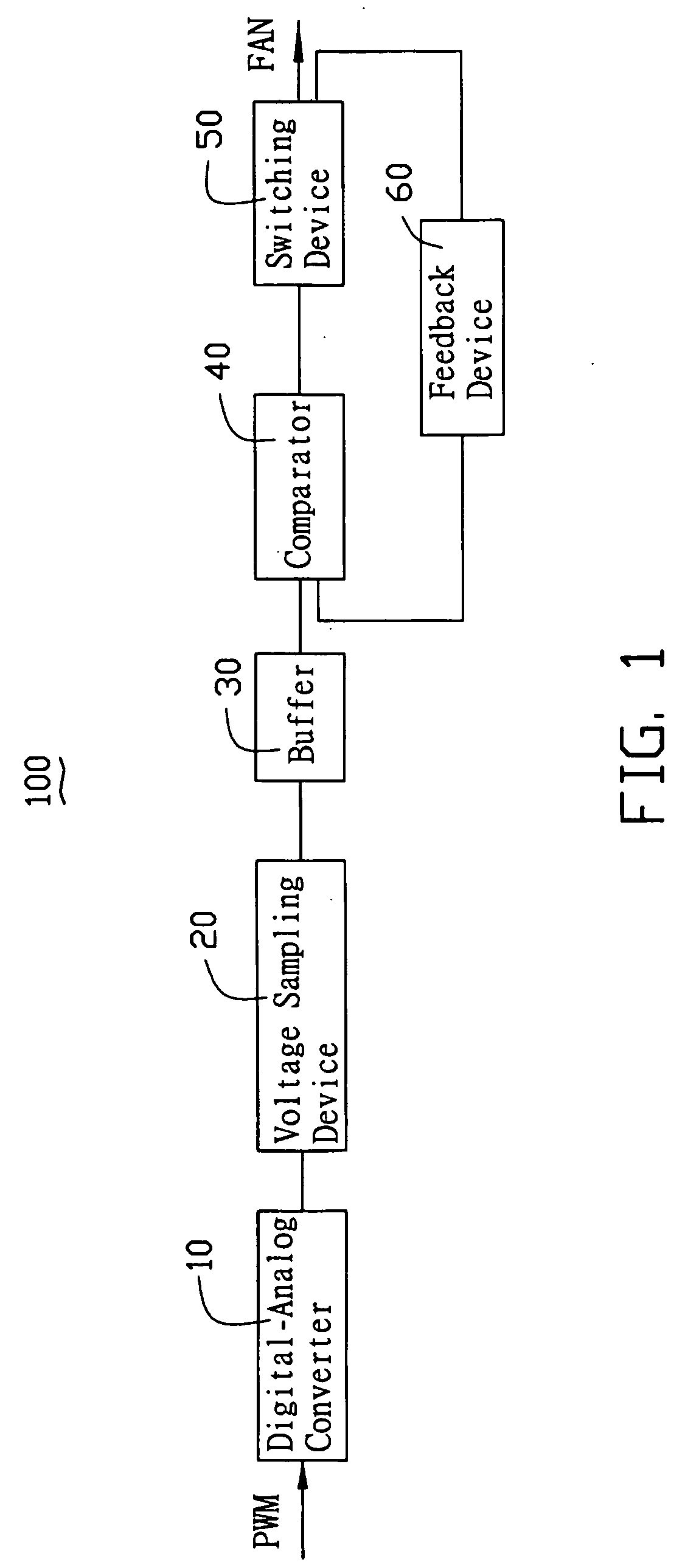

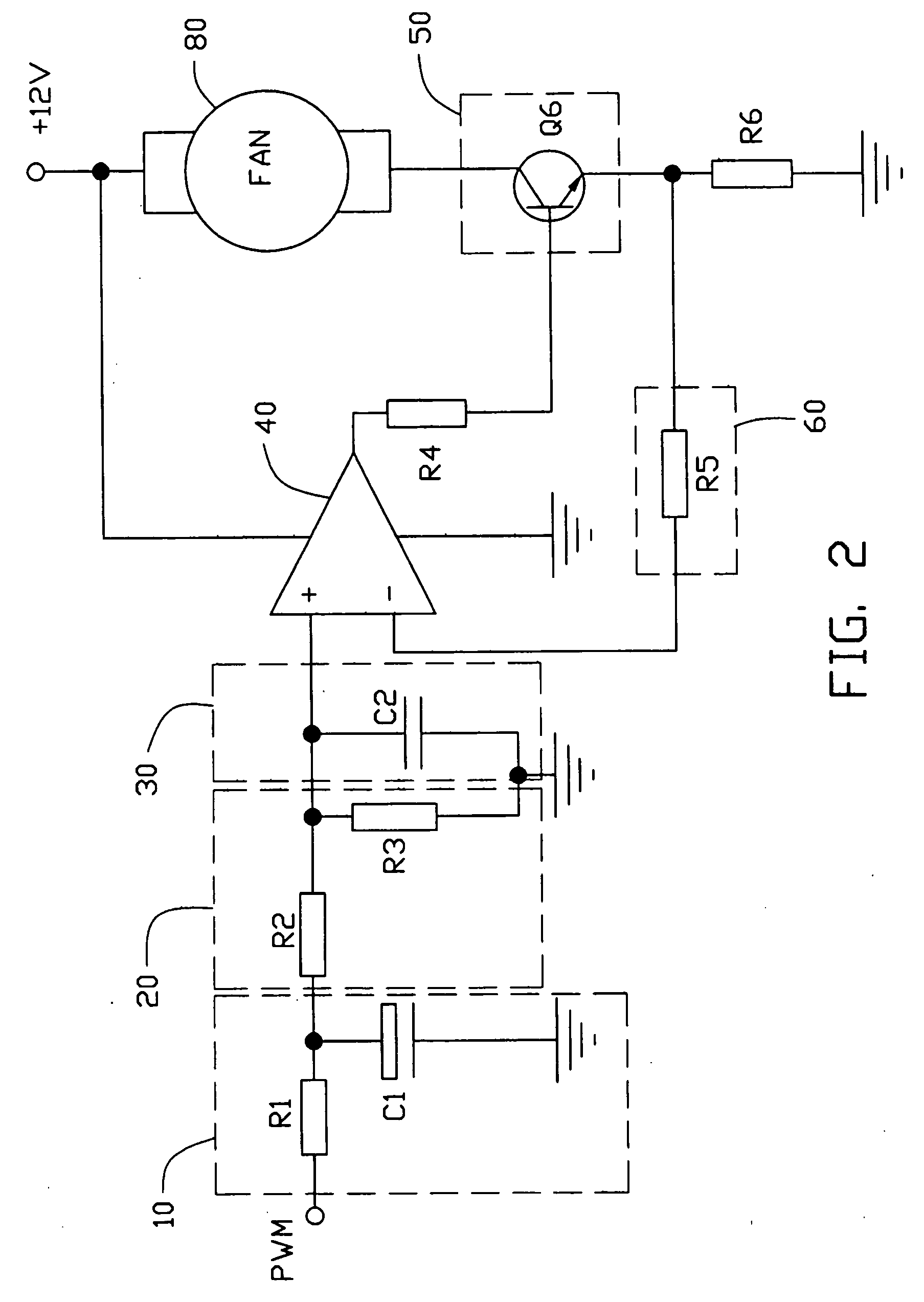

Start-up circuit for DC fan

InactiveUS7598690B2Lower average currentReduce noiseDC motor speed/torque controlAC motor controlDigital analog converterControl signal

A start-up circuit which decreases a start-up current and stabilizes running of a DC fan. The start-up circuit includes a digital-analog converter for convert a digital control signal from a control chip to an analog control signal, a voltage sampling device connected to an output terminal of the digital-analog converter, a comparator, a switching device for controlling start-up of the DC fan, and a feedback device adjusting current passing through the switching device. The comparator includes two input terminals and an output terminal. One input terminal is connected to an output terminal of the voltage sampling device. The switching device is connected to the output terminal of the comparator. An output signal of the switching device is inputted to the other input terminal of the comparator via the feedback device.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Start-up circuit for DC fan

InactiveUS20060076912A1Low noisePreventing large currentSynchronous motors startersDC motor speed/torque controlCurrent regulationDigital analog converter

A start-up circuit which decreases a start-up current and stabilizes running of a DC fan. The start-up circuit includes a digital-analog converter for convert a digital control signal from a control chip to an analog control signal, a voltage sampling device connected to an output terminal of the digital-analog converter, a comparator, a switching device for controlling start-up of the DC fan, and a feedback device adjusting current passing through the switching device. The comparator includes two input terminals and an output terminal. One input terminal is connected to an output terminal of the voltage sampling device. The switching device is connected to the output terminal of the comparator. An output signal of the switching device is inputted to the other input terminal of the comparator via the feedback device.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

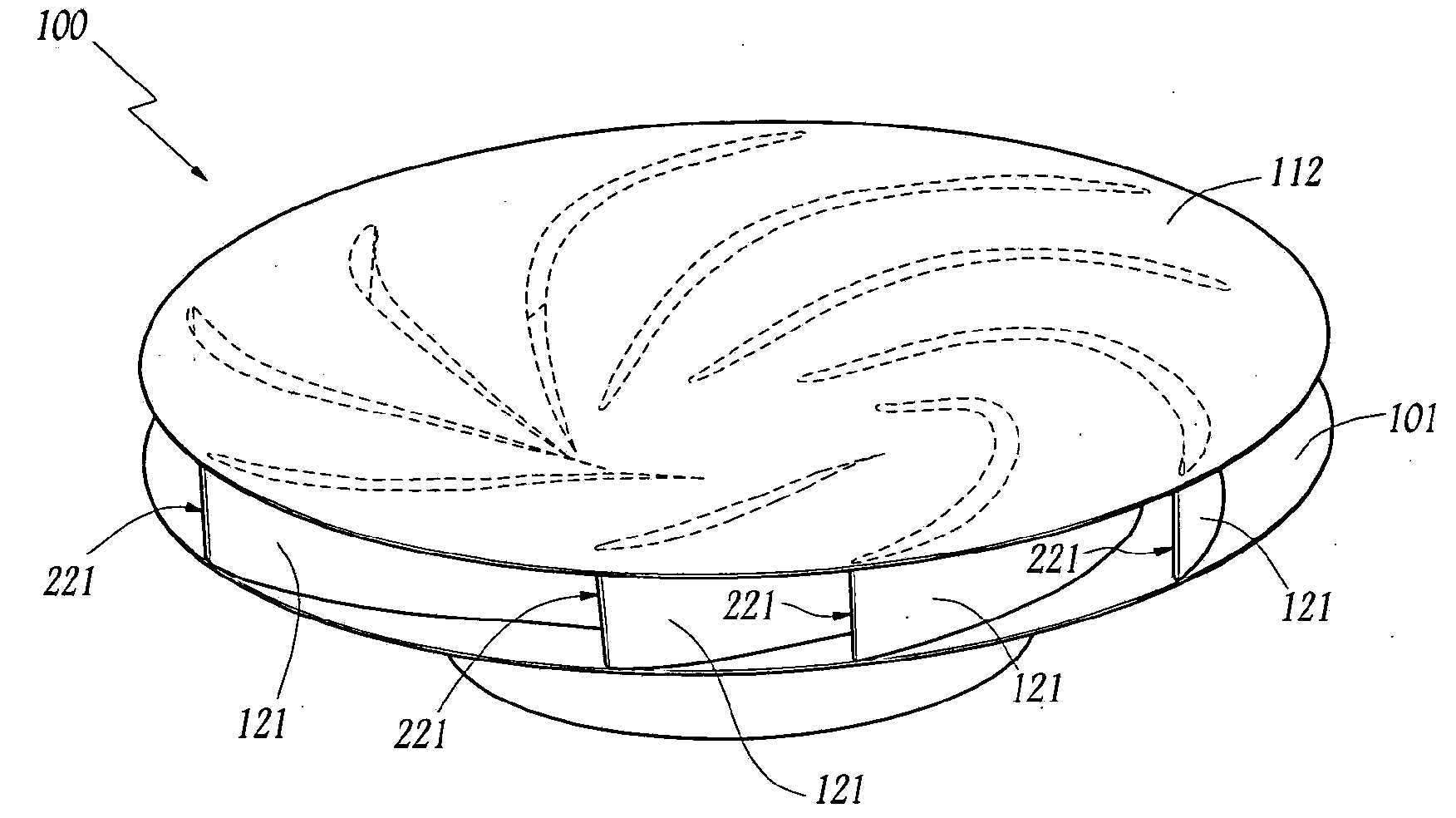

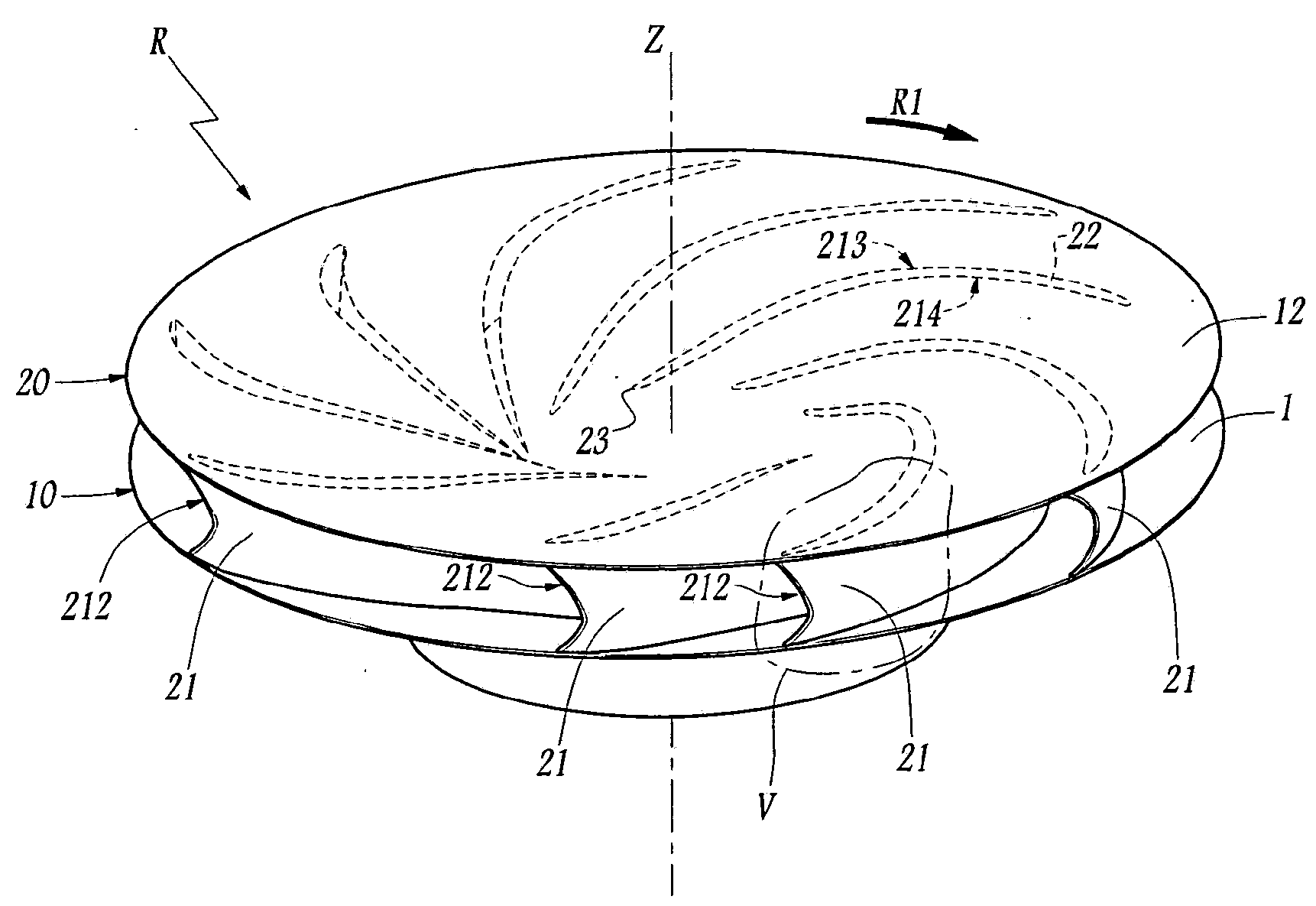

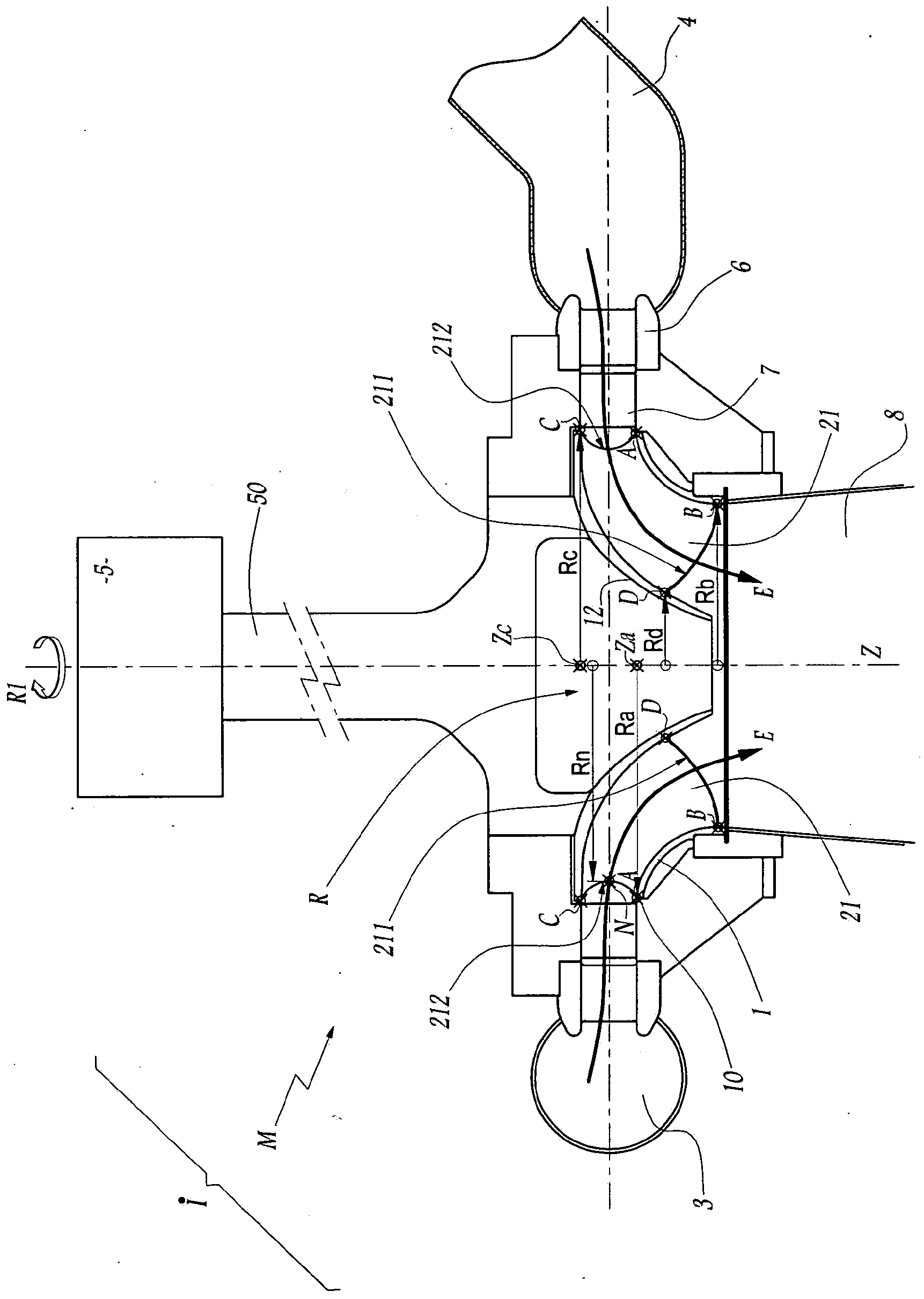

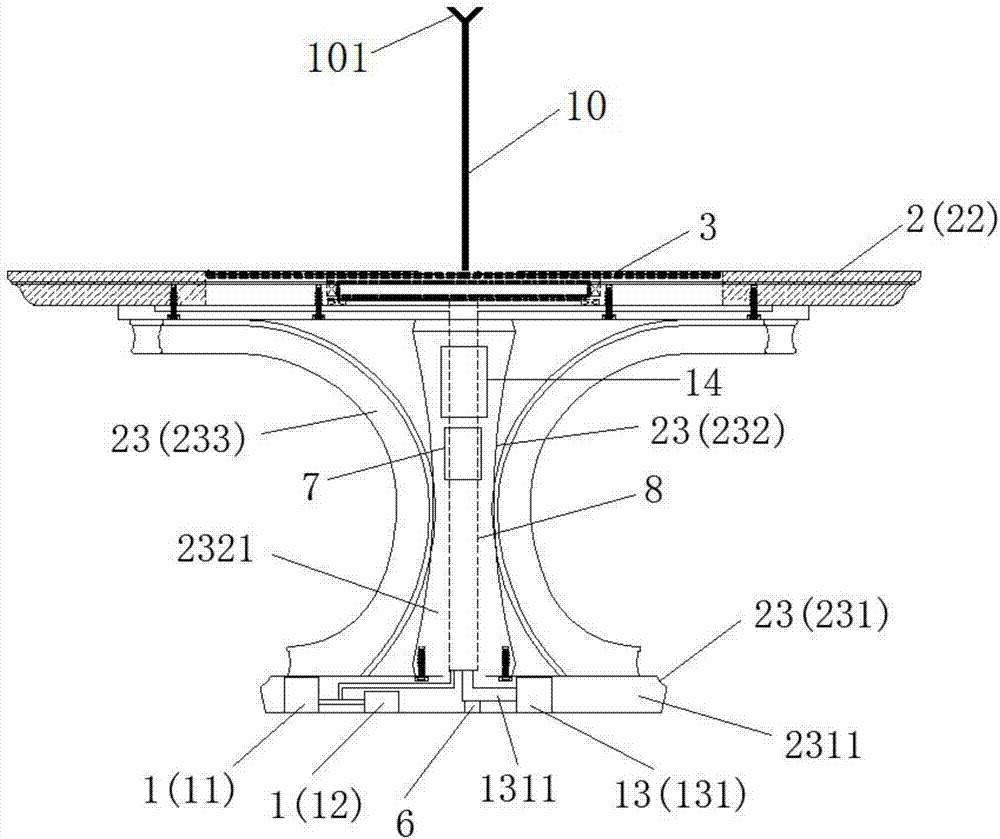

Runner for a hydraulic machine, hydraulic machine provided with such a runner, and power-conversion equipment including such a hydraulic machine

ActiveCN103649524AQuick connectionStable rotation speedHydro energy generationReaction enginesMechanical engineeringIntermediate point

The invention relates to a Francis runner (200) for a hydraulic machine, comprising: a wheel (1), which is rotationally symmetrical about an axis of rotation (Z) of the runner (200); a crown (12); and a plurality of inwardly curved vanes (21), each of which has a peripheral edge (212). The peripheral edge (212) of at least one of the vanes is curved, the concavity thereof facing toward the outside of the runner (200). The maximum value of the distance measured between any point on the peripheral edge (202) and a straight line passing through a first connection point between the peripheral edge (212) and the wheel (1), and through a second connection point between the peripheral edge (212) and the crown (12), is at an intermediate point on the peripheral edge (212). The radius (Rn) from the intermediate point (N) is strictly smaller than the radius (Ra) from the first connection point (A). The radius (Rn) from the intermediate point (N) is strictly smaller than the radius (Rc) from the second connection point (C).

Owner:GE RENEWABLE TECH

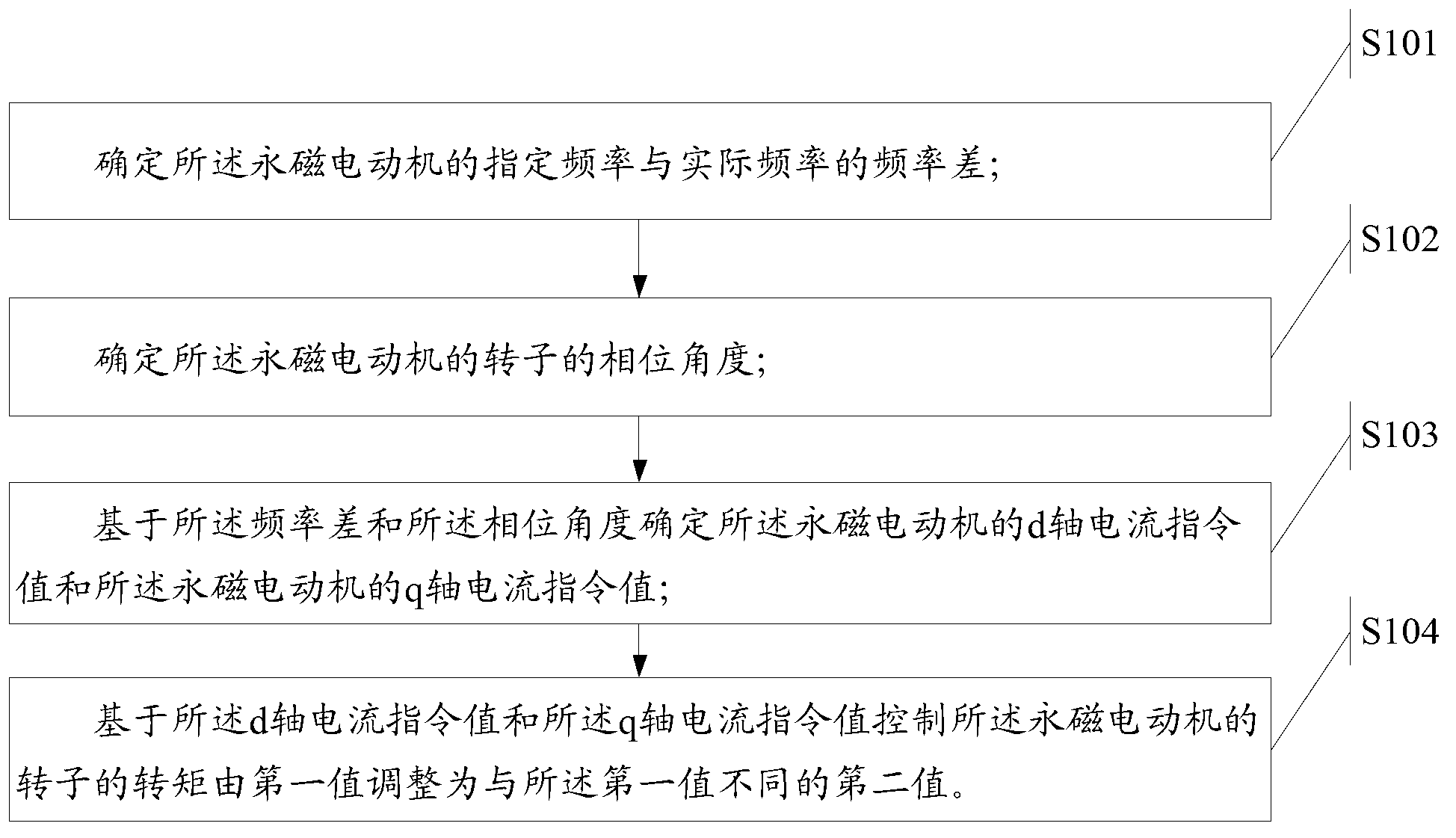

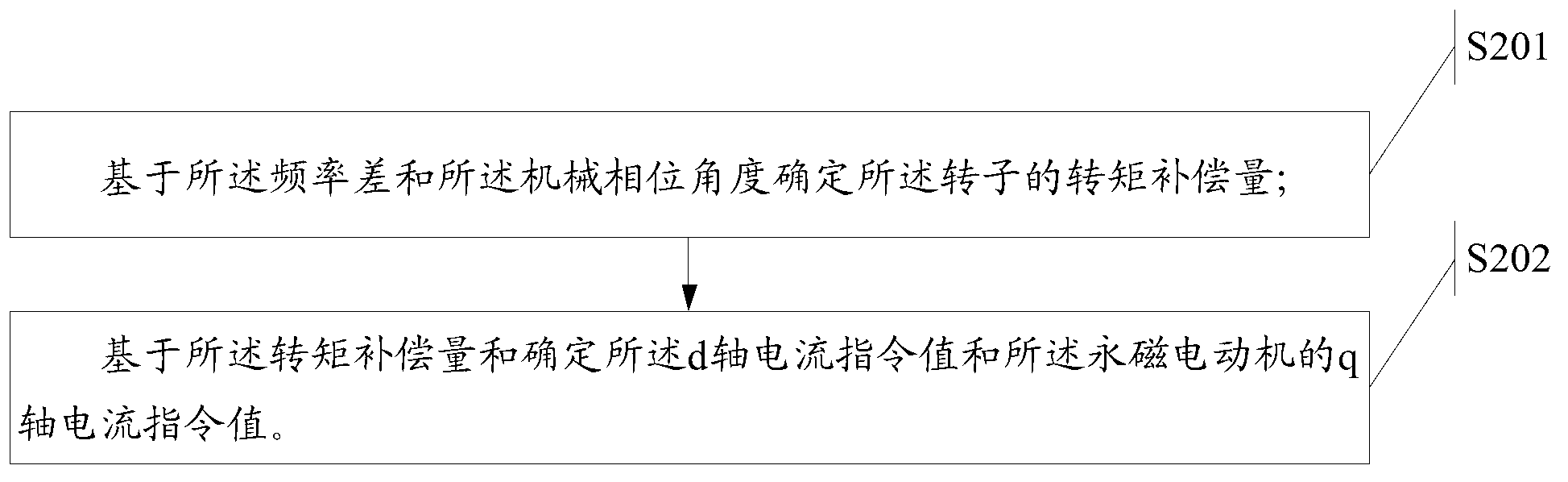

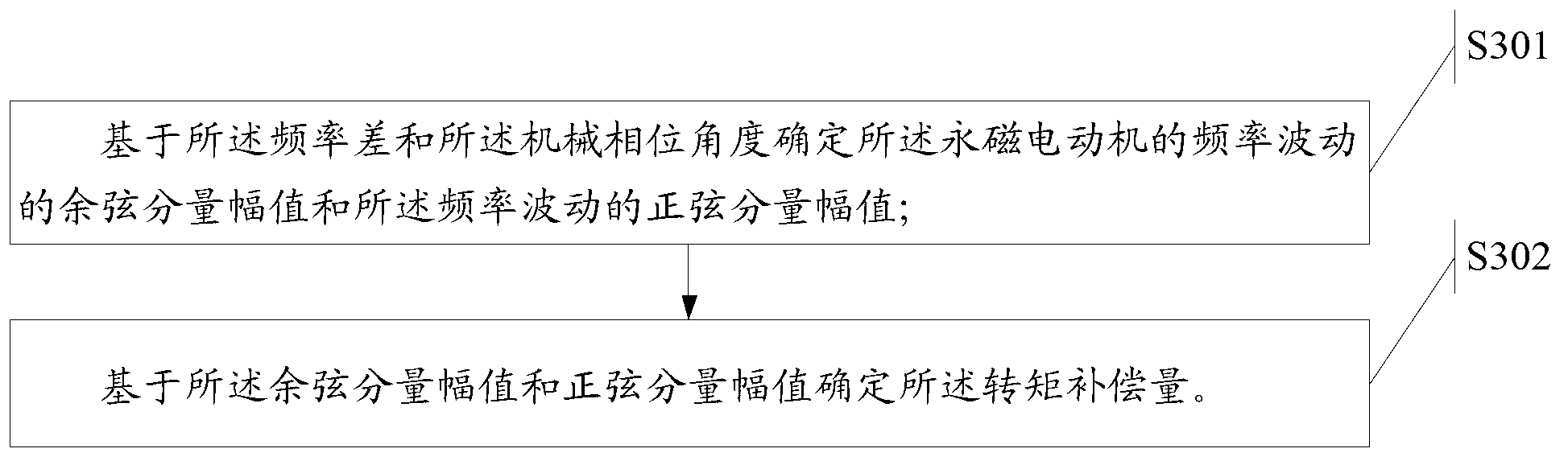

Method and system for automatically compensating torque

ActiveCN103296958AAvoid vibration noiseStable rotation speedElectronic commutation motor controlVector control systemsPermanent magnet motorControl theory

The invention discloses a method and a system for automatically compensating torque. The method and the system aim to solve the technical problem of fluctuation of the rotation speed of a permanent magnet motor in the prior art. The method is applied to a permanent magnet motor, and includes determining the frequency difference delta f between a specified frequency f<*> and an actual frequency f of the permanent magnet motor; determining a phase angle theta of a rotor of the permanent magnet motor; determining a torque compensation quantity for the rotor of the permanent magnet motor on the basis of the frequency difference delta f and the phase angle theta, and determining a current instruction value I<d><*> of a shaft d of the permanent magnet motor and a current instruction value I<q><*> of a shaft q of the permanent magnet motor by the aid of the torque compensation quantity; controlling and adjusting the torque of the rotor of the permanent magnet motor from a first value to a second value different from the first value on the basis of the current instruction value I<d><*> of the shaft d and the current instruction value I<q><*> of the shaft q.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Control system for a vehicle

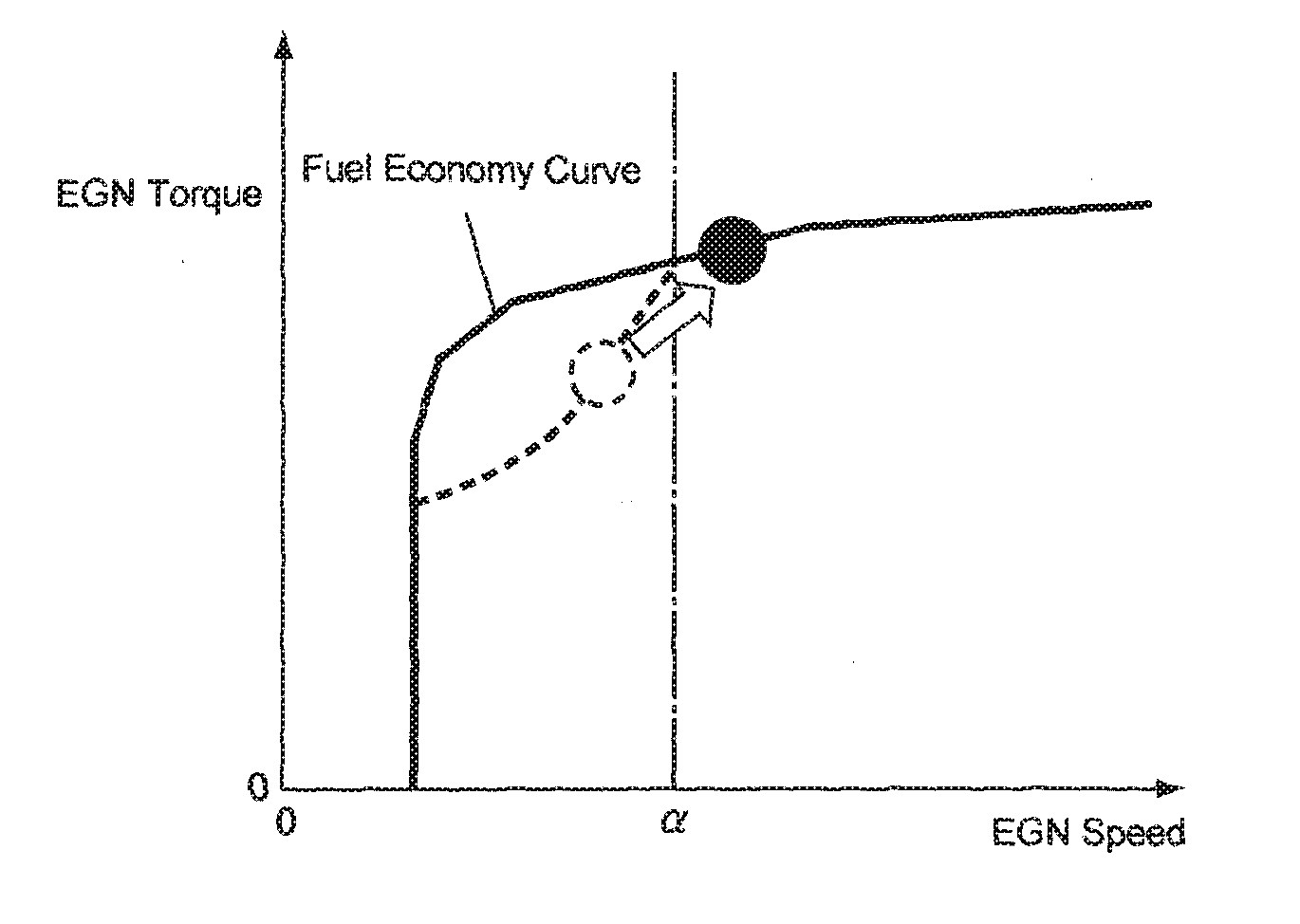

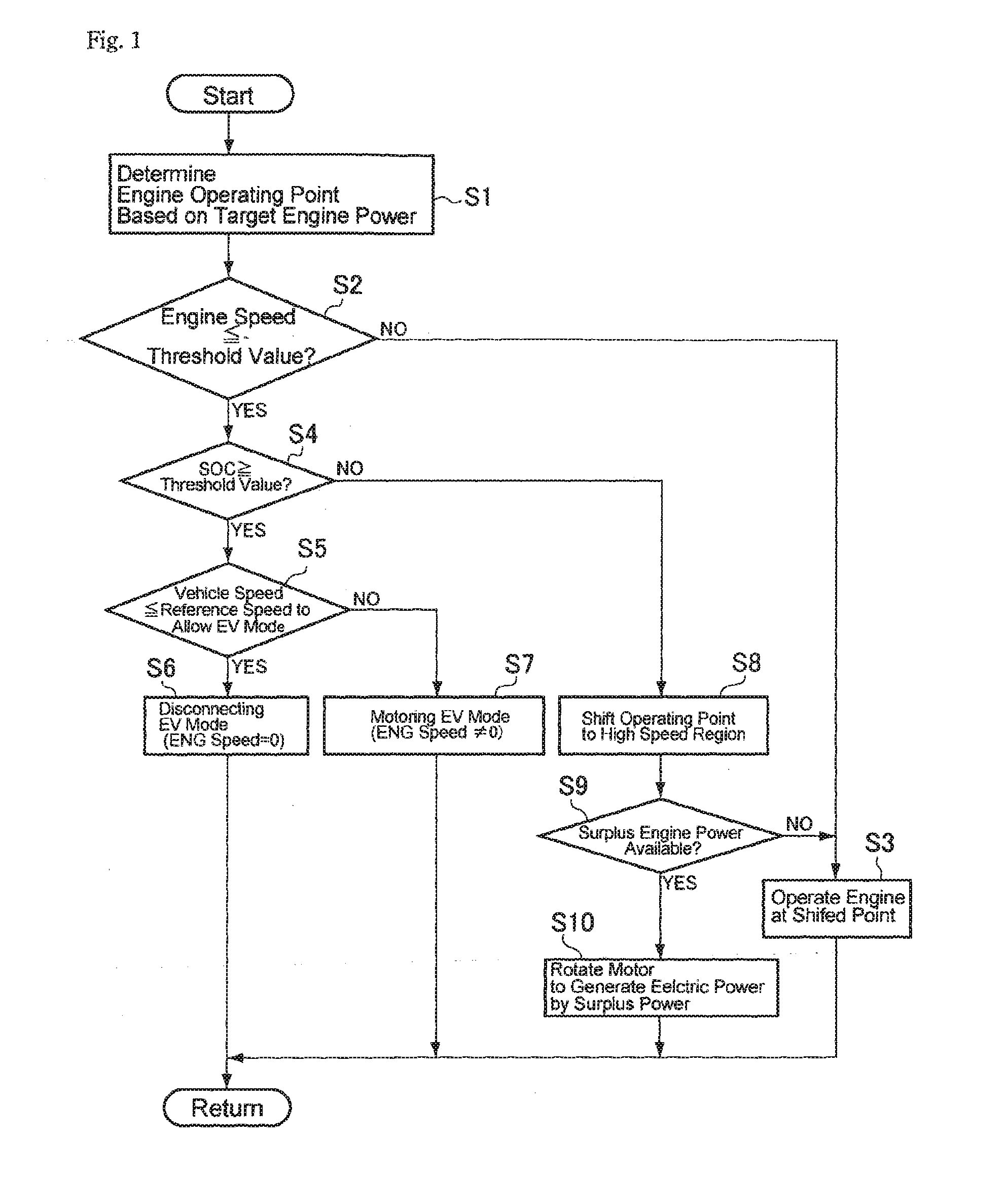

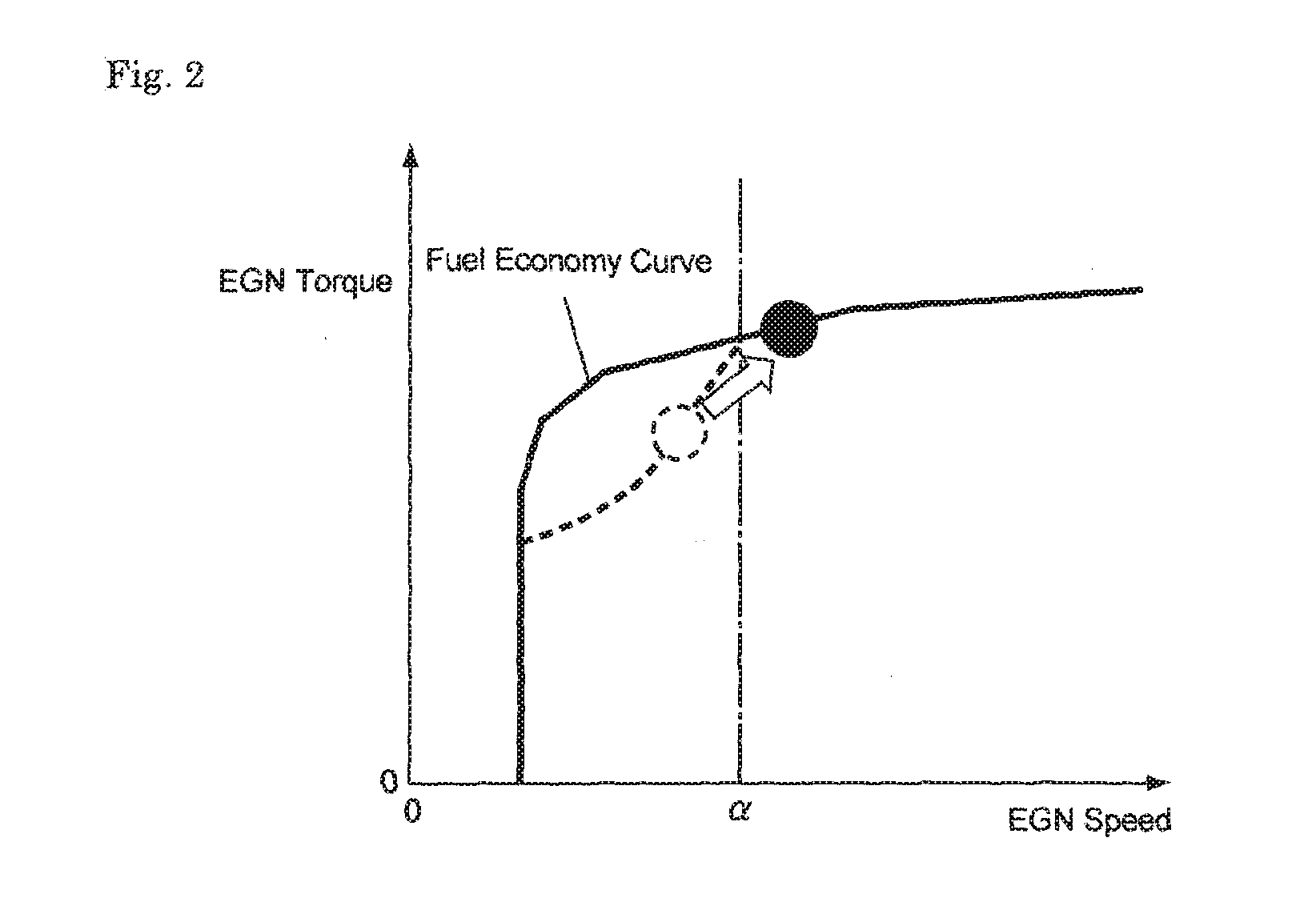

InactiveUS20160251010A1Increase stiffnessImprove responseHybrid vehiclesInternal combustion piston enginesOperating pointControl system

A control system for a vehicle having an engine and a motor configured to reduce torque pulses and vibrations. The control system is comprised of a determining means that determines a target operating point of the engine at which a target engine power based on a required driving force is generated while improving fuel economy (step S1); and an electric vehicle mode setting means that shift a driving mode to the EV mode to drive the vehicle by the motor, if a target engine speed to be achieved at the target operating point determined by the determining means is lower than a predetermined threshold value (steps S2, S6).

Owner:TOYOTA JIDOSHA KK

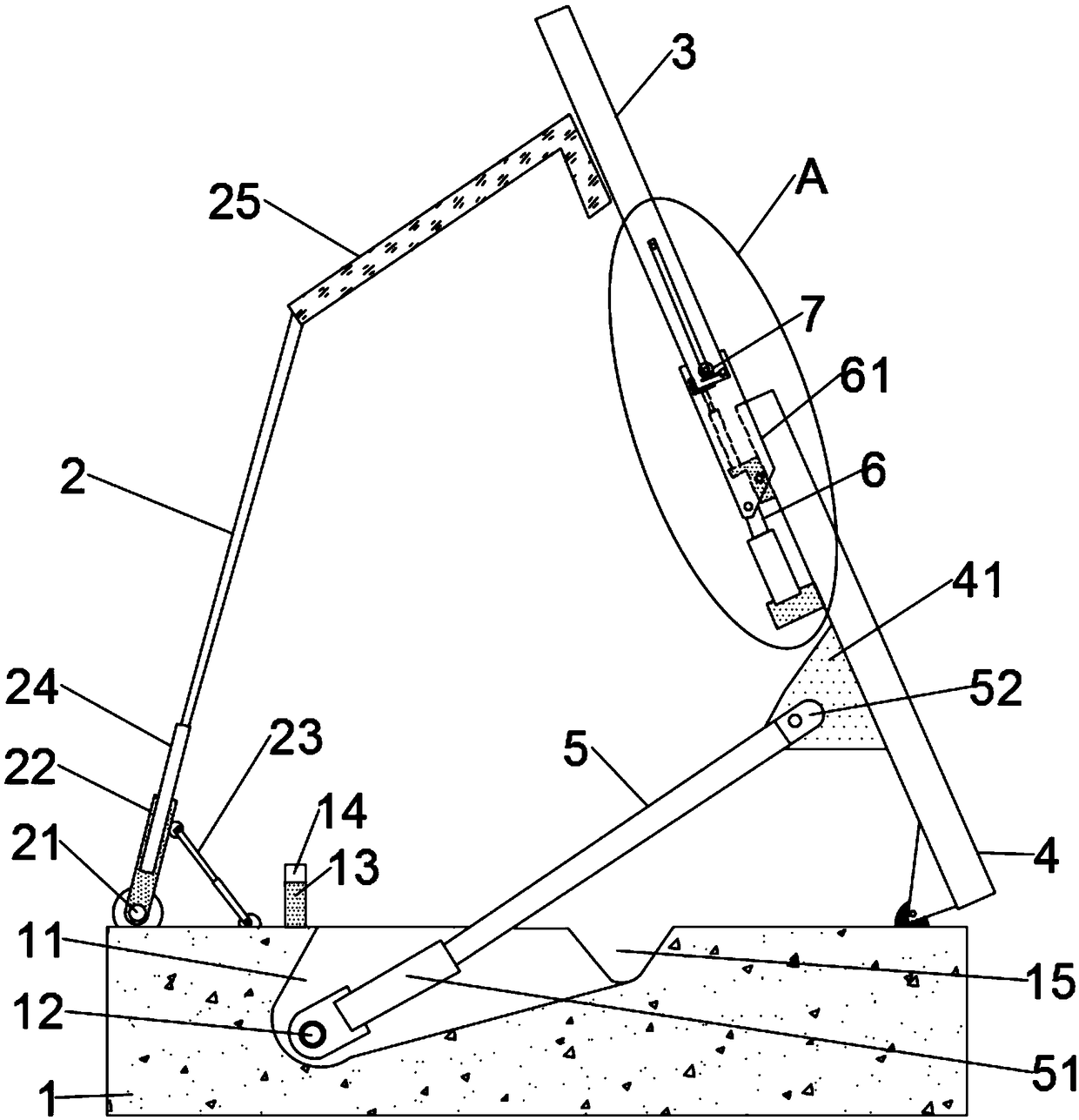

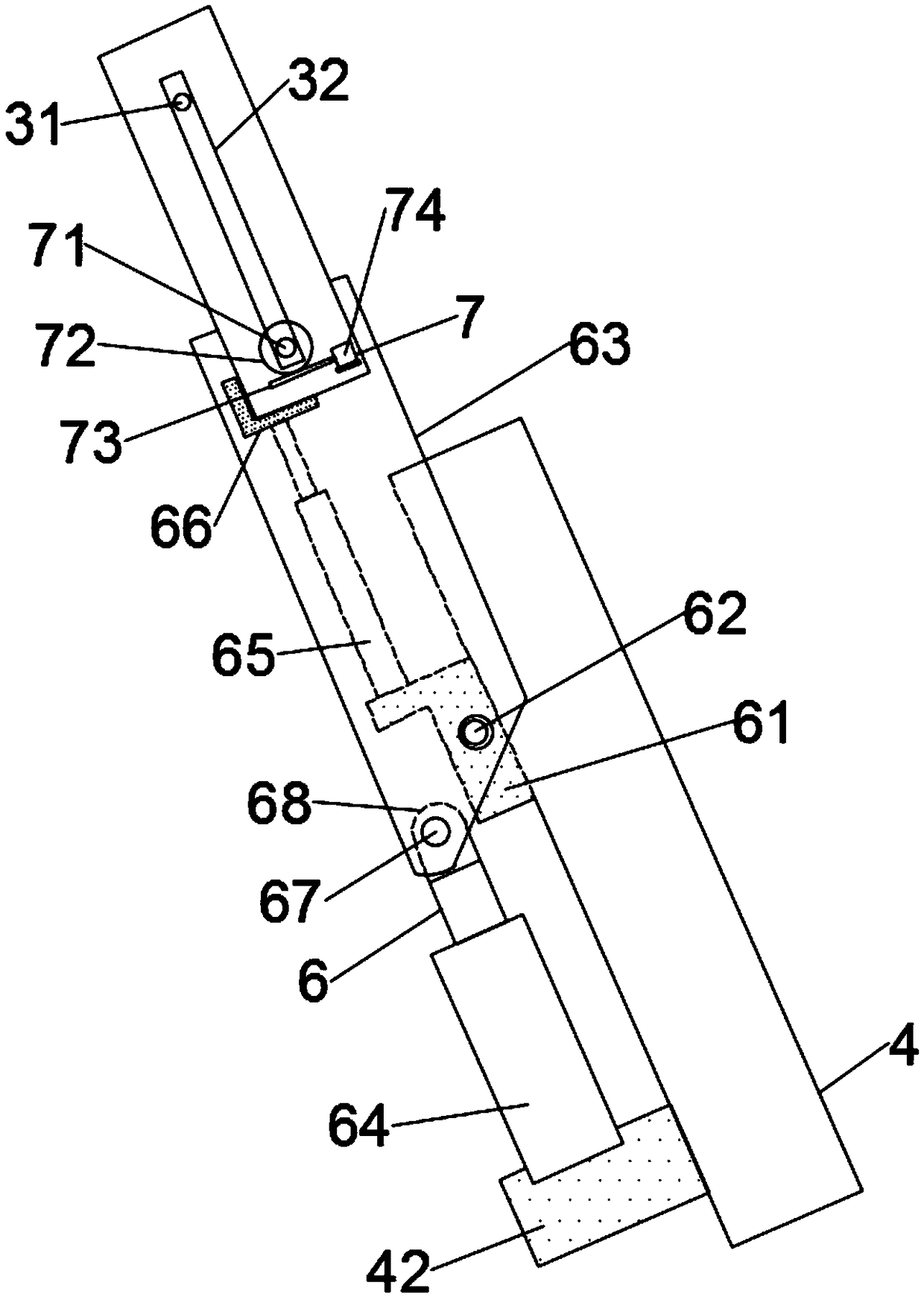

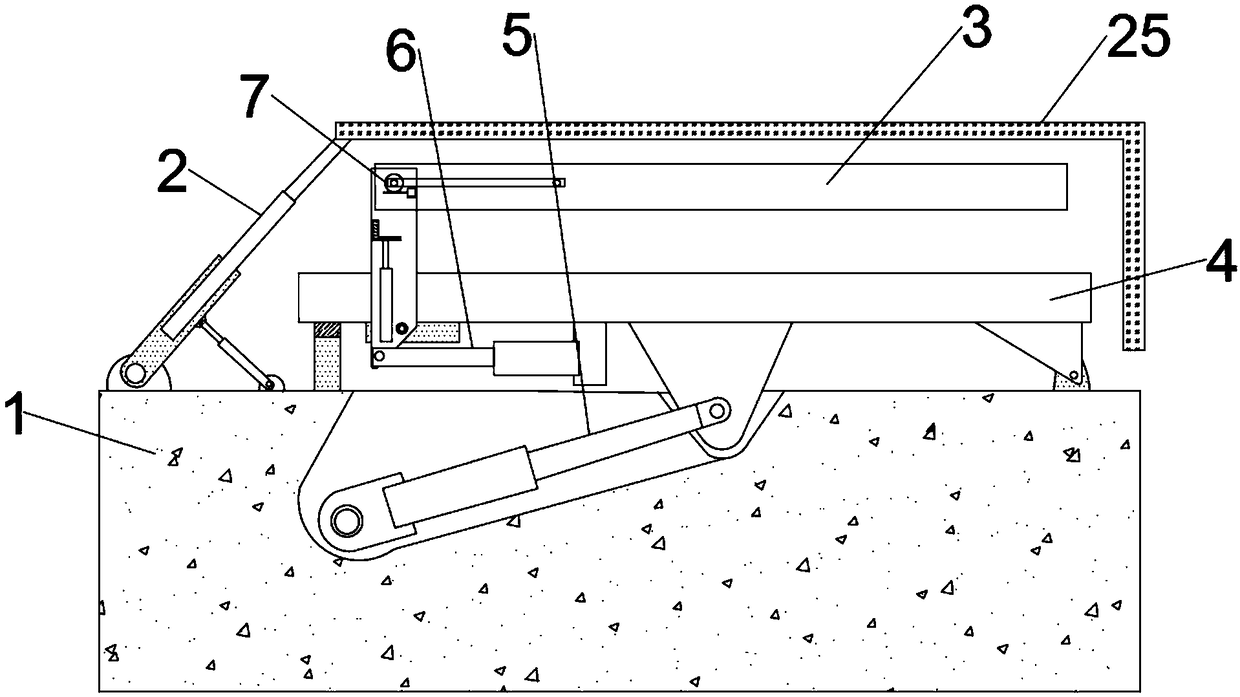

Folding device for onboard high-mobility large antenna array radar

ActiveCN108832258AReduce shakingExtended service lifeCollapsable antennas meansAntenna supports/mountingsRadarScratching

The invention discloses a folding device for an onboard high-mobility large antenna array radar. The folding device comprises an antenna base. A support protection device is arranged on the left end of the antenna base. A lower array antenna frame is installed on the top of the antenna base through a hinge seat. The left side of the top of the lower array antenna frame is connected to the antennabase by an overturning pitch mechanism. The top of the lower array antenna frame is connected with an upper array antenna frame through a folding rotating mechanism. The support protection device canprotect a radar in transit against the scratching by foreign objects. An L-shaped protective support plate can support the back of a radar array antenna when the radar is unfolded to operate, therebyreducing the shaking of the radar and improving the stability of a radar transmission signal. By an angle rotation mechanism, the upper array antenna can be automatically fixed when rotating to an appropriate position to operate or folded to an appropriate angle to contract. The upper array antenna has a slow and stable rotation speed and high angle adjustment precision.

Owner:嘉兴市恒泰化工科技有限公司

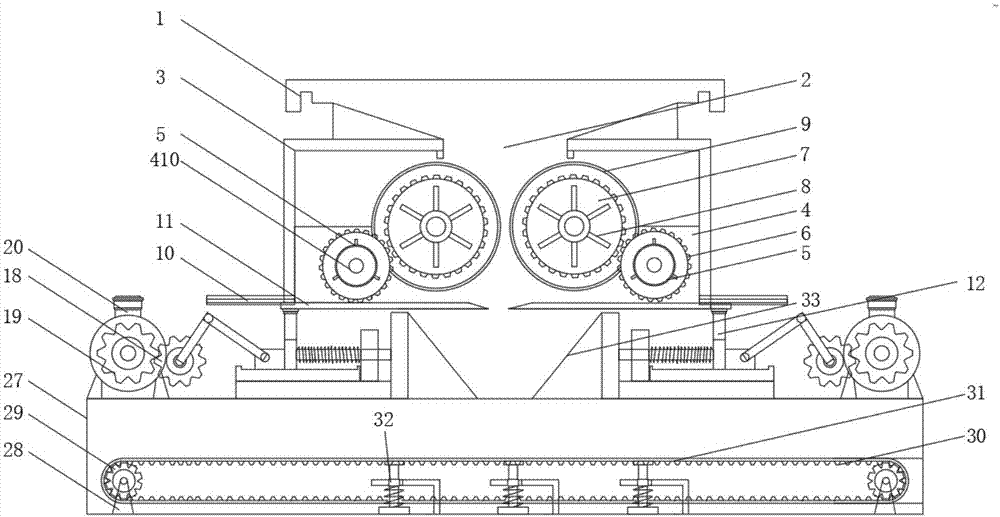

Steel ball polishing and transporting device

ActiveCN107877348AAchieve the purpose of polishingAchieve work uniformityPolishing machinesGrinding drivesGear wheelSteel ball

The invention discloses a steel ball polishing and transporting device, which comprises a feeding top cover. A feeding inlet is formed in the bottom part of the feeding top cover; a polishing work boxis fixedly connected to the bottom part of the feeding top cover; power devices are fixedly connected to two sides of the bottom part of an inner wall of the polishing work box and are fixedly connected with power rotating wheels; each power rotating wheel is rotatably connected with a first gear through an output shaft; each first gear is located on the upper part of the inner side of the polishing work box and is engaged with a second gear; each second gear is rotatably connected with a polishing roller wheel through a rotary shaft; and a detachable fixing handle is arranged on the surfaceof each second gear. The invention relates to the technical field of steel ball polishing transporters. The steel ball polishing and transporting device can be used for polishing, discharging and transporting steel balls, the stability of the rotating speed and the working evenness are ensured, the polishing quality and the polishing efficiency are ensured, the possible problems occurred during work are reduced, the transportation efficiency is ensured, and the automatic process is improved.

Owner:临沂临港经济开发区合顺物流有限公司

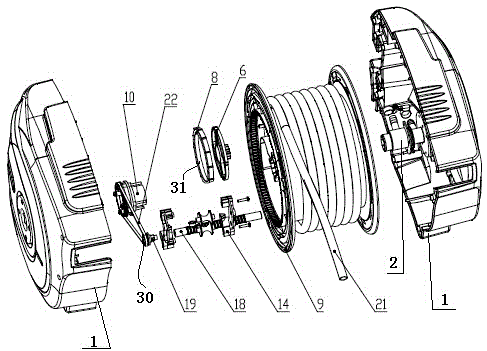

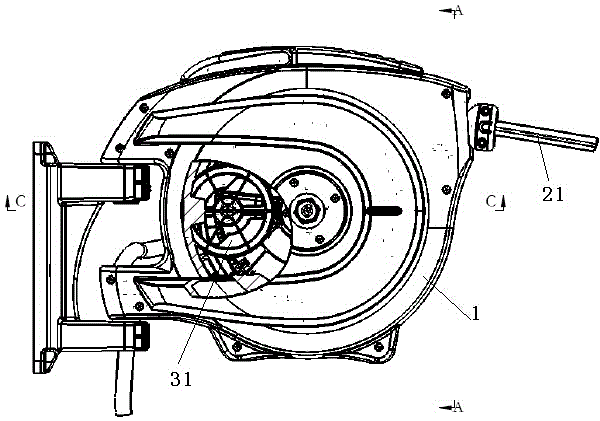

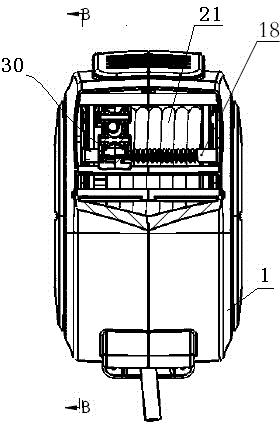

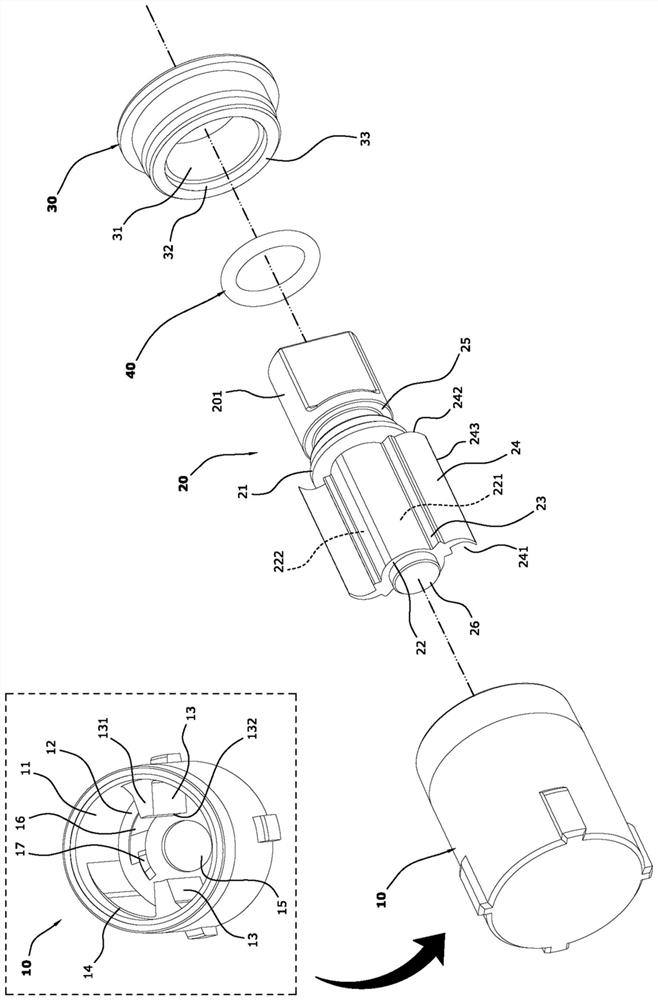

Automatic recovery speed-limiting sorting tube or wire winder

The invention relates to an automatic recovery speed-limiting sorting tube or wire winder. The middle of a shell is connected with a disc body in a rotating mode through a wheel shaft, a volute spiral spring is arranged in the disc body, one end of the volute spiral spring is connected with the wheel shaft, and the other end of the volute spiral spring is connected with the disc body. Tubes or electric wires are wound on the disc body. A sorting device used for the tubes or the wires is arranged on a tube or wire outlet of the front end of the shell. A speed limiting device used for slowly recovering the tubes or the wires is arranged between the side face of the disc body and the shell. Compared with the prior art, due to the fact that the sorting device and the speed limiting device for slow recovering are arranged on the automatic recovery tube or wire winder at the same time, the ordered arrangement of the tubes or the electric wires on the disc body can be achieved, the purpose for controlling and limiting the rotating speed of the disc body can also be achieved, hence, on the premise that the automatic recovery tube or wire winding function is not changed, the safety of a user can be protected, and the tube or wire winder, connected tools and the like cannot be damaged. The sorting device and the speed limiting device are simple in structure and can be mounted and used in an existing automatic recovery tube or wire winder.

Owner:士商(湖州)精密技术有限公司

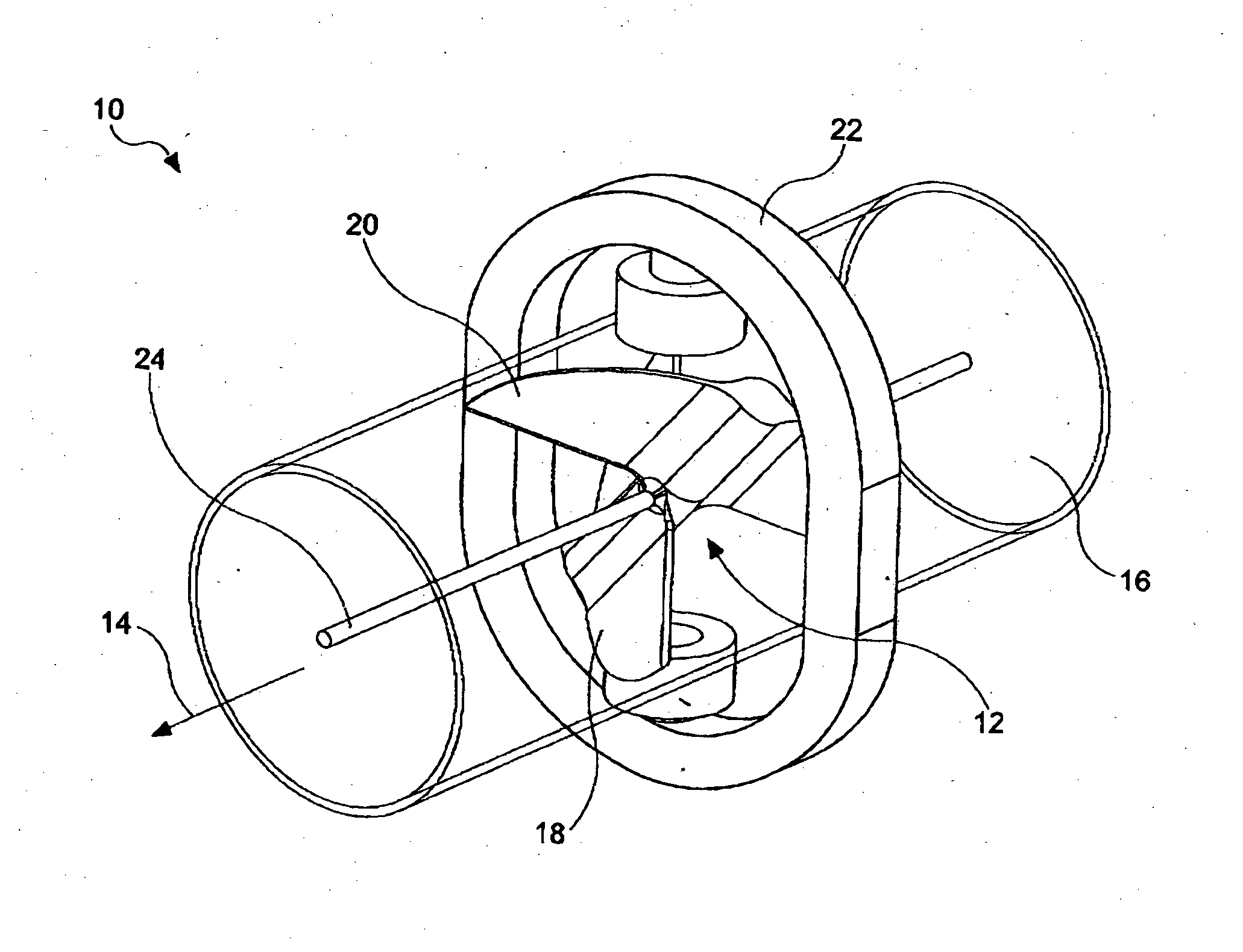

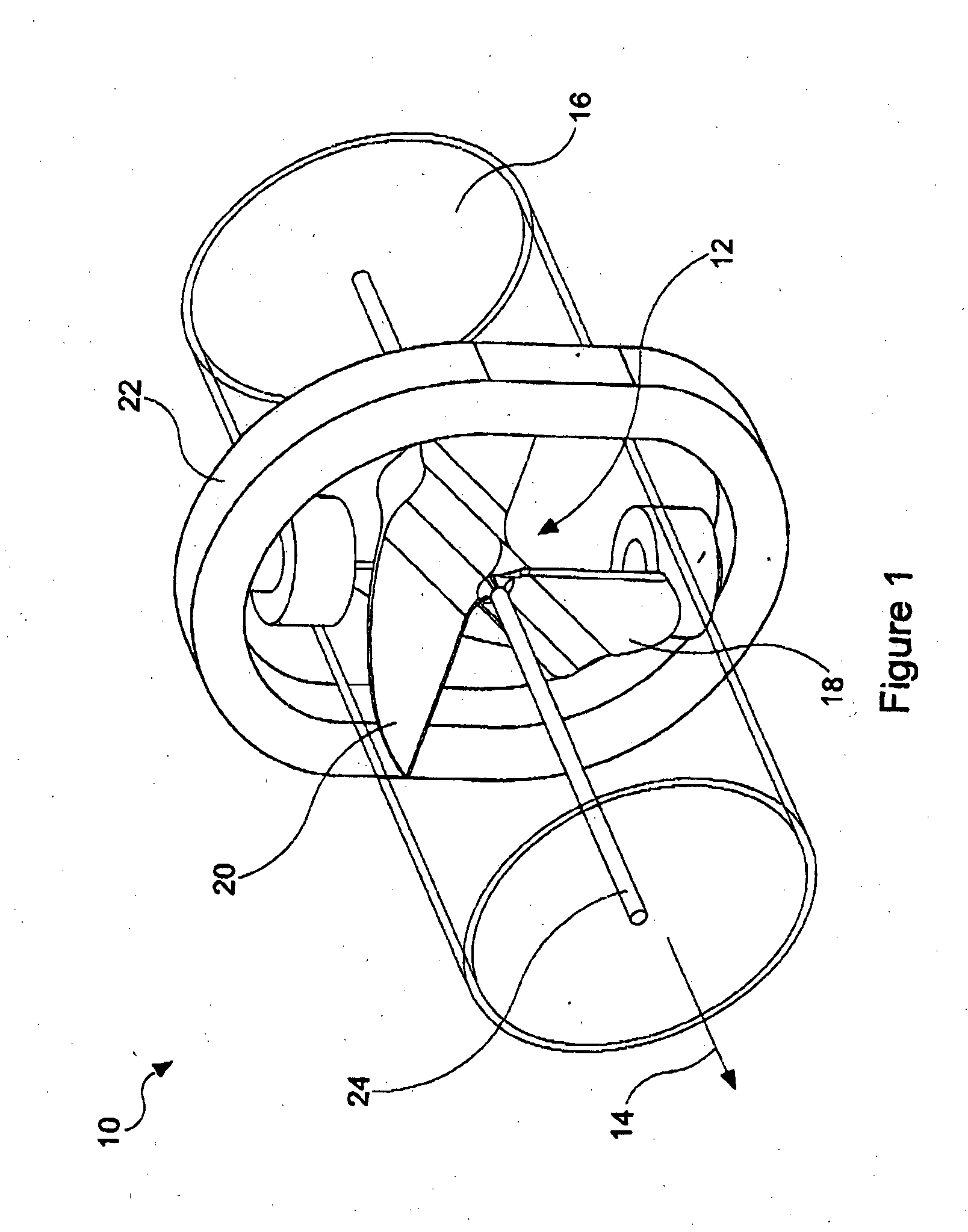

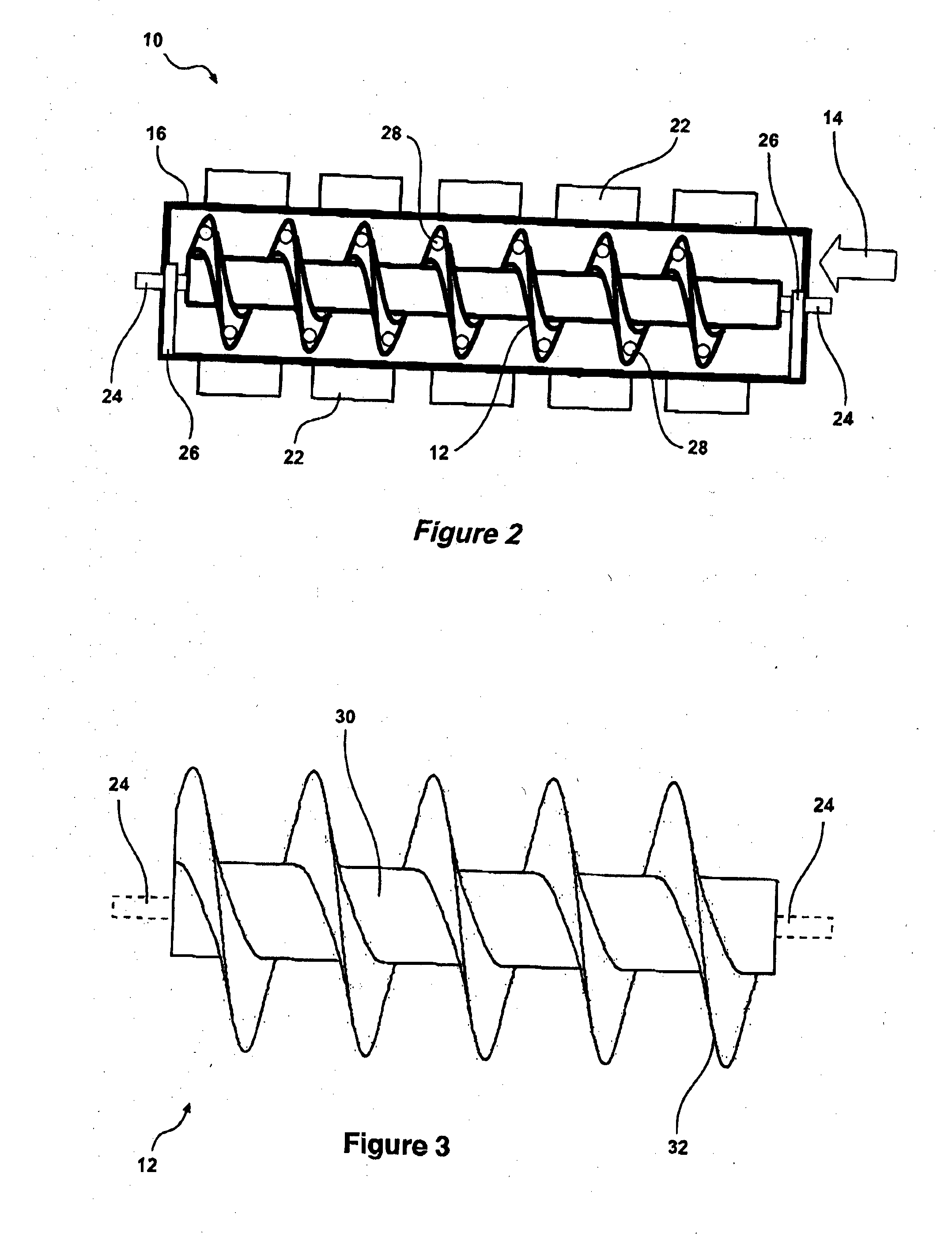

Inline power generator

InactiveUS20150192030A1Balanced weight distributionMaximize efficiencyWorking fluid for enginesGas turbine plantsImpellerElectric power

An electrical generator, comprising a rotatable impeller locatable within a flow path of a conduit. The impeller is rotated by fluid flowing along said flow path. The impeller comprises a magnetic portion, the generator further including a stator located external of the flow path. The stator generating electrical power in response to rotation of the magnetic portion.

Owner:SPINERGY PTY LTD

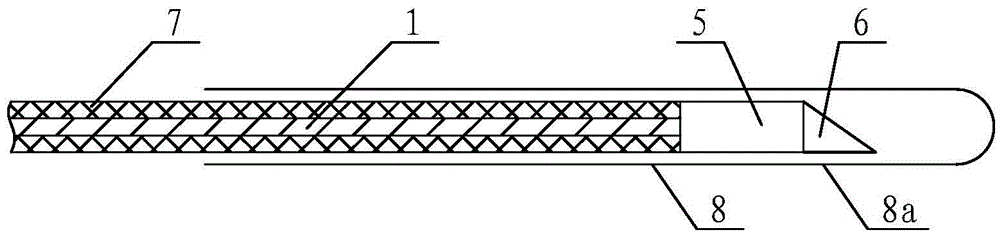

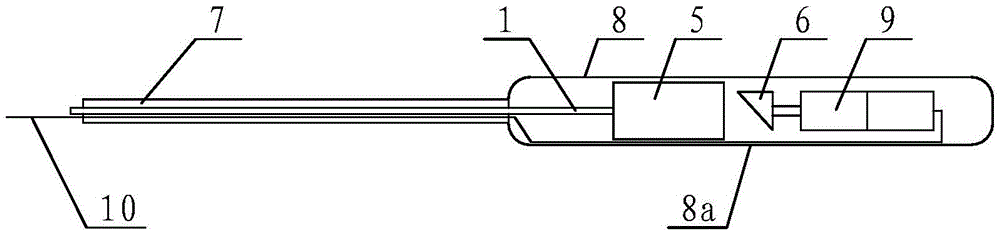

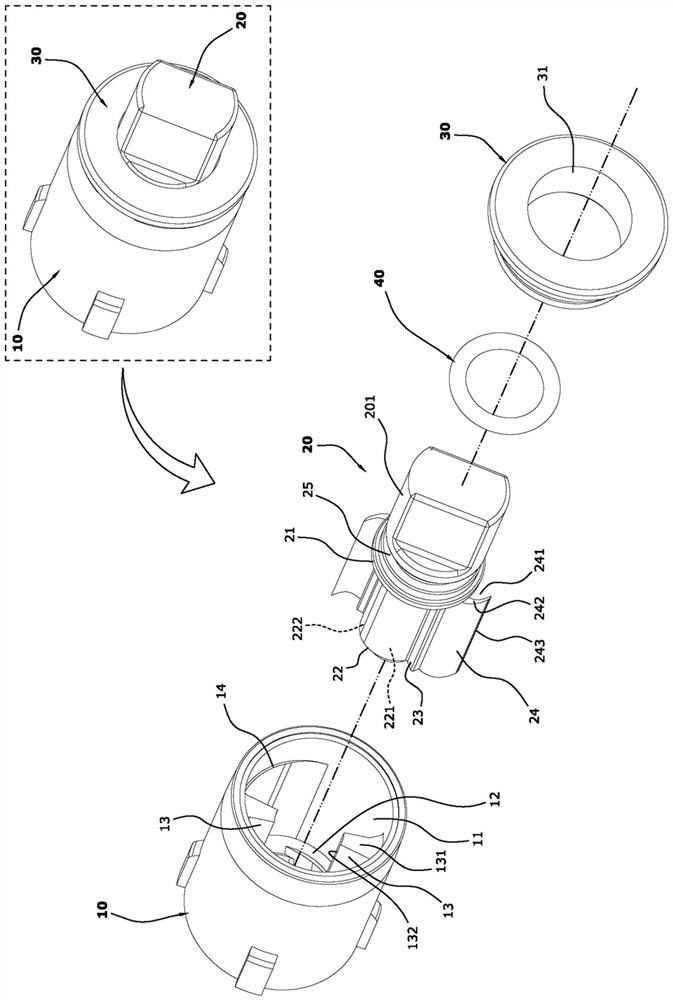

Separable endoscope

InactiveCN105476592AAchieve separabilityUnlimited detectionEndoscopesDiagnostic recording/measuringBiochemical engineeringLength wave

The invention provides a separable endoscope which comprises a first component and a second component. The first component comprises an oblique mirror, the plane end of the oblique mirror is fixedly connected with one end of a rotary shaft, the other end of the rotary shaft is fixedly connected with one end of a magnet, and the magnetic is arranged in a first pipe shell. A supporting sleeve is disposed on the outer side of the rotary shaft, one end of the supporting sleeve is fixedly connected with one end of the first pipe shell, and the other end of the supporting sleeve and the oblique mirror are arranged outside the first pipe shell to form an insertion end. The second component comprises a connection optical fiber connected with one end of a second pipe shell, an insertion opening is formed in the other end of the second pipe shell, and a self-focus lens is fixedly disposed in the second pipe shell. The separable endoscope is used for solving the problems that an OCT endoscope lateral imaging probe in the prior art is complex in design and low in flexibility, is limited by the MEMS technology and only can be used for single wavelength detection.

Owner:SHANGHAI JIAO TONG UNIV

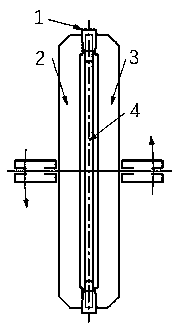

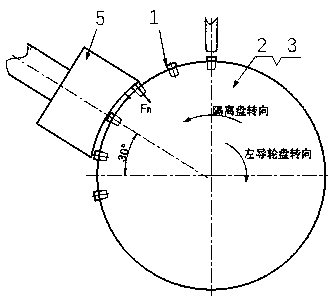

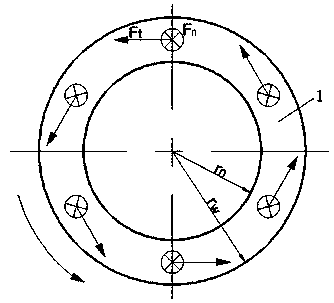

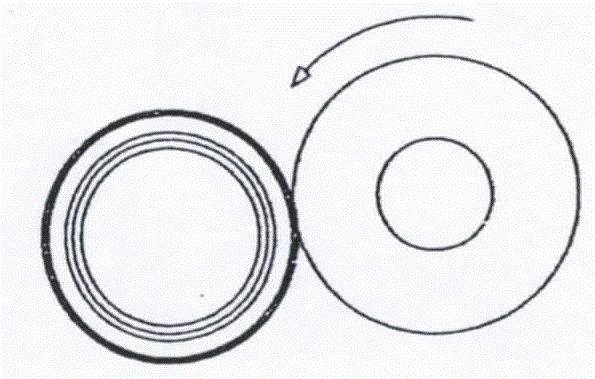

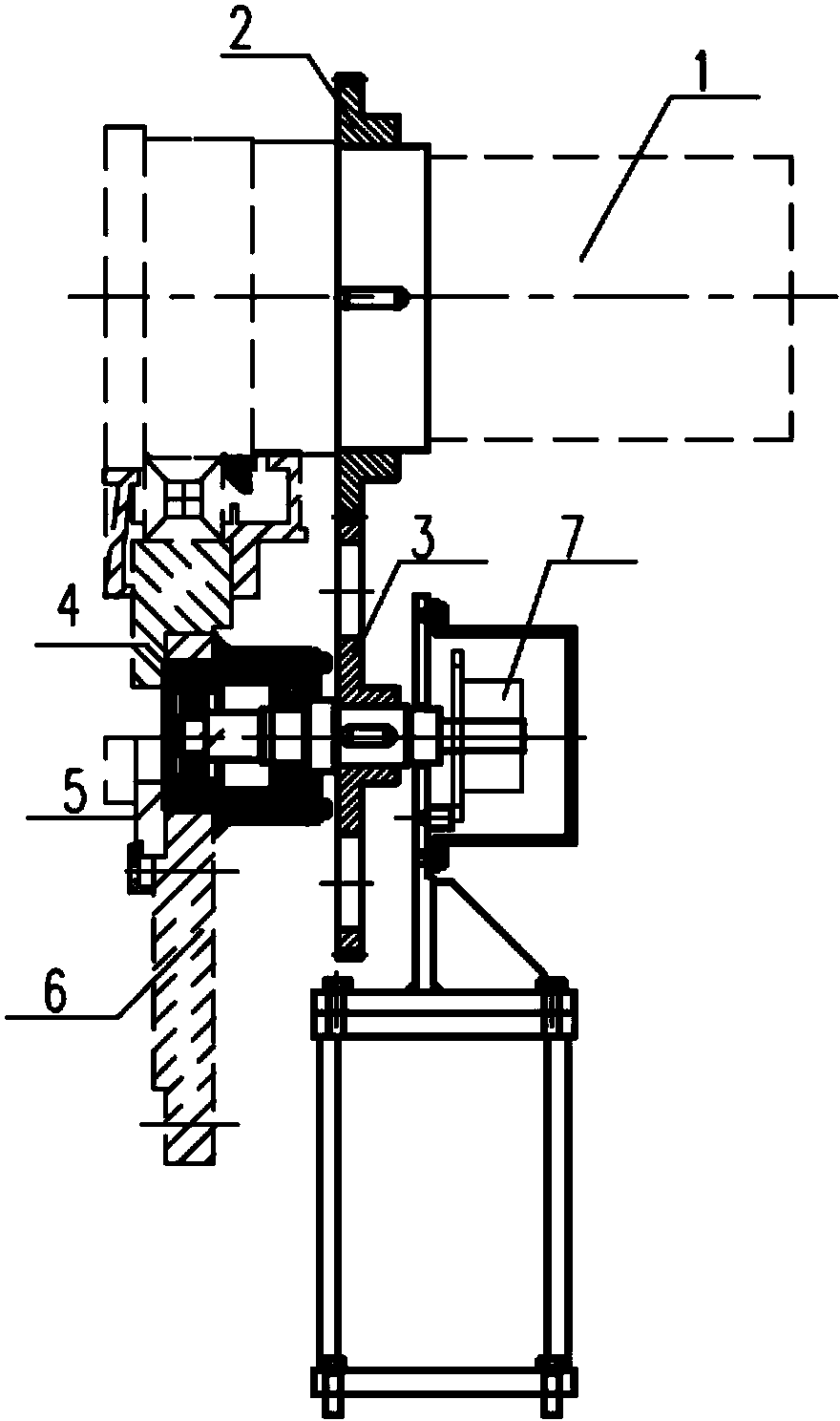

Calculation method of grinding force on spherical base surface of tapered roller

ActiveCN109746833AImprove grinding precisionStable rotation speedGrinding feed controlSpecial data processing applicationsEngineeringForce balance equation

The invention discloses a calculation method of grinding force of a spherical base surface of a tapered roller. According to the calculation method, the tapered roller is set to be in rigid contact with two guide wheel discs without sliding at a stable autorotation speed, the rotation speed of an isolating disc is equal to one half of the rotation speed difference between the two guide wheel discs, and the autorotation linear speed of the tapered roller is equal to the difference between the linear speed of the right guide wheel disc and the linear speed of the isolating disc; according to themachining principle of the spherical base surface of the tapered roller, when the spherical base surface of the tapered roller is ground, grinding force is divided into tangential grinding force andnormal grinding force; a force balance equation during grinding of the spherical base surface of the tapered roller is derived; and a grinding contact arc length of the spherical base surface of the tapered roller is calculated, the maximum undeformed cutting thickness is calculated, finally, the grinding force on the spherical base surface of the tapered roller is calculated. The method fully considers the grinding movement track and the forming contact arc length of the tapered roller, is suitable for analyzing the grinding process of the spherical base surface of the tapered roller, promotes the development of a grinding process parameter optimization technology, and improves the grinding machining precision of the tapered roller.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

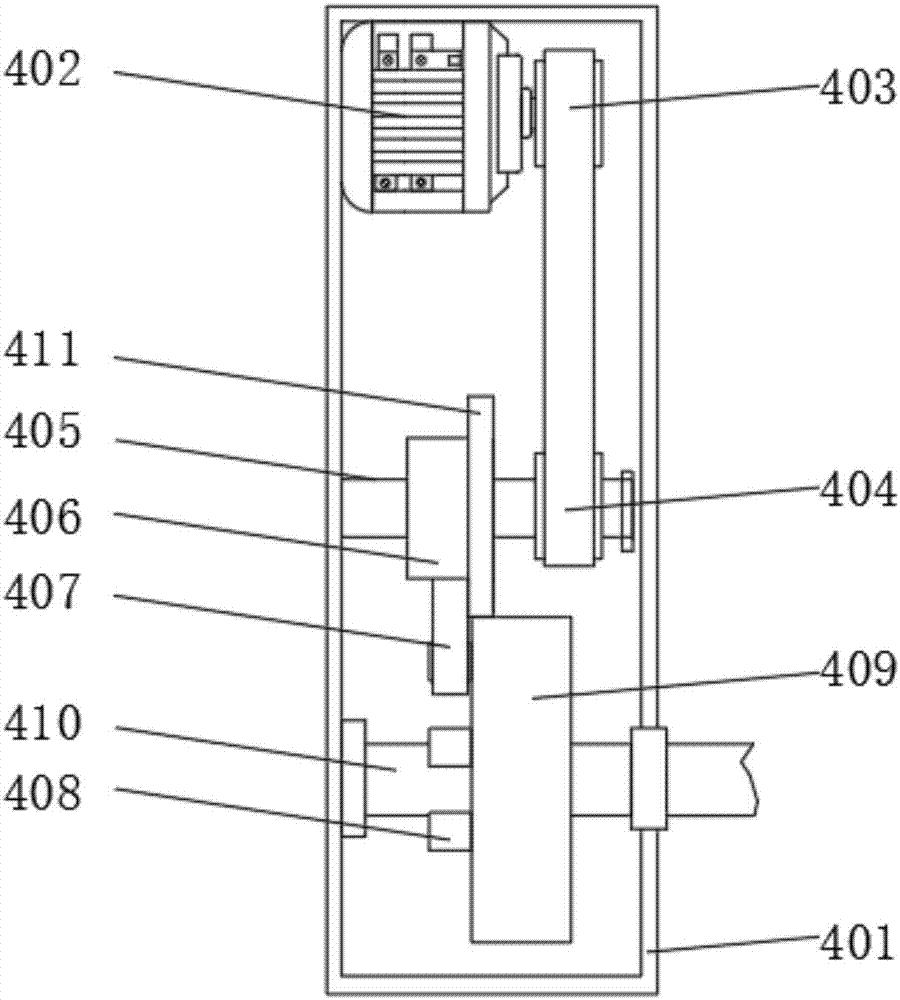

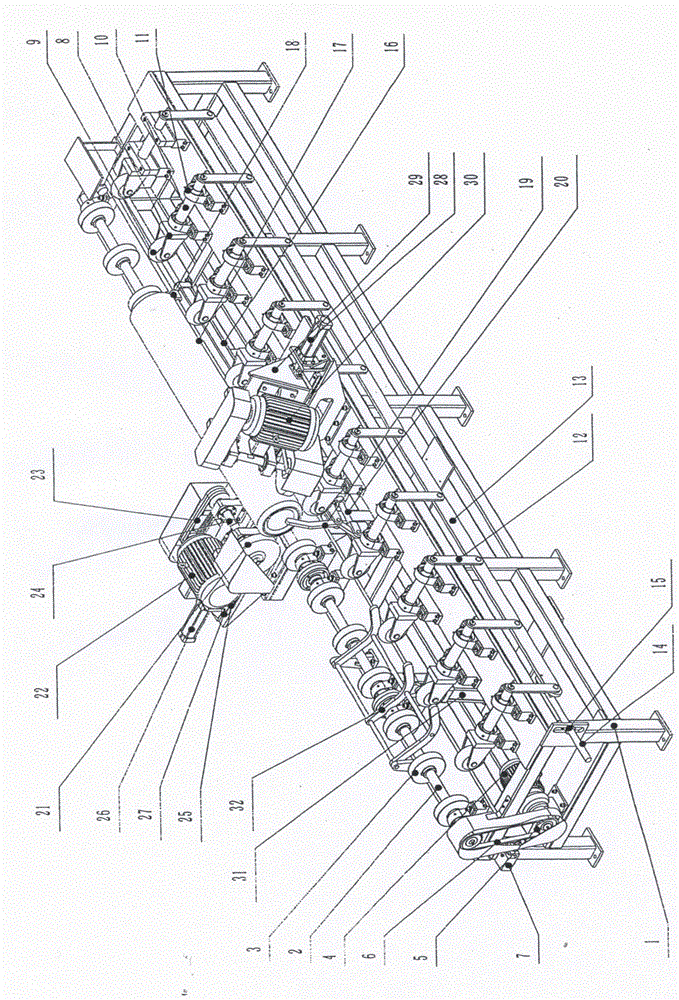

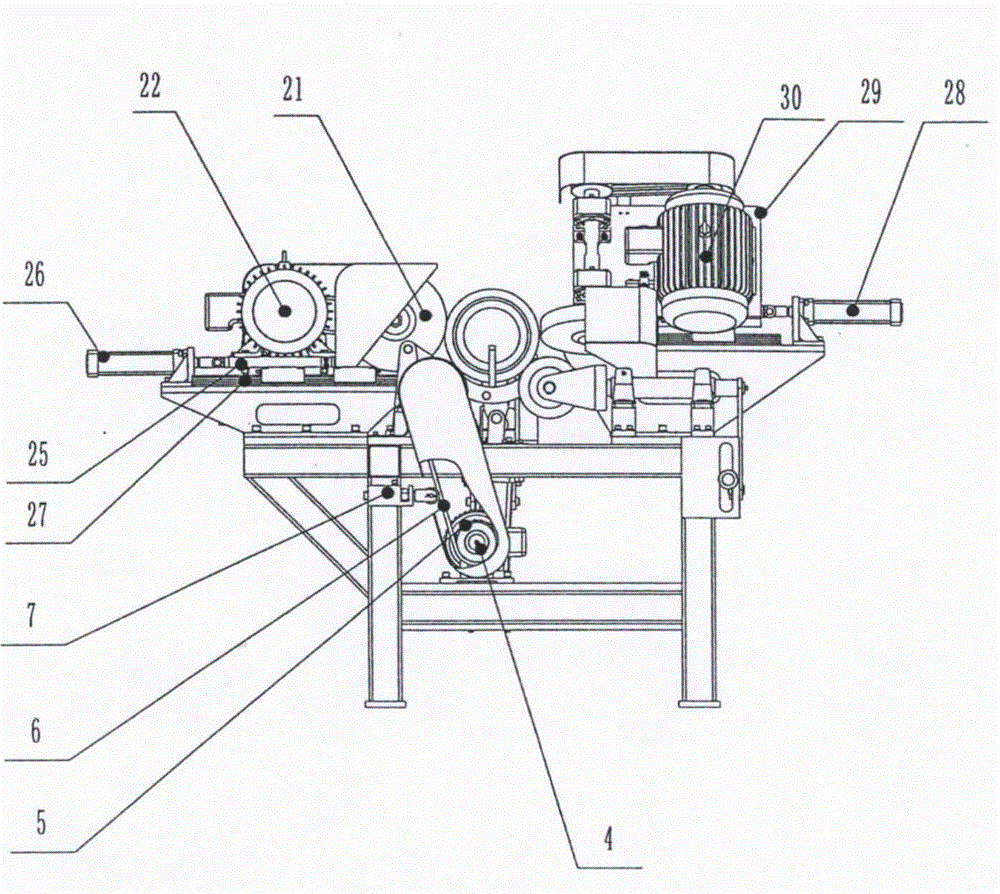

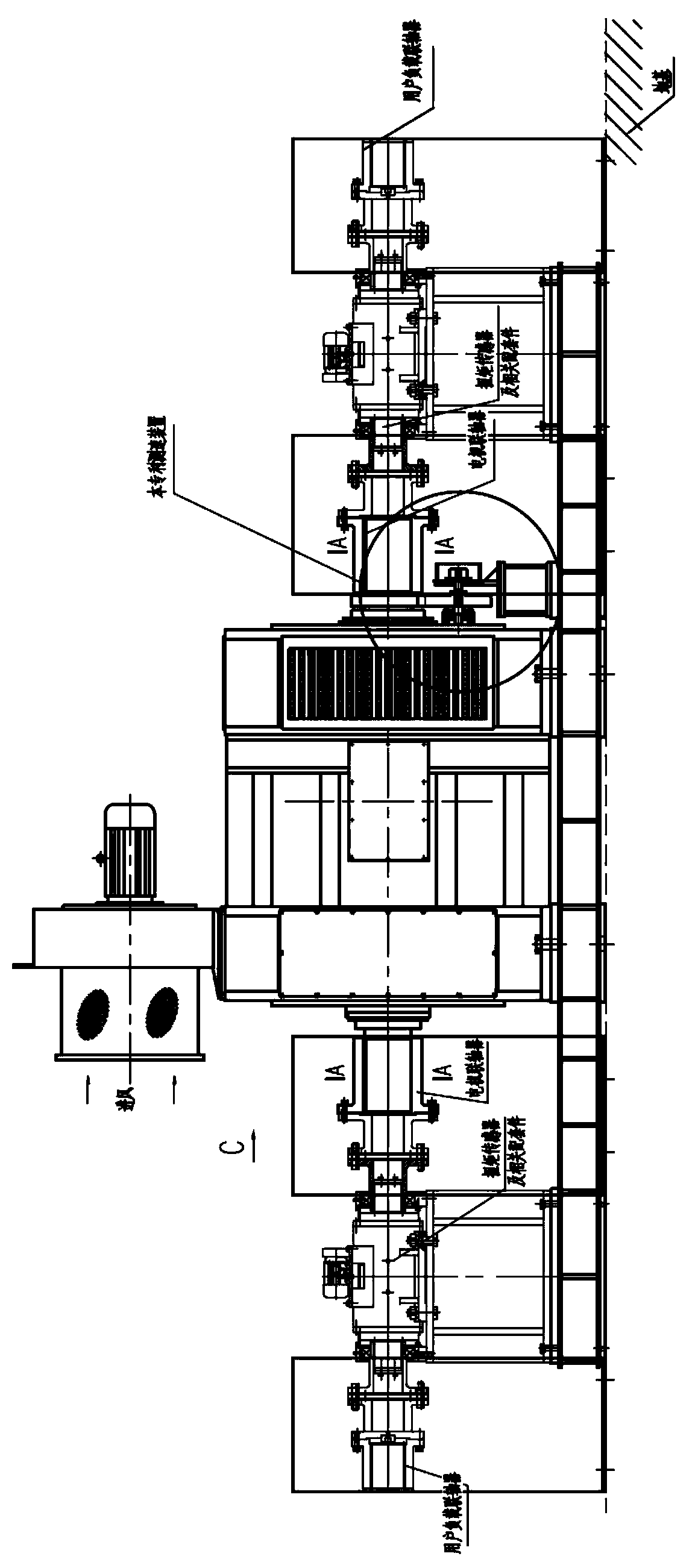

Steel seamless cylinder outer surface polisher

ActiveCN103551936AStable rotation speedControl travel speedRevolution surface grinding machinesGrinding feedersGas cylinderEngineering

The invention discloses the technology of a steel seamless cylinder outer surface polisher. A machine body is fixed with a motor, a shaft is fixed by a bearing, and a tensioner, a cross seat, a longitudinal seat, a D cylinder, an E cylinder, a material overturning device, an A cylinder, a guide sleeve and a bearing are all fixed; the motor is fixed with a chain wheel, the shaft is fixed with a driven chain wheel, the shaft is fixed with a roller, the bearing is fixed with a swing shaft fixed with a swing arm and a support, a connecting plate is fixed with a screw rod, the E cylinder is fixed with the material overturning device, the cross seat is fixed with a C cylinder and a guide track, a cross motor seat is fixed with a cross motor and a sand wheel shaft seat, a sand wheel shaft is fixed with a cross sand wheel, a longitudinal motor seat is fixed with a longitudinal motor and a longitudinal sand wheel shaft seat, a longitudinal sand wheel shaft is fixed with a longitudinal sand wheel, and the longitudinal seat is fixed with a B cylinder and a track; the chain wheel and the driven chain wheel are movably connected by a chain, the tensioner is movably connected with the chain, the support is movably connected with a driven roller, the swing arm is movably connected with the connecting plate, the guide track is movably connected with the cross motor seat, the cross motor is movably connected with the sand wheel shaft by a belt, the C cylinder is movably connected with the cross motor seat, the track is movably connected with the longitudinal motor seat, the longitudinal motor is movably connected with the longitudinal sand wheel shaft by a plate belt, a B cylinder is movably connected with the longitudinal motor seat, the A cylinder is movably connected with a push rod movably connected with the guide sleeve, and the D cylinder is movably connected with a hook member; the screw rod penetrates through the machine body to be in threaded connection with a nut. The steel seamless cylinder outer surface polisher is used for polishing a cylinder and has good effect.

Owner:宽城天海压力容器有限公司

Reaction chamber for producing aluminum oxide

InactiveCN107200341AImprove cooling effectRapid coolingAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideAgricultural engineering

The invention discloses a reaction chamber for alumina production, which comprises a reaction chamber outside the reaction chamber and a precipitation cylinder. The upper end of the reaction chamber outside the reaction chamber is provided with an equipment compartment, and a first drive motor is installed inside the equipment compartment. The front end of a drive motor is connected with a reducer, and the front end of the reducer is equipped with a connecting shaft, the outside of the connecting shaft is connected with a stirring blade, and the outer surface of the stirring blade is provided with a fan hole, and the inside of the fan hole is A rotating shaft is connected, and fan blades are installed on the outer surface of the rotating shaft, a bearing is arranged on the inner bottom surface of the precipitation cylinder, and a placement plate is installed on the lower end of the precipitation cylinder. The reaction chamber for alumina production is designed with sound-absorbing boards, reducers, stirring blades, bearings, refrigerators, gear plates, rollers, damping plates and pneumatic devices, which can absorb noise, increase the speed of precipitation, and reduce The cooling time can prevent the balance in the precipitation cylinder from being broken, causing the aluminum hydroxide crystals to dissolve into the solution again.

Owner:青海新高科材料研究院有限公司

Intelligent dining table automatic rotation control method and intelligent dining table

PendingCN107997374AInfrared sensing is accurateComprehensive infrared sensorServing tablesProgramme control in sequence/logic controllersInfraredControl system

The invention discloses an intelligent dining table automatic rotation control method which includes the steps: (1) preparing an intelligent dining table automatic rotation control system; (2) corresponding to a pulse counting value by a turntable rotating by one position; (3) receiving current infrared pulse signals transmitted by an infrared transmitting end in real time and transmitting the current infrared pulse signals to a PLC (programmable logic controller) by an infrared receiving end, comparing the current infrared pulse signals with standard infrared pulse signals by the PLC, judgingwhether the current infrared pulse signals are consistent with the standard infrared pulse signals or not, indicating existence of shield if not, calculating a current pulse counting value by the PLC, transmitting instructions to a positioning extension module and starting a servo motor and an incremental rotary encoder; (4) turning the turntable and the incremental rotary encoder at the same angular speed to generate two pulses with the phase difference of 90 degrees and determining a rotation direction; (5) turning the turntable in the determined rotation direction at an initial rotation speed by a corresponding angle. The invention further discloses an intelligent dining table implementing the method.

Owner:DONGGUAN FUBAO SOFA MFG

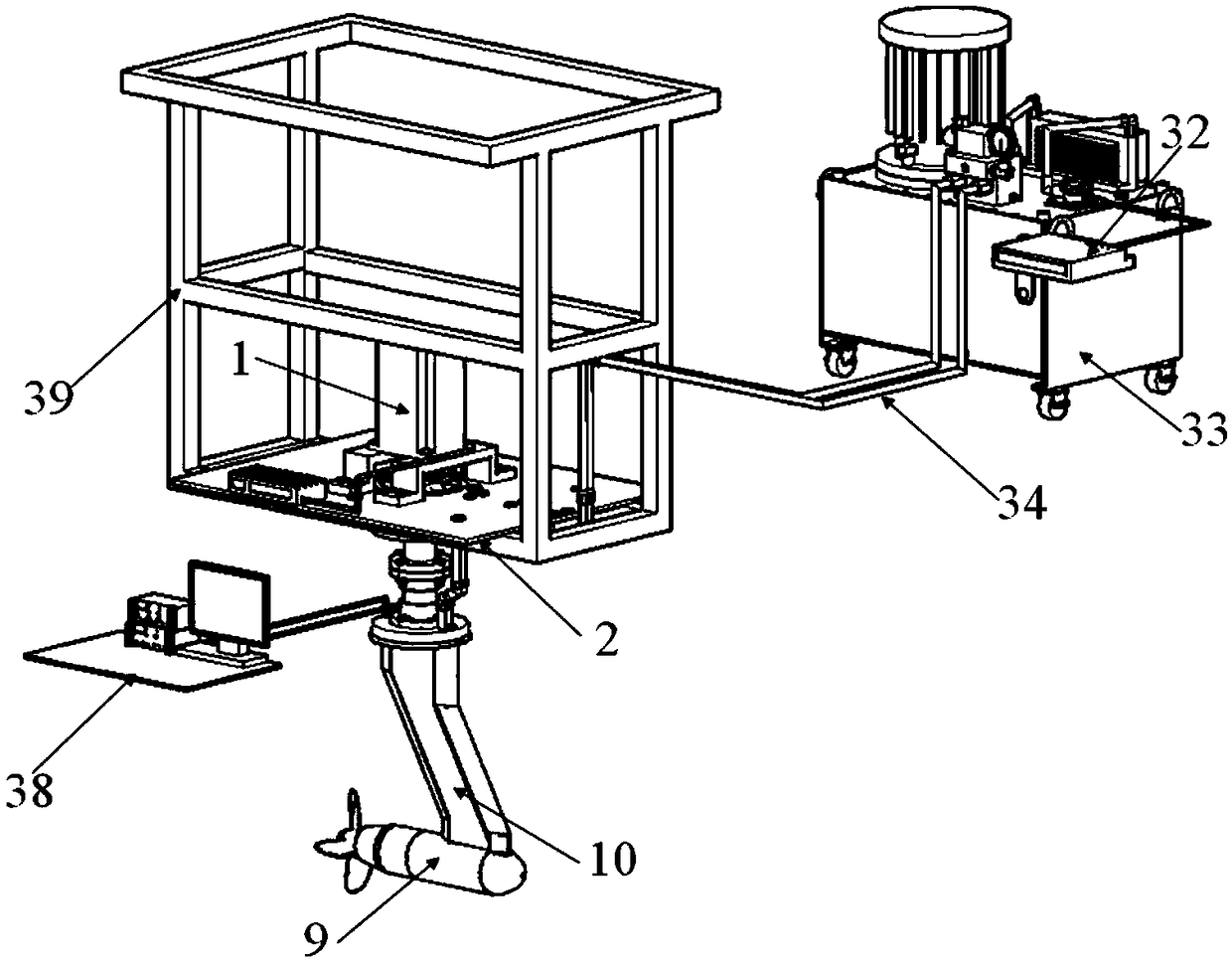

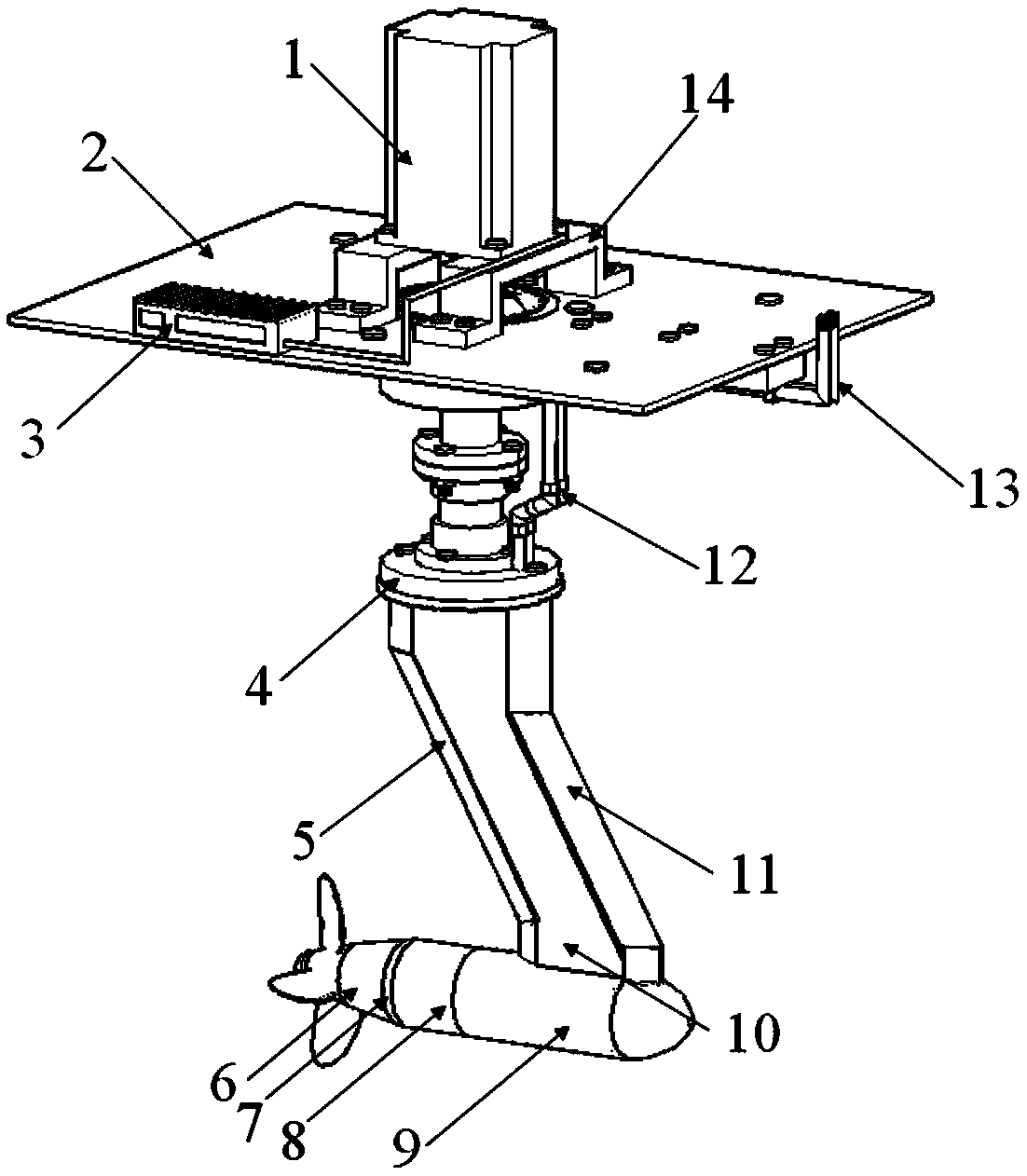

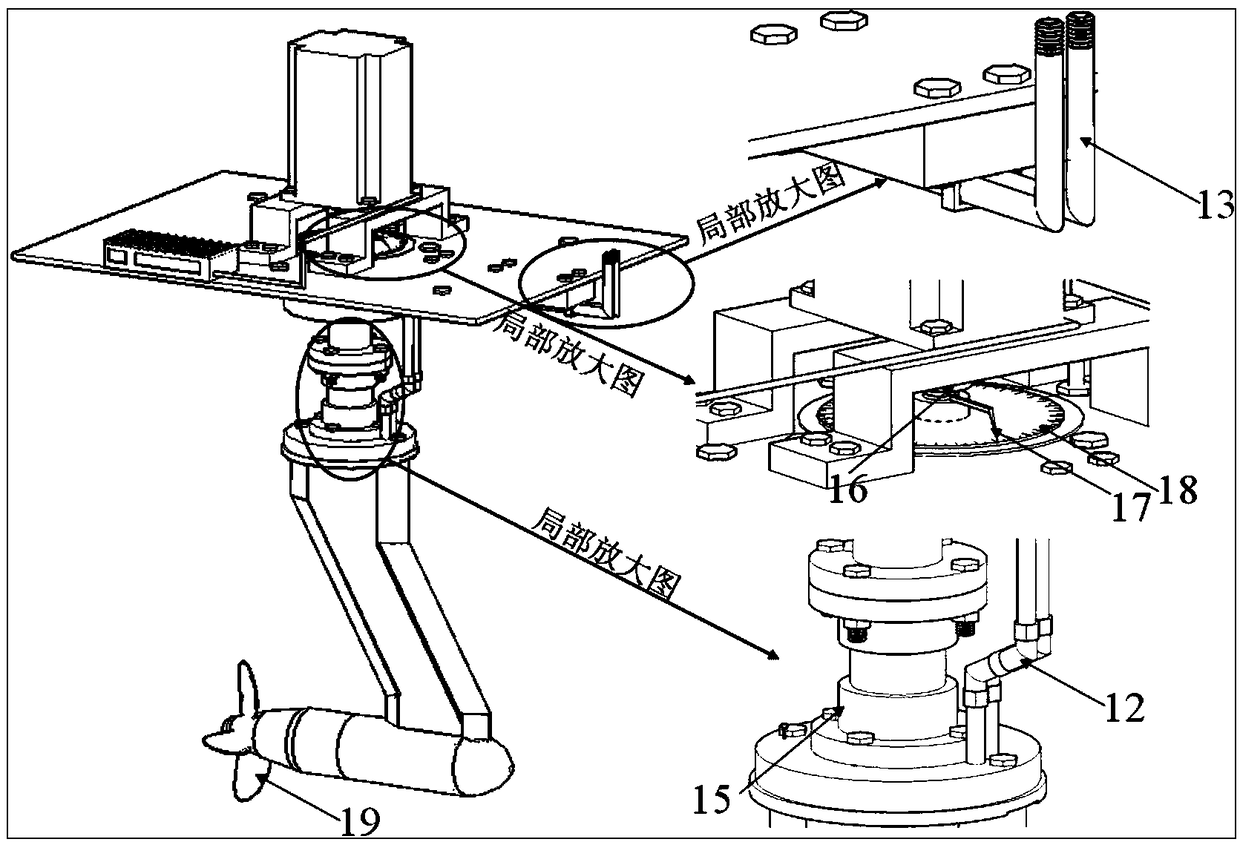

Hydraulicdrive type podded propulsor for testing

The invention provides a hydraulic drive type podded propulsor for testing. The hydraulic drive type podded propulsor for testing comprises a podded propulsor unit and further comprises a hydraulic control system; a propeller drive of the podded propulsor unit is a hydraulic motor; L-shaped rigid oil pipes are mounted on an oil inlet and an oil outlet of the hydraulic motor; the L-shaped rigid oilpipes are connected with a rigid oil pipe disposed along a pod supporting rod through a rigid oil pipe joint; the rigid oil pipe passes through a flange plate of the pod supporting rod; the rigid oilpipe on an upper end of the flange plate of the pod supporting rod is connected with a universal rotating joint; the universal rotating joint is then connected to one section of the rigid oil pipe; the hydraulic control system comprises a hydraulic pump station and a hydraulic motor controller; an oil outlet and an oil return port of the hydraulic pump station are connected with the last sectionof the rigid oil pipe through a flexible oil pipe. The hydraulic drive type podded propulsor for testing is suitable for development and research of the podded propulsor and has the advantages of small size, good stability, light weight and convenient assembly and disassembly.

Owner:HARBIN ENG UNIV

Method for preparing vitrified grinding wheels with metal matrixes for grinding stainless steel and titanium alloys

ActiveCN103056785AReduce labor intensityImprove working environmentAbrasion apparatusGrinding devicesTitaniumWorking environment

The invention relates to a method for preparing vitrified grinding wheels with metal matrixes for grinding stainless steel and titanium alloys. The method comprises subjecting raw materials to mixing, molding, drying, roasting and combining. The raw materials comprise, by mass, 60% to 85% of abrasives and 15% to 40% of binding agents, wherein the binding agents is composed of 15% to 35% of clay powder, 15% to 35% of feldspar powder and 35% to 60% of borax glass. The roasting process is performed in a weakly reducing atmosphere. The grinding efficiency of the vitrified grinding wheels produced by the method is 10 to 100 times of that of resin grinding wheels, and abrasions are only 0.01 of those of the resin grinding wheels; the vitrified grinding wheels can be used safely at a linear speed of 80 m / s; and simultaneously, the worker labor intensity is reduced, and the working environment is improved.

Owner:郑州新安华砂轮有限公司

Extremely-simple type hydraulic rotary buffer

PendingCN111779776AStable rotation speedSimple and reliable structure and functionLiquid resistance brakesBuilding braking devicesContact slidePhysics

The invention discloses an extremely-simple type hydraulic rotary buffer. The extremely-simple type hydraulic rotary buffer only comprises a shaft sleeve, a rotating shaft, a gland and a sealing ring,the shaft sleeve is symmetrically provided with two separation ribs connected with a cavity bottom surface, and two arc-shaped table sections are arranged on the oil cavity wall on one sides of the two symmetric separation ribs; a convex ring and an inner shaft section of the rotating shaft sleeve an oil cavity, two convex strips are symmetrically arranged on the inner shaft section, each convexstrip is provided with an elastic flexible oil wing, and the flexible oil wings are separated from the oil cavity wall or are elastically pressed against the arc-shaped table sections in a contactingmode; the oil cavity is fixed to the oil cavity in a pressing connection mode, the convex ring sleeves a step hole in the inner end face of the gland, the inner side face and the inner end face of theconvex ring are flush with the top surfaces of the separation ribs in a flush manner, and the flexible oil wings make contact sliding fit with the inner end face; the shaft sleeve and the gland is sealed by the sealing ring, the flexible oil wings, the oil cavity wall, and the arc-shaped table sections form a one-way oil passing switch for controlling the rotating speed of the rotating shaft. Theextremely-simple type hydraulic rotary buffer is ingenious in design, can realize one-way damping rotation, automatic voltage regulation and overload protection functions, does not need to add othercomponents, and is simple and reliable in structure function and low in production and manufacturing cost.

Owner:厦门精熠工贸有限公司

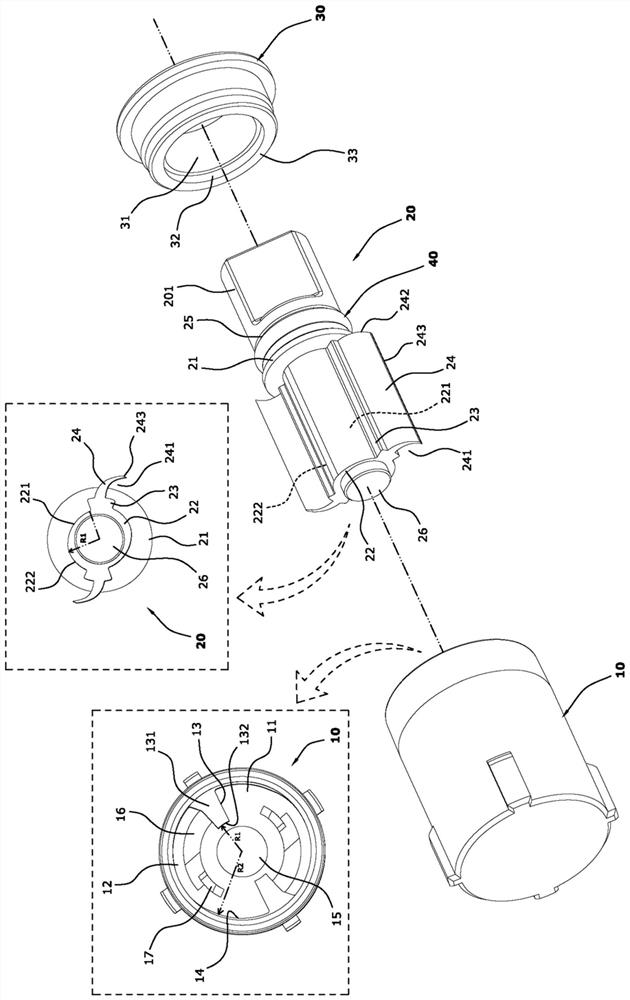

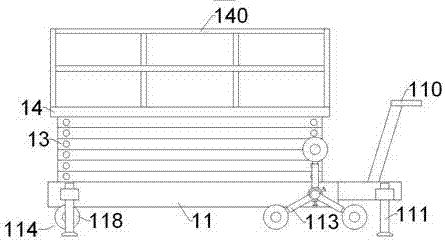

Folding lifting device for electric power equipment

The invention discloses a folding lifting device for electric power equipment and belongs to the technical field of electric power facilities. The folding lifting device for the electric power equipment comprises a trolley body, a shear fork lifter and a working platform. The trolley body is provided with a handle, walking assemblies and at least four supporting legs, and the trolley body is provided with a rotating sleeve. When the folding lifting device for the electric power equipment walks on the flat ground, one or two first wheels make contact with the ground, in case of obstacles, a first locking part is loosened, a first rotating shaft can rotate in the rotating sleeve, a power source is opened and drives the first rotating shaft to drive the second walking assembly to rotate, one first wheel making contact with the ground withstands the obstacles, the other first wheel making contact with the ground will be overturned, and thus wheel sets can make contact with the ground alternately and step over the obstacles. The operation mode is simple and convenient, and time and labor are saved.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

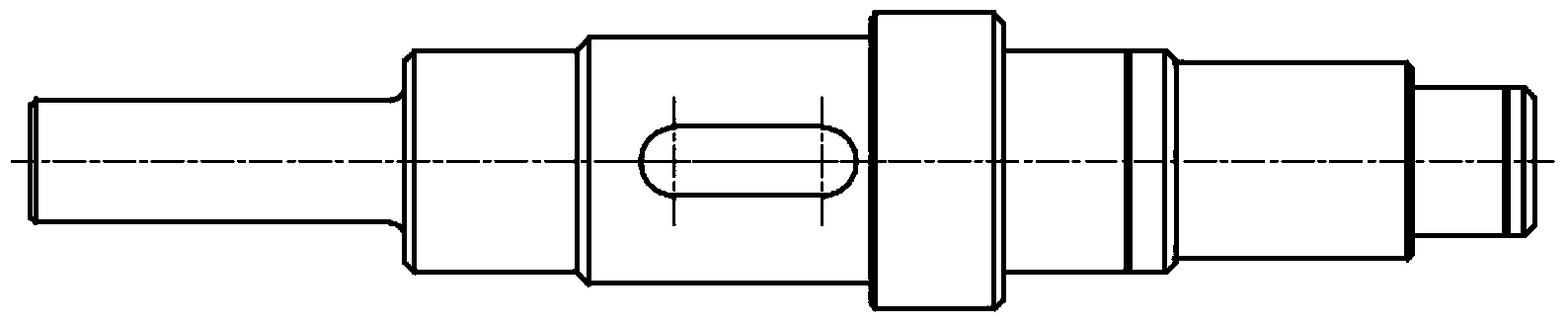

Motor speed measuring device

InactiveCN104251914ASolve the problem of not being able to installEasy to operateLinear/angular speed measurementSpeed/acceleration/shock instrument detailsMotor speedEncoder

The invention discloses a motor speed measuring device. The motor speed measuring device comprises a motor rotating shaft and a speed measuring rotating shaft, wherein the motor rotating shaft is hotly sleeved with a first gear; the speed measuring rotating shaft is hotly sleeved with a second gear; the first gear and the second gear are engaged by a gear; an encoder is mounted on the speed measuring rotating shaft; the speed measuring rotating shaft is mounted in a lug boss inner hole structure of an end cover by a bearing. The speed measuring device is simple and compact in structure, and reliable; the problem that the rotating speed of a motor cannot be accurately measured under the condition that double shaft extension motors have loads is solved, so that the structure guarantees for reliable speed measurement of the motors are provided.

Owner:SEC ELECTRIC MACHINERY

Vertical axis wind turbine

InactiveCN105065207ARotation safetyAvoid damageWind motor controlEnergy industryHydraulic pumpFuel tank

A vertical axis wind turbine comprises a base and blades. A rotation shaft is arranged in the base and provided with a fixed disc and a plurality of blade sets. The blade sets are evenly distributed. Each blade set comprises supporting rods hinged to the corresponding blades. A buffering and beneficiating device is arranged at the outer end of each blade in a matched mode. A hydraulic pump is disposed on the fixed disc. An inner gear is arranged on the inner wall of the base, and a hydraulic pump gear is engaged with the inner gear. An oil outlet of the hydraulic pump is sequentially connected with a pressure adjusting device and an execution mechanism. The pressure adjusting device comprises an adjusting valve shell. The adjusting valve shell is provided with an adjusting valve oil outlet, an adjusting valve oil inlet, an oil return opening and an oil return opening adjusting device matched with the oil return opening. The adjusting valve oil outlet is communicated with the execution mechanism. The adjusting valve oil inlet is connected with the oil outlet of the hydraulic pump. The oil return opening is communicated with an oil tank of the hydraulic pump. The vertical axis wind turbine can be started and rotated at a low wind speed, operation is stable, and the operation safety of the vertical axis wind turbine is improved.

Owner:河南省八面风新能源科技有限公司

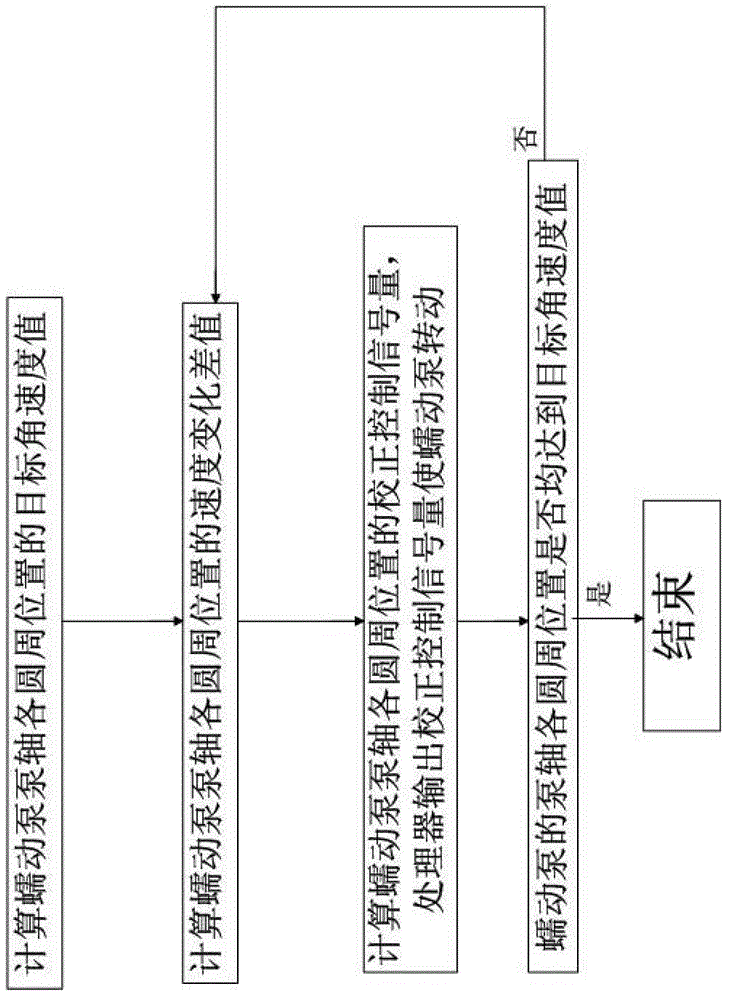

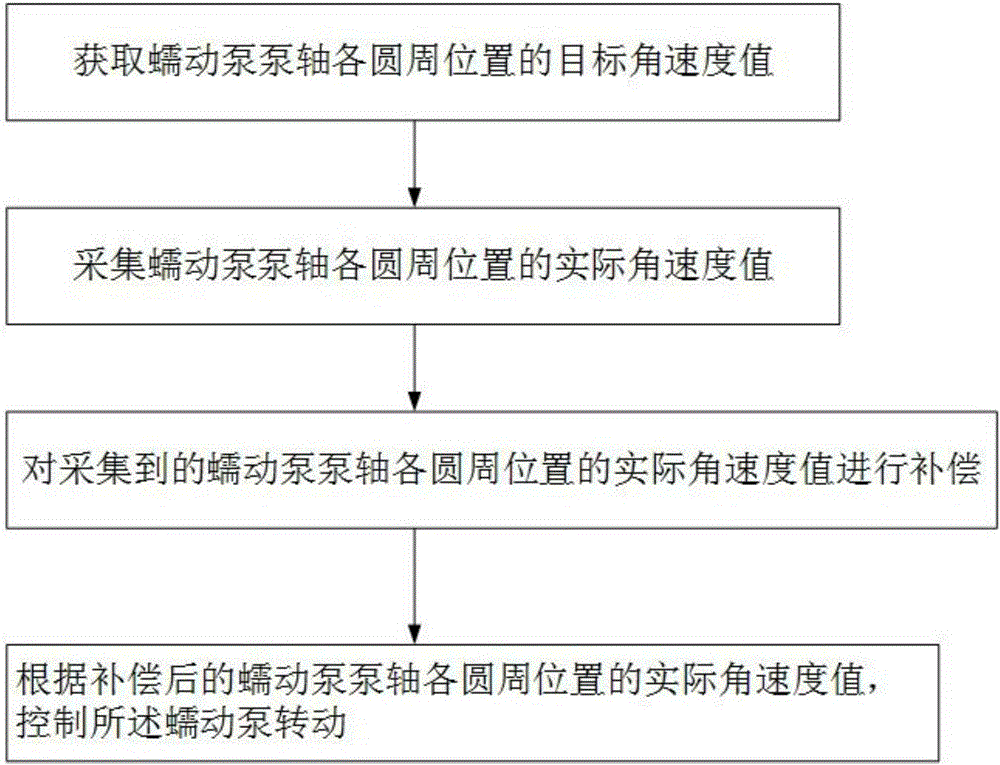

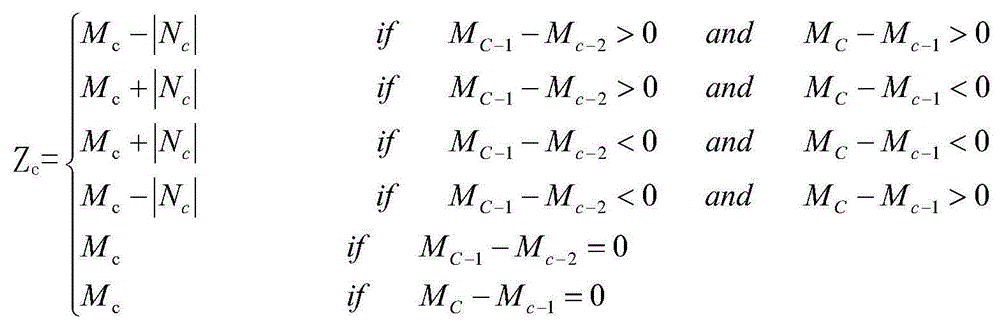

High-precision peristaltic pump control method

InactiveCN105233363AQuickly adjust the rotation speedSmooth rotationPressure infusionPeristaltic pumpControl system

The invention discloses a high-precision peristaltic pump control method, and relates to the field of automation control. Through compensation of an acquired magnitude of angular velocity, fluctuation interference caused by chance factors can be overcome effectively, and an accurate angular velocity acquiring unit value is provided for follow-up data processing. The acquired magnitude of angular velocity is compensated through computing of a compensating parameter of the magnitude of angular velocity. Because the magnitude of angular velocity acquired by the traditional peristaltic pump control system has large deviation and dynamic responsiveness is poor, the trend of change of the angular velocity cannot be considered fully, and the magnitude of angular velocity has to be compensated. By the parameter and mode for compensating the magnitude of angular velocity in the technical scheme, the acquired magnitude of angular velocity can be compensated dynamically according to the acquired magnitude of angular velocity and the trend of change of the angular velocity, so that the adjusting amount of the angular velocity can be accurately judged in advance, and accuracy and stability of peristaltic pump control are improved.

Owner:CHONGQING TECH & BUSINESS INST

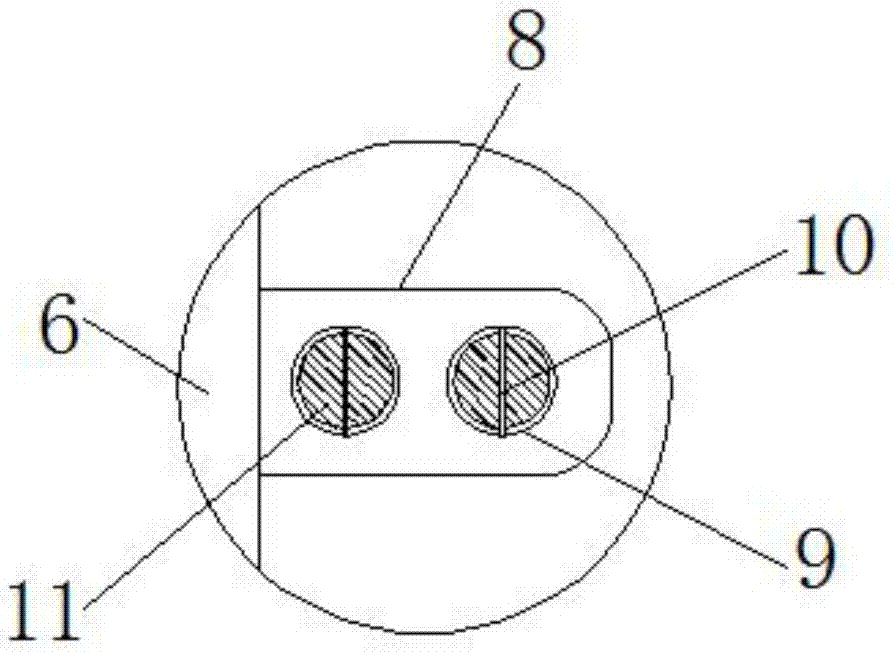

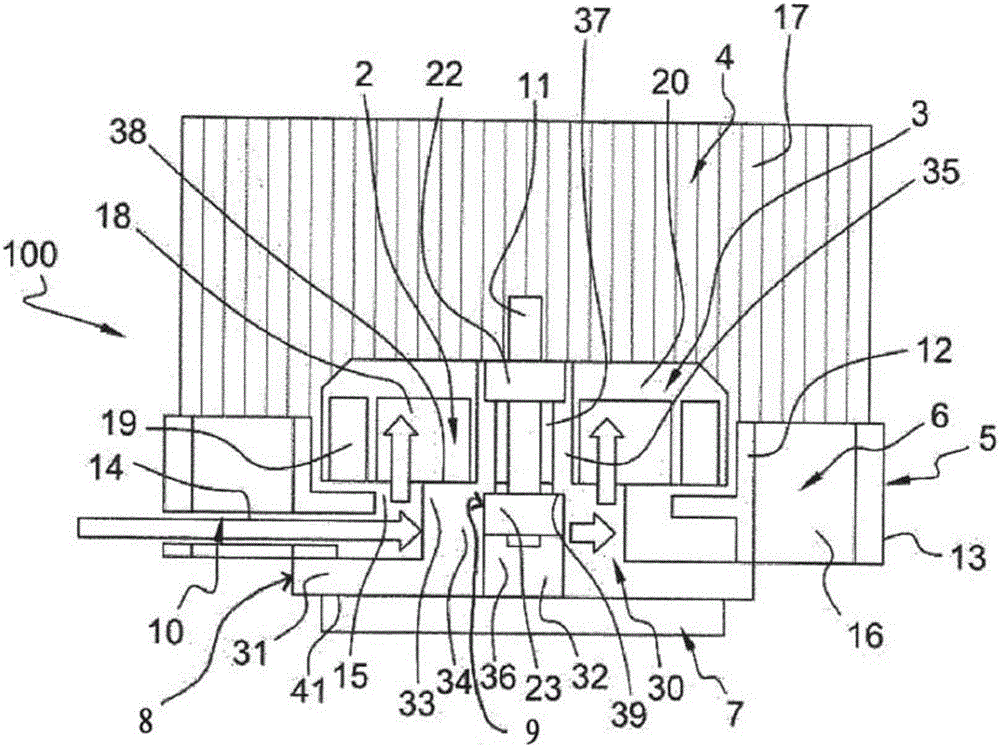

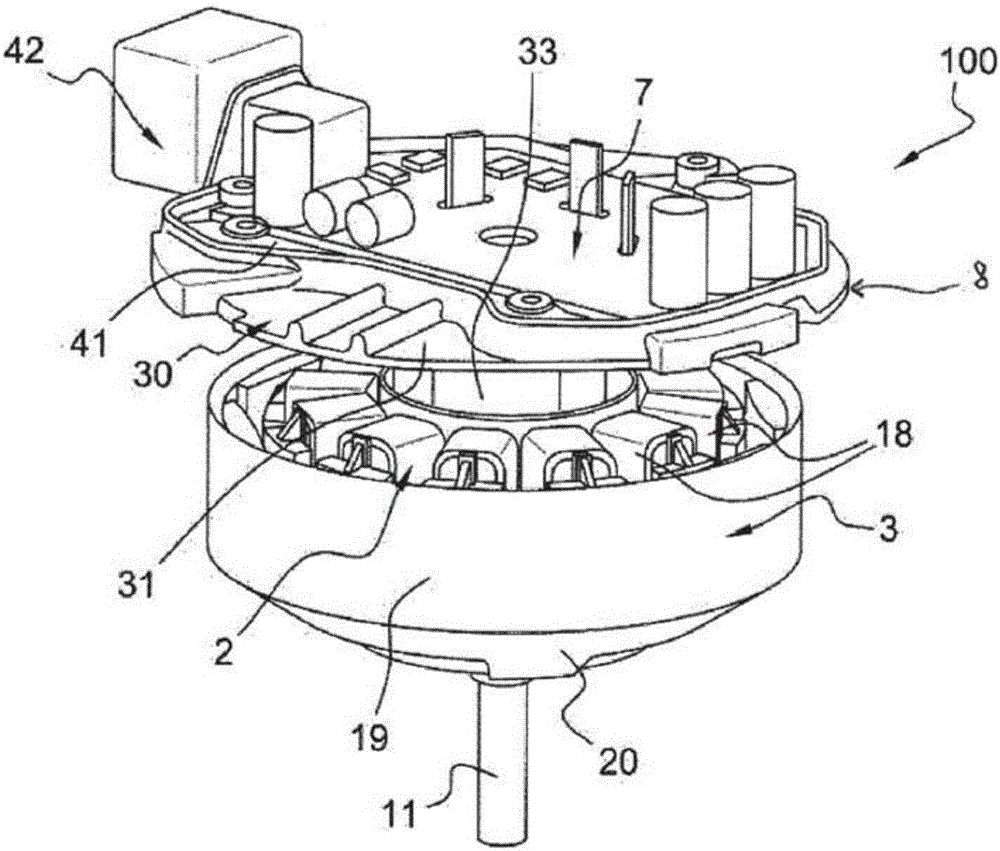

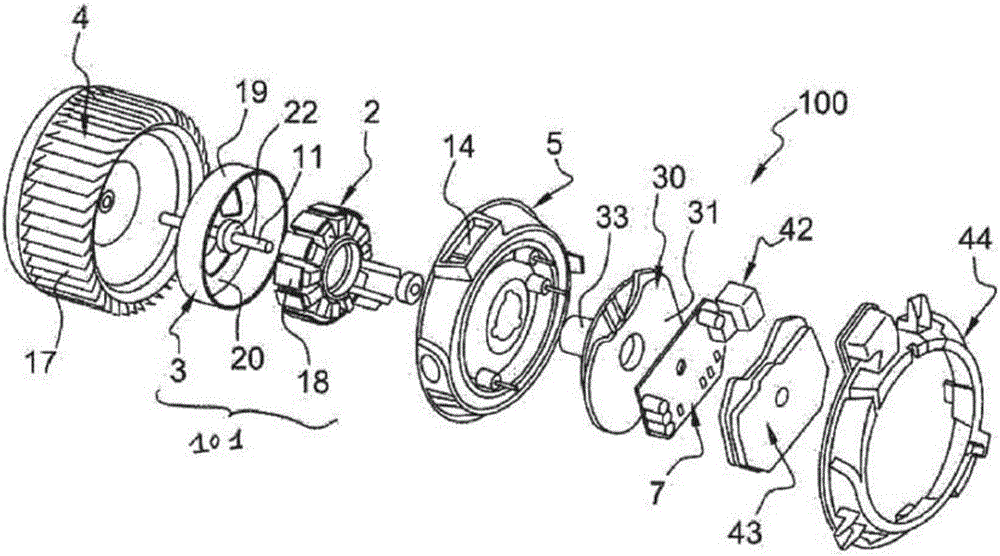

Electric motor, and air blast device and air-conditioning and/or heating ventilation system provided with such a motor

ActiveCN106415999AUniform and regular operationStable rotation speedAssociation with control/drive circuitsMagnetic circuit rotating partsStatorEngineering

The invention relates to an electric motor (100) comprising a stator (2) and a rotor (3), the rotor (3) being arranged around the stator (2), an element (9) for supporting said rotor (3) and said stator (2), a motor support (5) through which a stream of fluid flows, a radiator (8) and an electronic body (7), said radiator (8) being inserted between said motor (100) support (5) and said electronic body (7), characterised in that the element (9) for supporting the rotor (3) and the stator (2), and the radiator (8), form the same so-called bifunctional part (30).

Owner:VALEO SYST THERMIQUES

Pipe cutting device

InactiveCN105313156ASimple and efficient operationSimplify control proceduresMetal working apparatusProgram controlMechanical transmission

The invention discloses a pipe cutting device which comprises an air cylinder, a first rotary plate, a transmission rod, a second rotary plate, a third rotary plate, a first driving rod, two second driving rods, two third driving rods and two clamping heads, wherein a cutting wheel is mounted on the first rotary plate. When the air cylinder drives the first rotary plate to rotate, the cutting wheel moves up and down. When the first rotary plate rotates, the first rotary plate passes through the transmission rod, the second rotary plate, the third rotary plate, the first driving rod, the two second driving rods and the two third driving rods successively to drive the two clamping heads to meet each other or separate from each other, so that the two clamping heads clamp or loosen a pipe to be cut. Moreover, the pipe cutting device is provided with a hydraulic damper. When the first rotary plate rotates so that the cutting wheel moves down, the hydraulic damper can apply damping force to the first rotary plate. When the pipe cutting device cuts the pipe, a clamping mechanism is driven to automatically clamp the pipe in a mechanical transmission way, and manual control or programmed control is not needed.

Owner:NINGBO FUSHI AUTOMOBILE COMPONENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com