Cam jet dispensing device

A dispensing device and jet-type technology, which is applied in the field of jet-dispensing devices, can solve the problems of affecting the attraction force of the electromagnet, the wear of the displacement amplification mechanism, and the large output force of the piezoelectric stack, so as to achieve fast up and down movement of the firing pin, The effect of stable rotation speed and low coupling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

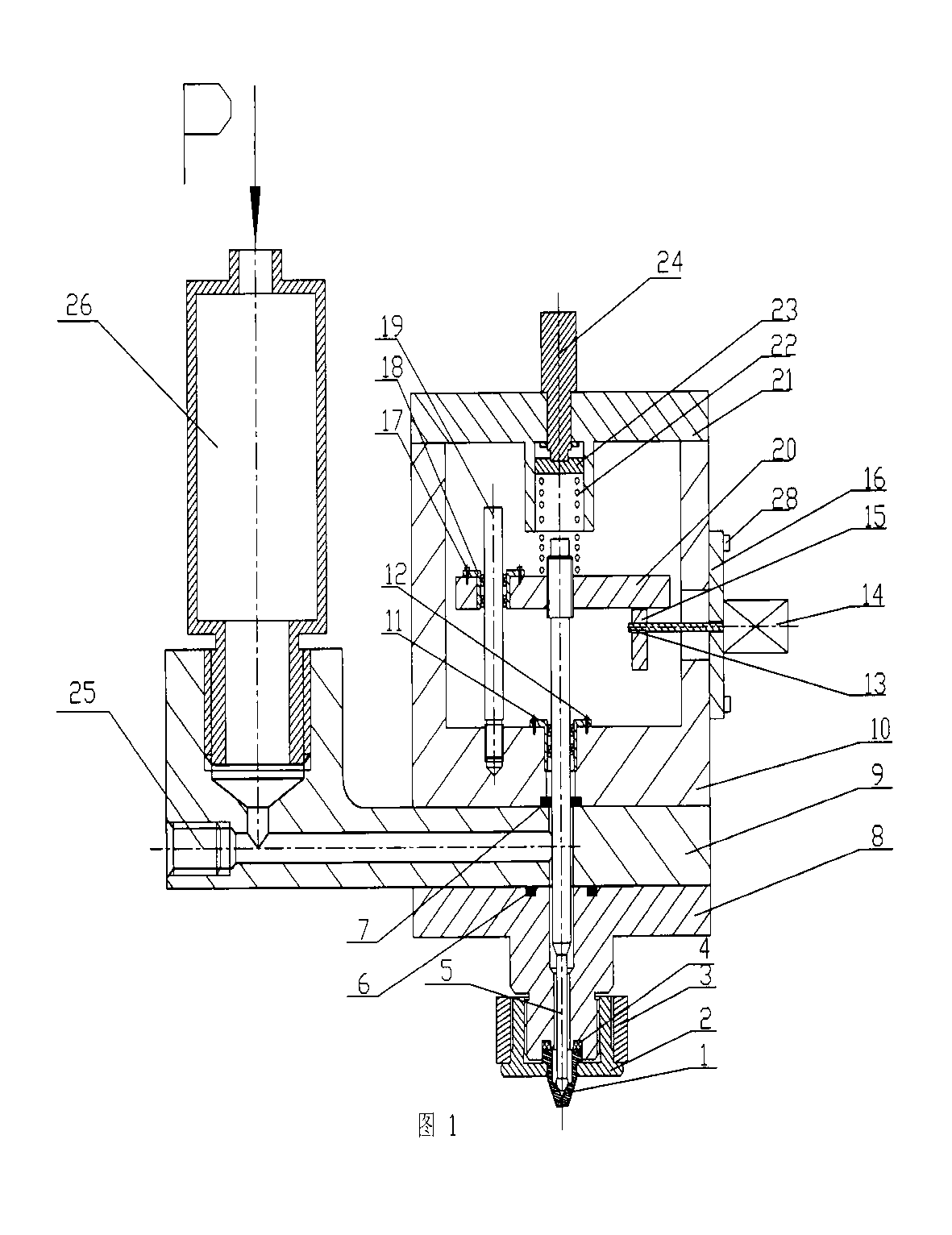

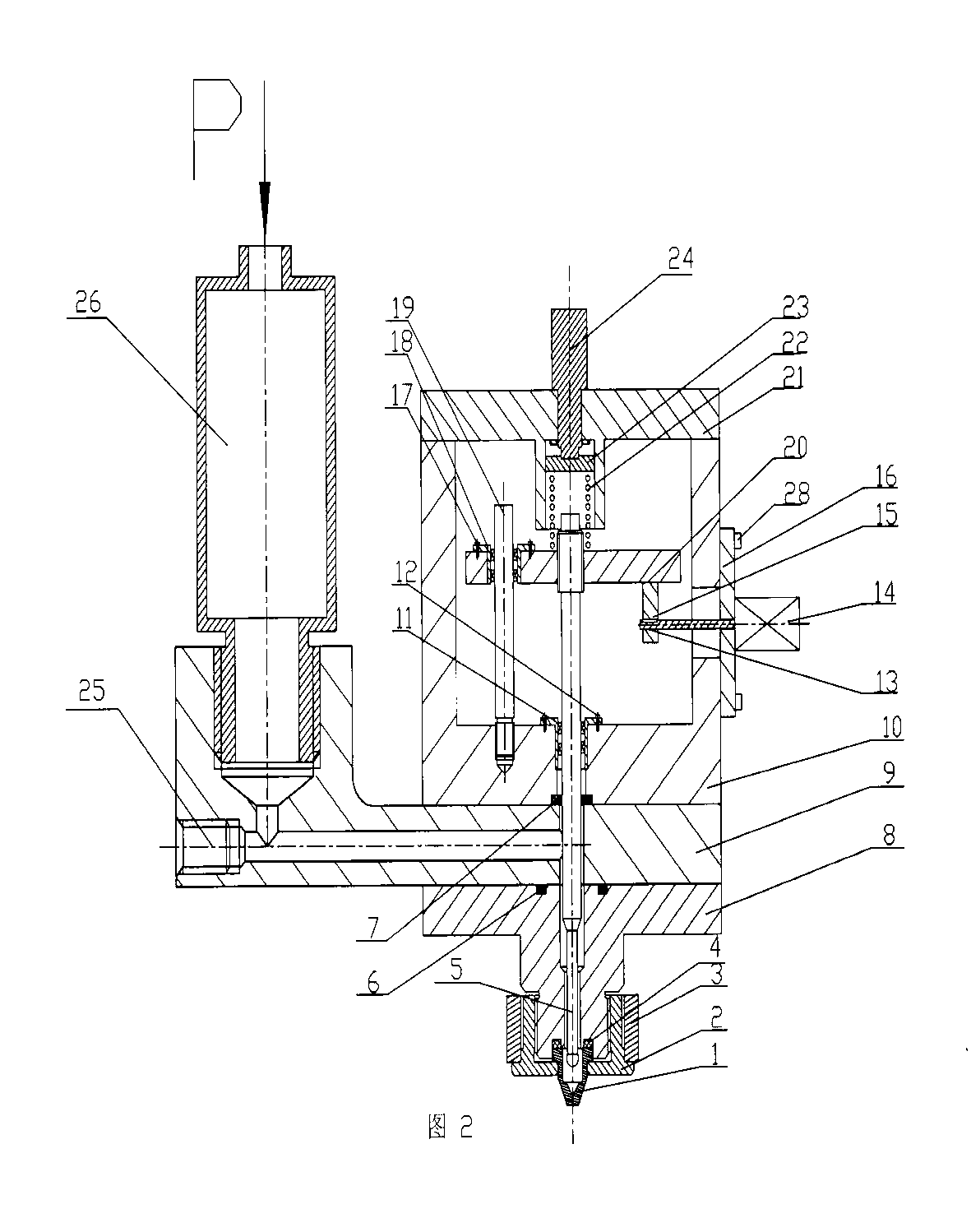

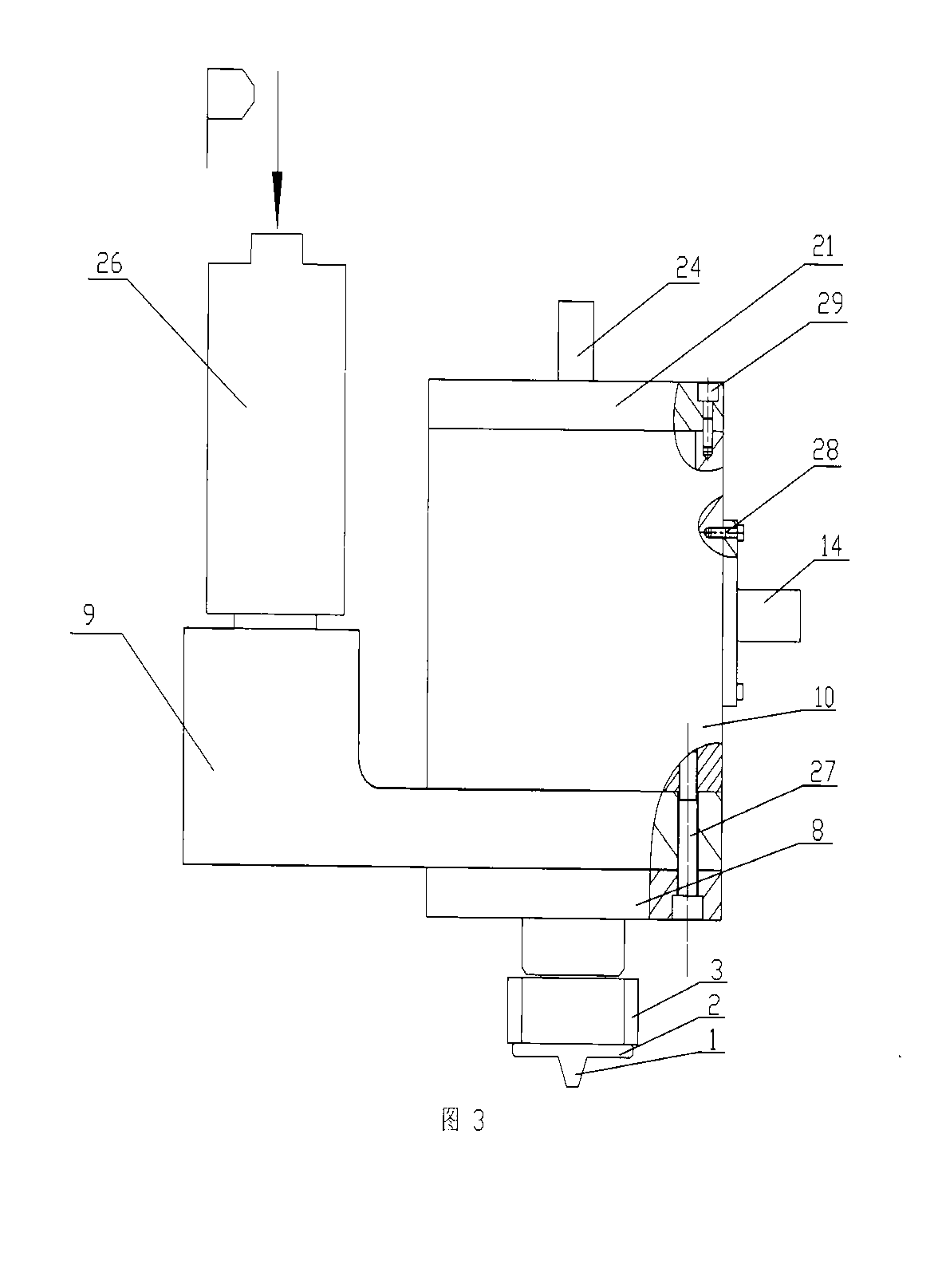

[0017] refer to figure 1 , figure 2 , image 3 , The cam jet dispensing device consists of nozzle 1, fixed nut 2, heater 3, O-ring 4, striker 5, O-ring 6, PTFE sealing ring 7, nozzle interface seat 8, glue inlet seat 9, machine Frame 10, linear bearing 11, screw 12, key 13, servo motor 14, cam 15, servo motor seat 16, screw 17, linear bearing 18, anti-rotation lever 19, moving arm 20, frame cover 21, spring 22, pressure Sheet 23, differential head 24, screw 25, rubber tube 26, screw 27, screw 28, screw 29 are formed.

[0018] The fixing nut 2 fixes the nozzle 1 on the bottom of the nozzle interface seat 8 . An O-ring 4 is installed on the top of the nozzle 1, and its function is to prevent glue with a certain pressure from leaking from the gap between the nozzle 1 and the nozzle interface seat 8. A heater 3 is installed on the fixed nut 2 to heat the glue at the nozzle 1 to reduce its viscosity, which is beneficial for the glue to be sprayed smoothly from the nozzle 1 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com