An ear punching machine

A punching machine and lug technology, applied in the direction of punching machines, presses, piercing tools, etc., can solve problems such as punching machines not being realized, battery replacement, and battery modules not being used normally, so as to achieve convenient and fast loading and unloading , high work efficiency, durable effect of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

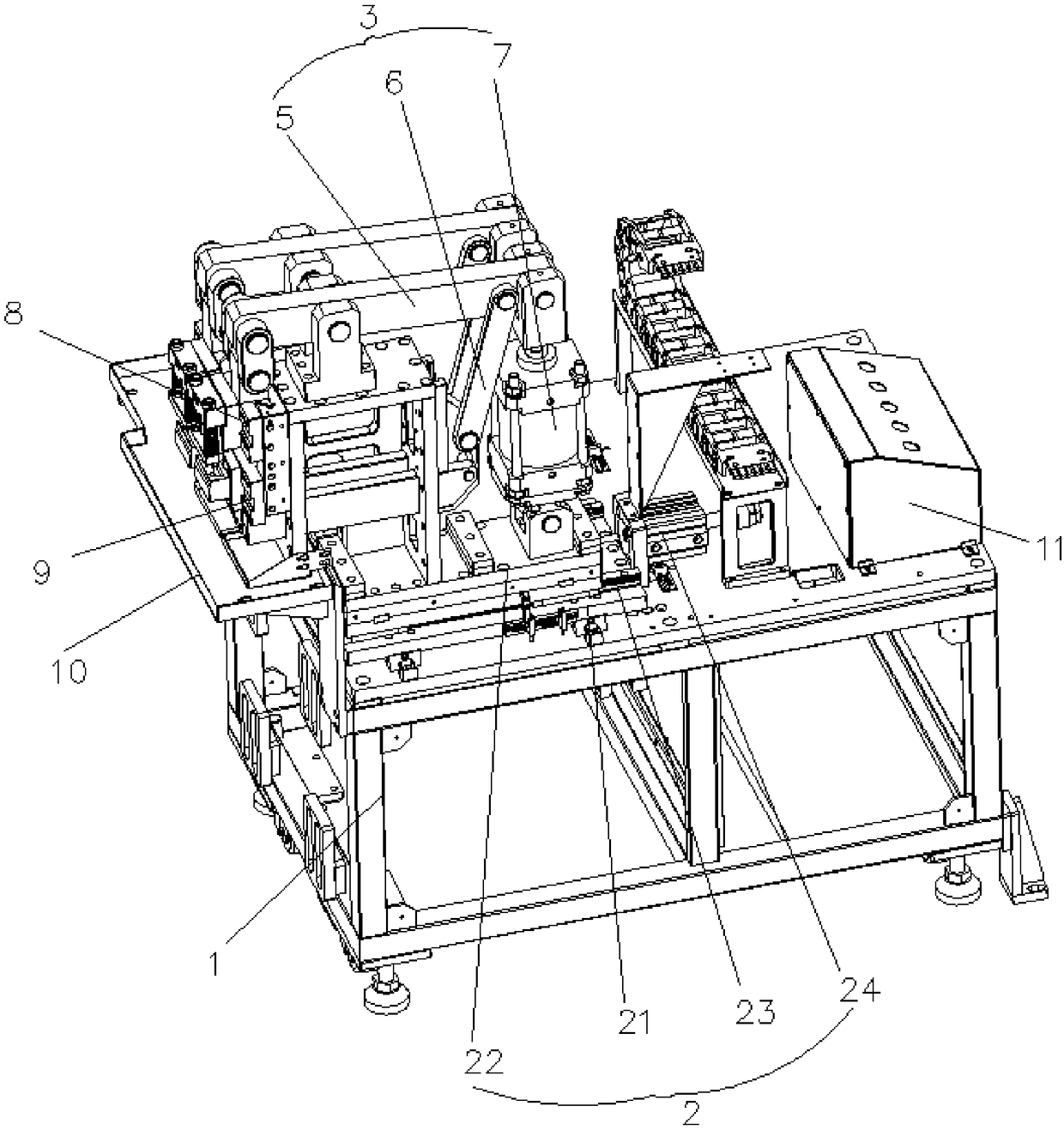

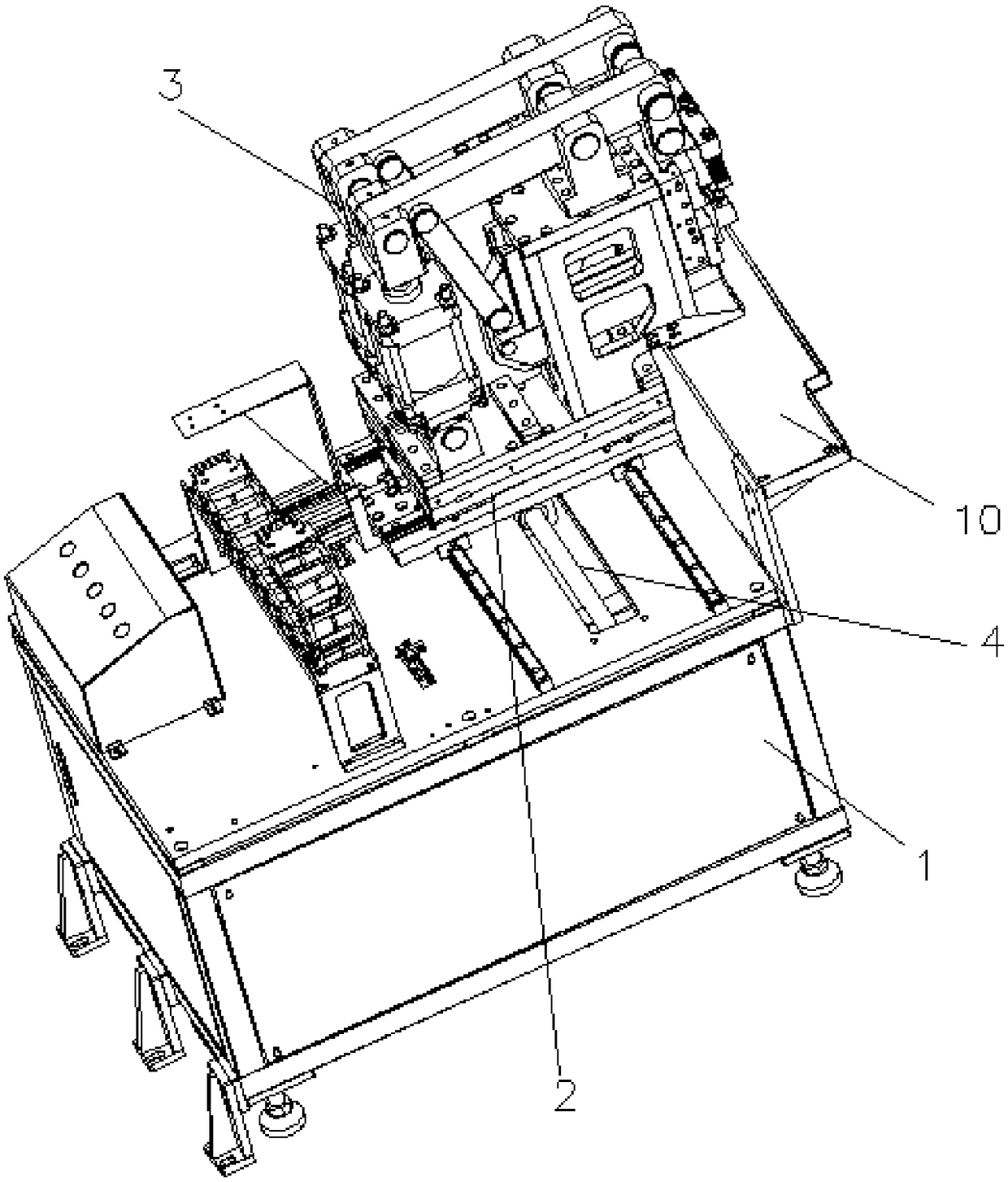

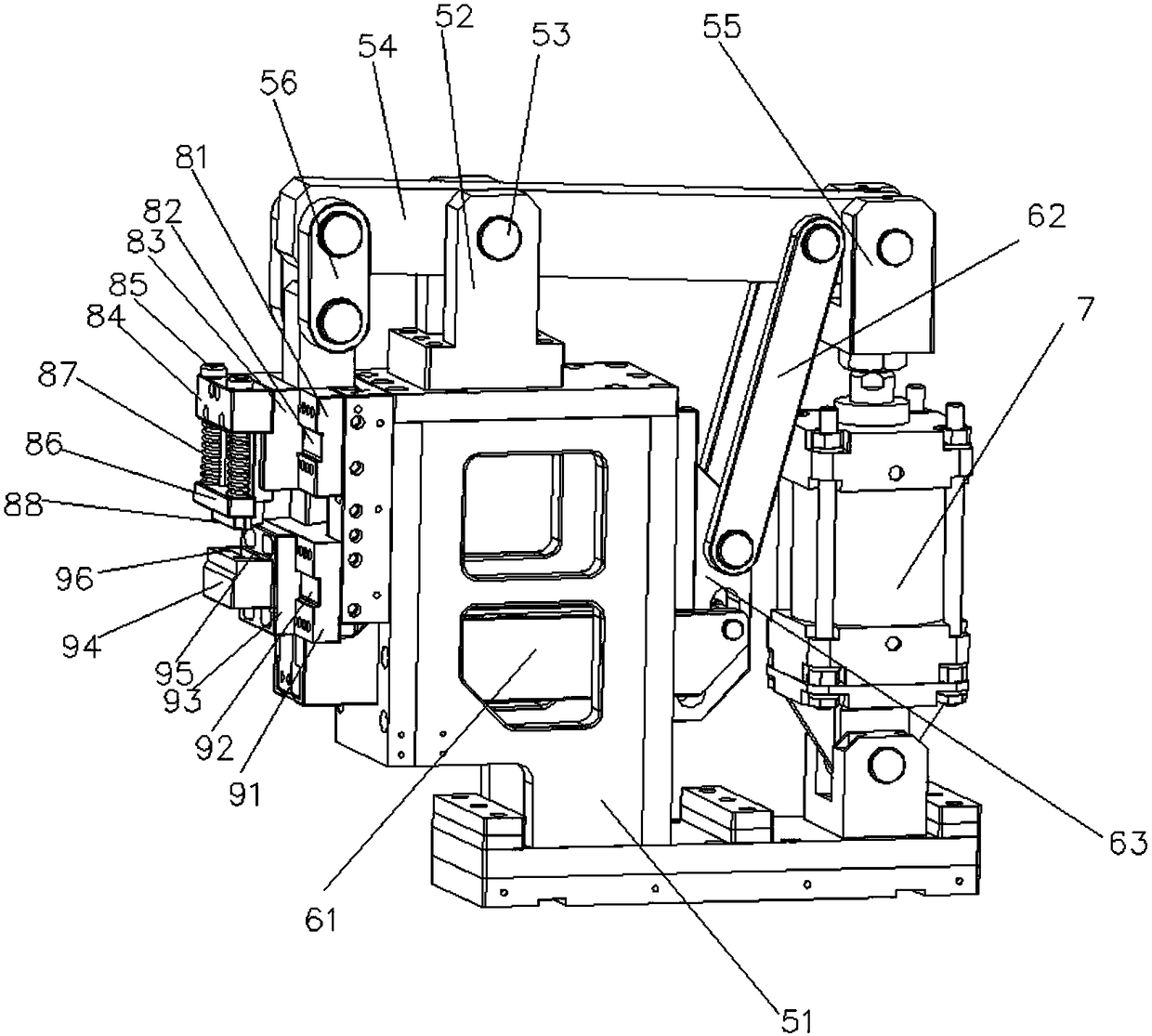

[0036] like figure 1 , figure 2 and image 3 As shown, a tab punching machine includes a frame 1, and the frame 1 is provided with a cylinder propulsion mechanism 2 and at least one set of cylinder connecting rod punching mechanisms 3, and the cylinder propulsion mechanism 2 controls the cylinder connecting rod punching mechanism 3 Left and right movement, the cylinder propulsion mechanism 2 is controlled by the servo motor to move the screw rod 4 back and forth, the cylinder connecting rod punching mechanism 3 includes the upper die connecting rod device 5, the lower die connecting rod device 6 and the jacking cylinder 7, the upper die connecting rod device 5 and the lower mold connecting rod device 6 are controlled by the jacking cylinder 7, when the cylinder connecting rod pun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com