Electronic knitting needle

An electronic needle and needle body technology, applied in knitting, textiles and papermaking, etc., can solve the problems of reducing work efficiency, affecting weaving speed, poor resource utilization, etc., to improve resource utilization, improve work efficiency, and simple and reliable control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

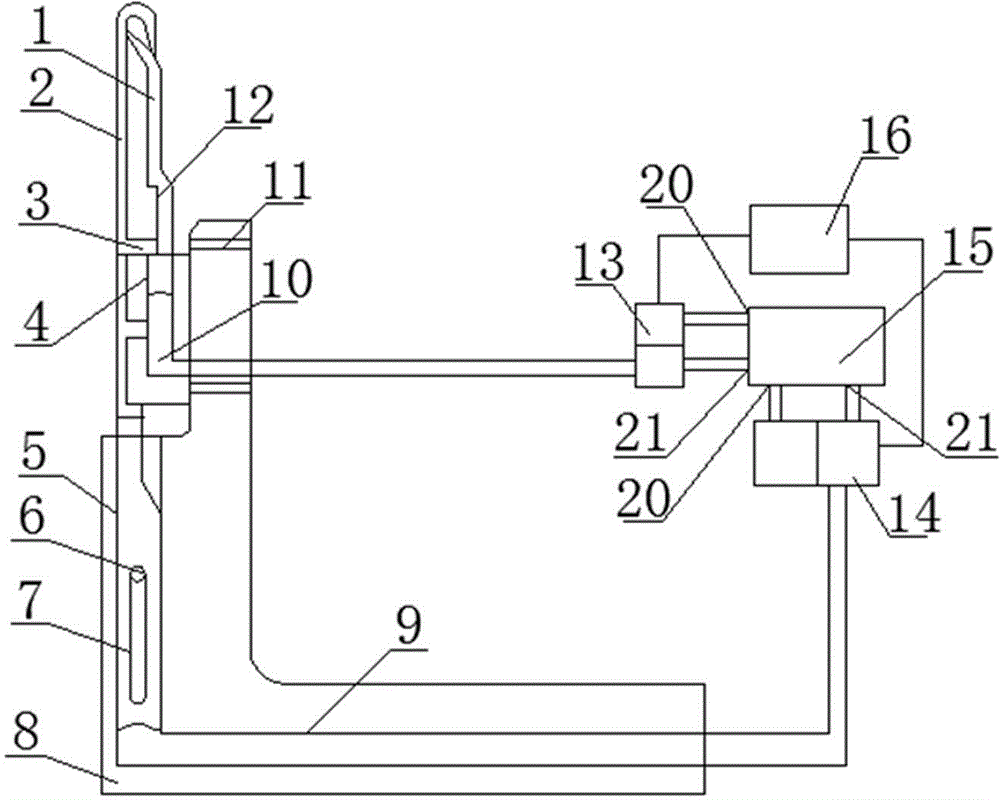

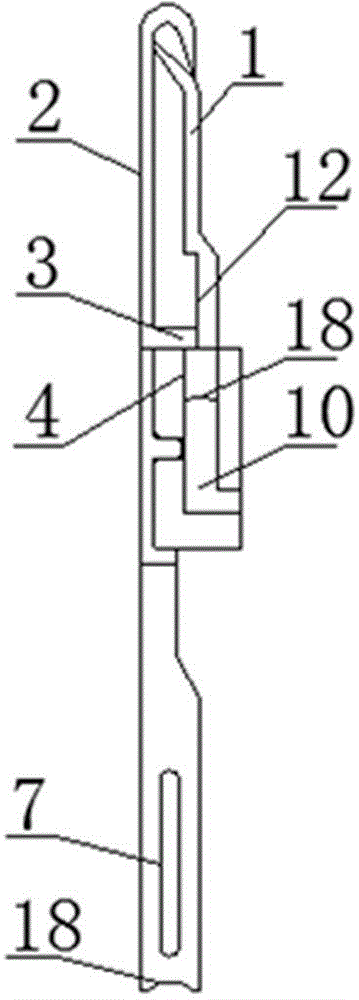

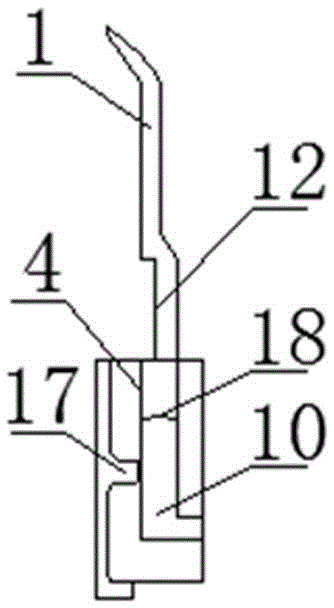

[0014] Referring to the accompanying drawings, a knitting electronic needle includes an inner needle 1, a needle body 2, a needle seat 8, an inner needle slideway 4, an inner needle air path 10, a needle body air path 9, an inner needle control solenoid valve 13, and a needle body Control the solenoid valve 14, the vacuum pump 15 and the program controller 16, the inner needle 1 is installed on the inner needle slideway 4 with a plug-in type, and the inner needle slideway 4 is installed on the needle body 2 with a plug-in type. Needle slideway 4 is provided with recessed hole 17, and described needle body 2 is provided with boss 19, and the recessed hole 17 on the described inner needle slideway 4 matches with the boss 19 on needle body 2, and described needle body 2 The needle body 2 is provided with a needle body limiting groove 7, and the needle holder 8 is provided with a needle body slideway 5, and the needle body 2 is installed on the needle holder through the needle body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com