Patents

Literature

91results about How to "Speed up installation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

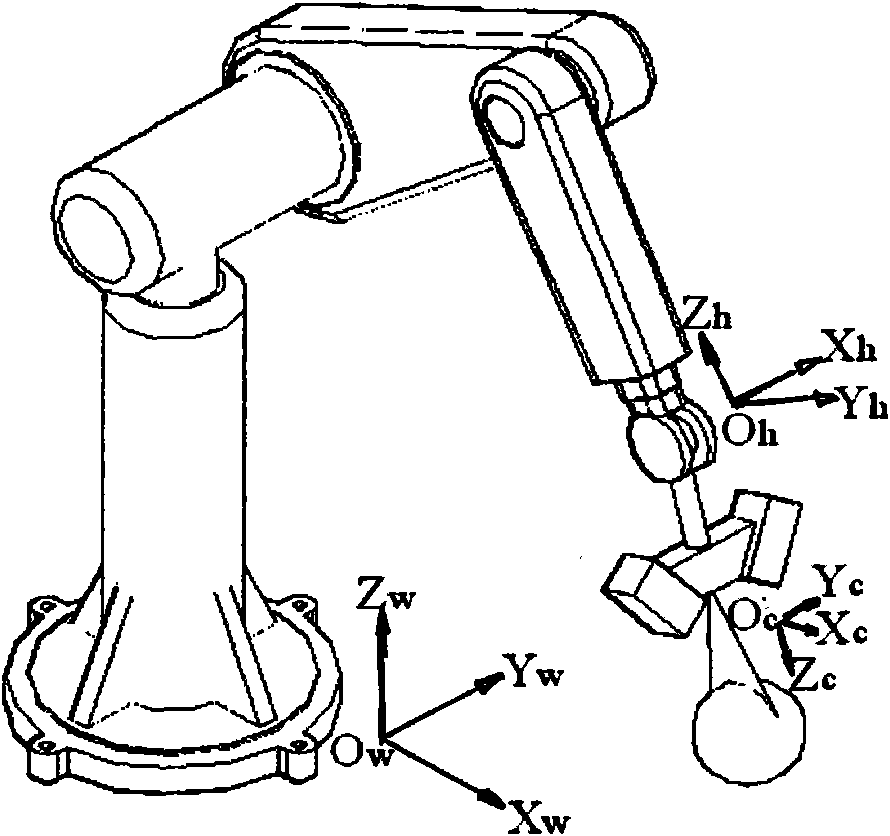

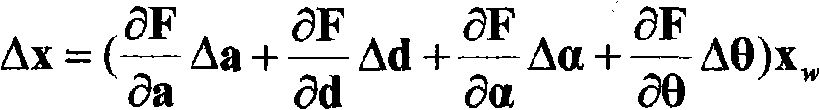

Kinematics calibration method of measurement robot

InactiveCN101660904AEasy to operateHigh precisionUsing optical meansKinematic calibrationEngineering

The invention relates to a kinematics calibration method of a measurement robot; the method mainly aims at computing kinematics parameter error of an industrial robot with a distance-measurement sensor; the method comprises a distance-measurement sensor, an industrial robot and a sphere with known radius, wherein the distance-measurement sensor is arranged at the end of the industrial robot, the sphere with known radius is used as a target and is arranged in a measurable range of a measuring head; the steps of kinematics parameter calibration are: firstly, the robot drives the sensor to measure spherical surface with more than seven poses, measurement data and pose data of the robot are recorded, and then, a centered spherical surface that measurement data is converted to a base coordinatesystem of the robot and spherical radius fixation are taken as a constraint condition, the kinematics parameter error of the robot is computed by nonlinear optimization, so as to realize simultaneouscalibration of a kinematics model and connecting relation of the sensor and the robot.

Owner:DALIAN MARITIME UNIVERSITY

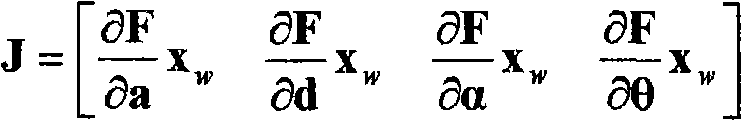

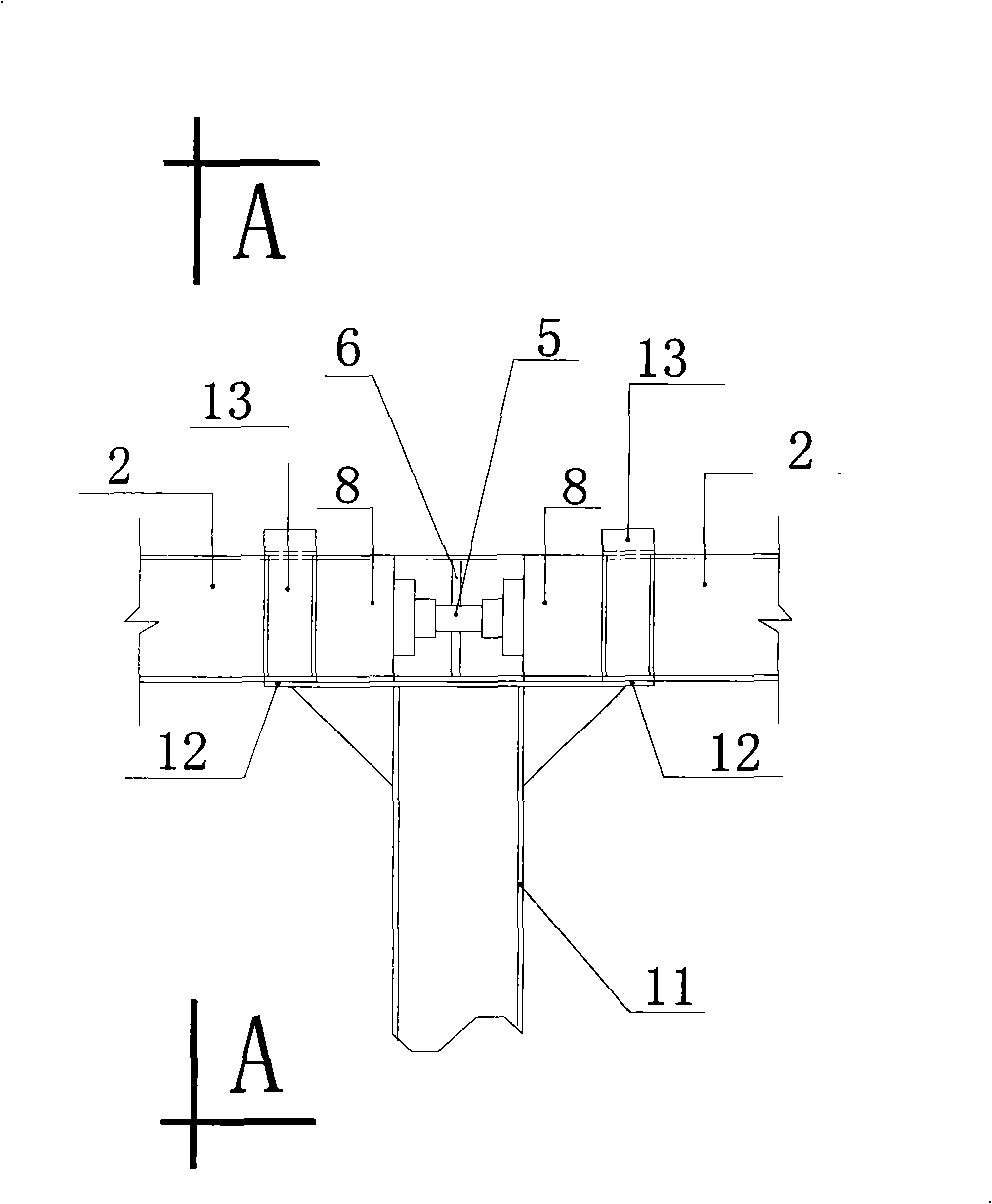

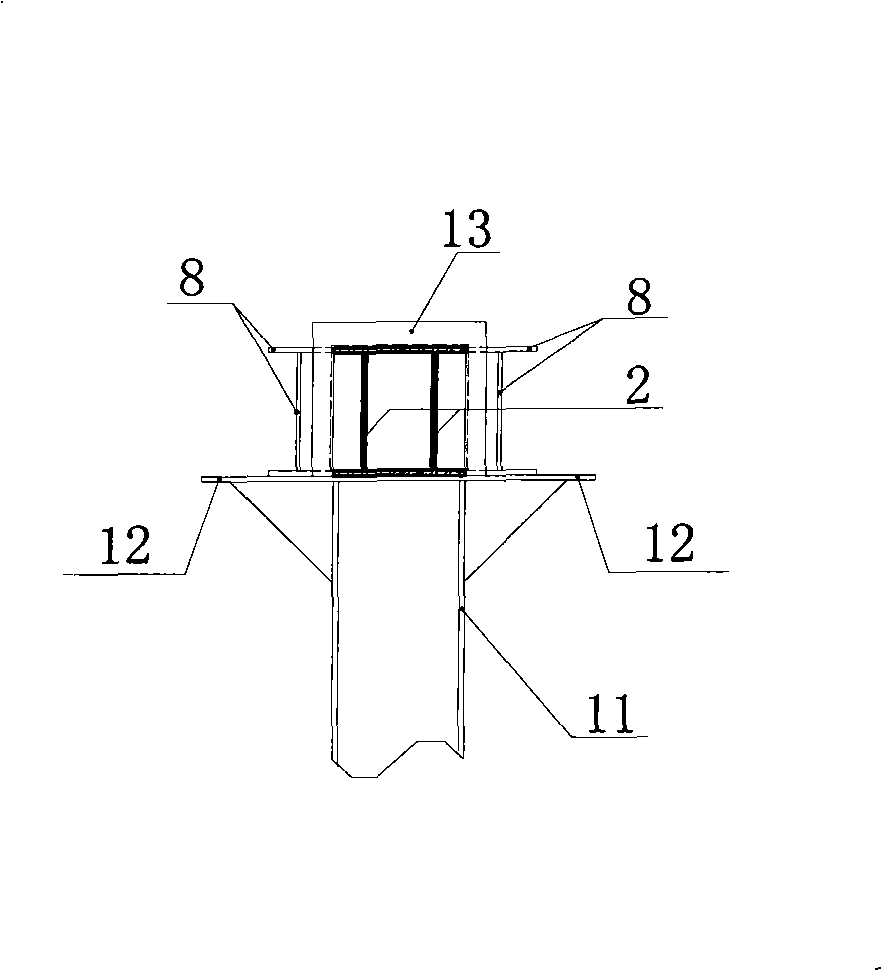

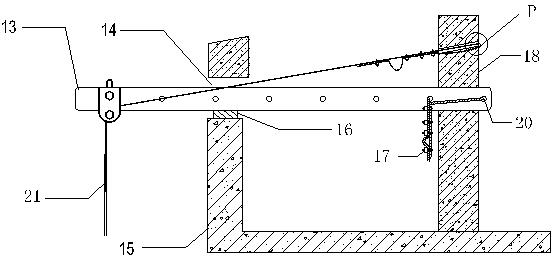

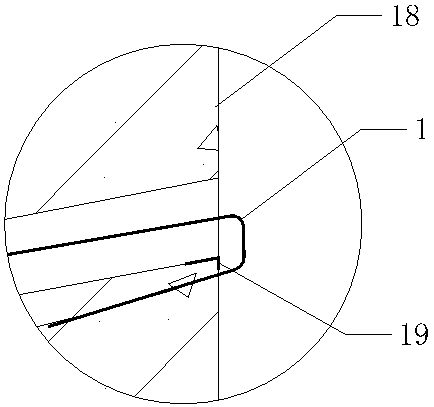

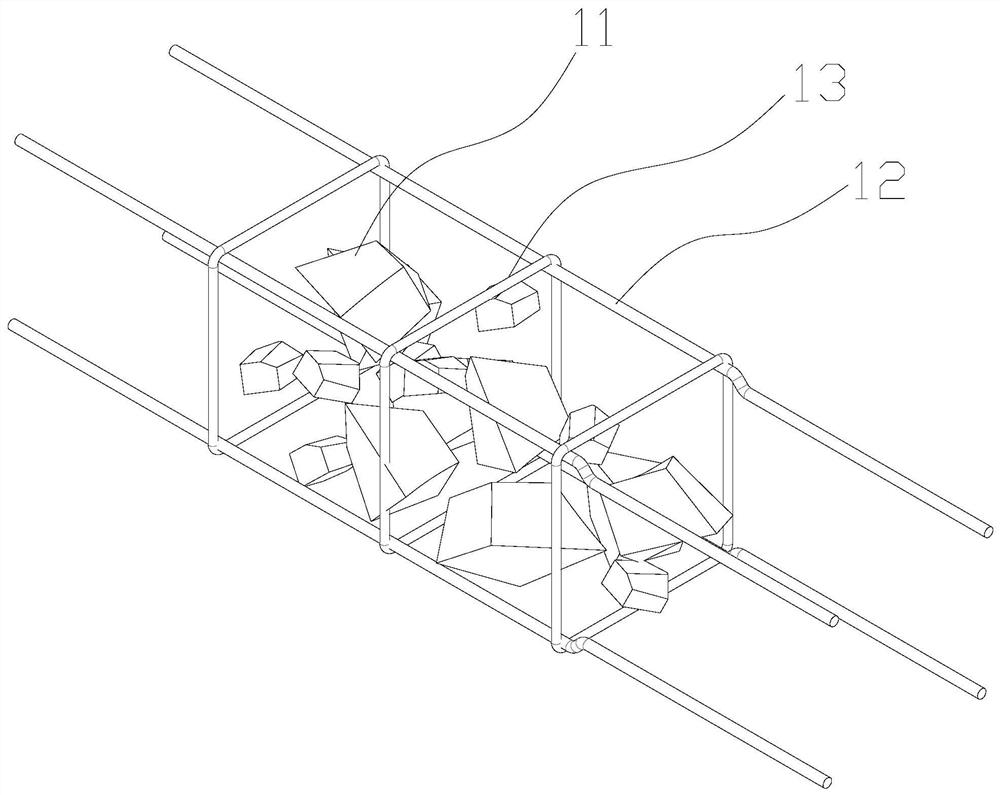

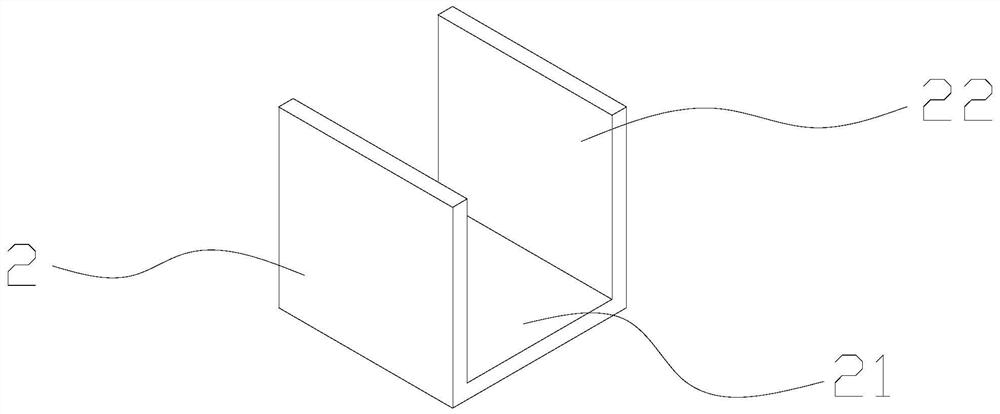

Deep building pit trussed-beam inner support integral application pre-stress method

InactiveCN101255697AWide range of applicationsIncrease the scope of applicationExcavationsPre stressingPre stress

The present invention relates to a method for wholly exerting pre-stress to the trussed internal bearing in the deep foundation pitch. The method comprises the following steps: installing an internal bearing which is composed of a principal top brace, a diagonal rod and a web rod or composed of a principal top brace and a web rod, and installing the trussed internal bearing between two pit walls of the deep foundation pitches; (2) installing a pre-stress force-transferring seat along the axial direction of the principal top brace on each principal top brace; (3) arranging a jack along the axial direction between two pre-stress force-transferring seats of each principal top brace; and (4) cutting off the principal top brace between two force-transferring seats of each principal top brace, exerting pre-stress with the jack, and when the pre-stress which should be exerted is obtained, reinforcing and welding the gap which is between the fracture surface of the cut principal top brace and is generated by exerting pre-stress with the steel material. The method has the advantages of quick installation, short time period for exerting pre-stress, being able to counteracting the compressing deformation of the member bar, and being able to quickly and effectively control the deformation in the deep foundation pitch.

Owner:CHINA FIRST METALLURGICAL GROUP

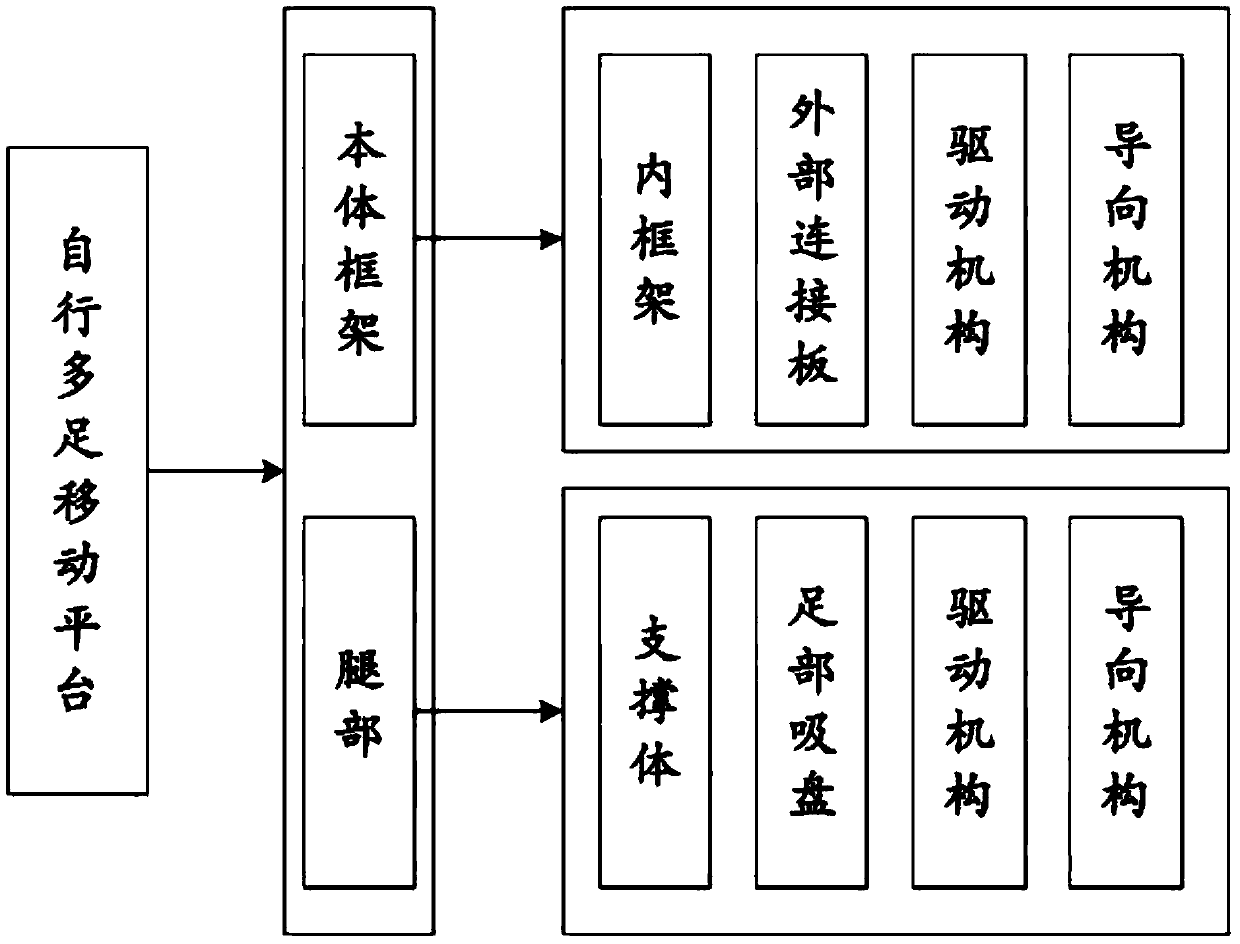

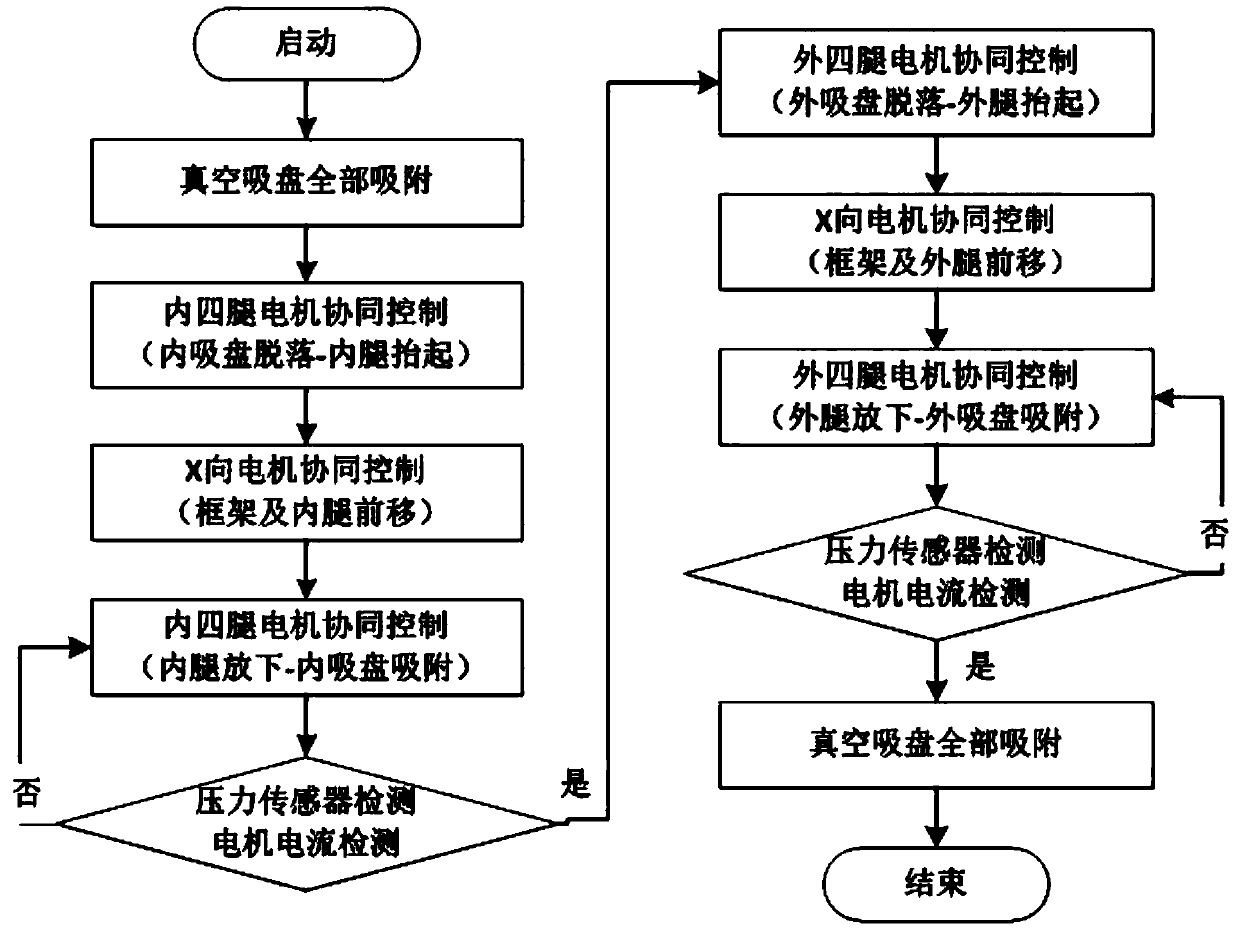

Walking mechanism and walking method of crawling robot

The invention discloses a walking mechanism of a crawling robot. The walking mechanism is characterized by comprising a moving frame, a plurality of outer legs and a plurality of inner legs, wherein the moving frame is rectangular; the outer legs are symmetrically mounted on two symmetrical lateral sides of the moving frame, and the inner legs are symmetrically mounted on the other two symmetrical lateral sides of the moving frame; each outer leg comprises an outer-leg frame and a telescopic leg arranged in the outer-leg frame; each inner leg comprises an inner-leg frame and a telescopic leg arranged in the inner-leg frame; suction cups are mounted at the bottoms of the outer legs and the inner legs; the telescopic legs of the outer legs are connected with the moving frame, and the moving frame ascends and descends with the telescopic legs of the outer legs; the inner-leg frames are rigidly connected with the moving frame, and the inner-leg frames ascend and descend with the moving frame; the outer-leg frames are mounted on the moving frame through guide rails; transverse feed motors are mounted on the moving frame, and the transverse feed motors drive transverse feed screws; the inner legs and the outer legs are both provided with longitudinal feed motors, and the longitudinal feed motors drive longitudinal feed screws.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

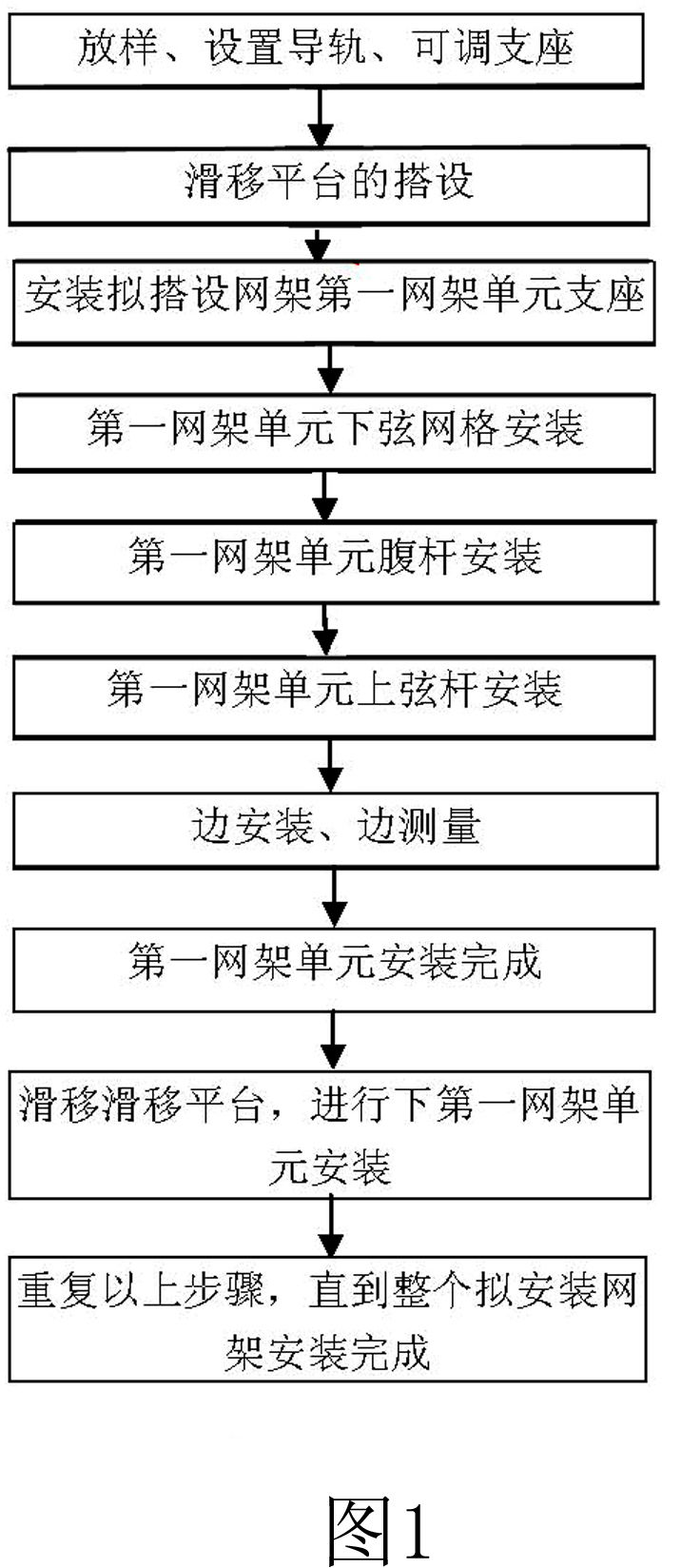

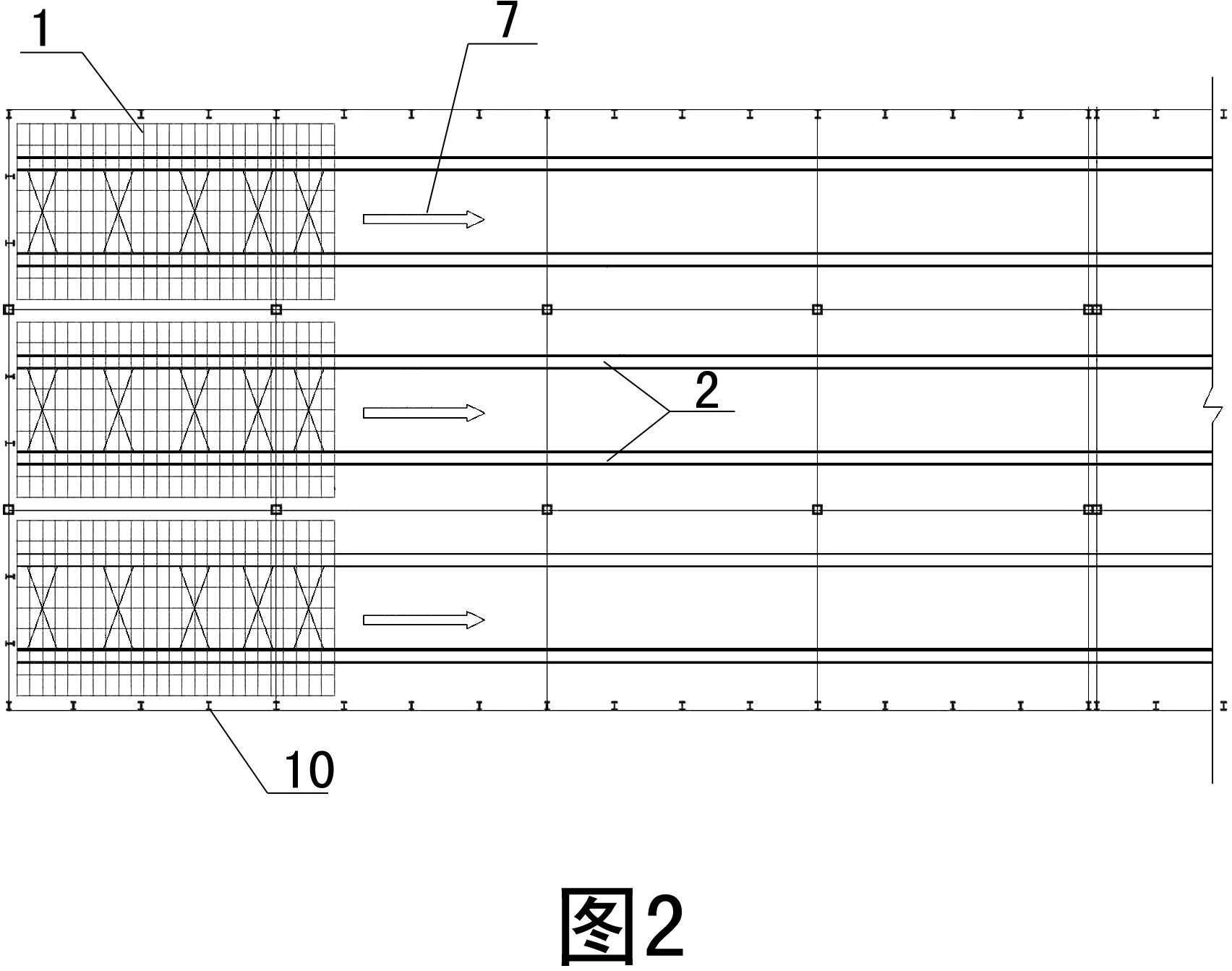

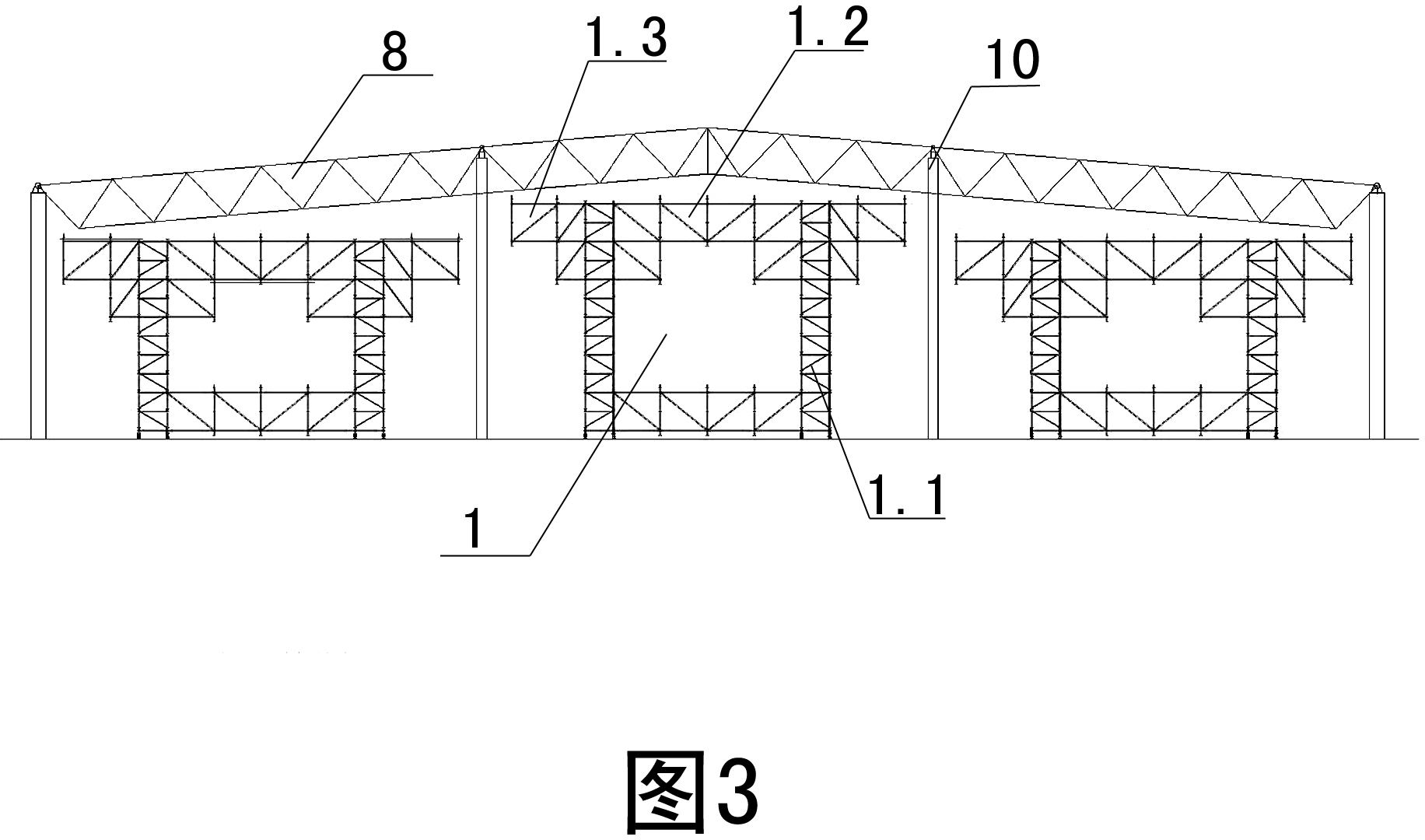

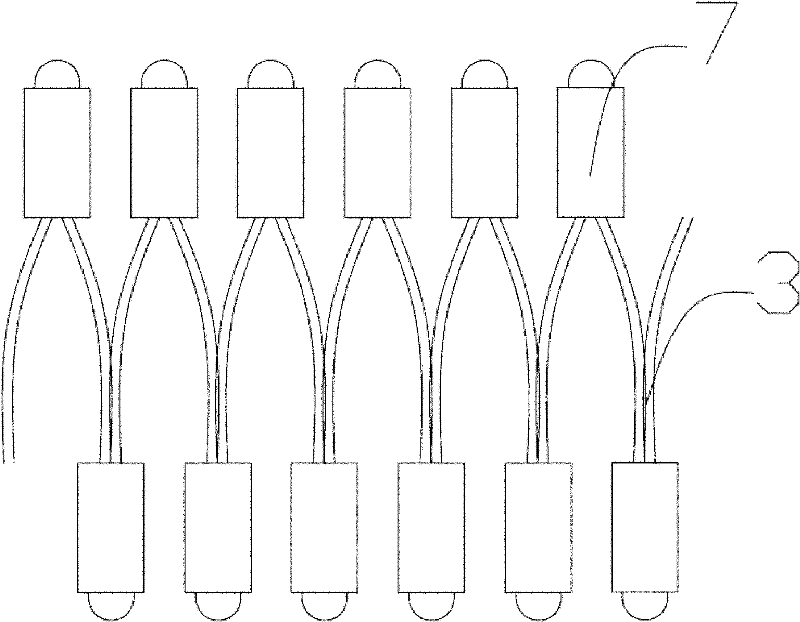

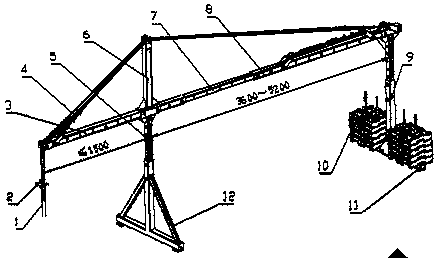

Pulley bracket platform with large-column-grid and large-area grid structure and construction method thereof by utilizing pulley bracket method

InactiveCN101974977ASave setup timeSpeed up installation timeBuilding material handlingTowerSpot welding

The invention relates to a pulley bracket platform with a large-column-grid and large-area grid structure and a construction method thereof by utilizing a pulley bracket method. A bracket body comprises a tower bracket, a suspended span bracket and a suspended overhang bracket; two longitudinal tower brackets are connected through a cross bracket; the bottoms and the tops of two traverse tower brackets are connected with the suspended span bracket; the top of the external side of the tower bracket is connected with the suspended overhang bracket; a steel pipe arranged on the bottom end of the tower bracket is sheathed on a pulley, and the axis of the steel pipe coincides to the axis of the pulley; the pulley is arranged on a guide rail; a sleeper is laid below the guide rail, and the sleeper and the guide rail are fixed in a spot welding mode; a pulley is arranged on the bottom surface of the pulley bracket platform; and the shift of a construction platform is realized by shifting the pulley. Compared with the traditional scaffold, the invention the advantages that the erecting amount and the dismantling of the scaffold can be reduced; the problems of overlarge deflection value and overlarge displacement deviation of a grid bracket to be erected because of overlarge integral settlement of a construction bracket are simultaneously avoided and can be widely applied to the installation and the construction of the large-column-grid and large-area grid structure.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU

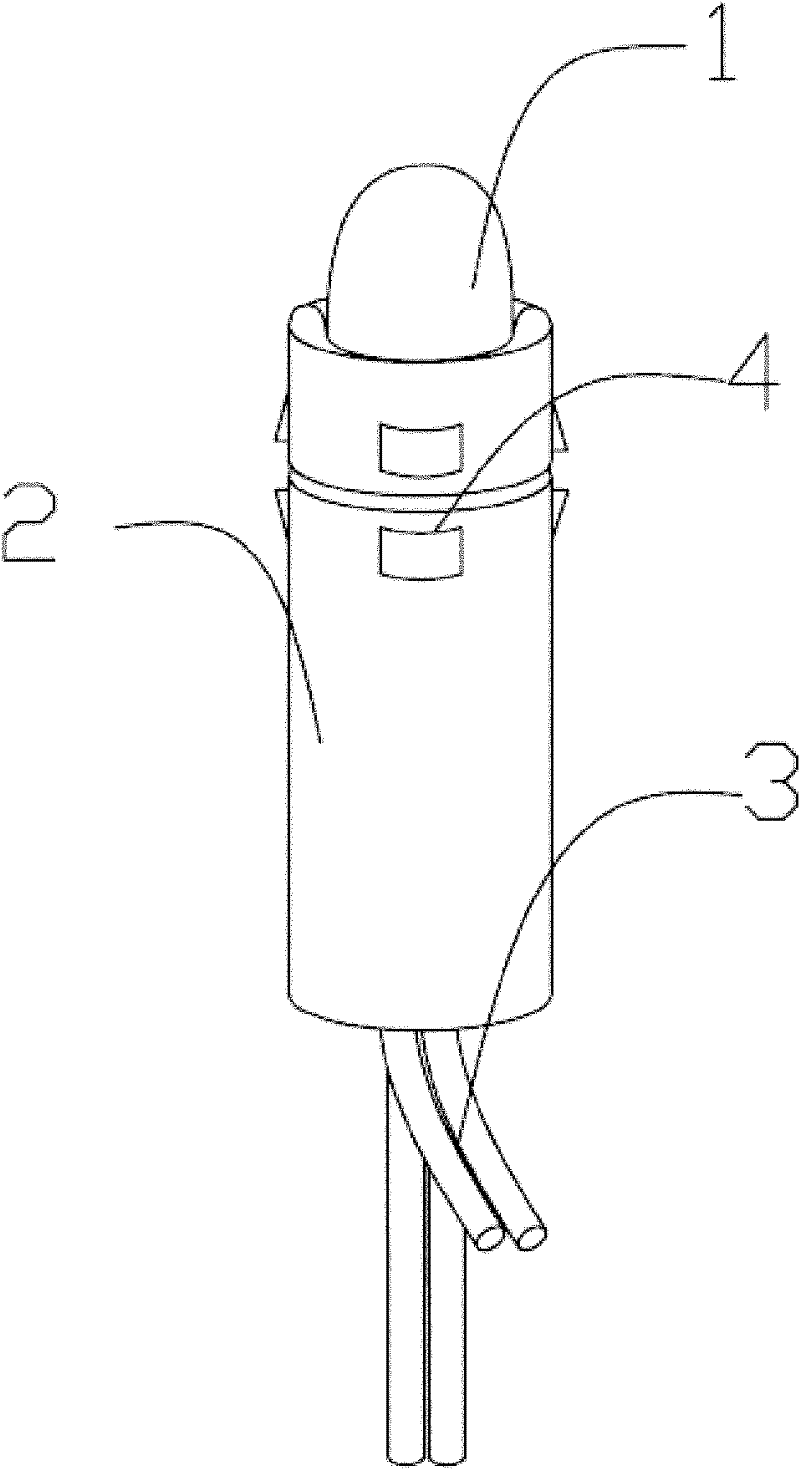

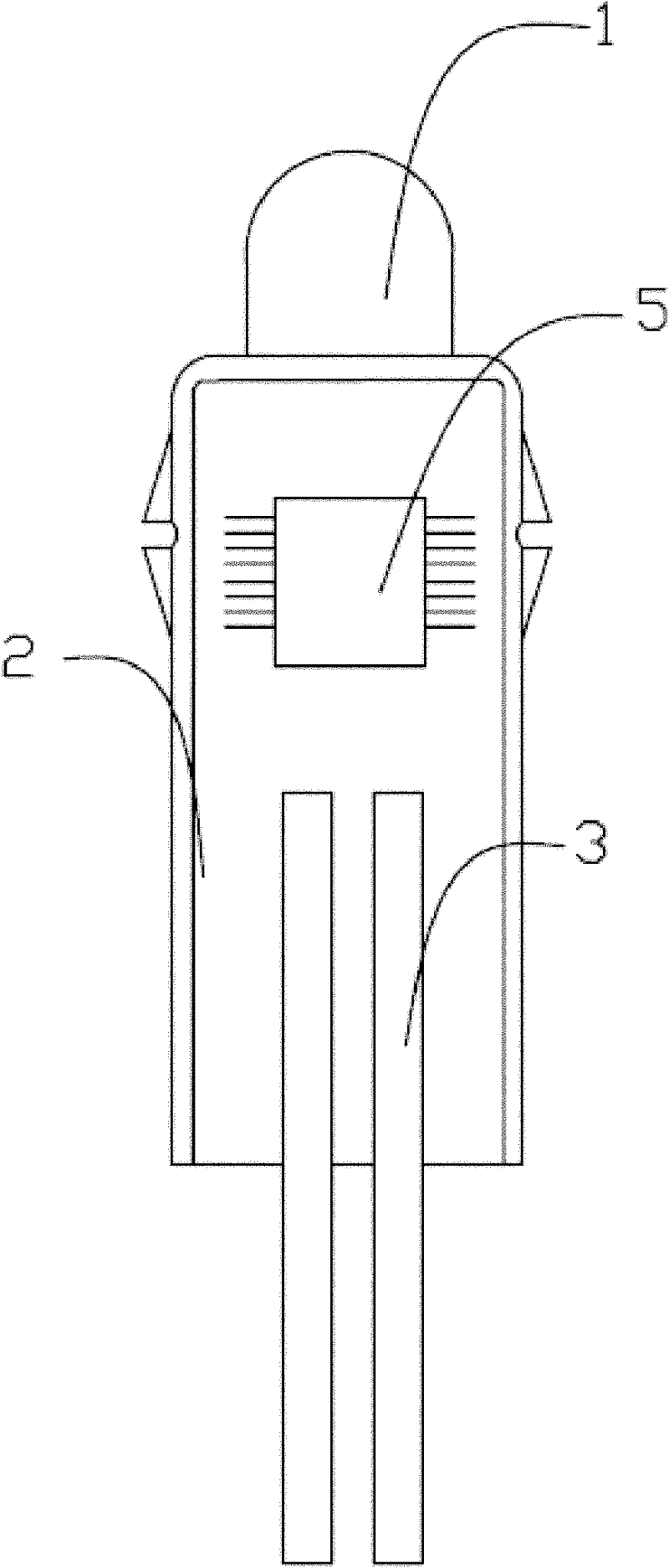

Light-emitting diode (LED)-exposed waterproof perforated lamp string and manufacturing process thereof

InactiveCN102454908AEasy to makeGive full play to the advantages of LED point light sourcePoint-like light sourceElongate light sourcesEpoxyUltraviolet

The invention provides a light-emitting diode (LED)-exposed waterproof perforated lamp string and a manufacturing method thereof. The LED-exposed waterproof perforated lamp string is formed by combining LED lamps, printed circuit boards (PCBs) and anti-ultraviolet (anti-UV) polyurethane (PU) wires together in a welding mode and an epoxy resin glue embedment mode and solidifying at the high temperature of between 50 and 60 DEG C. The problem that modified epoxy resin and polyvinyl chloride (PVC) cables cannot be firmly adhered and the problem of waterproof performance treatment are radically solved. When the LED-exposed waterproof perforated lamp string is actually used, a plurality of perforated lamps are connected together by a parallel circuit according to a certain rule; the LED-exposed waterproof perforated lamp string has the advantages of simple structure, low cost, long service life, large light-emitting angle, low light attenuation, uniform aperture, low power consumption, energy conservation and environment friendliness, is stable in work and safe in use and is driven by direct current (DC) the constant voltage of 5V; and a special bayonet design is adopted, and the perforated lamps are directly mounted after being perforated, so that mounting cost is lowered, the LED-exposed waterproof perforated lamp string is convenient to maintain, and various boards can be used after being perforated. The perforated lamps are designed in a bidirectional disassembling and assembling separated mode, so that the perforated lamps are easier to maintain and have wide application prospects.

Owner:RISHANG OPTOELECTRONICS

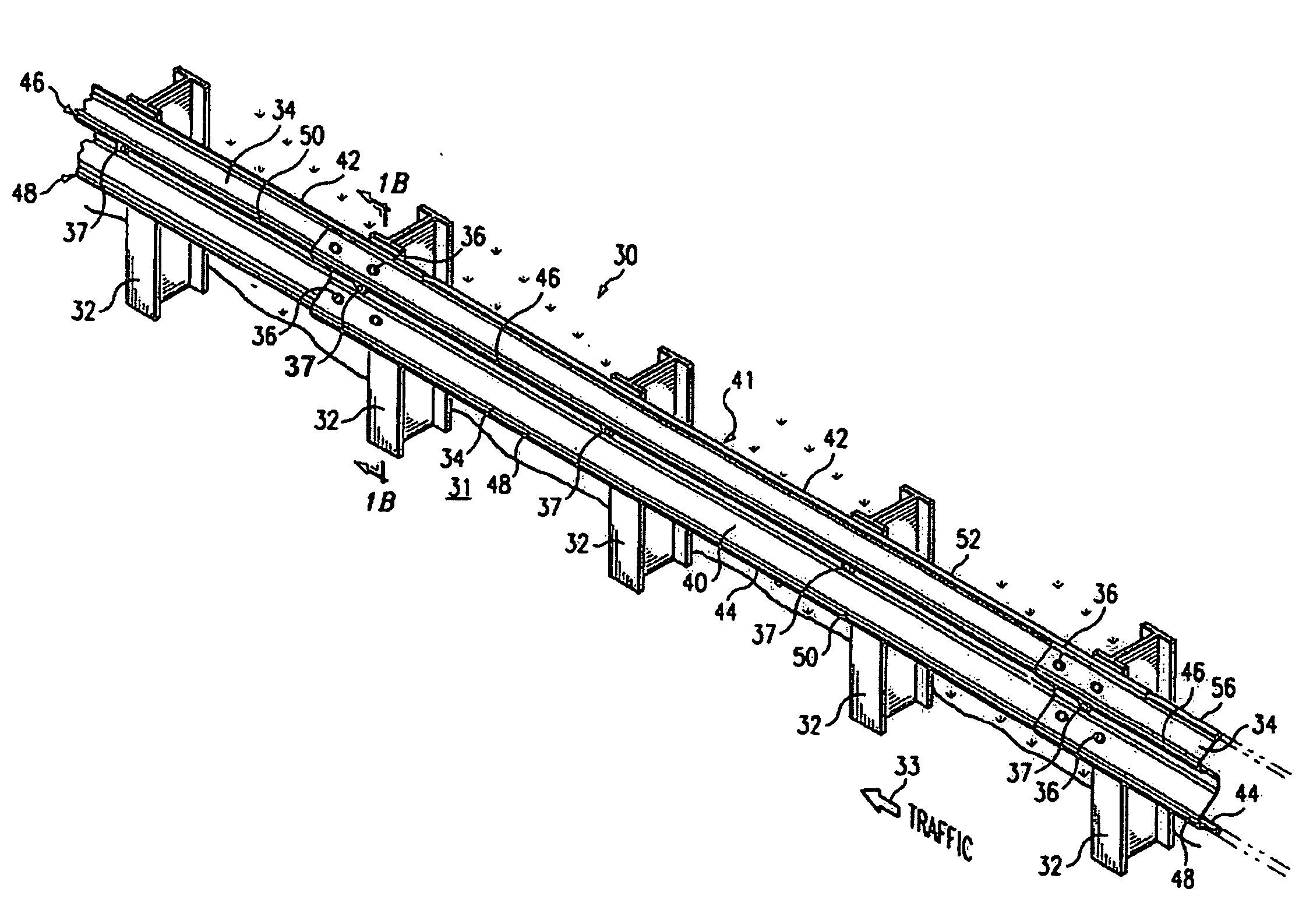

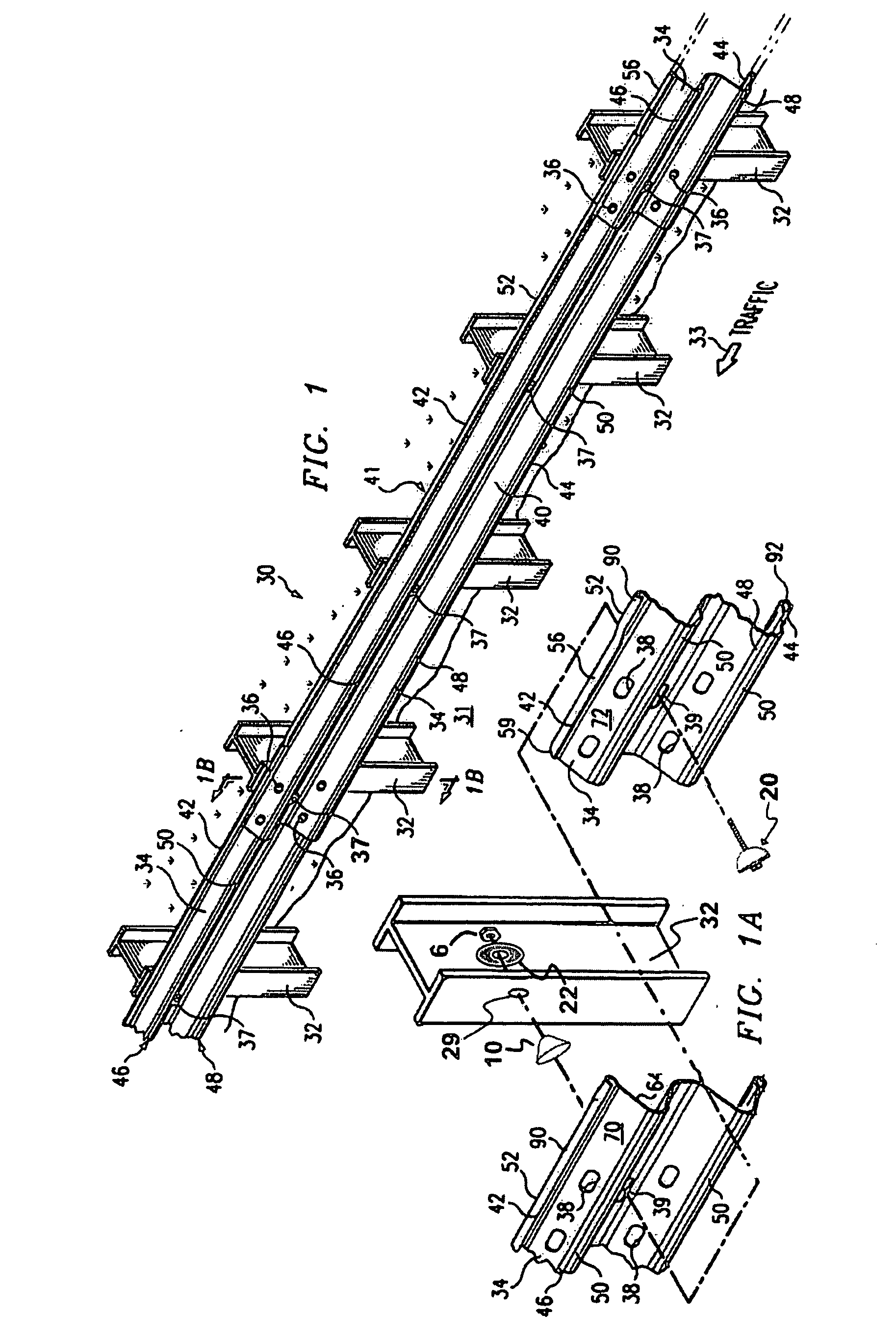

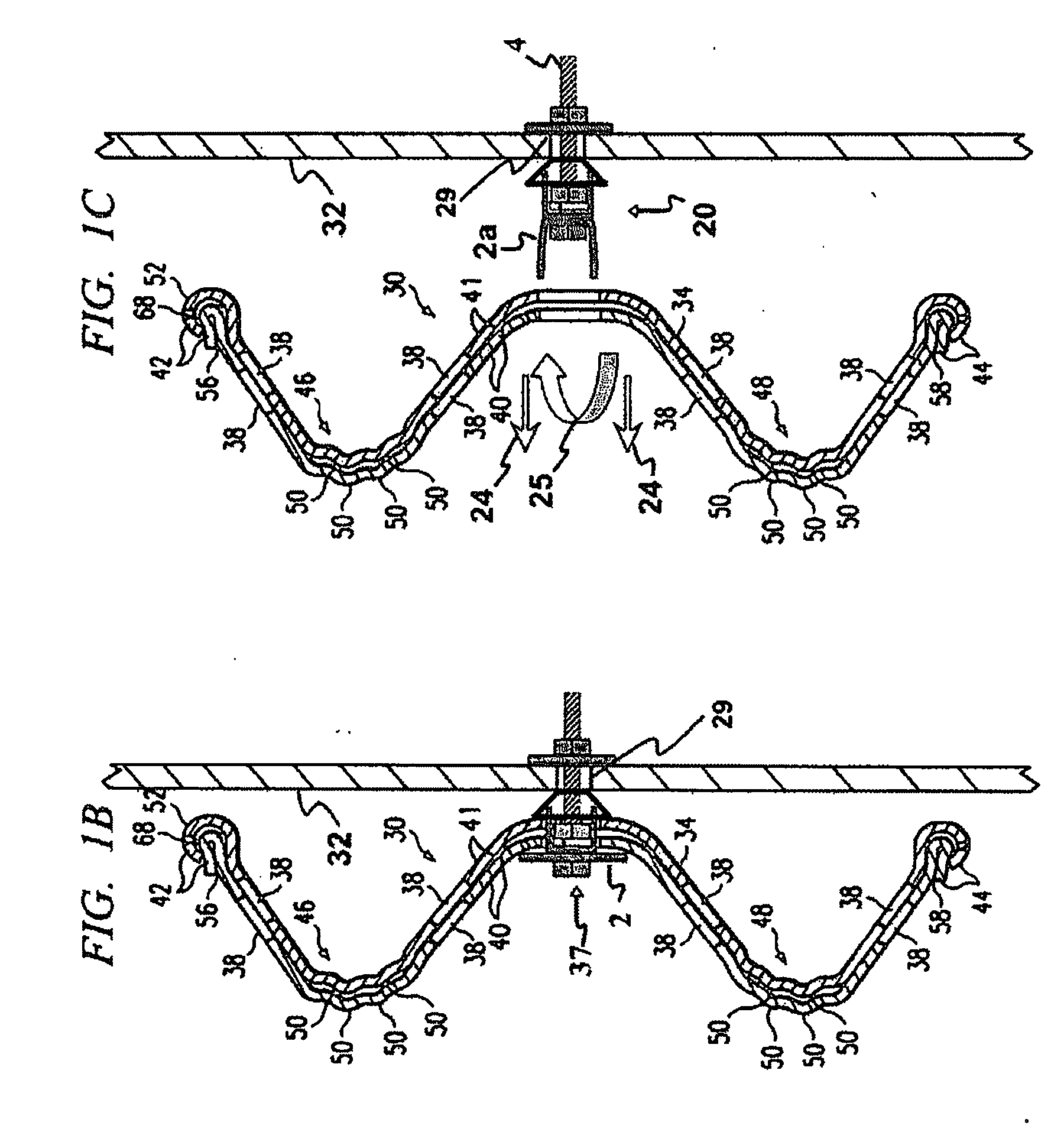

Posts and release mechanism for highway safety structures

InactiveUS20080083914A1Reduce variationMore securityPasturing equipmentRoadway safety arrangementsEngineering

A guardrail system for installation along a highway includes a plurality of spaced elongate support posts and a guardrail mounted on the plurality of support post by securing members. The system includes one of a releasing member and an edge portion of an opening in the guardrail or the support post for releasing the guardrail from the support post in response to a selected magnitude of release load. The magnitude of the release load is in the range of ⅖ to 1⅖ times a load magnitude that yields the support post when the post is unsecured to the guardrail.

Owner:OCHOA CARLOS M

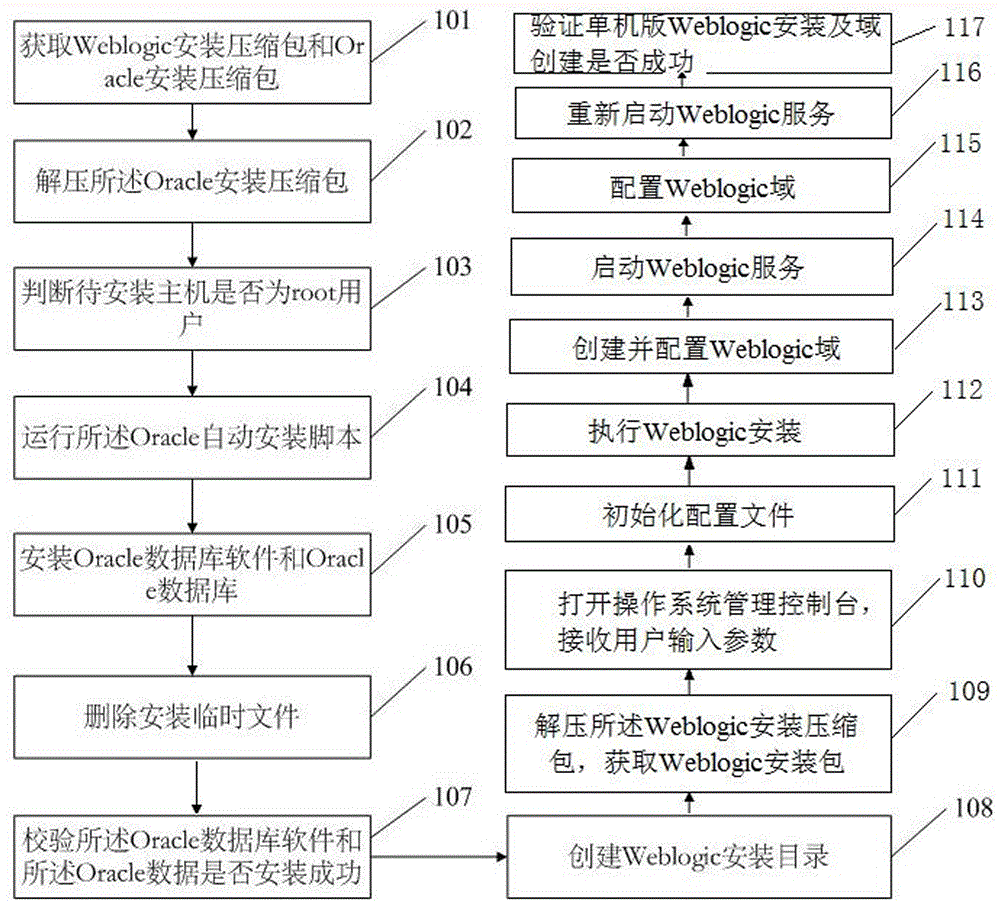

Oracle and Weblogic combined one-key automatic deployment method

InactiveCN106325954AImprove experienceSimple stepsProgram loading/initiatingSoftware simulation/interpretation/emulationOracle databaseApplication server

The invention discloses an Oracle and Weblogic combined one-key automatic deployment method, and relates to the technical field of application server and database installation. The Weblogic and Oracle automatic deployment is realized; the steps are simple and compact; the installation time is saved; the manual gradual input of corresponding configuration information is not needed; the user experience is improved. The method is characterized by comprising the steps of obtaining a Weblogic installation compression package and an Oracle installation compression package; decompressing the Oracle installation compression package to obtain an Oracle automatic installation script and an Oracle installation package; running the Oracle automatic installation script; installing Oracle database software and an Oracle database; creating a Weblogic installation catalogue; decompressing the Weblogic installation compression package to obtain a Weblogic installation package; running an auto_install.sh script; creating and configuring a Weblogic domain; initializing the Weblogic. The method is mainly used for Weblogic one-key deployment based on Oracle.

Owner:GUANGXI POWER GRID CORP

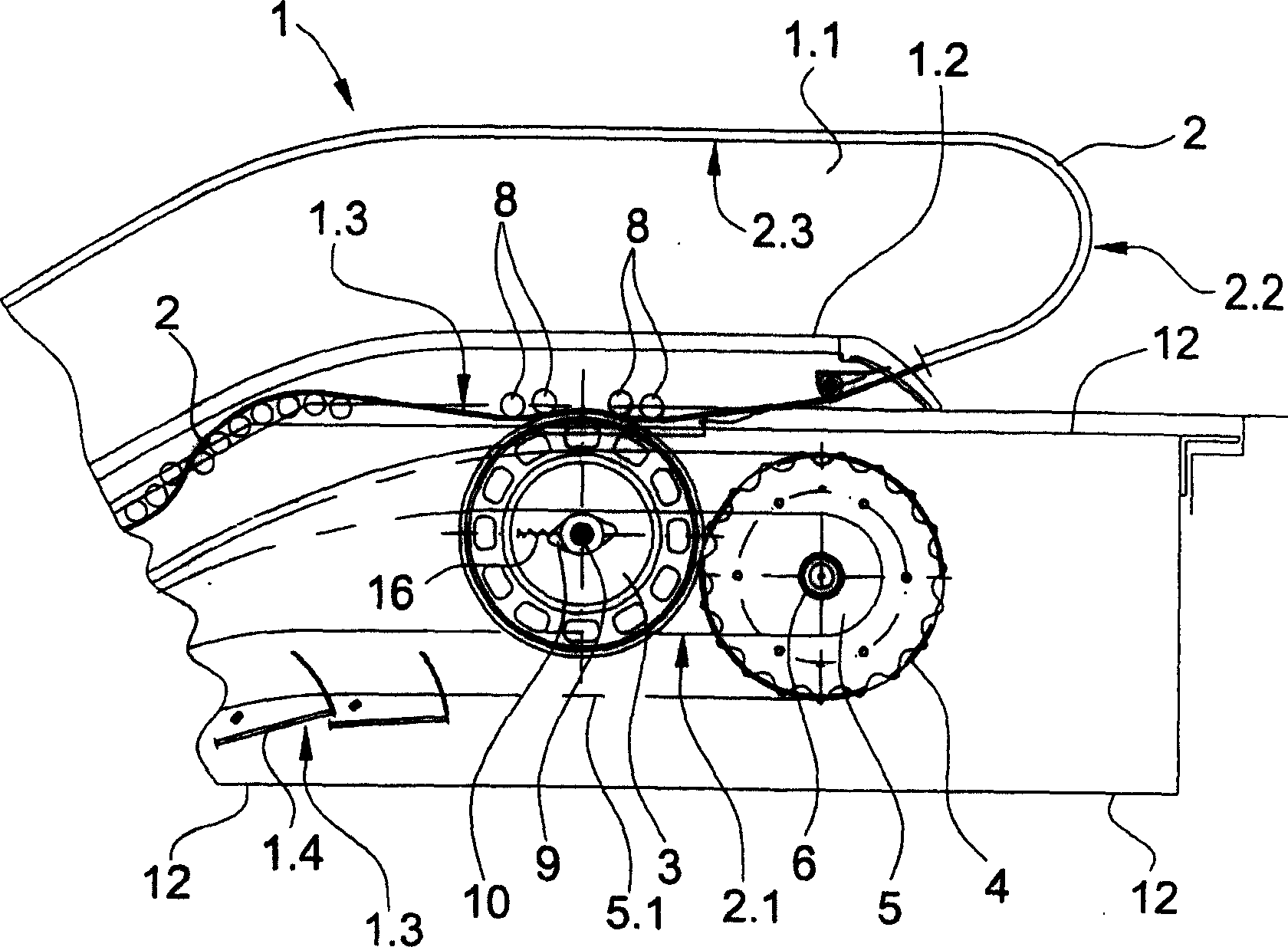

Handrail driving device for escalator or moving walkway

Owner:INVENTIO AG

Combination fire-proof door and method for making same

InactiveCN101457629AIntegrity guaranteedGuaranteed reliabilityFireproof doorsWater-setting substance layered productFoaming agentHazardous substance

The invention relates to a fire safety building equipment, in particular to a combination fire door and a fabricating method, in the scheme, a new expanding material is adopted and mixed with water and then poured into a door frame and a door leaf frame, the expanding material is composed of sulphate aluminium cement, silicate cement, coal ash and modifying agent, the contents of which are respectively 4-15 percent, 50-65 percent, 18-35 percent and 2-10 percent according to the weight percentages, wherein the modifying agent comprises early strength agent, water reducing agent, suspending agent, diffusing agent, foaming solution and foam stabilizer, the weight percentages of which in the modifying agent are respectively 5.4-34.6 percent, 3.3-39.6 percent, 5.4-28.8 percent, 2.7-21.6 percent, 3.8-27.4 percent and 1.1-25.9 percent; in the foaming solution, weight percentages of the foaming agent and water are 1.6-3.5 percent, weight percentages of the mixture of water and the expanding material is 45-72 percent. In the scheme, the adoption of the foam molding fillers of liquid materials can ensure the fillers in the door frame and the door leaf frame are solidly filled without dead corner, in addition, the material has no harmful substances, accounts for one tenth of concrete mortar, and can be directly poured by the manufacturer, therefore, the late-stage in-situ concreting procedure is avoided. The materials in use are uniform and free from peculiar smell, thus ensuring completeness, reliability and security of the fire door.

Owner:王本淼

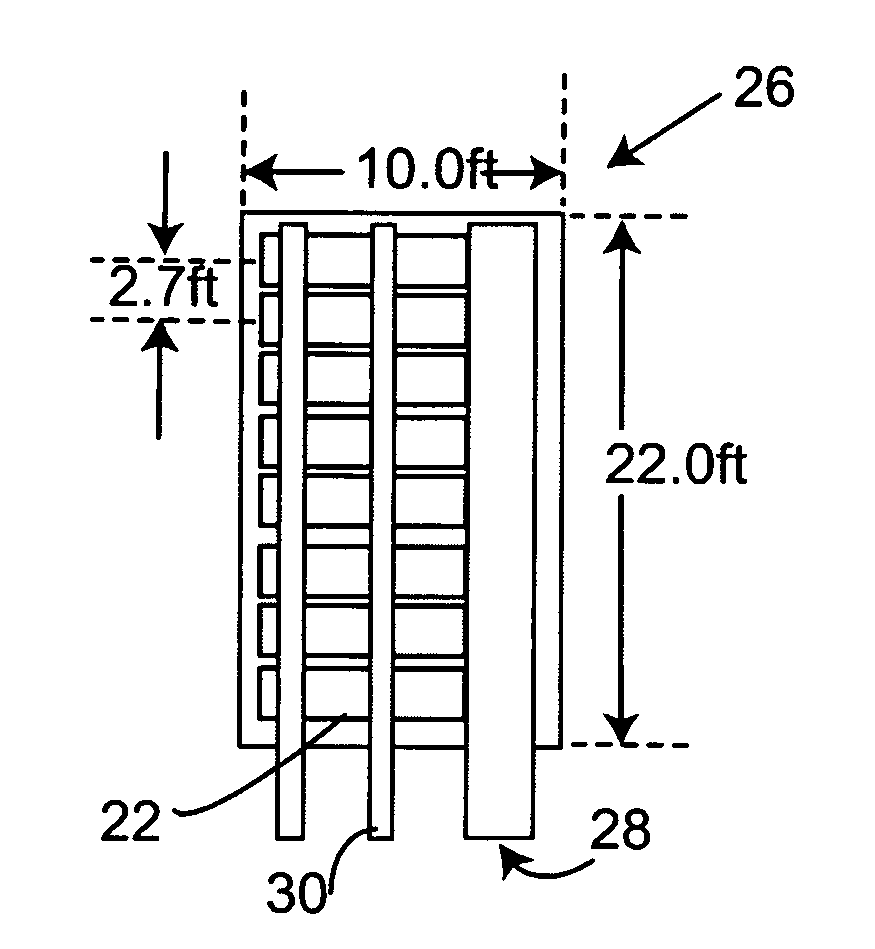

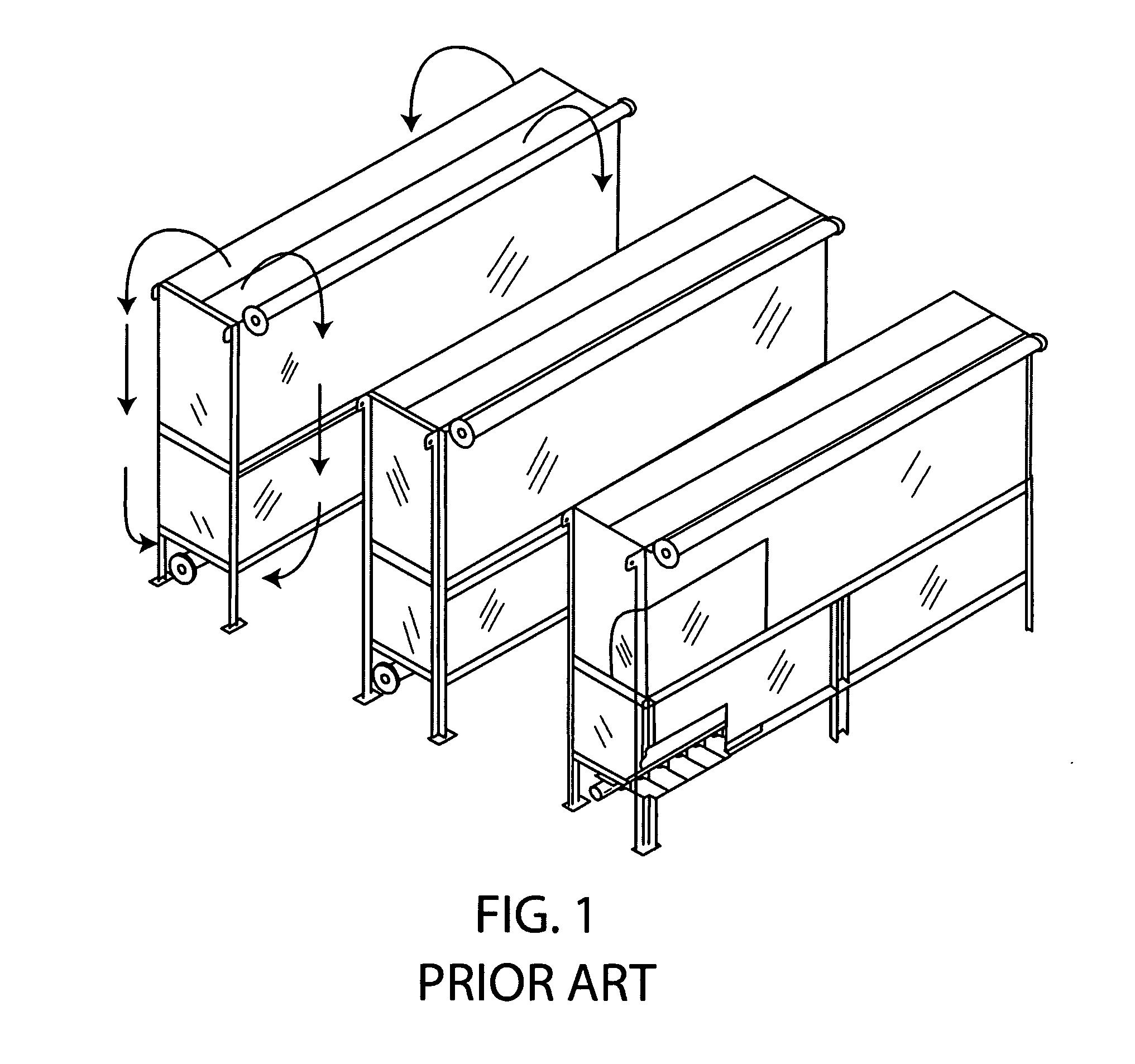

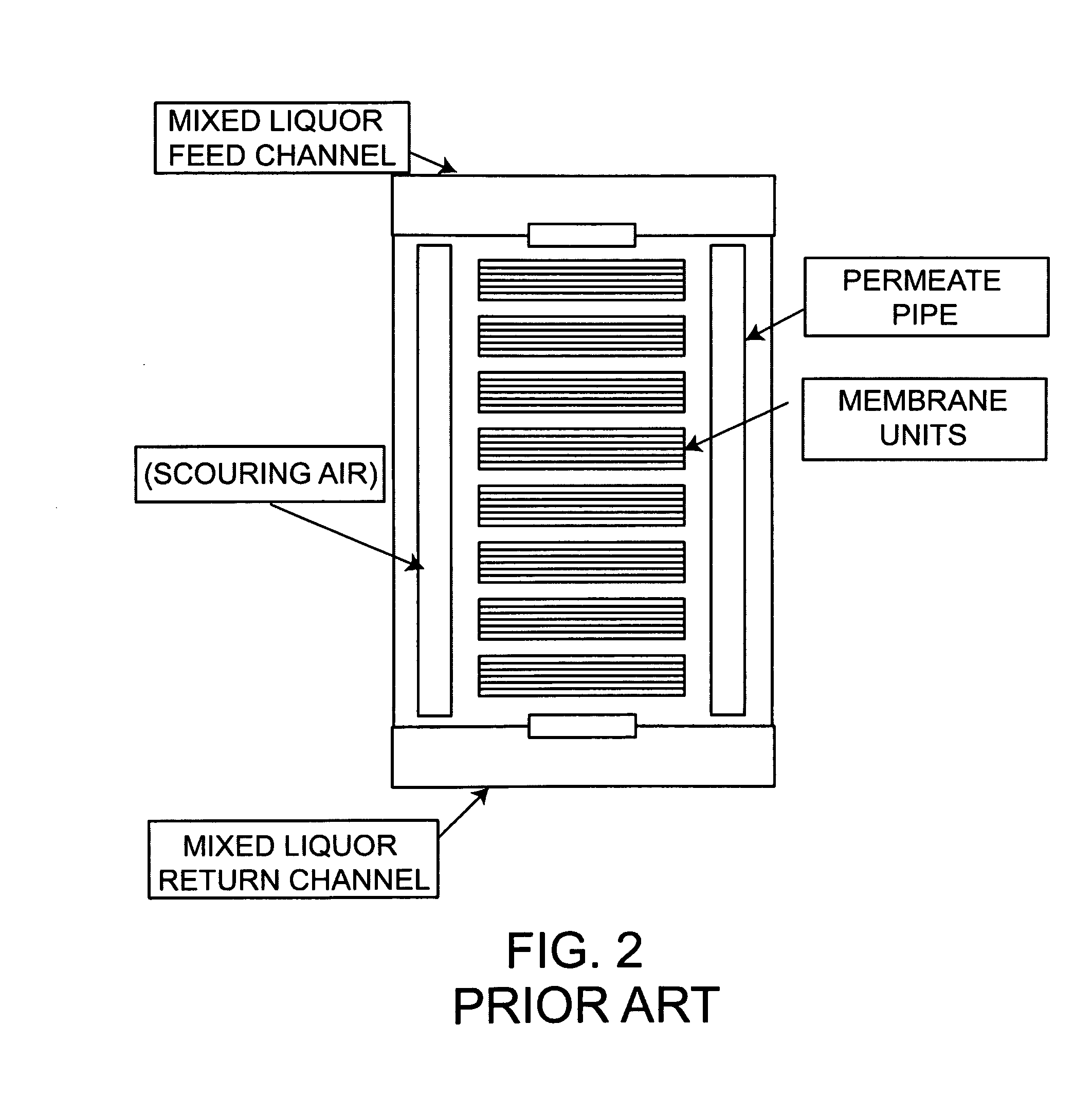

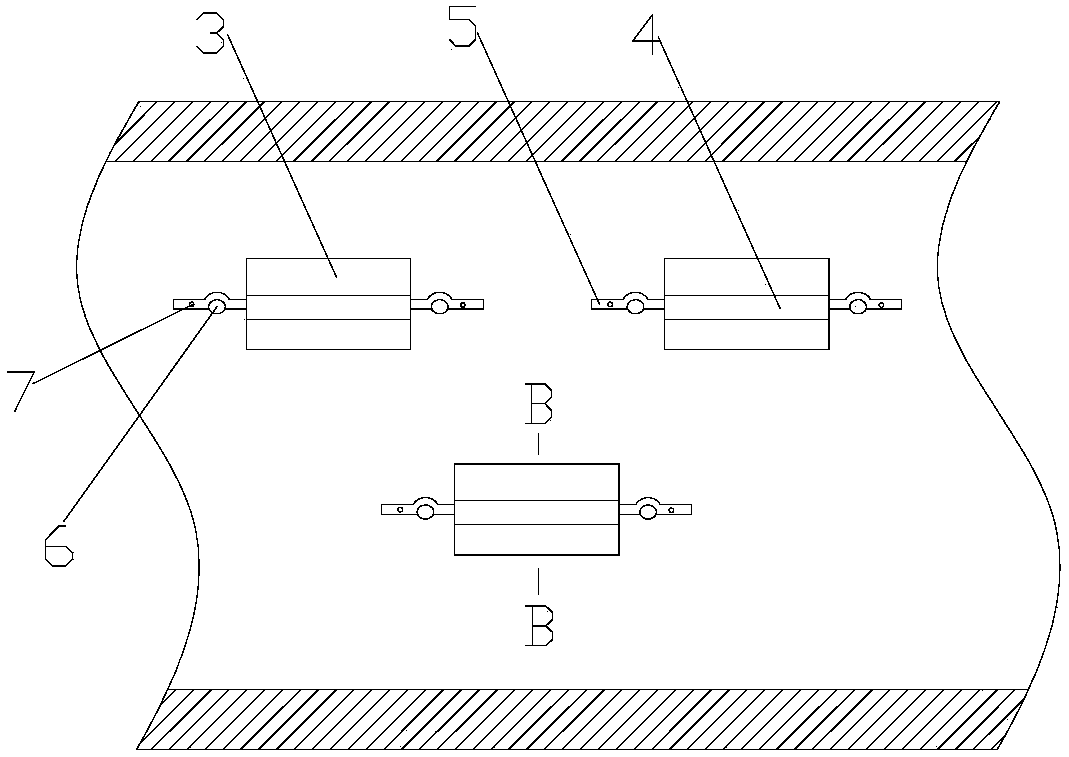

Efficient arrangement of membrane bioreactors

ActiveUS20110000836A1Low costReduce carbon footprintMembranesUltrafiltrationEngineeringReturn channel

Flat-sheet membrane filter assemblies require open space around equipment to form a viable path for an internal recycle or roll pattern. Creating a dedicated roll pattern for individual filter assemblies is space intensive and imposes process constraints on tank dimensions. A hollow wall or series of pipes forms a recycle wall designed to consolidate roll patterns and reduces space requirements. The recycle wall is designed such that the structural components also serve as a mixed liquor distribution system for the necessary roll pattern. Fixed vertically oriented conduit and sectional channel pieces allow for easy access and removal of membrane filter assemblies installed side by side. Feeding mixed liquor, air and or influent to the bottom of filter assemblies via submerged conduit improves process efficiency when coupled with return channels spaced not more than 10 feet away and above assemblies. The system is particularly advantageous for flat-sheet membrane filter units used in SMBR applications but is adaptable to other technologies including tubular and hollow-fiber membrane filter assemblies.

Owner:GLV FINANCE HUNGARY KFT A HUNGARIAN CO +1

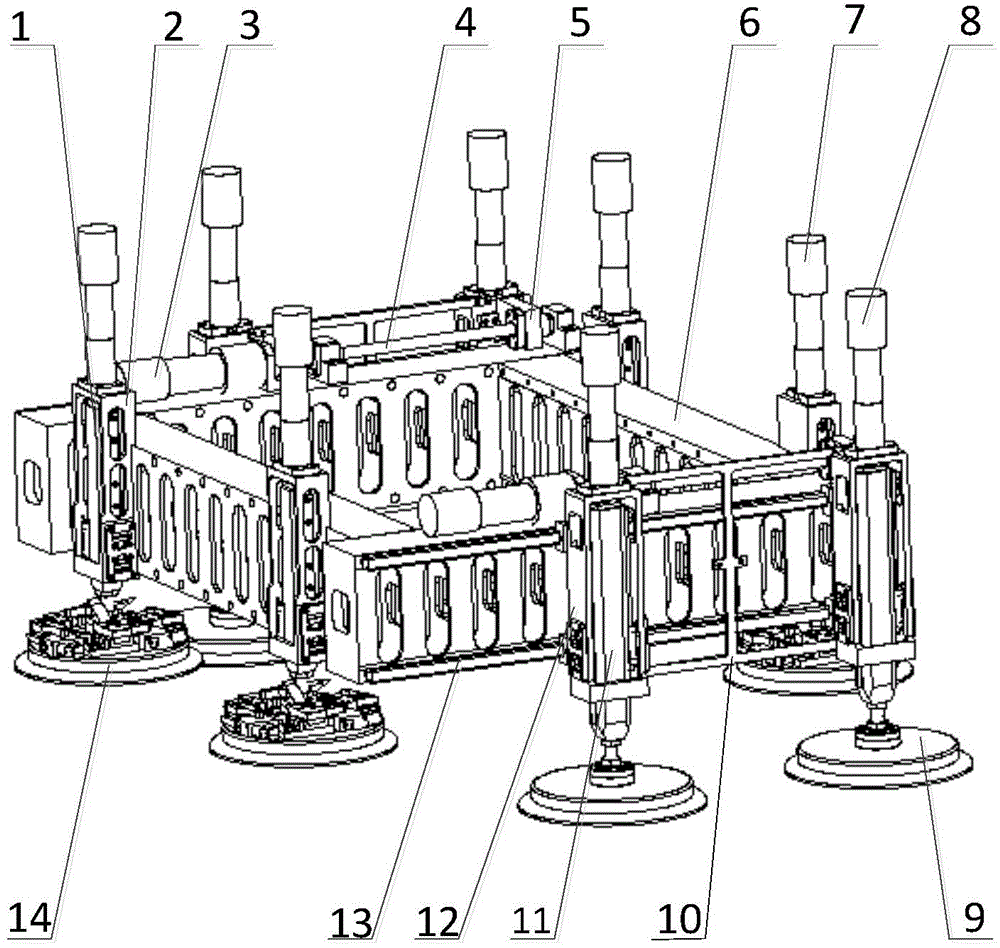

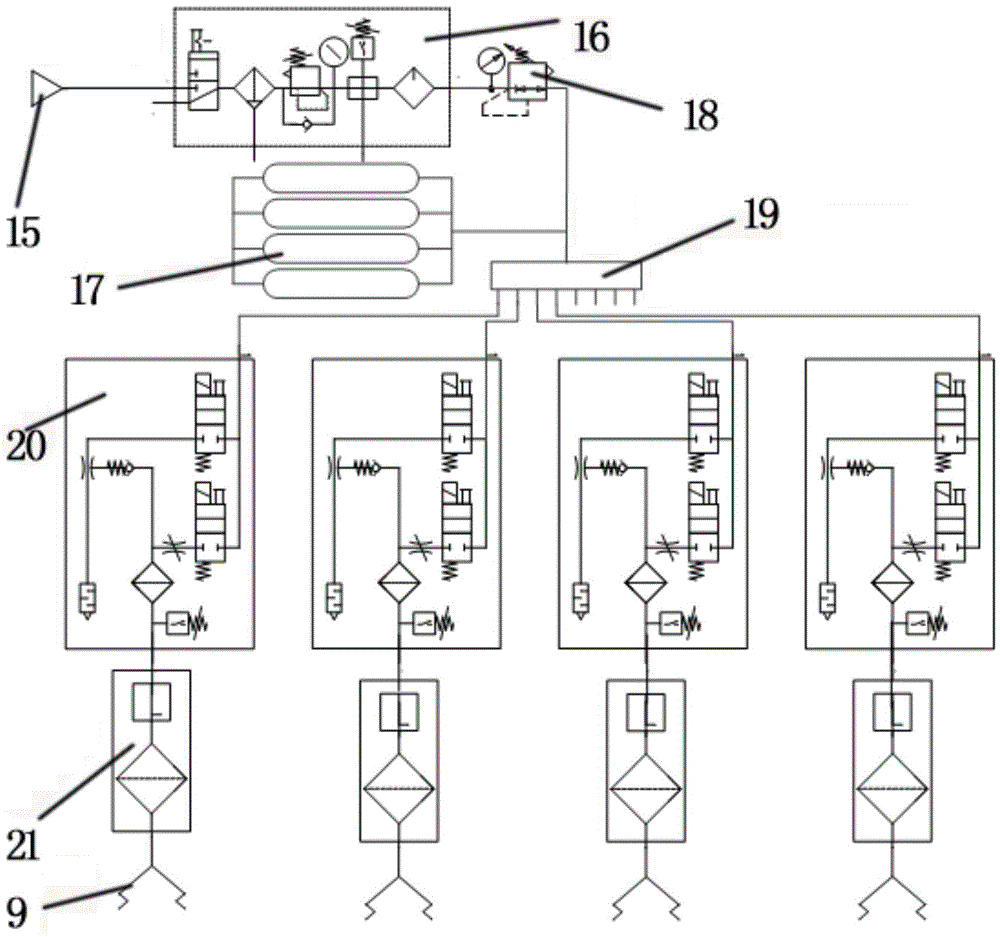

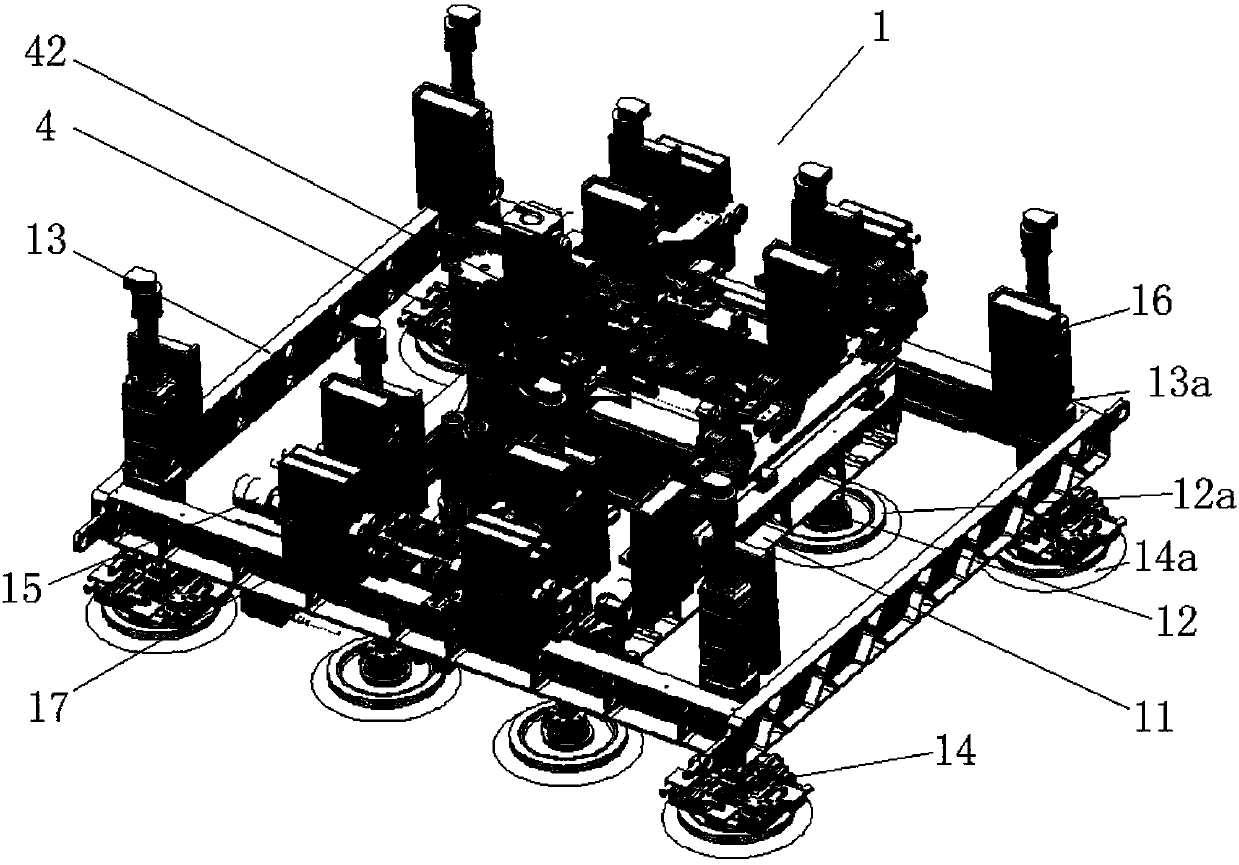

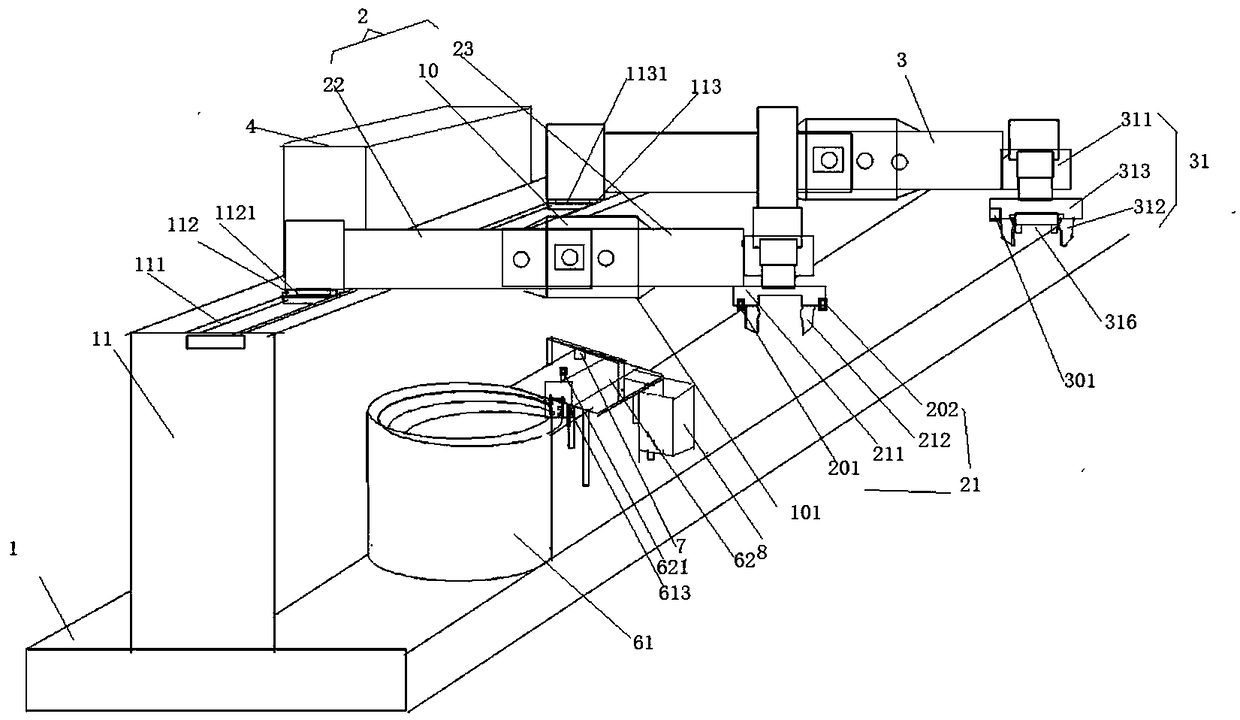

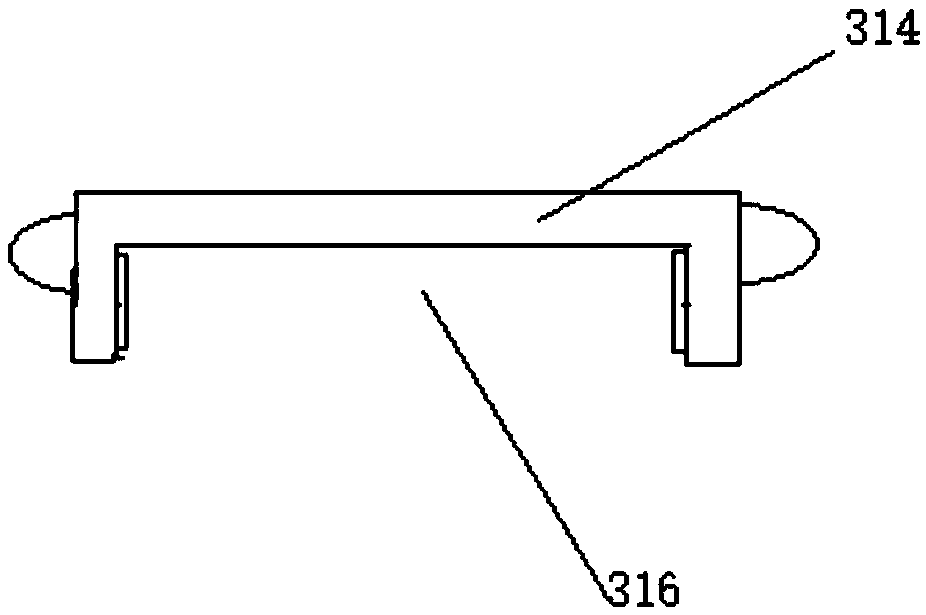

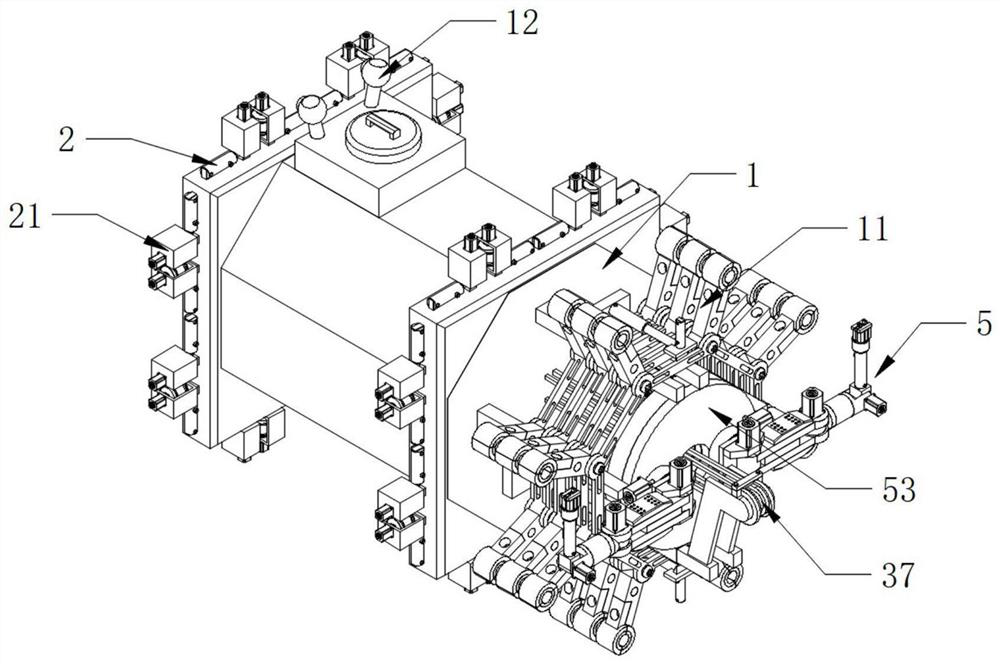

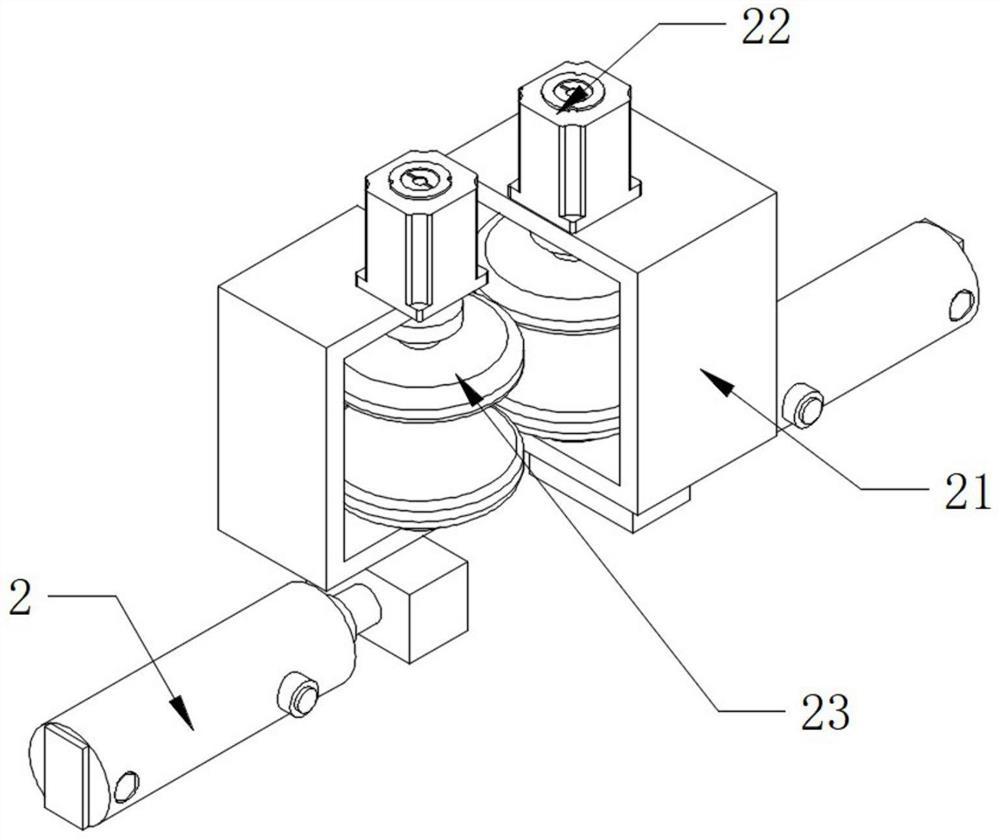

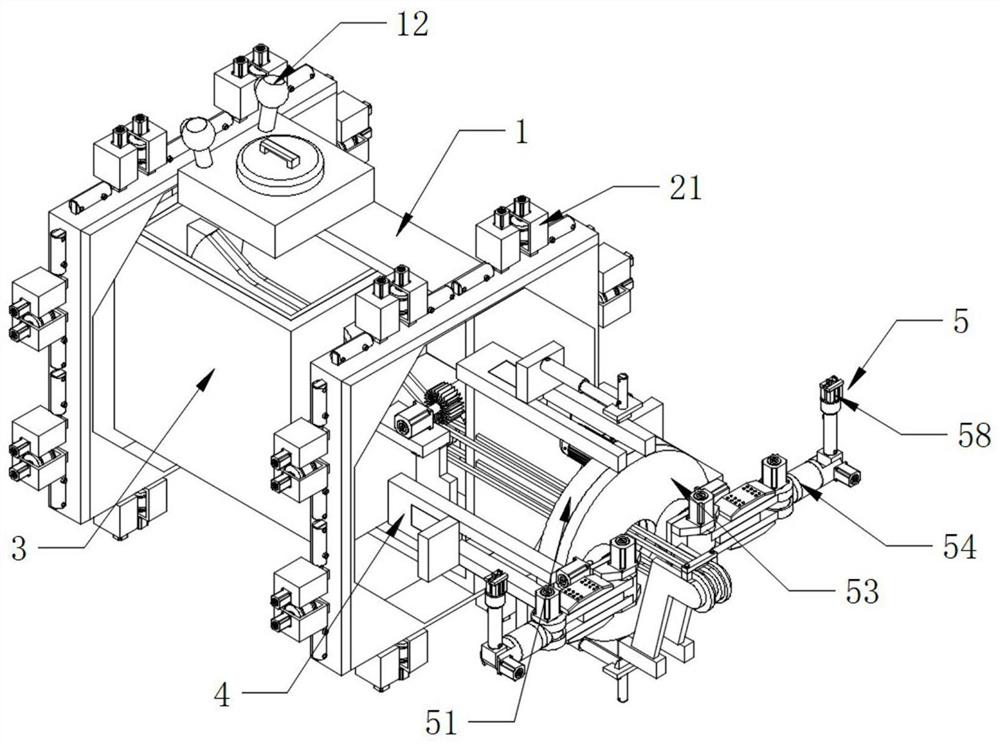

Autonomous-crawling drilling-riveting system and operation method thereof

ActiveCN107363296AMinimize impactMinor changesWork benchesMetal working apparatusDirection detectionControl theory

The invention discloses an autonomous-crawling drilling-riveting system and an operation method thereof. The autonomous-crawling drilling-riveting system comprises a robot adsorption walking device, a robot benchmark detection device, a robot normal direction detection and correction device, an integrated control device and a drilling-riveting device. The adsorption walking device comprises an inner frame, inner legs, an outer frame, outer legs, an X-direction motor and Z-direction motors. The benchmark detection device comprises a plurality of benchmark holes and a main frame body arranged in the middle of the inner frame, wherein the multiple benchmark holes are formed in a workpeice and are not connected into a straight line, and the lower surface of the main frame body is fixedly provided with a rotary camera. The integrated control device comprises a controller, the controller is connected with the X-direction motor, the Z-direction motors and vacuum generators and controls the X-direction motor, the Z-direction motors and the vacuum generators to operate, and the controller is connected with the camera and laser displacement sensors. A robot has the advantages of being high in application flexibility, low in structural weight, sable in assembling quality and the like and meets the requirements of advanced assembling technologies of current airplanes.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

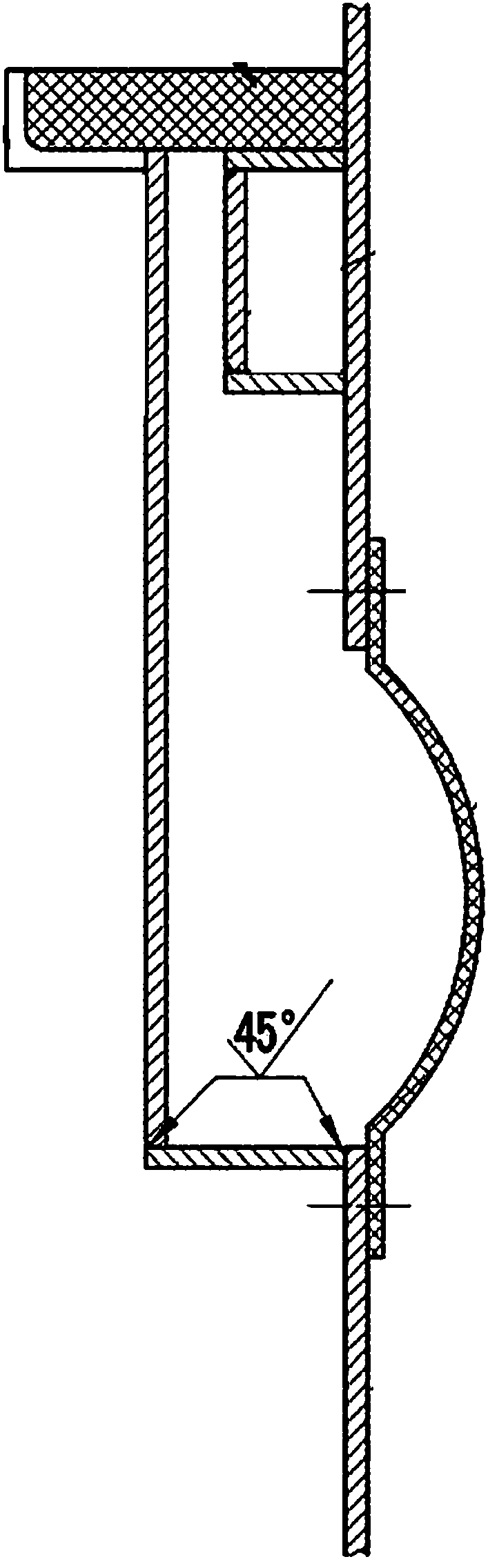

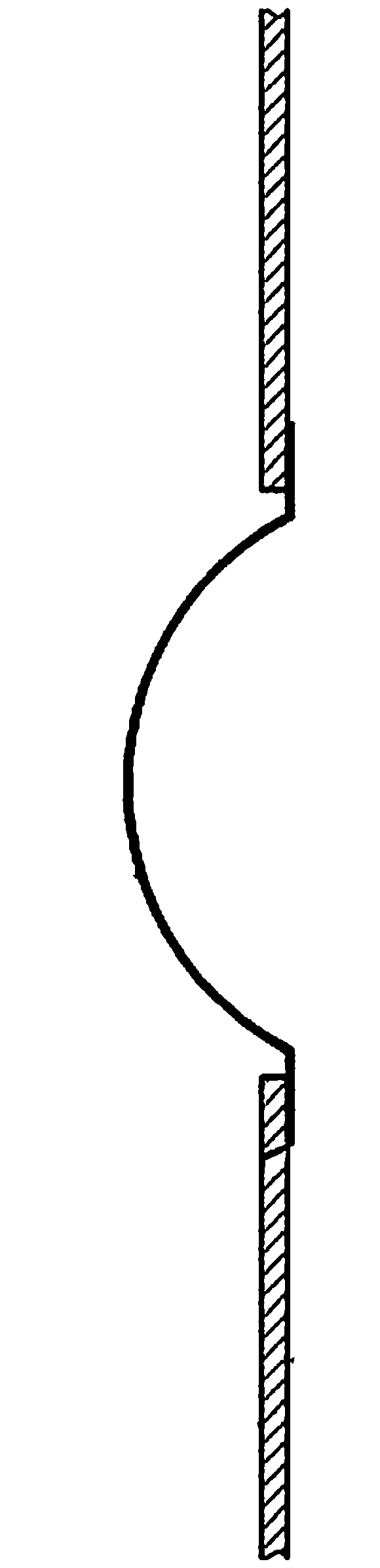

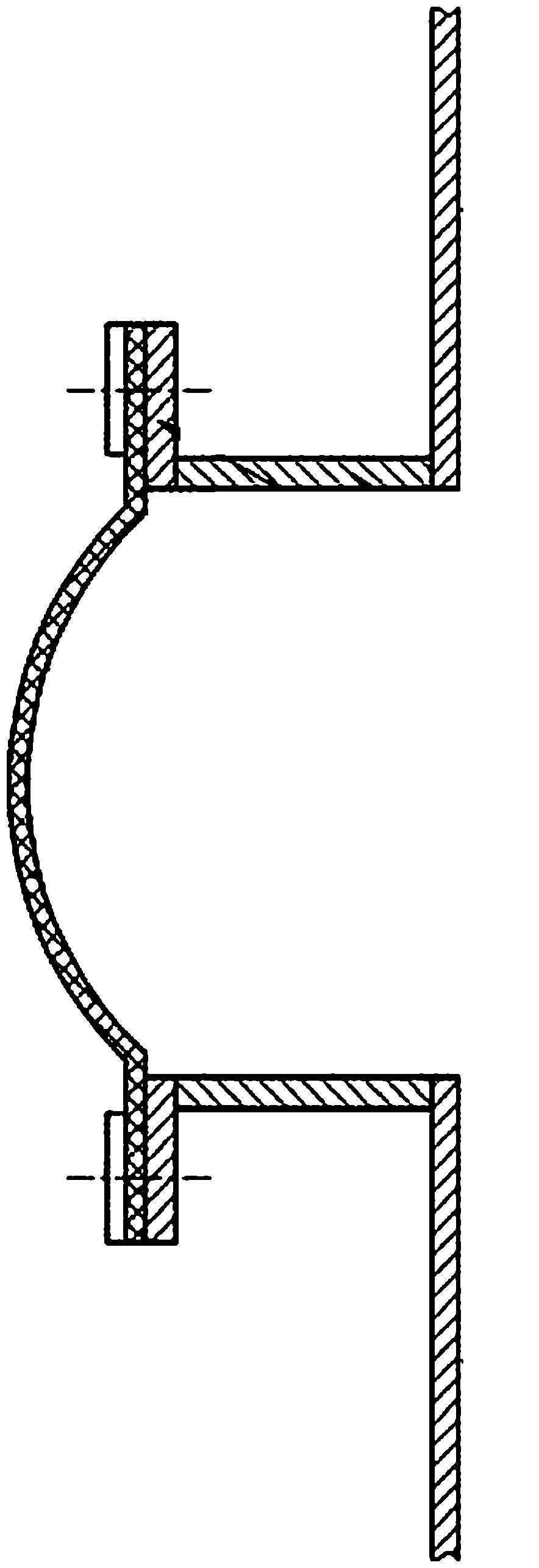

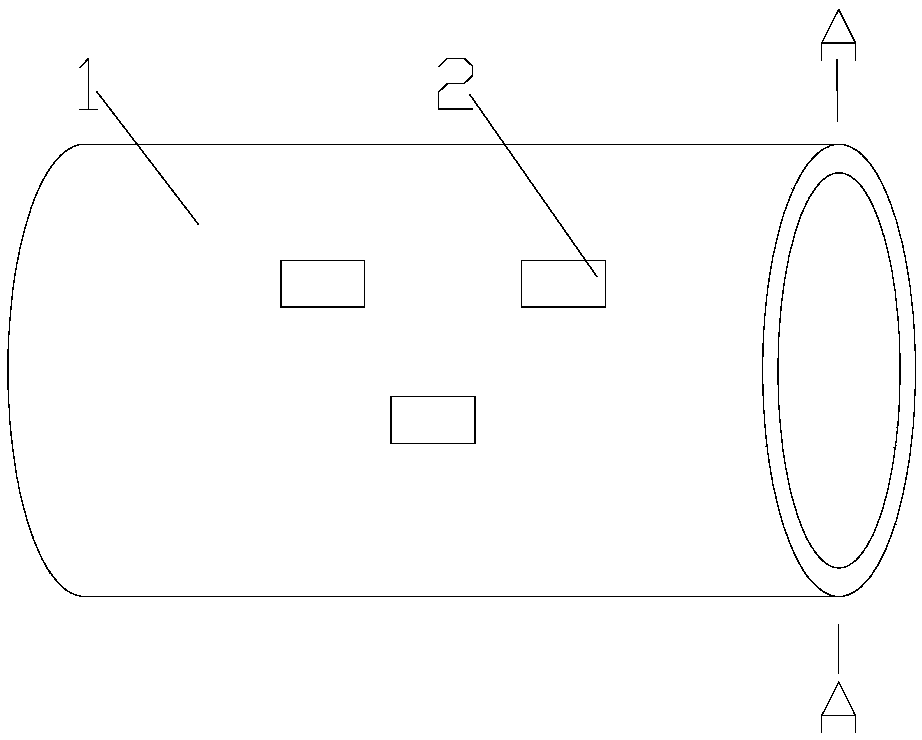

Chimney expansion joint

InactiveCN103075602AAvoid direct flushingAvoid scourPipeline expansion-compensationCorrosion preventionEngineeringExpansion joint

The invention discloses a chimney expansion joint. The technical scheme is that the chimney expansion joint comprises a steel inner cylinder, a flange rack part and a seal ring, wherein the seal ring is fixedly connected with the steel inner cylinder through the flange rack part; the flange rack part comprises an upper taper angle flange, a lower taper angle flange, an upper pressing flange, a lower pressing flange and a bolt component; inner rings of the upper taper angle flange and the lower taper angle flange are welded with the steel inner cylinder; mounting surfaces at the two ends of the seal ring are fixedly pressed between the upper taper angle flange and the lower taper angle flange through the upper pressing flange and the lower pressing flange; the mounting surfaces at the two ends of the seal ring are positioned between corresponding upper and lower taper angle flanges and upper and lower pressing flanges respectively; the upper and lower taper angle flanges and the upper and lower pressing flanges tilt upwards at an angle of 9-16 degrees; and anti-corrosion parts are arranged on corresponding welding parts of the upper and lower taper angle flanges and the inner side of the steel inner cylinder. By using the scheme, the manufacturing cost can be reduced, the construction period can be shortened, the maintenance is convenient, and the service life is prolonged.

Owner:山东龙泰电站技术有限公司

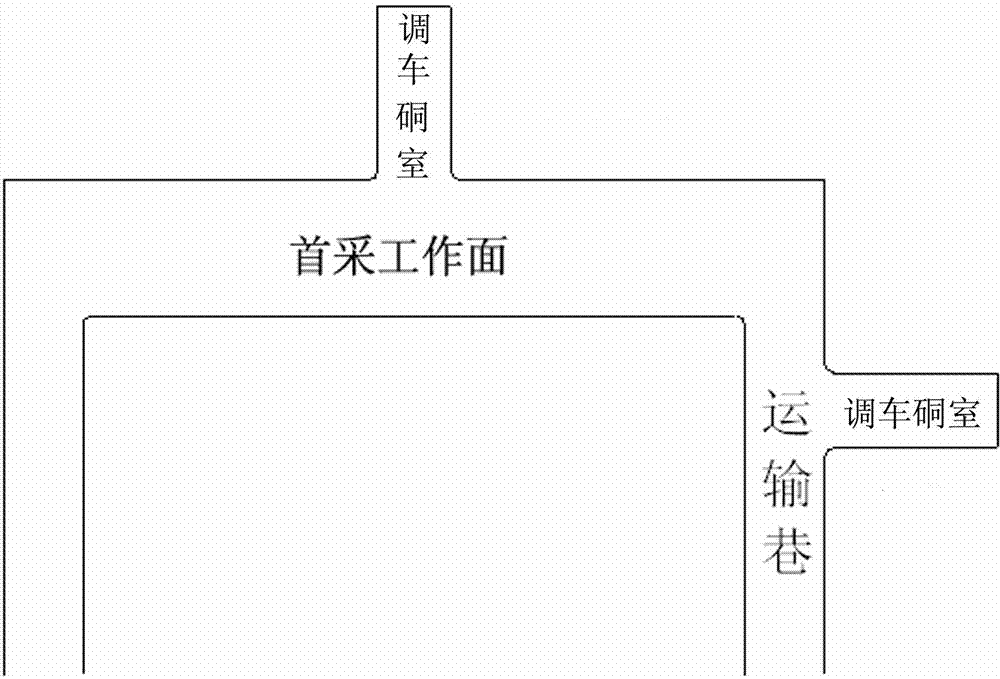

Method for rapidly and stably arranging equipment on fully mechanized coal mining face

InactiveCN103670416AReduce cost inputShorten the preparation cycleUnderground miningSlitting machinesEngineeringBelt conveyor

The invention relates to a method for arranging equipment on a fully mechanized coal mining face, in particular to a method for rapidly and stably arranging equipment on the fully mechanized coal mining face. The method comprises the following steps: arranging an equipment train; arranging a belt self-moving machine tail and a transfer smashing machine; arranging a crossheading rubber belt conveyor synchronously; arranging a front transporter head and a back transporter head; arranging a front transporter chute from the transporter head to a transporter tail; paving top and bottom chains of a front transporter; when the front transporter chute is formed on a machine stable, arranging a coal mining machine body; arranging all the rest of front coal mining machine chutes; arranging a back transporter chute from the transporter head to the transporter tail; arranging a hydraulic bracket synchronously; after the hydraulic bracket is arranged and the back transporter chute is formed, arranging a front transporter tail and a back transporter tail. According to the method, transporting and stable arranging processes are improved, so that the stable arranging time is shortened greatly, materials, working time and cost are saved, operation procedures are optimized, the operation efficiency is brought into fully play, and the stable installation speed is increased.

Owner:DATONG COAL MINE GRP

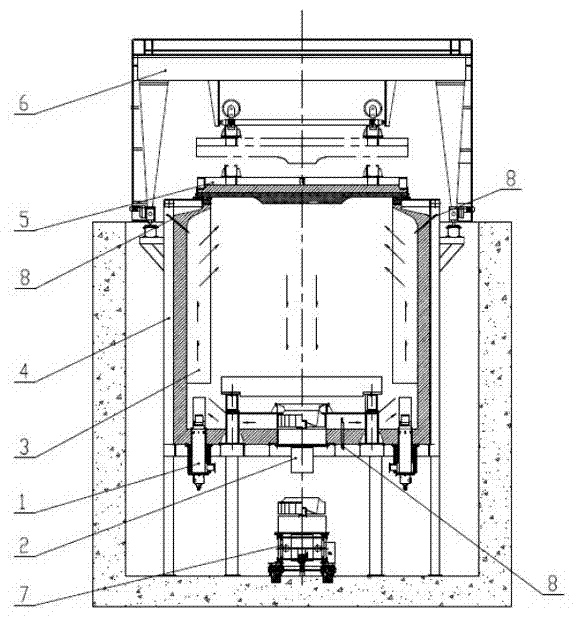

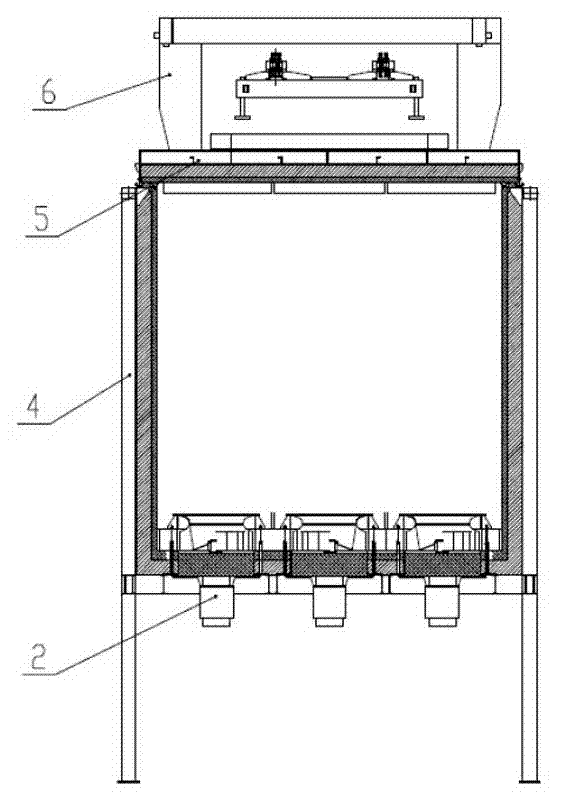

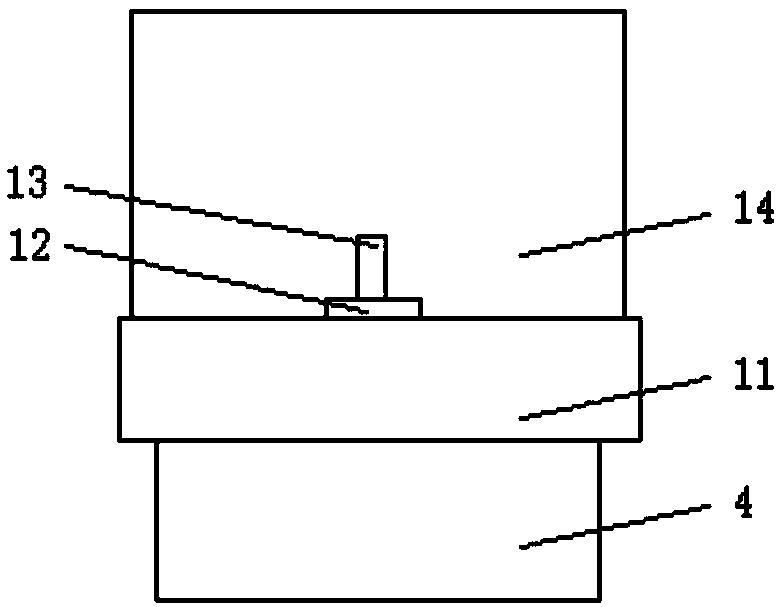

Pit-type aluminum ingot heating furnace

The invention provides a pit-type aluminum ingot heating furnace which comprises a furnace body, a circulating fan, a heating system, a diversion system, a jack-up furnace door, a furnace door lifting and transferring mechanism and a furnace temperature detection device, wherein the jack-up furnace door is positioned at the top of the furnace body; the port of the furnace door is flush with the floor of a workshop; a sealing device is arranged between the furnace door and the port of the furnace door; the furnace door lifting and transferring mechanism controls the opening and the closing of the furnace door; the heating system is arranged at the bottom of the furnace; the diversion system is distributed in a hearth; furnace gas flows orderly in the furnace along the diversion system under the action of the circulating fan; and the furnace temperature detection device is arranged on the furnace body. The pit-type aluminum ingot heating furnace can be used for realizing different requirements of various alloys on the heating temperatures and meeting the small-lot production requirements of multi-alloy series, and has the characteristic of strong production flexibility; and meanwhile, the furnace door lifting and transferring mechanism and a circulating fan installation and overhaul mechanism have strong community, so that the input cost for the increase in quantity of pit-type heating furnaces is lowered.

Owner:SUZHOU LONGRAY THERMAL TECH

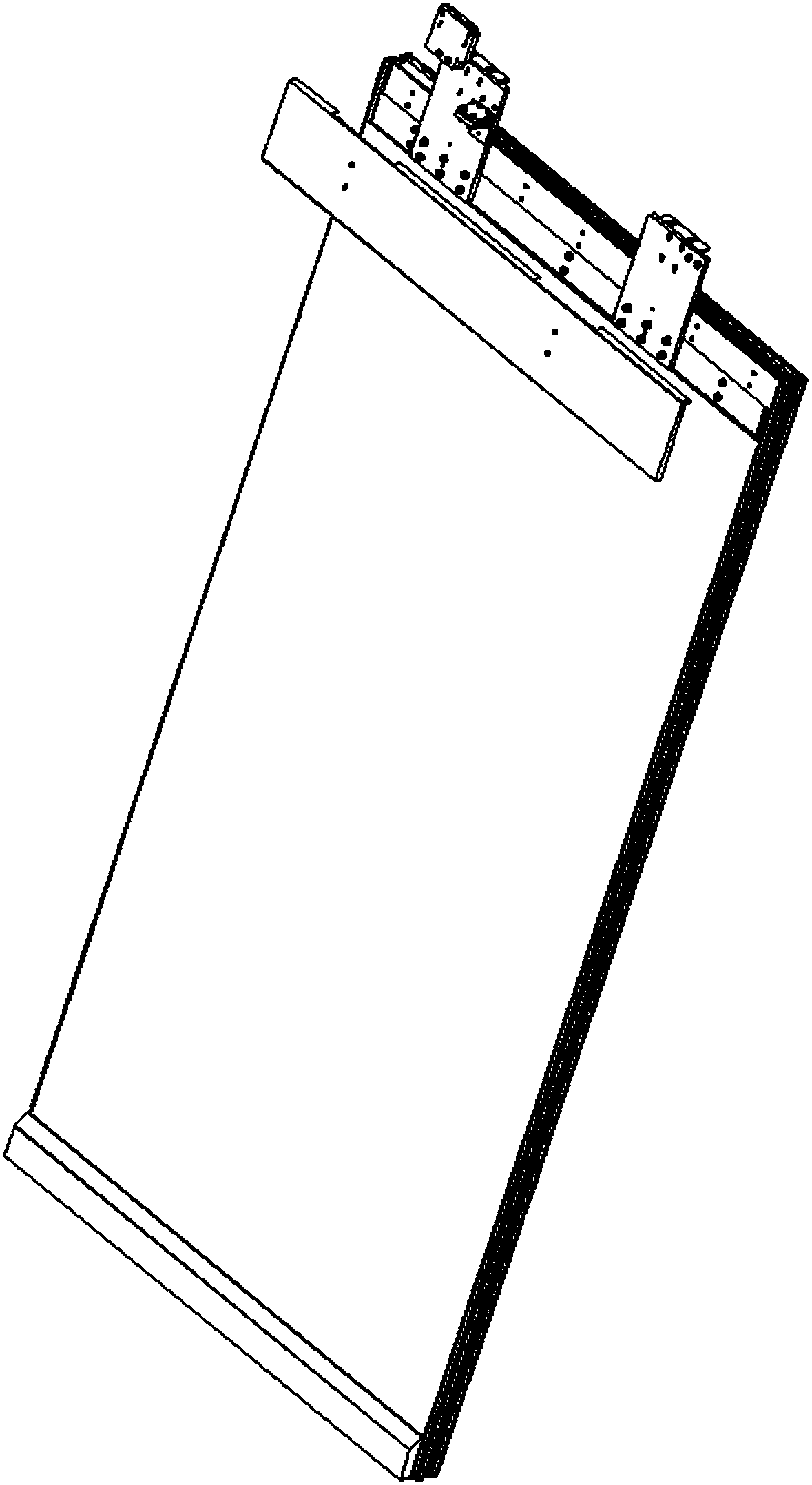

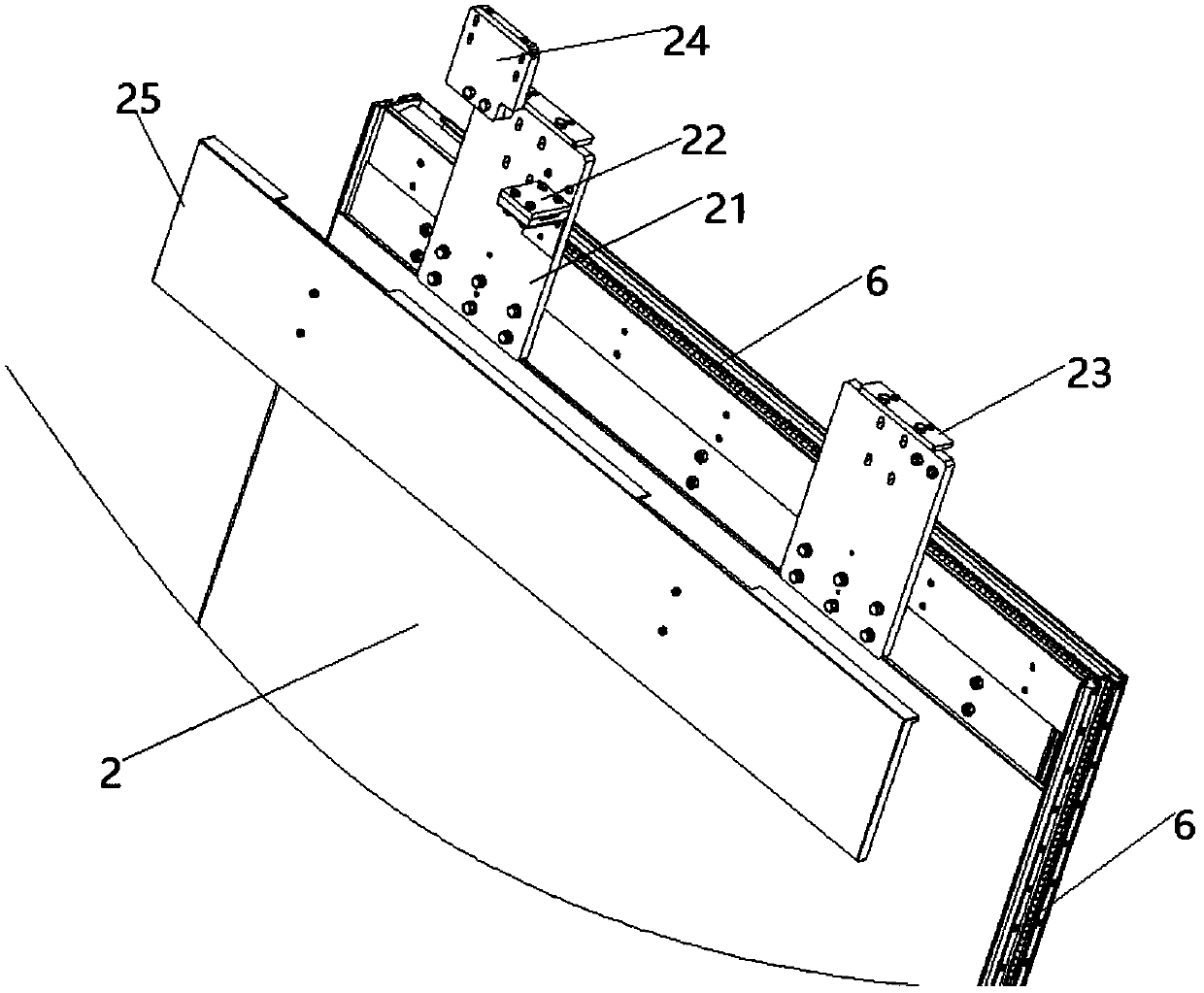

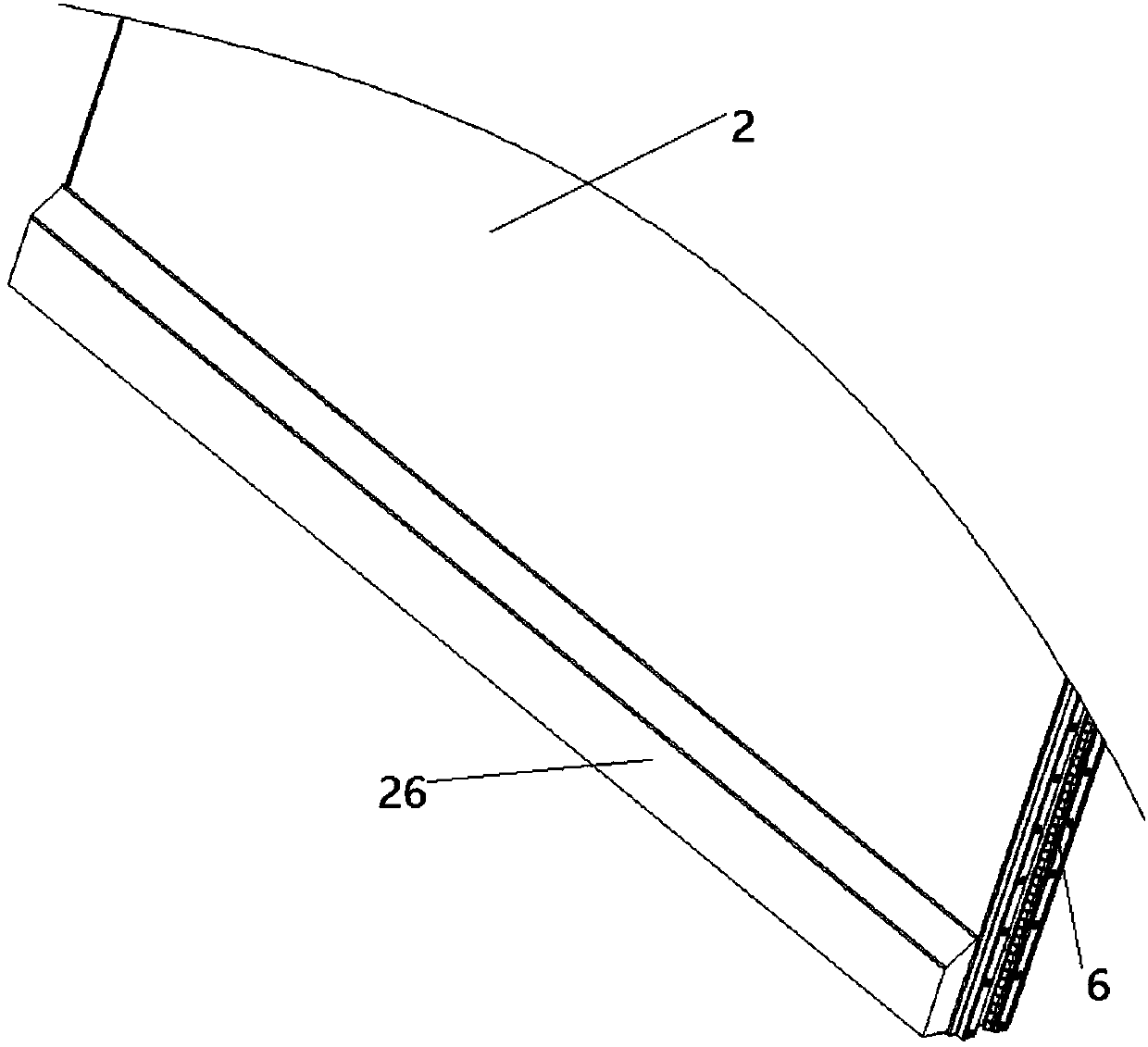

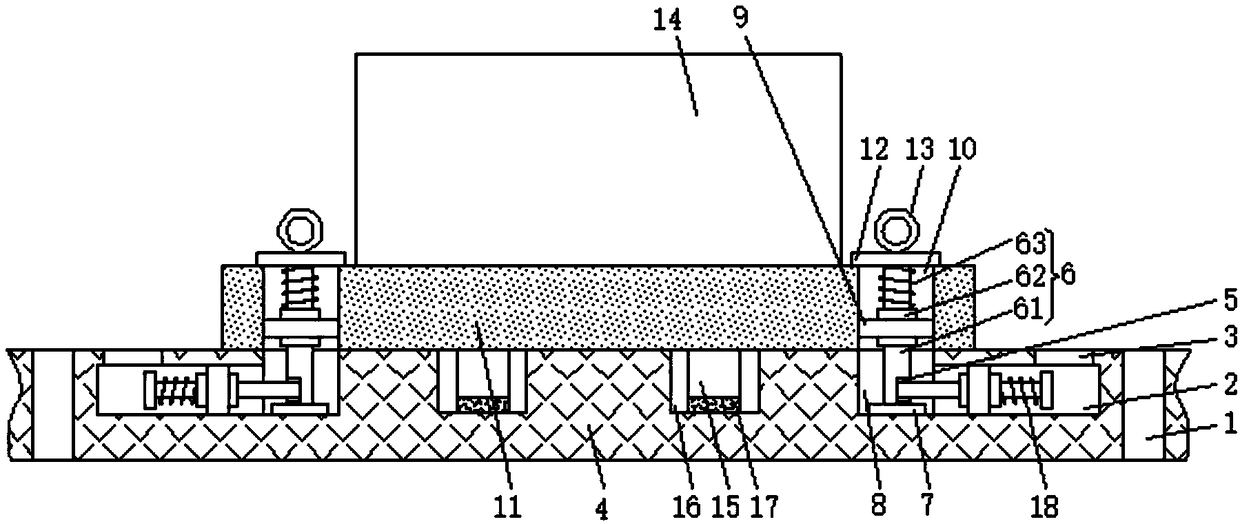

Double-fan sliding shielding door installing structure and method

ActiveCN107740656AAvoid waiting for the glue curing timeHigh precisionConstruction materialRadiation protectionKeelEngineering

The invention relates to the technical field of shielding, and discloses a double-fan sliding shielding door installing structure and method for a large nuclear magnetic laboratory and an intraoperative nuclear magnetic hybrid operation room. The double-fan sliding shielding door installing structure comprises a threshold installing structure and a door post installing structure. The threshold installing structure comprises a floor, plywood, an insulating layer and a shielding layer in sequence from bottom to top. The plywood is fixed to the floor and connected with the shielding layer and a threshold through bolts. The upper portion of the shielding layer and the periphery of the threshold are filled with PVC layers, and the ground of a final finished surface is formed. The door post installing structure comprises a door post and a shielding wall used for installing the door post. The shielding wall comprises a stainless steel shielding plate and a stainless steel shielding keel. Thedoor post is connected with the stainless steel shielding keel through the stainless steel shielding plate.

Owner:ZHUZHOU HELI ELECTROMAGNETIC TECH

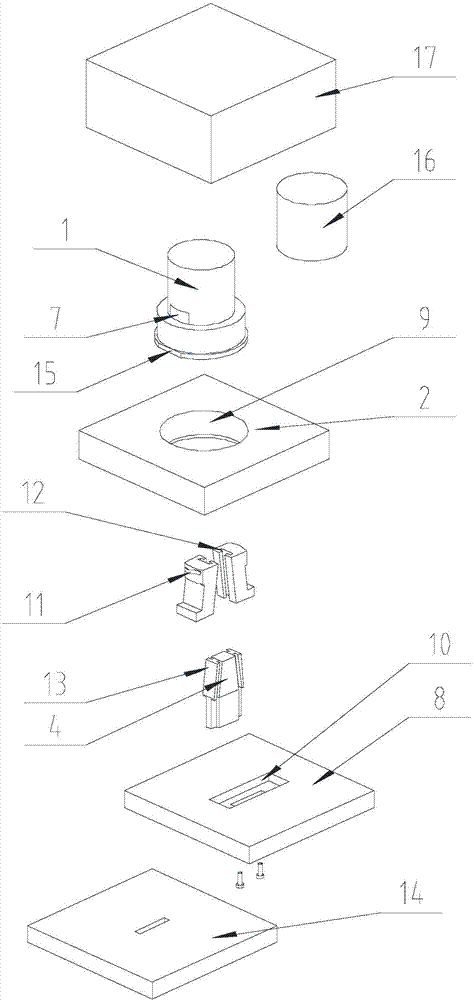

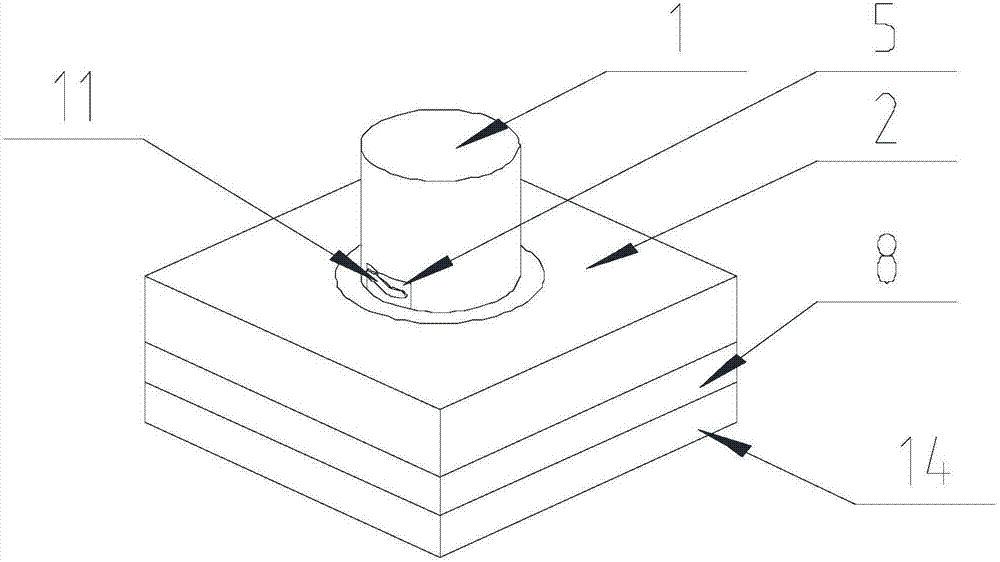

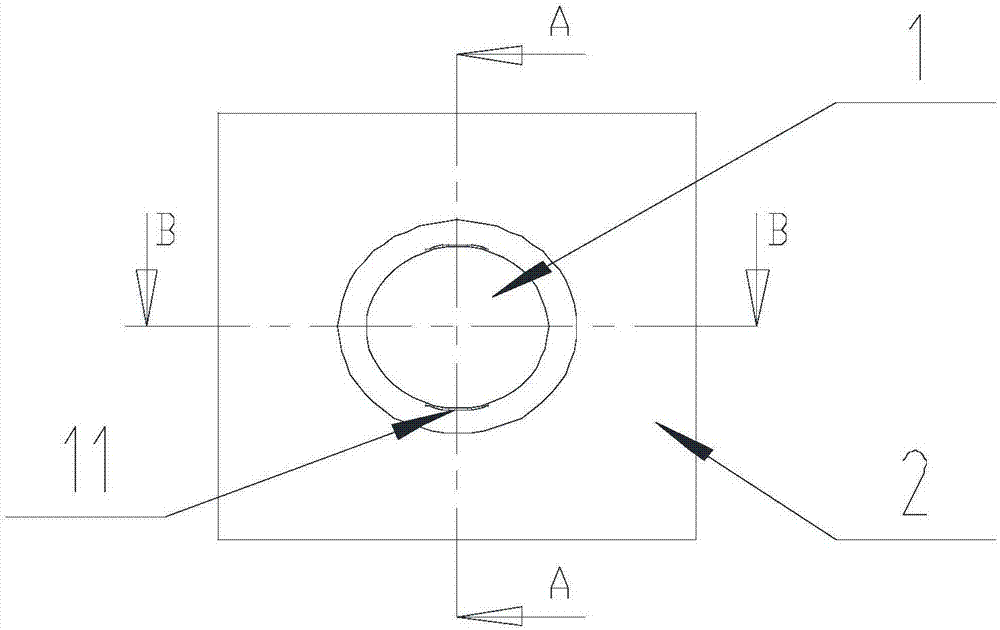

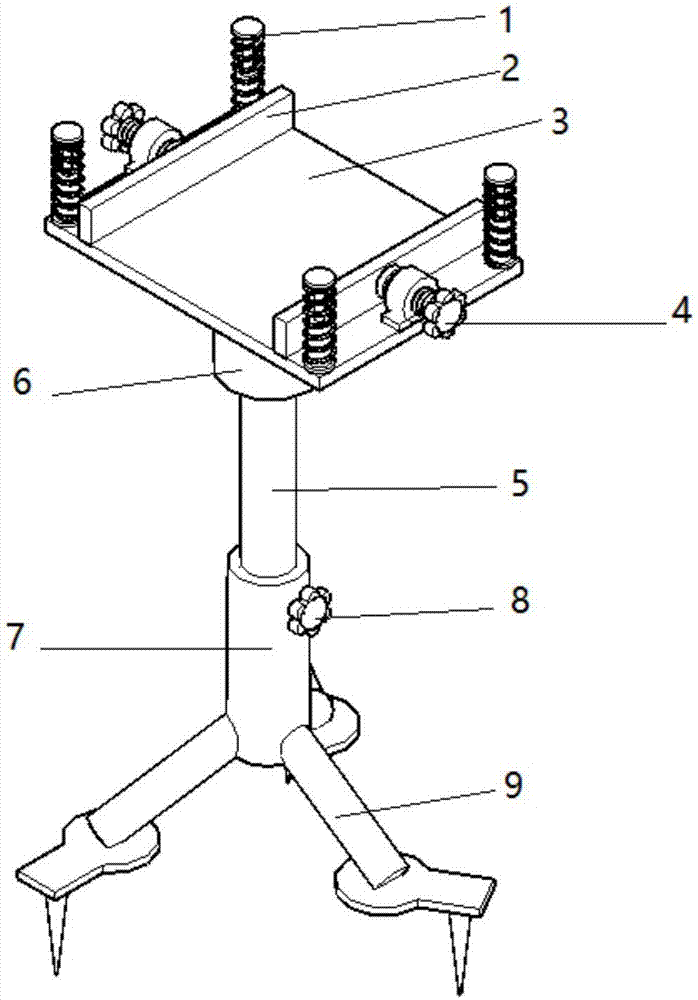

Auxiliary fixing device of safe and quick food detector and use method of auxiliary fixing device

InactiveCN108760630AShorten the timeImprove work efficiencyMaterial analysis by optical meansFood safetyEngineering

The invention discloses an auxiliary fixing device of a safe and quick food detector and a use method of the auxiliary fixing device. The device solves the problem that the safe and quick food detector is directly placed on the tabletop and easily knocked off in the prior art. The device has effects of preventing the safe and quick food detector from falling and improving working efficiency. The device comprises a placement plate for placing the safe and quick food detector and a connecting piece located at the bottom of the placement plate, wherein first grooves are symmetrically formed in the placement plate; second grooves are formed on the inner sides of the first grooves; the first grooves are communicated with the second grooves through first through holes; second through holes are formed in positions, corresponding to the second grooves, of the placement plate; first elastic devices are mounted in the second through holes and the second grooves; second elastic devices perpendicularly connected with the first elastic devices in a clamping manner are arranged in the first through holes and the second grooves; the first elastic devices keep a tension state due to a clamping effect of the second elastic devices; and auxiliary fixing of the safe and quick food detector is achieved.

Owner:SHANDONG NORMAL UNIV

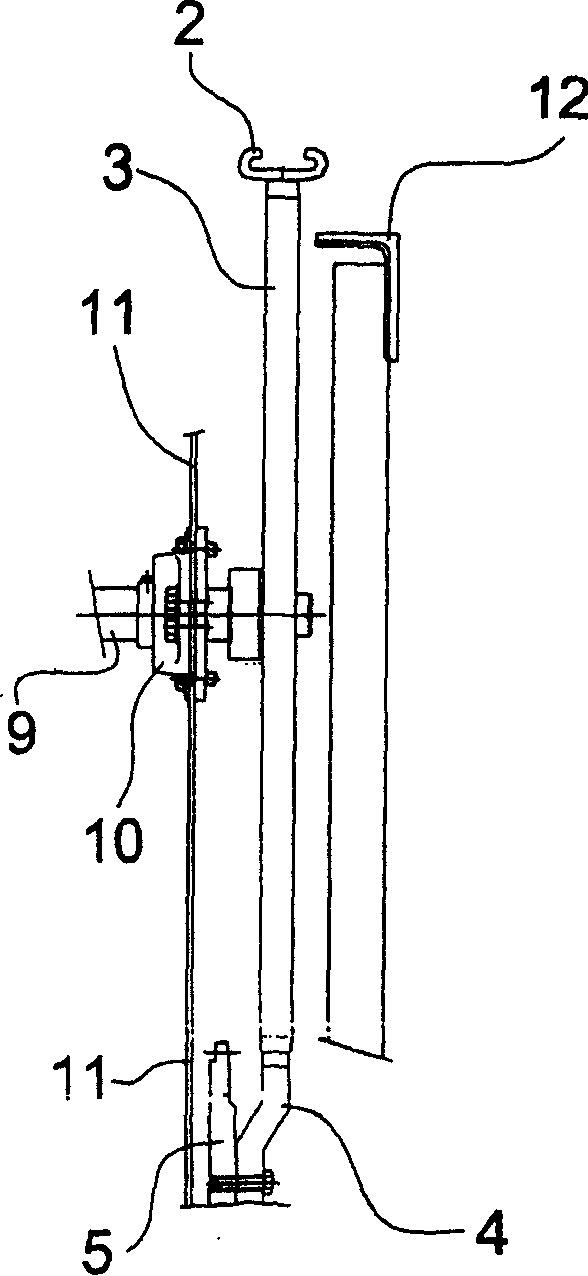

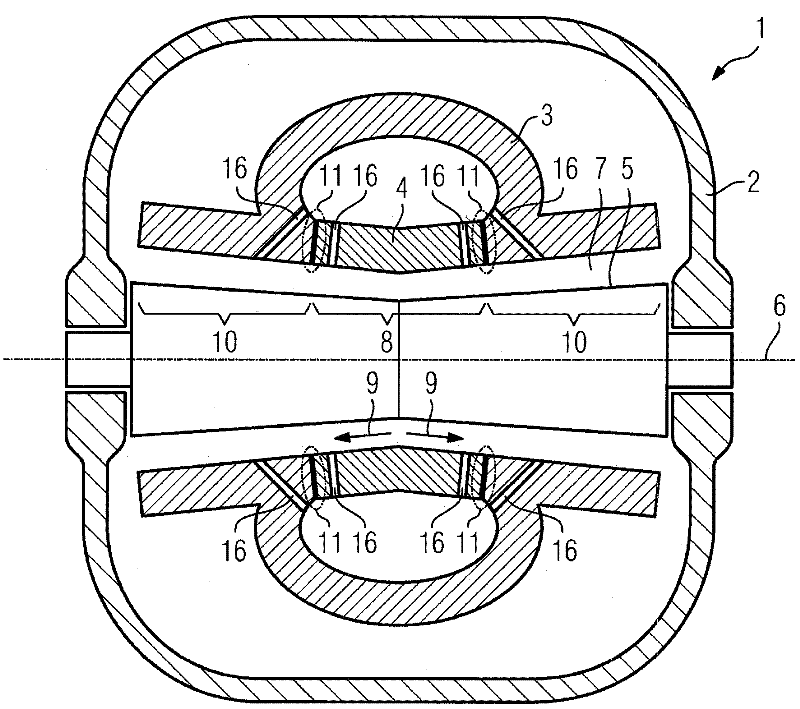

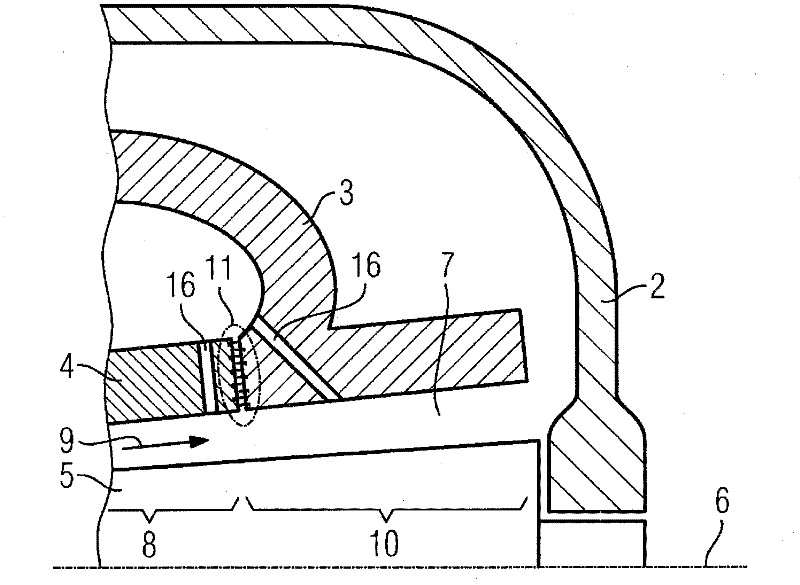

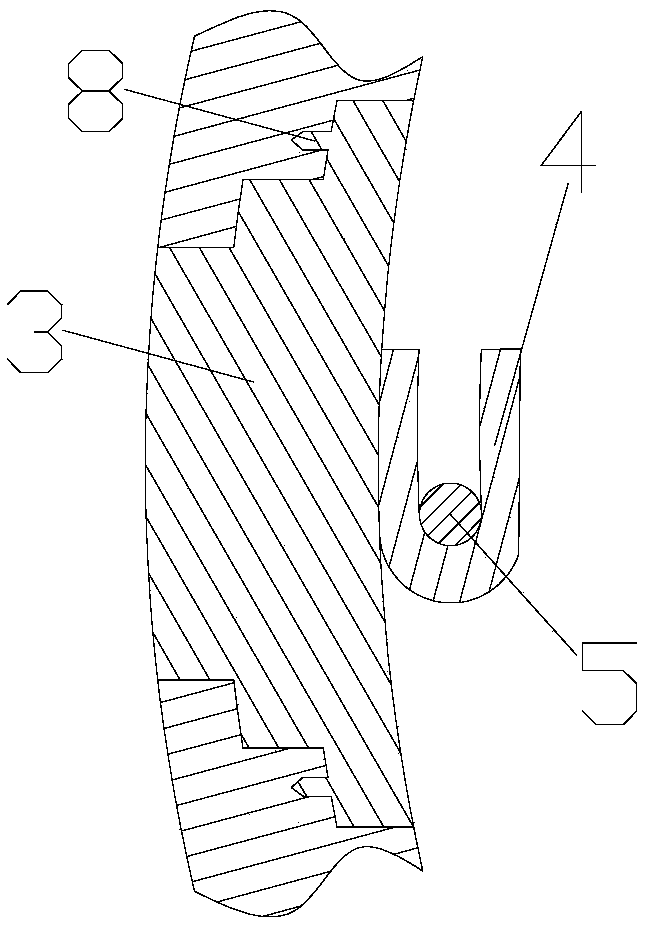

Turbo engine having steam tapping

InactiveCN102472110AEasy to installImprove sealingLeakage preventionGas turbine plantsEngineeringSteam turbine

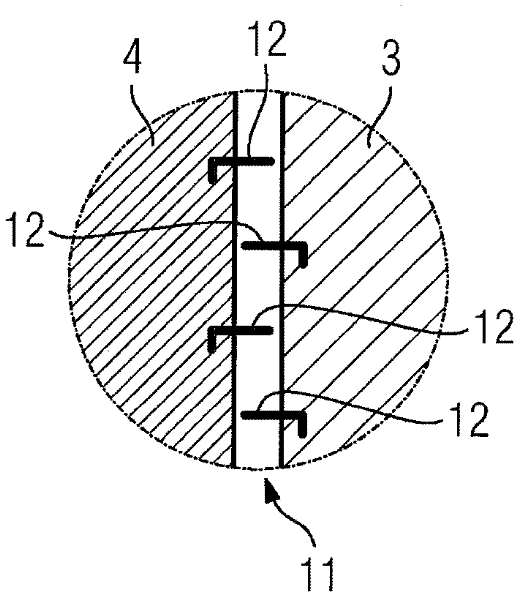

The invention relates to a three-shelled steam turbine (1), wherein a rotor (5) is rotatably supported and an internal inner housing (4) and an external inner housing (3) are disposed about the rotor (5), wherein the joint (11) between the internal inner housing (4) and the external inner housing (3) is sealed and tapping holes (16) are disposed in the internal inner housing (4) and / or the external inner housing (3).

Owner:SIEMENS AG

Broadband distributed antenna system and data communication method

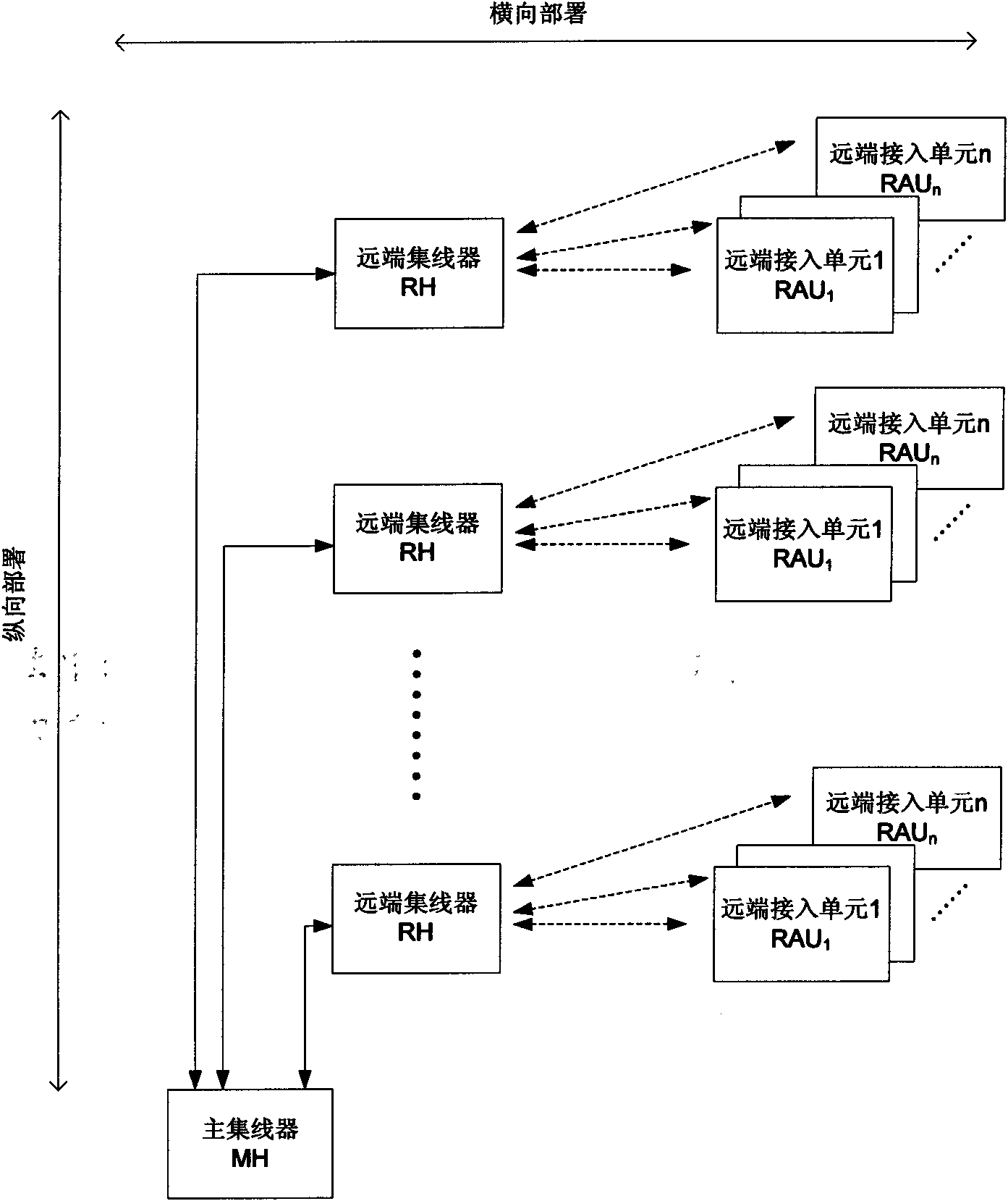

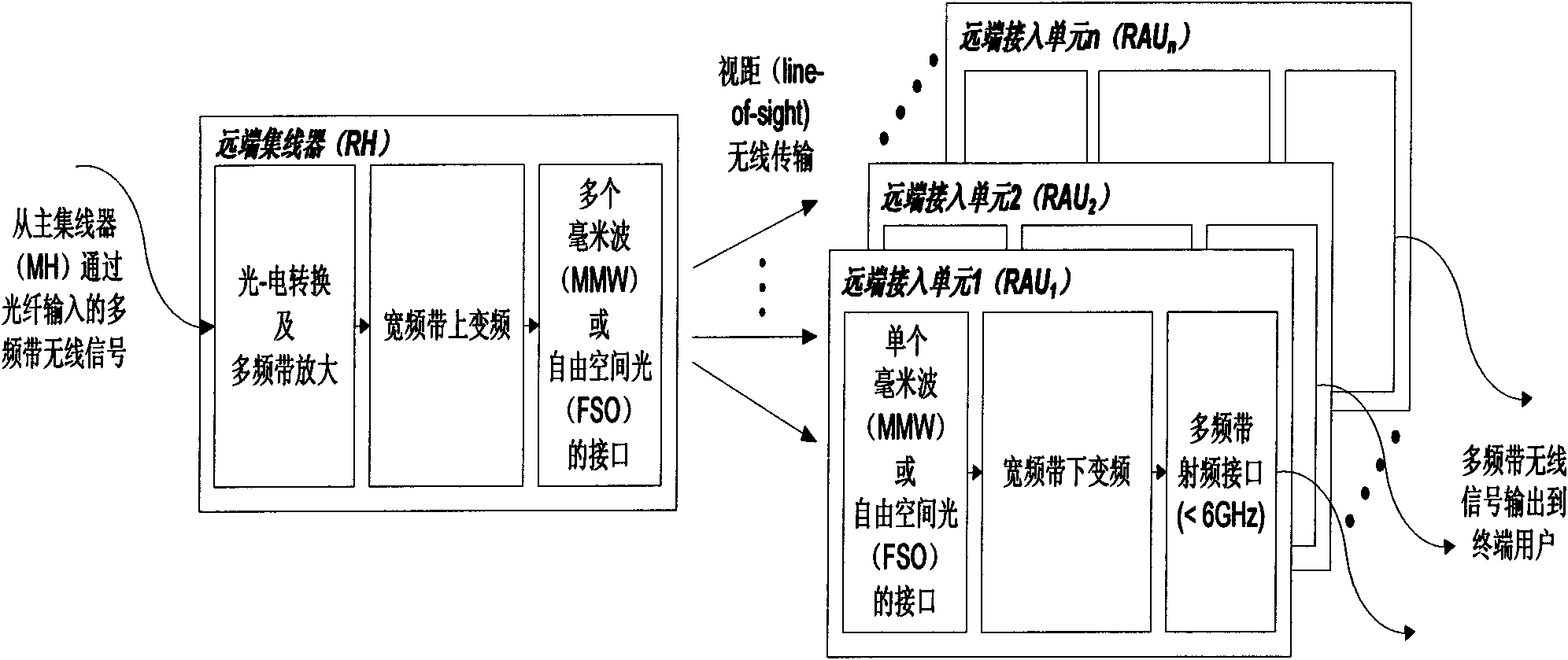

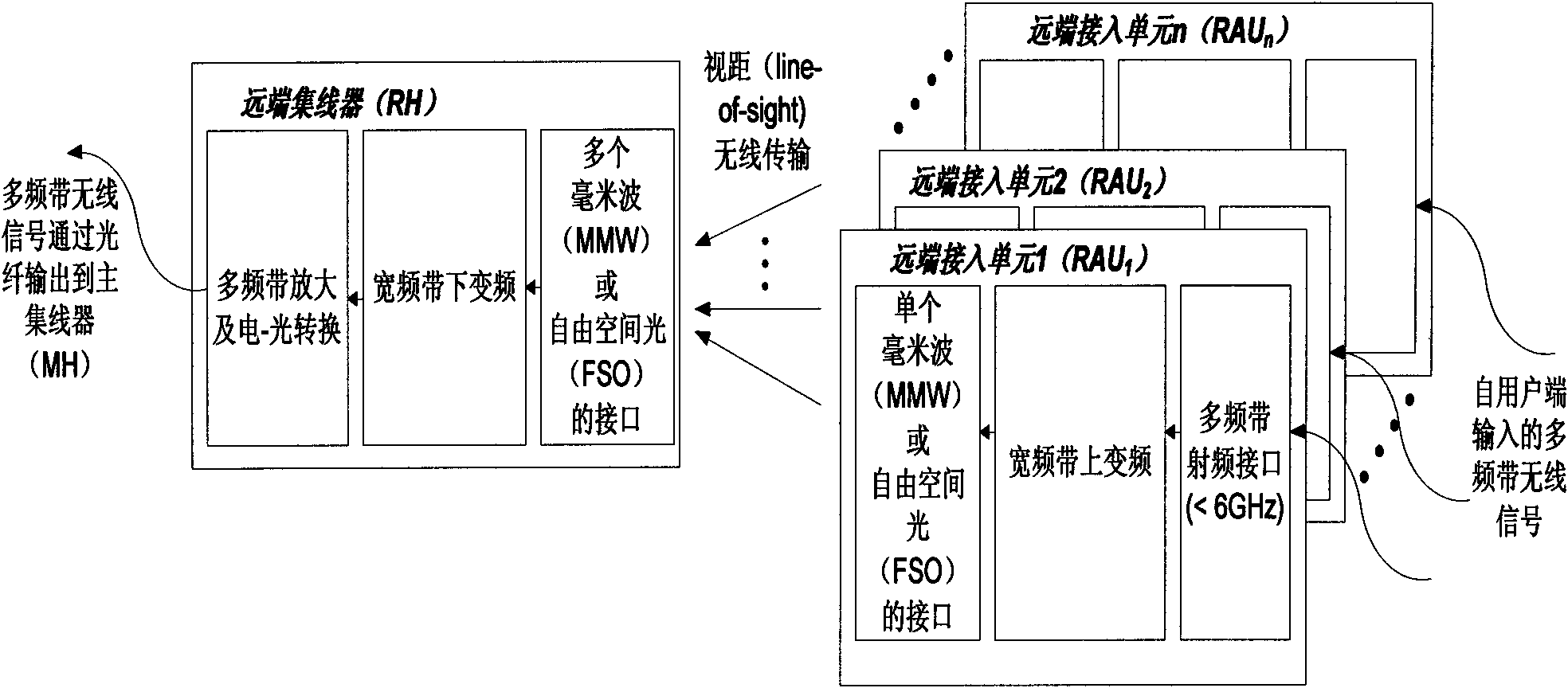

InactiveCN103001673AFlexible connection configurationSpeed up installation timeSpatial transmit diversityNetwork planningDistributed antenna systemEngineering

An embodiment of the invention provides a broadband distributed antenna system and a data communication method and relates to the technical field of networks. A remote hub is in data communication with remote access units in a free space communication mode. Compared with the mode that all devices in an existing broadband distributed antenna system are connected by laying optical fibers, cables and the like, the data communication method can shorten mounting time and save wiring cost. Additionally, the remote hub and each remote access unit are connected and configured flexibly so as to facilitate technological upgrading and adjustment.

Owner:孔令斌

Quick supporting method for cleaning blocked segments in pipe jacking

ActiveCN108374931AHigh speedImprove installation completion timePipe laying and repairEngineeringPetroleum engineering

The invention discloses a quick supporting method for cleaning blocked segments in pipe jacking. The quick supporting method includes the construction steps of planning out quantity and position of cleaning pipe joints according to needs for arrangement of each intermediate jacking station and installing the cleaning pipe joints among segments before pipe jacking construction; on the circumstancethat segments are blocked, installing one telescopic separating mechanism between each two tooling pipe joint and separating the tooling pipe joints from a spacing pipe joint through the telescopic separating mechanism; driving the blocked segments to move, connecting the tooling pipe joints with the corresponding spacing pipe joint through retraction of the telescopic separating mechanism; cleaning rock wall dregs at the backs of the segments which have been moved through cleaning equipment or manual manner, and transporting the collected dregs out of the construction site; installing a rocksupport arch ring to the cleaned rock walls through a support installation mechanism of the supporting device; starting a jacking mechanism at the end of each intermediate jacking station and jackingthe cleaned segments forwards. Compared with the prior art, the quick supporting method has the advantages of increasing construction speed of cleaning blocked segments in pipe jacking and lowering cost.

Owner:CHONGQING CONSTR RESIDENTIAL ENG +3

Lifting basket girder end fixing method

InactiveCN110397259AEliminate the installation and fixingSpeed up installation timeScaffold accessoriesBuilding support scaffoldsHanging basketOperation safety

The invention discloses a lifting basket girder end fixing method. The method is characterized by including the following steps that a, a lifting basket is installed on the floor next to the roof according to the on-site actual conditions; b, a girder is arranged at a window of the floor next to the roof or arranged at an opening of a hole of a concrete wall; c, one end of the girder is fixed to the window or the opening of the hole of the concrete wall; and d, one side of a second steel wire rope is connected with the lifting basket through a free wheel along with the girder, the other side of the second steel wire rope is fixed to the position, higher than a first steel wire rope concrete fixing point, of a shear wall body structure, and the second steel wire rope which penetrates through a reserved hole is fixed through a rope clamp. The lifting basket girder end fixing method has the advantages that installation and fixing of a front support and a back support are omitted, the mounting and dismounting time are shortened, the working efficiency is improved, the working area is widened for roof construction, the construction period is shortened, the steel wire rope fixing effectis good, the lifting basket operation safety is guaranteed, the equipment rent expense is reduced, and the engineering cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

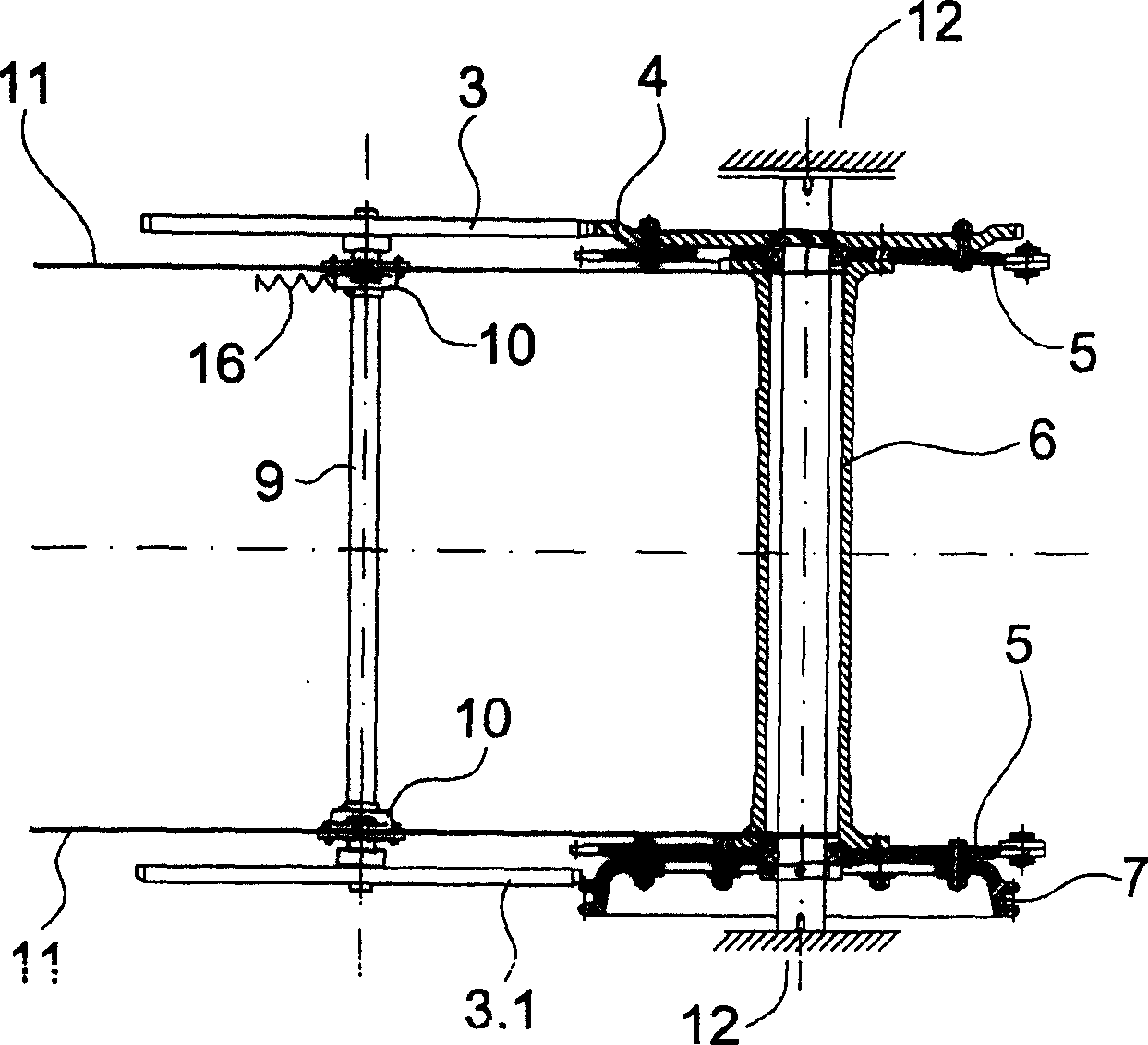

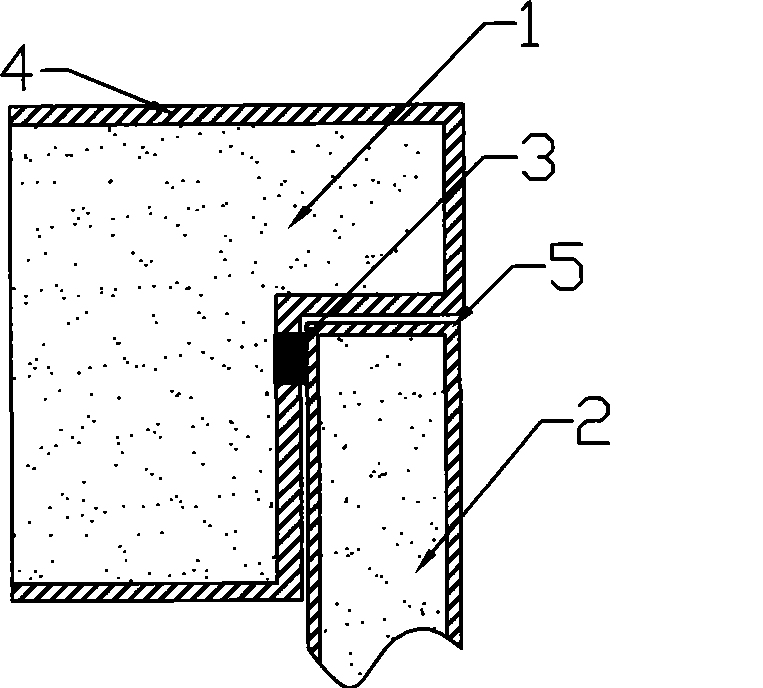

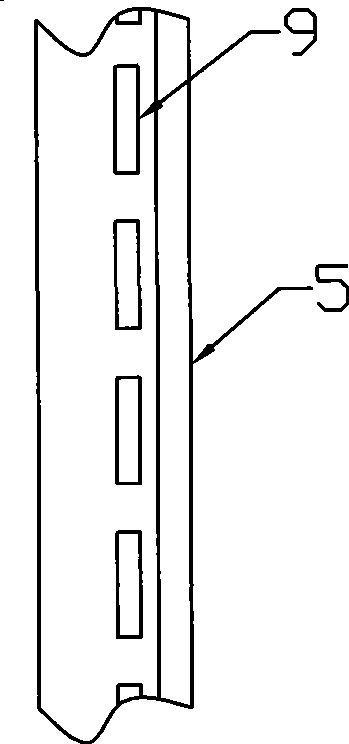

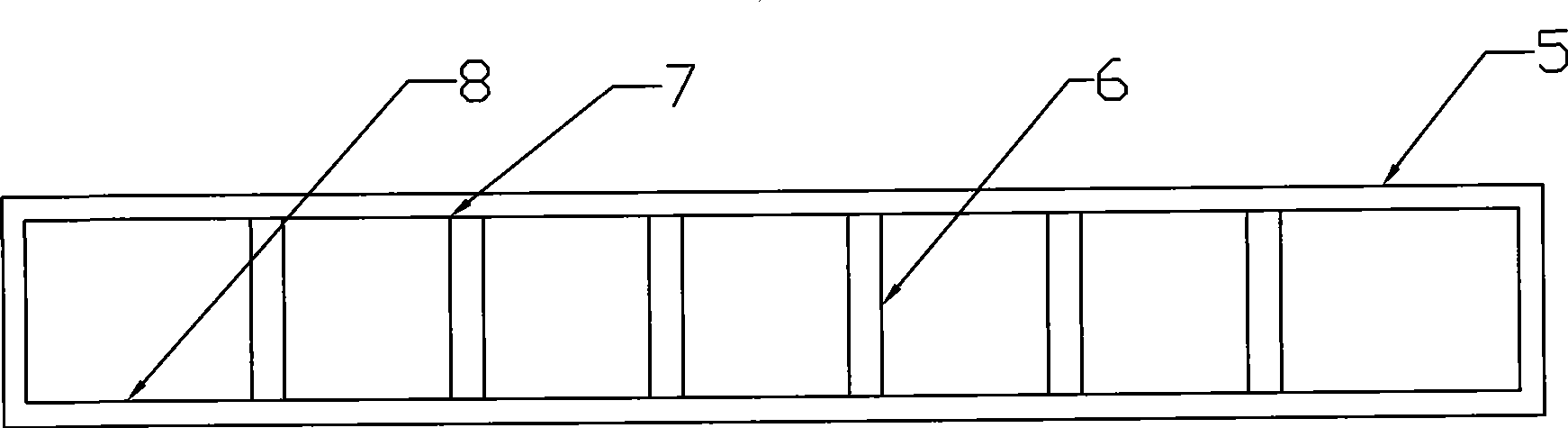

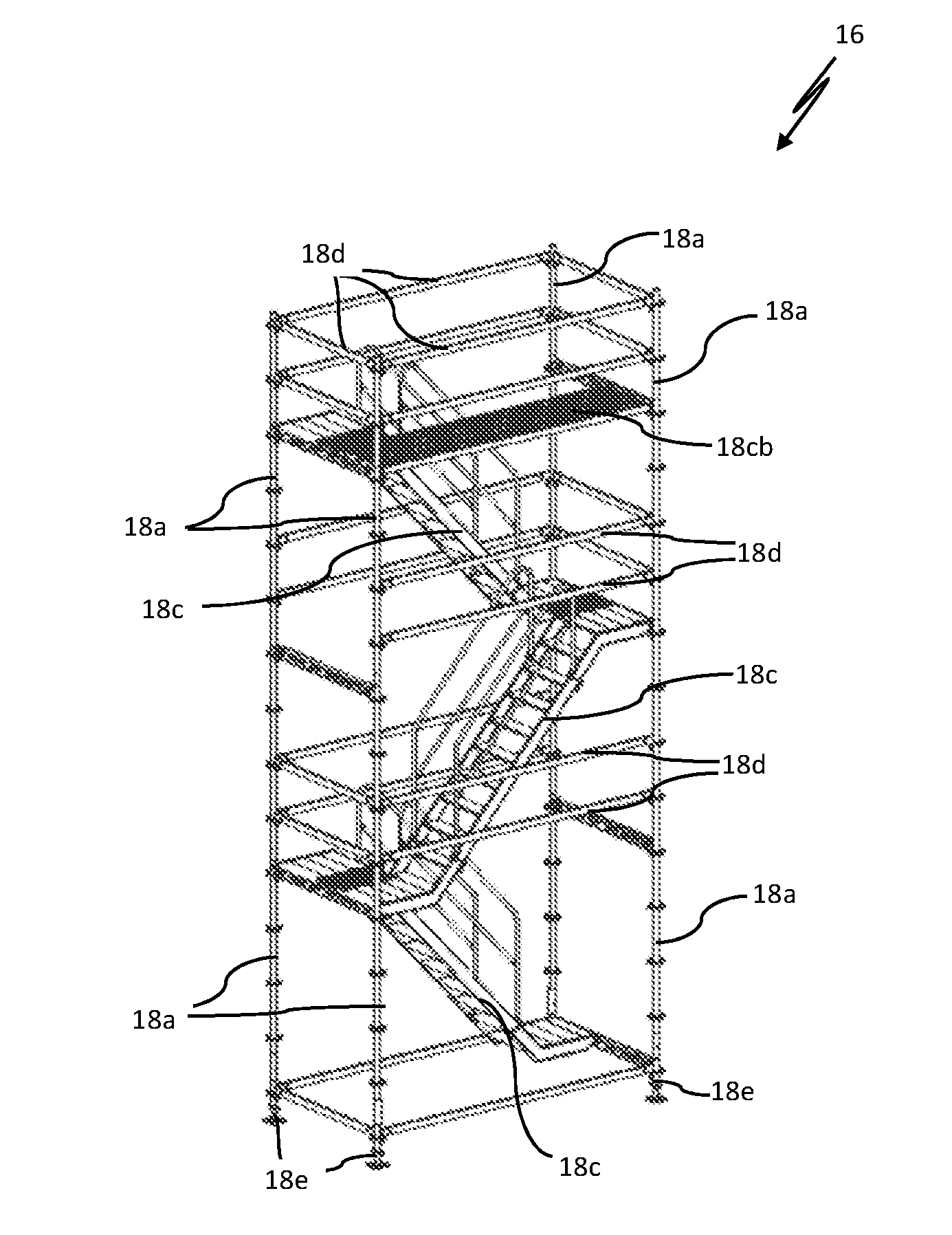

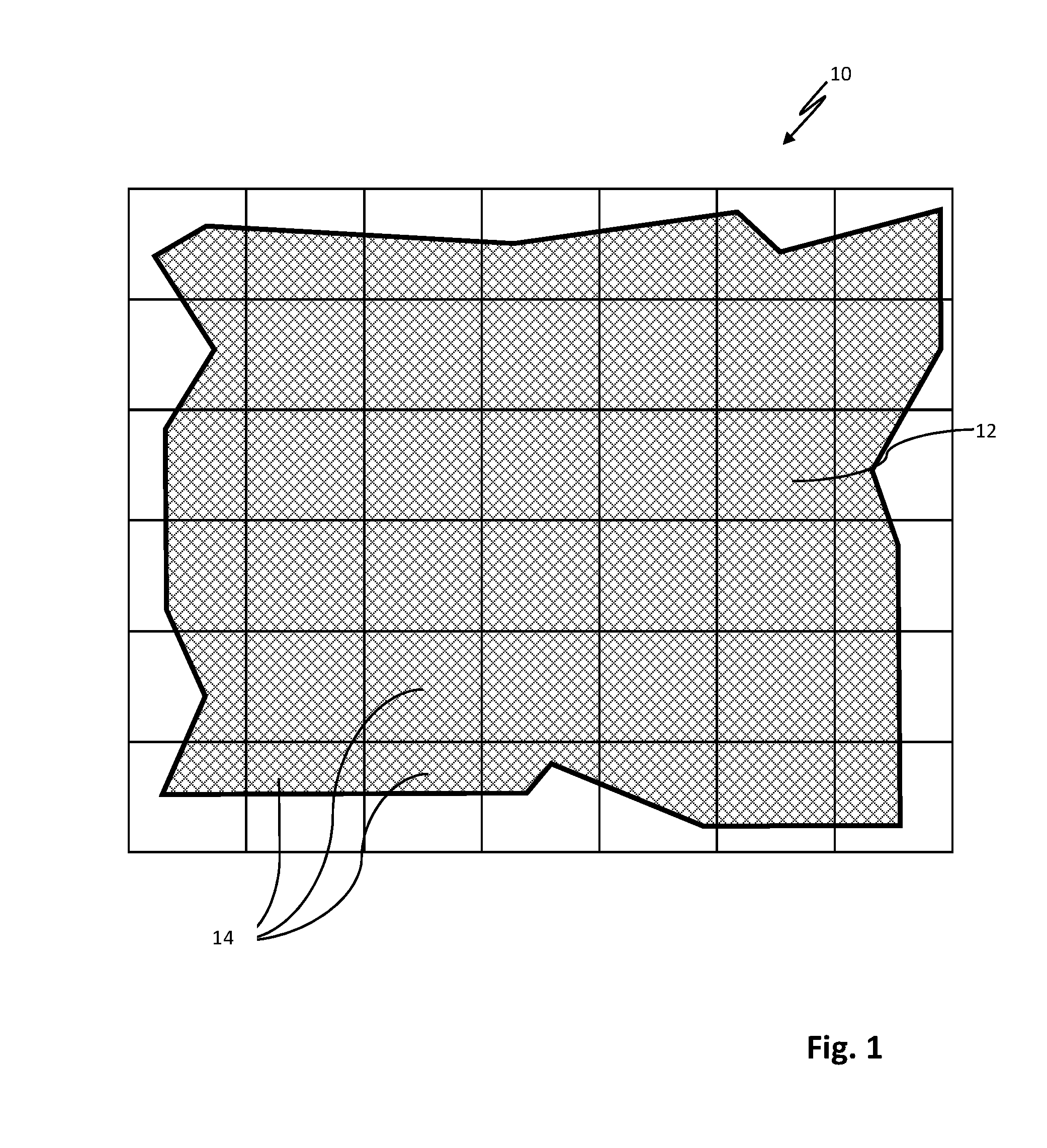

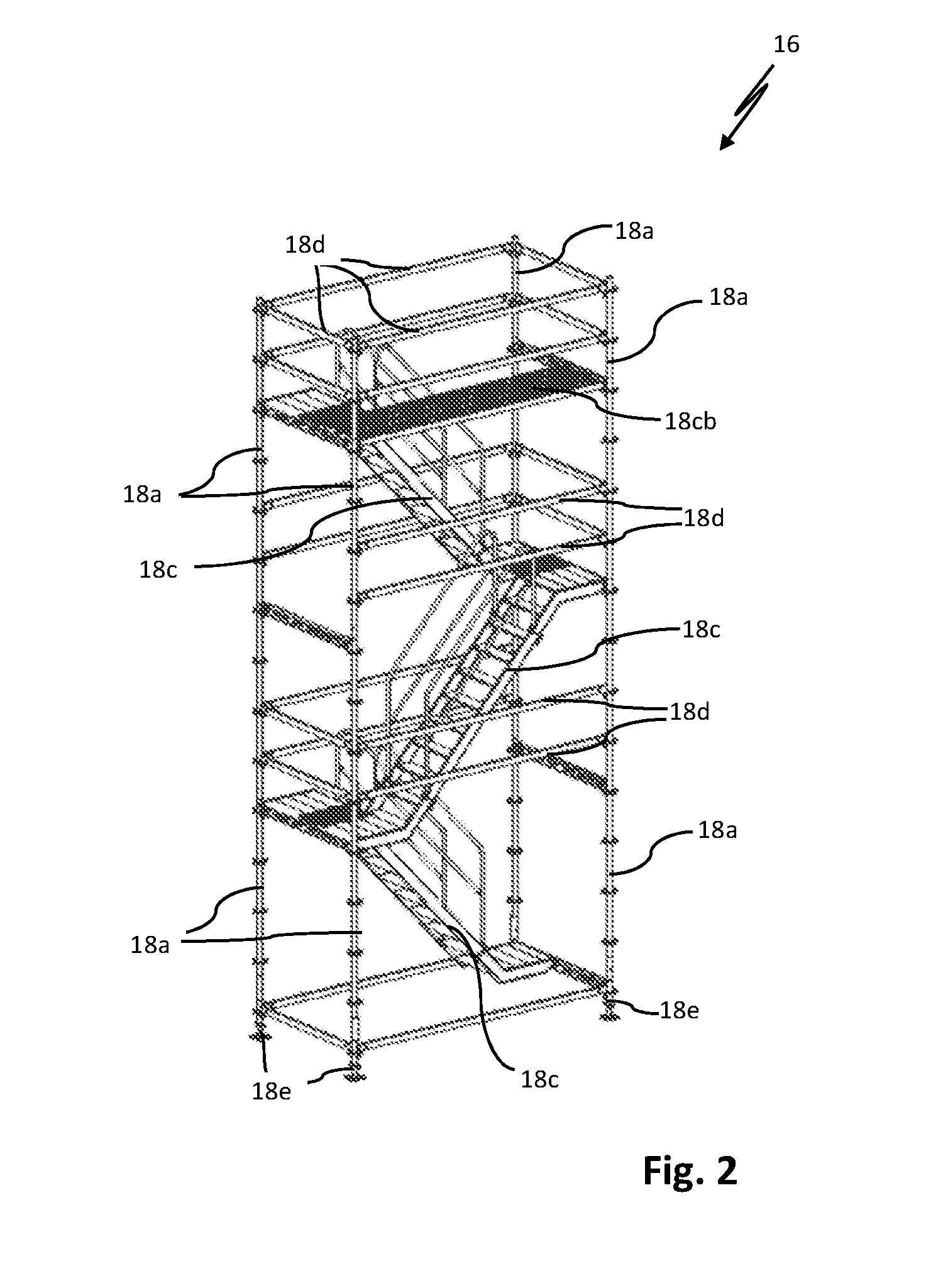

Method for providing and assembling scaffolding units, each of which will be assembled from individual scaffolding components for constructing an industrial plant, in particular a petroleum refinery

ActiveUS20160292311A1Inhibit progressClear and easy implementationGeometric CADScaffold connectionsPetroleumConstruction plan

The present invention relates to a method for providing and assembling scaffolding units, each of which will be assembled from individual scaffolding components (of a scaffolding system) for constructing an industrial plant, in particular a petroleum refinery, comprising the following steps:a) Providing a 3D construction plan of the industrial plant;b) Providing a construction schedule for the industrial plant in order of occurrence, depicting the individual sections / phases of construction of the industrial plant to be realized simultaneously and / or successively;c) Selecting and drawing of scaffolding units to be used in the individual sections or phases of construction of the industrial plant in the 3D construction plan;d) Specifying the erection time required to erect the respective scaffolding unit;e) Specifying the dismantling time required to dismantle the respective scaffolding unit;f) Dividing the construction schedule into time intervals;g) Calculating for every single time interval, while taking into consideration the erection and dismantling times of the scaffolding units, the respective number of scaffolding components of identical design which are used simultaneously;h) Determining the maximum number of scaffolding components of identical design which are used simultaneously across all time intervals;i) Providing, for constructing the industrial plant, the maximum number of scaffolding components of identical design alone, or providing the maximum number of scaffolding components of identical design including a defined number of a buffer of scaffolding components of identical design;j) Beginning of assembly of the scaffolding units to be used in a respective phase of construction from the scaffolding components each required for this purpose on-site at a point in time chosen in dependency of the specified erection time each at the latest prior to a start of construction in the respective section of construction specified in the construction schedule.

Owner:PERI GMBH

Stripping mold for small pipe fitting with closed end

InactiveCN106881833AAvoid strainAvoid the situation that cannot be demolded smoothlyPipe fittingEngineering

The invention discloses a demoulding mold for a small pipe with one end sealed, comprising a rear mold insert, a mounting plate, a limiting plate, a push assembly and a total block, the rear mold insert is cylindrical, and an installation groove is arranged at one end thereof , the side of the rear mold insert is provided with a matching hole communicating with the bottom of the installation groove, the total block includes a moving block and a forming block connected in sequence, and the forming block is located in the matching hole; the arc of the forming block There is a groove forming part on the surface, the moving block is located in the installation groove; the pushing assembly is located in the installation groove, and contacts with the surface of the moving block close to the axis of the rear mold insert, and moves the pushing assembly, moving the block and forming The blocks are movable radially of the rear mold insert. This not only prevents the product from sticking to the mold and the product cannot be demoulded smoothly, but also avoids the situation that the groove is strained due to direct demoulding, which improves the product quality.

Owner:泸州市胜科模具制造有限公司

Efficient and intelligent bottle cap mounting robot arm

PendingCN108821207ASolve the costSolve the problem of land occupationCapsCapping machinery safety/controlSimulationBottle cap

The invention discloses an efficient and intelligent bottle cap mounting robot arm. The efficient and intelligent bottle cap mounting robot arm comprises a base, a first robot arm, a second robot armand a control device. The base is provided with a stand column, and the first robot arm and the second robot arm are both mounted on the stand column. A transmission mechanism is disposed between thefirst robot arm and the second robot arm, and the first robot arm and the second robot arm are matched with each other. A cap feeding mechanism for grasping bottle caps is arranged on the end portionof the first robot arm, and the second robot arm is provided with a tightening mechanism for tightening the bottle caps. The cap feeding mechanism is provided with a bottle cap position detecting mechanism and a bottle mouth position detecting mechanism, and the tightening mechanism is provided with a position detecting mechanism for detecting the position of a bottle body. According to the efficient and intelligent bottle cap mounting robot arm, the structure is simple and optimized, and the transmission mechanism is arranged between the first robot arm and the second robot arm, so that the first robot arm and the second robot arm realize the pipelined operation, two stations are subjected to cap feeding and screwing simultaneously and each of the two stations performs own duties, and thus the work efficiency is effectively improved.

Owner:薛敏强

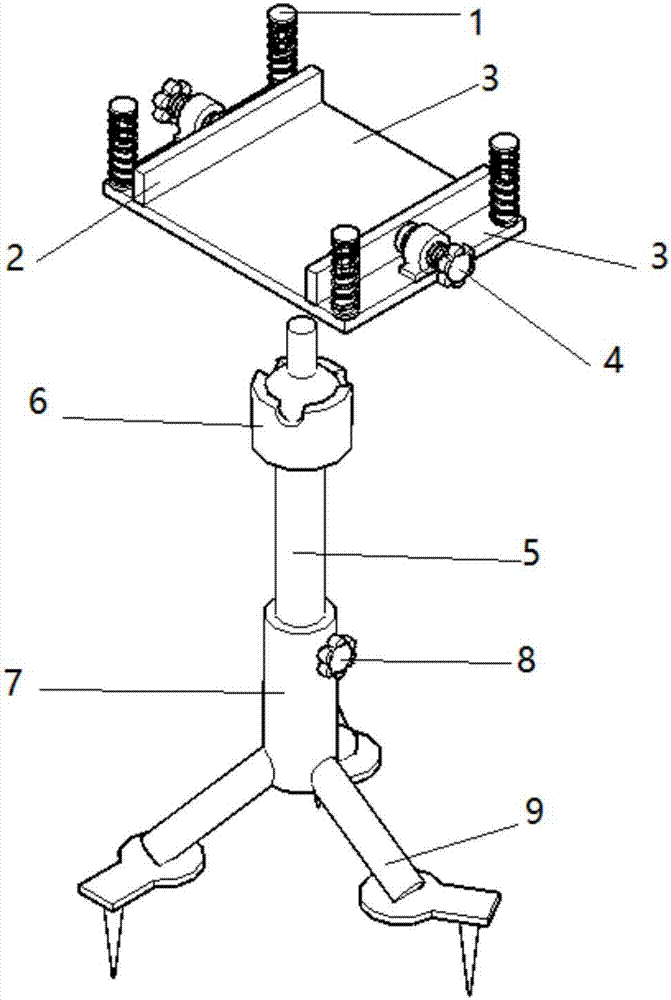

Angle-adjustable directional blasting device for blasting

The invention discloses an angle-adjustable directional blasting device for blasting. The angle-adjustable directional blasting device for blasting comprises a universal joint, a sleeve rod, a tightening screw and a supporting frame; tightening springs are fixedly arranged at the top end of a supporting plate, and are located on the left side and the right side of two clamping plates; the clamping plates are rotationally connected with tightening screw rods; the supporting plate is welded and fixed to the top end of a turning rolling ball of the universal joint; threads of the tightening screw rods are fastened in thread fixing rings at the left end and the right end of the supporting plate; a piston rod is inserted in the sleeve rod; the universal joint is welded and fixed to the top end of the piston rod; a thread of the tightening screw is fastened to the outer wall of the tightening screw; and the sleeve rod is welded to the top end of the supporting frame. The angle-adjustable directional blasting device for blasting is provided with the universal joint, a blasting device body is folded and turned through the universal joint, so that the blasting device body can be placed at the bottom of a blasted face in an ejected manner, and can also be parallelly attached to the side wall of the blasted face, installation of the blasting device body is facilitated, and the blasting device body can be used more conveniently.

Owner:GUIZHOU UNIV

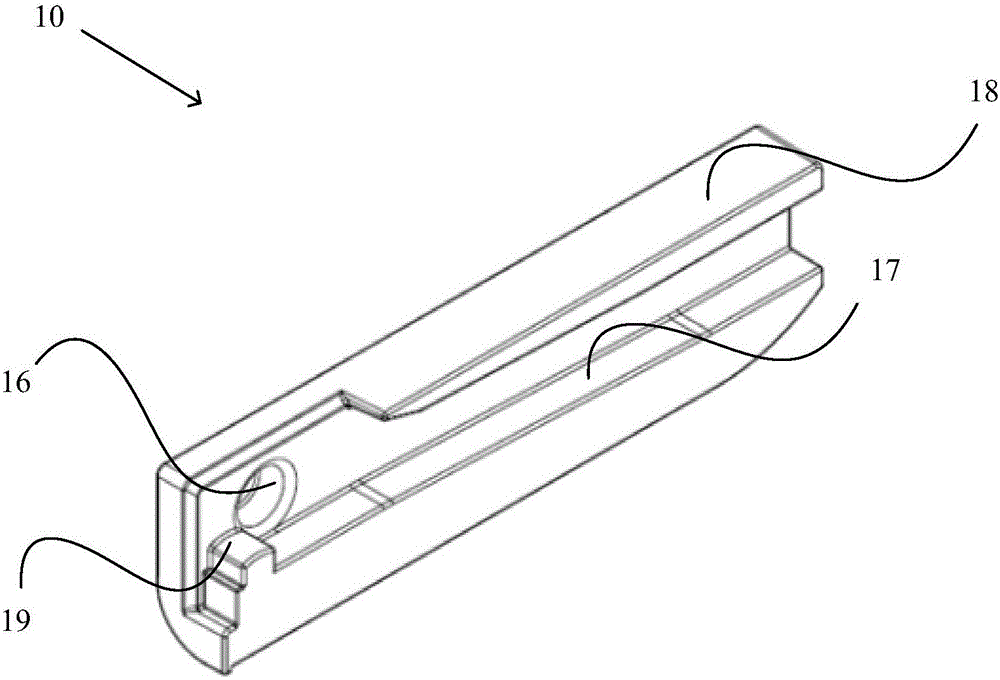

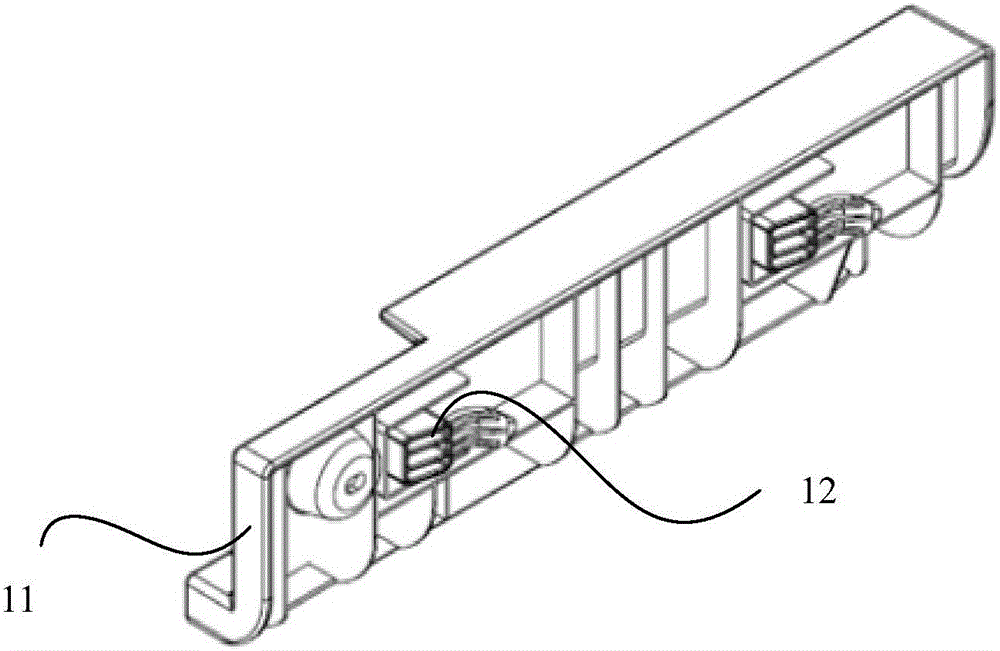

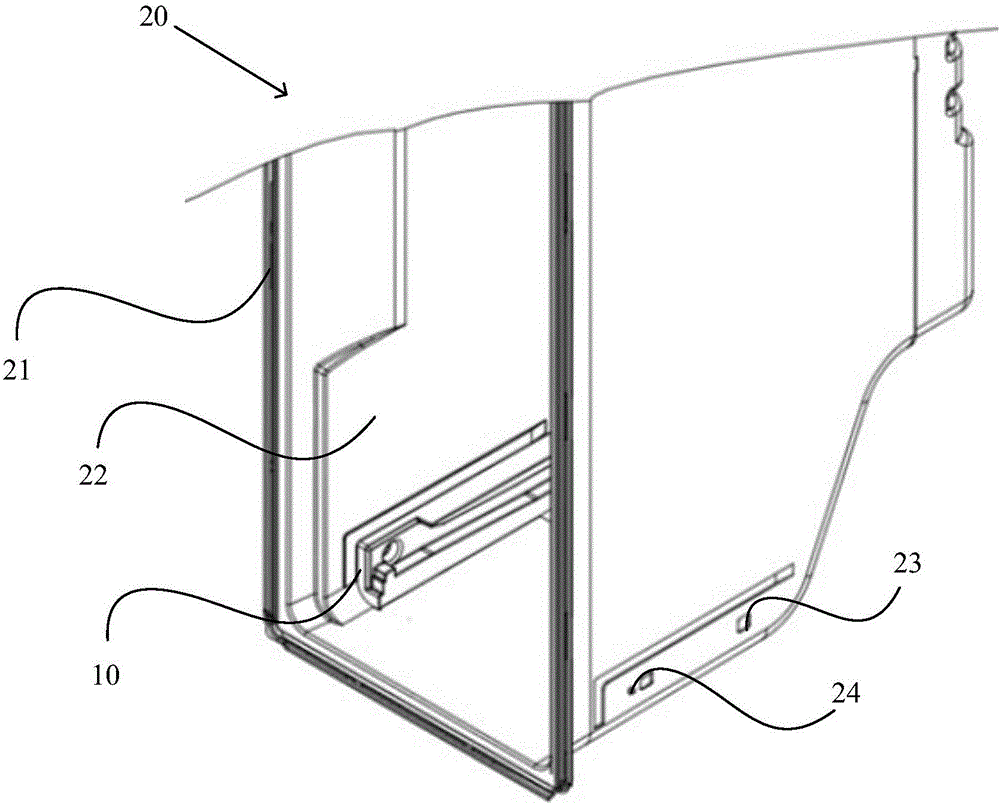

Refrigerator guide rail, refrigerator and installation method of refrigerator guide rail

ActiveCN106016945AQuick and easy joiningGuaranteed tightnessLighting and heating apparatusSupportRefrigerator carFoaming agent

The invention discloses a refrigerator guide rail, a refrigerator and an installation method of the refrigerator guide rail. The refrigerator guide rail comprises a body and a connecting part. The first side of the body is used for installing a refrigerator drawer in a sliding manner. The connecting part is arranged on the second side of the body. The second side is opposite to the first side. The connecting part comprises a fixed part and an elastic piece which is fixedly arranged on the fixed part and has elastic force being partially pressed towards the body. The refrigerator comprises the refrigerator guide rail and filler pressing the elastic piece of the refrigerator guide rail. The installation method of the refrigerator guide rail includes the steps that firstly, the refrigerator guide rail is installed on the refrigerator body; and then a foaming agent presses the elastic piece of the refrigerator guide rail in a foaming manner. The refrigerator guide rail can be fast and conveniently connected to the refrigerator body, and the connecting firmness is guaranteed.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

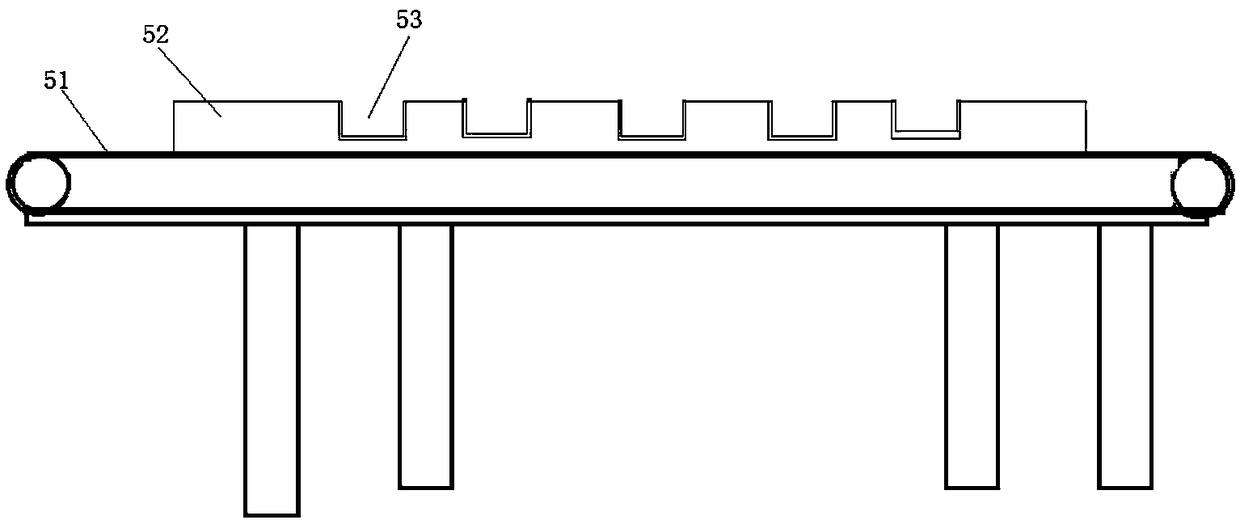

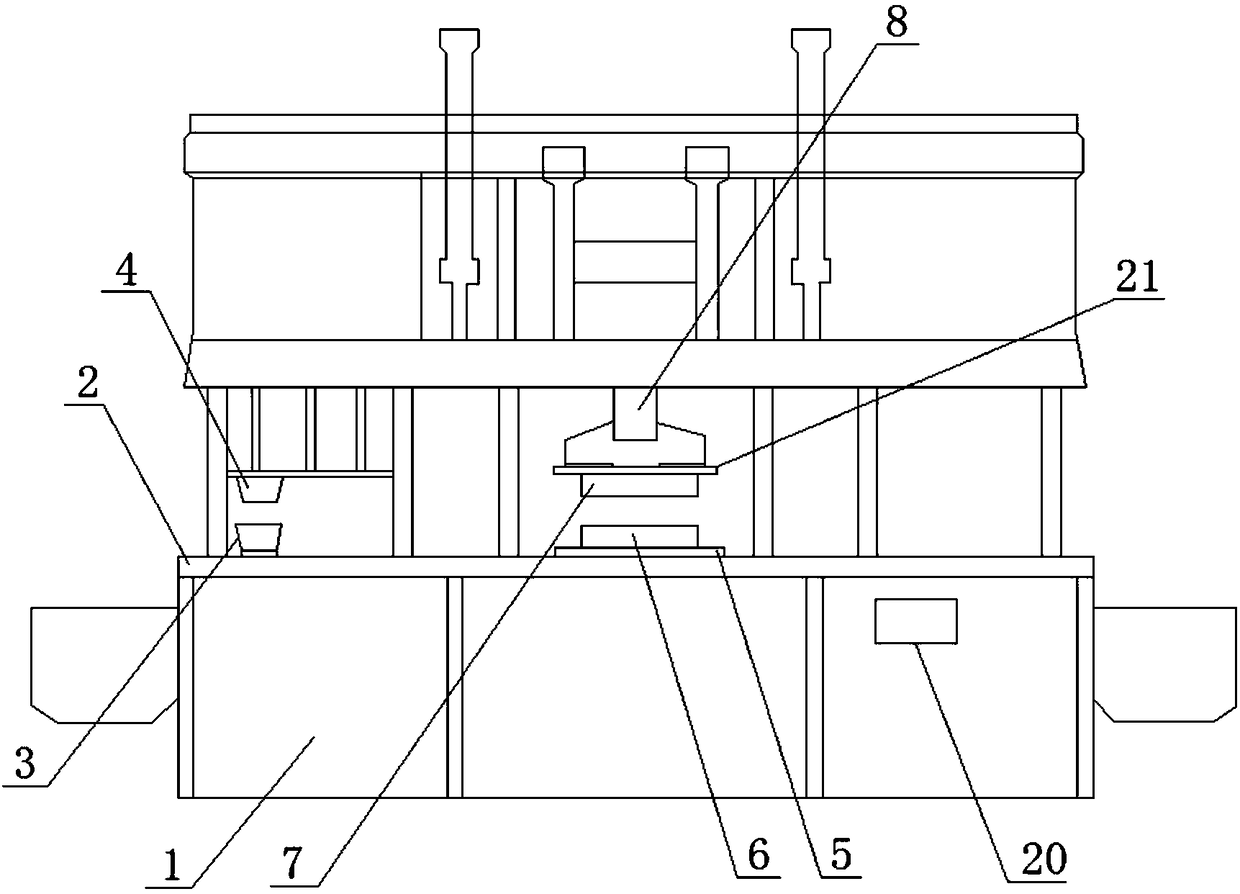

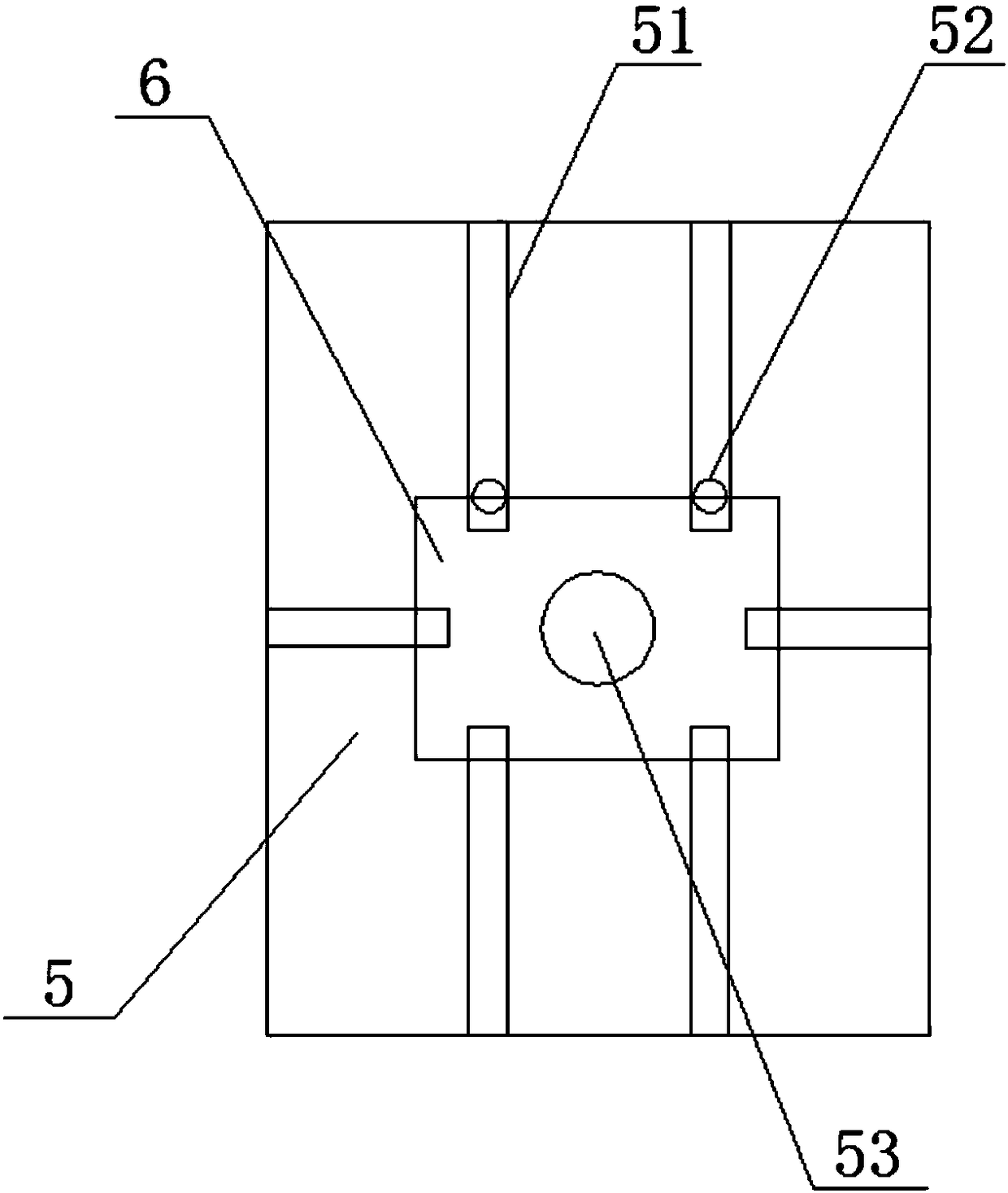

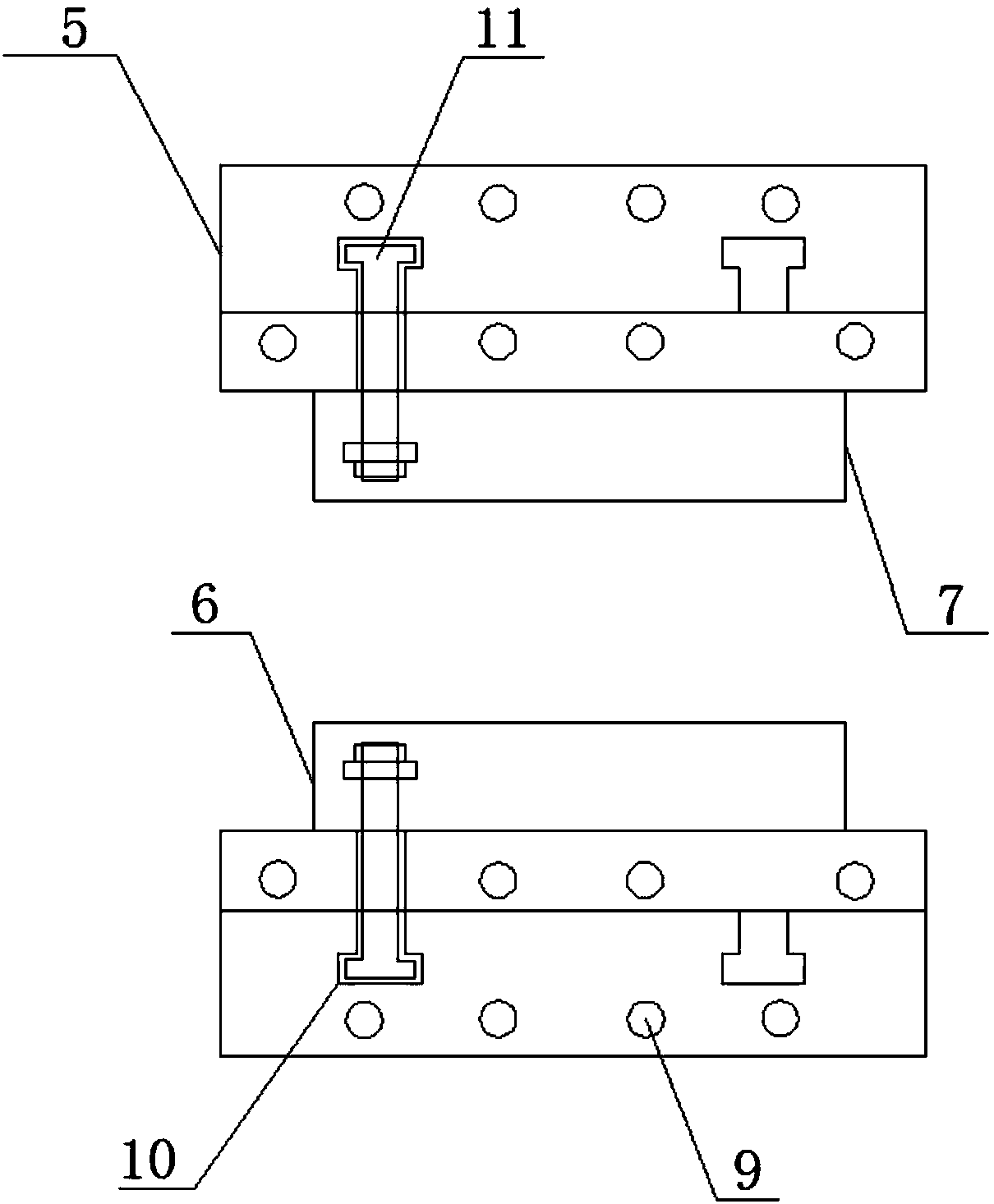

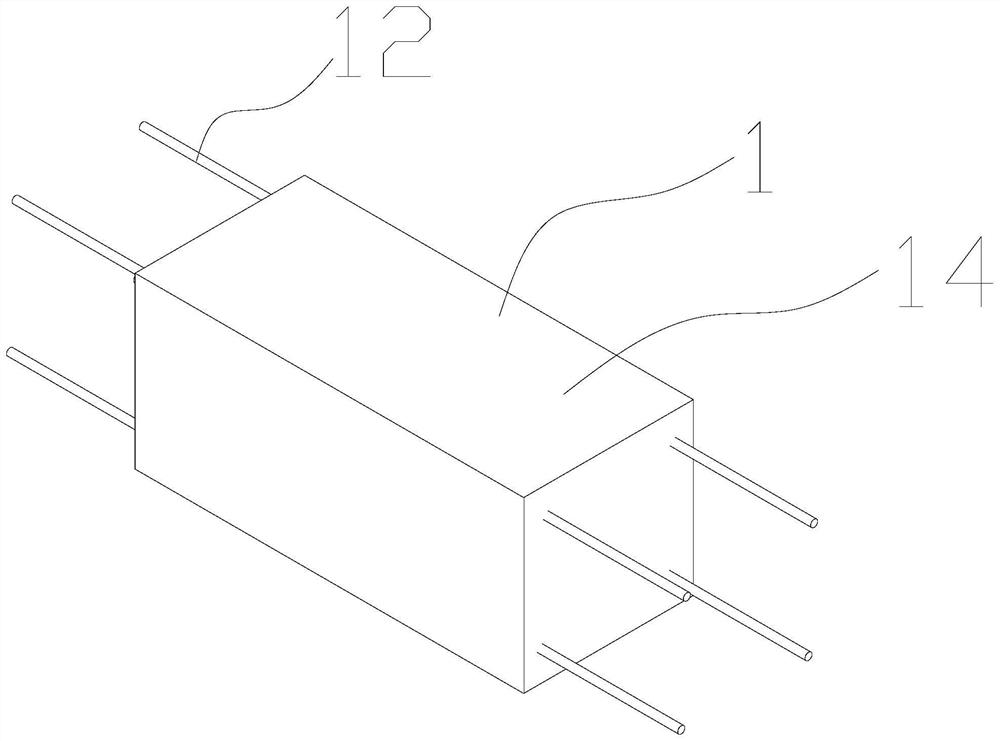

Linkage production line for rapid clamping, positioning and debugging of paper pulp moulds

PendingCN108425290AAvoid damageShorten the timeTextiles and paperProduction linePulp and paper industry

The invention discloses a linkage production line for rapid clamping, positioning and debugging of paper pulp moulds. The production line comprises a forming machine; the forming machine comprises a lower table and an upper table; the upper table is arranged above the top of the lower table; the surface of the lower table is provided with a pulp absorbing die; an extruding die is arranged above the top of the pulp absorbing die; the top of the lower table and the bottom of the upper table are both provided with a base plate; a hot-press lower die is arranged at the top of one base plate on thetop of the lower table; and a hot-press upper die is arranged above the top of the hot-press lower die. According to the invention, heating pipelines are uniformly arranged in the base plates for quickly heating the base plates and the dies, so that wasted time for waiting is reduced; the installation and debugging time is improved, so that the subsequent production is facilitated, and the production efficiency is improved; a positioning hole is arranged in each base plate, and the positioning holes are set according to the sizes of different molds, so that the requirement of quick positioning of the molds are met, all different molds can be used, and good universality can be achieved; and the base plates are prepared of a 6061 aluminum material, so that the processing performance is excellent, the corrosion resistance is good, and the toughness is high.

Owner:WING FAT (HENAN) MOLDED FIBER TECH DEV CO LTD

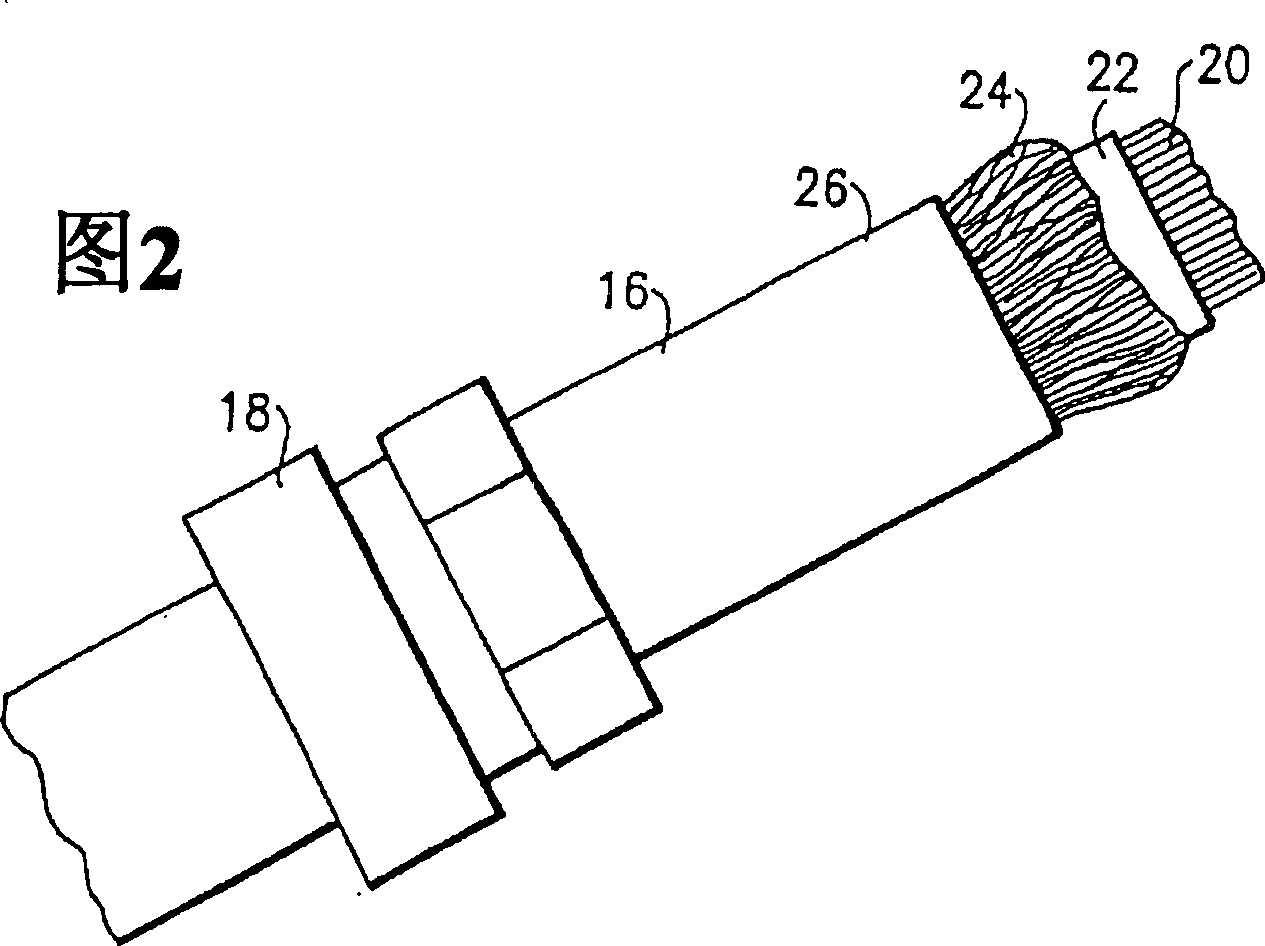

Product and method for wire seal

ActiveCN101803118AImprove high temperature resistanceGood install timeElectric/fluid circuitThin material handlingEngineeringElectrical wiring

A heat-shrinkable tubular article for forming a wire splice comprising (i) a heat-shrinkable jacket material, and (ii) a thixotropic heat-flowable inner adhesive layer, the tubular article having at least one of a maximum internal diameter of no more than 15mm or a maximum length of no more than 100mm.

Owner:TYCO ELECTRONICS (UK) LTD

Recycled block concrete prefabricated assembly type ring beam structure and construction method thereof

ActiveCN113374171ASpeed up installation timeReduce labor costsGirdersJoistsArchitectural engineeringStructural engineering

The invention discloses a recycled block concrete prefabricated assembly type ring beam structure and a construction method thereof. The ring beam structure comprises recycled block concrete sections and non-disassembling formwork sections, the recycled block concrete sections comprise waste concrete blocks, longitudinal bars, ring beam inner stirrups and common concrete, the ring beam inner stirrups and the longitudinal bars are bound to form reinforcement cages, the waste concrete blocks are placed in the reinforcement cages, the common concrete is wrapped round the waste concrete blocks and the reinforcement cages, the two ends of the longitudinal bars extend out of the end faces of the recycled block concrete sections, the non-disassembling formwork sections comprise bottom plates and side plates that are connected with each other, each non-disassembling formwork section is placed between every two adjacent recycled block concrete sections, a cavity with the top open is defined by the bottom plates, the side plates and the end faces of the at least two adjacent recycled block concrete sections, the longitudinal bars of the at least two adjacent recycled block concrete sections are bound in the cavity, and the cavity is filled with the common concrete to be wrapped round the longitudinal bars.

Owner:SOUTH CHINA UNIV OF TECH +1

High-voltage transmission line spacer on-line installation robot

InactiveCN113725780AEasy to grabSpeed up installation timeMetal working apparatusApparatus for overhead lines/cablesRobot handElectric machine

The invention belongs to the technical field of high-voltage power transmission lines, and particularly relates to a high-voltage power transmission line spacer online installation robot which comprises a machine shell and a spacer and further comprises a camera set, moving mechanisms, a feeding device, a fixing device and an installation mechanical arm. The lower surface of the camera set is fixedly mounted on the upper surface of the machine shell; and the moving mechanisms are located on the outer surfaces of the two ends of the machine shell and drive the machine shell and the multiple spacer rods to move on the high-voltage transmission line. According to the high-voltage transmission line spacer on-line installation robot, through the arrangement of the adjusting mechanism, two mechanical arms can conveniently and rapidly install bolts in bolt holes in locking blocks at different positions of an eight-split spacer and fix the two locking blocks, the spacer installation time is shortened, a supporting disc is driven by an adjusting motor to rotate, the positions of the two mechanical arms on the supporting disc can be changed, and therefore bolt holes in the spacer can be rapidly installed.

Owner:南京荟聪网络科技有限公司

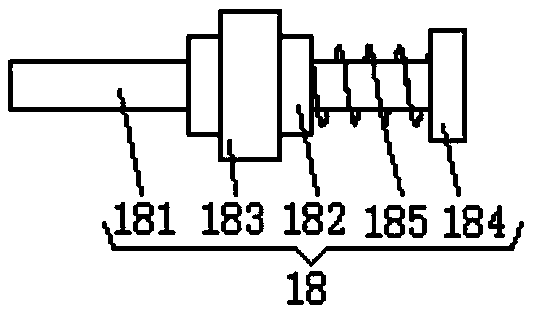

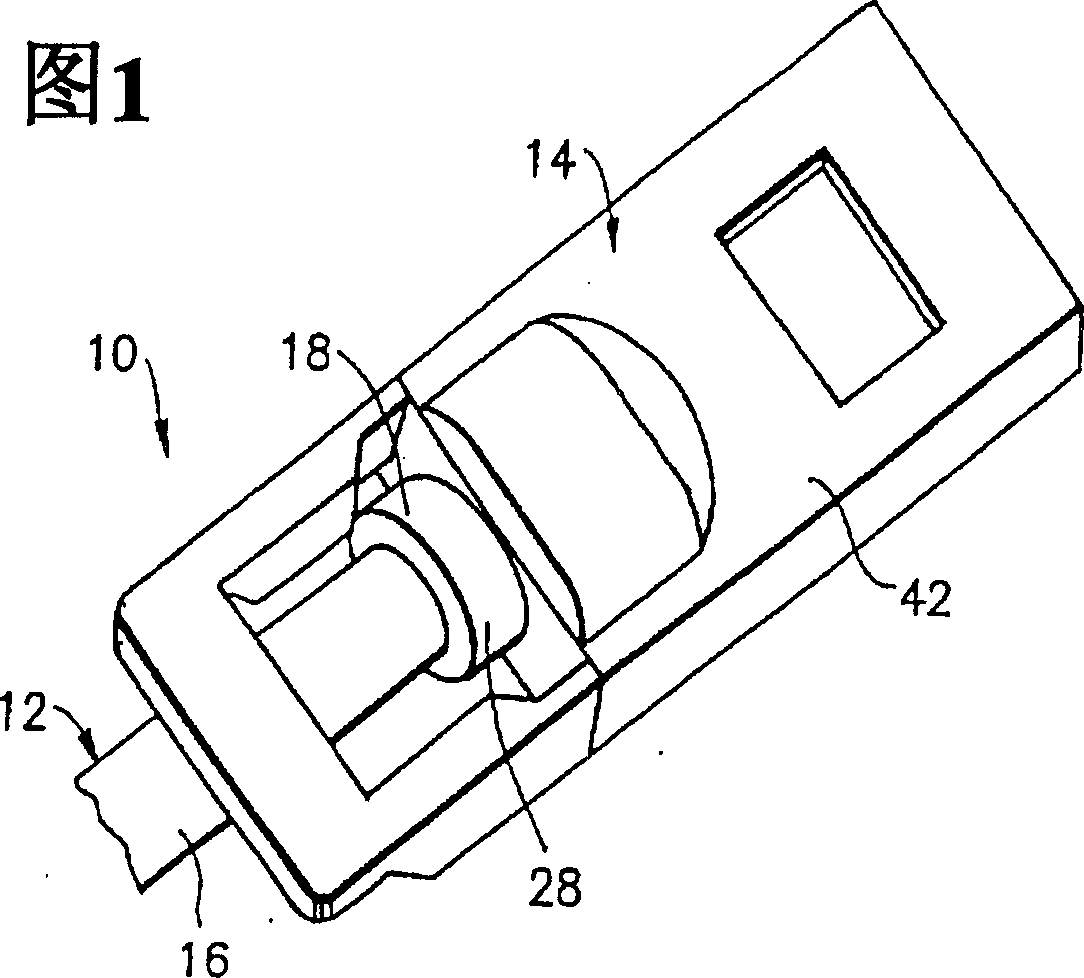

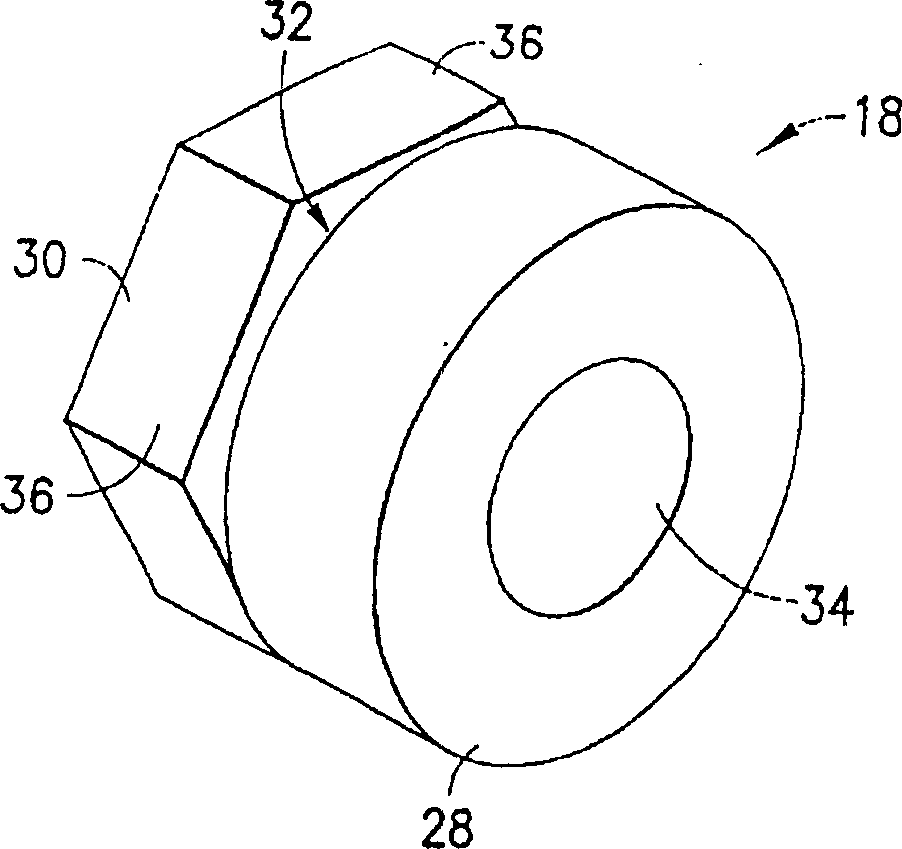

Electrical cable strain relief and electrical closure

InactiveCN1706078ASpeed up installation timeSave on installation costsLine/current collector detailsElectrically conductive connectionsElectricityElectrical conductor

Disclosed herein are methods and apparatus for providing as strain relief (18) for use in the assembly of an electrical connector (14) on an end of an electrical conductor (16) having at least an outer braided portion (24), which may be surrounded by an insulating cover. The methods and apparatus disclosed herein provide a low cost approach for installation using minimal tooling, while providing a precise and robust relief that ensures electrical performance.

Owner:新美亚通讯设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com