Stripping mold for small pipe fitting with closed end

A technology for small pipe fittings and demoulding, which is applied in the field of demoulding molds for small pipe fittings. It can solve problems such as unsmooth demoulding of products, groove scratches, and product stickiness, so as to avoid grooves from being strained and increase mold clamping. The trouble, the effect that is conducive to product production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

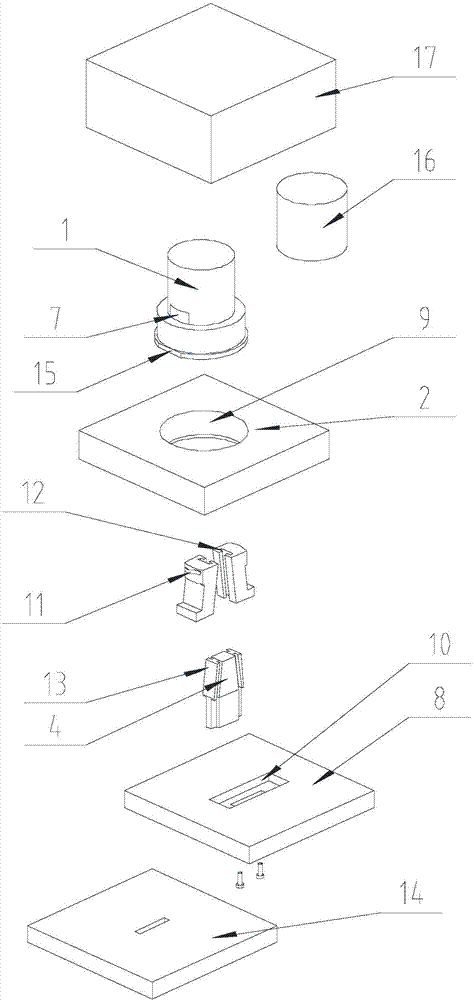

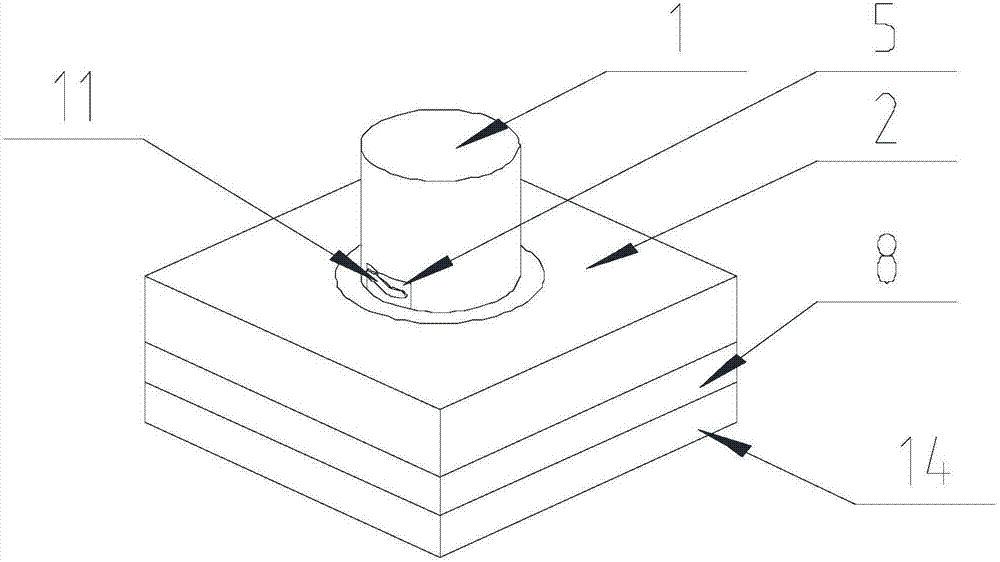

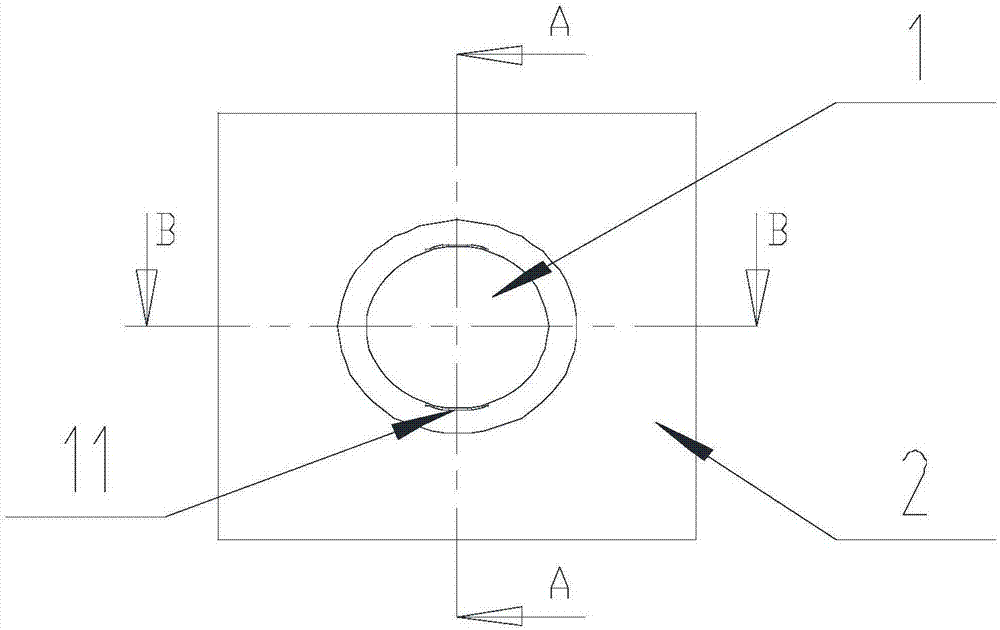

[0040] Such as Figure 1-Figure 10 Shown, label 16 among the figure is the product that glue is arranged on top surface; Label 17 is front mold. The demoulding mold for a small pipe with one end sealed in the present invention comprises a rear mold insert 1, a mounting plate 2, a limiting plate 8, a push assembly and a total block, and the rear mold insert 1 is cylindrical, and one end thereof is provided with The mounting groove 6 is provided with a matching hole 7 communicating with the bottom of the mounting groove 6 on the side of the rear mold insert 1. The total block includes a moving block 3 and a forming block 5 connected in sequence, and the forming block 5 is located in the matching In the hole 7, and the size of the forming block 5 is consistent with the size of the matching hole 7, and the surface of the forming block 5 away from the axis of the rear mold insert 1 is an arc-shaped surface with the same diameter as the side wall of the rear mold insert 1, that is, ...

Embodiment 2

[0047] The present invention is based on embodiment 1, and the present invention is further described.

[0048] Such as Figure 1-Figure 10 As shown, the demoulding mold for small pipe fittings sealed at one end of the present invention, the installation groove 6 is coaxial with the rear mold insert 1, and the longitudinal section of the installation groove 6 is an isosceles trapezoid, and its small end communicates with the matching hole 7;

[0049] There are two matching holes 7 and the total block, and the matching holes 7 are symmetrically arranged on the side wall of the rear mold insert 1 along the axis of the rear mold insert 1, and the matching holes 7 are respectively matched with a total block;

[0050] The push assembly includes a tightening block 4 that is symmetrical along the axis of the rear mold insert 1, and the tightening block 4 is located between the general blocks and is in contact with the assembly block;

[0051] The projection of the axis of the rear m...

Embodiment 3

[0056] The present invention is based on embodiment 2, and the present invention is further described.

[0057] Such as Figure 1-Figure 10 As shown, the demoulding mold for small pipes with one end sealed in the present invention also includes a moving plate 14, and the end of the push assembly away from the rear mold insert 1 moves through the limit plate 8 and is located in the moving plate 14, and is passed through the bolt The push assembly is fixed on the moving plate 14. The bolts are countersunk head bolts.

[0058] During mold opening and mold closing, the movement of the tightening block 4 is driven by moving the moving plate 14, and the movement of the total block has been completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com