Handrail driving device for escalator or moving walkway

A technology for moving walks and escalators, applied in escalators, transportation and packaging, etc., can solve the problems of no longer guaranteeing handrail drive, adverse lifespan of handrails, influence, etc., to achieve less maintenance and manufacturing costs, short installation time, shortening effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

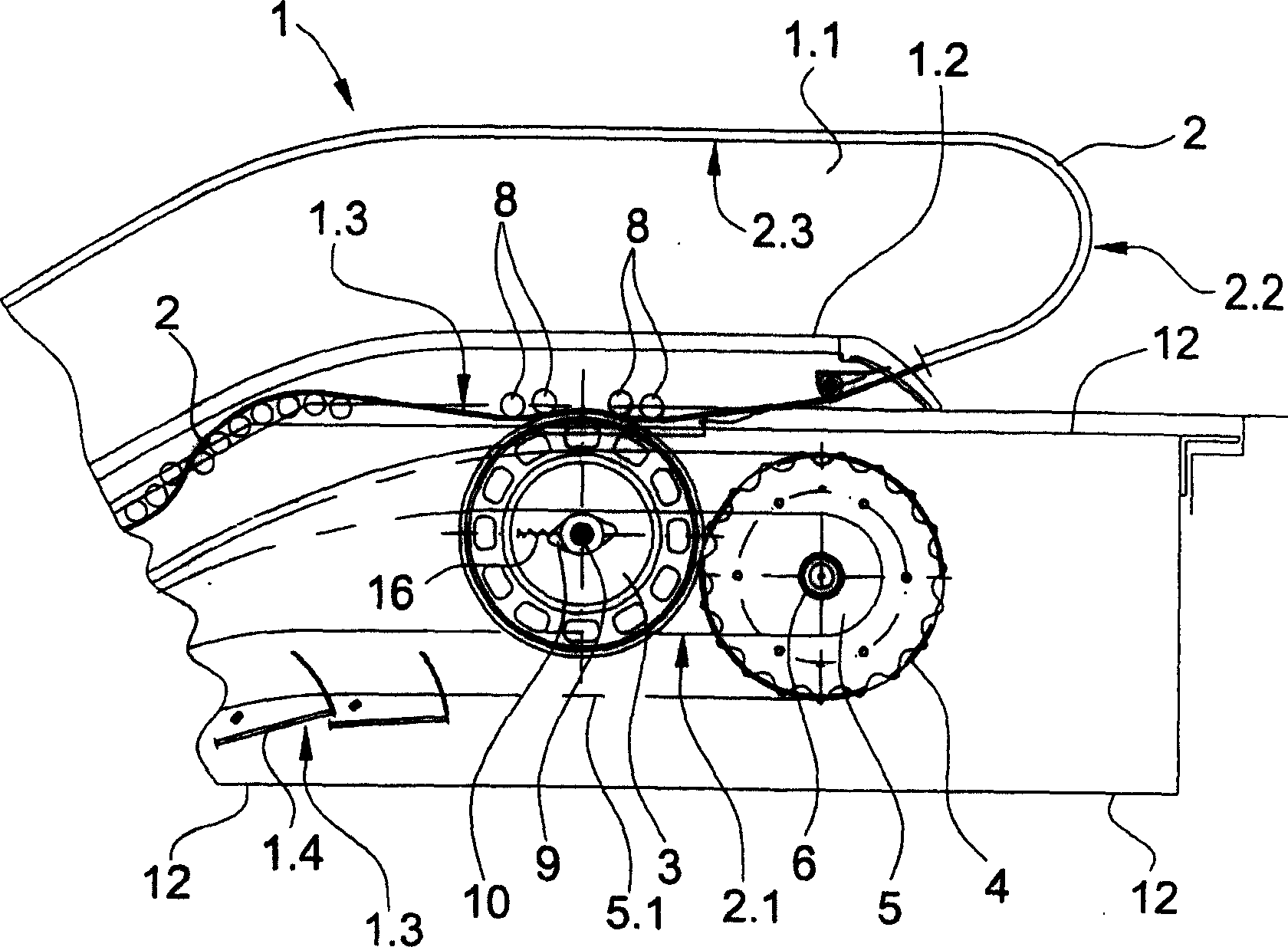

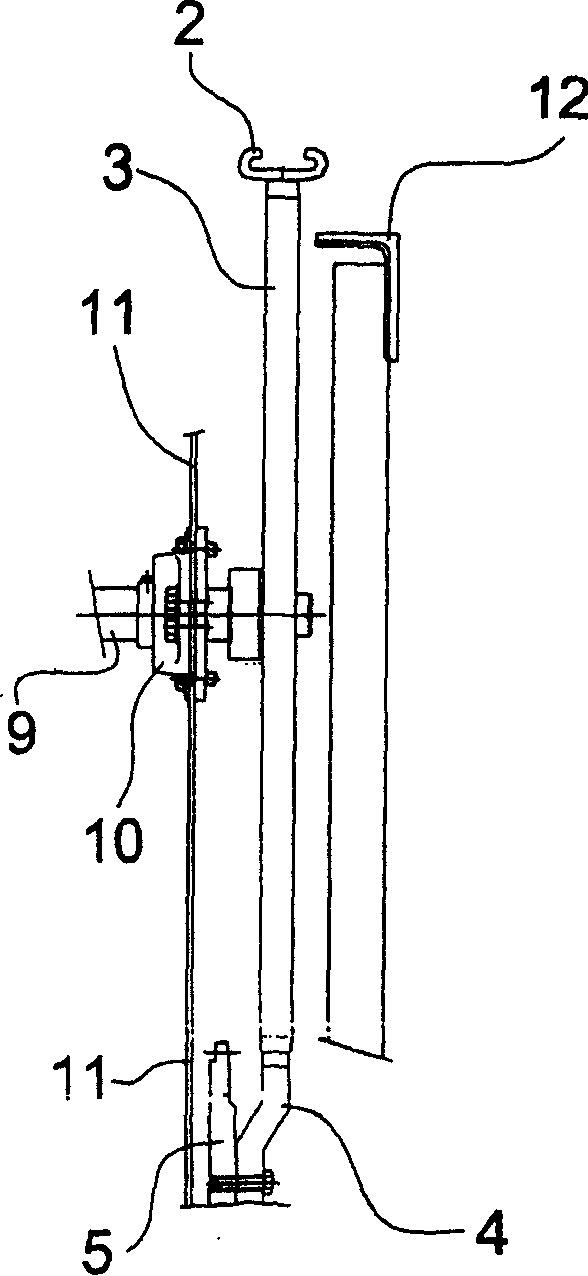

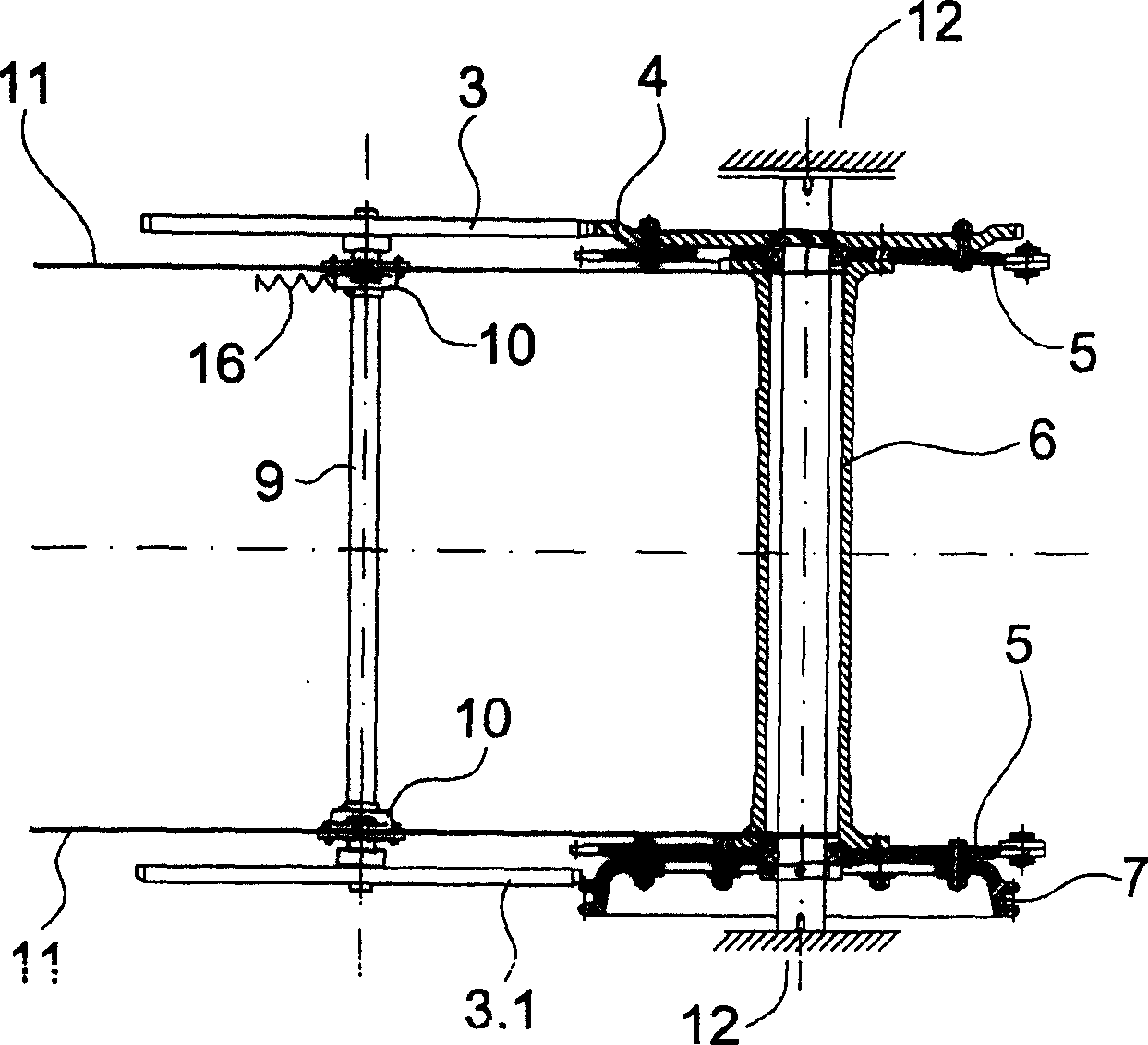

[0025] figure 1 An escalator 1 is shown having a guardrail 1.1 with a handrail 2 on each side, wherein the guardrail 1.1 is supported by a guardrail seat. A ladder belt 1.3 with steps 1.4 for conveying personnel is connected with guardrail seats 1.2 on both sides. The handrail driving device 2.1 drives the handrail 2, wherein the friction wheel 3 drives the outer side 2.2 of the handrail 2 or the side of the handrail through friction fit. The inboard or sliding side roller 8 of the handrail 2 presses the handrail 2 against the friction wheel 3 . A drive wheel 4 arranged on the stepped sprocket 5 drives the friction wheel 3 in a friction fit or form fit manner. The step sprocket 5 moves the step chain 5.1 on which the steps 1.4 are arranged.

[0026] figure 1 5 to 5 show the frictional drive of the friction wheel 3 , wherein a frictional engagement exists between the drive wheel 4 and the friction wheel 3 .

[0027] A drive sprocket 7 drives a main shaft 6 supporting the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com