Recycled block concrete prefabricated assembly type ring beam structure and construction method thereof

A prefabricated assembly and concrete technology, applied in truss structures, joists, girders, etc., can solve the problems of dust emission from wet work of cast-in-place concrete, the length of steel bar binding and lap does not meet the specification requirements, and the cast-in-place concrete is not easy to vibrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

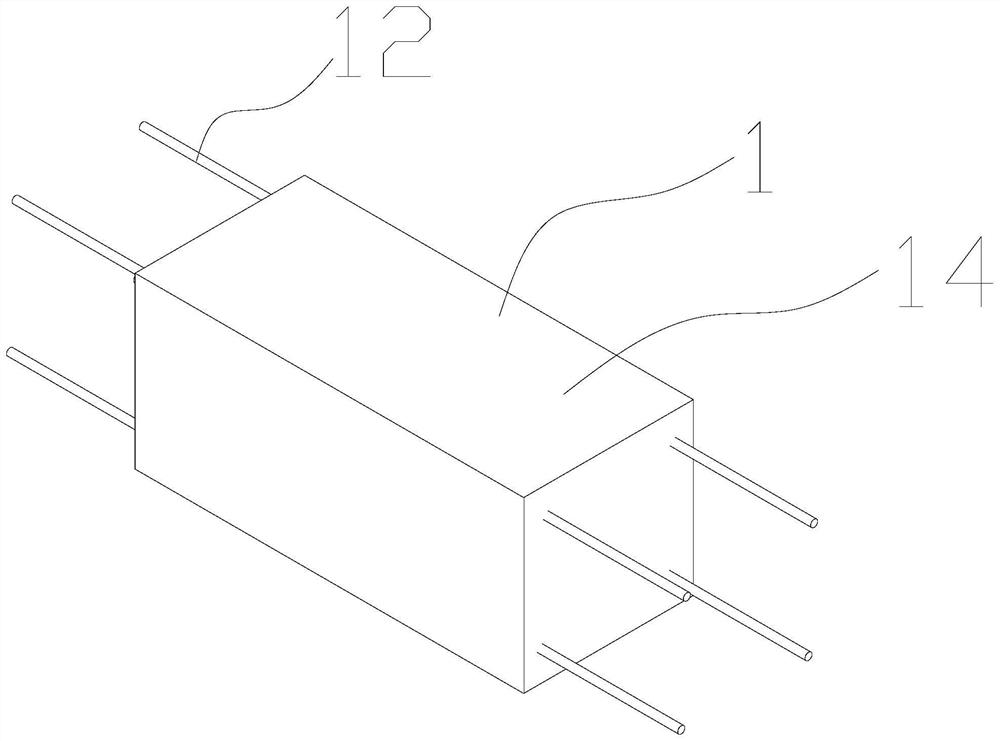

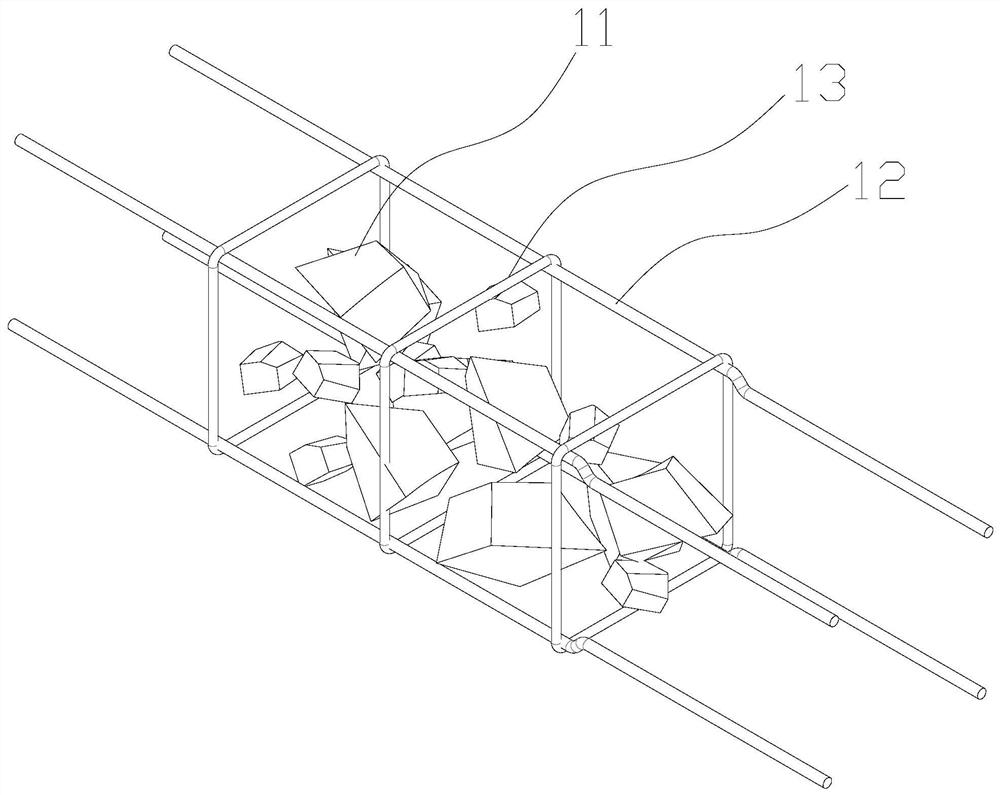

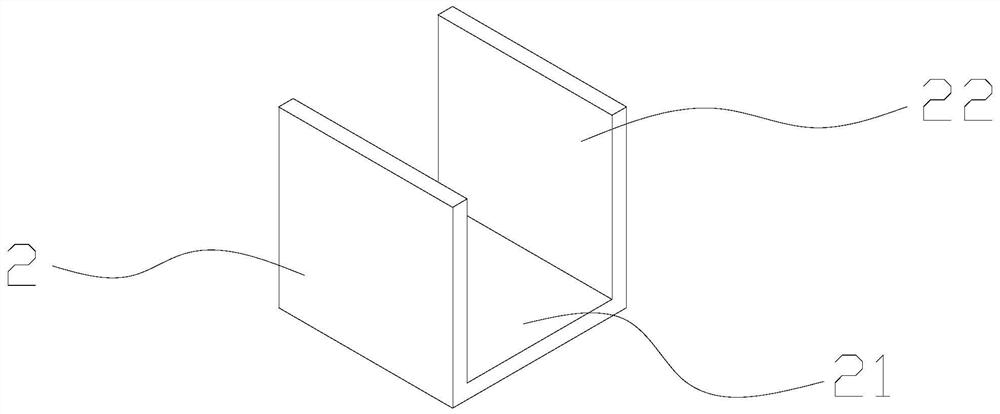

[0039] Such as figure 1 and image 3 As shown, this embodiment provides a recycled block concrete prefabricated assembled ring beam structure, including a recycled block concrete segment 1 and a demolition-free formwork segment 2;

[0040] Such as figure 1 and figure 2 As shown, the recycled block concrete segment includes waste concrete blocks 11, longitudinal bars 12, ring beam inner stirrups 13 and ordinary concrete 14, the ring beam inner stirrups and longitudinal bars are bound into a reinforcement cage, and the waste concrete blocks are placed in Inside the reinforcement cage, ordinary concrete covers the discarded concrete block and the reinforcement cage, and the ends of the longitudinal bars extend out from the end faces of the recycled block concrete segments. The manufacturing method of the recycled block concrete segment is as follows: Firstly, the longitudinal bars and stirrups are bound to form a reinforcement cage, the reinforcement cage is placed in the for...

Embodiment 2

[0060] Such as Figure 9 As shown, for the connection between the cast-in-place structural column 3 and the prefabricated ring beam, it is necessary to pre-embed 4 steel bars extending 200 mm from the side of the structural column at the connection between the structural column and the ring beam before pouring. If the structural column is prefabricated in the factory, it is necessary to pre-embed 4 steel bars with a protruding length of 200mm in the block connecting the structural column and the ring beam during the prefabrication stage. For structural columns that do not pre-embed steel bars in advance, it is necessary to plant reinforcement at the connection between the structural column and the ring beam. Finally, the steel bars protruding from the side of the structural column and the longitudinal bars of the recycled block concrete section are placed on the U-shaped demolition-free formwork section. Inner lashing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com