Linkage production line for rapid clamping, positioning and debugging of paper pulp moulds

A production line, fast technology, applied in the direction of textiles and papermaking, etc., can solve the problems of formwork screws that cannot be locked, complex formwork installation and debugging, waste of cost and time, etc., to improve production and commissioning, and increase installation and commissioning time , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

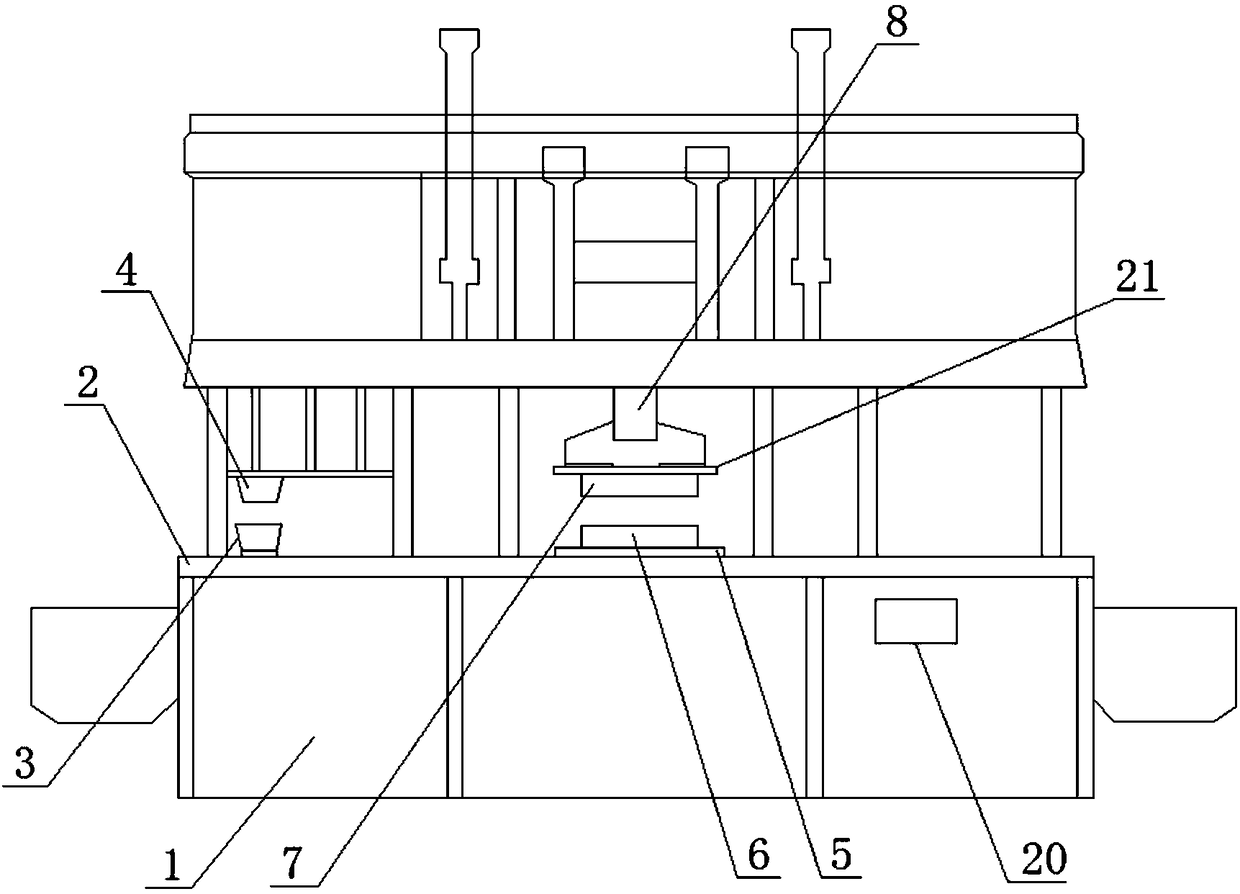

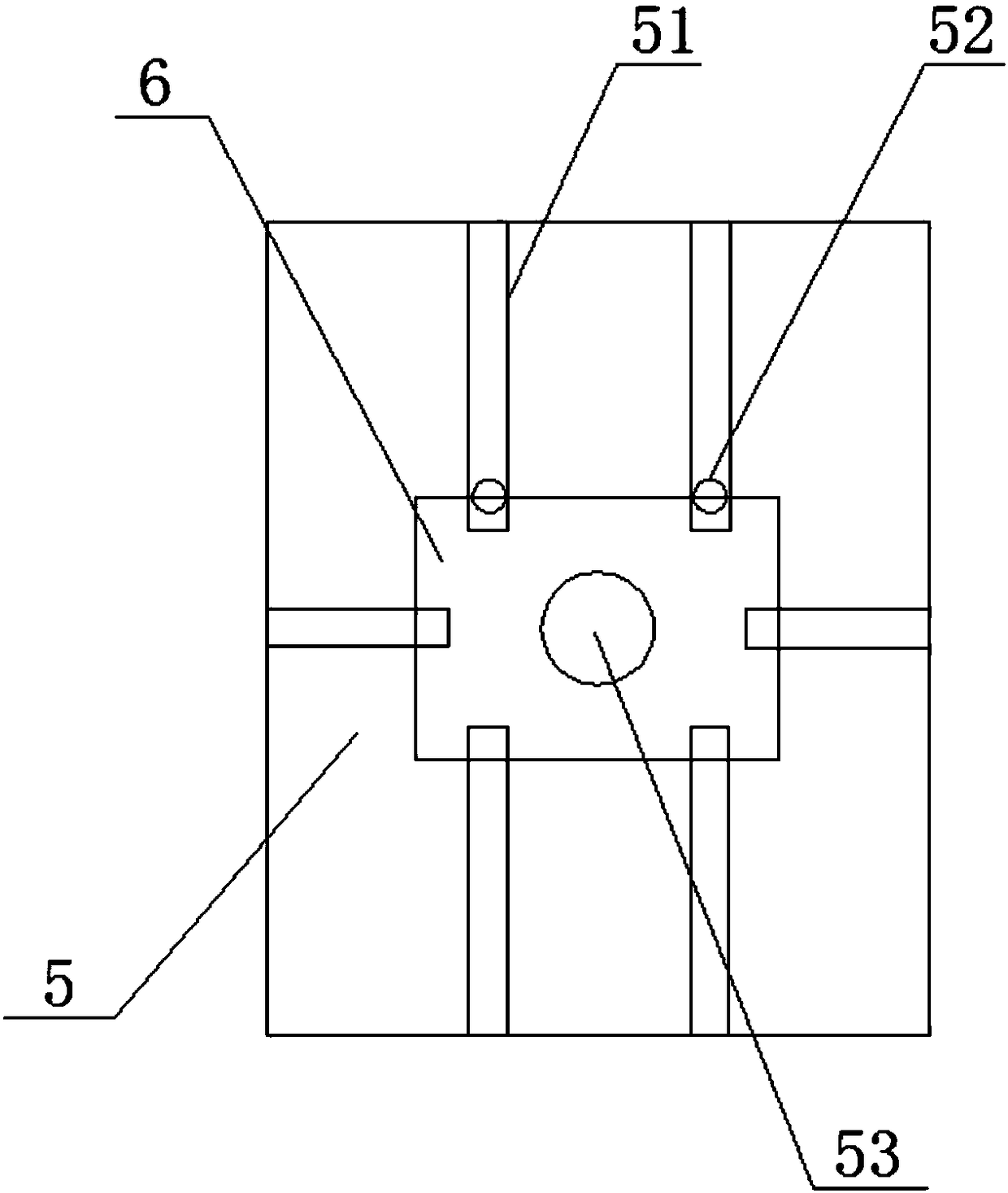

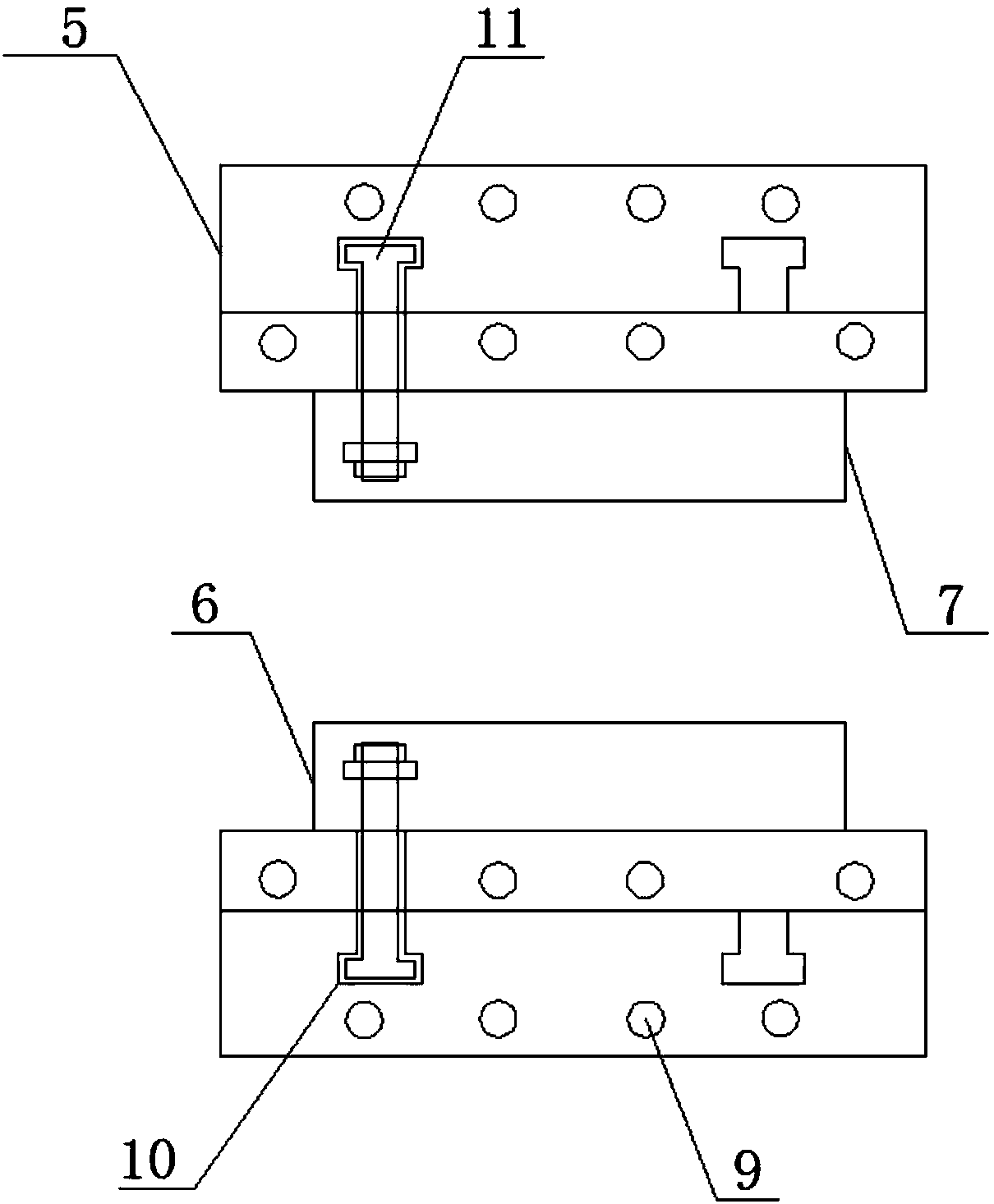

[0028] Embodiment one, such as Figure 1-5A pulp mold rapid clamping, positioning and debugging linkage production line is shown: during installation and positioning, a cylindrical positioning column with a diameter of 24 mm and a height of 80 mm is inserted into the positioning hole 53 on the surface of the backing plate 5, and a cylindrical positioning column with a diameter of 24 mm and a height of 80 mm is inserted. Positioning and after the mold fixture is installed, the positioning column can be taken out for subsequent safe production, and then the hot-pressing lower die 6 and the hot-pressing upper die 7 are respectively docked with the backing plate 5, and the joint pin holes 12 connect the backing plate 5 with the backing plate 5 respectively. After the hot-pressing lower die 6 and the hot-pressing upper die 7 are connected, the fast and accurate clamping and positioning work is realized by locking the quick mold frame screws 11 in the die groove 10. When debugging, s...

Embodiment 2

[0029] Embodiment two: if figure 1 , Image 6 and Figure 7 A pulp mold rapid clamping, positioning and debugging linkage production line shown: when installing and positioning, the pulp suction die 3 is used as the reference, the pulp suction die 3 and the original hot-pressing lower die 18 pairs of gaps, the pulp suction die 3 and the extrusion die 4 pairs of gaps, the original hot-pressing upper die 15 and the original hot-pressing lower die 18 pairs of gaps, the original hot-pressing lower die 18 and the transfer die. After the mold is closed, the upper and lower molds can be locked. After the mold is closed, the installation starts. There are hexagon socket screw holes in the mold to fix the mold fixture. The positions of the screw holes are different, and there is no standard , each time a new mold is tested, its staff first drills the screw holes, and then selects a suitable transition plate. After drilling holes on the transition plate, the next step can be performed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com