Pulley bracket platform with large-column-grid and large-area grid structure and construction method thereof by utilizing pulley bracket method

A grid structure, large-area technology, applied in building construction, construction, building materials processing and other directions, can solve problems such as grid deformation, and achieve the effects of easy error control, convenient feeding, stacking and evacuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

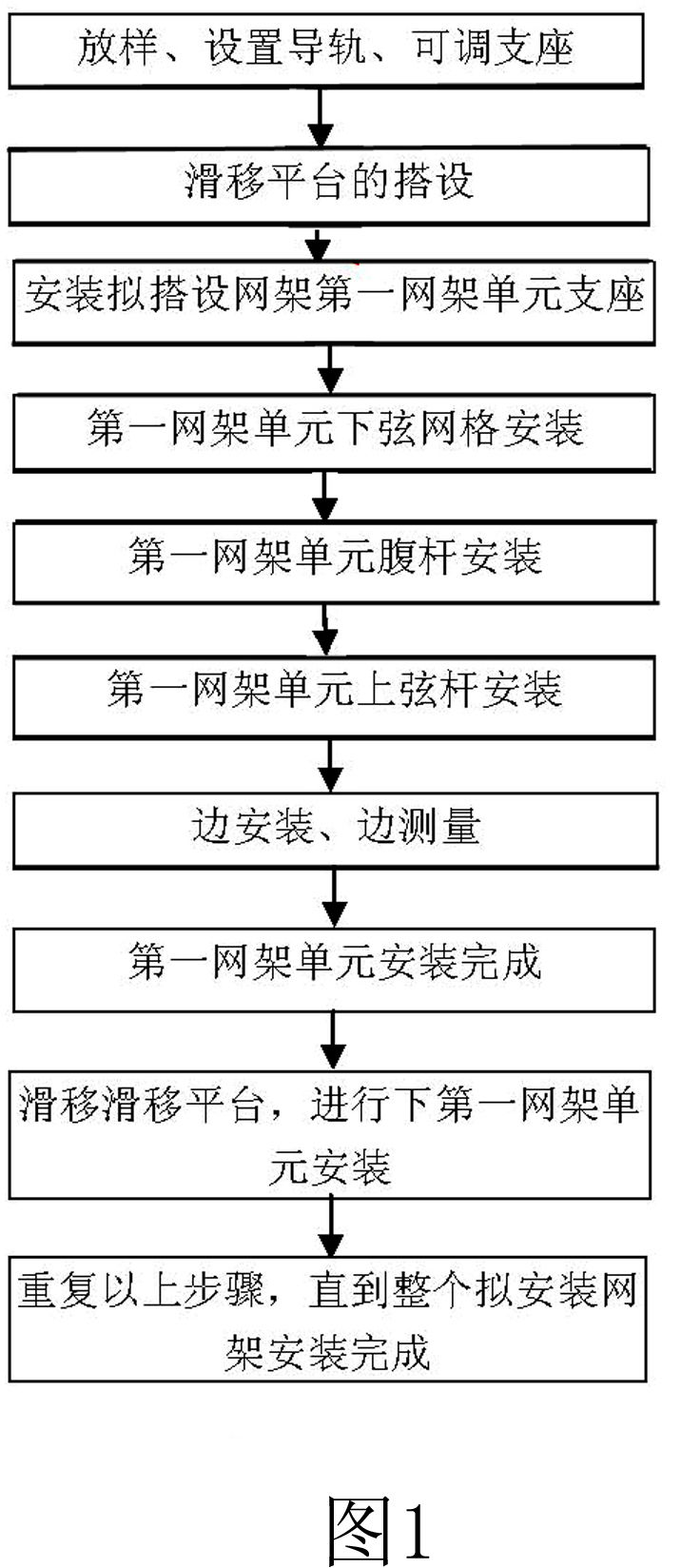

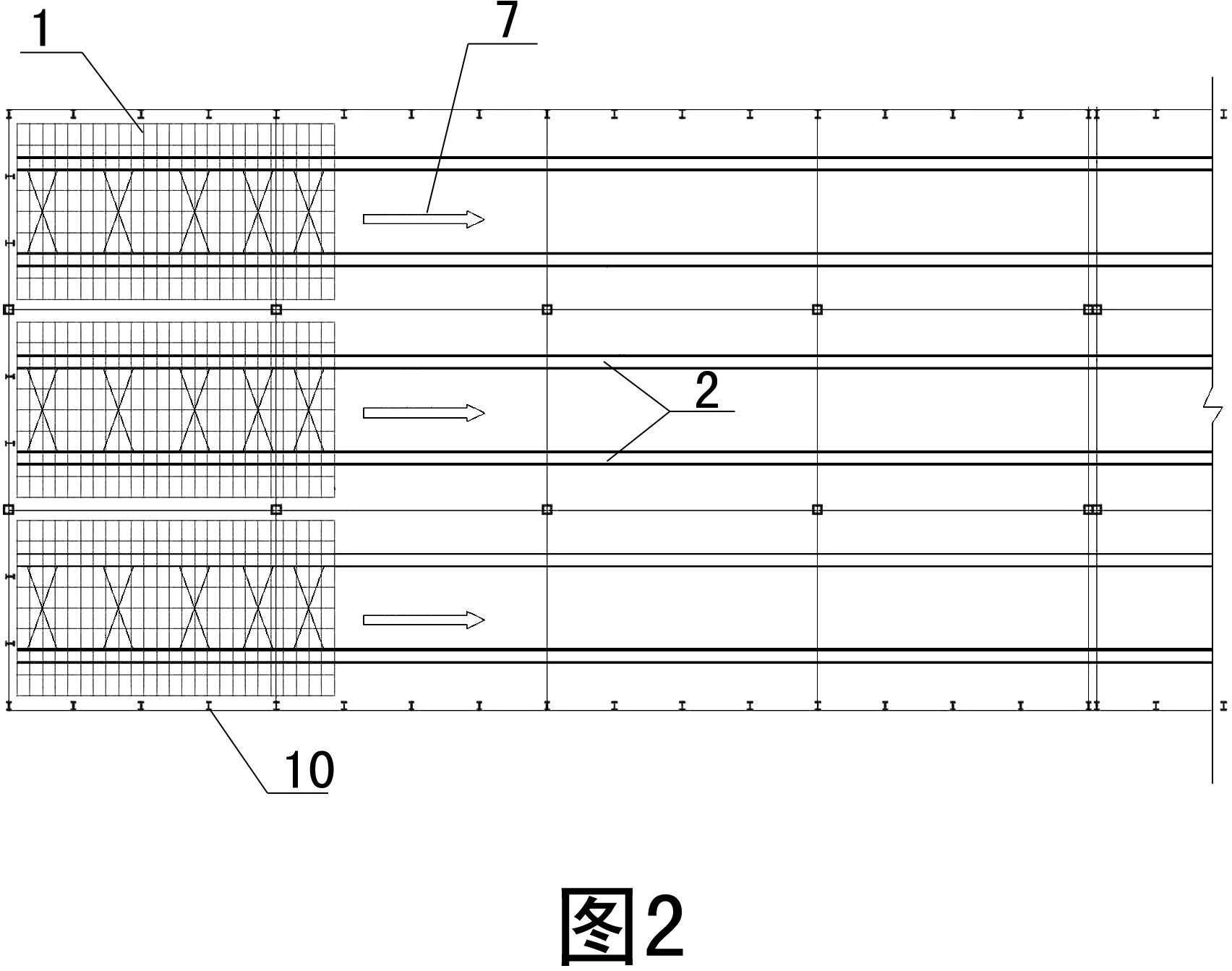

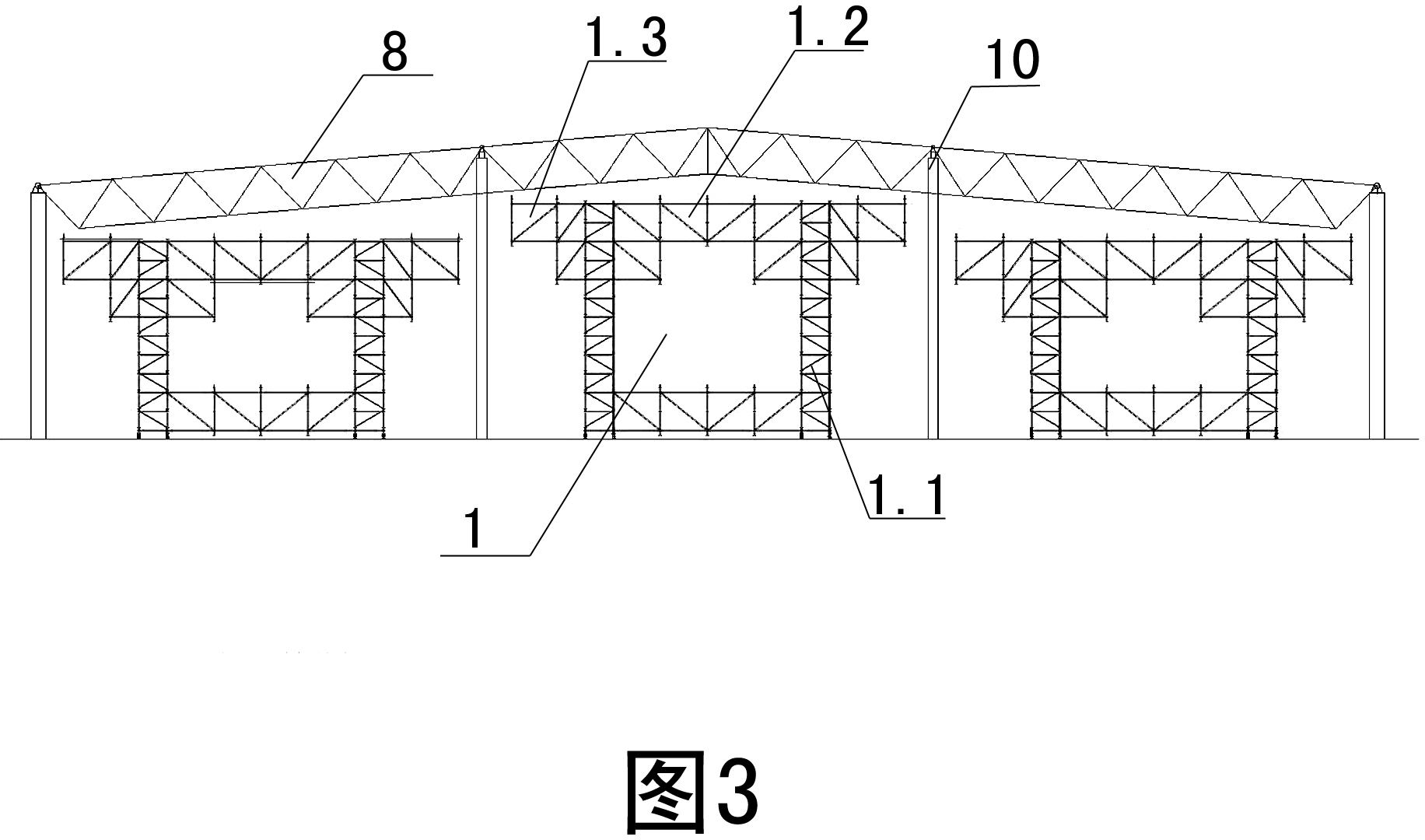

[0041] Examples see Figure 2 to Figure 9 As shown, a large-area grid structure sliding frame platform with a large column network includes a frame body for sliding a space steel truss structure between two columns of columns 10 and composed of steel pipes, and the frame body It is composed of a tower 1.1, a suspension frame 1.2 and a suspension frame 1.3. The tower frame 1.1 has at least two rows, and the two longitudinal towers are connected by a horizontal frame 12. The bottom and top of the two horizontal towers are connected with the suspension frame. 1.2 Connection, the outer top of the tower is connected to the cantilever frame 1.3, the steel pipe 4 at the bottom of the tower is set on the pulley 5, its axis coincides with the pulley axis 6, the pulley 5 is placed on the guide rail 2, and the guide rail 2 is laid with The sleeper 3 is fixed by spot welding.

[0042] The tower is a space vertical cantilever steel truss structure composed of steel pipes, the suspension s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com