Reverse building board construction structure and construction method thereof

It is a construction method and reverse method technology, which is applied in basic structure engineering, excavation, construction, etc. It can solve the problems that cannot meet the requirements of reverse slab structure, beam and slab structure requirements, and the bending method cannot meet the construction conditions, etc., and achieve significant economic results. , reduce the erection time, and improve the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

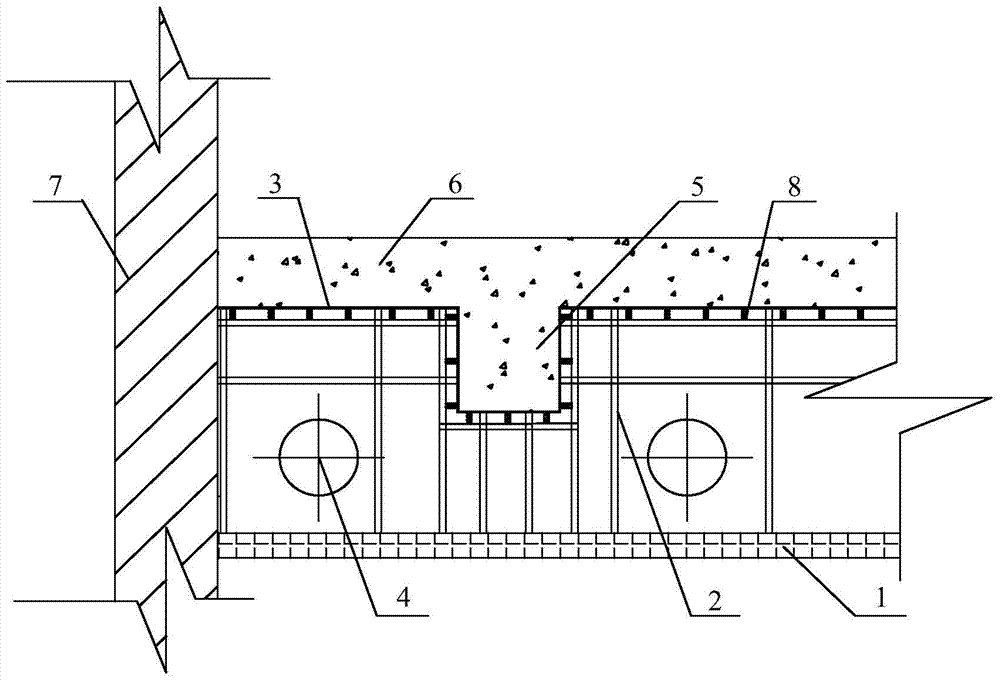

[0030] see figure 1 , the present embodiment discloses a construction structure of an upside-down slab, which is used to realize the construction of an upside-down slab 6 in the upside-down method or the semi-upside down method, including temporary steel supports 4 and cushion layers 1, The short bent frame 2 and the template 3, the temporary steel support 4 is spaced through the short bent frame 2 along the horizontal direction, and the two ends of the temporary steel support 4 are respectively connected with the vertical structure of the foundation pit, such as The underground diaphragm wall 7 is fixedly connected, and the foundation pit is excavated to the elevation X, which satisfies X=Y-r-d, where Y is the elevation of the bottom of the counterwork slab 6, r is the sum of the heights of the short bent frame 2 and the formwork 3, and d is the pad Layer 1 thickness. In this embodiment, the temporary steel support 4 can be used to effectively control the deformation of the ...

Embodiment 2

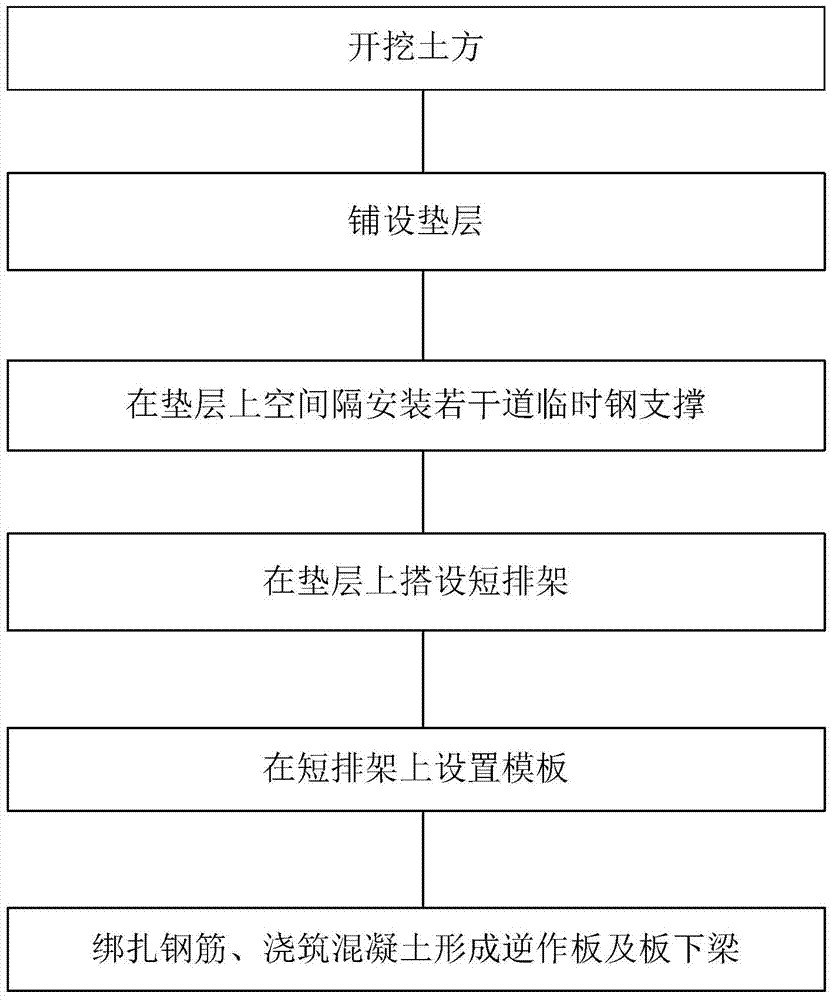

[0036] Accordingly, see figure 2 , and please combine figure 1 , the present embodiment discloses a construction method for reversed slabs, comprising the following steps:

[0037] The first step is to excavate to the elevation X, X=Y-r-d, wherein, Y is the elevation of the bottom of the reverse slab 6, r is the sum of the heights of the short bent frame 2 and the formwork 3, and d is the thickness of the cushion layer 1;

[0038] The second step is to lay the cushion 1. Preferably, the thickness range of the cushion layer 1 is 80-120mm, and the cushion layer 1 is poured from C25 plain concrete.

[0039] The third step is to use the cushion layer 1 as the supporting surface of the short bent frame 2, and install several temporary steel supports 4 at intervals on the cushion layer 1. In this embodiment, the temporary steel support 4 can be set at a height of 600-1000 mm above the cushion layer 1, specifically, the temporary steel support 4 is set at a height of 800 mm above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com