Method for turning complex thin-wall part profile by adopting quasi-symmetric layered circulation

A thin-walled parts, symmetrical technology, applied in the field of deformation control of complex thin-walled parts using quasi-symmetric layered cycle turning, can solve problems affecting product quality, collapse deformation, etc., to avoid repeated alignment errors and control processing Deformation, deformation control effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Example: The processing of a thin-walled 1-2 mm weakly rigid "rim" part of a disc.

[0038] See attached Figure 1~5 , carry out processing according to the following steps:

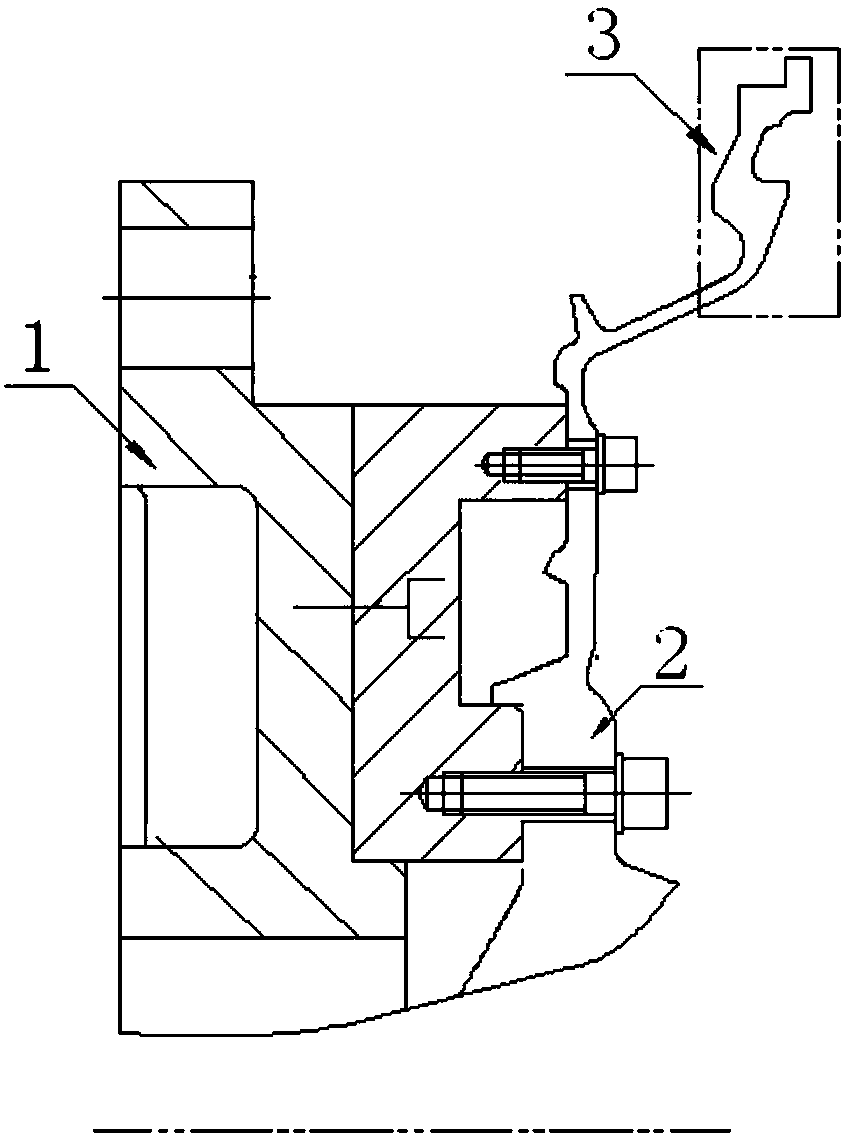

[0039] Step 1: Local unconstrained clamping of parts. Such as figure 1 , clamp the revolving part 2 with the fixture 1 once on the horizontal lathe, and place the thin-walled "rim" part 3 of the revolving part 2 in an unconstrained free state. Avoid plastic deformation due to the influence of other limiting factors when the profiles at both ends of the part are processed in the same process.

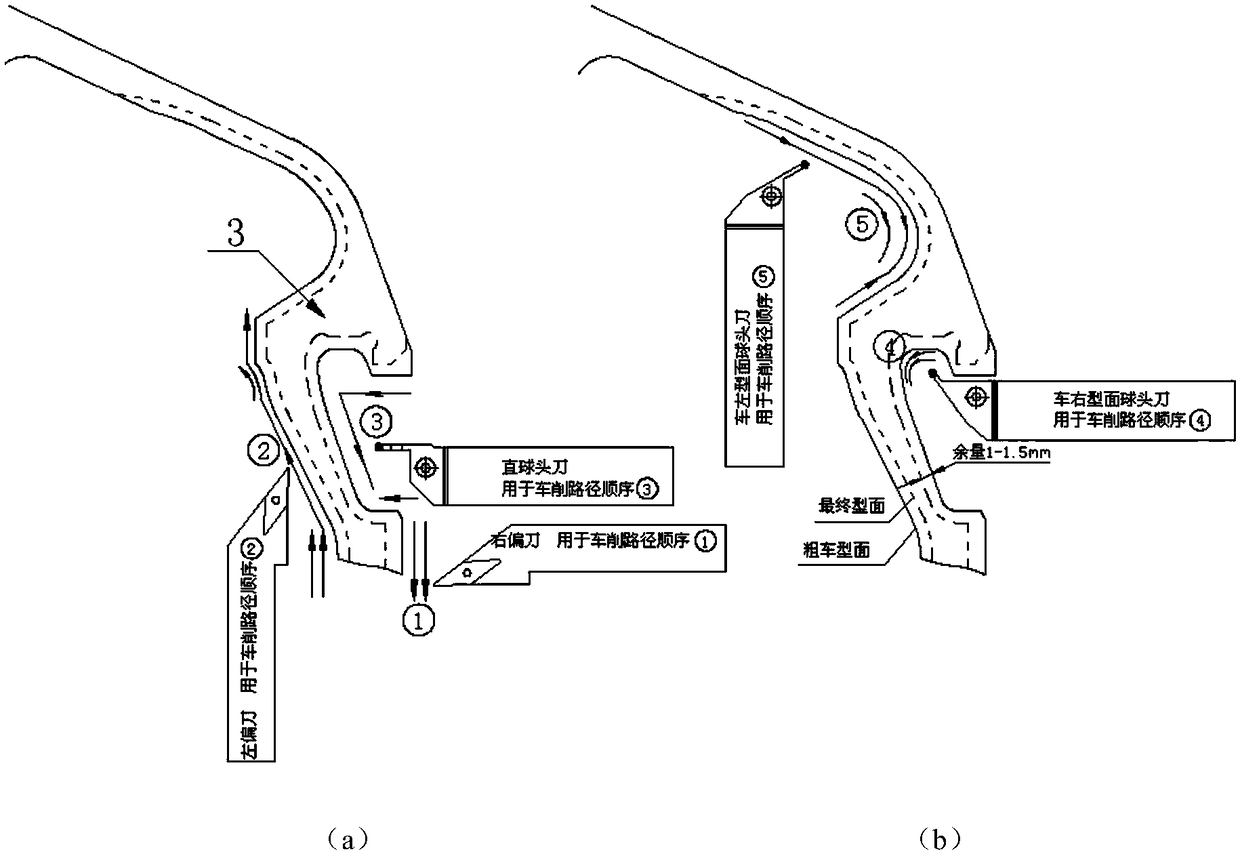

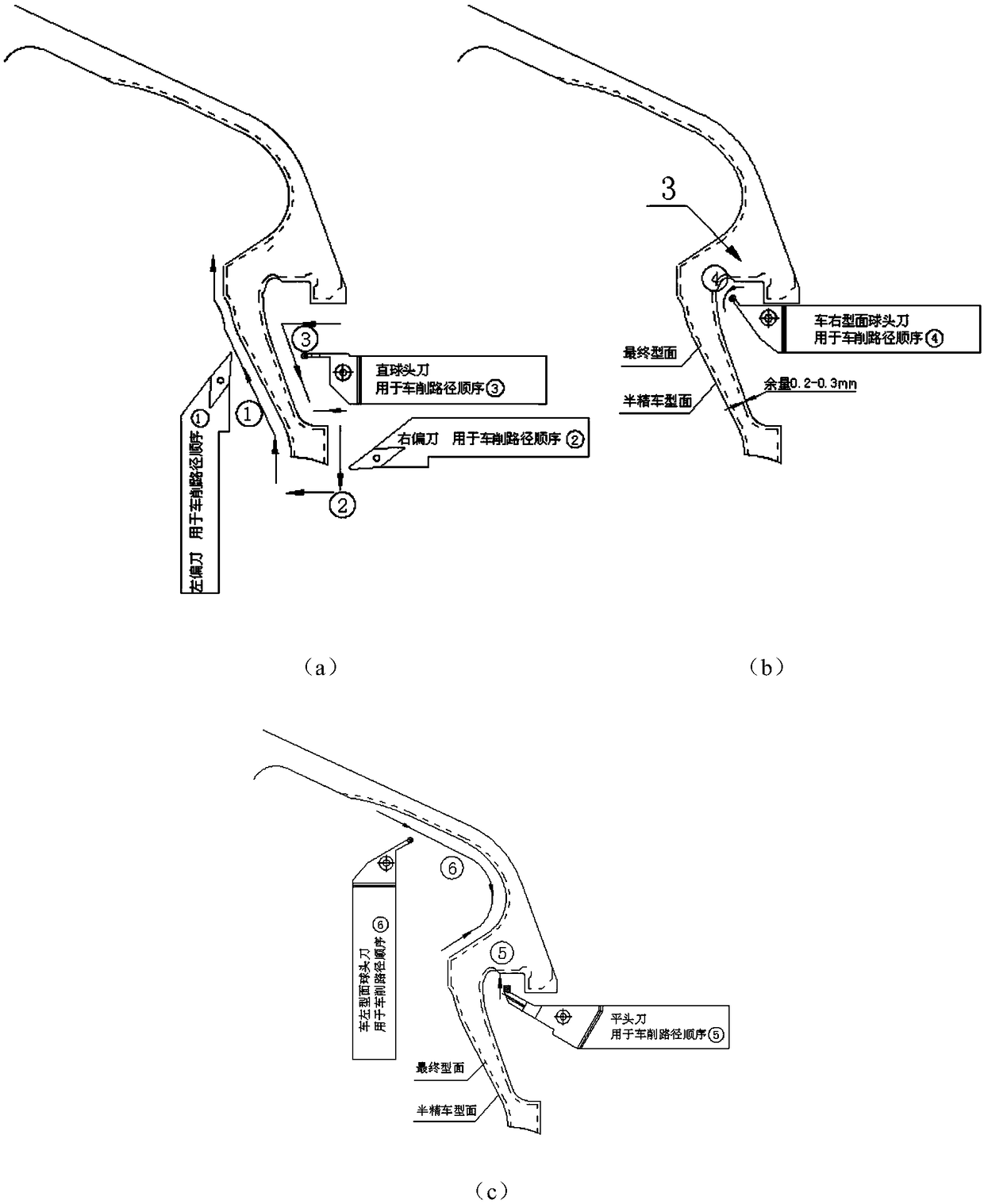

[0040] Step 2: single-process layered cycle rough turning. Such as figure 2 , according to the sequence of turning paths marked in ①~⑤ and the corresponding tool type used, quasi-symmetrical rough turning of the profile at both ends of the "rim" part 3, leaving a margin of 1 to 1.5 mm to achieve rough removal of excess profiles at both ends The purpose of measuring and trimming the amount of deformati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com