Cooling device generating flat jet and manufacturing method thereof

A cooling device, flat technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., to achieve rapid and uniform cooling, ensure uniformity, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

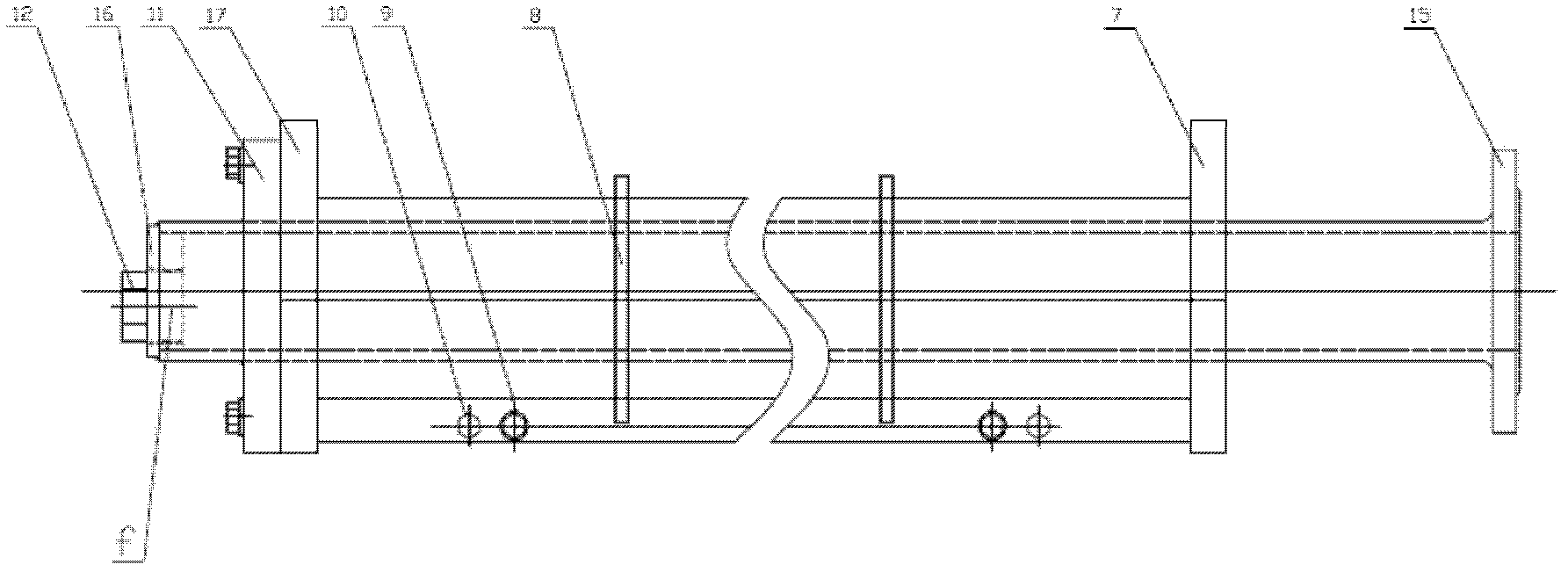

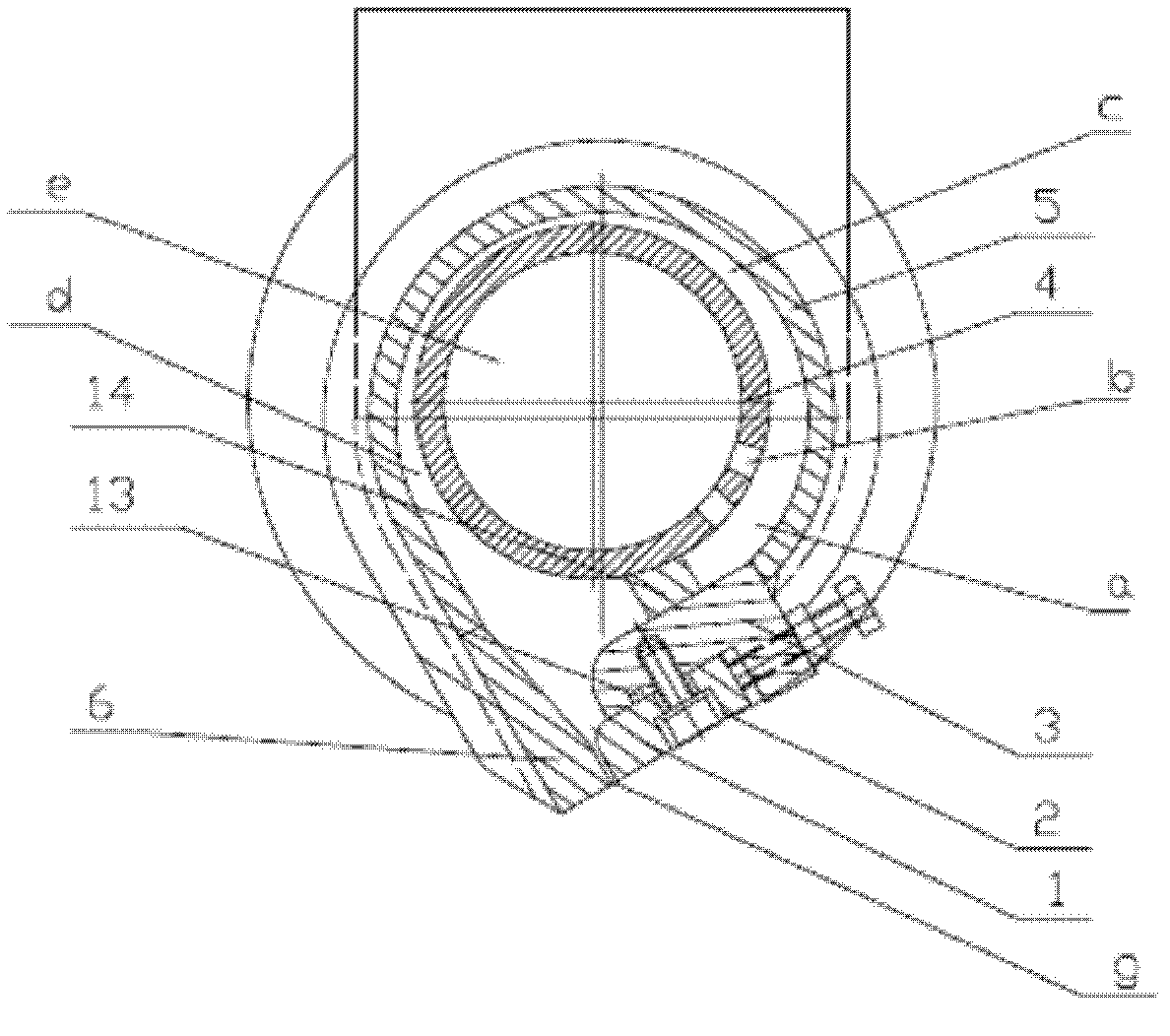

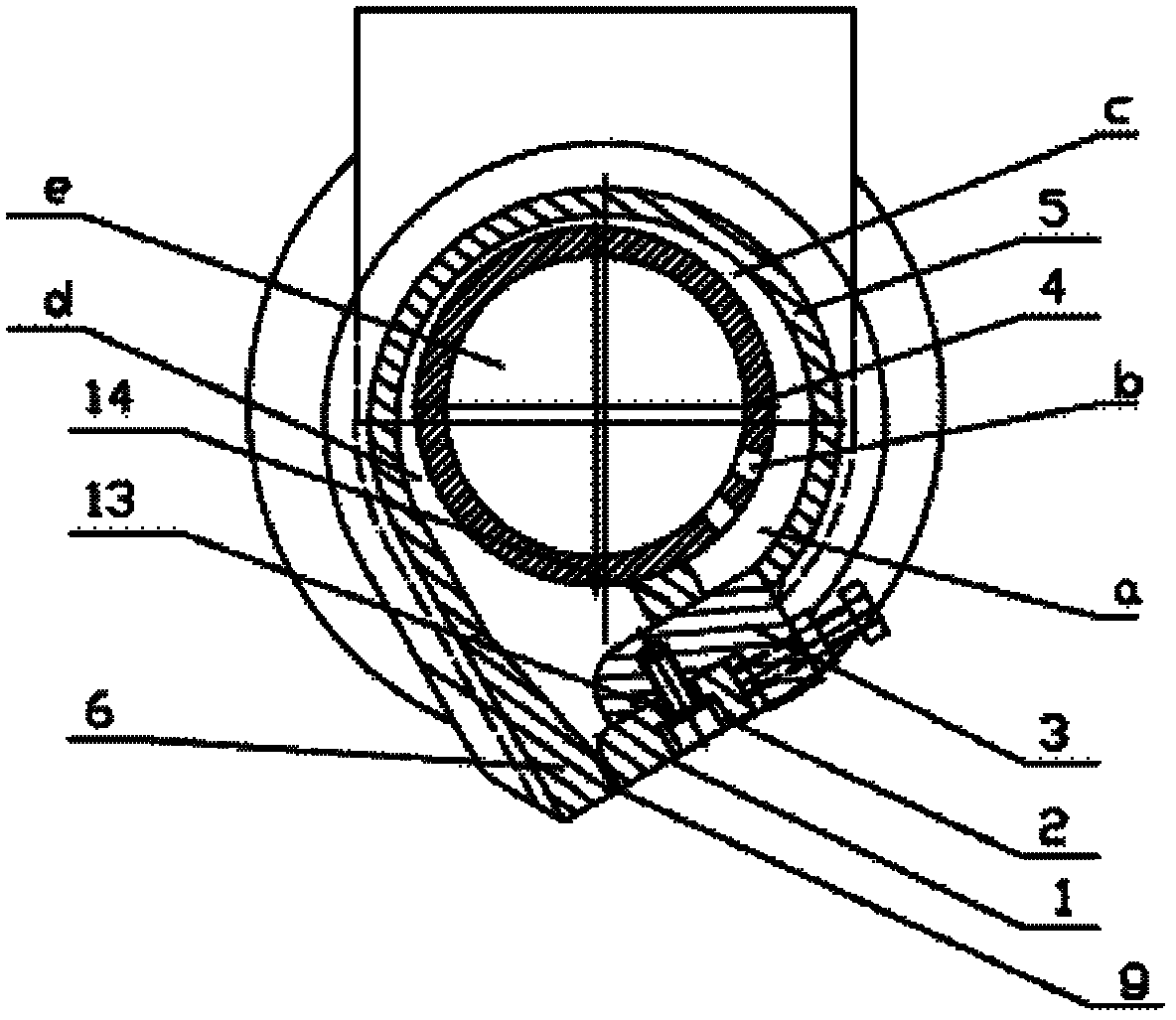

[0015] In the device for producing flat jets of the present invention, the C-shaped pipe 5, the first strip 3 and the second strip 6 are welded into an outer tube with a slit by welding technology. An inner tube 4 with two rows of neat flow holes and the outer tube are eccentrically fixed by positioning strips 14 to form a cavity between the inner and outer tubes, and the cavity is divided into cavity one a, the minimum distance point c, and cavity two d three parts. The flange 15 at the inlet end of the inner pipe is connected to the cooling medium pipeline, and the outlet end of the inner pipe is welded and sealed with a steel plate 16, and a sewage outlet f is set, and the inner cavity e is discharged by opening the screw plug 12. The inlet end of the cavity between the inner and outer tubes is welded and sealed by the end plate 17, and the outlet end is sealed by the end plate 2 17 and the flange 11, and the cavity between the inner and outer tubes can be discharged by ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com