Patents

Literature

144results about How to "Convenient processing work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

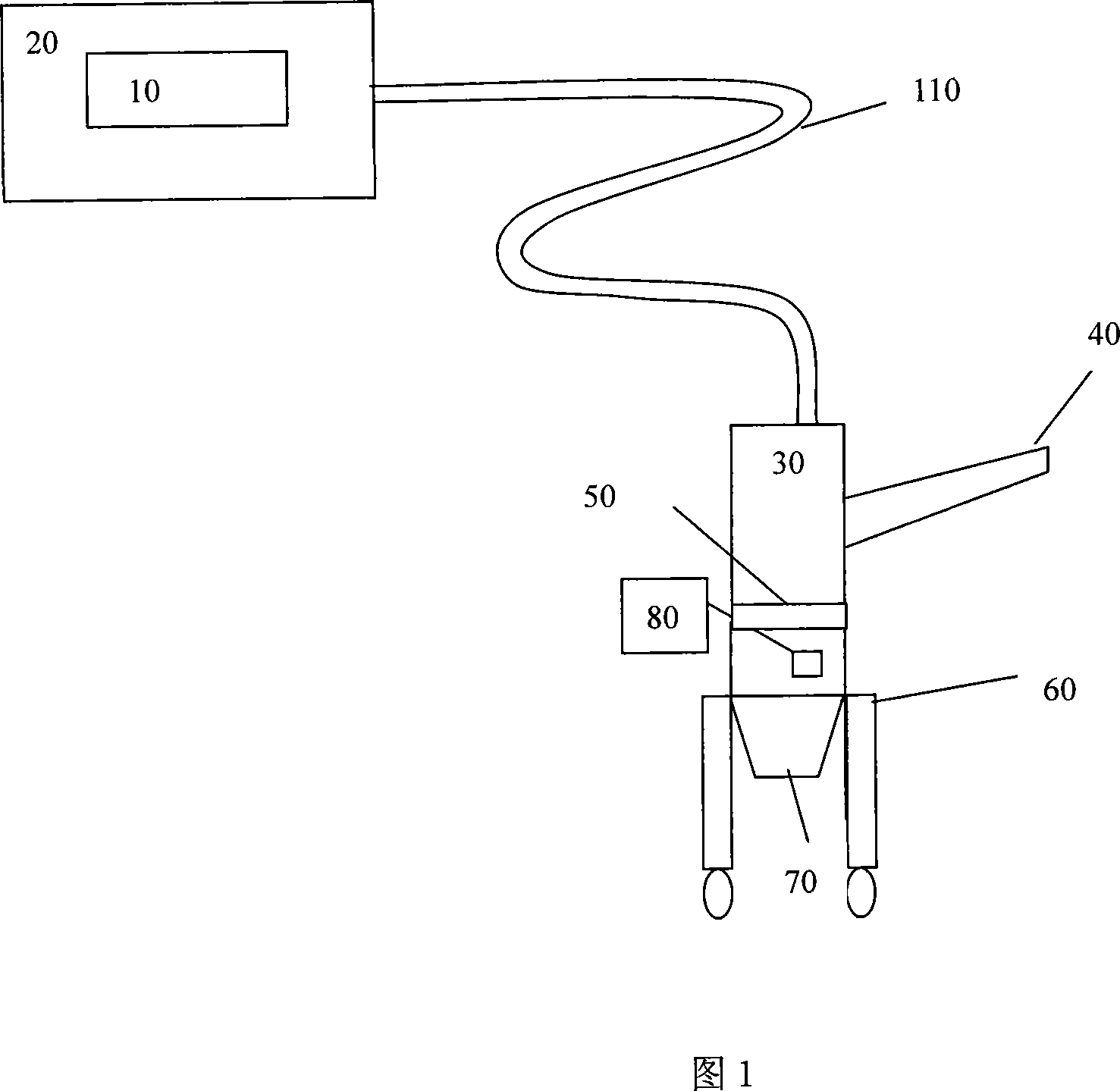

Hand-hold laser processing spear system

InactiveCN101176949ASimple structureReduce volumeLaser beam welding apparatusLaser processingLaser Nozzle

The invention discloses a hand-held laser processing gun system, comprising a fiber laser (10), a control system (20), a body of a laser gun (30), a focusing system (50), a laser nozzle (70), a focus-controlling and rotating wheel for the processing gun (60), and an optical fiber. The invention is characterized in that: the fiber laser (10) is connected with the control system (20); the laser is also connected with a laser head integrated in the body of the laser gun (30) through the optical fiber; the focus-controlling and rotating wheel (60) is fixed at the bottom of the body for the laser gun; laser beam from the laser (10) is output by the laser head, and focuses and works on a workpiece through the focusing system (50) and the laser nozzle (70). The invention has the advantages of convenience in portability due to compact size, light weight and good light speed quality of the fiber laser and the characteristics of hand-held laser processing gun, and avoidance of inconvenient manufacturing due to the position, cost and other reasons in the past.

Owner:BEIJING UNIV OF TECH

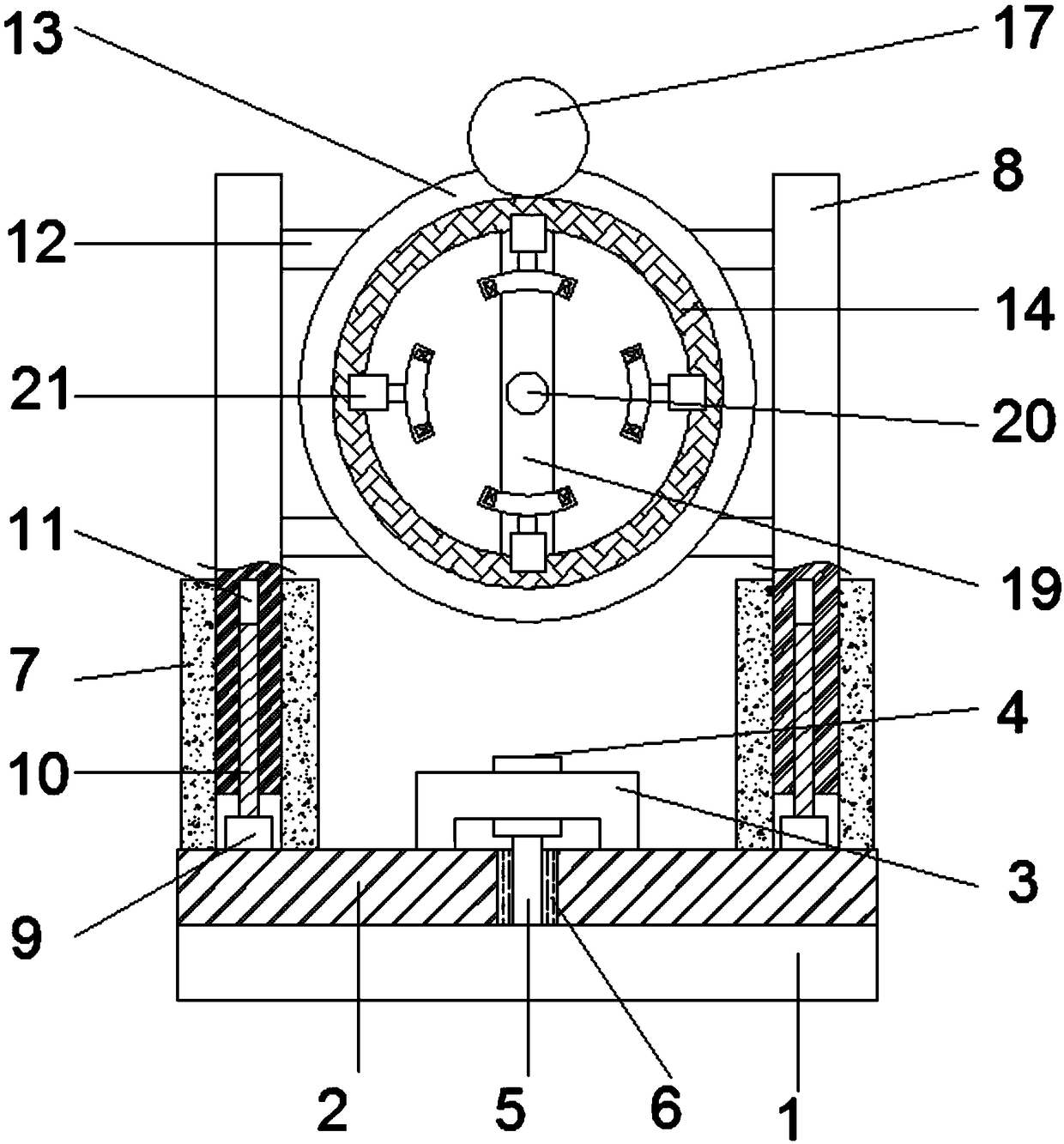

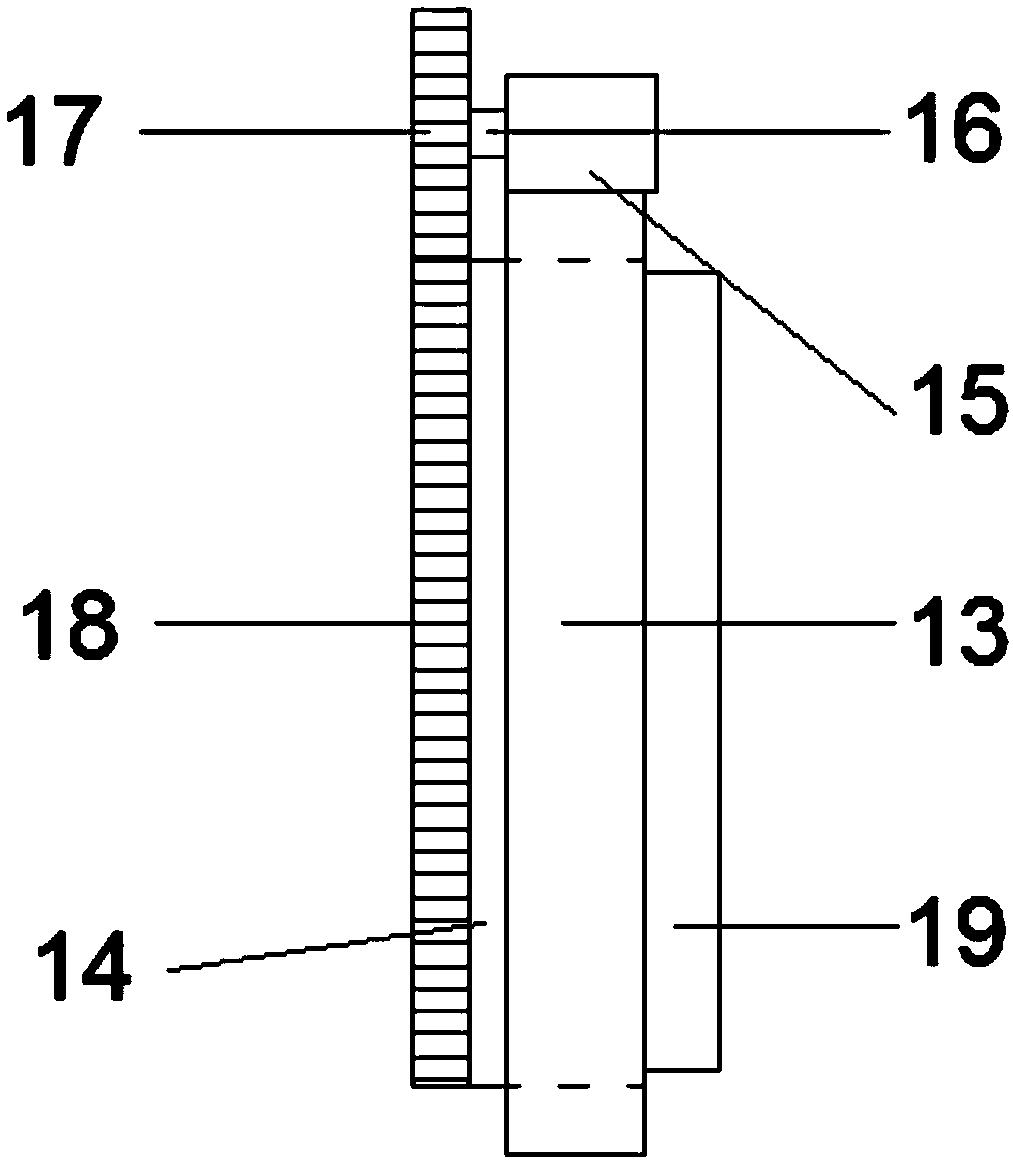

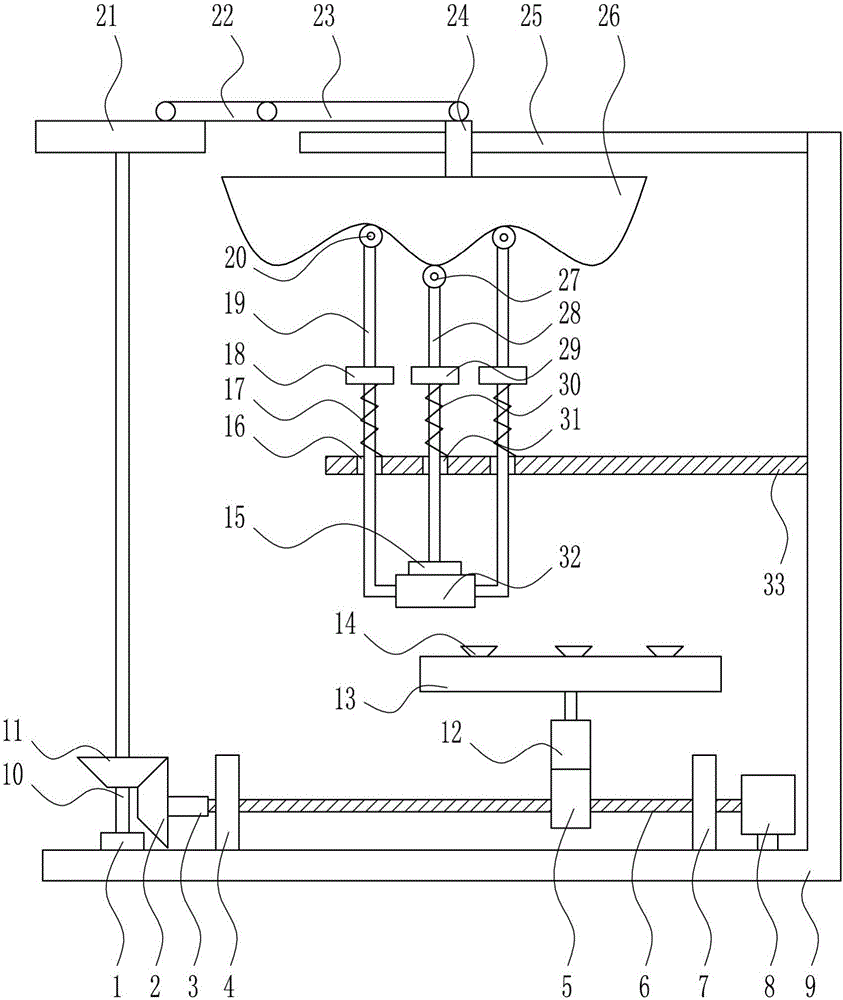

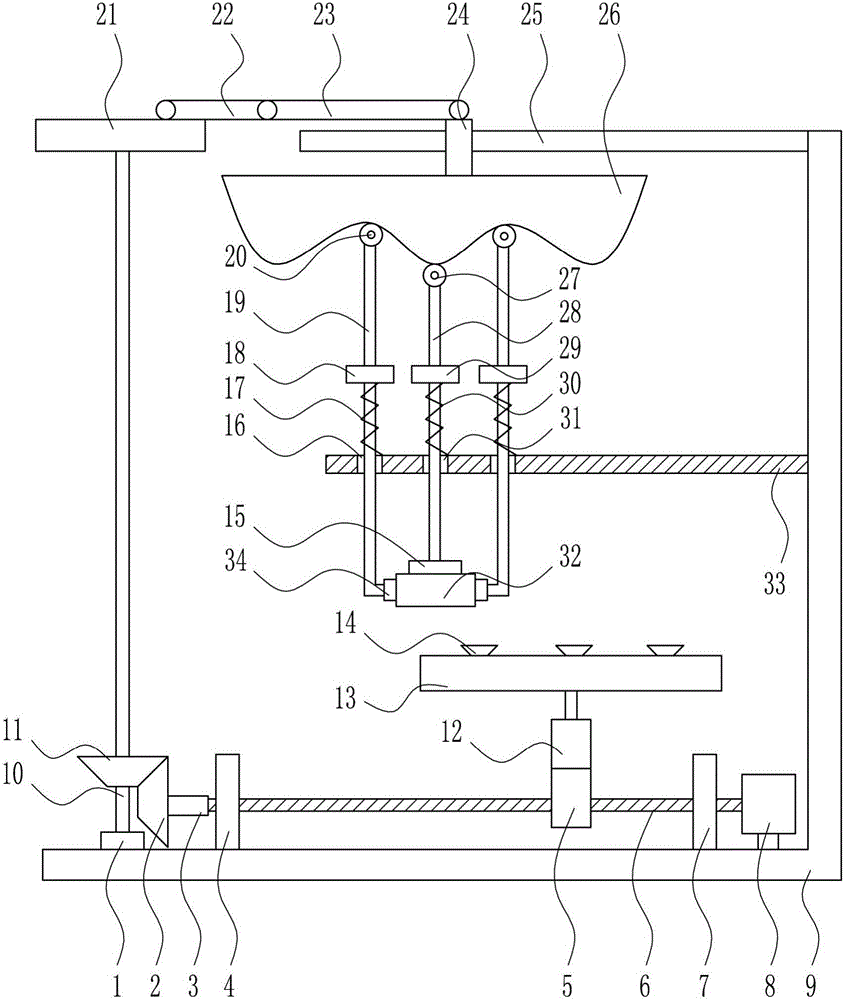

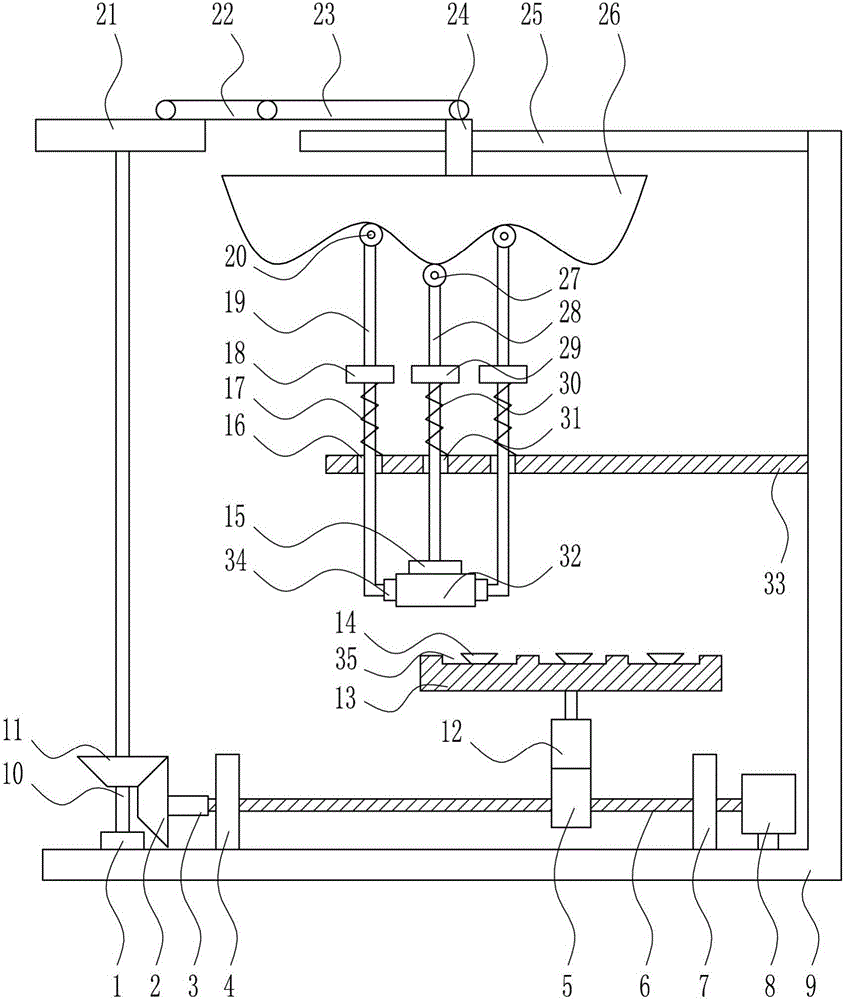

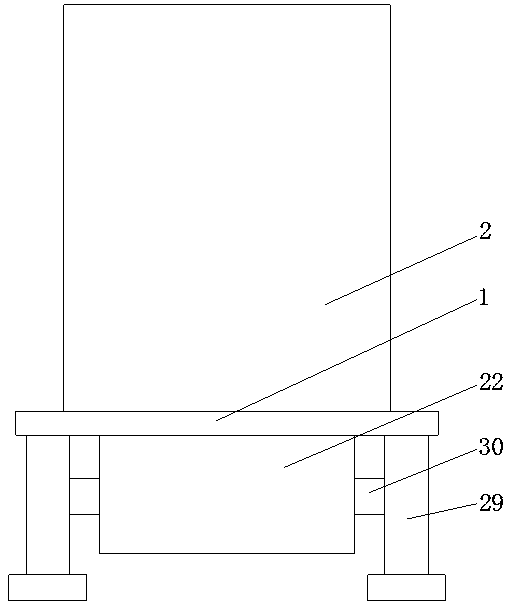

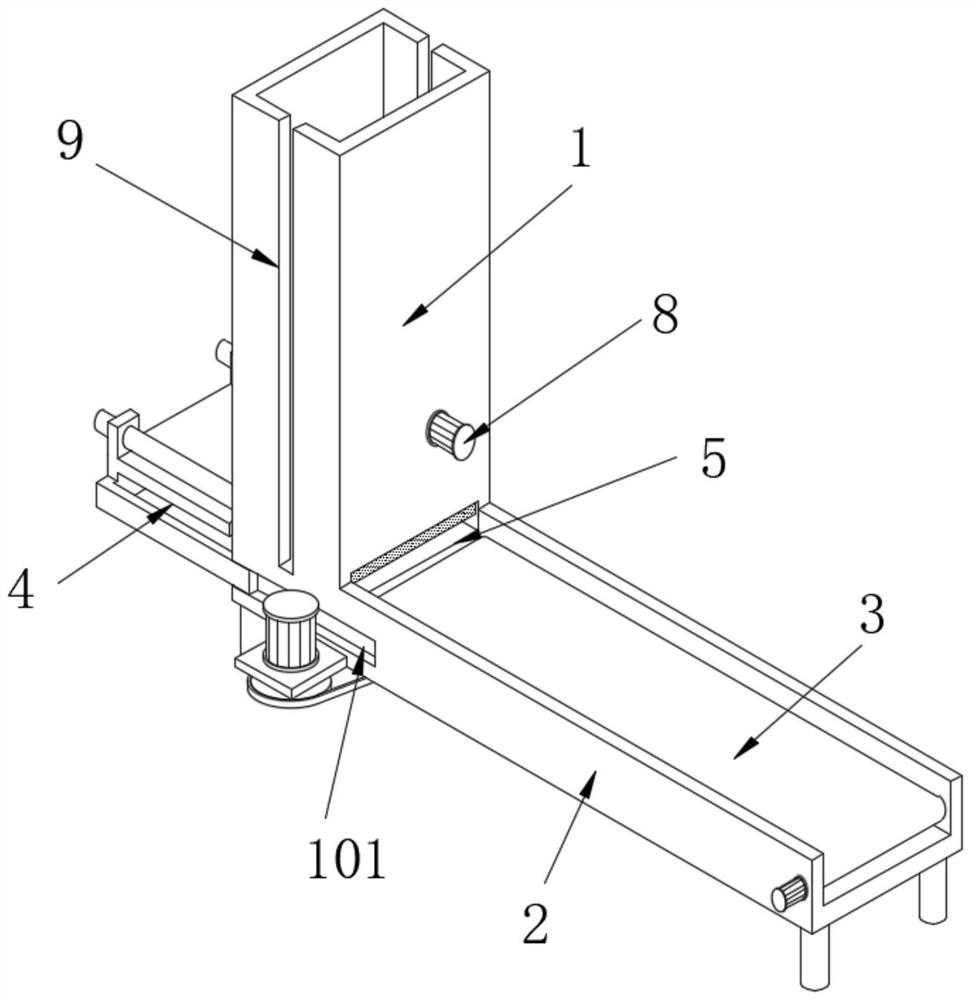

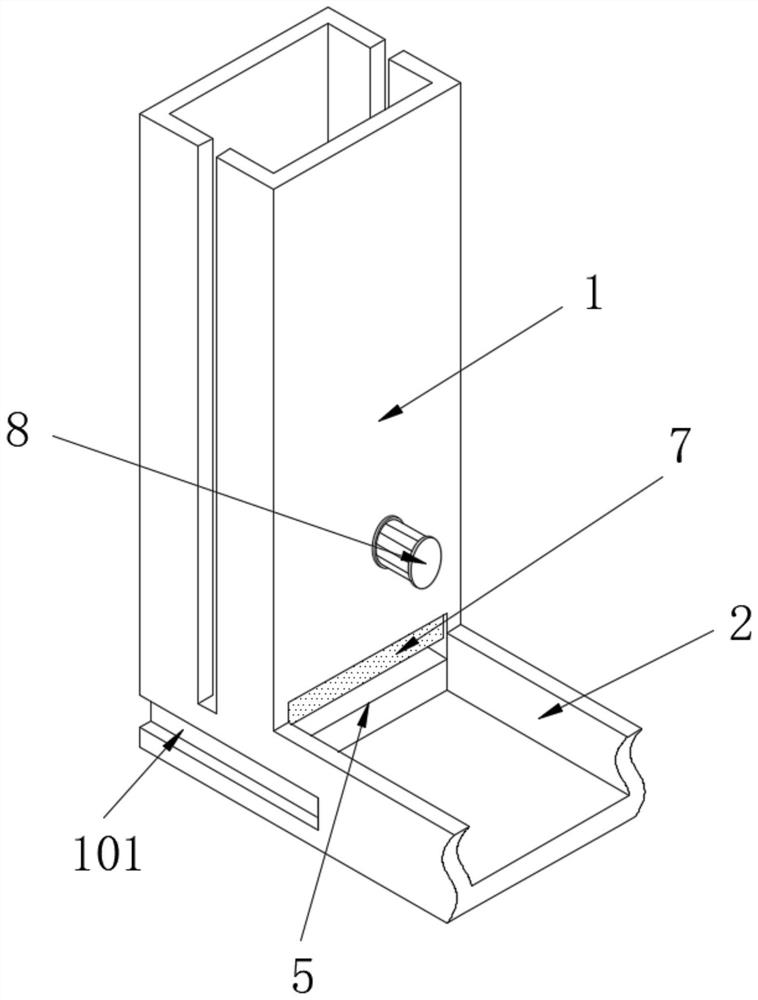

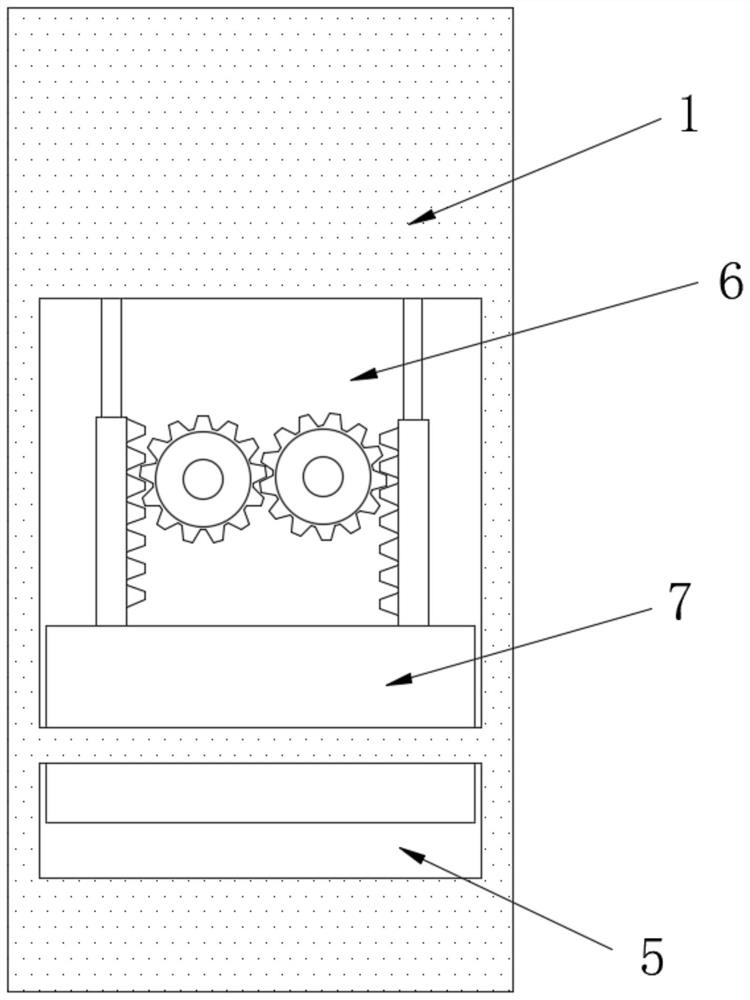

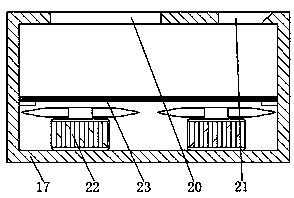

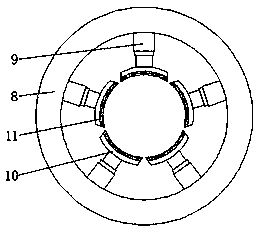

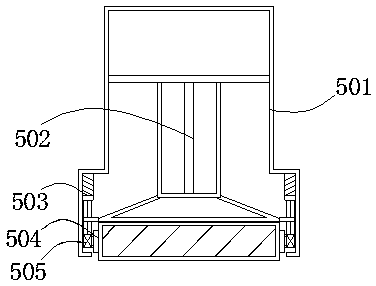

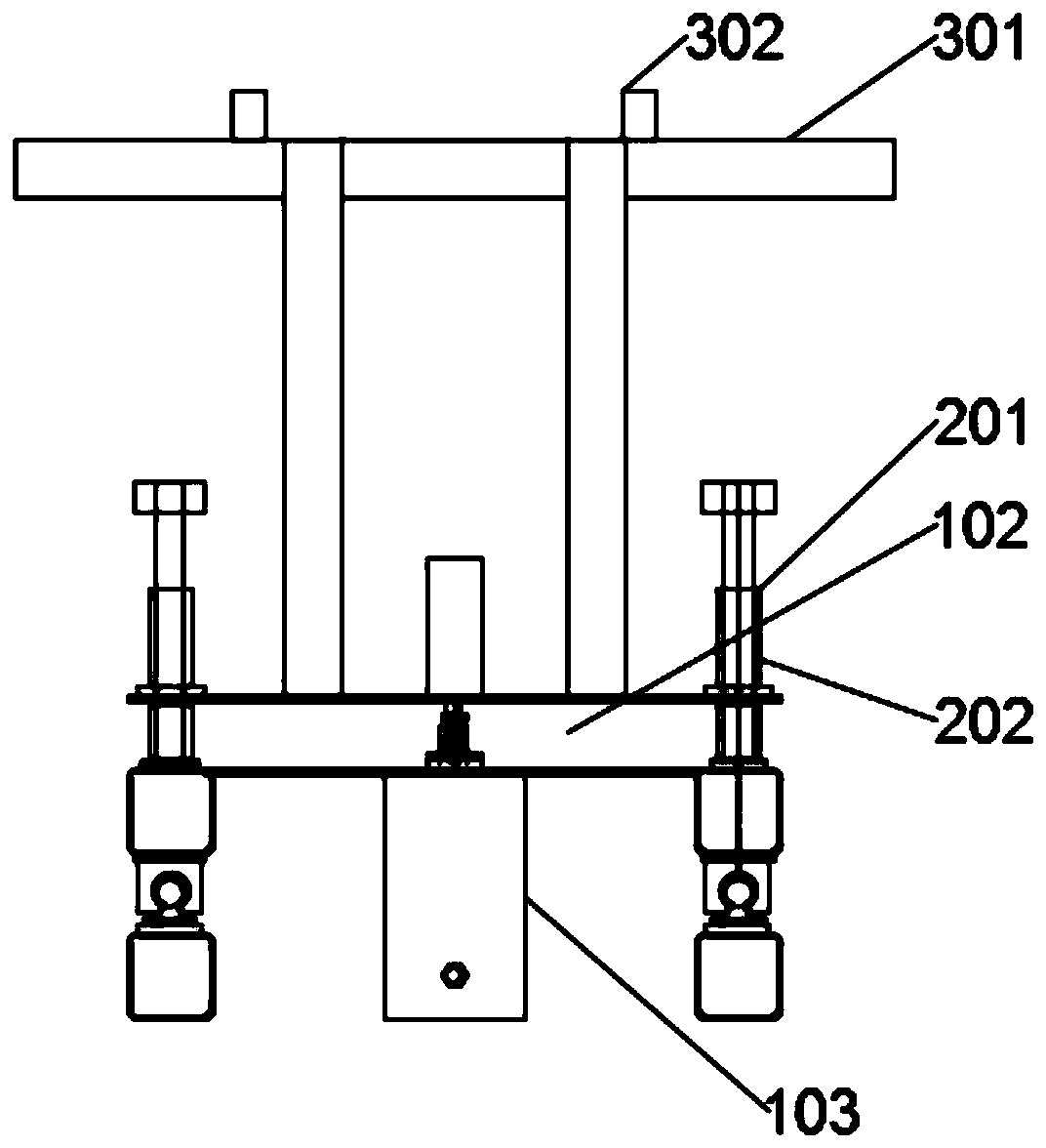

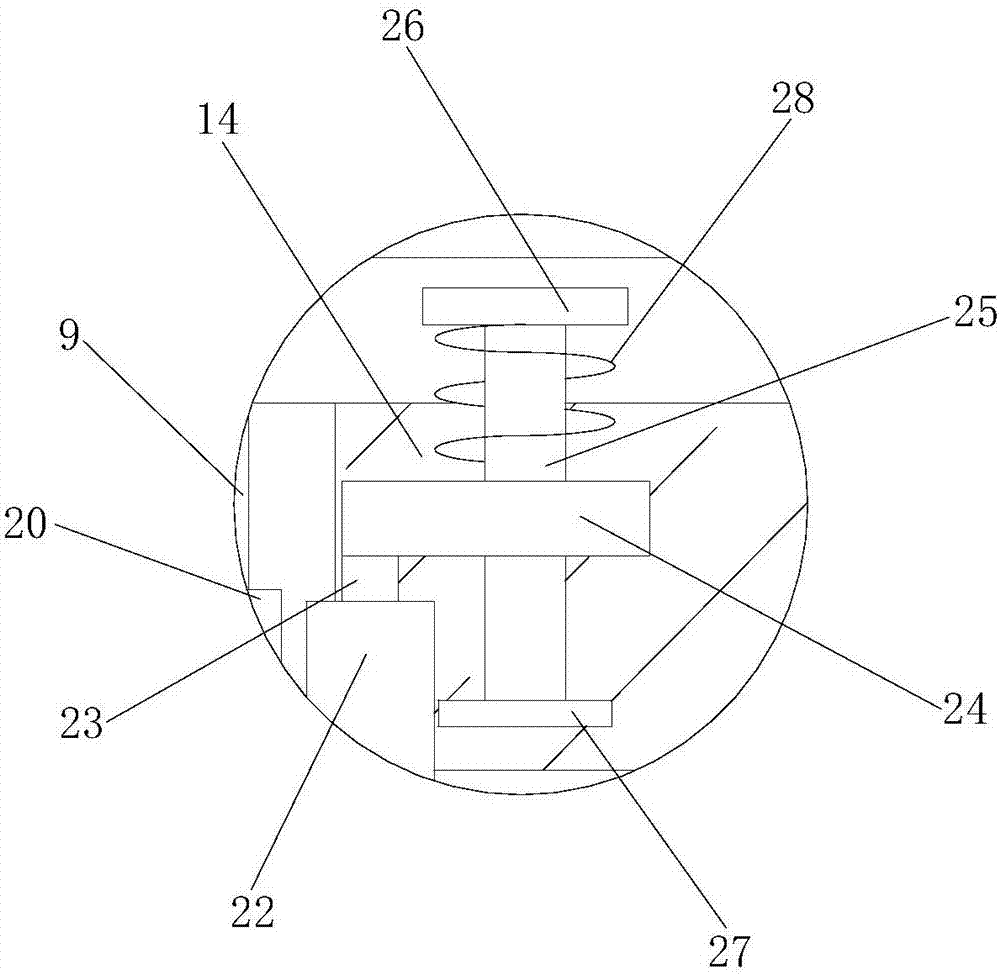

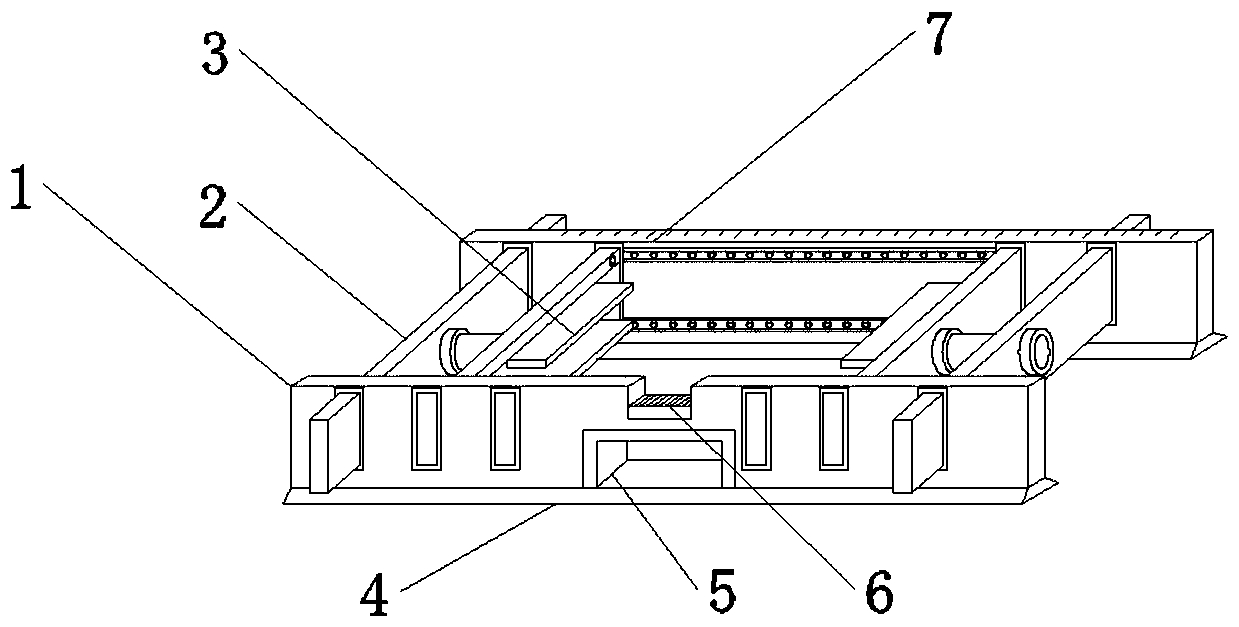

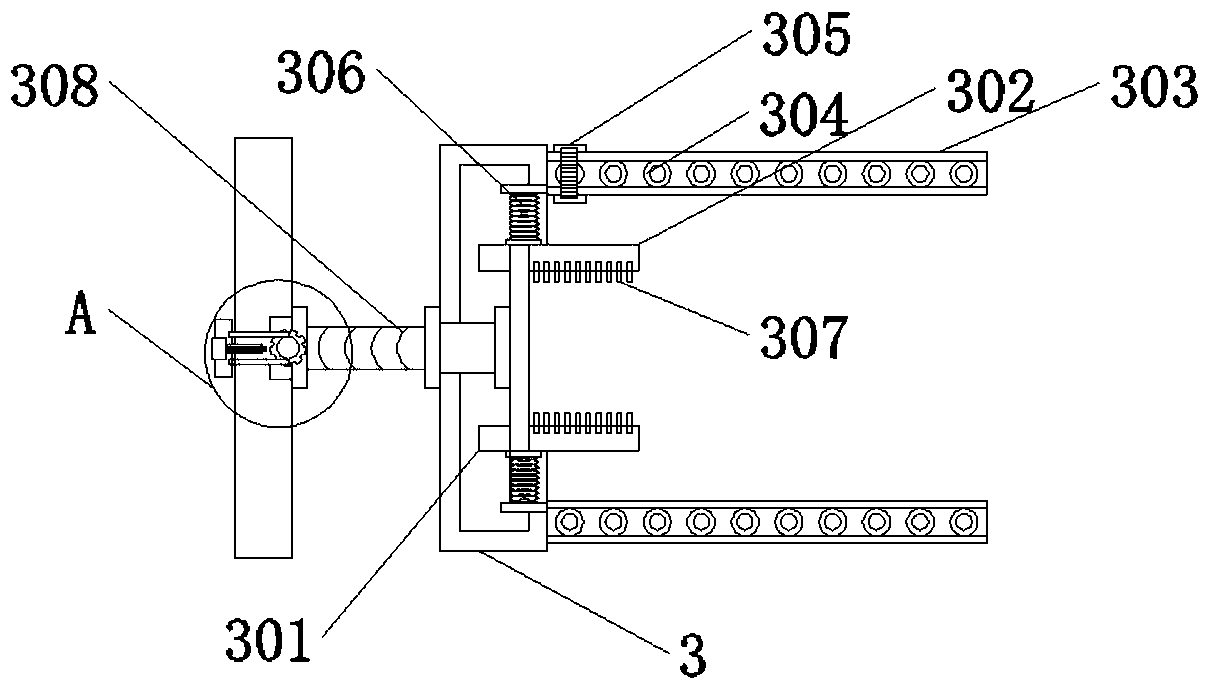

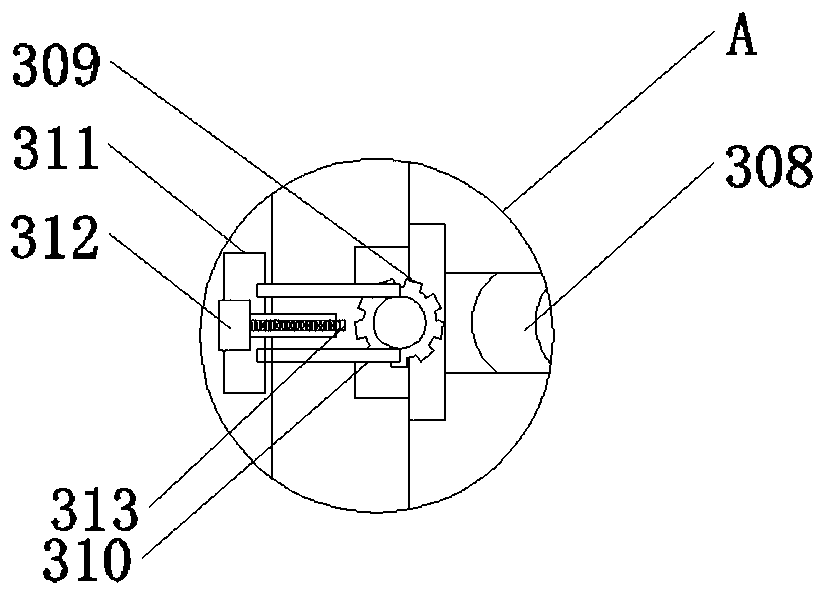

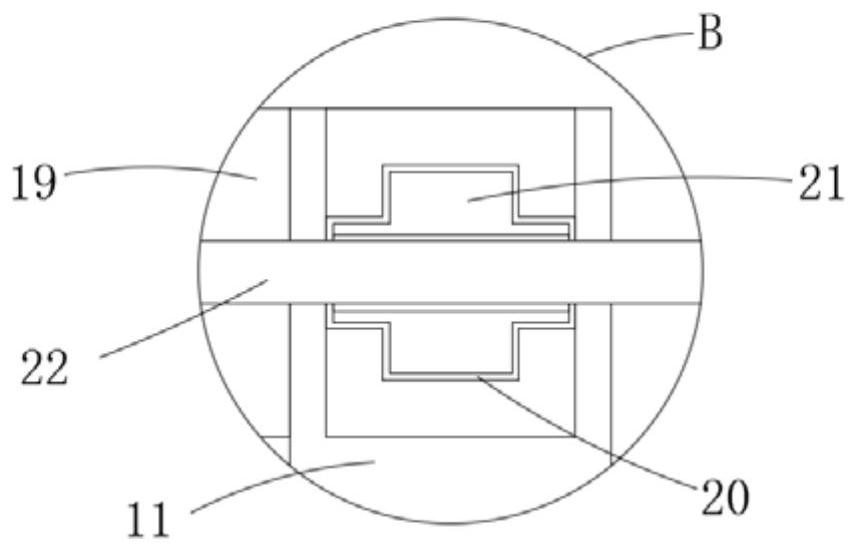

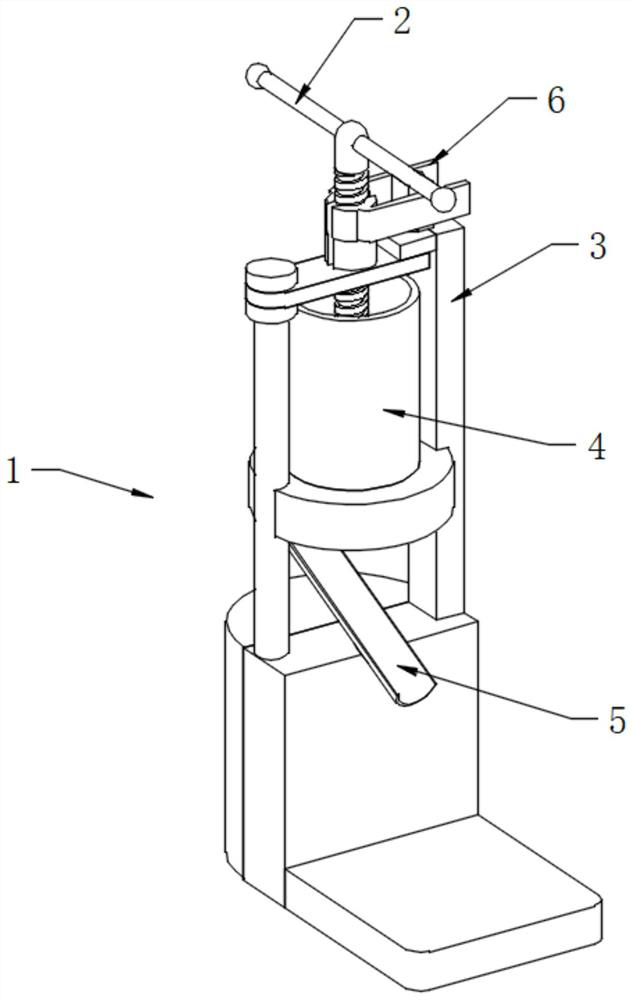

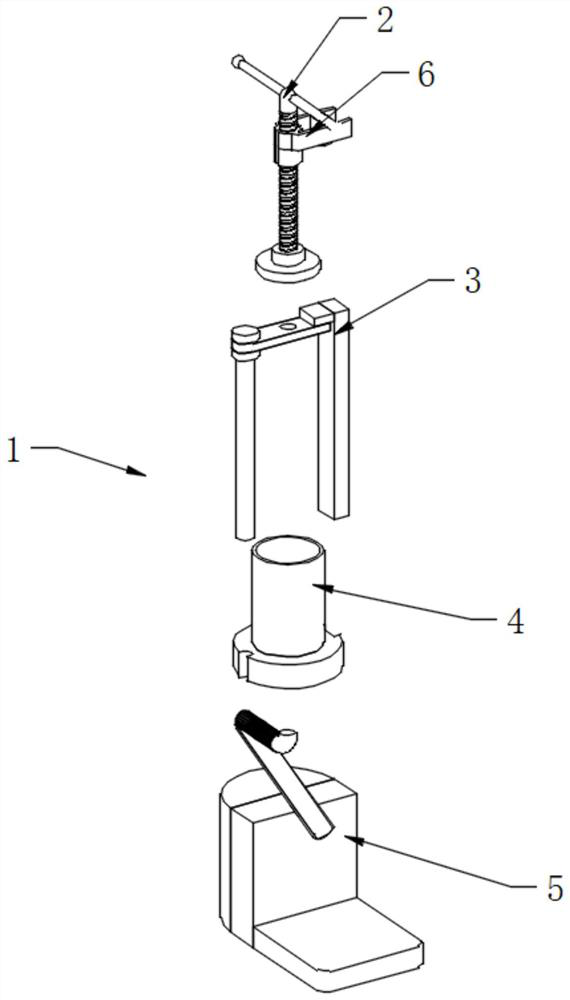

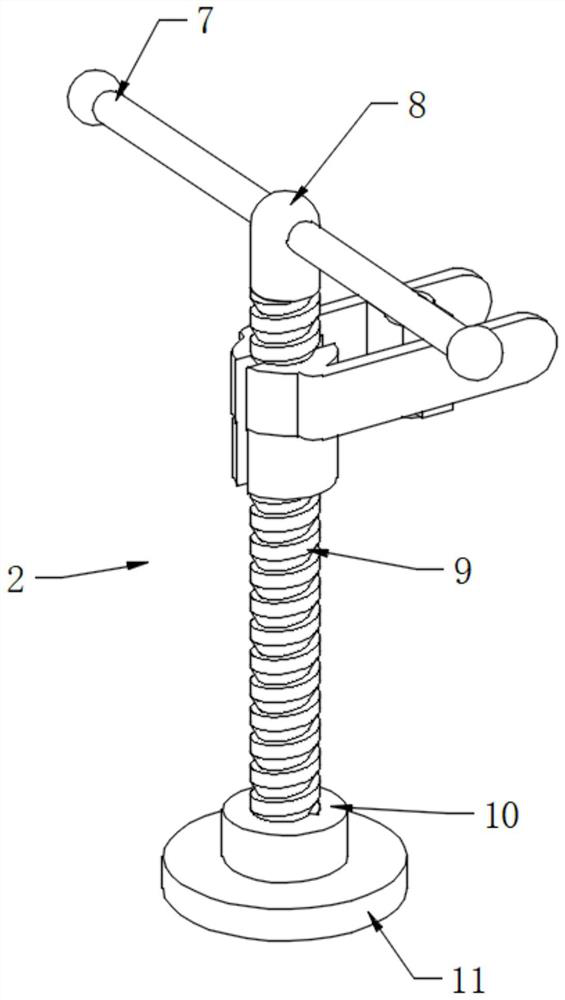

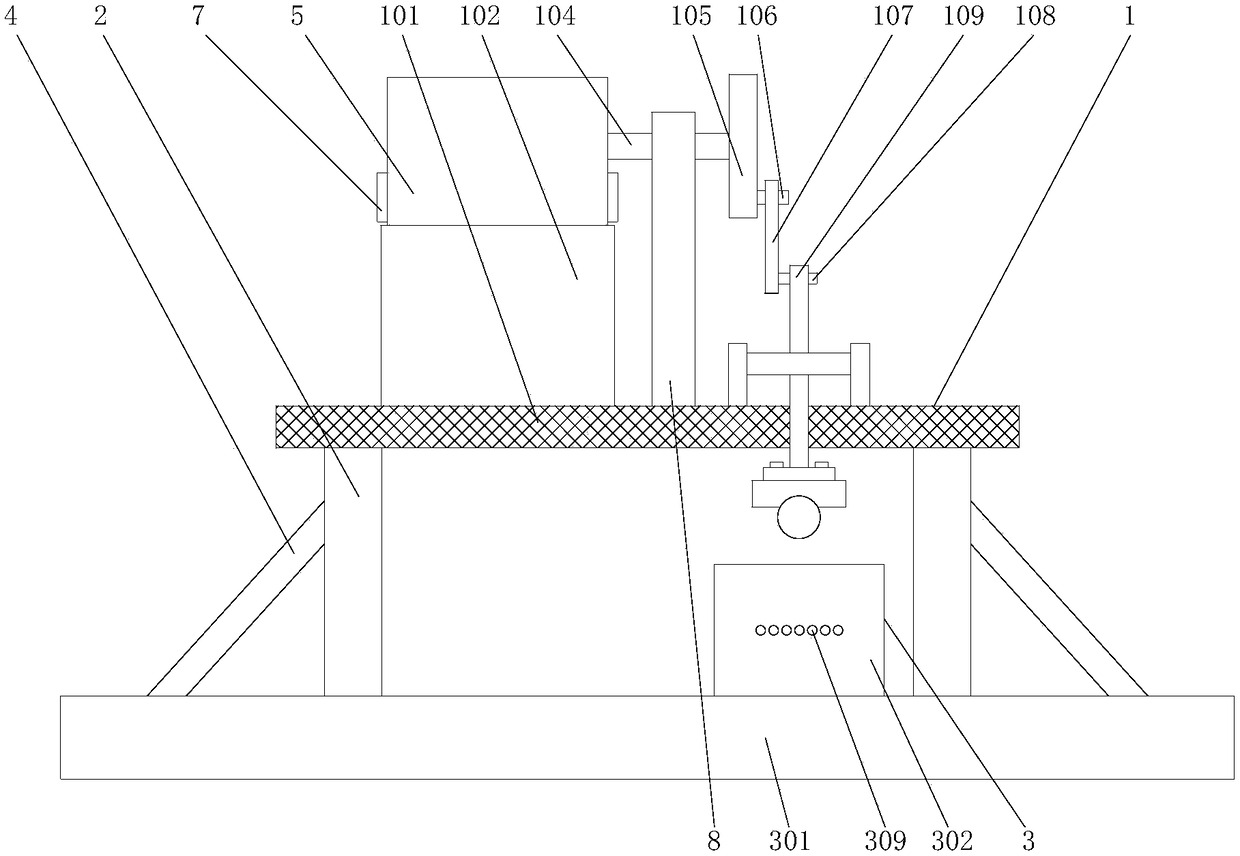

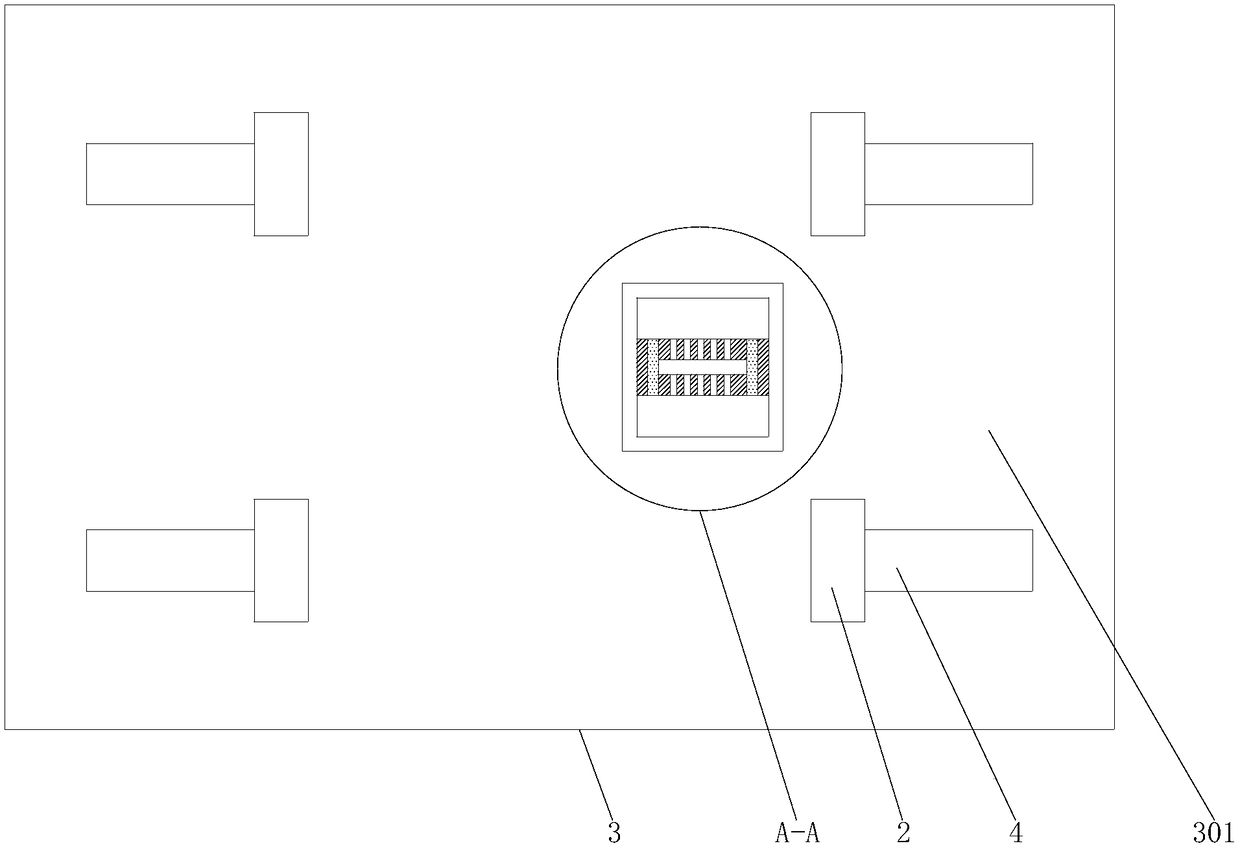

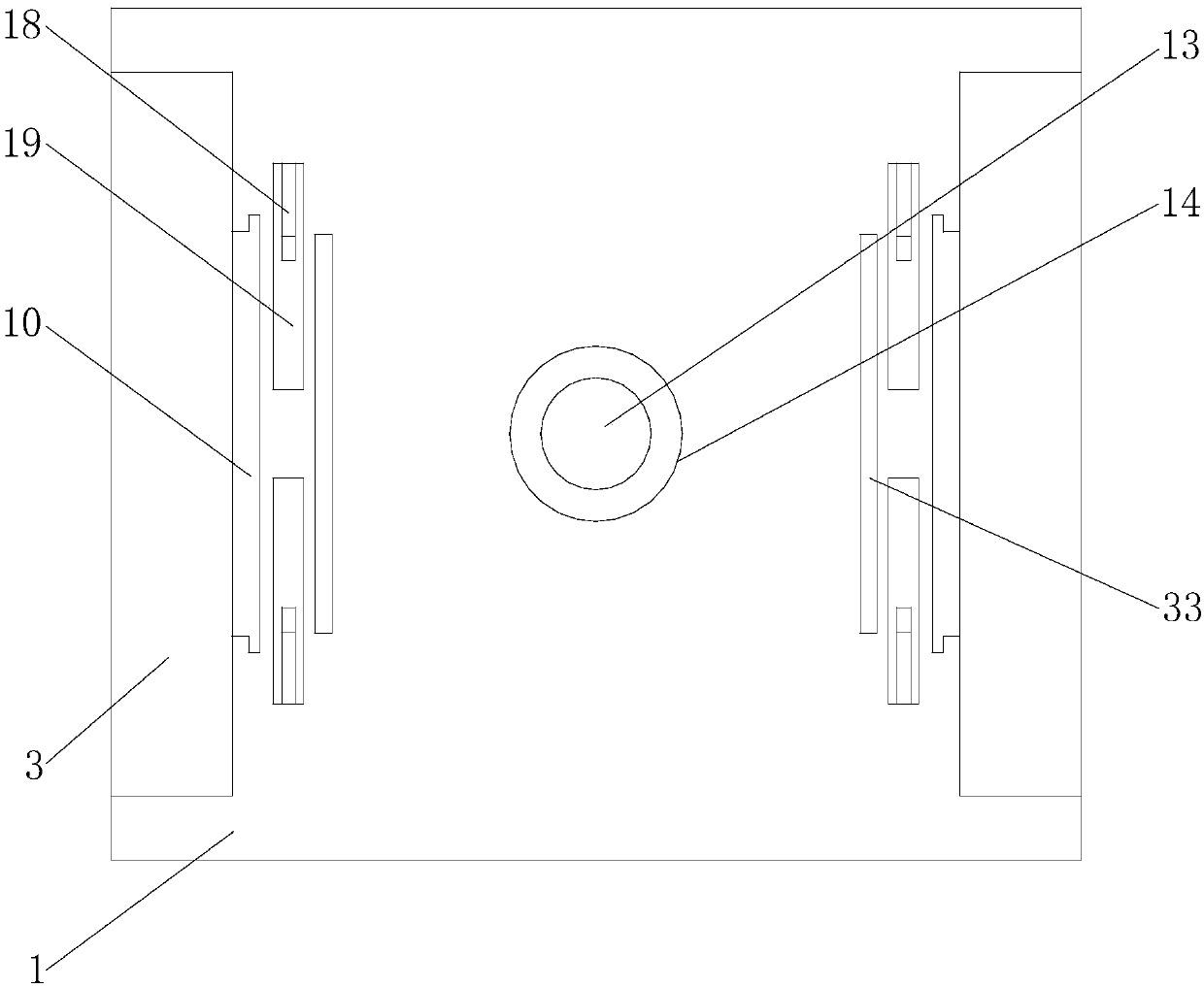

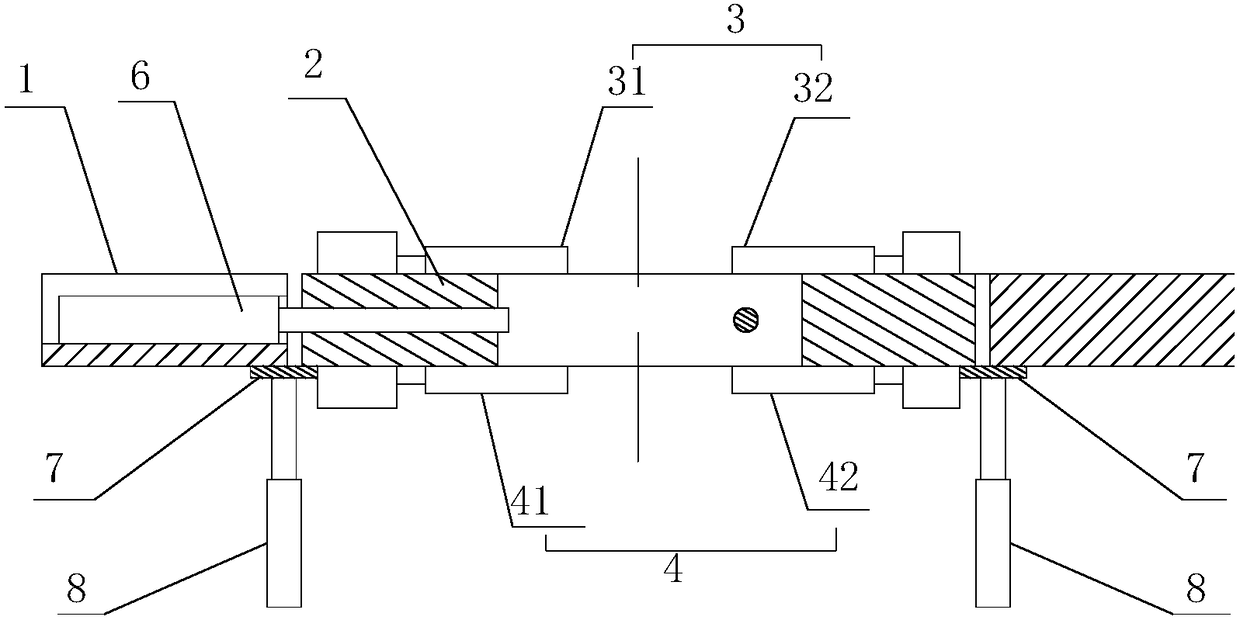

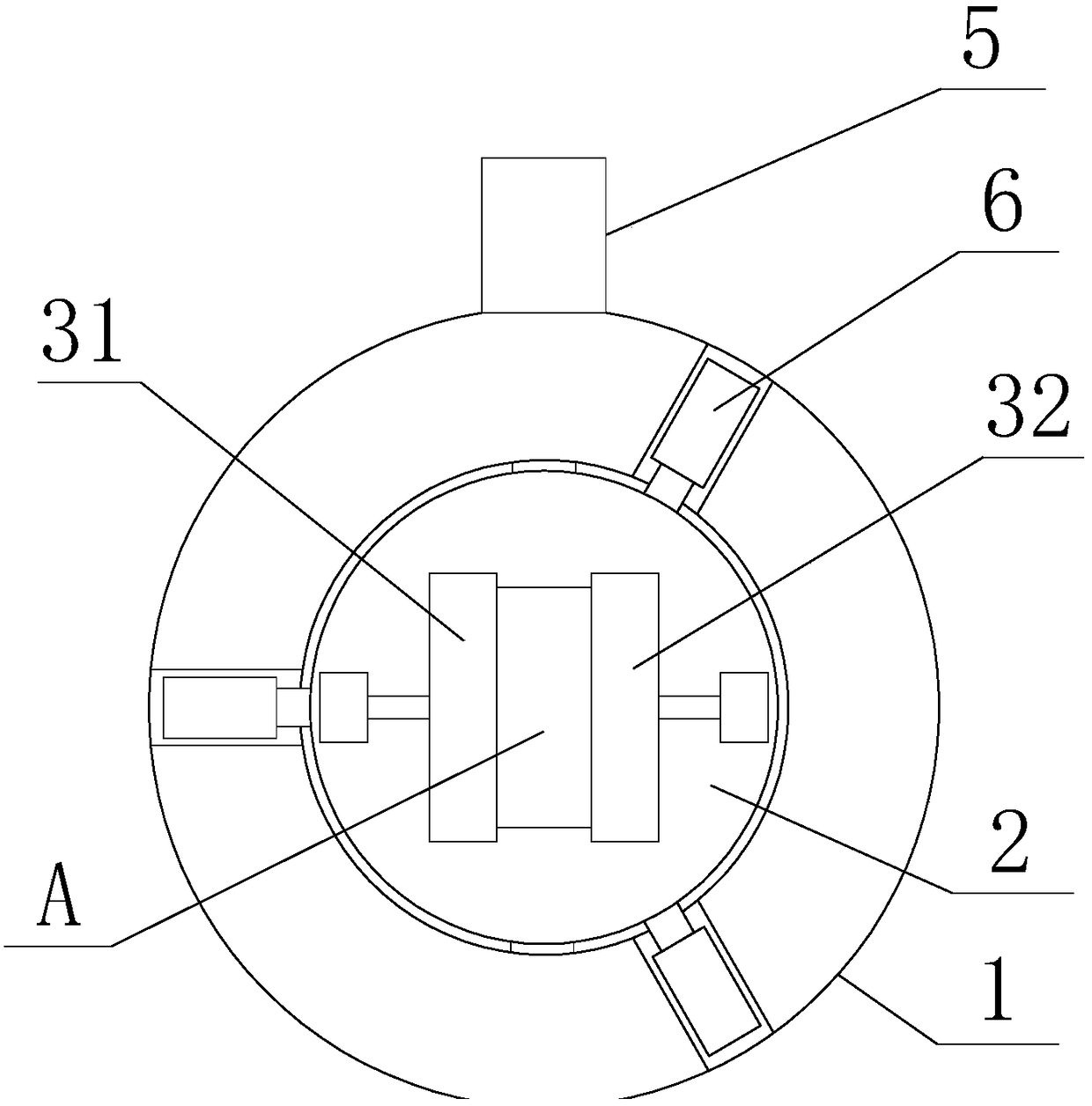

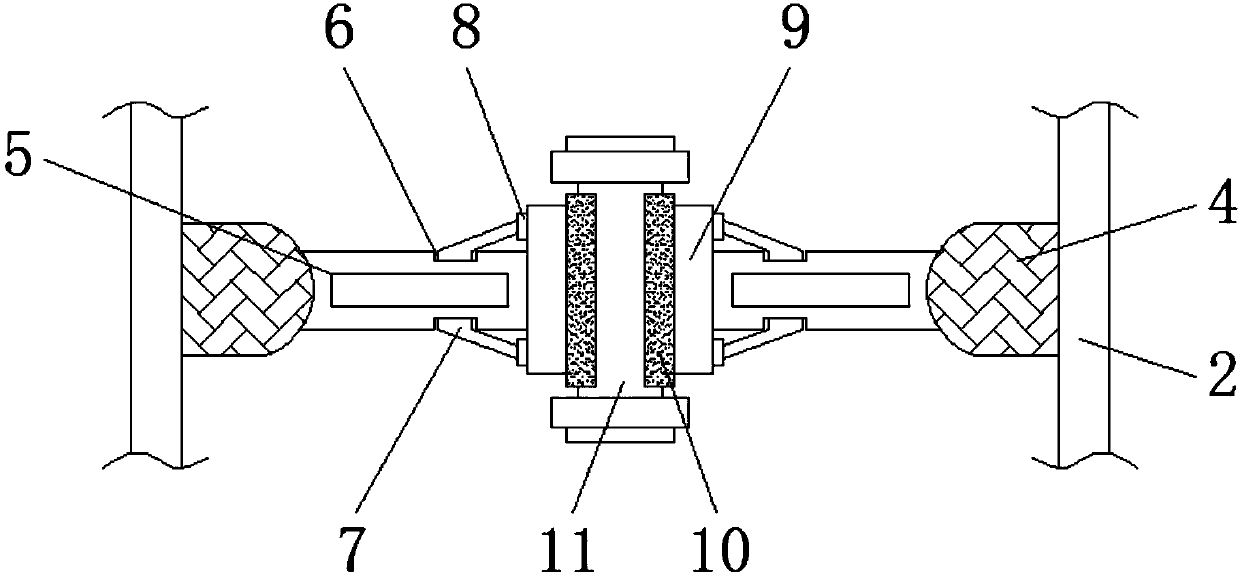

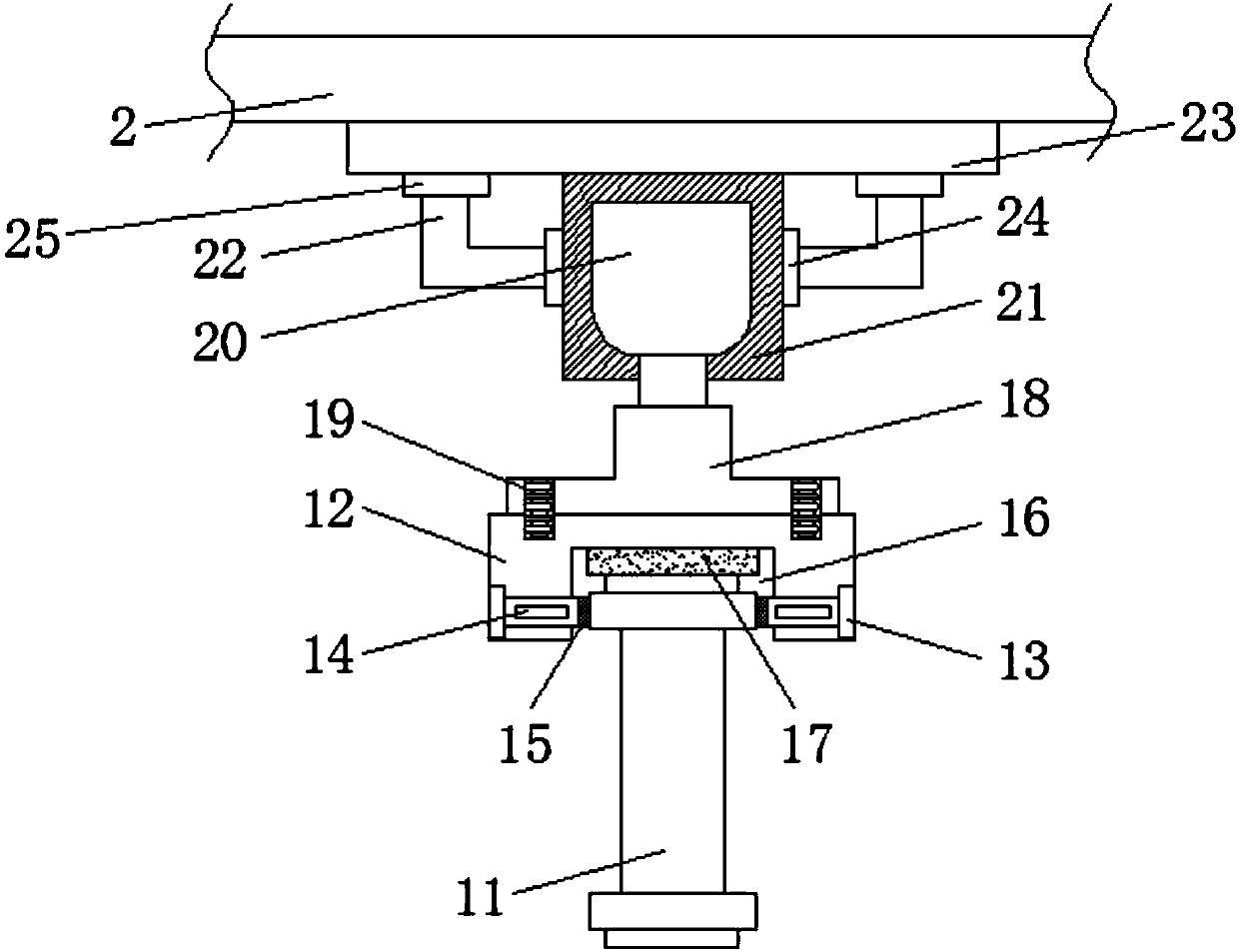

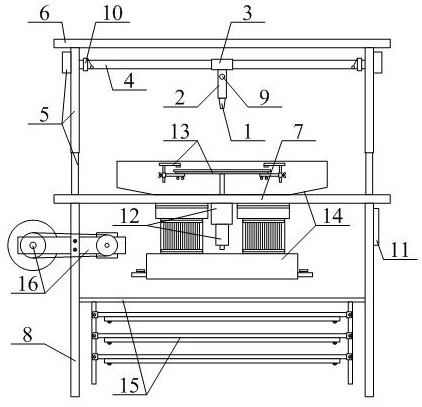

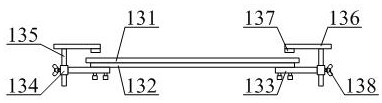

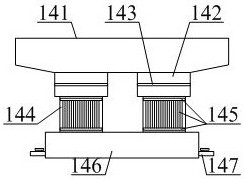

Fixing frame used for automotive brake disc processing

ActiveCN109227189AFixed firmlyConvenient processing workPositioning apparatusMetal-working holdersEngineeringBrake pad

The invention discloses a fixing frame used for automobile brake disc processing. The frame includes a fixed base, a first motor, a screw rod, a gear structure and a fixing component. The upper end ofthe fixed base is provided with a rotating base, and the middle of the upper end of the rotating base is provided with the first motor. The middle of the lower end of the first motor is connected with a first rotating shaft, and the lower end of the first rotating shaft runs through the rotating base, and the lower end of the first rotating shaft is connected with the fixed base. Fixed pipes aresymmetrically arranged on the left and right sides of the upper end of the rotating base, and the inner sides of the fixed pipes are slidably connected with the lower parts of lifting rods, and secondmotors are arranged on the bottoms in the fixed pipes. The center of a brake disc is located through a central fixing shaft, an electromagnet is electrified, a fixing block moves towards the side edge of the brake disc to attract the side edge of the brake disc, the side edge of the brake disc is then fixed, this design can allow the fixing frame used for automobile brake disc processing to fix various brake blocks different in size, and fixation is firm.

Owner:广德亚太汽车智能制动系统有限公司

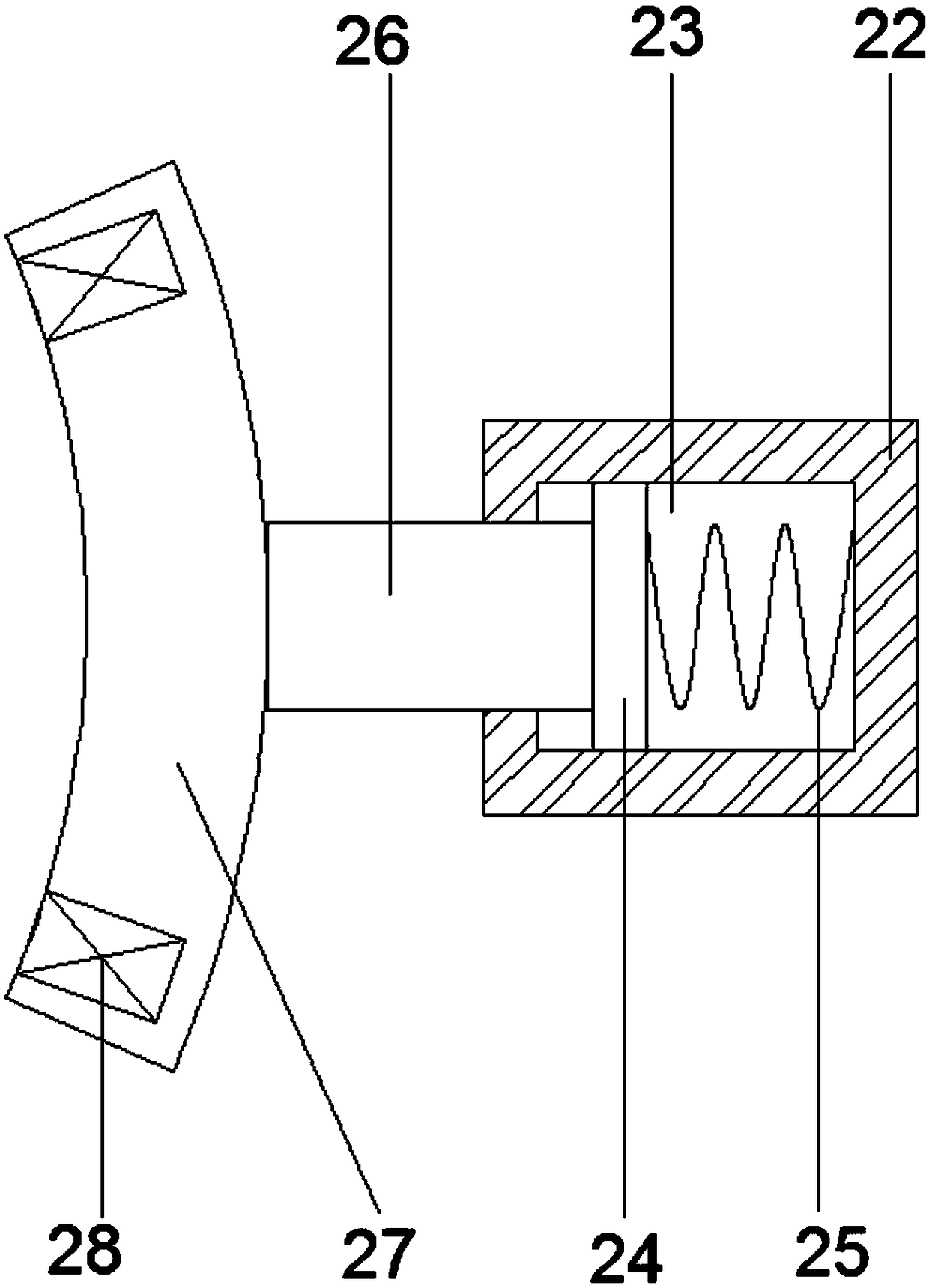

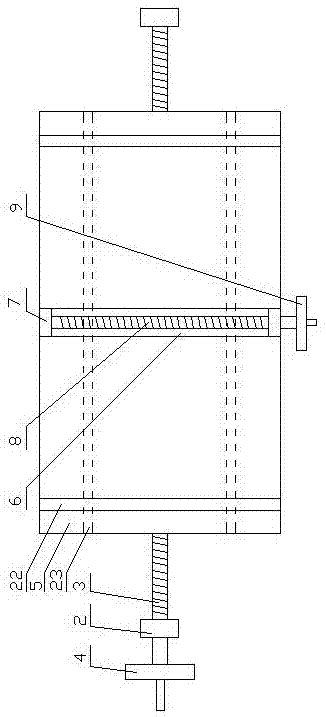

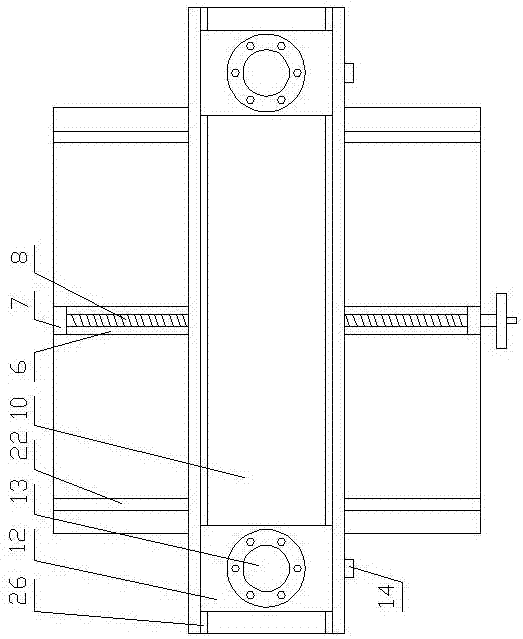

Highly efficient processing device for sole groove in shoe making

The invention relates to a processing device, particularly relates to a highly efficient processing device for sole groove in shoe making, The technical problem to-be-solved by present invention is to provide a highly efficient, high speed processing device for sole groove in shoe making. To solve the above technical problem, the present invention provides such a highly efficient processing device for sole groove in shoe making, including a first shaft block, a first bevel wheel, a first revolving shaft, a left shaft block, a nut, a screw rod, a right shaft block, a rotating motor, a support, a second revolving shaft, a second bevel wheel, an electric driven rod, a placement board, an electric sucker, a heating device, a first elastic component, a first fixed block, a first lifting rod, a first touch wheel and a round plate and more; the bottom part inside the support rod is installed from the left to the right in sequence with the first shaft block, the left shaft block, the right shaft block, and the rotating motor. The present invention achieves the effects of fast in processing speed, high in processing efficiency, simple in device operation, simple in device structure, low cost in device preparation.

Owner:山东凤墩皮革制品有限公司

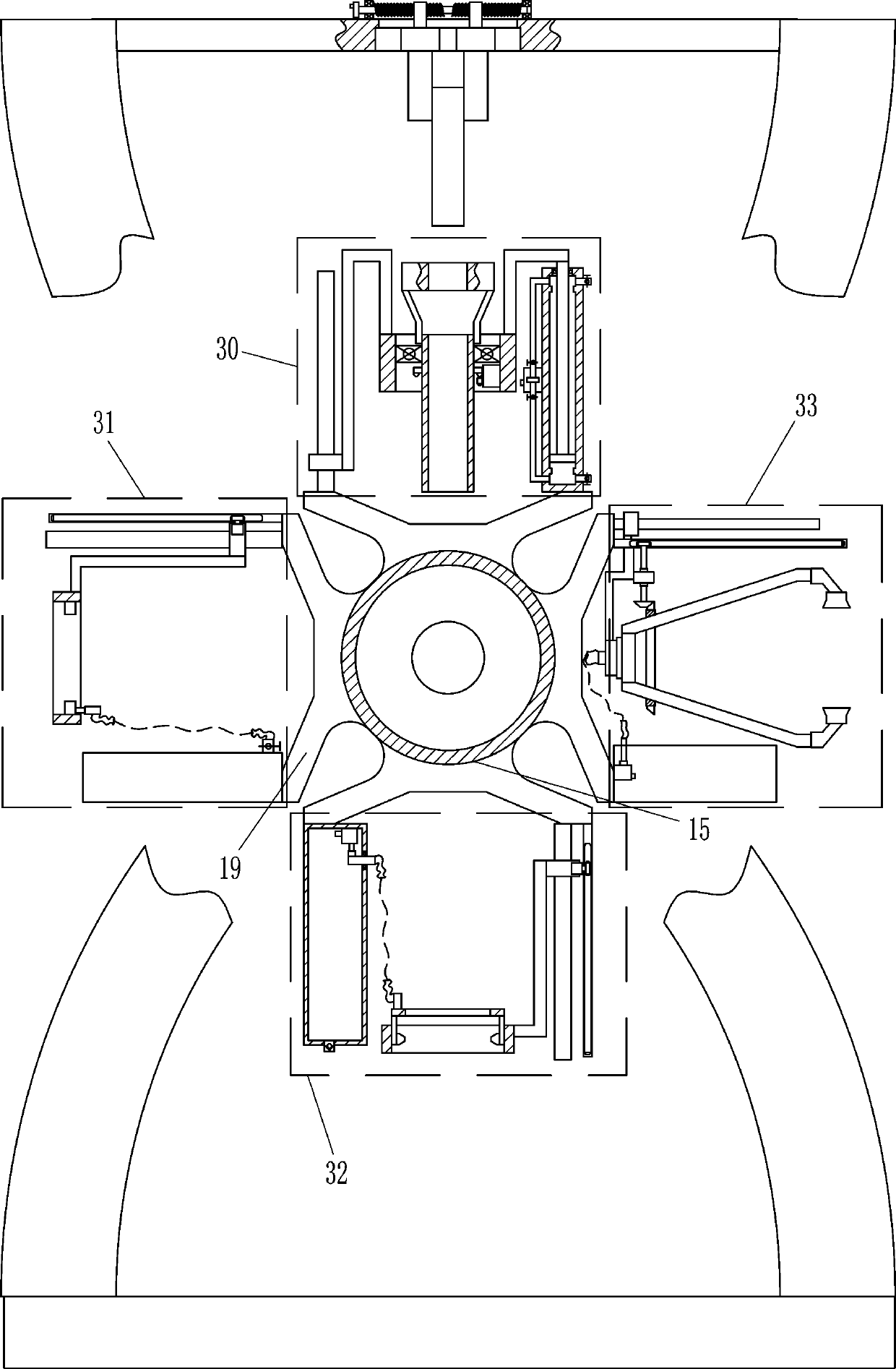

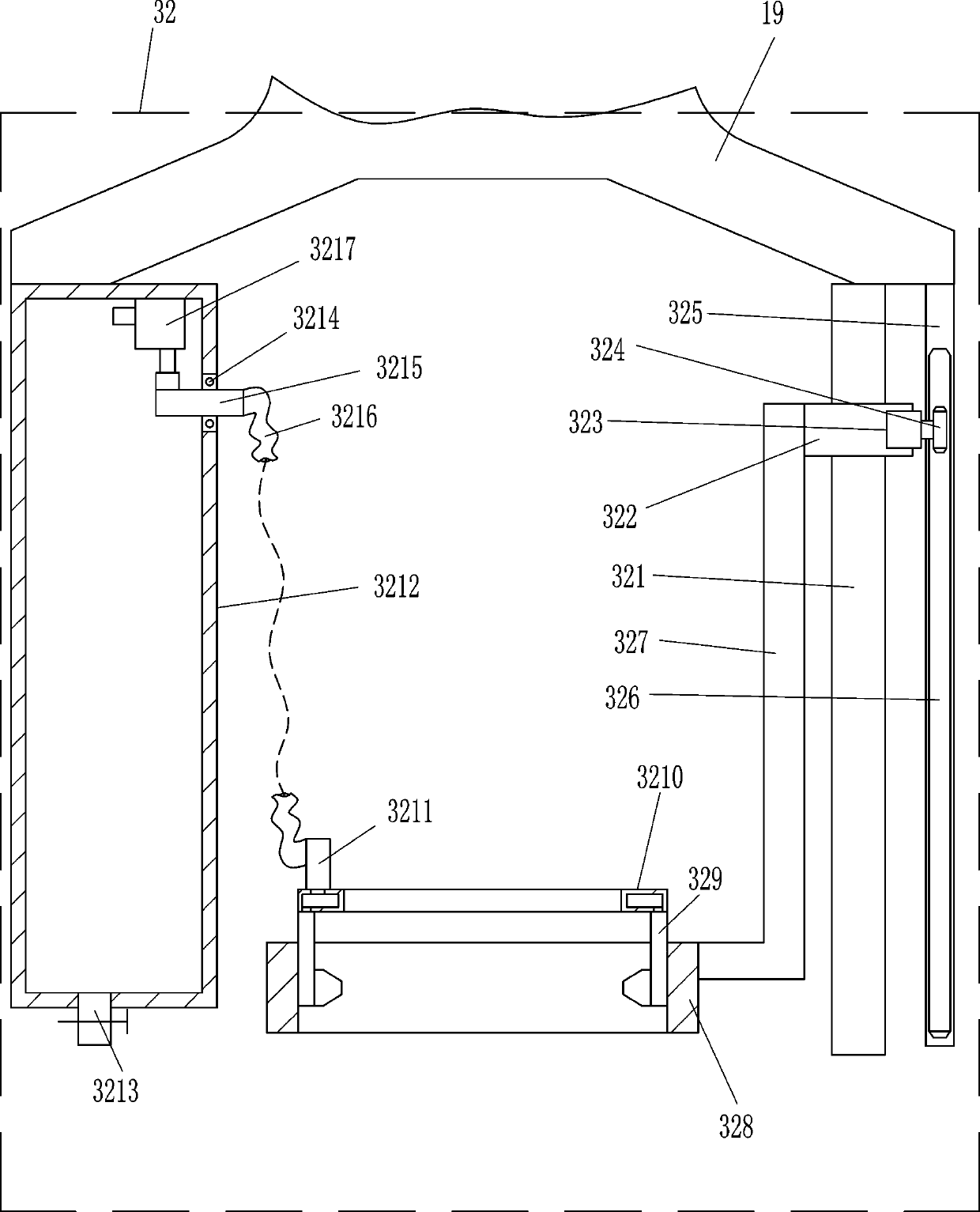

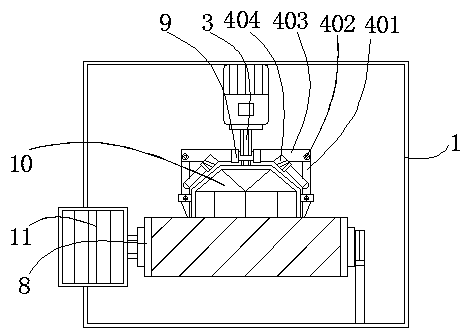

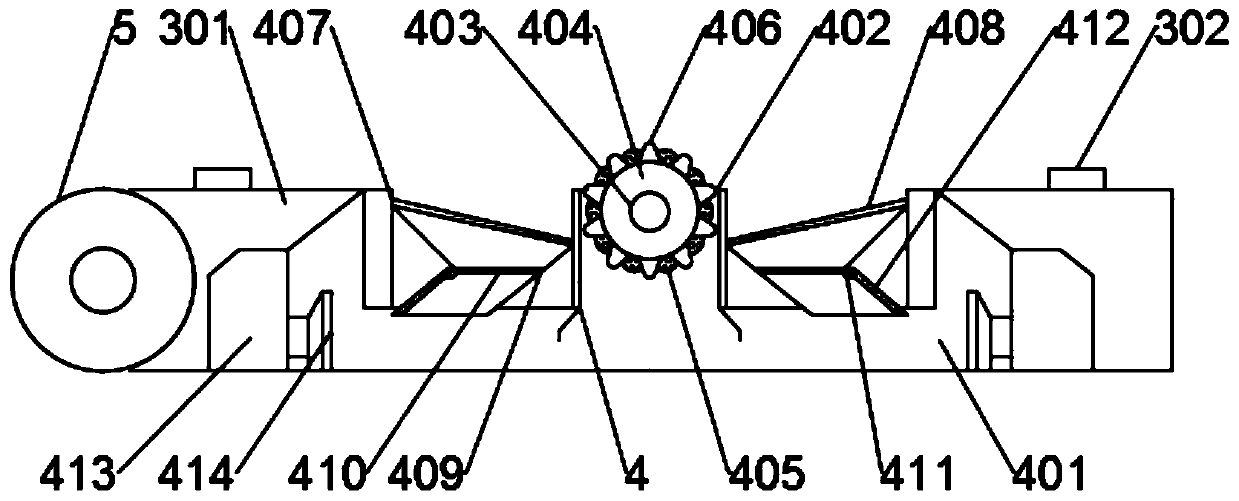

Outer tooth milling machine

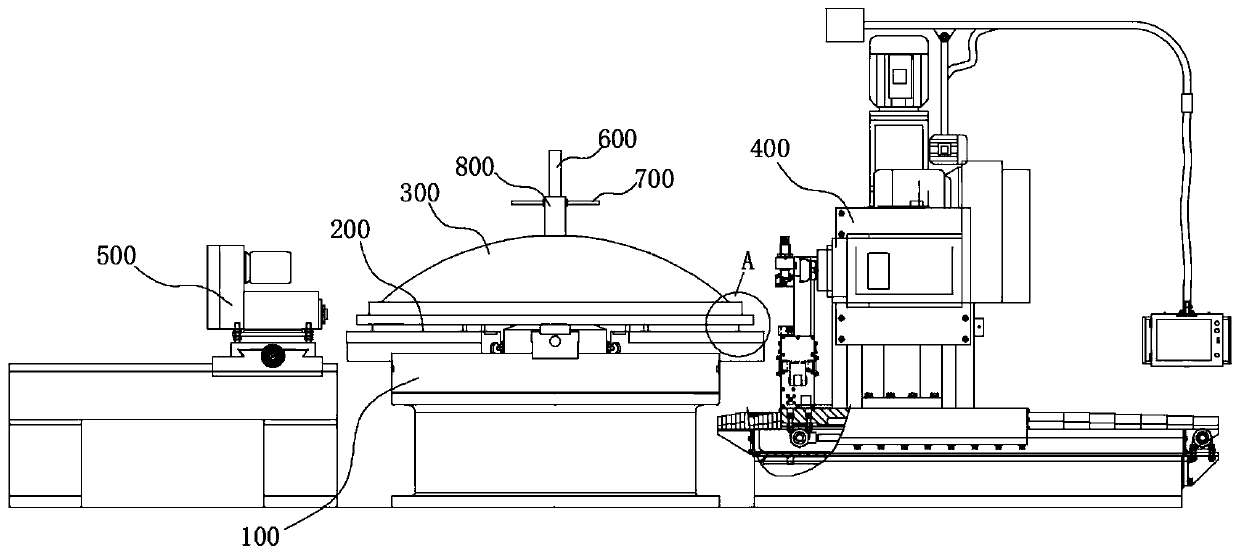

ActiveCN110788409AStable processingThere will be no problem of interference with milling gear machiningOther manufacturing equipments/toolsLarge fixed membersEngineeringMachine

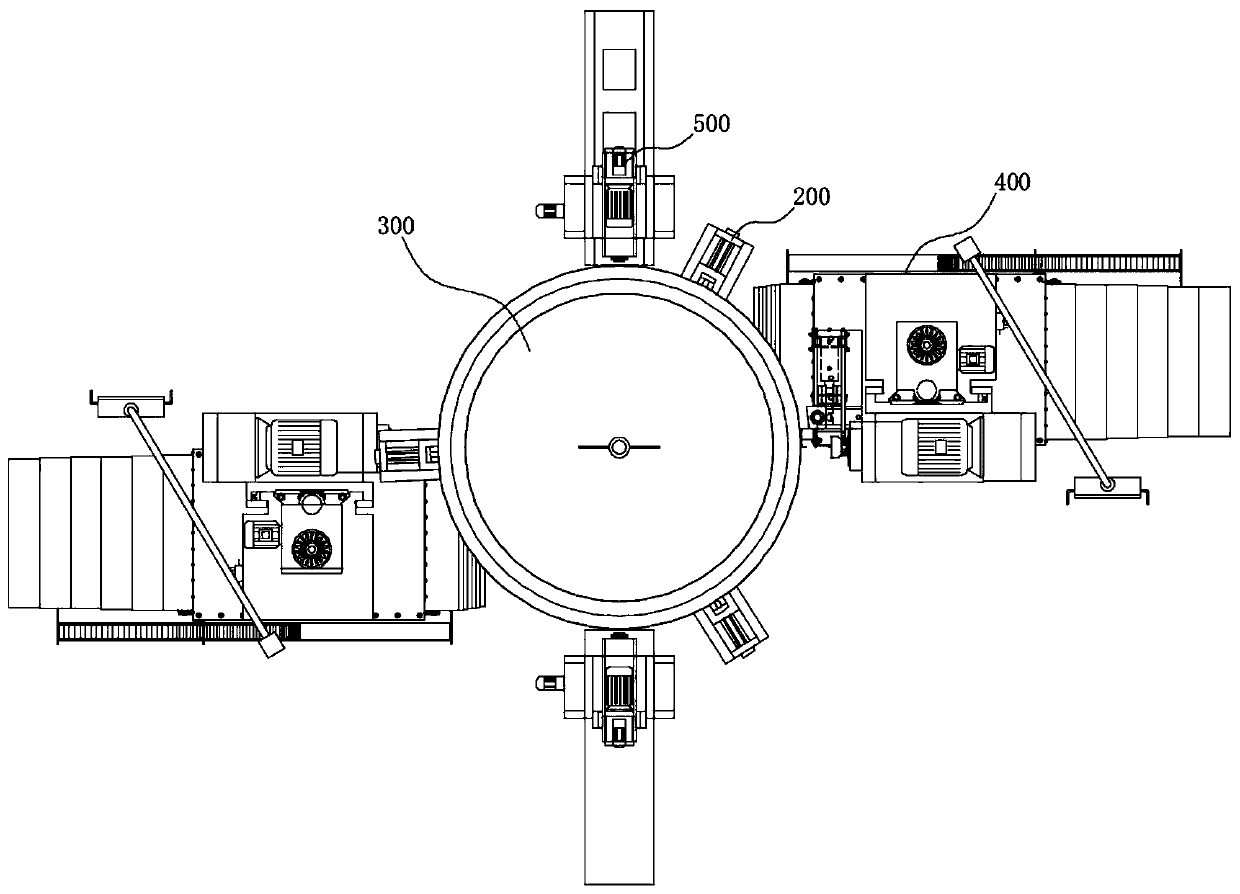

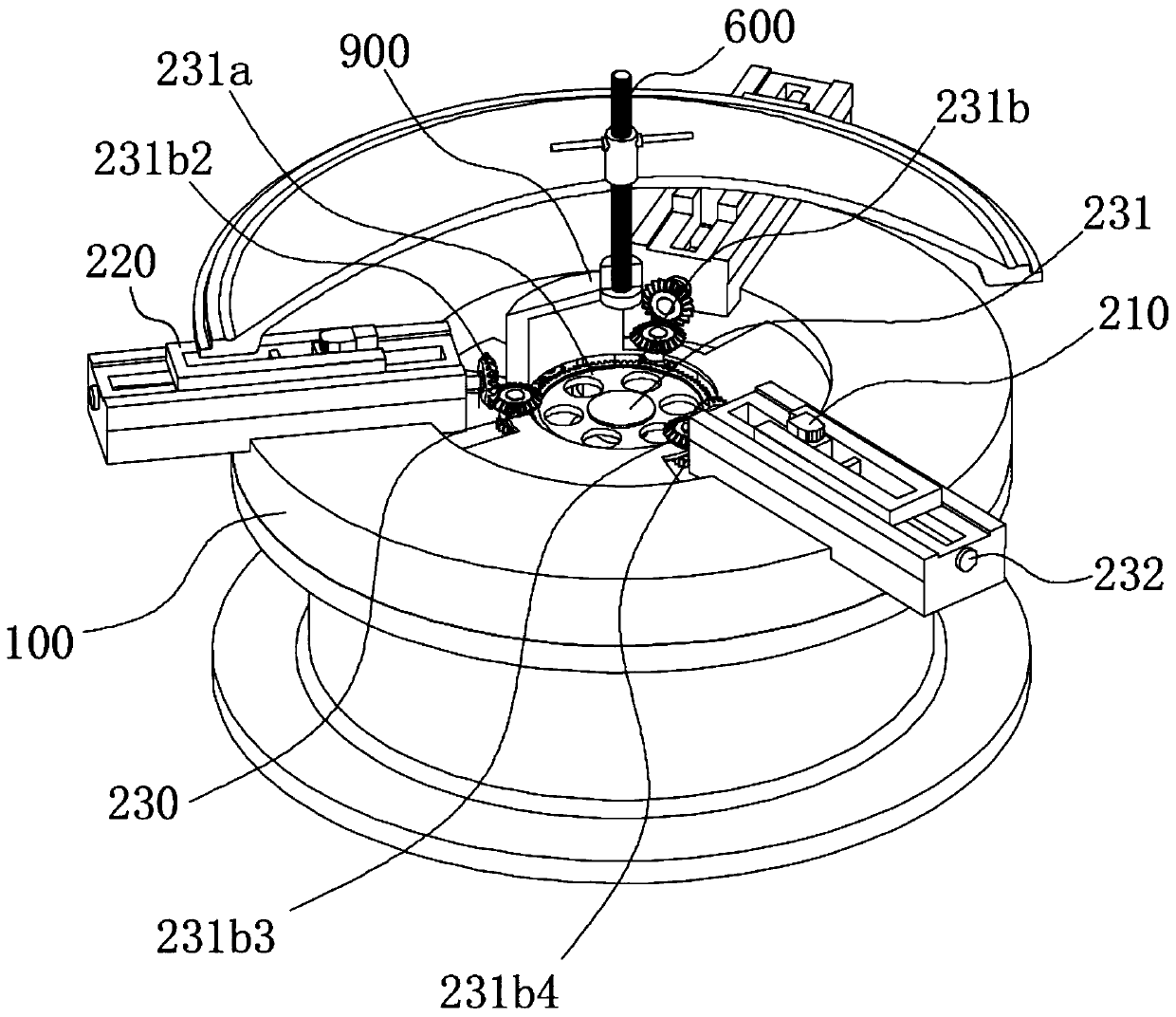

The invention relates to an outer tooth milling machine. The outer tooth milling machine comprises a machine frame. A rotary table is installed on the machine frame. A tooth milling device and an exhaust groove machining device are arranged around the rotary table. Clamping devices are arranged on the rotary table and are used for clamping and positioning corresponding workpieces to make the to-be-machined outer ring walls of the workpieces in a machined state. The outer tooth milling machine is reasonable in layout, stable in structure, capable of automatically positioning and clamping workpieces with different sizes and making the outer ring walls of the workpieces with the different sizes in the machined state, and high in applicability, and meets existing using requirements.

Owner:安徽金马热能设备有限公司

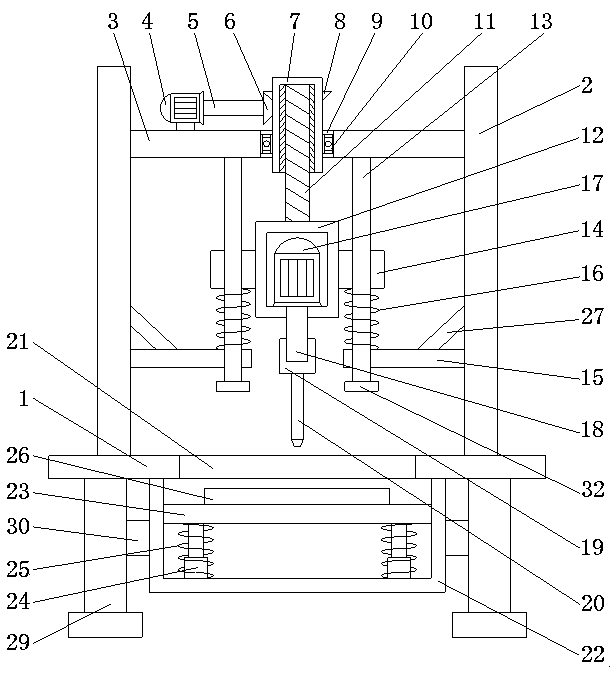

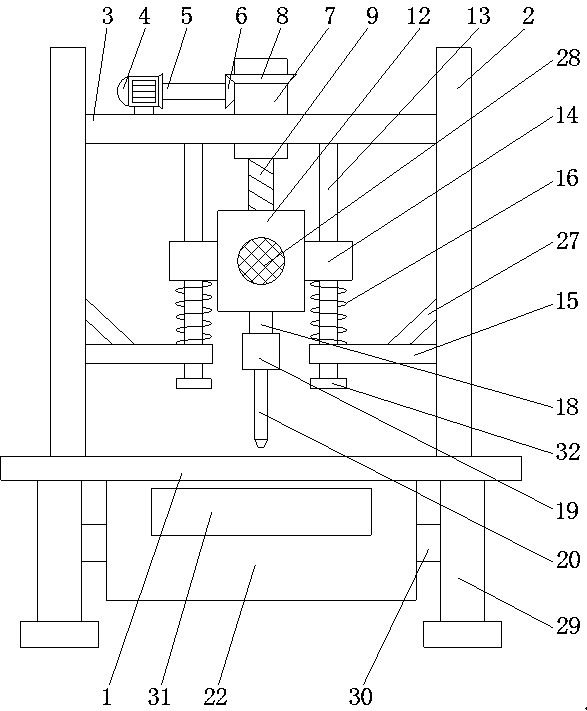

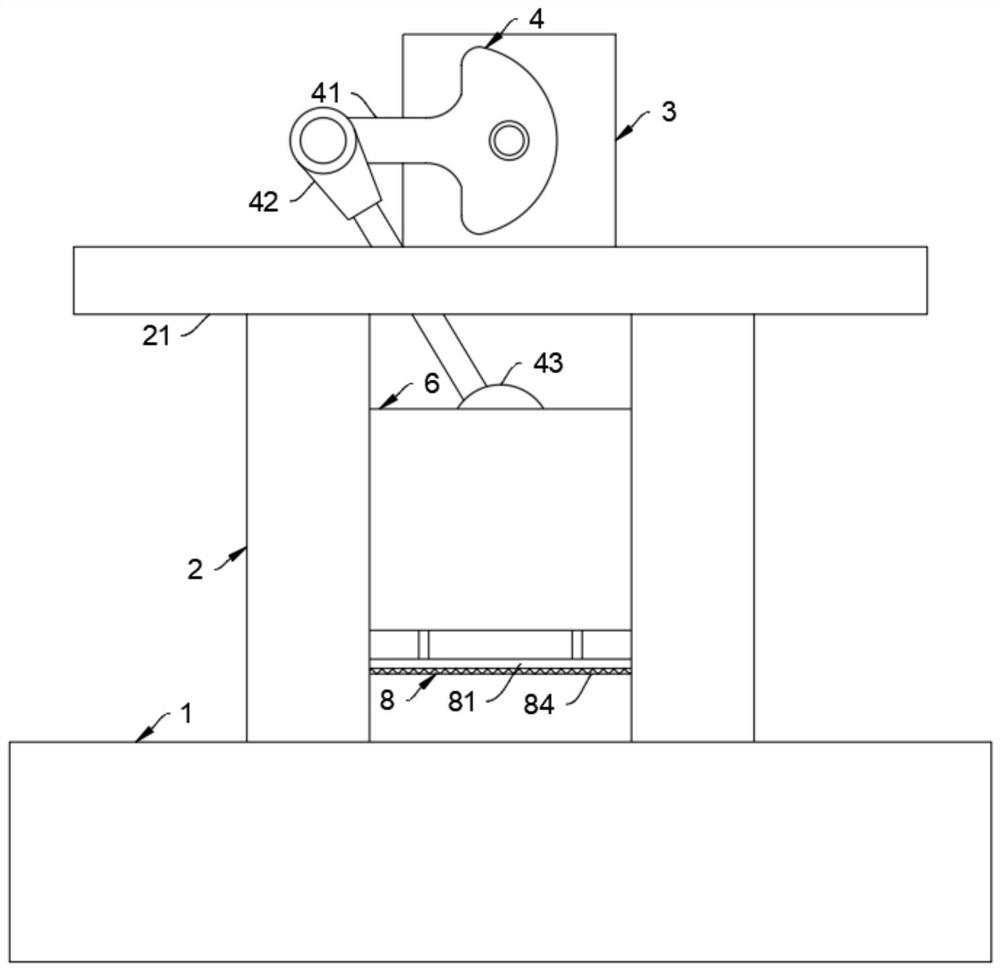

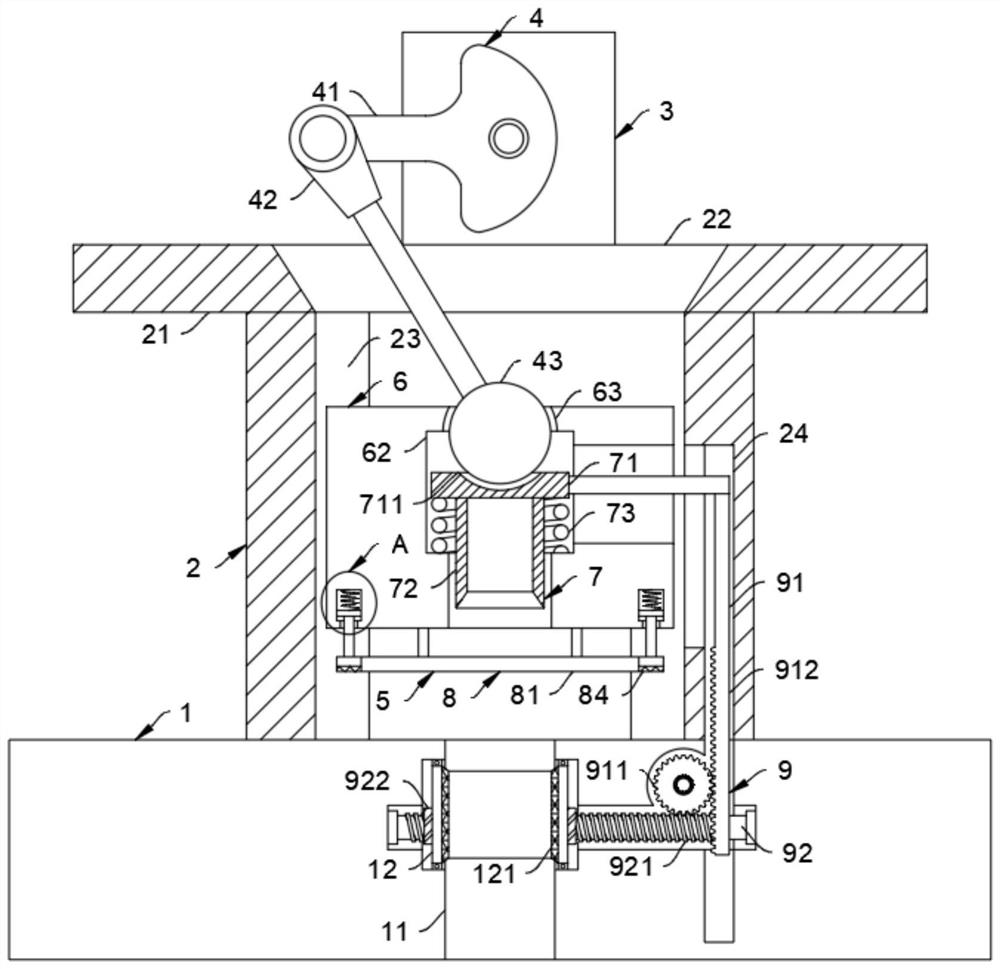

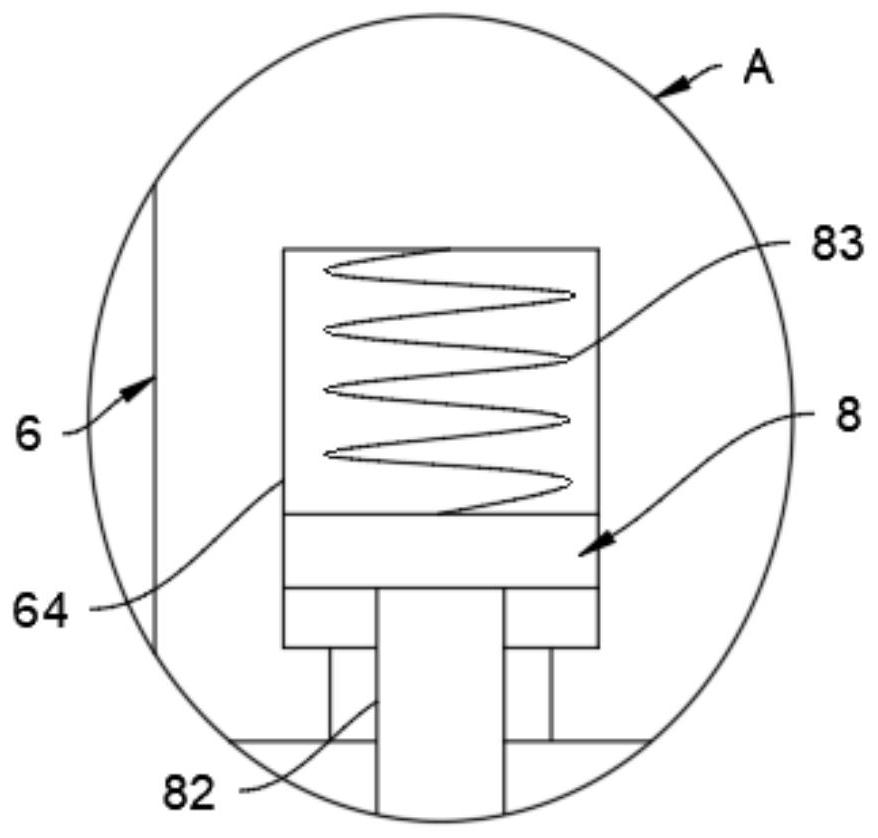

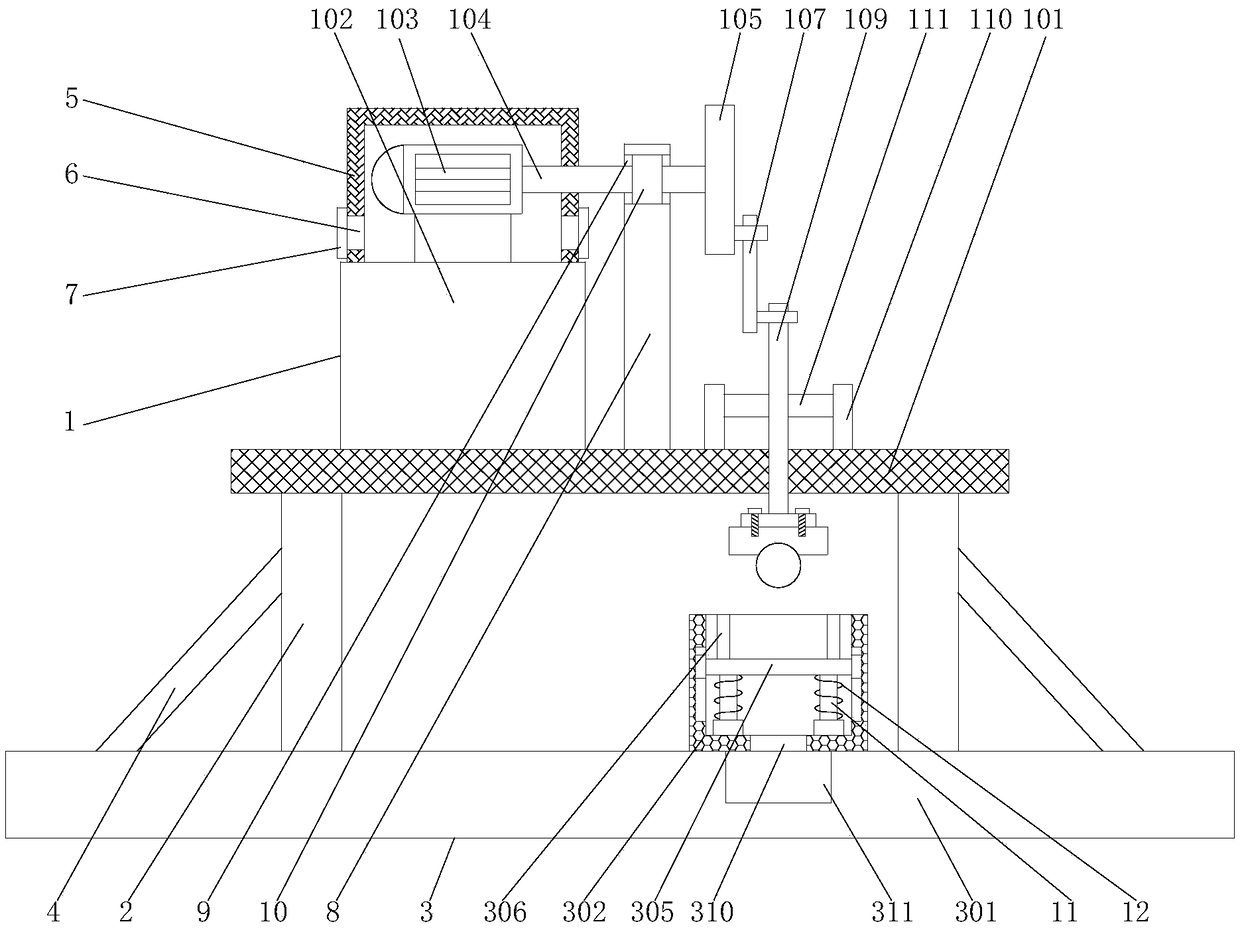

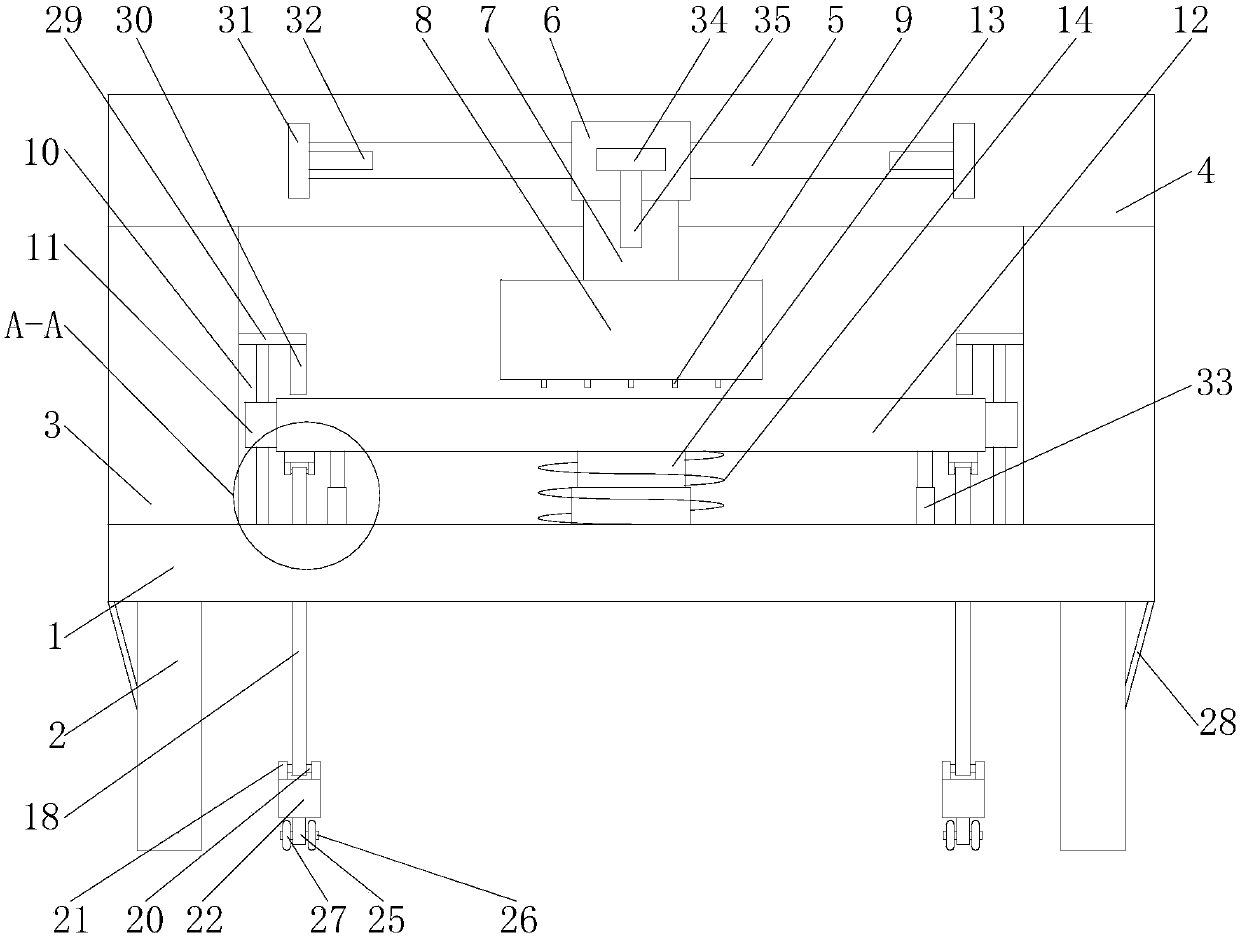

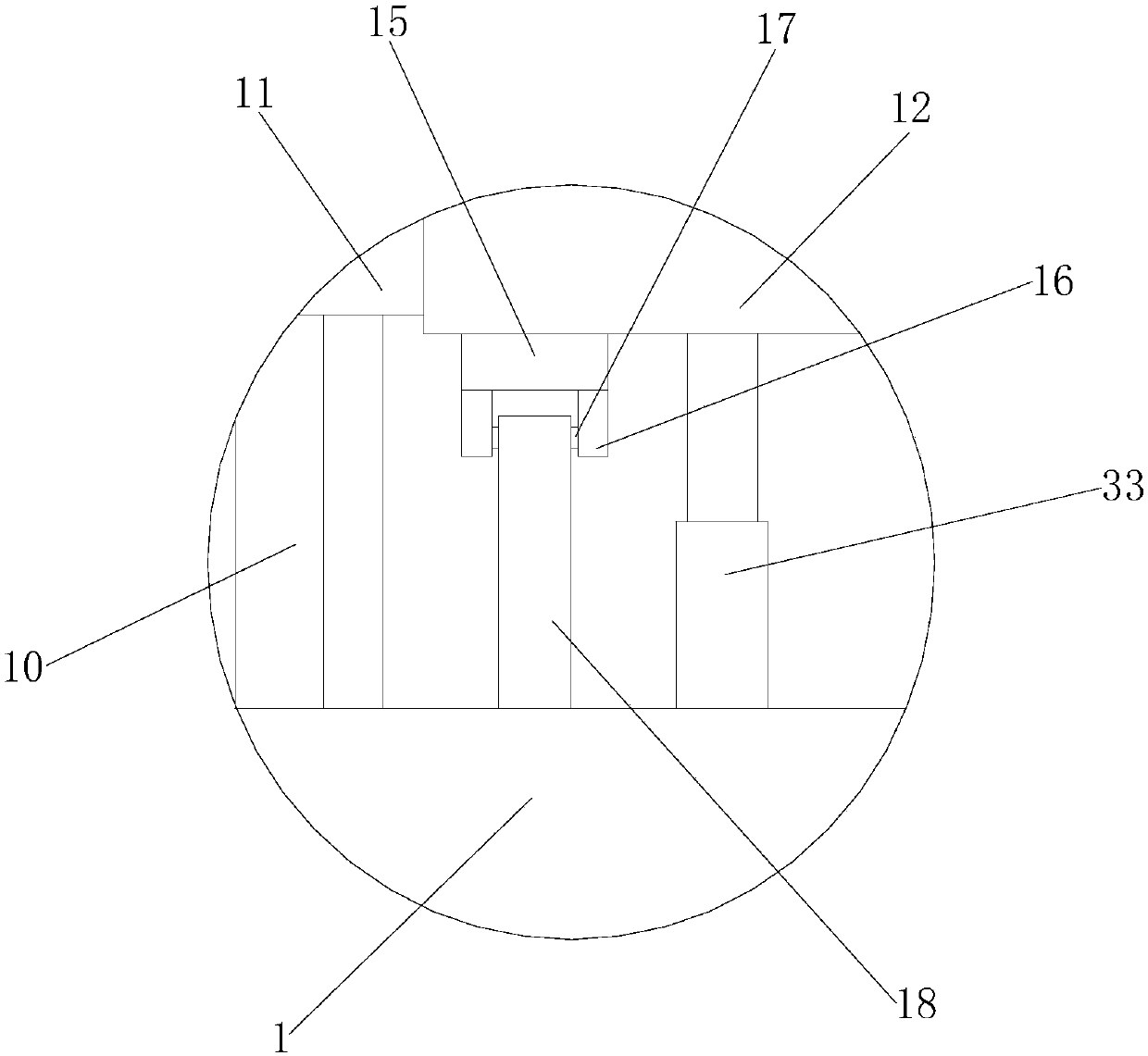

Perforating machine with good stability effect for furniture processing

InactiveCN109318301APlay a shock absorbing roleAvoid shakingStationary drilling machinesPunchingEngineering

The invention discloses a perforating machine with good stability effect for furniture processing. The perforating machine with good stability effect for furniture processing comprises a fixing plate,wherein supporting plates are fixedly connected to the left side and the right side of the top of the fixing plate, the tops of the two supporting plates are fixedly connected through a connecting plate, a driving motor is fixedly connected to the left side of the top of the connecting plate, and the output shaft of the driving motor is fixedly connected with a driving rotating shaft. According to the perforating machine, the driving motor, the driving rotating shaft, a first gear, the threaded sleeve, a second gear, a threaded rod, a sliding rod, a sliding block, a connecting block, a firstspring, a punching motor, a punching rotary shaft, a punching head, a punching table, a telescopic rod and a second spring are arranged in a matched mode, the first spring and the second spring are coordinated with each other, so that the effect of damping the punching head is achieved, the punching head can be prevented from shaking during the rotating and advancing process, so that the drillingerror is caused, the processing quality of furniture is improved, and great convenience is brought to furniture processing.

Owner:徐州喜木阁家具有限公司

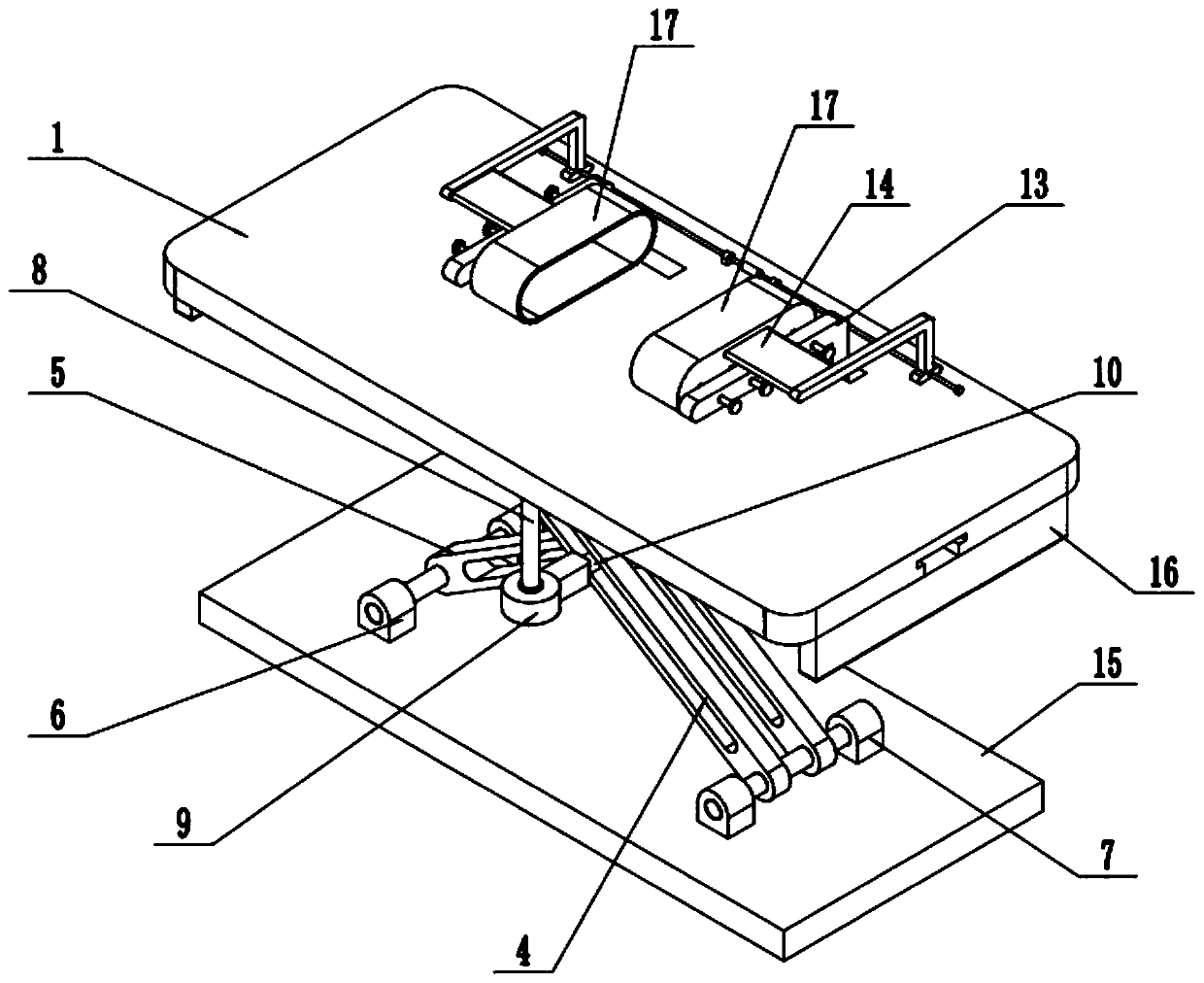

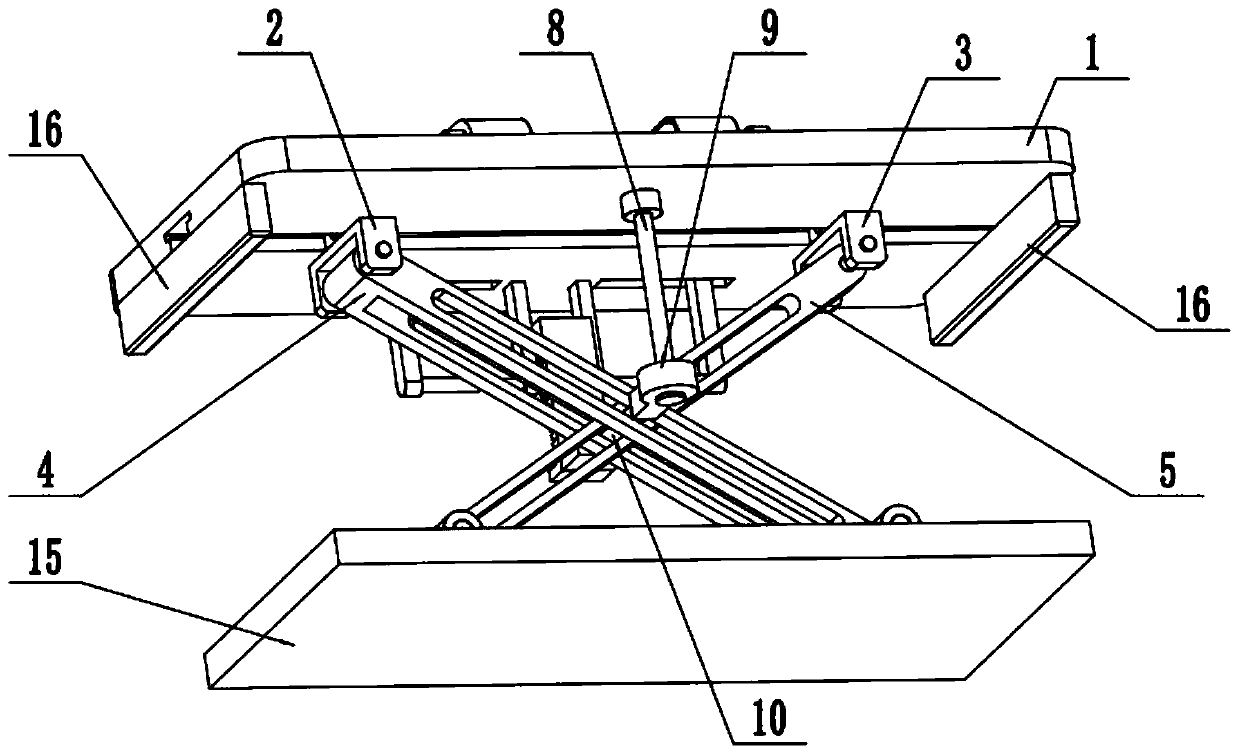

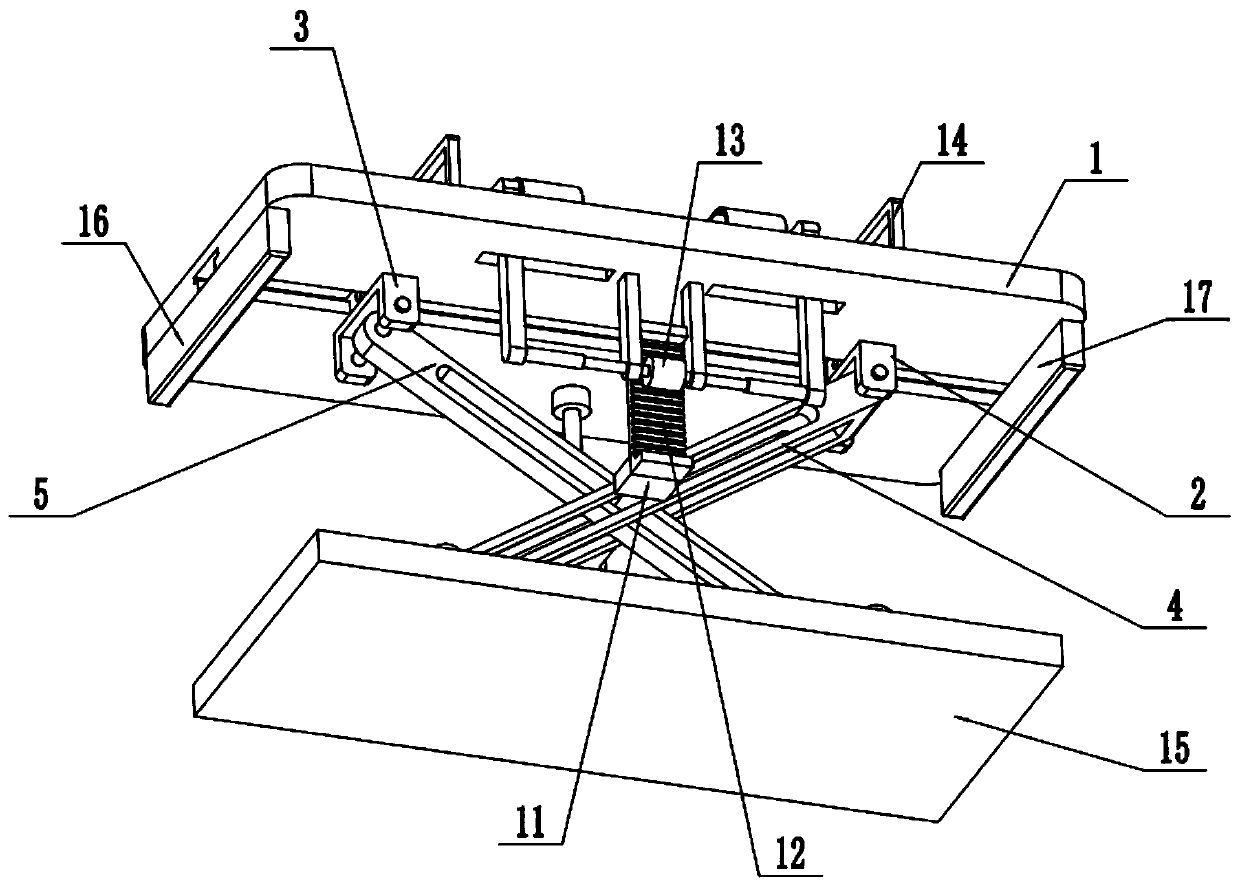

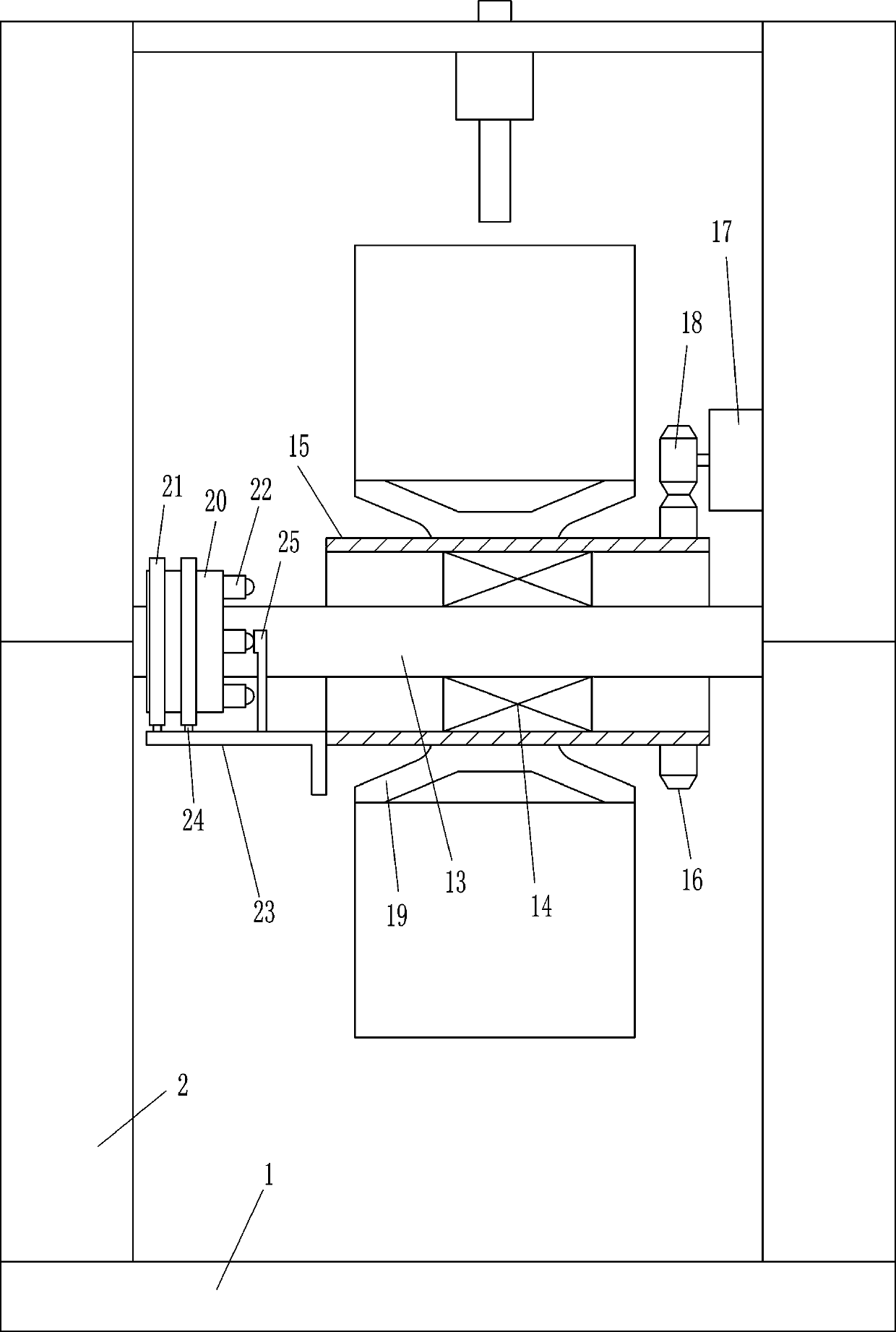

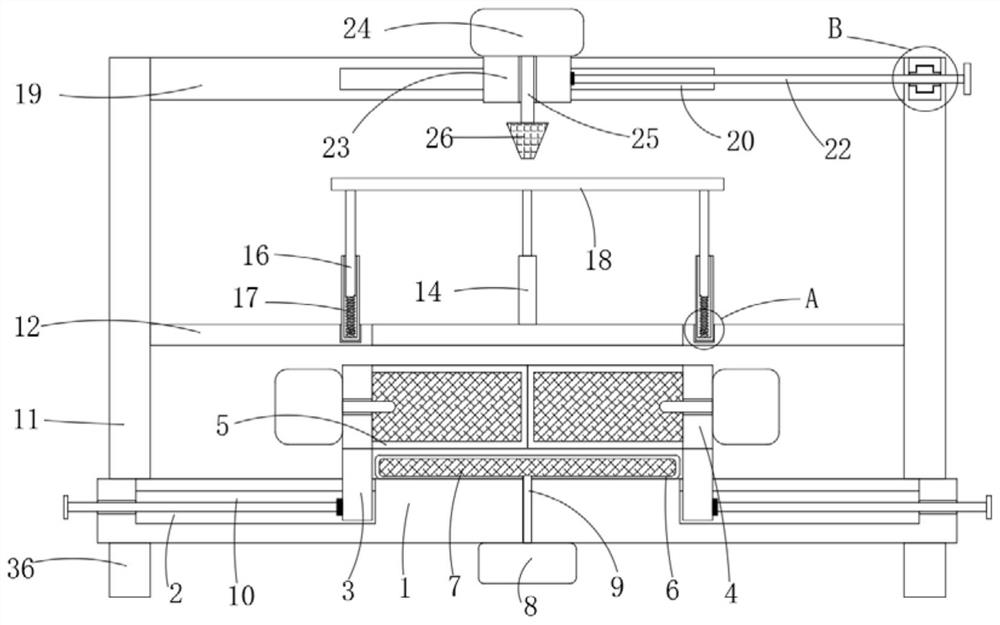

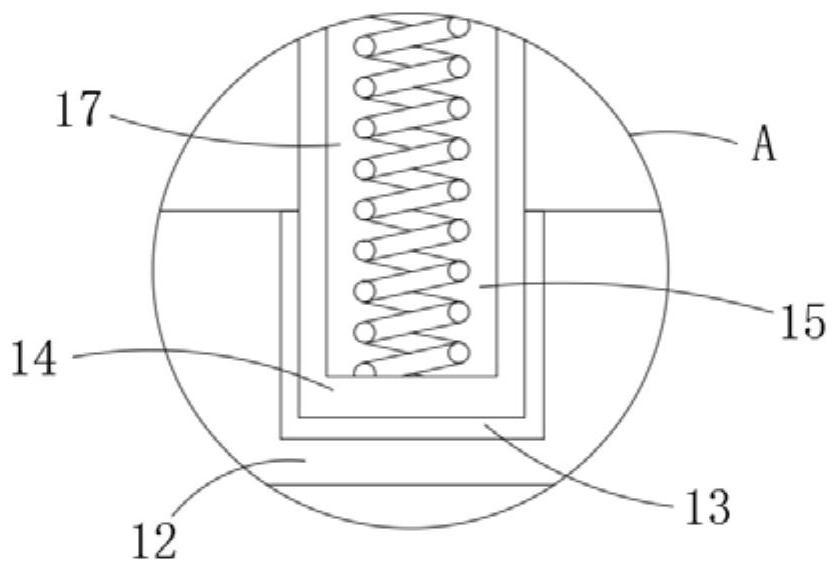

Adjustable injection mold machining workbench

The invention relates to a machining workbench, in particular to an adjustable injection mold machining workbench. The adjustable injection mold machining workbench comprises a machining workbench body, a left sliding base, a right sliding base, a left supporting leg, a right supporting leg, a left fixing base, a right fixing base, an electric pushing rod, a lifting base, a sliding rod, a linkagebase, a rack, a mold fixing frame, ejectors and a base plate; a T-shaped sliding groove is formed in the middle end of the bottom face of the machining workbench body; the left sliding base and the right sliding base are symmetrically connected to the two ends of the interior of the T-shaped sliding groove in a sliding fit mode; and the left fixing base and the right fixing base are symmetricallyand fixedly connected to the two ends of the top face of the base plate. According to the adjustable injection mold machining workbench, two halves of injection molds fixedly installed on the mold fixing frame are buckled or separated by adjusting the height of the machining workbench body, and mold machining work can be conveniently conducted through the injection molds; and in addition, the ejectors capable of achieving adjusting are arranged in the machining workbench, therefore, a mold obtained after injection molding can be ejected out, the structure is novel, and the practicability is high.

Owner:高伟刚

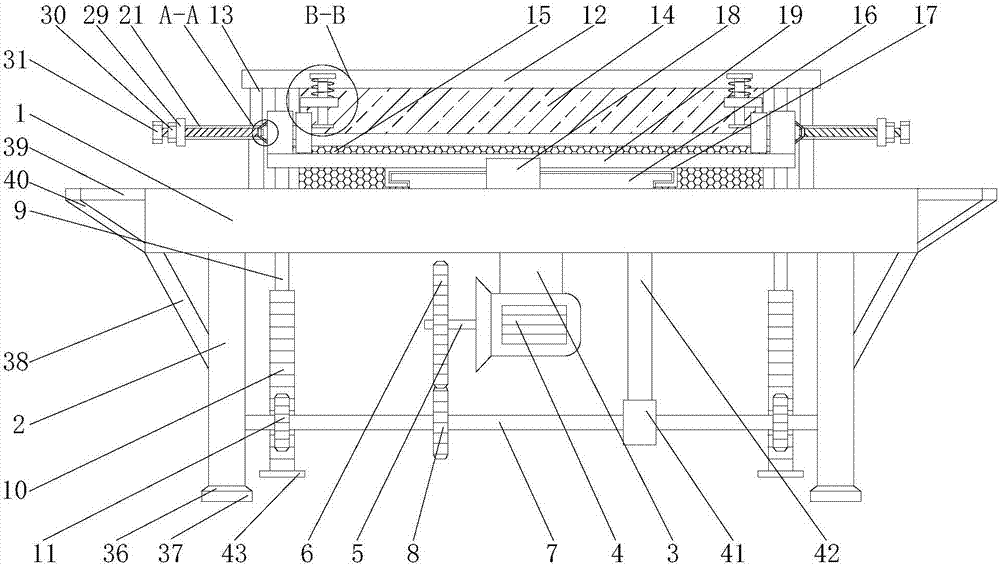

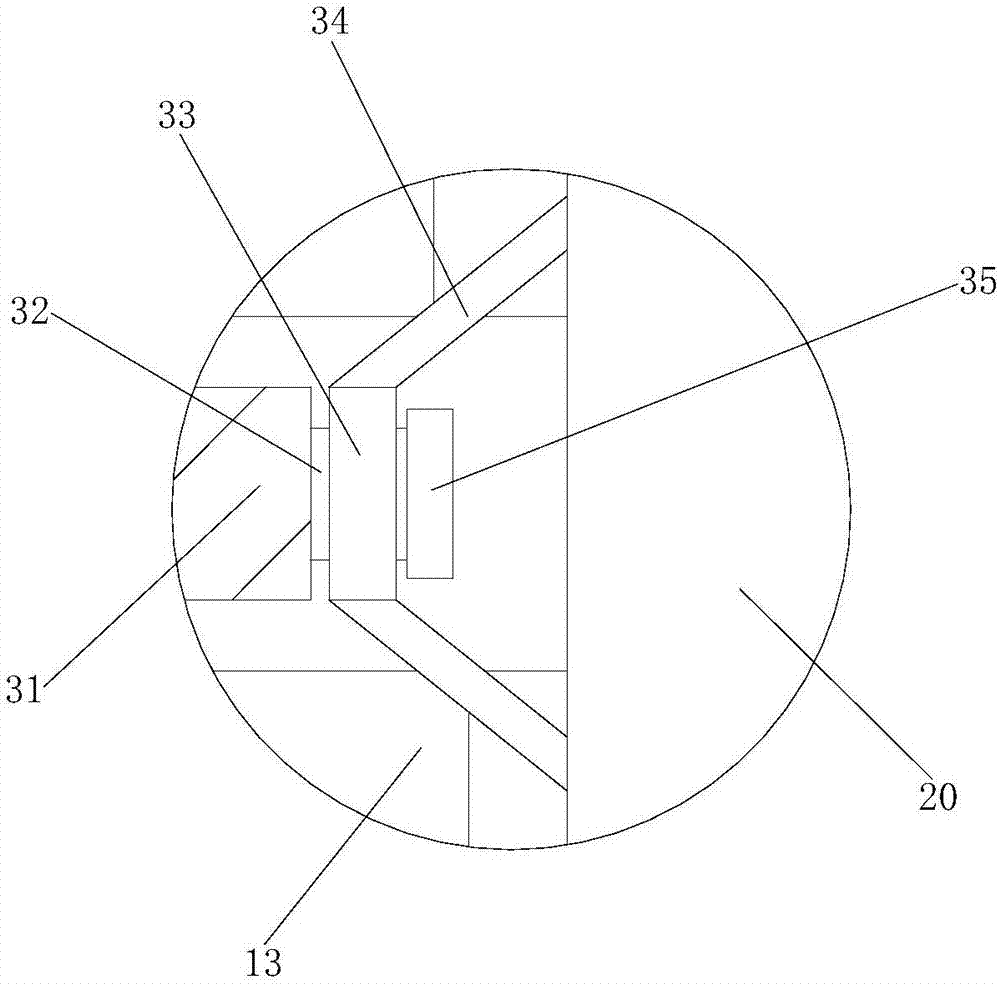

Waterproof pad production device with heat preservation function and production process thereof

ActiveCN112774538AEvenly blendedEfficient integrationShaking/oscillating/vibrating mixersTransportation and packagingProcess engineeringHeat conservation

The invention discloses a waterproof pad production device with a heat preservation function and a production process thereof, which relate to the technical field of waterproof material production. The waterproof pad production device comprises a bottom plate, a shell and a mounting plate, wherein a first cavity is formed in the bottom plate, a lifting mechanism is arranged in the first cavity, a leakage hole is formed in the upper surface of the bottom plate, and a recovery mechanism is arranged in the leakage hole; a connecting block is hinged to the upper surface of the bottom plate by arranging a first pin shaft, and a mounting plate is fixedly connected to the upper surface of the connecting block. Through the power mechanism and the linkage mechanism, a worker can add a chemical raw material and a waterproof raw material into the shell through the feeding port, so that the waterproof raw material and the chemical raw material can be more effectively fused, and stirring work along a fixed angle is avoided; and therefore, part of waterproof raw materials and other chemical raw materials cannot be uniformly and perfectly fused, and later processing work is not facilitated, and the production quality of the production device is guaranteed.

Owner:安徽金川防水防腐新型材料有限公司

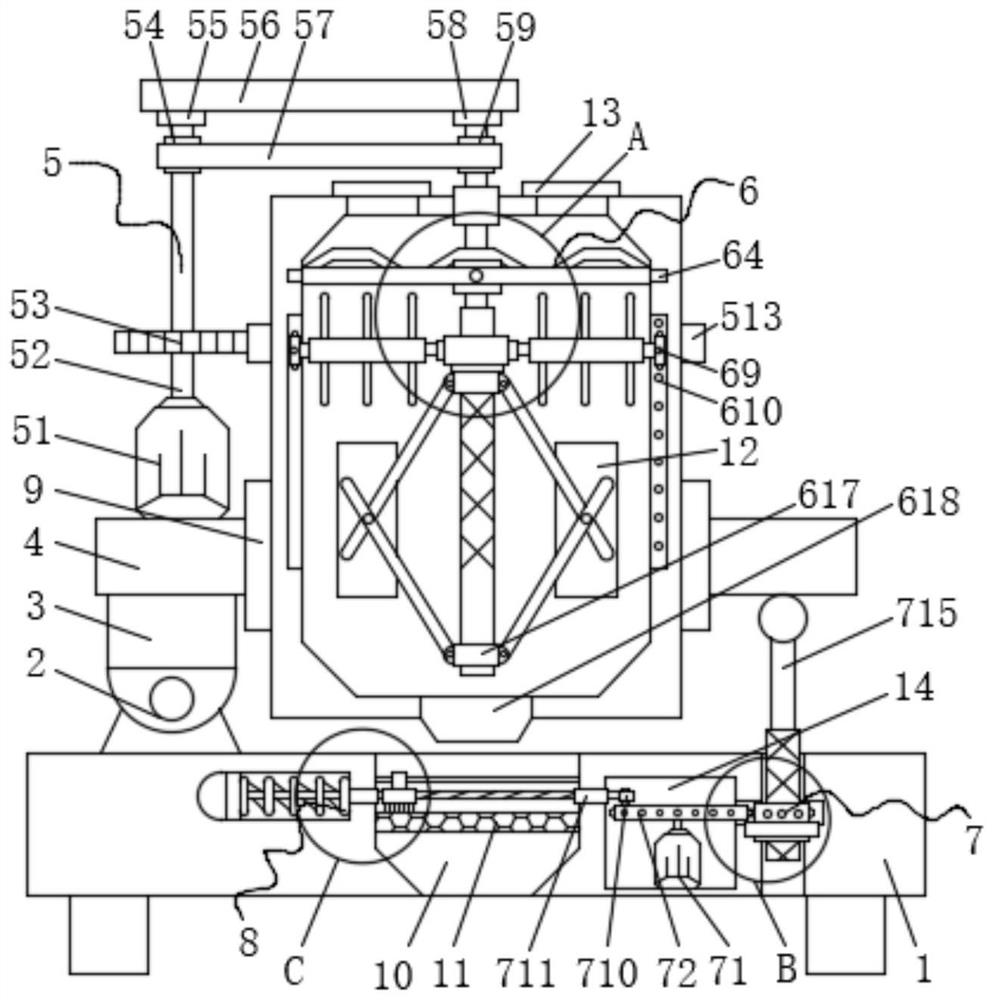

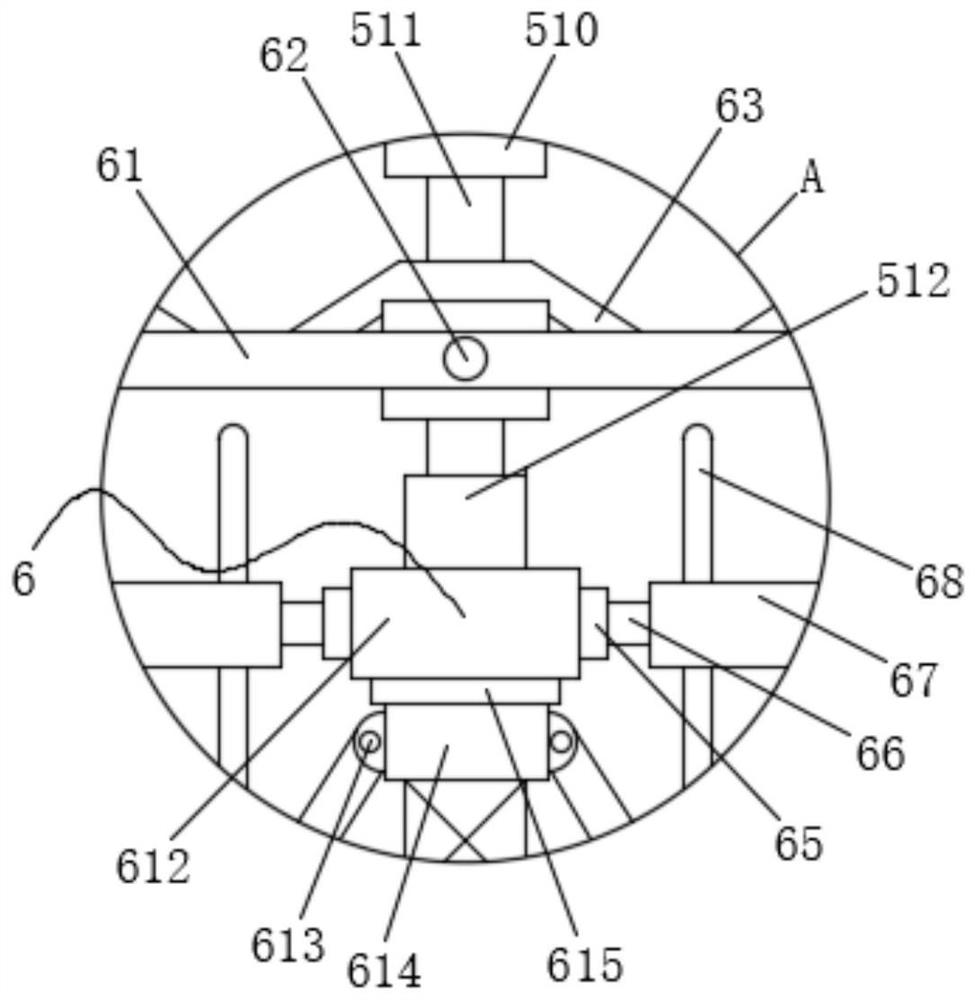

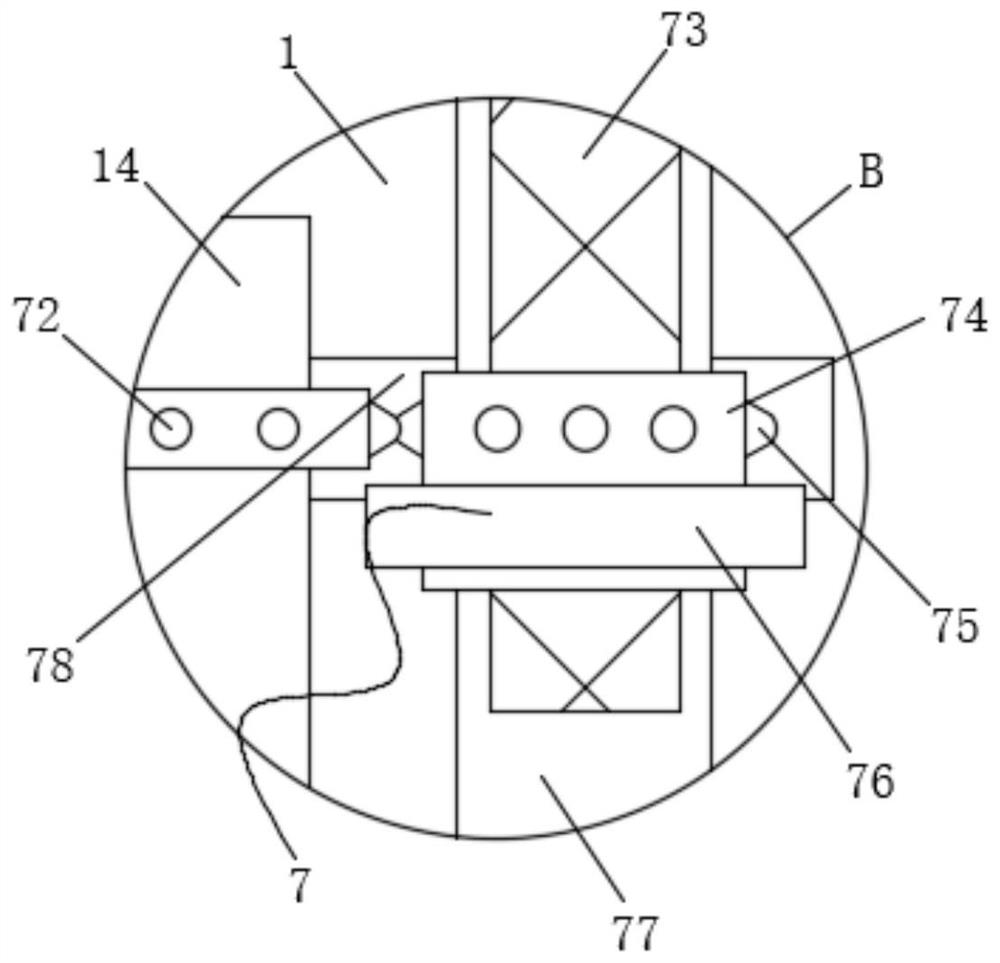

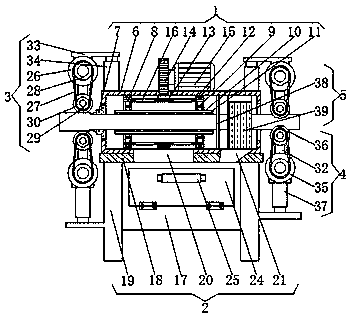

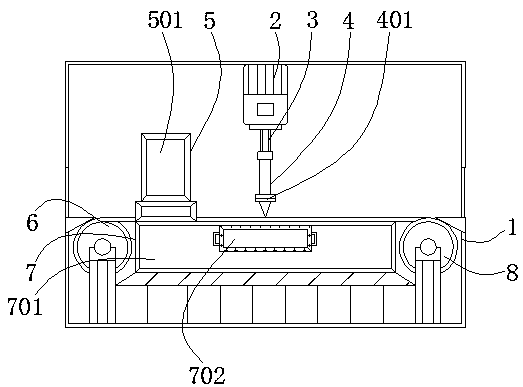

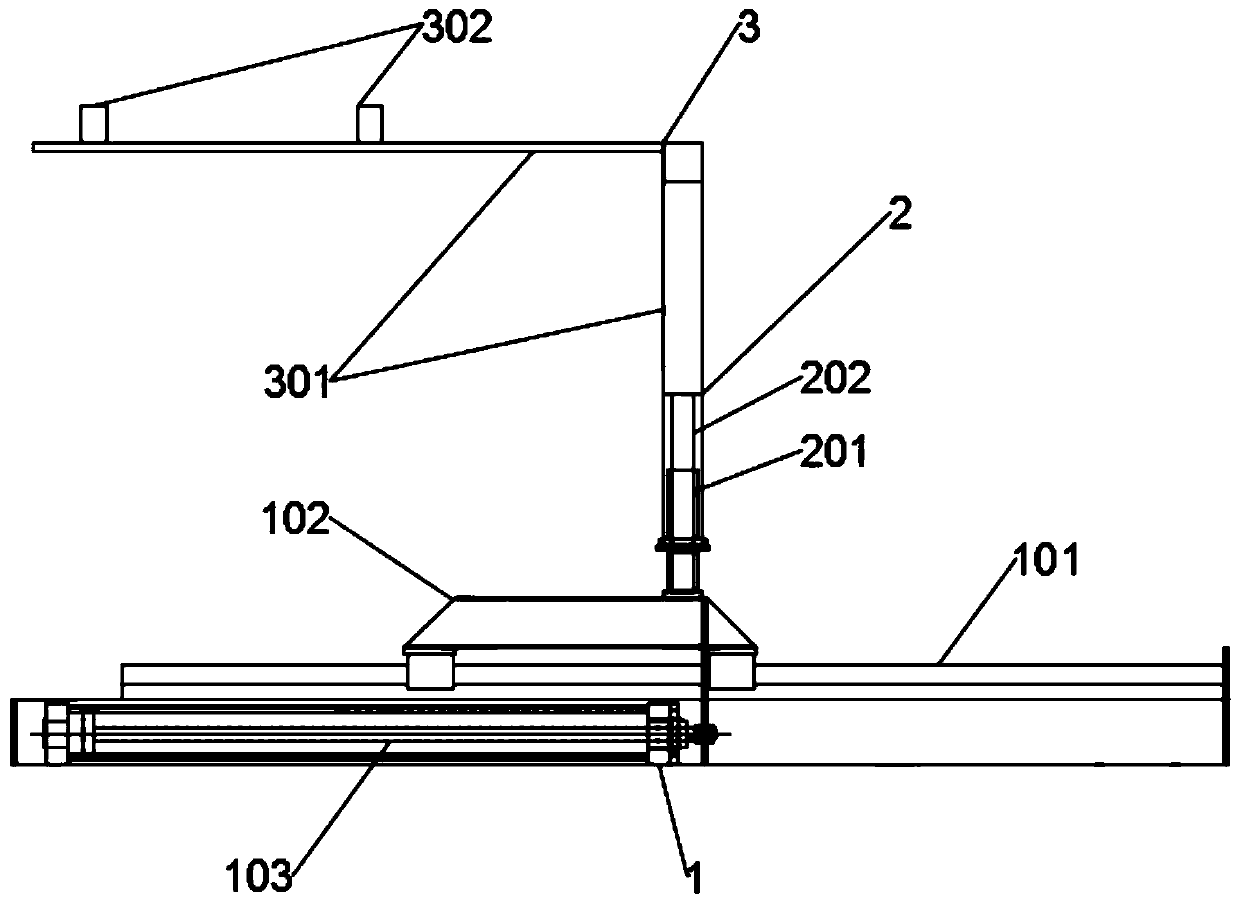

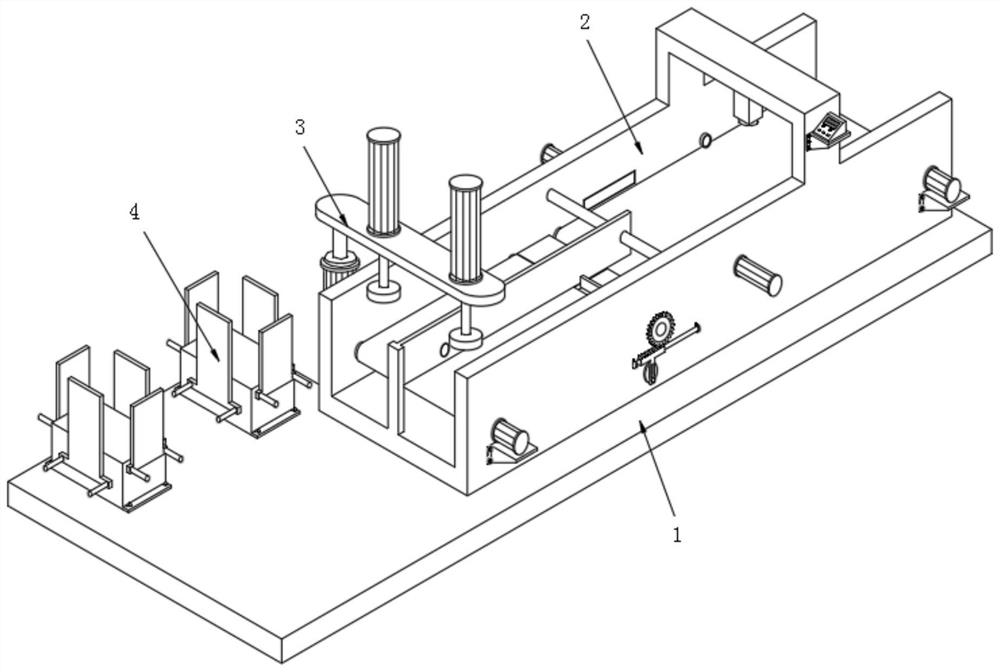

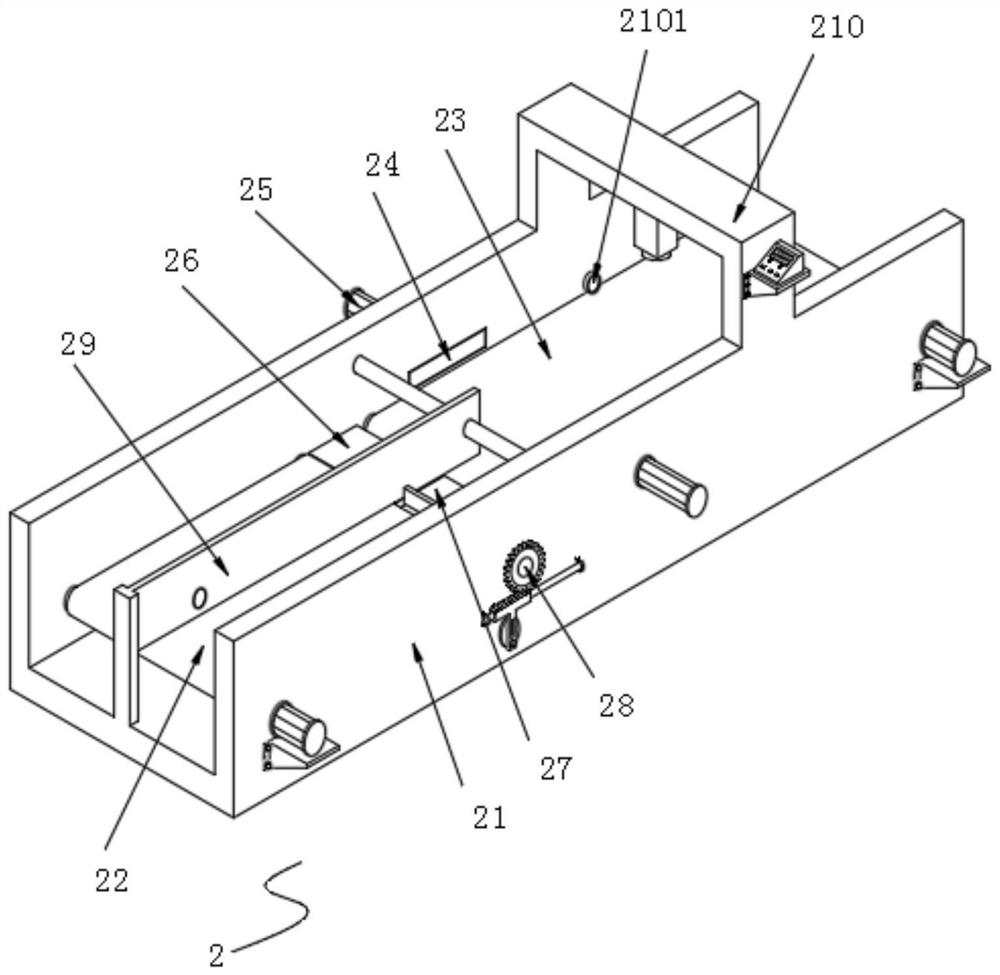

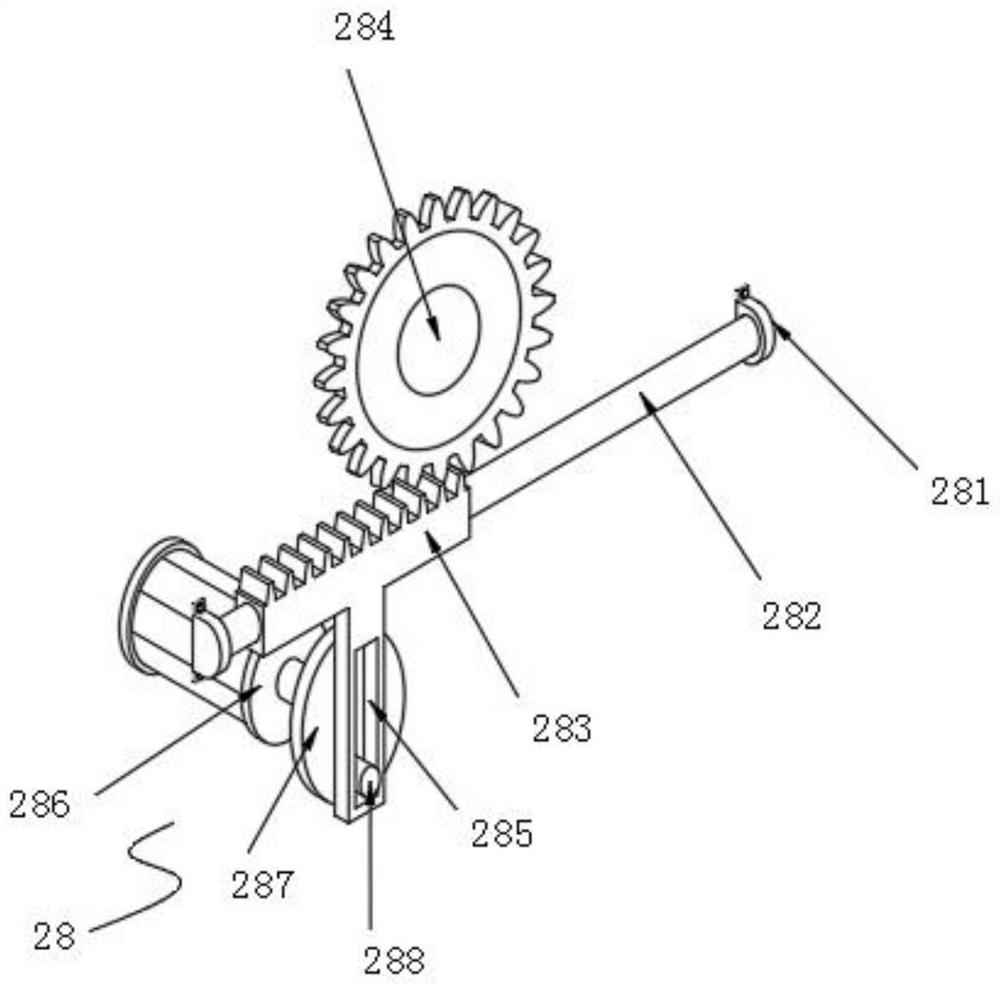

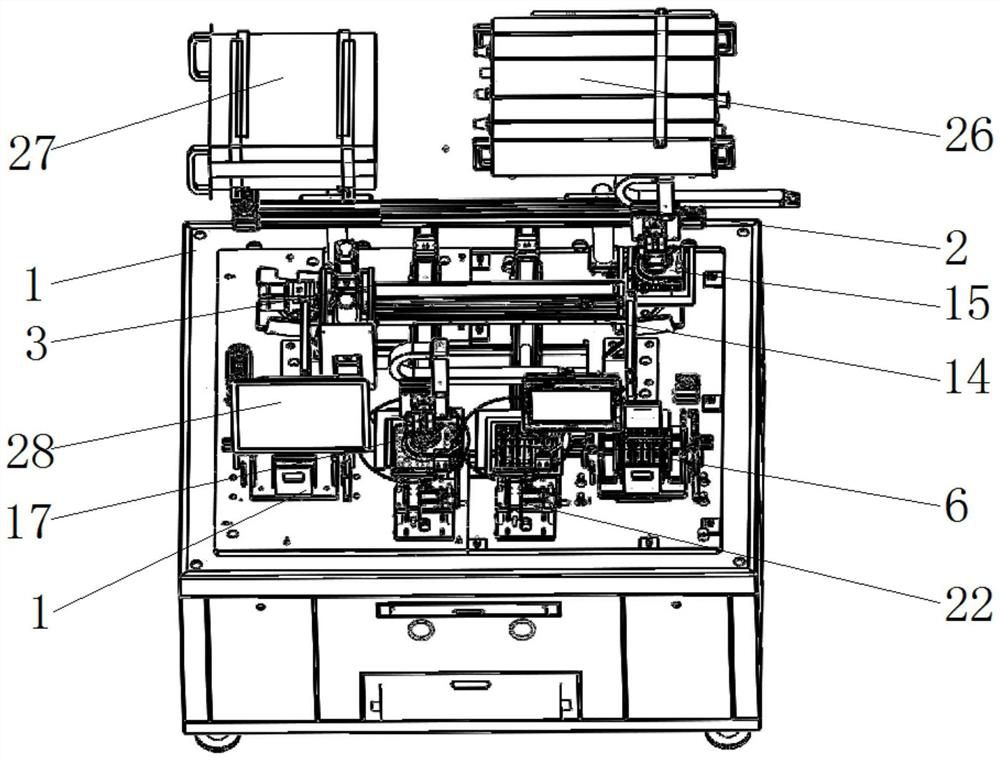

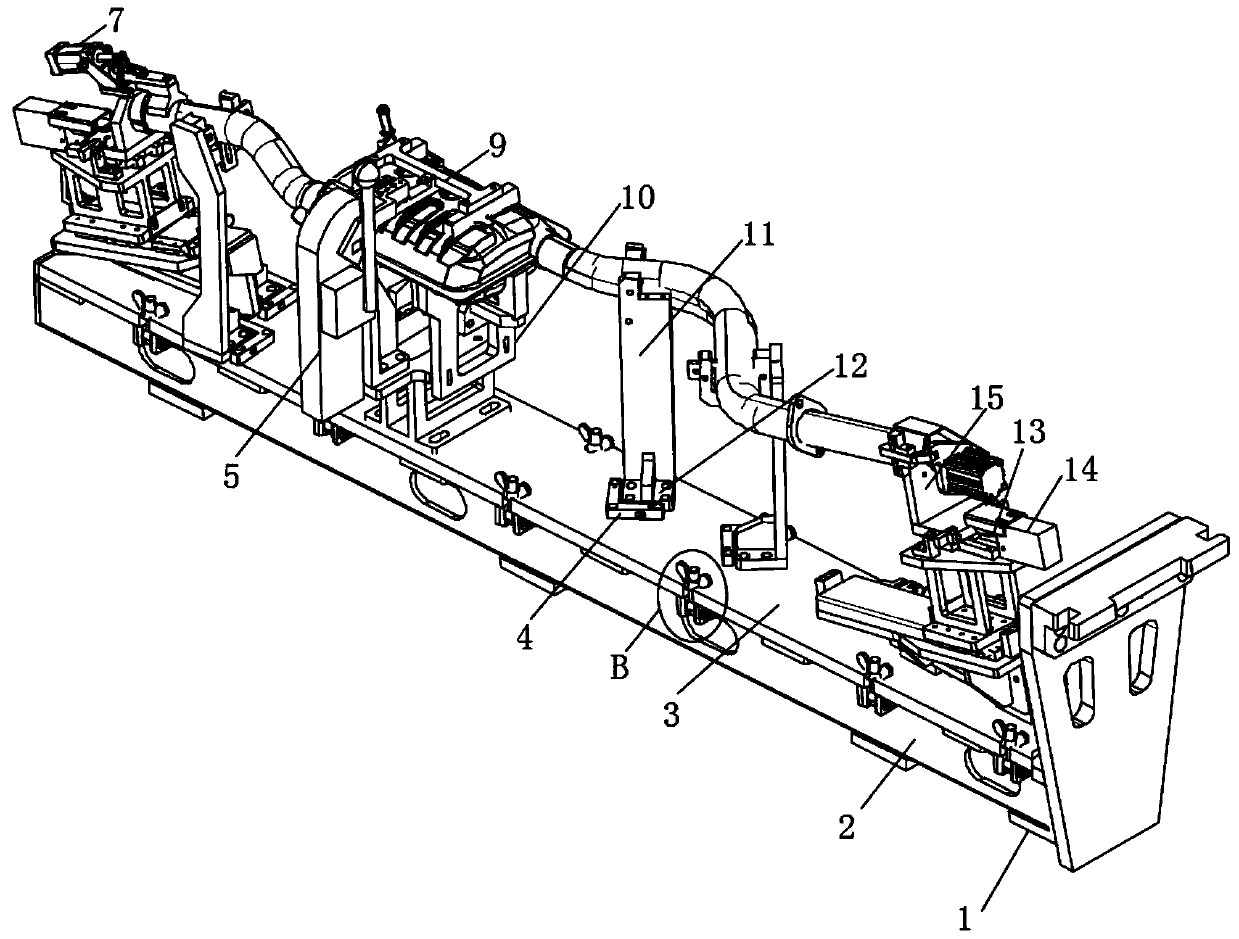

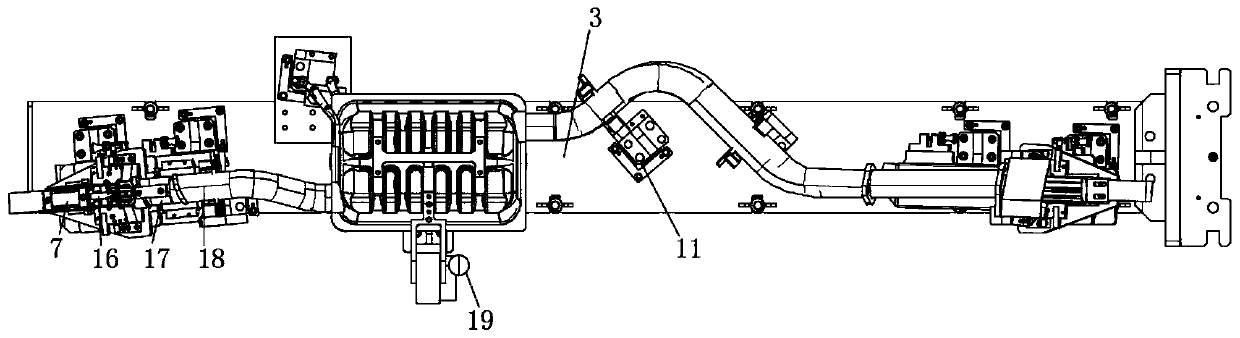

Automatic machining equipment for mass production of threaded rods

InactiveCN110293407AConvenient processing workHigh hardnessOther manufacturing equipments/toolsEngineeringThreaded rod

The invention relates to threaded rod machining equipment, in particular to automatic machining equipment for mass production of threaded rods. The automatic machining equipment is capable of saving manpower, high in safety and high in machining efficiency. According to the technical scheme, the automatic machining equipment comprises a bottom plate, a control box, a power main switch, an installation frame, an installation plate, a sliding rail, a sliding block, a clamp, a nut, a first bearing seat, a first rotating rod, a screw rod and the like; the control box is arranged in the middle of the top of the bottom plate and comprises a power supply module and a control module; the power supply module is connected with a switching power supply through a wire; and the control module is connected with the power supply module through a wire. According to the automatic machining equipment, a crank handle is rotated anticlockwise so as to drive the nut to move inwards through the screw rod, therefore, an iron rod is clamped through the clamp, and machining of the threaded rods is convenient; and through a tapping device, the iron rod can be tapped without using a threading die manually, so that manpower is saved.

Owner:叶玉芳

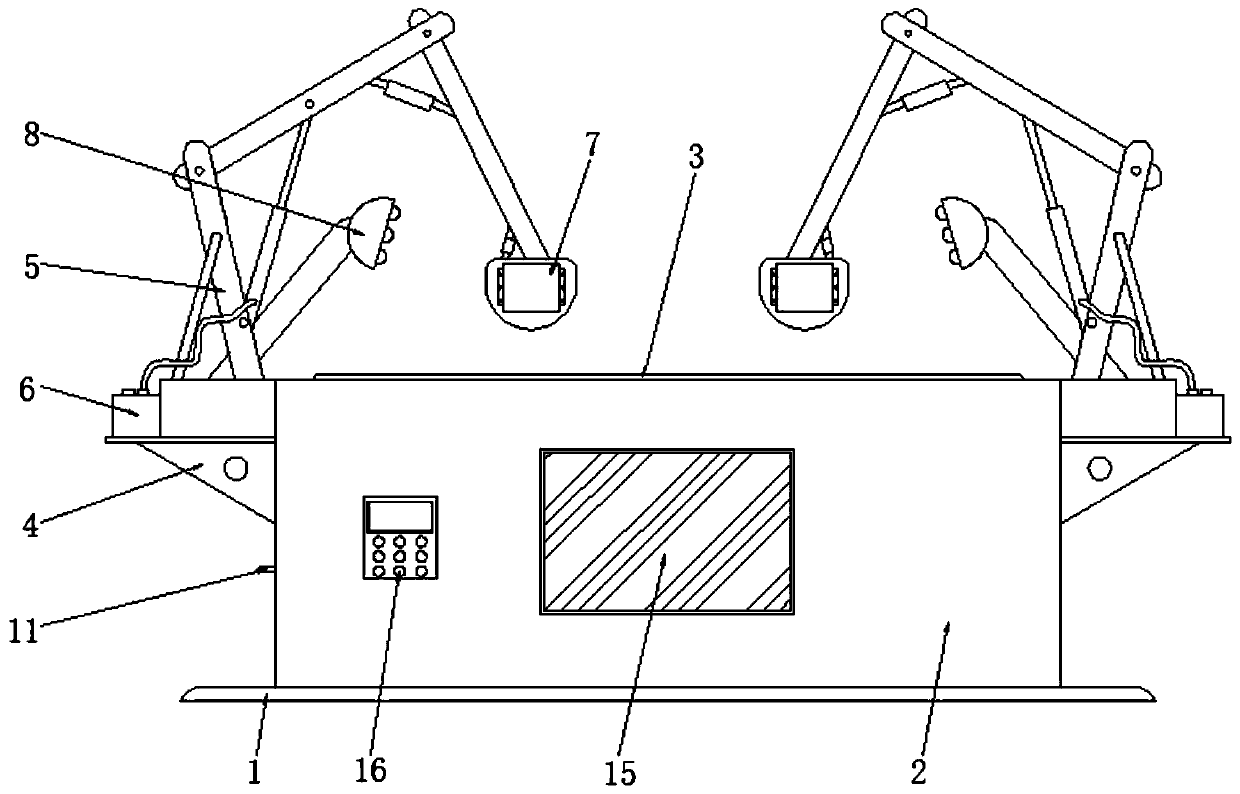

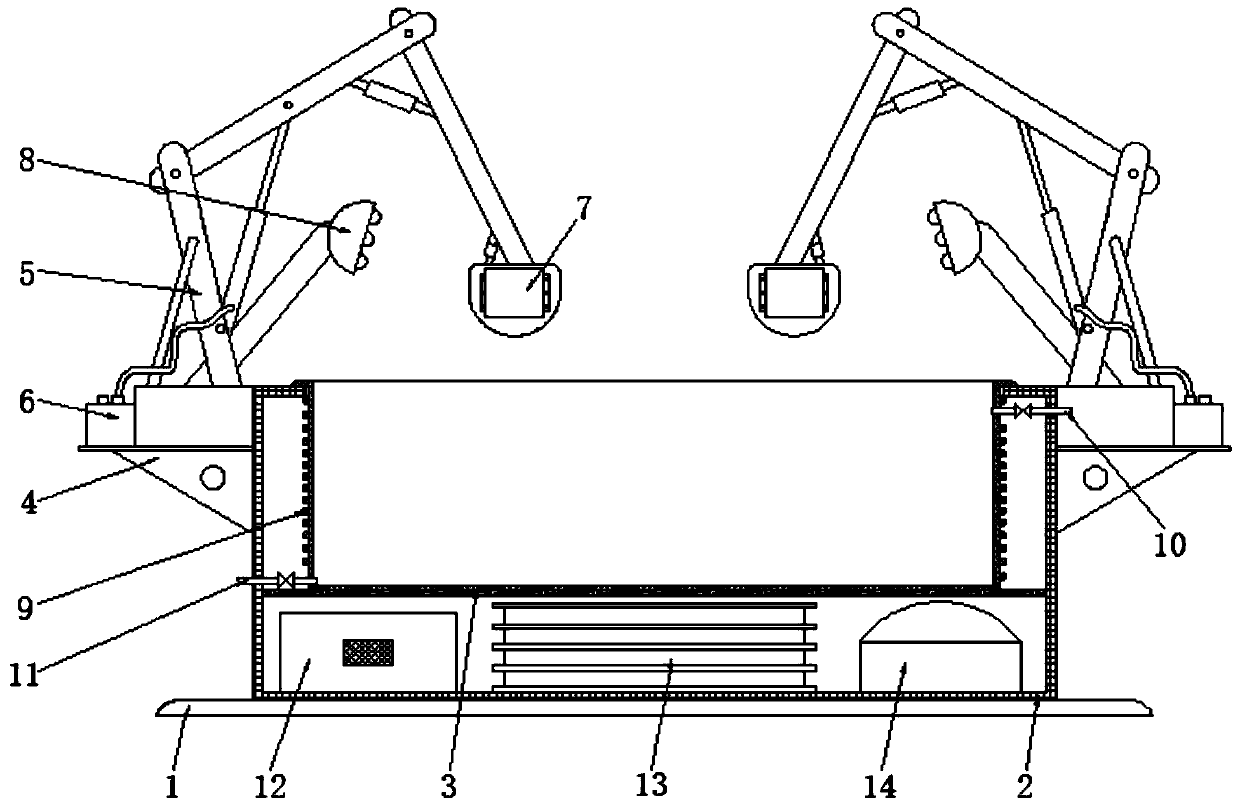

Cleaning and rust preventing integrated device based on automobile crankshaft processing

InactiveCN110947677AEasy to cleanControlled Ultrasonic CleaningPretreated surfacesCoatingsCrankshaftWorking hours

The invention discloses a cleaning and rust preventing integrated device based on automobile crankshaft processing. The cleaning and rust preventing integrated device based on automobile crankshaft processing comprises a base, a case fixedly connected to the top of the base and a cleaning cylinder fixedly mounted in the case. Triangular supporting racks are fixedly connected to two sides of the case through screws, and a beam frame mechanism and a hydraulic assembly are fixedly connected to the tops of the triangular supporting racks, separately. The invention relates to the technical field ofauto part processing. The cleaning and rust preventing integrated device based on automobile crankshaft processing can integrate two steps: cleaning and rust preventing, so that the production efficiency of a crankshaft is improved greatly. The crankshaft is cleaned and dust preventing surface treatment can be carried out without costing a lot of working hours of production staff, so that the labor intensity of the production staff is alleviated, and the work efficiency of the production staff is improved. The cleaning and rust preventing surface treatment steps can be finished well by clamping at one time, so that a purpose of carrying out surface treatment on the crankshaft can be achieved quickly and efficiently.

Owner:湖南耀岷专用汽车制造有限公司

High-speed centrifugal spray dryer with uniform spray function

InactiveCN109248460AGuaranteed to be uniformImprove processing qualityEvaporator accessoriesEvaporation by sprayingPulp and paper industryRotating disc

The invention discloses a high-speed centrifugal spray dryer with a uniform spray function. The high-speed centrifugal spray dryer comprises a high-speed centrifugal spray dryer body; an atomizer is fixedly connected to the left side of the top of the high-speed centrifugal spray dryer body, a feeding hopper communicates with the top of the atomizer; the left side of the high-speed centrifugal spray dryer body communicates with an air inlet pipe, the right side of the high-speed centrifugal spray dryer body is fixedly connected with a suction pump, the bottom of the suction pump communicates with a hose, and the end, away from the suction pump, of the hose communicates with the bottom of the right side of the high-speed centrifugal spray dryer body. According to the high-speed centrifugalspray dryer, through cooperative use of the high-speed centrifugal spray dryer body, the atomizer, the feeding hopper, the air inlet pipe, the suction pump, the hose, a conveying pipe, a connecting plate, spraying heads, a supporting plate, a bracket, a fixing block, a motor, a rotating disc and a crank and connecting rod mechanism, the spraying angle of the spraying heads can be adjusted in a reciprocating mode, spray uniformity is better ensured, and the processing quality is improved.

Owner:汤云峰

Material sheet positioning and arranging device

InactiveCN113526106AImprove work efficiencyReduce labor intensityConveyorsDe-stacking articlesPhysicsPush out

The invention discloses a material sheet positioning and arranging device. The device comprises a material storage box, a u-shaped base is arranged on the front surface of the lower portion of the material storage box, a conveying belt is arranged in the upper portion of the u-shaped base, a material pushing assembly is arranged on the rear surface of the lower portion of the material storage box, a discharging groove is formed in the position, located in the u-shaped base, of the front surface of the lower portion of the material storage box, and a containing cavity is formed in the position, located above the discharging groove, in the material storage box. The invention to the technical field of material sheet machining. According to the material sheet positioning and arranging device, through the arrangement of the material pushing assembly, when material sheets are machined, the material sheets needing to be machined are placed into the material storage box, under the work of a rotating motor, a transmission disc can drive an adjusting rod to do eccentric motion, then a u-shaped sliding plate can be driven to move back and forth, the material sheets in the material storage box are pushed out by an L-shaped push plate on the u-shaped sliding plate, so that the material sheets are arranged on the conveying belt one by one and are uniformly arranged, and line production is formed.

Owner:祺芯苏州智能科技有限公司

Wood processing equipment

InactiveCN109571652AImprove processing efficiencyIncrease frictionProfiling/shaping machinesPlane surface grinding machinesScrapEngineering

The invention discloses wood processing equipment. A processing device is included. A dust suction device is fixedly connected to the bottom of the processing device. A feeding device and a discharging device are fixedly connected to the two sides of the processing device correspondingly. The right side of an inner cavity of the processing device is fixedly connected with a cleaning device. The processing device comprises a processing box. The left side of the processing box is in threaded connection with a tool. First bearings are fixedly connected to the two sides of an inner cavity of the processing box. Inner cavities of the first bearings are fixedly connected with first electric telescopic rods. The ends, away from the first bearing inner cavities, of the first electric telescopic rods are fixedly connected with a connecting plate. Through cooperative usage of the processing device, the dust suction device, the feeding device, the discharging device and the cleaning device, wooddifferent in specification can be processed and can be ground as well, waste scraps generated during grinding can be adsorbed, the processing efficiency is greatly improved, and great convenience is brought to daily processing work.

Owner:吴良桂

Mask paper anti-folding cutting device for mask processing

The invention discloses a mask paper anti-folding cutting device for mask processing and relates to the technical field of mask processing. The mask paper anti-folding cutting device comprises a mainbody and an anti-folding mechanism; a carrying mechanism is disposed at the bottom end of the inner side of the main body; the anti-folding mechanism is arranged on one side of the top of the carryingmechanism; the inner side of the anti-folding mechanism comprises a shell; a scraper blade is movably disposed at the top end of the interior of the shell; and second electric push rods are fixedly installed on the two sides of the inner wall of the shell. The mask paper anti-folding cutting device for mask processing has the beneficial effects that by arranging a pressing barrel, the second electric push rods, the shell, a first roller and a second roller, the pressing barrel and the shell form a lifting structure through the second electric push rods, when mask paper slides along a carryingtable, the mask paper passes through the anti-folding mechanism, the mask paper which is winded and tightened through the first roller and the second roller can be spread under the pressing action ofthe pressing barrel, and thus the phenomenon of folding of the mask paper is effectively prevented.

Owner:DONGGUAN XIANGFEI INTELLIGENT EQUIP TECH CO LTD

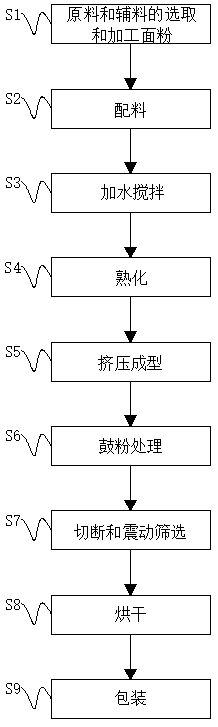

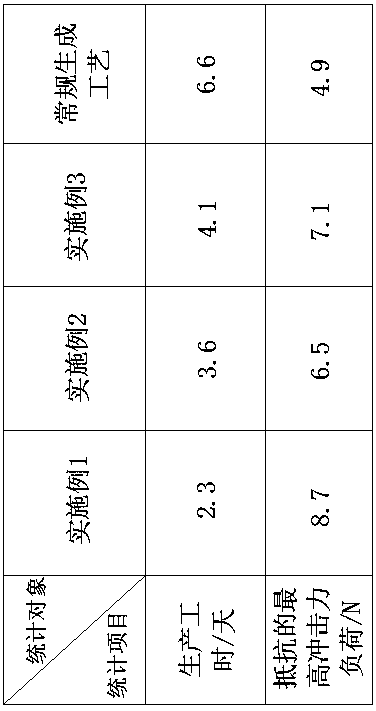

Novel noodle production process

InactiveCN110089679AImprove toughnessAvoid breakingFood ingredient as thickening agentFood ingredient as emulsifierWarm waterEngineering

The invention discloses a novel noodle production process. The production process specifically comprises the following steps: S1, selecting raw materials and auxiliary materials, and processing flour;S2, blending the materials; S3, stirring the materials with water; S4, curing the materials; S5, performing extrusion molding; S6, blowing flour powder; S7, cutting and performing vibration screening; S8, drying the product, and S9, packaging the product. The invention relates to the field of food production technology. The novel noodle production process can blow the outer flour to the surface of the noodle before the formed noodle is cut, the humidity is reduced to a certain extent for the noodle to reduce the adhesion of the noodle surface, the workload of the production staff is reduced,the production efficiency of the noodles is greatly improved, intermittent stirring and dough kneading is carried out by using warm water, two processes of stirring and dough kneading as well as ripening are combined, which can well achieve the purpose of increasing the noodle gluten by adding warm water for dough kneading, the production cost is reduced, and the production efficiency is increased.

Owner:马和平

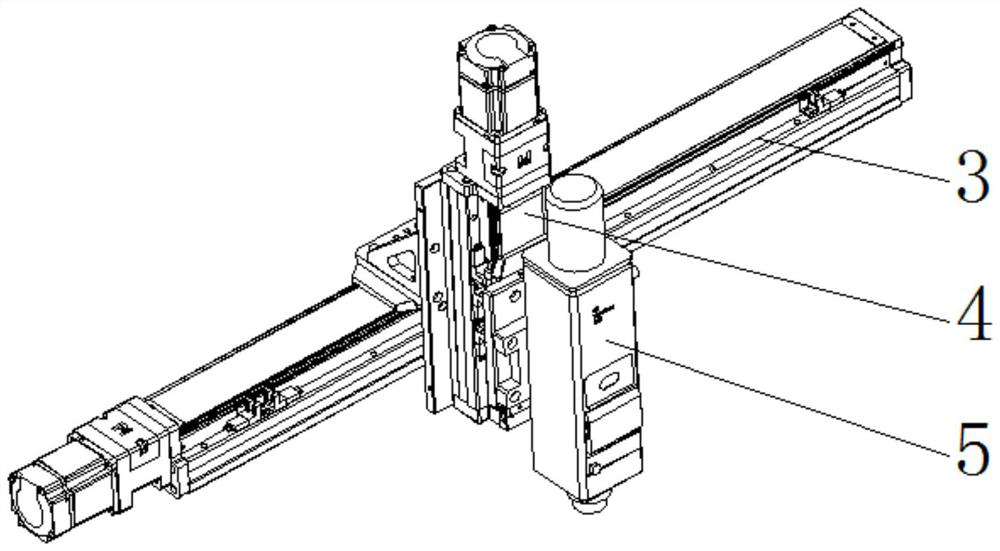

Automatic sampling surface density measurement mechanism for gypsum board production line

The invention discloses an automatic sampling surface density measurement mechanism for a gypsum board production line. The mechanism comprises a set of horizontal moving air cylinder system, a set ofvertical lifting moving air cylinder system and a set of weight measuring system; the vertical lifting moving air cylinder system is connected to the horizontal moving air cylinder system in a sliding manner; the weight measuring system is mounted at the top end of the lifting moving air cylinder system and is used for detecting the weight of a sample; the weight measuring system comprises a sampling weighing platform; a plurality of weight sensors used for detecting the weight of the sample are arranged on the sampling weighing platform; and a sample cleaning mechanism is further mounted onthe sampling weighing platform. The sample can be automatically taken out on the high-speed production line to measure the surface density, so that the operation process of measuring the surface density by manual sampling at present is replaced; and the sample can be automatically cleaned, so that the accuracy of a surface density detection result can be improved.

Owner:NINGBO BEIXIN BUILDING MATERIAL +1

Automatic plate shearing machine with good plate fixing effect

ActiveCN107876854AThe effect of fixing the plate is goodImprove clippingShearing machinesShearing machine accessoriesAgricultural engineeringDrive motor

The invention discloses an automatic plate shearing machine with the good plate fixing effect. The automatic plate shearing machine comprises a bottom plate, and storing plates are fixedly connected to the left side and the right side of the bottom of the bottom plate correspondingly. A mounting block is fixedly connected to the middle point of the bottom of the bottom plate, the bottom of the mounting block is fixedly connected with a driving motor, and a driving rotating shaft is fixedly connected to an output shaft of the driving motor. According to the automatic plate shearing machine, byarranging a sliding rail, a sliding block, a limiting baffle, a plate storing plate, a fixing baffle, fixing rods, a movable baffle, a connecting block, a connecting transverse plate, a limiting rod,a spring fixing plate, a limiting plate, a spring, nut fixing plates, nuts, bolts, a rotating block, a limiting sleeve ring, a supporting rod and a limiting block, the plate fixing effect of the automatic plate shearing machine becomes better, plates of different specifications can be well fixed, shearing errors are avoided, the plate shearing effect is improved, plate machining work is advantageously conducted, and great convenience is brought to users.

Owner:HT METALFORMING EQUIP MFG

Positioning device of PCB

InactiveCN110744509AFlexible foldingEasy to foldWork benchesControl engineeringMechanical engineering

Owner:云梭(宁波)科技有限公司

Blanking device for production of pressure sensor diaphragms

PendingCN111940808AHigh pressureSmall amount of deformationEdge grinding machinesShearing machinesPunchingElectric machine

The invention belongs to the field of diaphragm production devices, and particularly relates to a blanking device for production of pressure sensor diaphragms. The blanking device comprises a workbench, the workbench is provided with supports, the supports are fixedly connected with a motor, an output shaft of the motor is movably connected with a blanking device body through a rotating part, andthe blanking device body comprises a lifting table, a blanking part and a pressing part. The lifting table is connected with the supports in a sliding manner, the pressing part is connected with the lifting table in a sliding manner, the workbench is provided with a punched hole, the blanking part and the punched hole are cooperatively arranged, and the punched hole is rotationally connected witha grinding sleeve. According to the blanking device for production of the pressure sensor diaphragms, excessive punching force in the machining process of the blanking device is avoided, the deformation amount of a metal wafer in the punching process of a blanking tool is reduced, the blanking quality of the metal wafer is improved, meanwhile, burrs on the edge of the metal wafer can be ground inthe blanking machining process of the device, the machining efficiency of the diaphragms is improved, and the blanking device is suitable for being popularized.

Owner:滨海永达电子科技有限公司

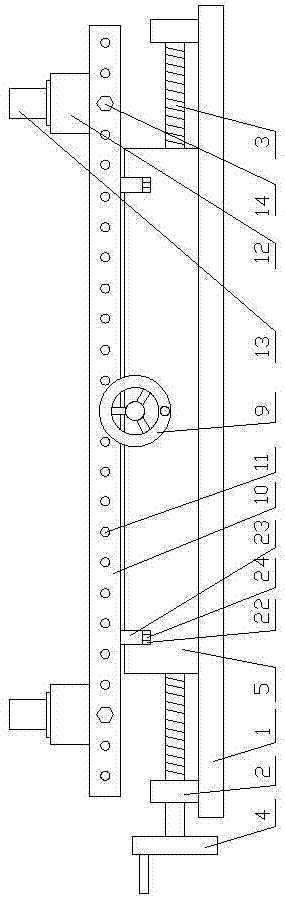

Mechanical clamp table for board part machining

InactiveCN107414548AAdjustable distanceMeet the clamping requirementsPositioning apparatusMetal-working holdersOn boardEngineering

The invention discloses a mechanical fixture platform for processing plate parts, which comprises a base on which a traverse screw seat is arranged, the traverse screw seat cooperates with the traverse screw, and the traverse screw is connected with the traverse screw The middle frame cooperates, and the upper part of the middle frame is provided with a screw groove, and the screw groove is matched with the vertically moving screw, and the vertically moving screw is matched with the main table, and a group of oil cylinder frames are slidably installed on the main table , an oil cylinder is installed on the oil cylinder frame, and the oil cylinder frame is positioned and matched with the main table surface through positioning bolts, and the oil cylinder is matched with the pressure plate seat, and the pressure plate seat is connected with the pressure plate through a set of thrust springs, and the pressure plate Contacts are connected to the top, and a storage battery is installed on the press plate seat, and the storage battery is electrically connected with the lamp bead and the switch. The mechanical fixture table for processing plate parts can quickly clamp plate-shaped or bar-shaped parts, facilitate processing work, and has a wide range of applications, and can be applied to the fixing work of plate parts of various specifications.

Owner:芜湖挺优机电技术有限公司

Clamping and fixing device for processing treatment of complex-form materials

InactiveCN112059669AImprove stabilityConvenient positioning and processing workPositioning apparatusMetal-working holdersStructural engineeringManufacturing engineering

The invention discloses a clamping and fixing device for processing treatment of complex-form materials. The clamping and fixing device comprises a base, wherein two sliding grooves which are symmetrically arranged are formed in the upper end surface of the base; sliding blocks are connected in the two sliding grooves in a sliding mode; clamping plates are fixedly connected to the side walls, faraway from the sliding grooves, of the two sliding blocks; elastic bags are fixedly connected to the side walls, close to each other, of the two clamping plates; a supporting bag is fixedly connected to the upper end surface of the base; electrorheological fluid is arranged in the elastic bags and the supporting bag; power supply equipment is arranged on the side walls, far away from each other, ofthe two clamping plates and the lower end surface of the base; and power supply rods are arranged on the three pieces of power supply equipment. According to the clamping and fixing device, the stability of clamping and fixing work during the processing of the complex-form materials is improved, the accuracy of material processing is improved, and the use of a user is greatly facilitated.

Owner:赵静

Fruit crushing device for beverage processing

InactiveCN112060661AConvenient crushing workConvenient processing workJuice extractionPress ramBiotechnologySliding contact

The invention discloses a fruit crushing device for beverage processing. The fruit crushing device for beverage processing comprises a fruit crushing structure. The fruit crushing structure comprisesan operation main body, an operation frame, a crushing main body, a solid-liquid separation main body and a control main body, the middle of the operation main body is installed at the inner end of the control main body in a threaded manner, and the lower portion of the operation main body makes sliding contact with the crushing main body. The lower portion of the operation main body is located onthe inner side of the crushing main body, the operation main body is inserted into the inner end of the upper portion of the operation frame in a sliding manner, the lower end of the operation frameis fixedly installed at the upper end of the solid-liquid separation main body, and the outer end of the crushing main body is fixedly installed at the inner end of the upper portion of the operationframe. The upper end of the solid-liquid separation main body and the crushing main body are fixedly installed together, and the internal space of the crushing main body communicates with the upper space of the solid-liquid separation main body. According to the fruit crushing device for beverage processing, juicing work can be directly carried out after crushing, slag can be automatically discharged, and the use requirement can be better met.

Owner:绍兴市上虞裕润农业科技有限公司

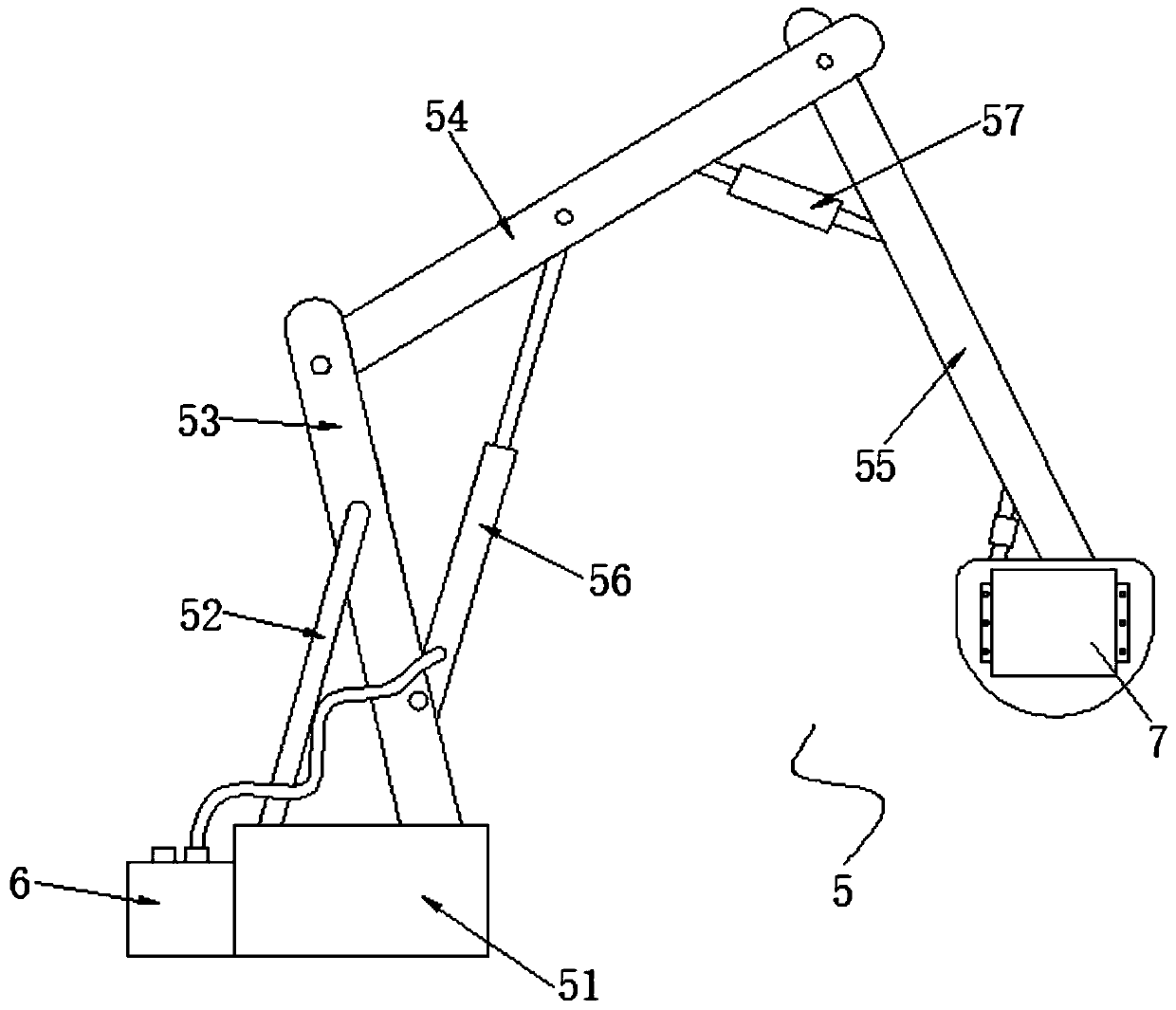

Product stacking production equipment with self-checking function

InactiveCN113120630AConvenient processing workPrecise palletizingConveyorsStacking articlesMechanical engineeringIndustrial engineering

The invention discloses product stacking production equipment with a self-checking function. The product stacking production equipment with the self-checking function comprises a base plate, a conveying mechanism is arranged on the upper surface of the base plate, a stacking assembly is arranged on one side face in front of the conveying mechanism, and two stacking and aligning assemblies corresponding to the stacking assembly are arranged on the upper surface of the front side of the base plate. The product stacking production equipment with the self-checking function belongs to the technical field of product stacking. According to the product stacking production equipment with the self-checking function, a detection assembly is fixedly connected to the position, close to one side of a push plate, of the upper surface of a U-shaped base, when plates pass through the position of a camera in the conveying process, the front faces and the back faces of the plates can be automatically detected, whether the front faces of the plates face upwards or not is detected, when the back faces of the plates face upwards, the device can convey the plates with the back faces facing upwards to the position of an L-shaped plate, then the plates with the back faces facing upwards can be turned over under the work of a transmission assembly, and therefore all the plates with the front faces facing upwards can be stacked.

Owner:马治国

Efficient cutting equipment for automotive cables

ActiveCN109108188AConvenient processing workSave time at workApparatus for cutting/splicing cablesMotor driveReciprocating motion

The invention discloses efficient cutting equipment for automotive cables. The efficient cutting equipment comprises a cutting device, four corners of the bottom of the cutting device are all fixedlyconnected with support legs, the bottoms of the four support legs are fixedly connected through a position-limiting device, the cutting device comprises a top plate, the bottom of the top plate is fixedly connected with the support legs, the left side of the top of the top plate is fixedly connected with a base, and the top of the base is fixedly connected with a cutting motor. According to the efficient cutting equipment for the automotive cables, by means of the mutual coordination of the cutting device and the position-limiting device, in the use process, the multiple cables are inserted into fixing slots through position-limiting slots correspondingly, then the cutting motor drives a rotating disc to rotate through a cutting rotating shaft, the rotating disc drives a rotating rod to rotate through a first rotating shaft, the rotating rod drives a cutting rod to rotate through a second rotating shaft, the cutting rod is limited to perform reciprocating motions up and down, the multiple cables can be cut simultaneously, the working time is saved, the cutting efficiency of the efficient cutting equipment is improved, and great convenience is brought for the cable processing work.

Owner:长沙恒太自动化科技有限公司

Numerical control press good in shock absorption effect

ActiveCN108043935AImprove shock absorptionExtended service lifeNon-rotating vibration suppressionShaping safety devicesNumerical controlTransverse plane

The invention discloses a numerical control press good in shock absorption effect. The numerical control press comprises a fixed transverse plate; the four corners of the bottom of the fixed transverse plate are fixedly connected with landing legs; the left side and the right side of the top of the fixed transverse plate are fixedly connected with fixed vertical plates; and the tops of the two fixed vertical plates are fixedly connected through a cover plate. With the adoption of vertical sliding rails, vertical sliding blocks, a workbench, telescopic blocks, a vertical spring, first fixing blocks, first baffles, first connection rotating shafts, supporting rods, through grooves, second connection rotating shafts, second baffles, second fixing blocks, a telescopic rod, a transverse spring,connecting plates, roller rotating shafts and rotating rollers, the shock absorption effect of the numerical control machine is improved, the quality of a formed workpiece is ensured, the numerical control press cannot be damaged, unnecessary economic loss is avoided, the service life of the numerical control machine is prolonged, workpiece machining work is carried out advantageously and great convenience is brought to a user.

Owner:YIZHENG DINGSHENG MACHINERY MFG

Silicon wafer cutting machine

PendingCN112719639AGuaranteed finenessImprove cutting effectLaser beam welding apparatusConveyor partsPhysicsSilicon chip

The invention discloses a silicon wafer cutting machine which comprises a machine body and first material boxes, the upper end of the machine body is connected with a moving module, the upper end of the interior of the machine body is provided with a cutting module, the front end of the cutting module is movably connected with a laser cutting head, and the upper end of the laser cutting head is embedded with a fiber laser light path integration; and the first material boxes are arranged at the left end and the right end in the machine body, the lower ends of the first material boxes are connected with jacking lower blocks, jacking upper blocks are fixed to the upper ends of the first material boxes, and material box cushion blocks are arranged on the upper sides of the first material boxes. The silicon wafer cutting machine is provided with the laser cutting head, the laser cutting head is in sliding connection with the cutting module, the laser cutting head can slide left and right along the surface of the cutting module, adjustment within a certain range is achieved, different parts of a silicon wafer can be cut conveniently, the silicon wafer cutting fineness is guaranteed, and the cutting effect is improved; and meanwhile, the slidable laser cutting head can be switched back and forth between two machining tables for machining, and the machining effect is improved.

Owner:无锡烁邦智能设备制造有限公司

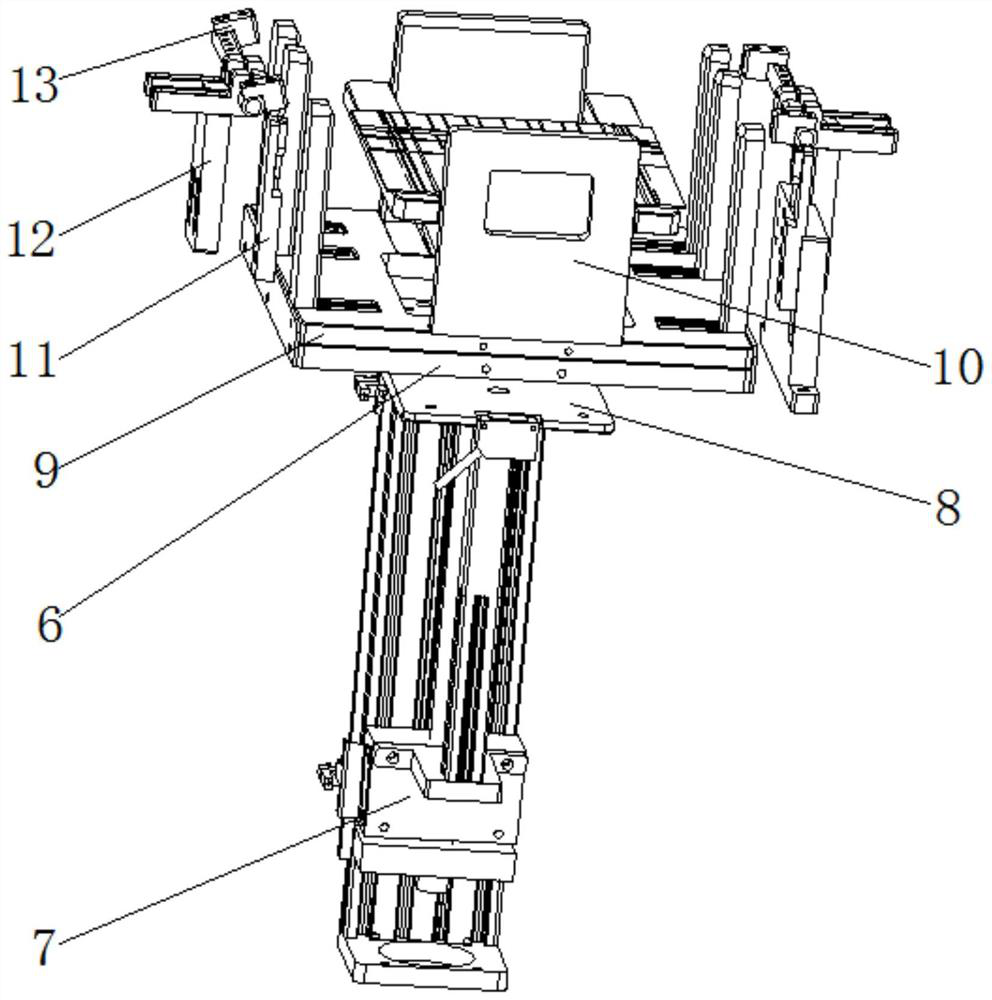

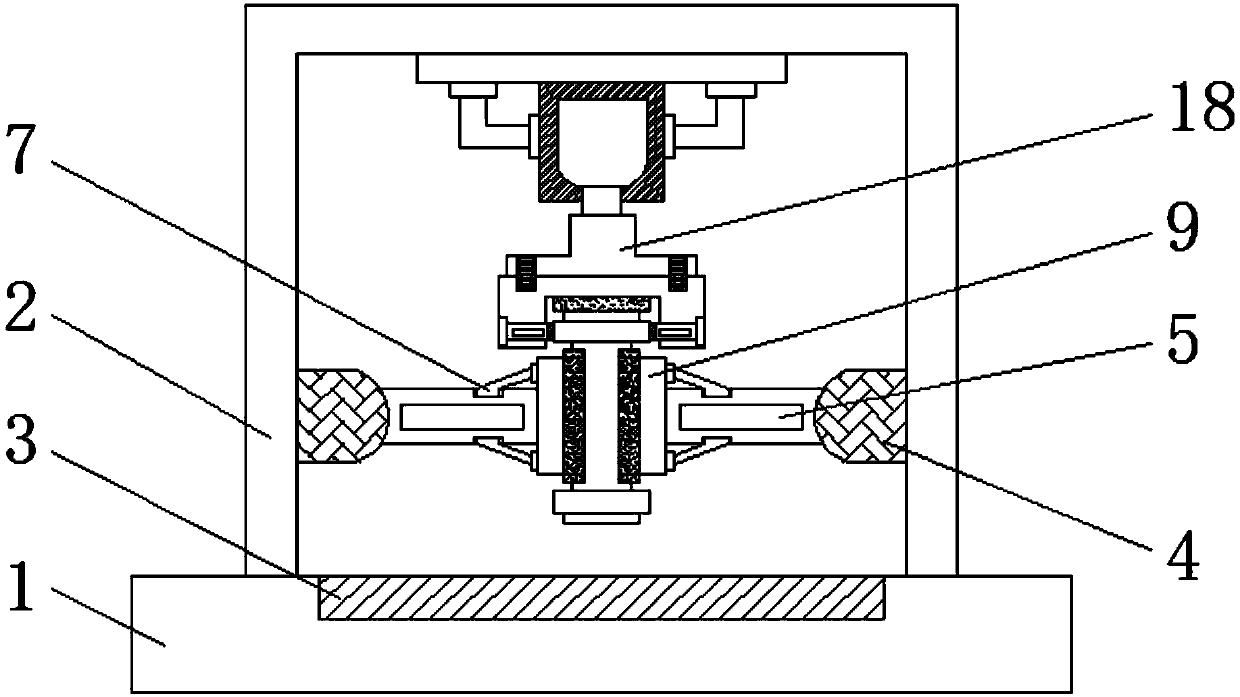

Double open type workbench for double-surface machining of workpieces

ActiveCN108356581AConvenient processing workGuaranteed stabilityMetal working apparatusPositioning apparatusEngineeringPower unit

The invention discloses a double open type workbench for double-surface machining of workpieces. The workbench comprises an outer ring table and a center table, wherein a through groove is formed in the middle of the outer ring table, and the center table is located on the inner side of the through groove; a placement groove is formed in the center table; a first movable plate assembly and a second movable plate assembly which can automatically so as to control opening / closing of a port of the placement groove are arranged on the front side and the reverse side of the center table correspondingly; at least three guide holes which are annularly formed around the placement groove are formed in the center table; a first driving mechanism is arranged on the outer ring table and is used for driving the center table to turn over; every time the first driving mechanism acts, the center table turns over by 180 degrees; a second driving mechanism is arranged at the end, located at any one of the guide holes, of the outer ring table; and each second driving mechanism comprises an ejector rod and a power unit, wherein the ejector rod is coaxially arranged with the corresponding guide hole andcan extend into the corresponding guide hole, and the power unit is used for driving the ejector rod to extend in the direction of the corresponding guide hole. The workbench has the advantage that the production efficiency of double-surface machining of the workpieces can be effectively improved.

Owner:TIANCHANG CYLINDER HEAD

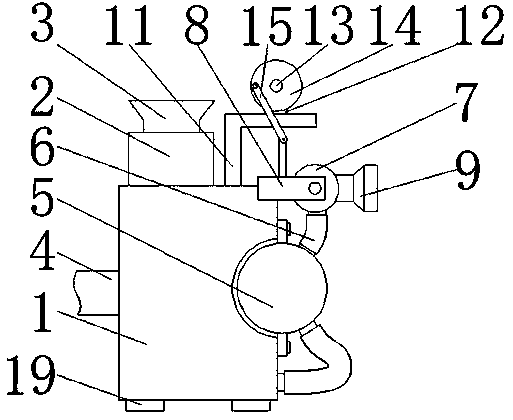

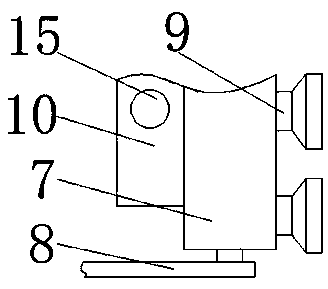

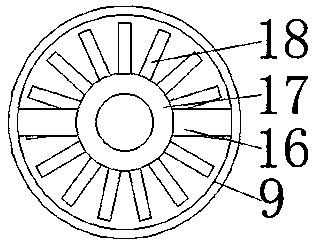

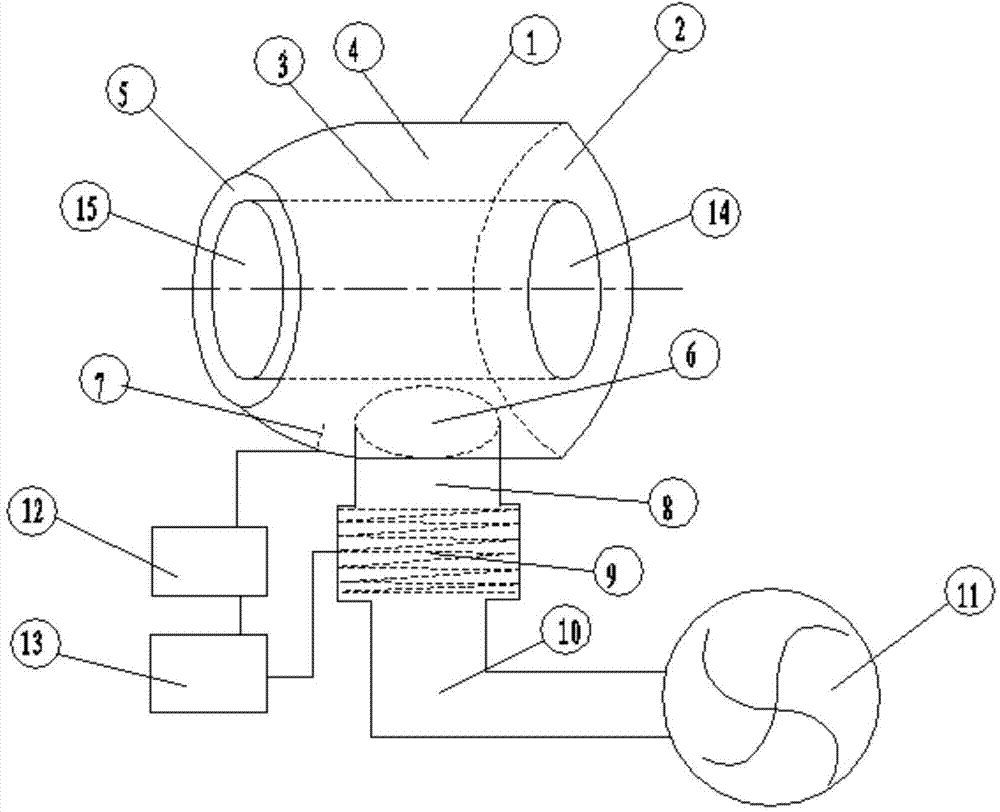

Annular hot air blow-drying equipment for welding cables

InactiveCN103594209AImprove drying effectControl speedCable/conductor manufactureControl engineeringTurbine

The invention relates to annular hot air blow-drying equipment for welding cables. The annular hot air blow-drying equipment comprises a cable passing inner pipe and a shell. The cable passing inner pipe and the shell are both horizontally arranged, and the shell is coaxially mounted on the outer side of the cable passing inner pipe in a sleeved mode; a cable inlet in the right side of the cable passing inner pipe and the right end face of the shell are connected through a mounting plate to form a closed end face; an air cavity is formed by a gap between the outer wall of the cable passing inner pipe and the inner wall of the shell; an air blowing port is formed between a cable outlet in the left side of the cable passing inner pipe and the left end face of the shell; a heating pipe is installed on the lower portion of the shell, the front end of the heating pipe extends into the air cavity, a heating unit is installed in the heating pipe, and the rear end of the heating pipe is connected with a turbine fan. The annular hot air blow-drying equipment for the welding cables is ingenious in design, reasonable in structure and high in practicability. Furthermore, when the equipment is used, the blow-drying effect can be improved, blow-drying efficiency is enhanced, and convenience is brought to the next step of processing the welding cables.

Owner:TIANJIN KEBO ELECTRIC POWER TECH DEV

Valve machining fixing device with good clamping effect

InactiveCN107756100AEasy to holdEasy to fixPositioning apparatusMetal-working holdersHydraulic cylinderArchitectural engineering

The invention relates to the technical field of valve machining and discloses a valve machining fixing device with a good clamping effect. The valve machining fixing device comprises a base. A frame is fixedly connected to the upper surface of the base. A collection tank is arranged on the portion, located in the frame, of the upper surface of the base. Hydraulic cylinders are correspondingly andfixedly connected to the two sides in the frame. The output ends of the hydraulic cylinders are movably connected with hydraulic rods. Fixing grooves are correspondingly formed in the surfaces of theouter sides of the hydraulic rods. Connecting plates are fixedly connected to the ends, away from the hydraulic cylinders, of the hydraulic rods. Fixing rods are correspondingly and fixedly connectedinto the fixing grooves. First connecting blocks are fixedly connected to the ends, away from the fixing grooves, of the fixing rods. According to the valve machining fixing device with the good clamping effect, by arranging the fixing grooves and the fixing rods, the fixing rods are fixedly connected into the fixing grooves, and when valves are clamped and fixed by the hydraulic rods, the connecting plates can be effectively reinforced by the fixing rods, so that the good fixing effect of the valve machining fixing device with the good clamping effect is guaranteed.

Owner:陈可艳

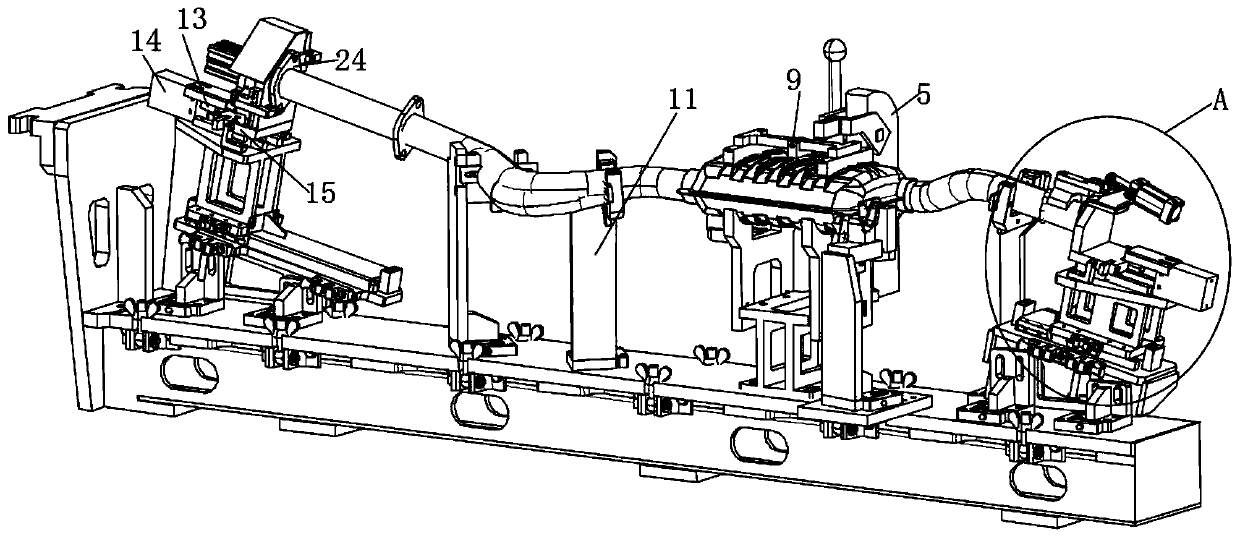

Finished automobile pipeline connecting tool and working method thereof

PendingCN110480382AAvoid shakingEasy to processPositioning apparatusMetal-working holdersHydraulic cylinderEngineering

The invention discloses a finished automobile pipeline connecting tool. The finished automobile pipeline connecting tool comprises a pedestal, a base plate and a supporting rod; the base plate is arranged at the top of the pedestal; the edges of the two sides of the base plate are symmetrically provided with two rows of clamping slots; the part, positioned below each clamping slot, of the sidewallof the pedestal is provided with two clamping blocks; between every two clamping blocks is provided with a rotating shaft; the two ends of each rotating shaft are correspondingly arranged on the twocorresponding clamping blocks and are rotationally connected with the two clamping blocks; a first hydraulic cylinder is used for controlling a first hydraulic rod therein to move toward the outer side of the cylinder body so that the first hydraulic rod can push the top end of a supporting plate to move, thus a pressing disc moves down to tightly press the opening of a pipeline and fix the position of the pipeline; when the opening of the pipeline is warped, the first hydraulic cylinder is used for controlling the first hydraulic rod therein to move toward the inner side of the cylinder bodyso that the pressing disc moves upwards to make sure that the pipeline makes contact with the pressing disc and the position of the pipeline is fixed; shake of the pipeline is prevented when the pipeline is processed; and thus the processing quality is not affected.

Owner:ANHUI ANKAI AUTOMOBILE

Intelligent multi-functional printing and dyeing device for non-woven fabric for processing paper diapers

InactiveCN112342707AEasy to fixEasy to moveLiquid/gas/vapor removalTextile treatment machine arrangementsElectric machineProcess engineering

The invention provides an intelligent multi-functional printing and dyeing device for non-woven fabric for processing paper diapers. The intelligent multi-functional printing and dyeing device comprises a printing and dyeing nozzle, a printing and dyeing spray pipe, an automatic sliding block, a linear sliding rail, an electric moving rod, a rack, a machine base, supporting legs, a dye connector,a limiting switch, an intelligent control screen, a speed reduction rotating motor, an anti-shifting pressing and fixing plate structure for non-woven fabric printing and dyeing, and a left printing dye left-collecting and filtering box structure. Through arrangement of a dye collection hopper, a flow guide pipe, a filter screen, a treatment barrel, an adsorption core, a collection box and a discharge pipe with a valve, collection of dye left during printing and dyeing is facilitated, environmental pollution is avoided, the dye is collected through the dye collection hopper, impurities are filtered through the filter screen in the flow guide pipe, and fine chippings are adsorbed through the adsorption core in the treatment barrel and finally collected and stored through the collection box,so that environmental pollution is avoided, discharging and recycling can be conducted through the discharging pipe with the valve, resources are saved, and resource losses are reduced.

Owner:邵庆河

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com