Hand-hold laser processing spear system

A laser processing and hand-held technology, applied in the field of effective systems, can solve the problems of high workpiece position requirements, limited processing, inconvenient portability, etc., and achieve the effects of small size, easy processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

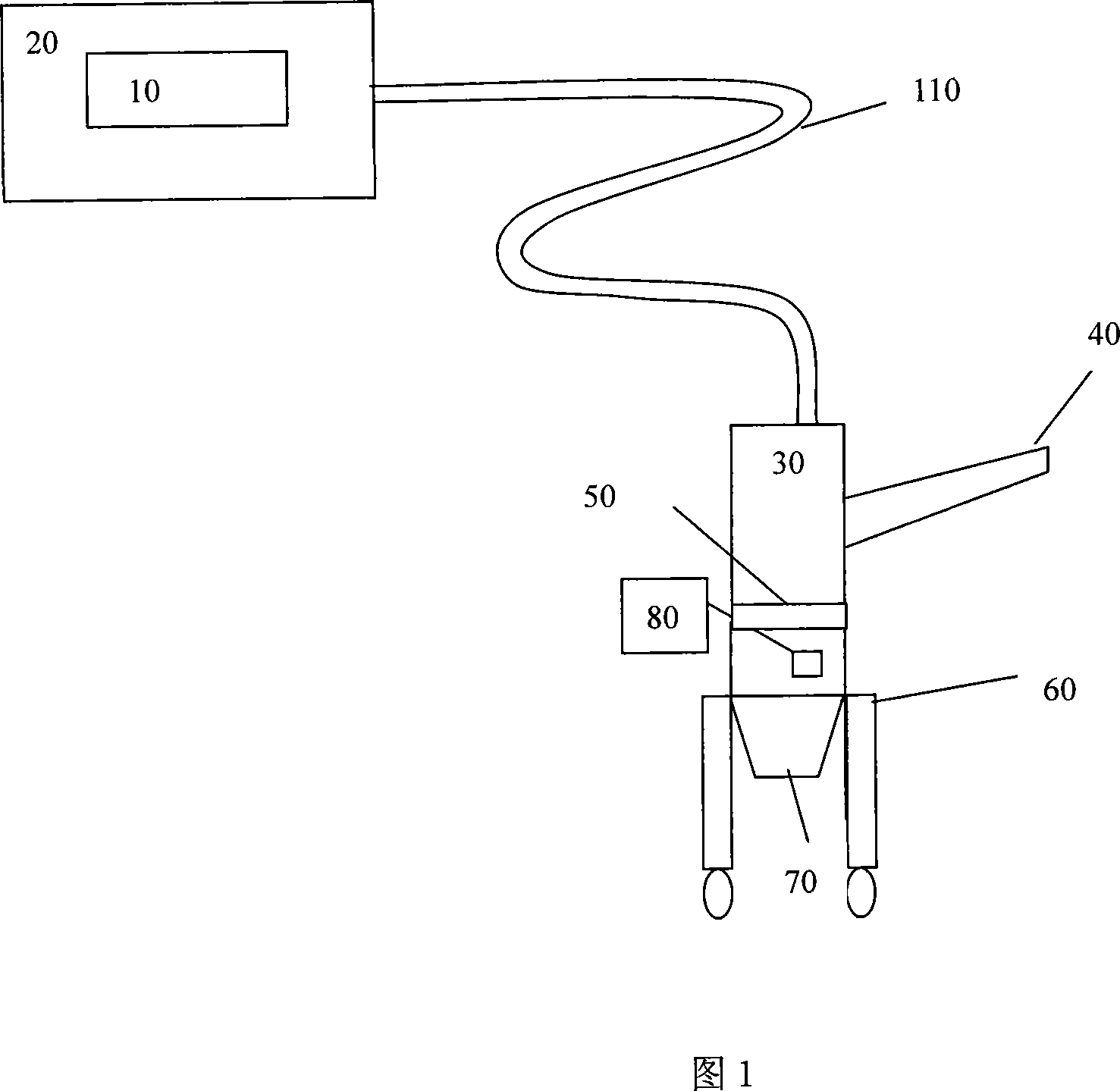

[0013] The present embodiment will be described below in conjunction with FIG. 1 .

[0014] Various entities of the present invention shown in accompanying drawing 1 all relate to the hand-held laser gun system that is suitable for the workpiece of laser processing such as laser welding and cutting in various different positions indoors and outdoors.

[0015] The hand-held laser processing gun system includes a fiber laser 10 , a control system 20 , a laser gun body 30 , a laser nozzle 70 , and a processing gun focusing and moving wheel 60 . Under the control of the control system 20, the fiber laser 10 emits a laser beam with high beam quality. This laser beam can be transmitted through the optical fiber 110. The end connector of the optical fiber 110 can be embedded in the laser gun body 30. The focus system 50 in the gun body comes out through the nozzle 70, and can act on the workpiece that is in contact with the processing gun focus and the moving pulley 60. During proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com